Patents

Literature

84results about How to "Improve surfacing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

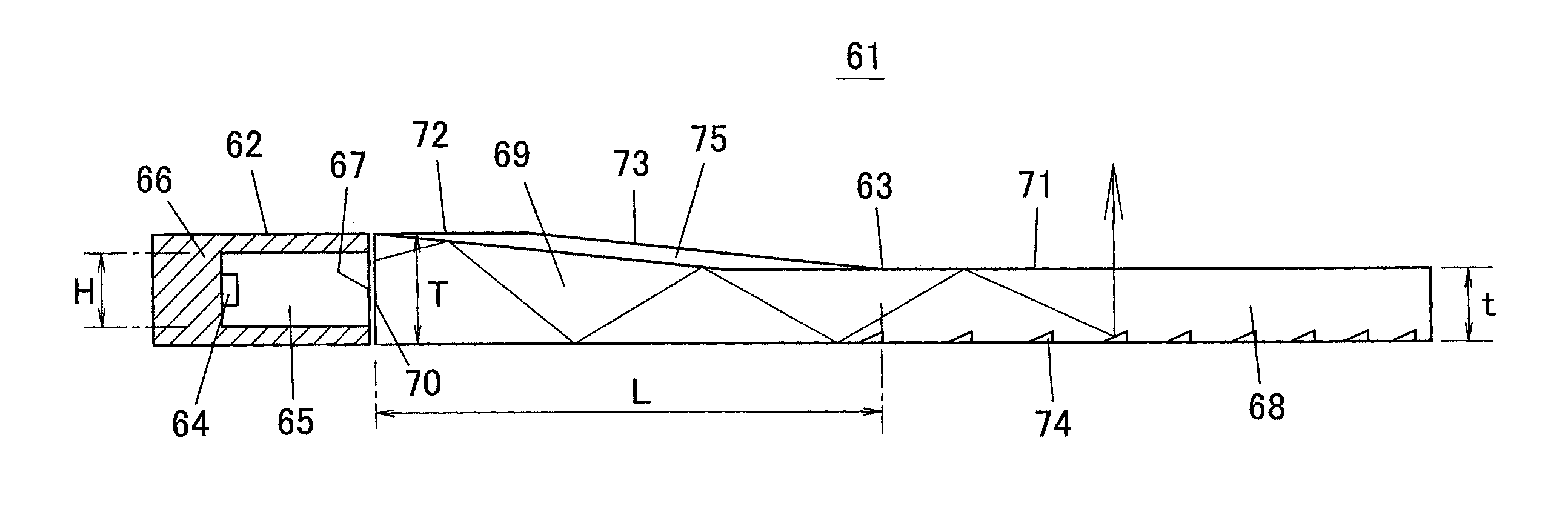

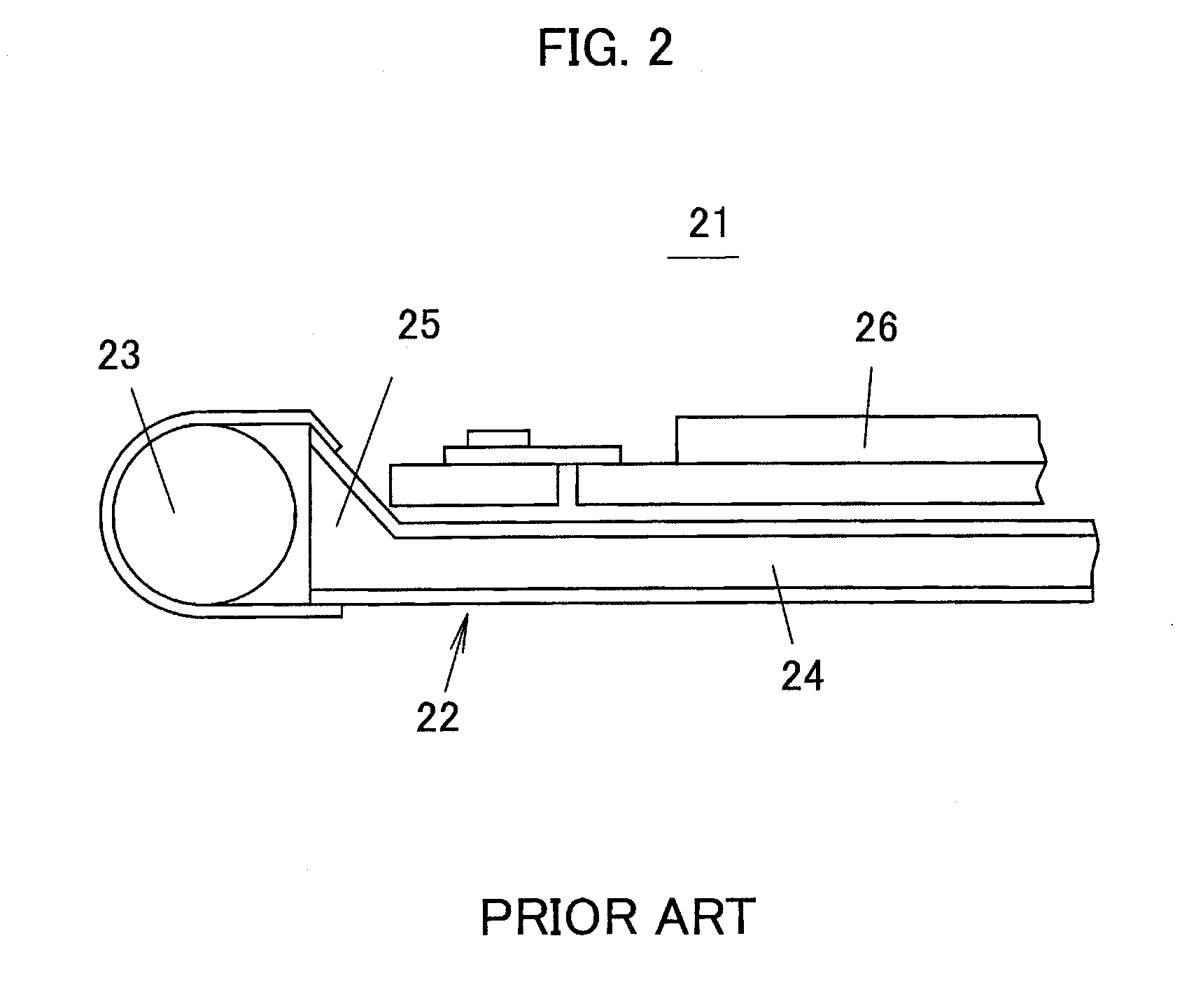

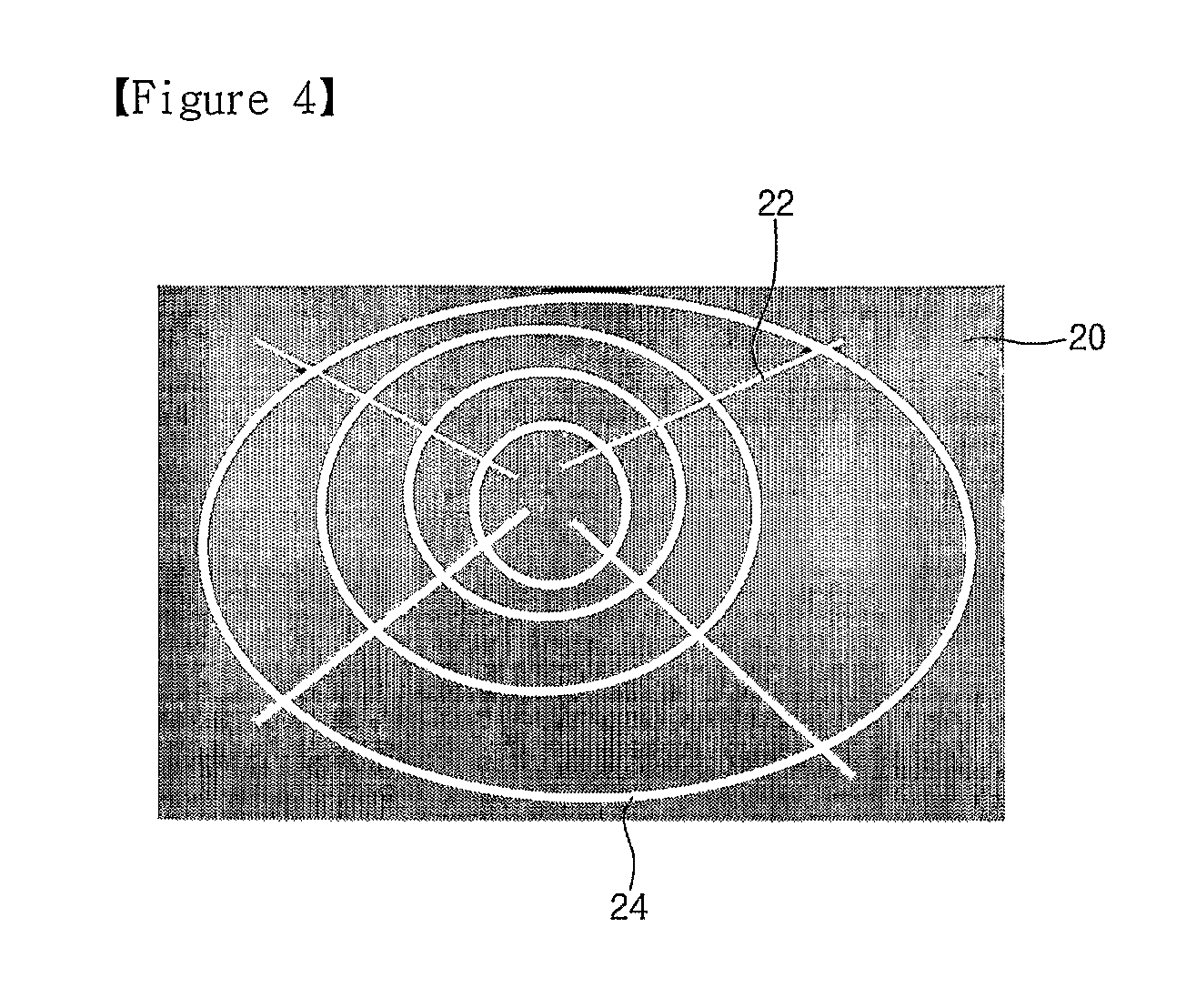

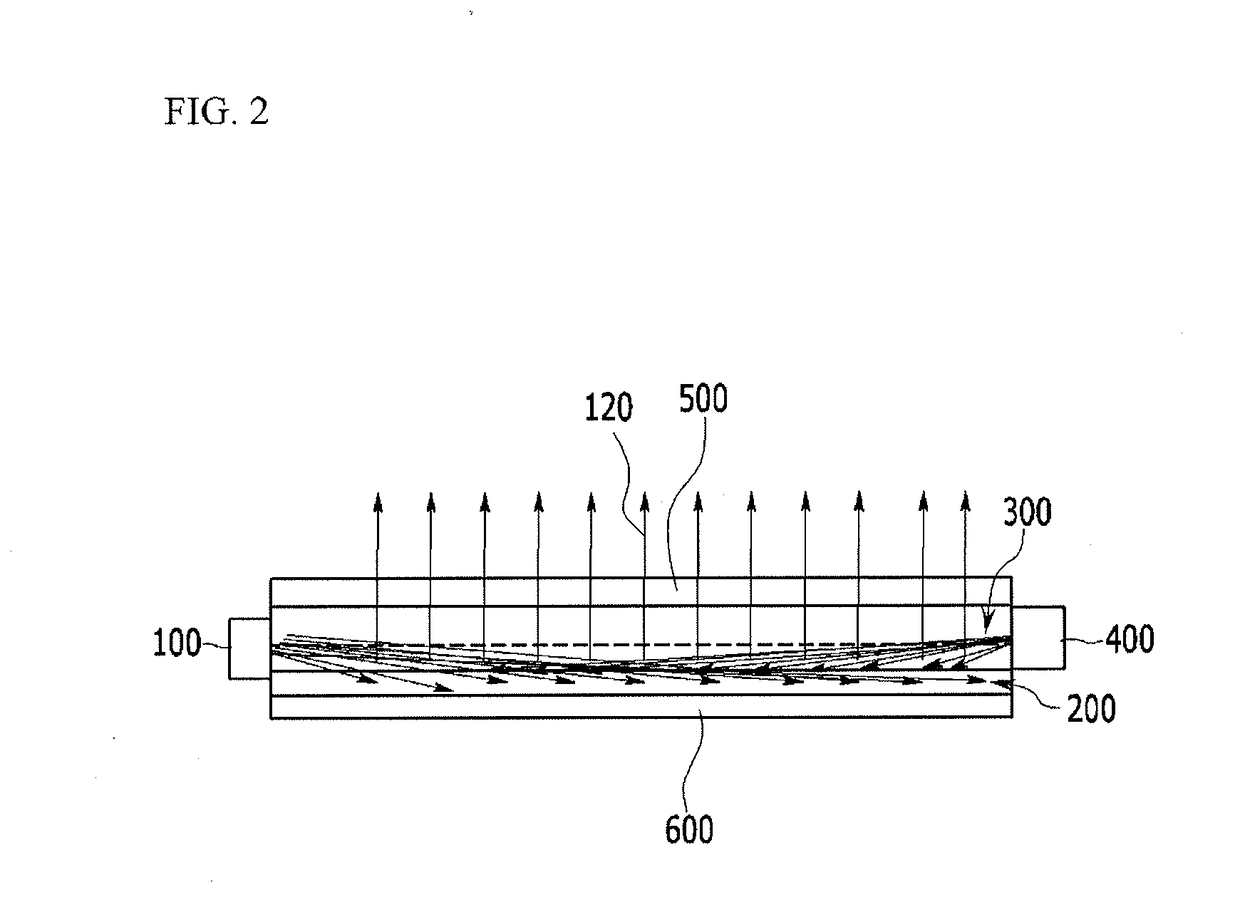

Surface light source device

ActiveUS20110286237A1Easy to manufactureExcessive light leakageMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

