Flux-cored steel belt containing steel wire for surfacing and preparation method thereof

A technology for steel strips and steel wires, which is applied to the field of flux-cored steel strips containing steel wires for surfacing welding and its preparation field, can solve the problems of difficulty in manufacturing, limited application scope, few varieties, etc., and achieves low production cost and expanded application scope. , the effect of increasing the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

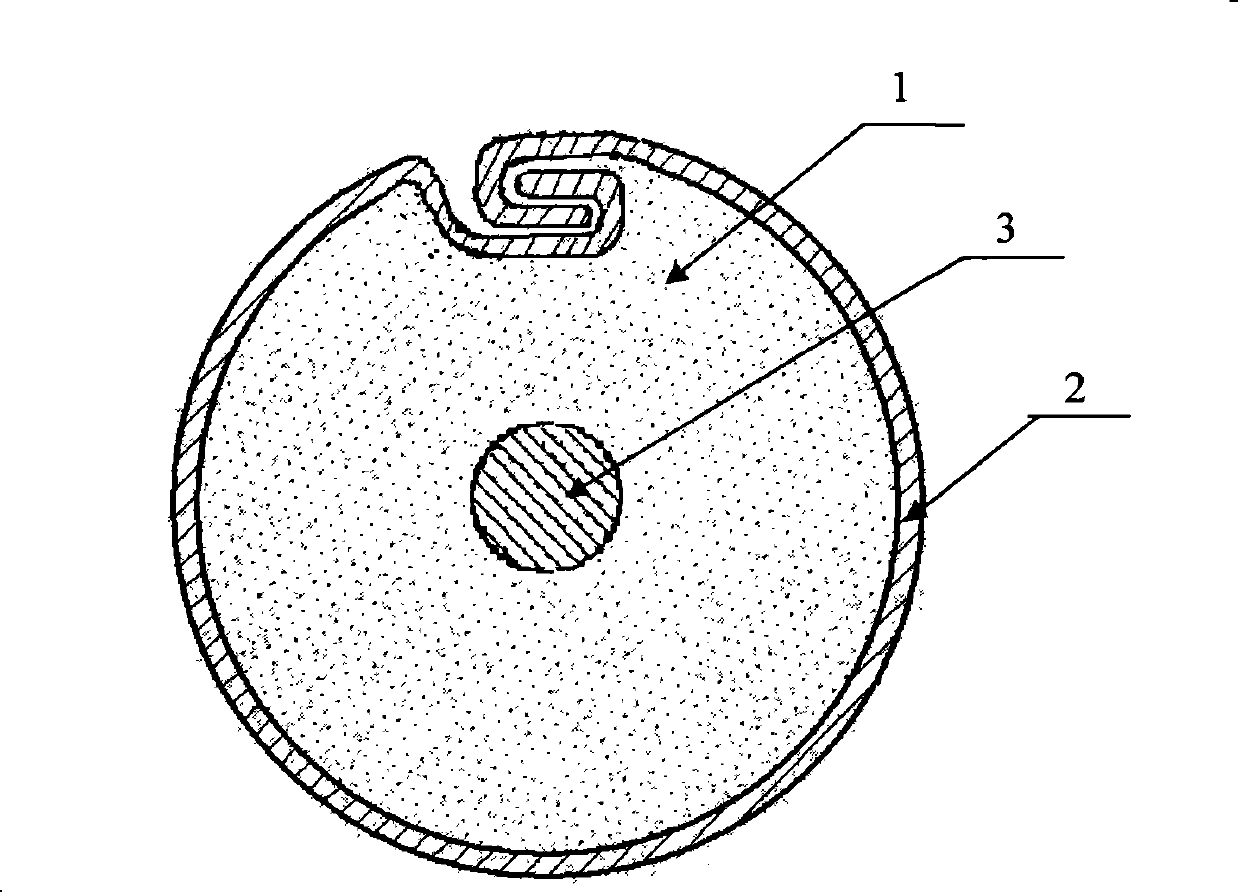

[0057] (1) select the H08A cold-rolled steel strip that width is 39mm, thickness is 0.3mm, utilize existing steel-making cored wire production equipment, it is rolled into cross-section along the steel strip length direction to be U shape;