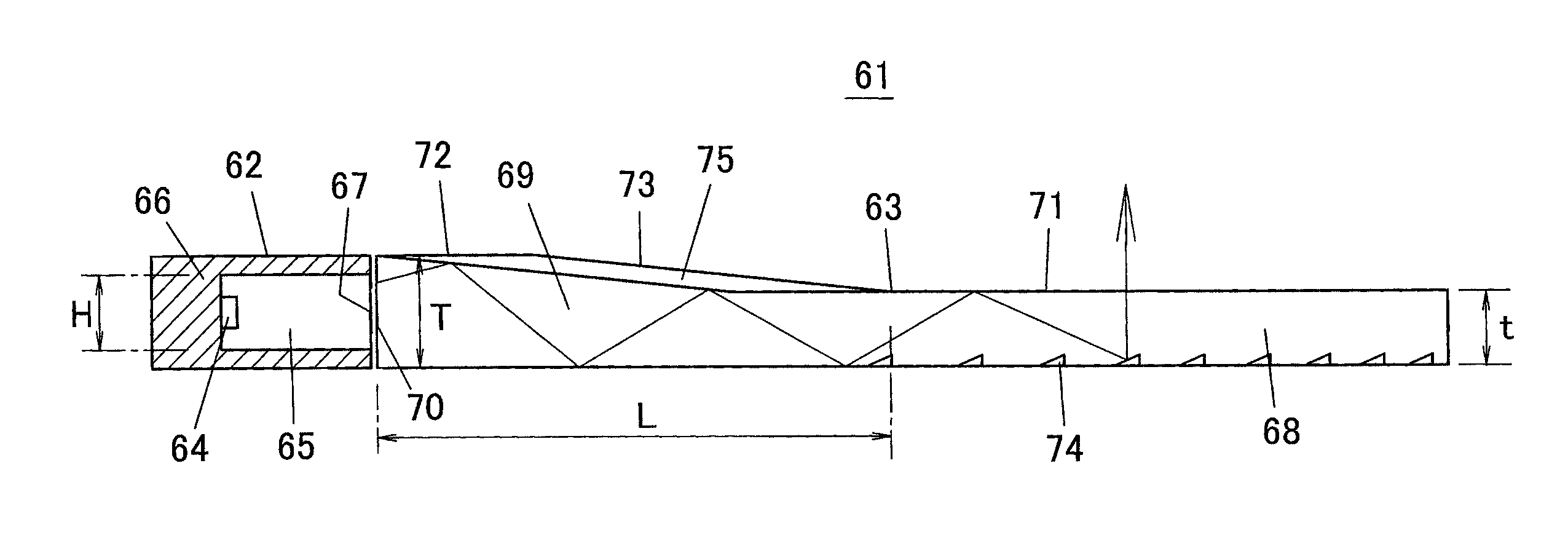

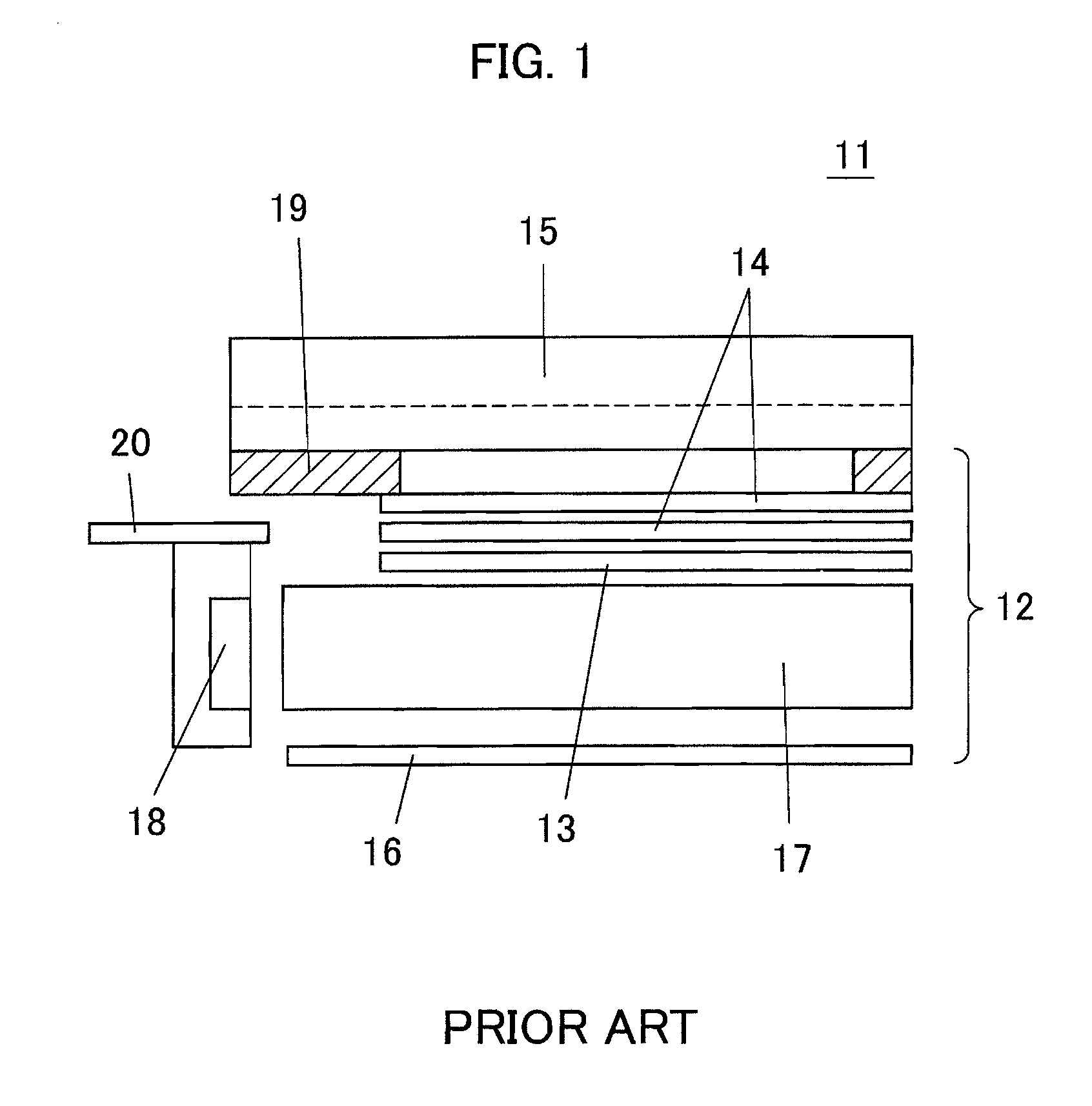

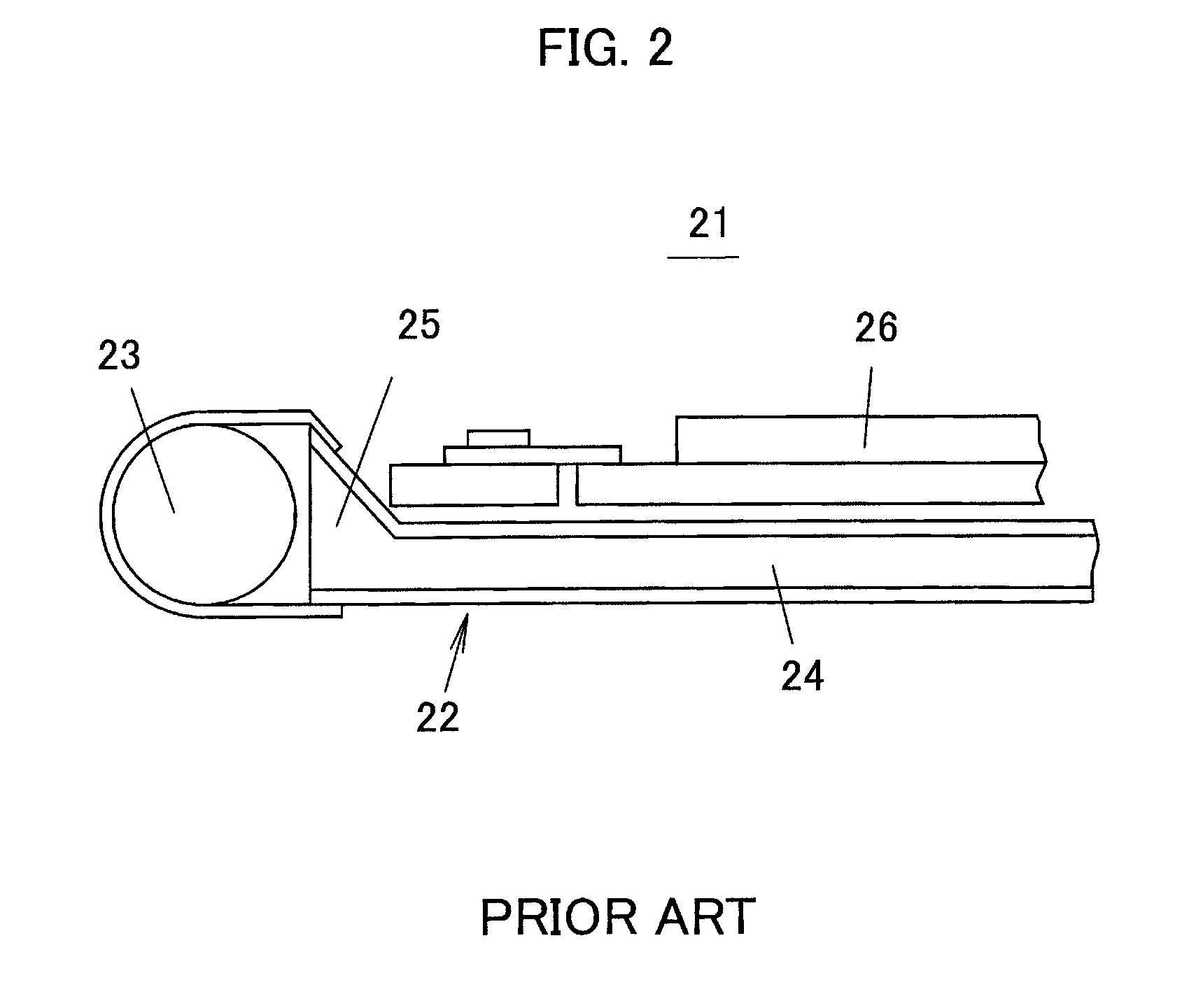

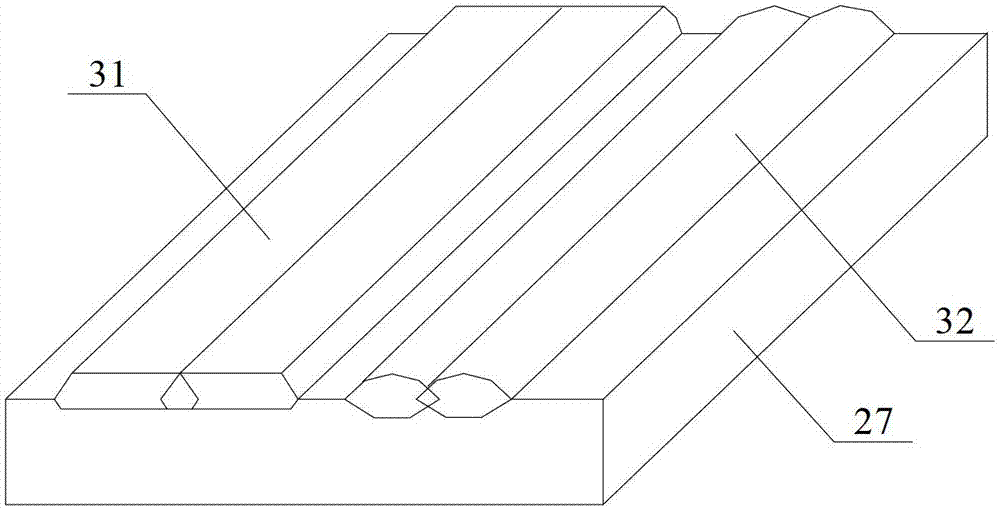

A light guide plate is formed of a light introducing part positioned to face a point light source for confining light and a light guide plate body having a thickness smaller than the thickness of an end of the light introducing part on a point light source side and causing the confined light to be output from a light exit surface to outside. The light introducing part has an inclined surface, and a directivity conversion pattern formed on the inclined surface. The directivity conversion pattern is configured by arranging V grooves in parallel to each other, each having a vertical angle of 120°, and each extends in a direction approximately perpendicular to a light incidence end face of the light guide plate. The length of the inclined surface in a inclination direction where part of light incident to the light introducing part enters the inclined surface at least twice.

Owner:TOHOKU DENSHI CO LTD

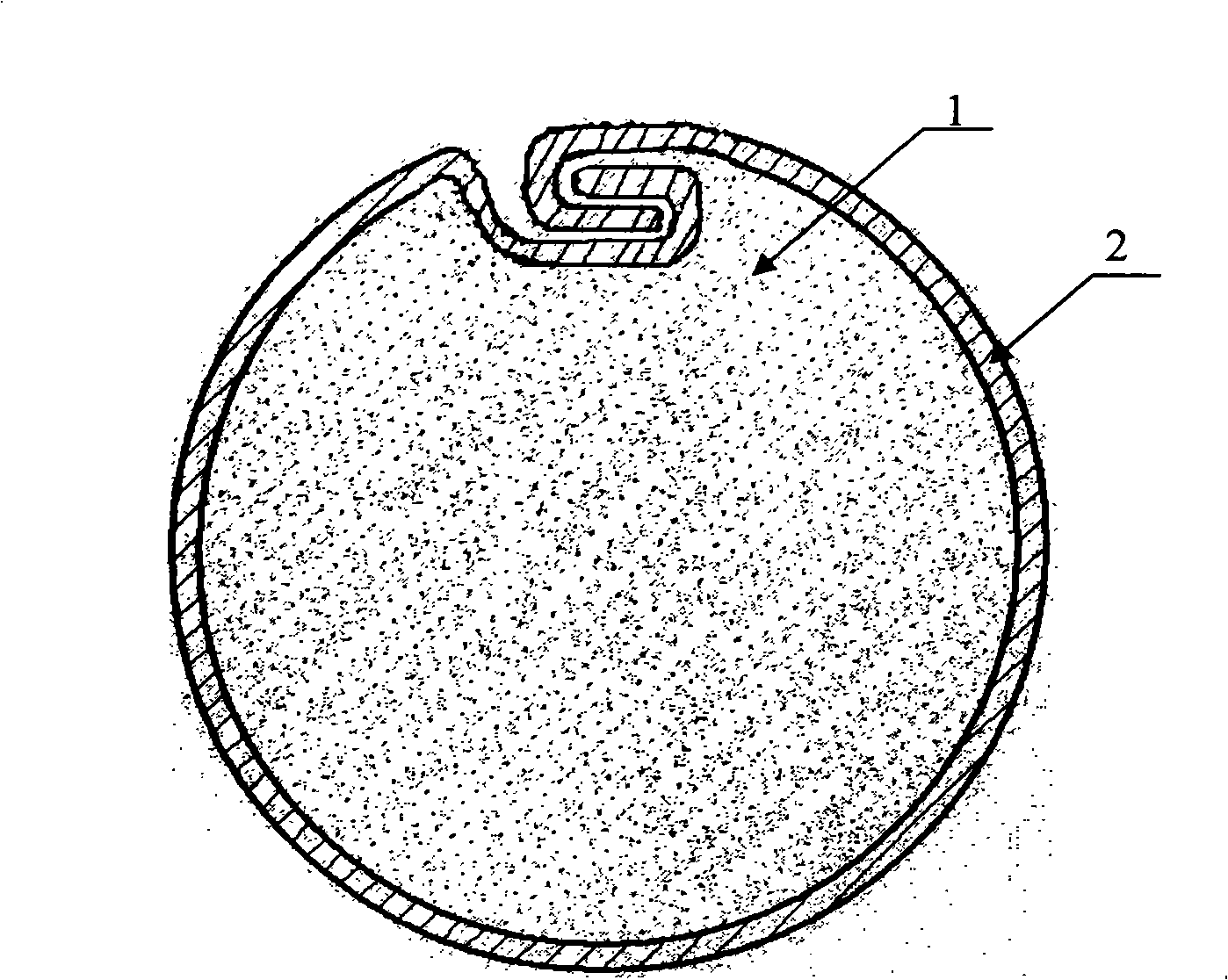

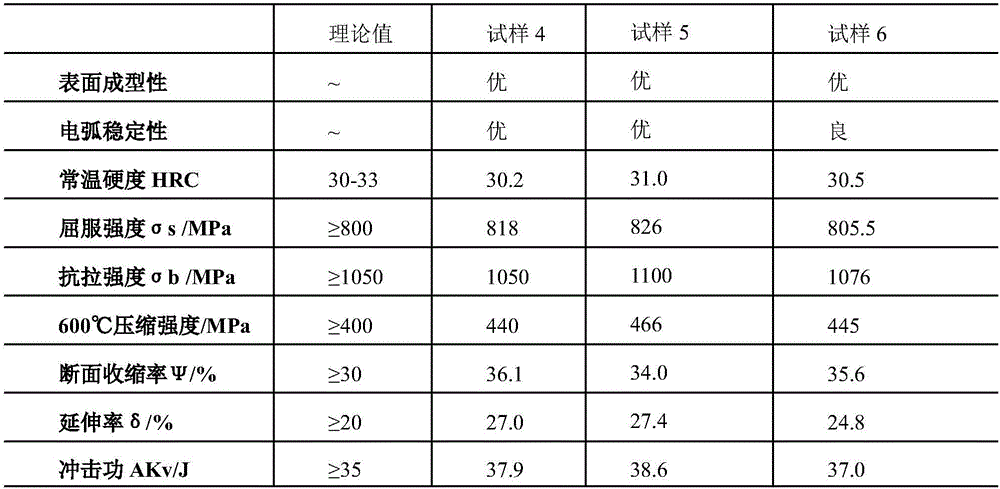

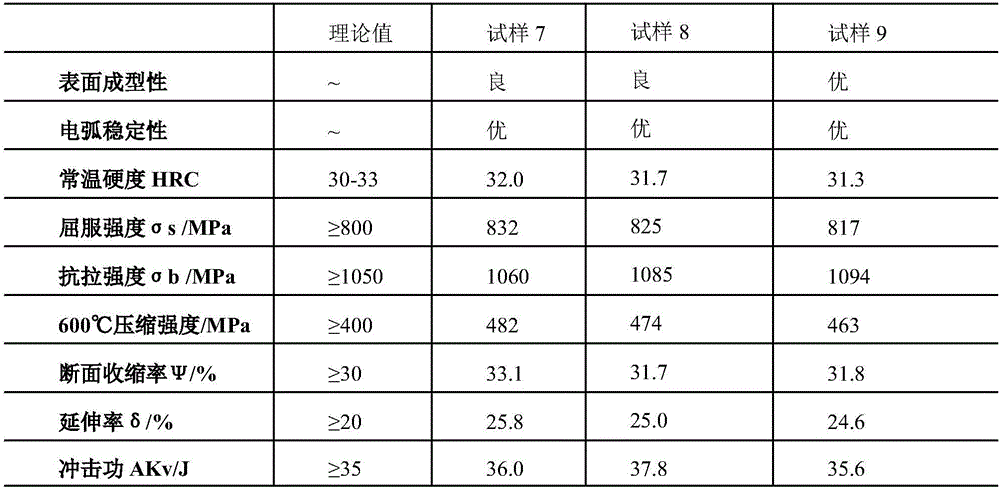

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

Cored welding strip applied in resurfacing welding and preparation method thereof

InactiveCN101596653AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaSteel beltDrug powder

The invention discloses a novel resurfacing welding cored welding strip which consists of a steel tube circled by steel strips and drug powder wrapped in the steel tube, the steel strips comprises an upper steel strip and a lower steel strip which can be purchased in the market. The shape of the steel tube circled by steel strips is that the longitudinal cross section is long flat form or rectangle-like shape, the longitudinal length is determined at will, and the steel tube can be cut out at will or winded into a tray according to requirements. The transverse edges of the upper steel strip and the lower steel strip are connected at the upper steel strip side in a related joint form, and the drug powder is filled in the steel tube circled by the steel strips evenly with the filling rate being 20-80%. According to the different types of resurfacing metals, the content of alloy element in the resurfacing welding cored welding strip is different. The cored welding strip has simple production equipment and technique, and low production cost, thus overcoming the defect that alloy welding filament used for filament resurfacing welding is difficult to produce and the problems of large investment on production equipment, high production cost and expensive price in cored welding filament production.

Owner:SHANDONG UNIV

Surface light source device

ActiveUS8167474B2Easy to manufactureExcessive light leakagePlanar/plate-like light guidesNon-linear opticsLight guideOptoelectronics

A light guide plate is formed of a light introducing part positioned to face a point light source for confining light and a light guide plate body having a thickness smaller than the thickness of an end of the light introducing part on a point light source side and causing the confined light to be output from a light exit surface to outside. The light introducing part has an inclined surface, and a directivity conversion pattern formed on the inclined surface. The directivity conversion pattern is configured by arranging V grooves in parallel to each other, each having a vertical angle of 120°, and each extends in a direction approximately perpendicular to a light incidence end face of the light guide plate. The length of the inclined surface in a inclination direction where part of light incident to the light introducing part enters the inclined surface at least twice.

Owner:TOHOKU DENSHI CO LTD

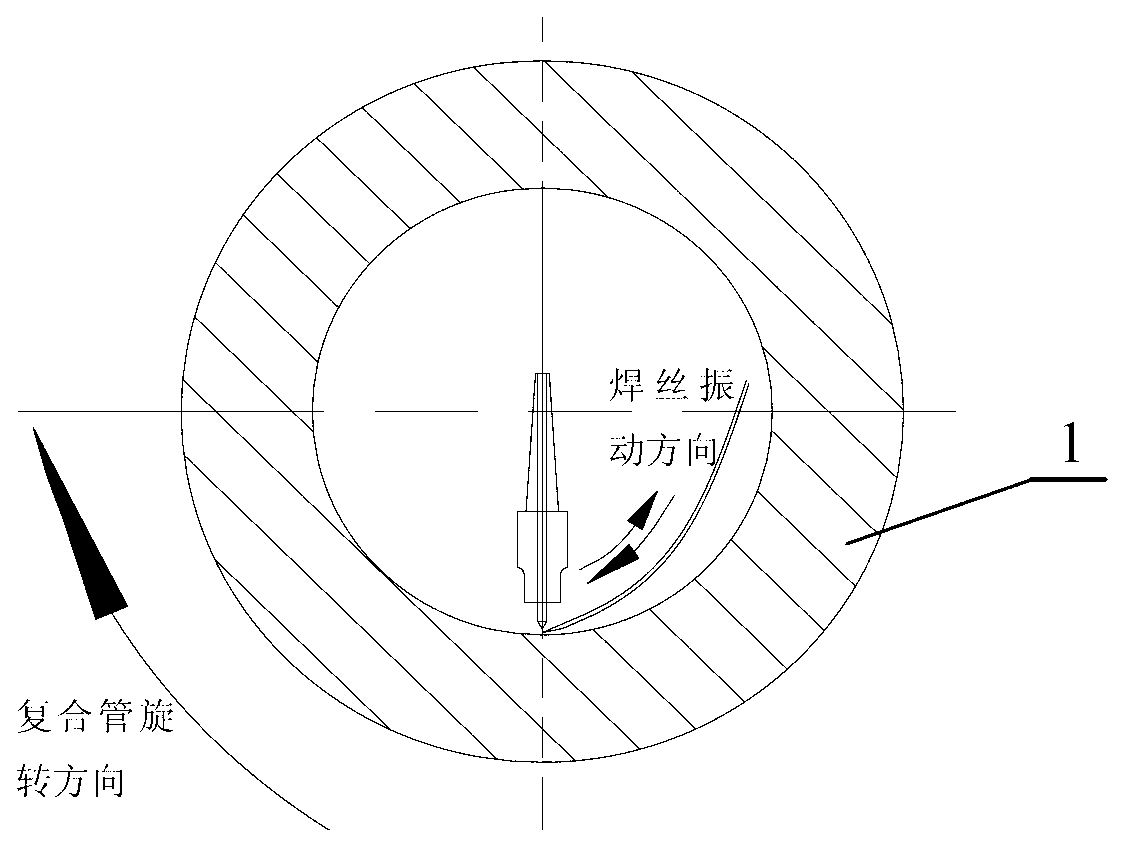

Vibrating wire-feeding surfacing method

The invention relates to a vibrating wire-feeding method which is characterized in that right and left swinging of a welding gun is combined with reciprocating vibration of a welding wire; the automatic wire-feeding process is accompanied by the axial vibration of the welding wire; a molten welding material is deposited on the internal wall of a pipe, and the fluidity of a welding pool is greatly improved, so as to further improve the surfacing efficiency; the vibrating welding wire can uniformly stir the molten pool in the melting process of the welding wire, especially for the material with poor fluidity, such as nickel-base alloy, so that gas can escape rapidly when metal in the molten pool is stirred, and hot welding cracks and pores are reduced; as the vibrating wire-feeding stirs the molten pool, solidification and crystallization in the molten pool are uniform; the metallurgical structure of a surfacing layer is uniform and exquisite; the mechanical property of the surfacing layer is greatly superior to those of normal argon tungsten-arc welding and gas metal-arc welding; the quality of a surfacing joint is improved to a great extent; the property is good; the yield of products is greatly increased; and the property of the surfacing joint is greatly improved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Flux-cored steel belt containing steel wire for surfacing and preparation method thereof

InactiveCN101310913AStable meltingEvenly meltedWelding/cutting media/materialsSoldering mediaMetallurgySteel belt

The invention discloses a flux-cored steel-belt that contains steel wires and is used for surfacing and a preparation method thereof. The flux-cored steel-belt is produced from low-carbon steel belts and powder and a steel wire enwrapped therein. The shape of the steel belts is a tube, of which the vertical cross section is in a long flat shape or a rectangle-like shape and the horizontal sides are connected in a closing form or a lapping form. The powder is evenly filled in the tube rolled from the steel belts and the steel wire which is arranged vertically along the tube, has the same length with the tube and positioned at the geometric center of the vertical cross section of the flux-cored steel-belt is clamped in the middle of the powder. Through the adjustment of clamping the steel wire and the powder flux-cored steel-belt of the invention, the variety of steel belts used for surfacing is added, thus reducing cost. The flux-cored steel-belt can be wound into a disk-like shape, thus being suitable for continuous automatic surfacing, leading the application field of strip surfacing to expand, increasing the stability of electric arc and reducing the technical requirements against welding equipment.