[0058] (2) Add medicated powder (filling rate 48%) in above-mentioned U-shaped pit, wherein: the particle diameter of described medicated powder is less than 120 μ m, and medicated powder composition is in parts by weight (kg), comprises high-carbon ferrochromium 60, vanadium iron 8 , 75# ferrosilicon 5, high carbon ferromanganese 1, aluminum magnesium alloy 5, ferroboron 4, ferrotitanium 5, ferromolybdenum 6 and fluorite 2;

[0059] The above-mentioned medicated powder is applied after 10 minutes of powder mixing with a conventional powder mixer;

[0060] (3) At the same time, lay an ER50-6 steel wire with a diameter of 0.8mm and the same length as the steel strip along the length direction of the steel strip in the middle of the powder i...

Embodiment 2

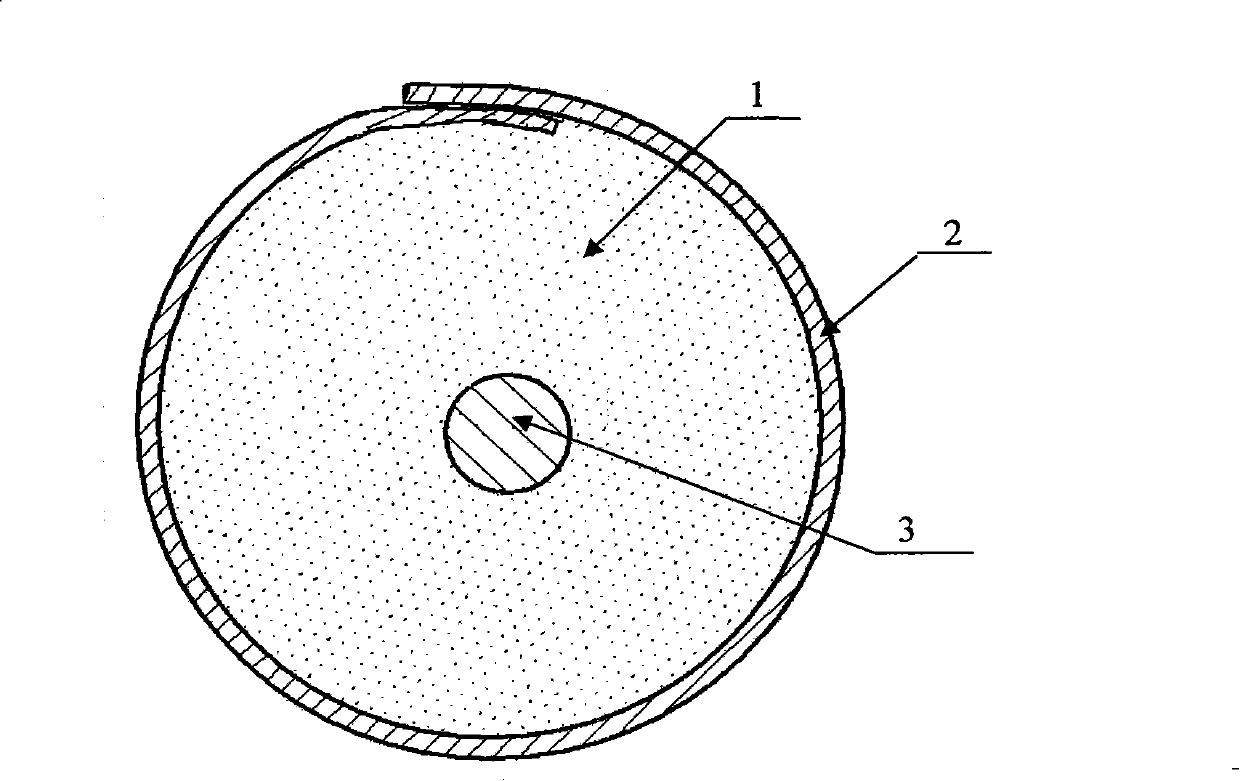

[0066] (1) select the H08A cold-rolled steel strip that width is 130mm, thickness is 0.4mm for use, utilize existing steelmaking to use the cored wire production equipment, it is rolled into cross section along the steel strip length direction and be U shape;