Owner:SHANDONG UNIV

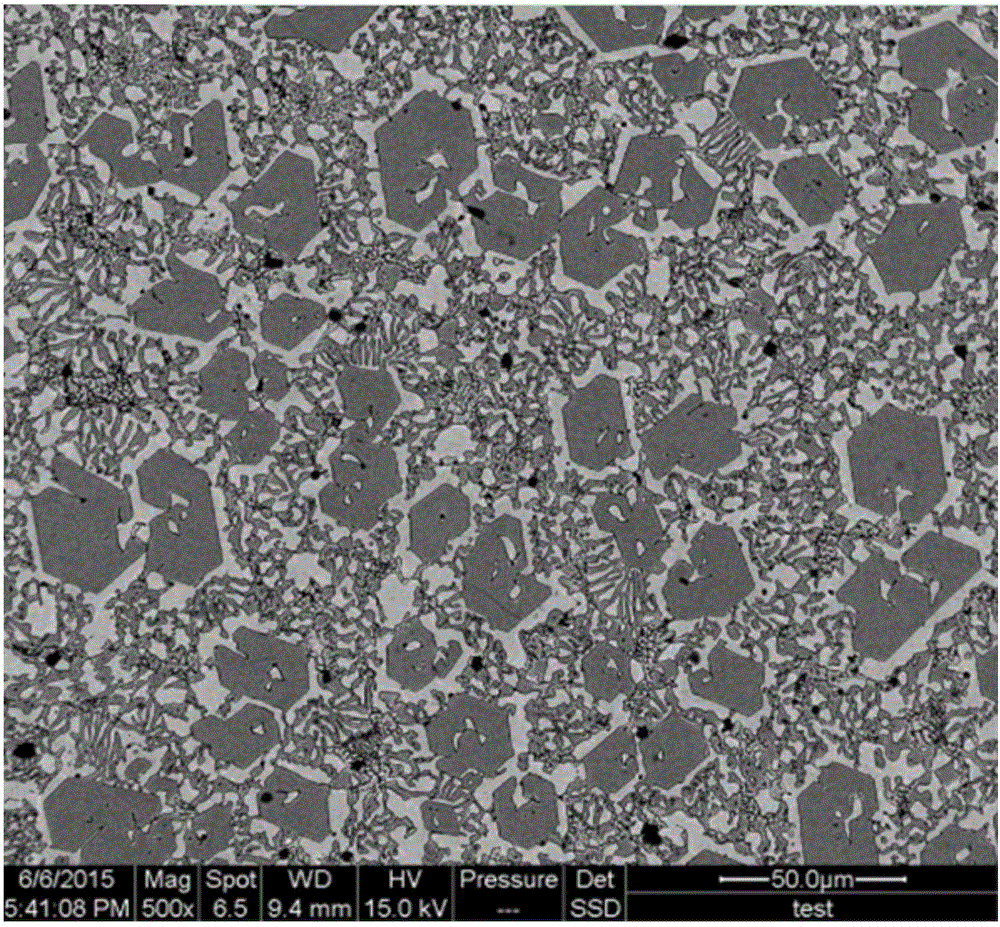

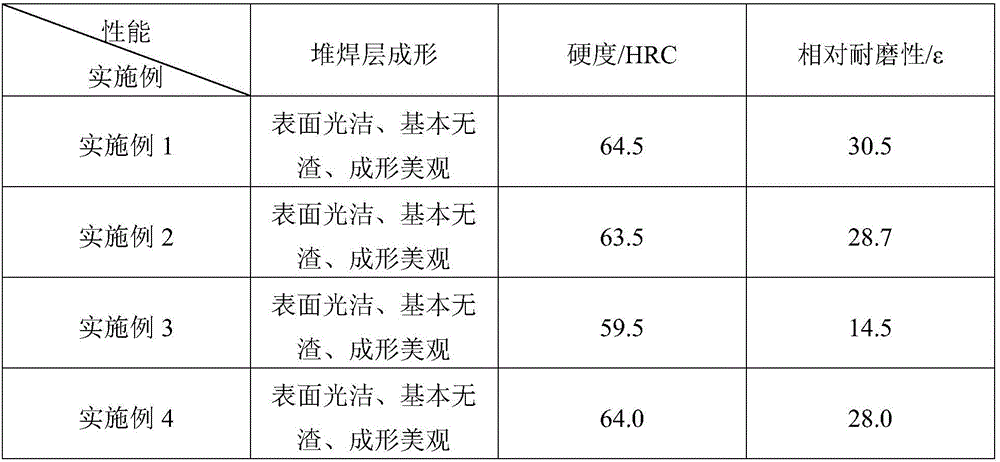

Flux core for nano-modified boron-containing high-chromium iron hardfacing self-protection flux-cored wire

ActiveCN105269183AImprove surfacing efficiencyLow costWelding/cutting media/materialsSoldering mediaCrusherGrinding wheel

The invention relates to a flux core for a high-chromium iron hardfacing self-protection flux-cored wire, in particular to the flux core for a nano-modified boron-containing high-chromium iron hardfacing self-protection flux-cored wire. The flux core aims to solve the technical problem that existing high-chromium iron surfacing alloy is poor in abrasion resistance. The flux core is prepared from high-chromium iron powder, electrolytic manganese powder, silicon iron powder, ferro-boron powder, graphite powder, aluminum magnesium alloy powder and a nano-modified agent. The organization of the nano-modified boron-containing high-chromium iron surfacing alloy is composed of primary M7C3 carbide, eutectic M7C3 carbide, martensite and retained austenite. The chromium iron hardfacing self-protection flux-cored wire can be used for repairing and manufacturing a mine cement vertical grinding roller, a coal mill grinding roller, a grinding wheel, a blast-furnace top bell, a hopper, a crusher hammerhead and the like.

Owner:HARBIN INST OF TECH

Roller surfacing technology

The invention relates to a roller surfacing technology. The roller surfacing technology comprises the steps of firstly, checking before welding; secondly, preheating before welding; thirdly, performing surfacing machining; and fourthly, performing post-weld heat treatment. The roller surfacing technology has the advantages that a worn part of a roller can be repaired, meanwhile, the hardness and the wear resistance of the roller can be greatly improved, and therefore the service life of the roller can be prolonged, and the roller surfacing efficiency can be improved.

Owner:ANHUI REMFG ENG DESIGN CENT

In-situ stress-free resurfacing welding repair process of abrasion of large-sized rotor journal

InactiveCN101704152AGood restorativeReduce lossesArc welding apparatusAcute angleUltimate tensile strength

The invention relates to an in-situ stress-free resurfacing welding repair process of the abrasion of a large-sized rotor journal. The process comprises the following steps of: (1), carrying out the preparation work of resurfacing welding, filing and shaping burrs, acute angles and the like at the abraded positions of the large-sized rotor journal, cleaning oil spots and rusty scales chemically, then removing repaired positions and covering fatigue layers; (2), carrying out stress-free resurfacing welding, melting a welding wire coldly by adopting a stress-free resurfacing welding machine, carrying out resurfacing welding without temperature rise on the abraded positions of the journal and remaining a processing redundancy; (3), carrying out rough grinding, then carrying out resurfacing welding on defects after rough grinding and afterwards carrying out polishing and fine grinding; and (4), finally, polishing to reach the required size of the rotor journal. The invention adopts a stress-free resurfacing welding technique, has high strength, good quality, high efficiency, short construction period and low cost, enables the in-situ high-quality repair of the abrasion of the large-sized rotor journal to become actual and provides powerful guarantee for the long-term safe running of a generator set; and a resurfacing welding layer and a rotor basal body are in metallurgical bonding.

Owner:LANZHOU REMAKE ELECTRIC POWER SCI & TECH

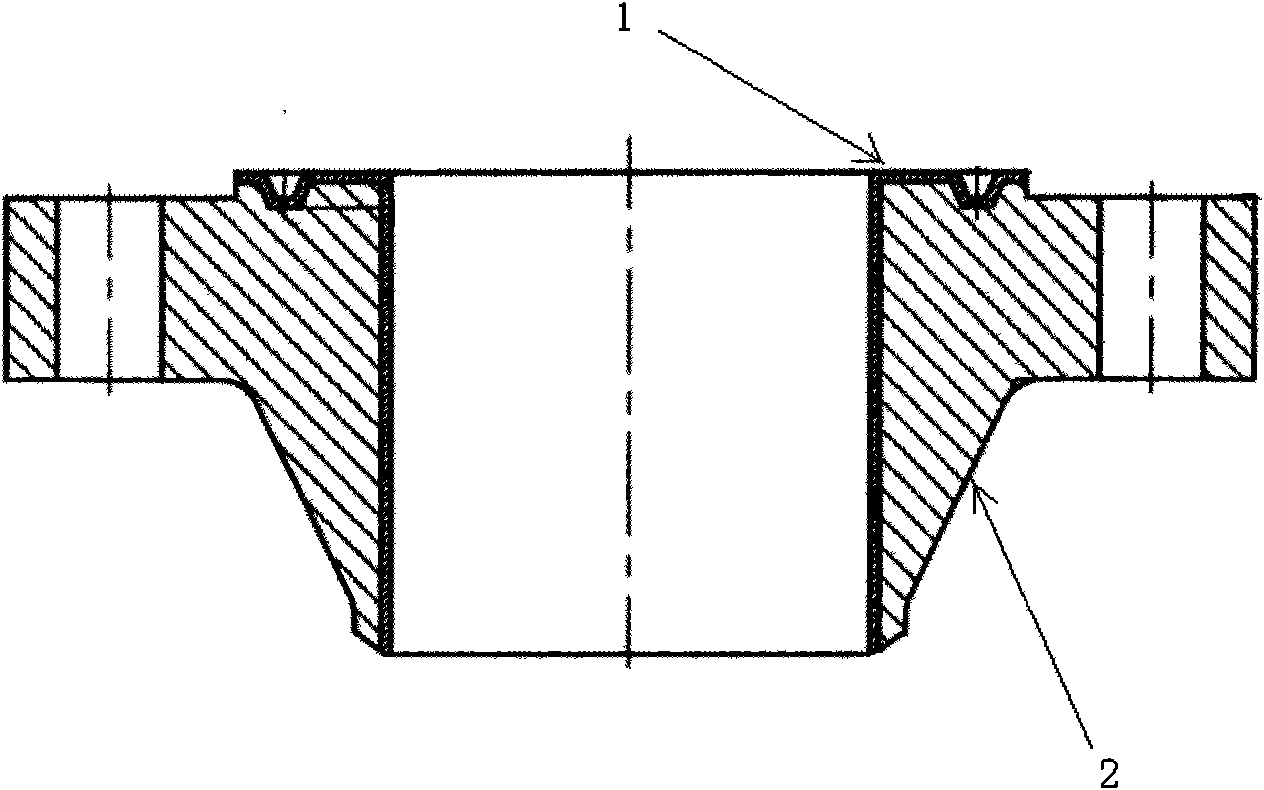

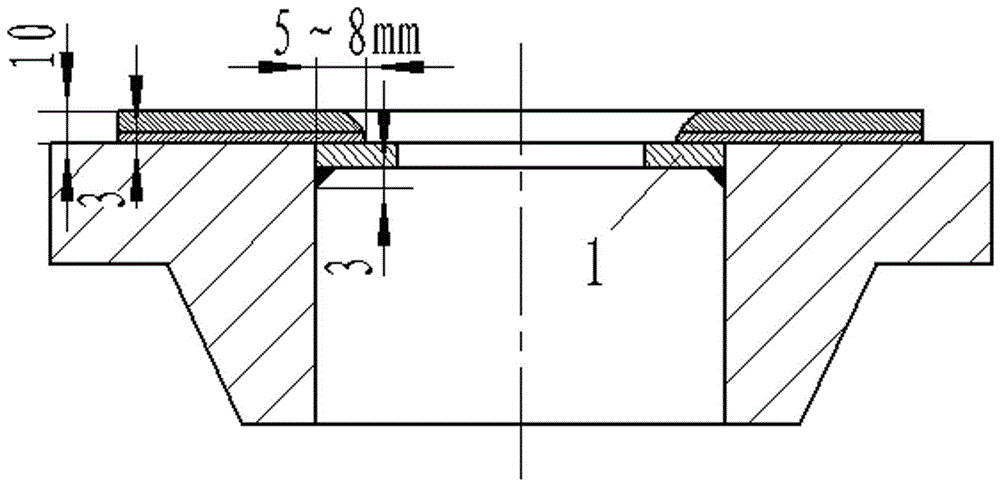

Flange resurfacing welding method

InactiveCN101642843AImprove corrosion resistanceLow efficiencyArc welding apparatusShielding gasRust

The invention provides a flange resurfacing welding method which is characterized in that the method comprises the following specific steps: step 1. performing rough machining to the surface of flanges while reserving working allowance, drying welding rods, removing iron rust, greasy dirt and oxide on the surface of welding rods; step 2. using an electrothermal equipment to preheat the surface offlanges, step 3. adopting argon tungsten-arc welding method for the overlaying of flanges under conditions that the protective gas is argon gas with the purity of 99.99%, the flow of the protective gas is 15-20L / Min, the current adopts direct current electrode negative polarity, the current value is 150-200A, the voltage value is 12-15V, the welding speed is 140-220mm / Min, the wire feed rate is 1600-2000mm / Min, and step 4. annealing the flanges after overlaying at 610-720 DEG for 2.5-4h. The invention has the advantage that compared with ordinary flange overlaying, the process of the inventionhas high overlaying efficiency, stable quality control and low dilution rate, thus the corrosion resistance is greatly improved.

Owner:上海锐迈重工有限公司

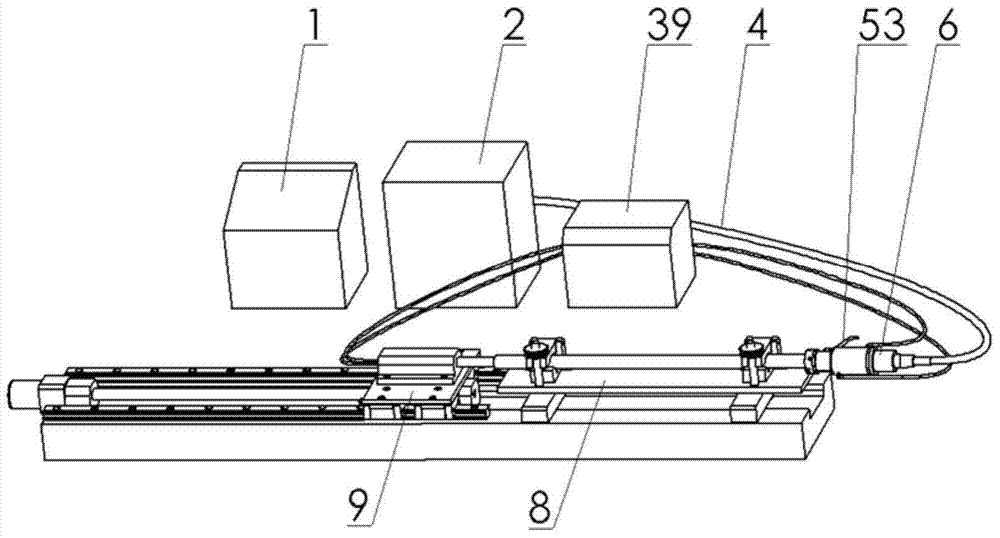

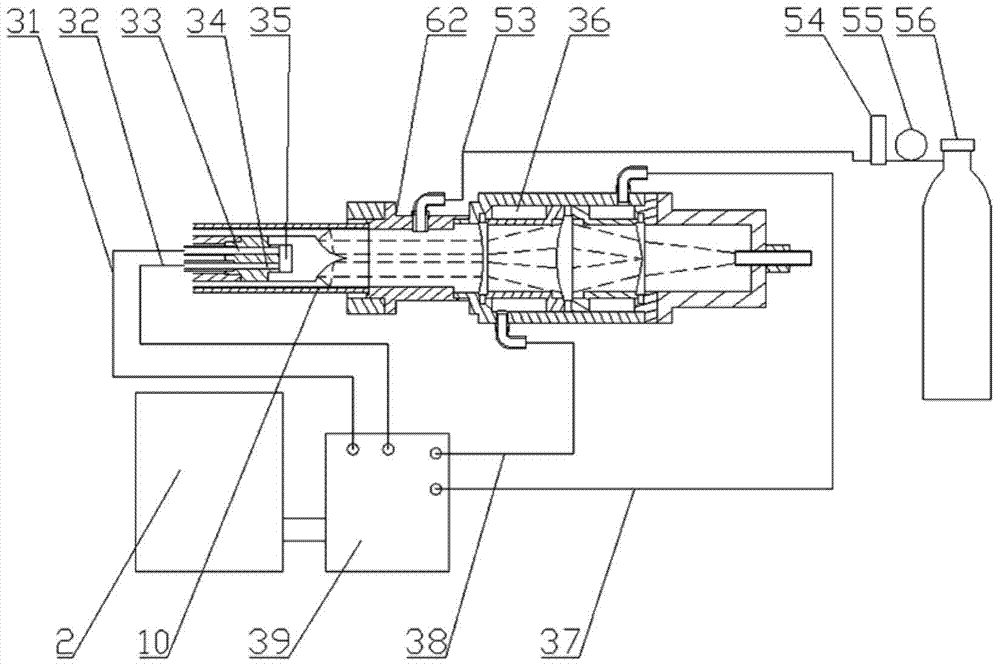

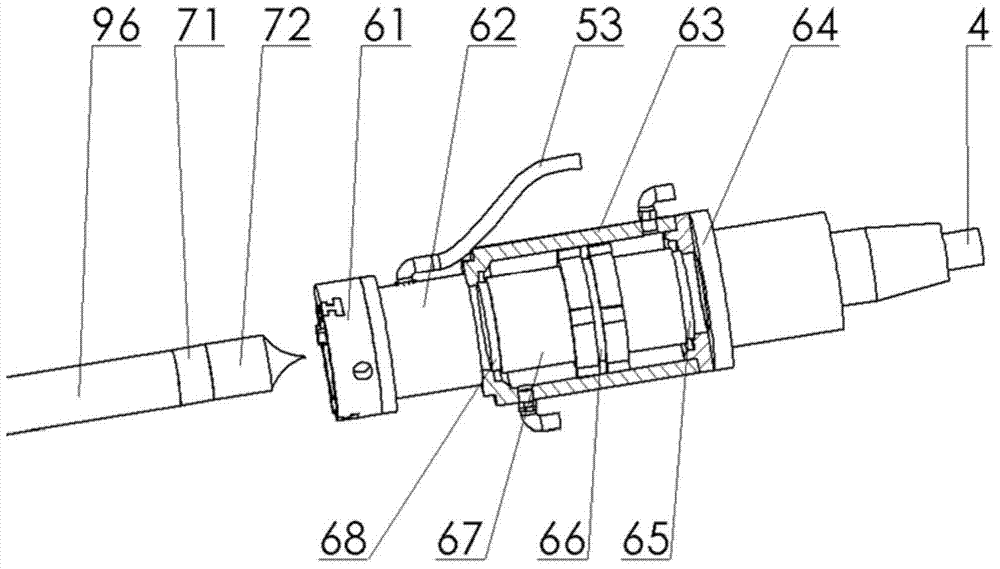

Small-caliber pipe inner wall laser bead welding device

ActiveCN103567638APromote repairImprove maintenance qualityMetal working apparatusLaser beam welding apparatusShielding gasEngineering

The invention provides a small-caliber pipe inner wall laser bead welding device. The small-caliber pipe inner wall laser bead welding device comprises a laser emitting device and a circumferential reflecting focusing device. The emitting end of the laser emitting device is provided with a protective gas communication pipe which is connected with one end of a small-caliber pipe. The circumferential reflecting focusing device can be inserted into an inner cavity of the small-caliber pipe from the other end of the small-caliber pipe, the back end of the circumferential reflecting focusing device is connected with a linear driving mechanism, and the front end of the circumferential reflecting focusing device is provided with a conical cambered surface reflecting focusing lens opposite to the emitting end of the laser emitting device. The side wall of the protective gas communication pipe is provided with a gas inlet connected with a protective gas pipeline. The small-caliber pipe inner wall laser bead welding device can be used for carrying out automatic bead welding on the small-caliber metal pipe, a non-metal pipe and a composite pipe, can be used for field maintenance, and can also be used for factory production of composite pipes. The small-caliber pipe inner wall laser bead welding device is very wide in application range, good in bead welding quality and low in cost.

Owner:STATE NUCLEAR POWER PLANT SERVICE

High-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire and manufacture method thereof

ActiveCN106041356ALow melting pointReduce surface tensionWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a high-efficient energy-saving and surfacing layer well-forming self-shielded flux-cored welding wire. A low-carbon steel belt is an outer skin; and a flux core comprises the following components in percentage by mass: 42-60% of high carbon ferro-chrome with the particle size of 80 meshes, 10-18% of ferrosilicon, 16-25% of ferroboron, 2-8% of rare earth silicon, 2-8% of graphene, 1-4% of aluminum magnesium alloy, 2-5% of manganese powder and the balance of iron powder, wherein the graphene, the aluminum magnesium alloy and the manganese powder are added with two kinds of particle sizes of 60 meshes and 200 meshes, and the weight of the flux core powder accounts for 49-53% of the total weight of the welding wire. According to the welding wire provided by the invention, by adding the flux core components with different particle sizes, good welding technological performance is ensured; and by adding B, Si and other self-fluxing alloy elements simultaneously in the flux core, the fusing point of the welding wire is effectively lowered; a welding process window is expanded; the surfacing efficiency is improved; a high-efficient and energy-saving effect is realized; and the surface tension of a surfacing welding bead is effectively lowered, and the forming of the surfacing welding bead is effectively improved.