[0067] (2) Add medicated powder (filling rate 55%) in above-mentioned U-shaped pit, wherein: the particle diameter of described medicated powder is less than 120 μ m, and medicated powder composition is in parts by weight (kg), comprises high-carbon ferrochrome 70, ferro-vanadium 10 , 75# ferrosilicon 2, high carbon ferromanganese 1, aluminum magnesium alloy 2, ferroboron 12, ferrotitanium 3, ferromolybdenum 3 and graphite 4;

[0068] The above-mentioned medicated powder is applied after 20 minutes of powder mixing using a conventional powder mixer;

[0069] (3) Simultaneously, in the middle of the medicine powder in the U-shaped pit, lay a H08A steel wire with a diameter of 1.2mm along the length direction of the steel...

Embodiment 3

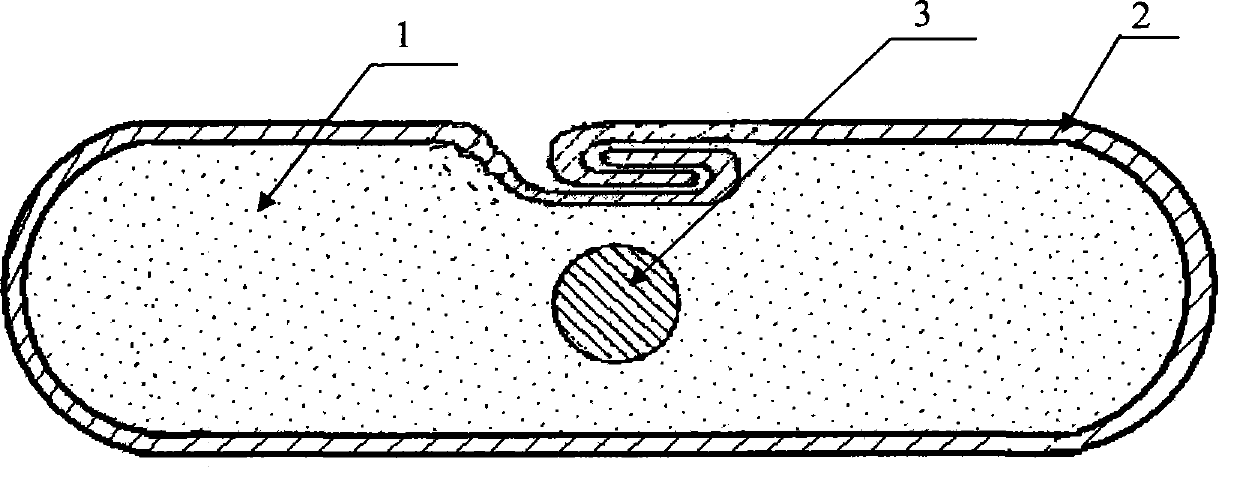

[0075](1) select the Q195 cold-rolled steel strip that width is 45mm, thickness is 0.3mm for use, utilize existing steelmaking to use the cored wire production equipment, it is U-shaped to be rolled into cross-section along the strip length direction;

[0076] (2) Add medicated powder (filling rate 50%) in above-mentioned U-shaped pit, wherein: the particle diameter of described medicated powder is less than 120 μ m, and medicated powder composition is in weight part (kg), comprises high-carbon ferrochrome 65, vanadium iron 5 , 75# ferrosilicon 4, high carbon ferromanganese 2, aluminum magnesium alloy 5, boron iron 6, titanium iron 4, molybdenum iron 5, fluorite 2 and potassium titanate 2;

[0077] The medicated powder is applied after 15 minutes of powder mixing using a conventional powder mixer;

[0078] (3) At the same time, lay an ER50-6 steel wire with a diameter of 1.0 mm and the same length as the steel strip along the length direction of the steel strip in the middle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com