Owner:JIANGSU UNIV OF SCI & TECH

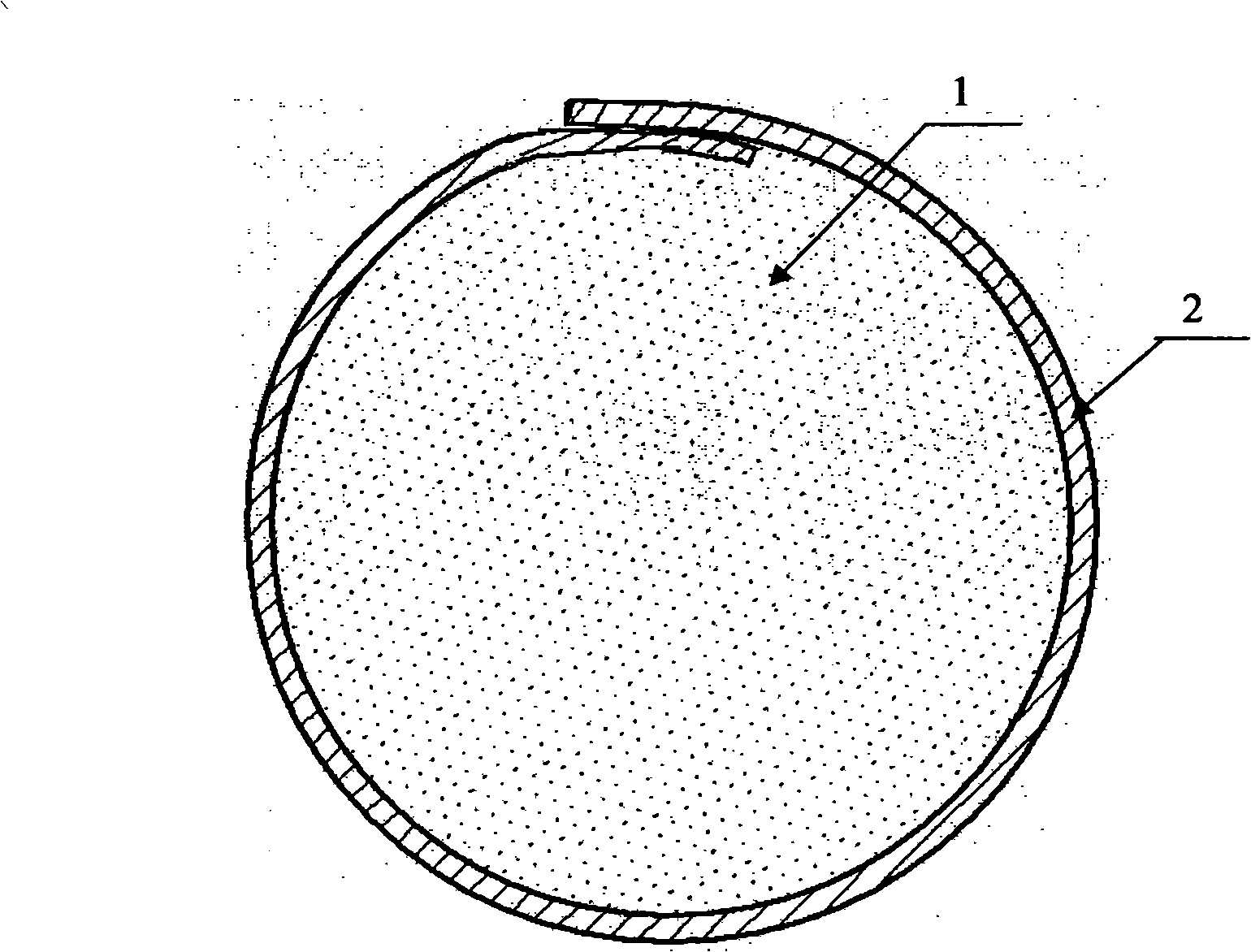

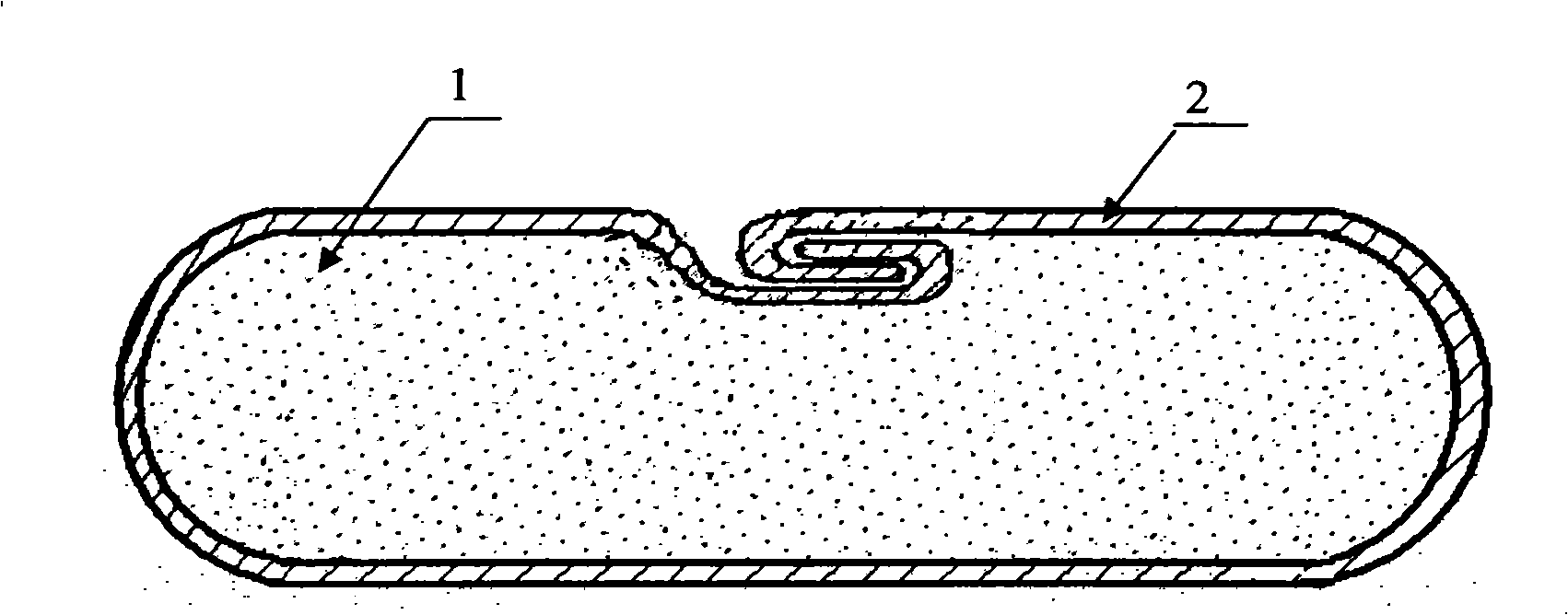

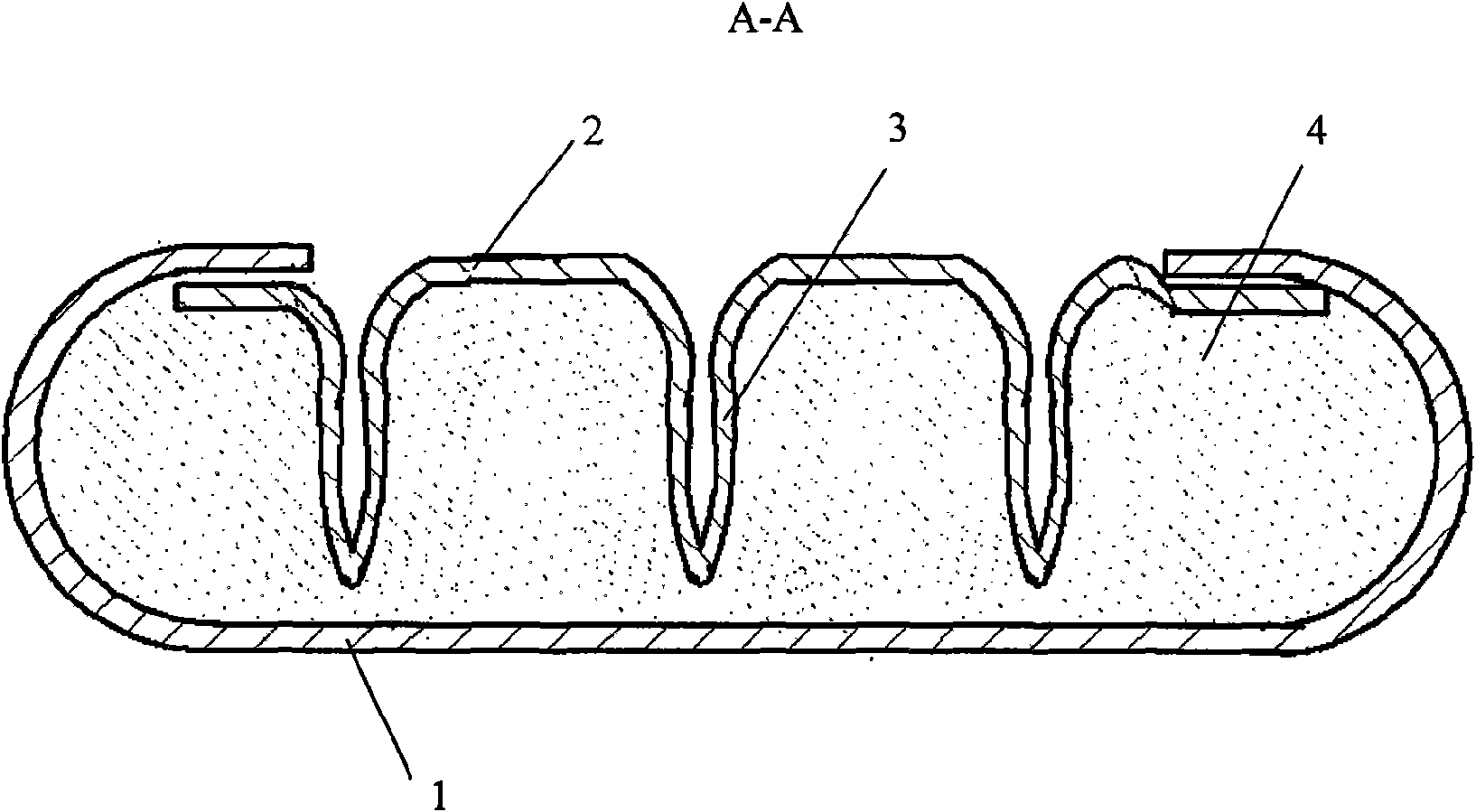

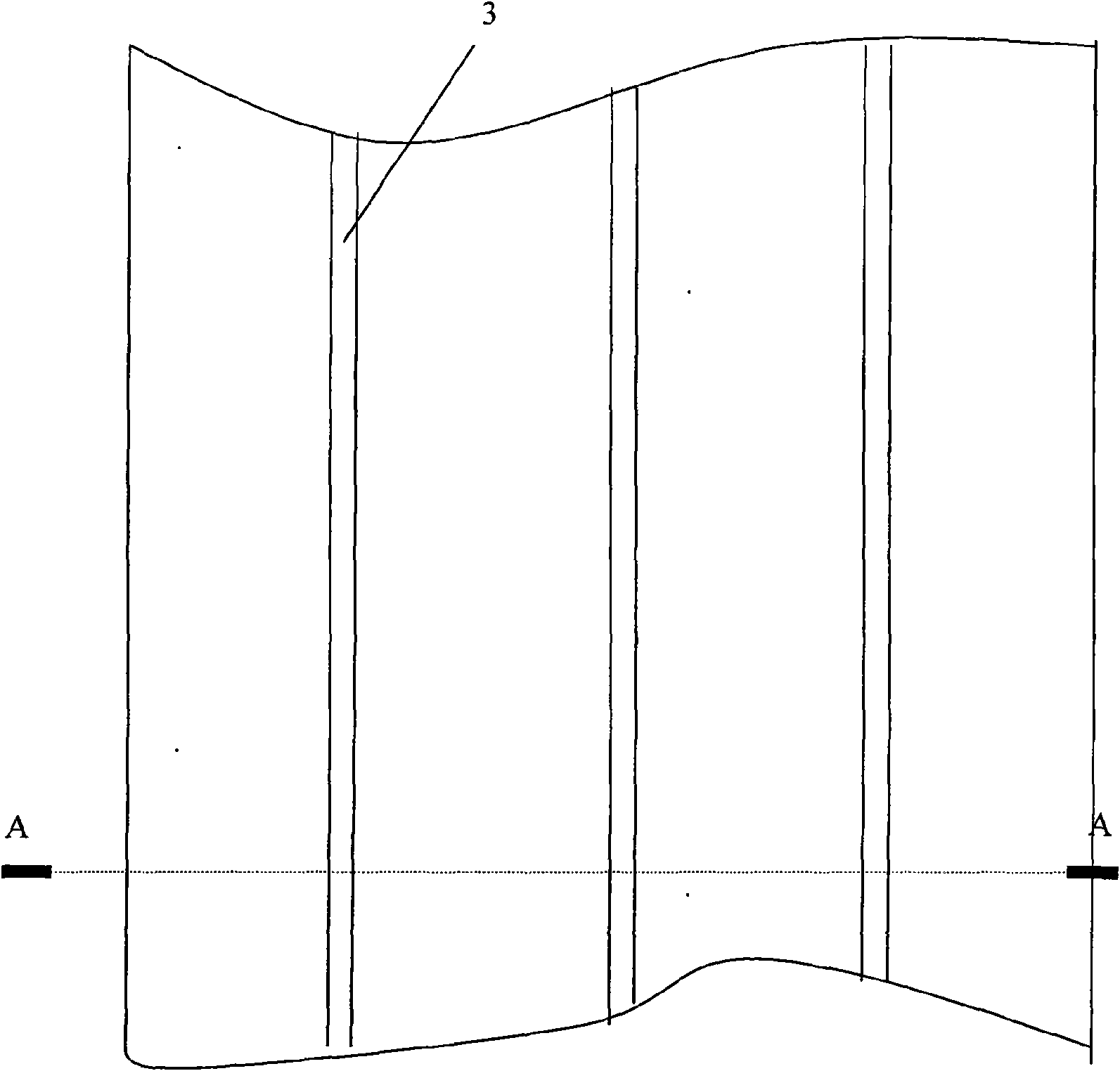

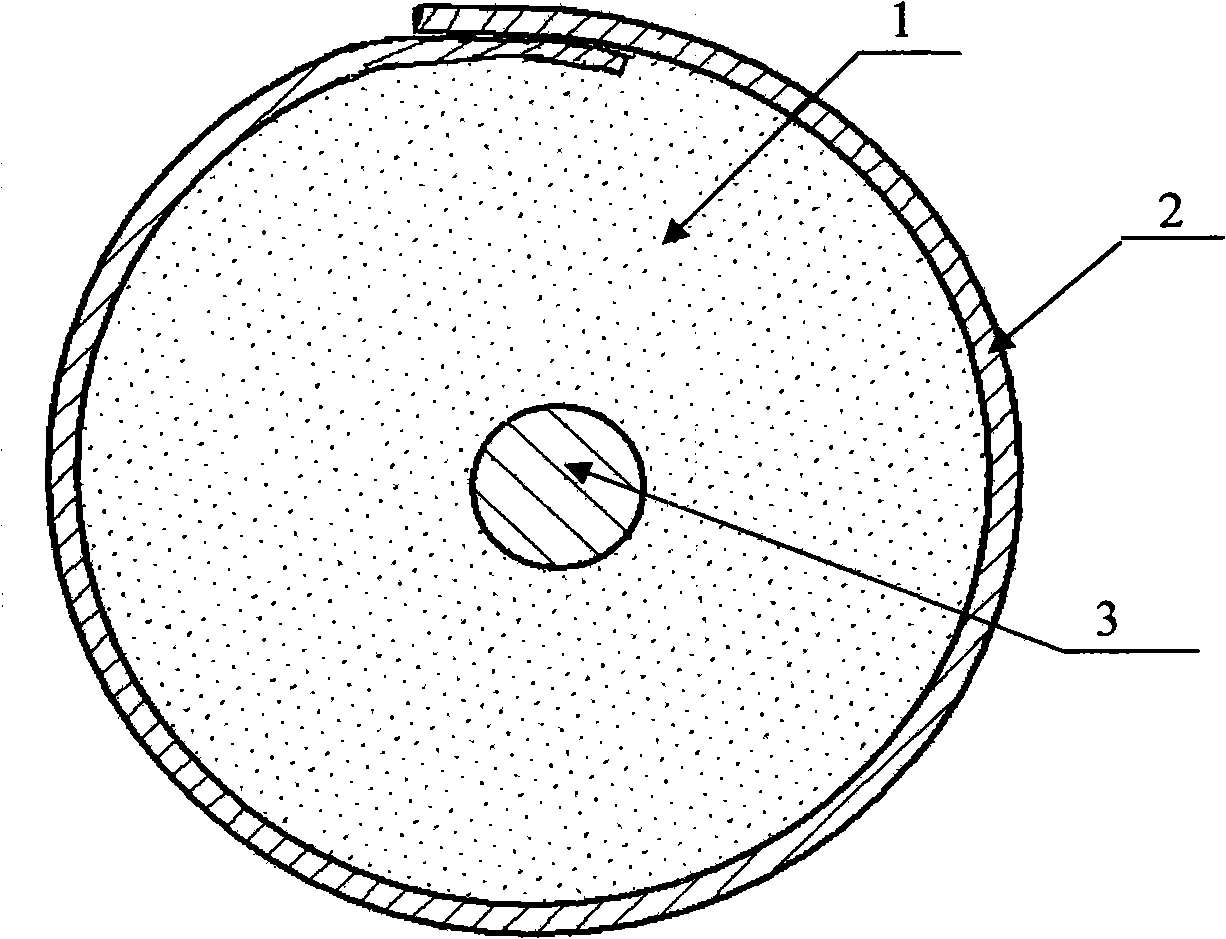

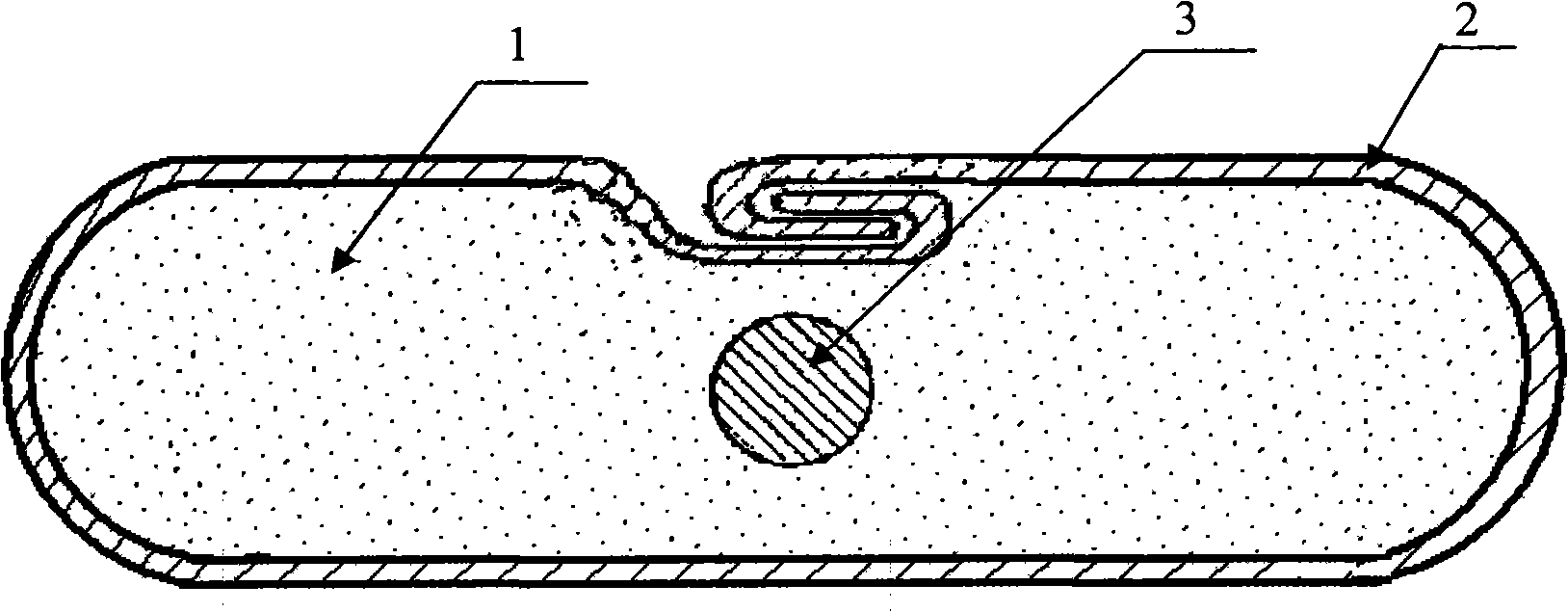

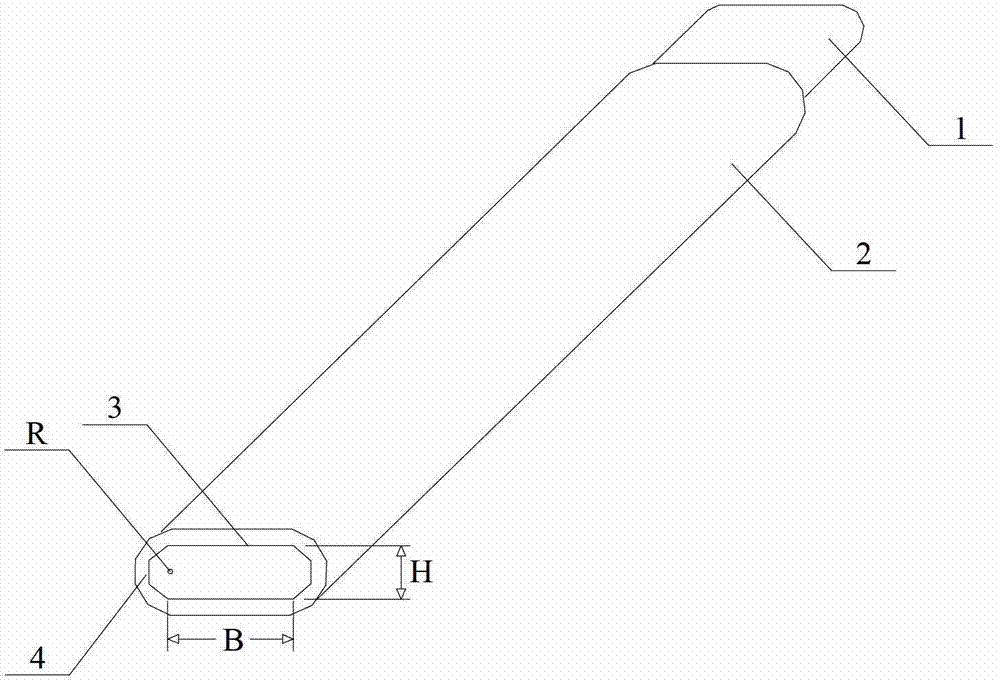

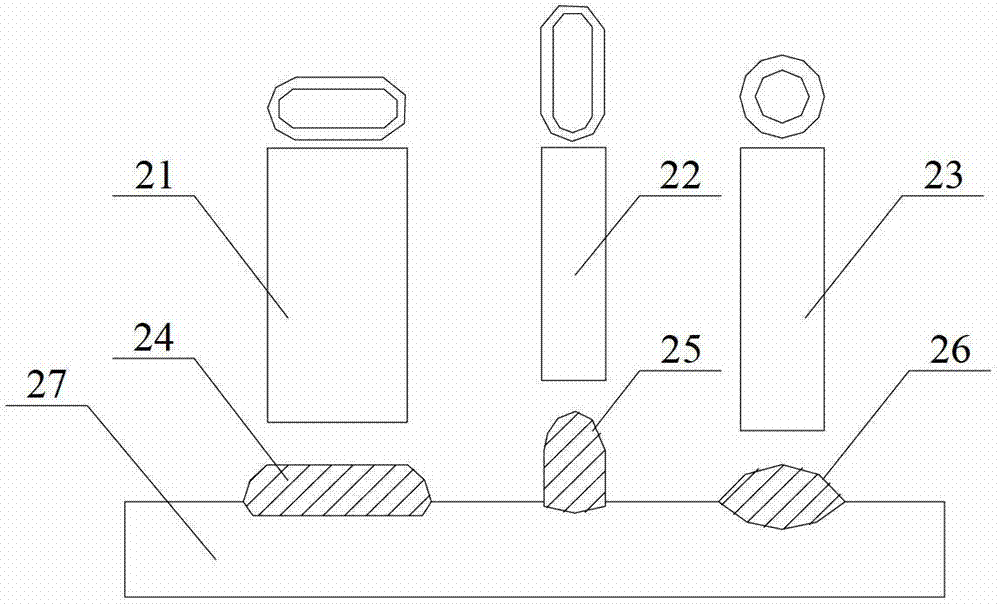

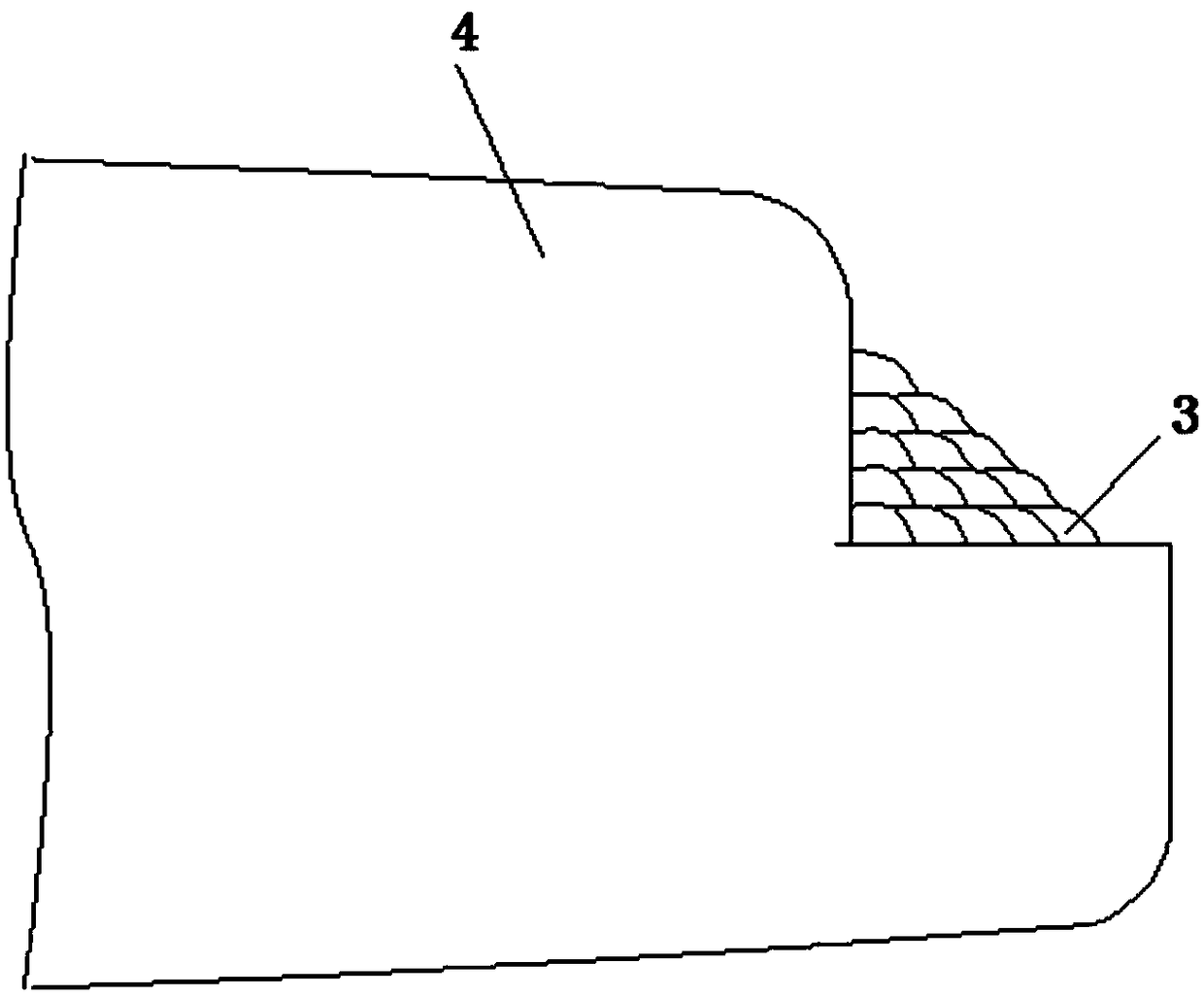

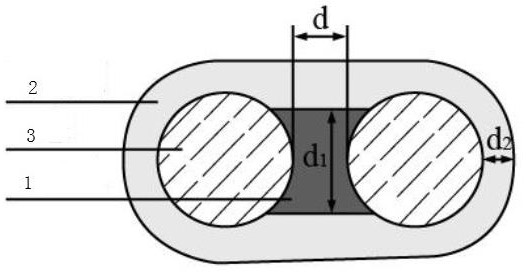

Flat round-corner-shaped bead welding rod having coatings with different thicknesses

InactiveCN103170755AStable combustionNo deflectionWelding/cutting media/materialsSoldering mediaArc stabilityAlloy

The invention provides a flat round-corner-shaped bead welding rod having coatings with different thicknesses. The section of a welding core is in a flat round corner shape, the width ratio of the welding core and each flat plane is 1;1.5-3, and the radius of each round corner is half of the thickness of the welding core. The sections of coatings are in different thickness shapes, the thicknesses of the coatings coated on the outside of the two flat planes are 1.6-3 mm, and the thicknesses of the coatings coated on the outside of the two round corners are 1.2-2.0 mm. The flat round-corner-shaped bead welding rod can obviously increase the weight ratio of the coatings of welding rods (effective areas of the coatings coated on the flat-round-corner-shaped welding core having the same section are much larger than that of a round-bar-shaped welding core), and much abrasion-resistant alloy is melted and transited into bead welding joints to improve abrasion-resistant performance. Much alloy material having good electrical conductivity is added to improve melting speed and arc stability of the coatings, and the technical problems that two coatings of the two round corners of the welding rod, on two sides, fall off and are melted incompletely because of ultra-thicknesses of the coatings are resolved.

Owner:HARBIN INST OF TECH

Corrosion-resistant and wear-resistant composite metal plate

InactiveCN103192162AImprove corrosion resistanceImprove wear resistanceWelding/cutting auxillary devicesArc welding apparatusWear resistantCarbon steel

The invention discloses a corrosion-resistant and wear-resistant composite metal plate. A low-carbon steel plate or a low-alloy steel plate is taken as a base plate, a special corrosion-resistant and wear-resistant bead weld flux-cored wire is arranged at a bead weld composite layer on the surface of the base plate to obtain a corrosion-resistant and wear-resistant composite metal plate blank, and flaws on the surface of the leveled composite metal plate blank is sealed by a prepared special gap seal agent to obtain the corrosion-resistant and wear-resistant composite metal plate. The composite metal plate disclosed by the invention is few in transverse flaws, and high in bonding force between the bead weld layer and the base plate; and the gap seal agent effectively leaks into the transverse flaws, so that the corrosion resistance of the composite metal plate can be observably improved, and the service life of the composite metal plate under the corrosion work condition can be observably prolonged.

Owner:SHANDONG UNIV

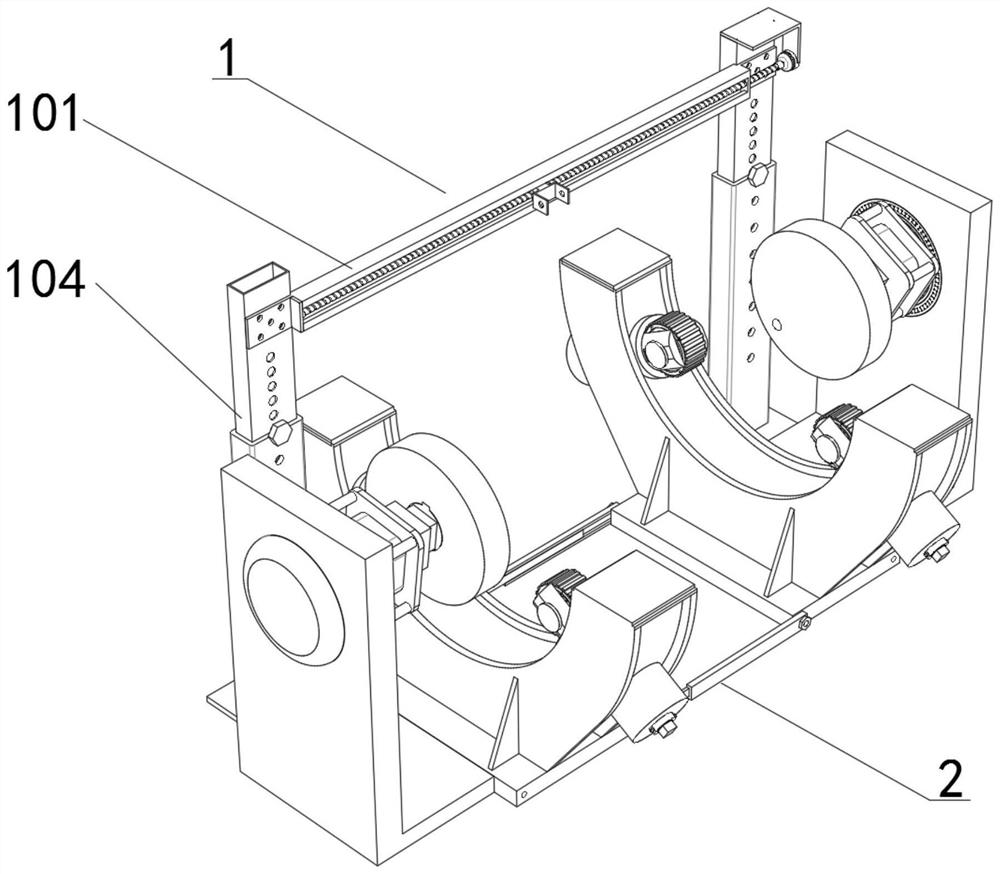

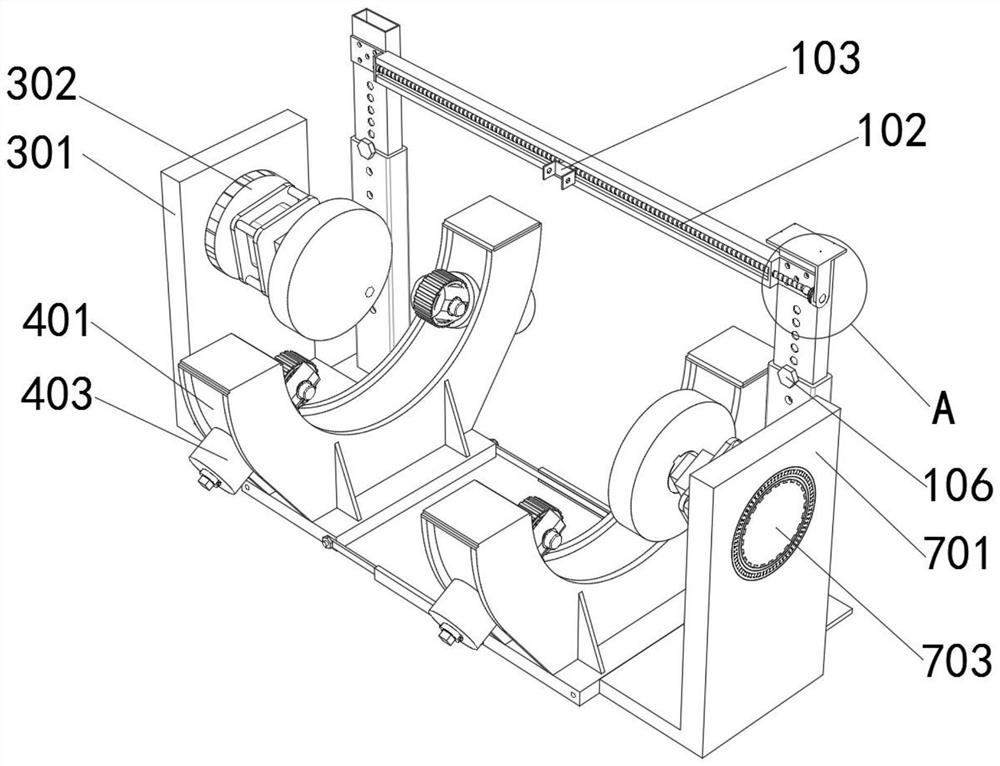

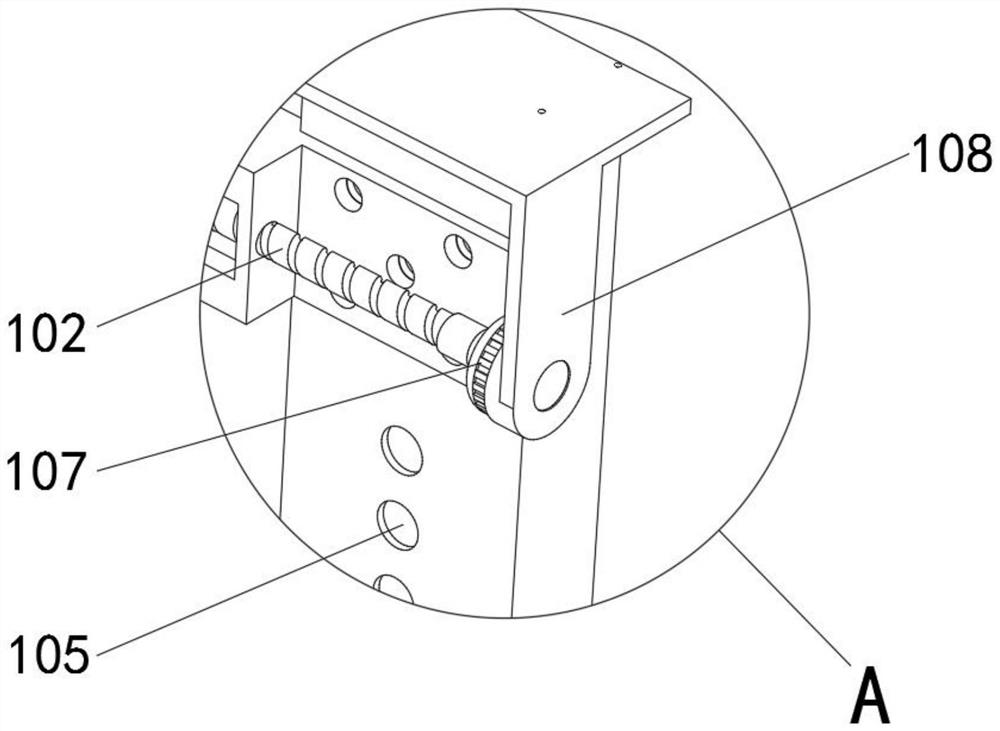

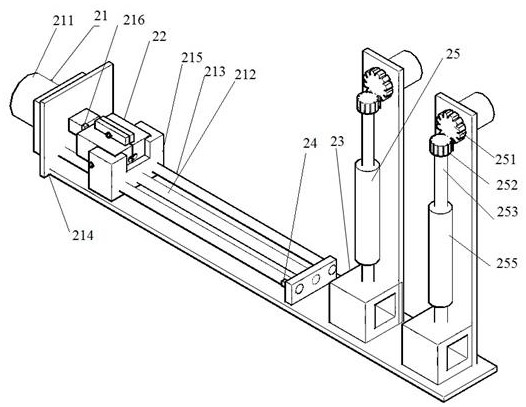

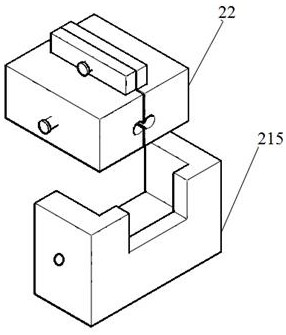

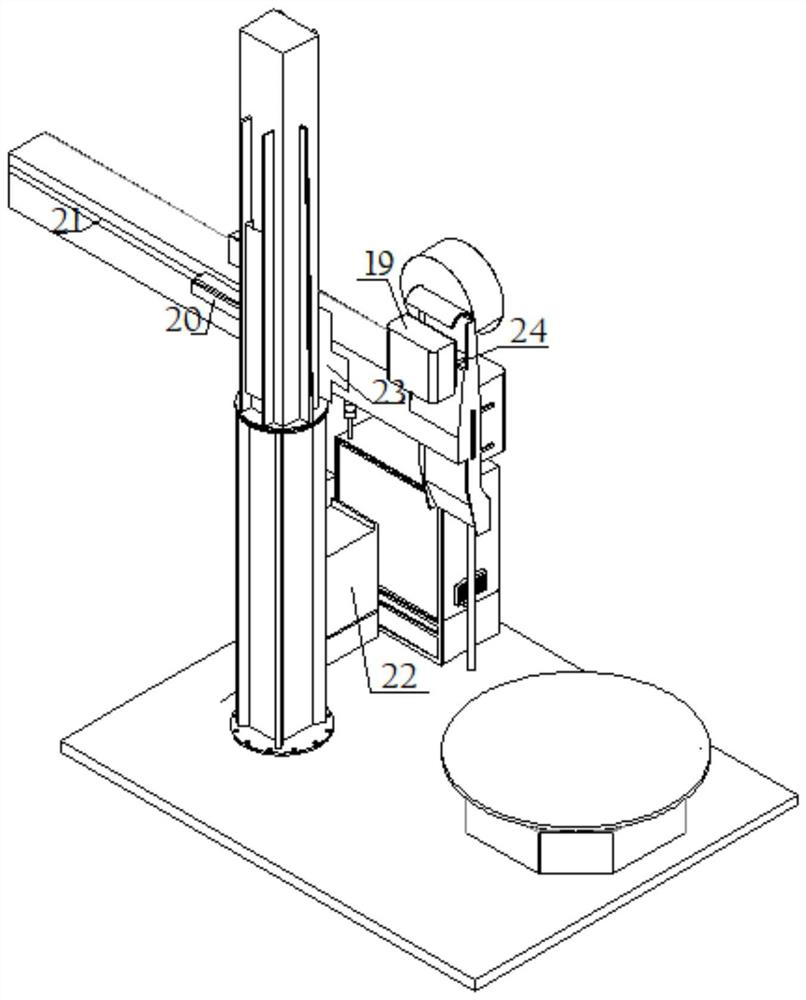

Surfacing control equipment for roller press surface repair

PendingCN112077473AAccurate surfacingReduce the hassle of manual screeningWelding/cutting auxillary devicesAuxillary welding devicesElectric machineControl engineering

The invention relates to the technical field of roller press surfacing repair, and discloses surfacing control equipment for roller press surface repair. The surfacing control equipment comprises a surfacing bracket, a roller press part clamping mechanism is arranged at one side of the surfacing bracket, the clamping mechanism comprises a driving mechanism, the driving mechanism comprises a firstfixing frame, a driving motor is fixedly arranged in the upper end of the first fixing frame, a first servo electric cylinder is fixedly arranged at the output end of the driving motor, a first auxiliary rotating device is arranged at one side of the driving mechanism, a sliding device is arranged at the other side of the first auxiliary rotating device, and the sliding device comprises a slidingrail; and a second auxiliary rotating device is arranged at the other end of the sliding device, the structure of the first auxiliary rotating device is completely consistent with that of the second auxiliary rotating device, and a driven mechanism is arranged at one side of the second auxiliary rotating device. According to the surfacing control equipment, the trouble of manual screening can be reduced, the working efficiency is improved, surfacing errors are reduced, and the surfacing efficiency is improved.

Owner:合肥中都机械有限公司

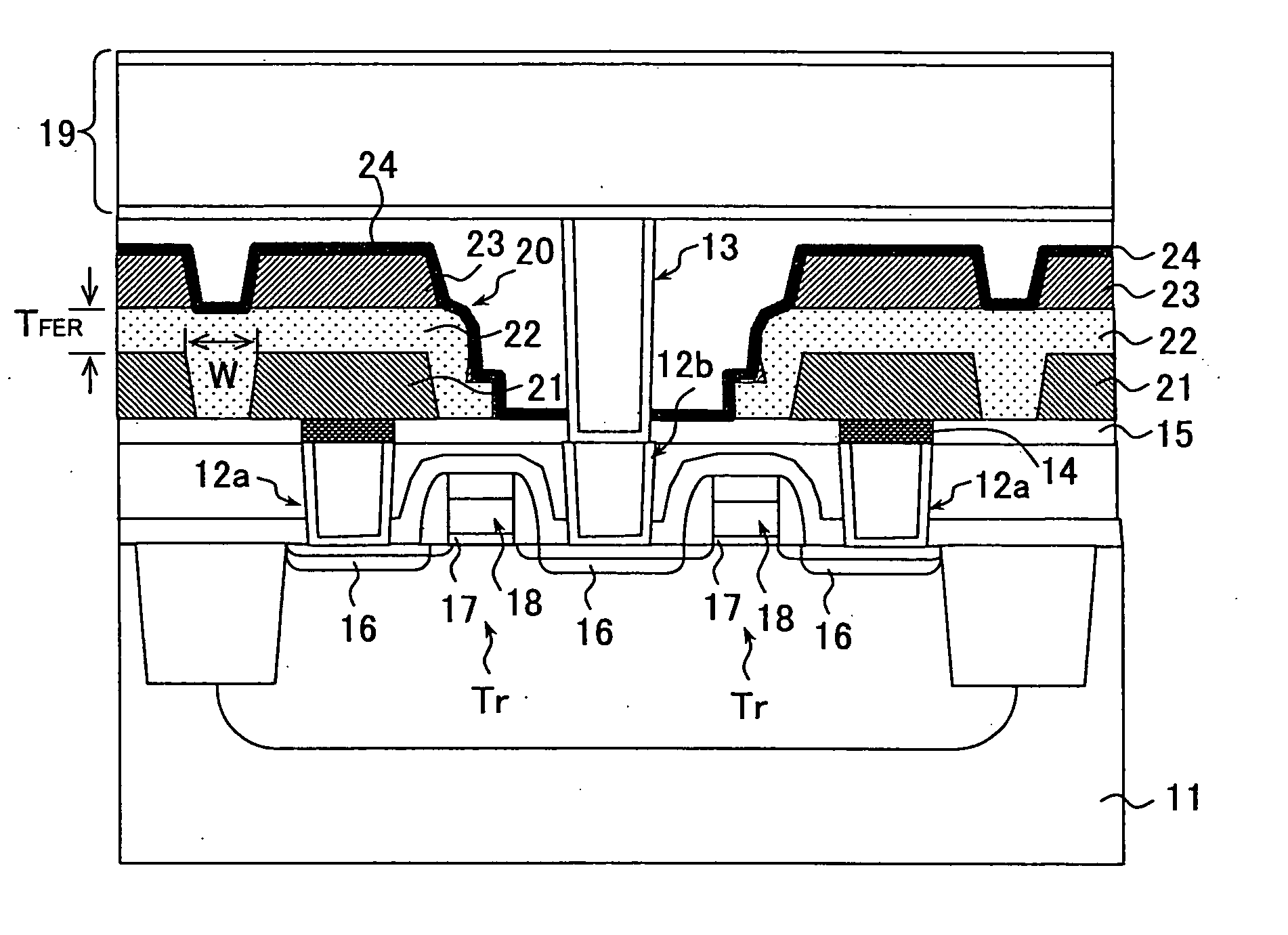

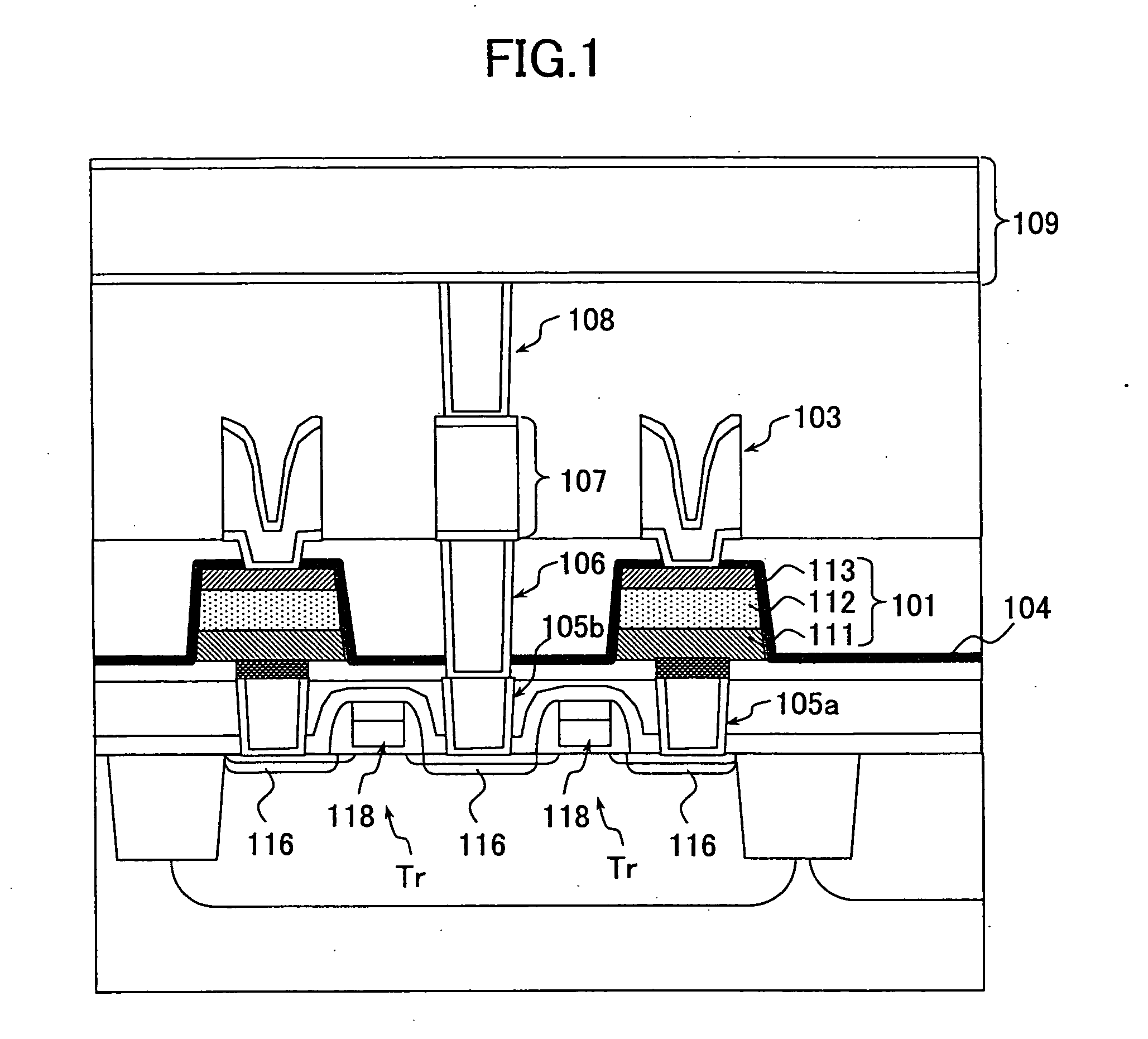

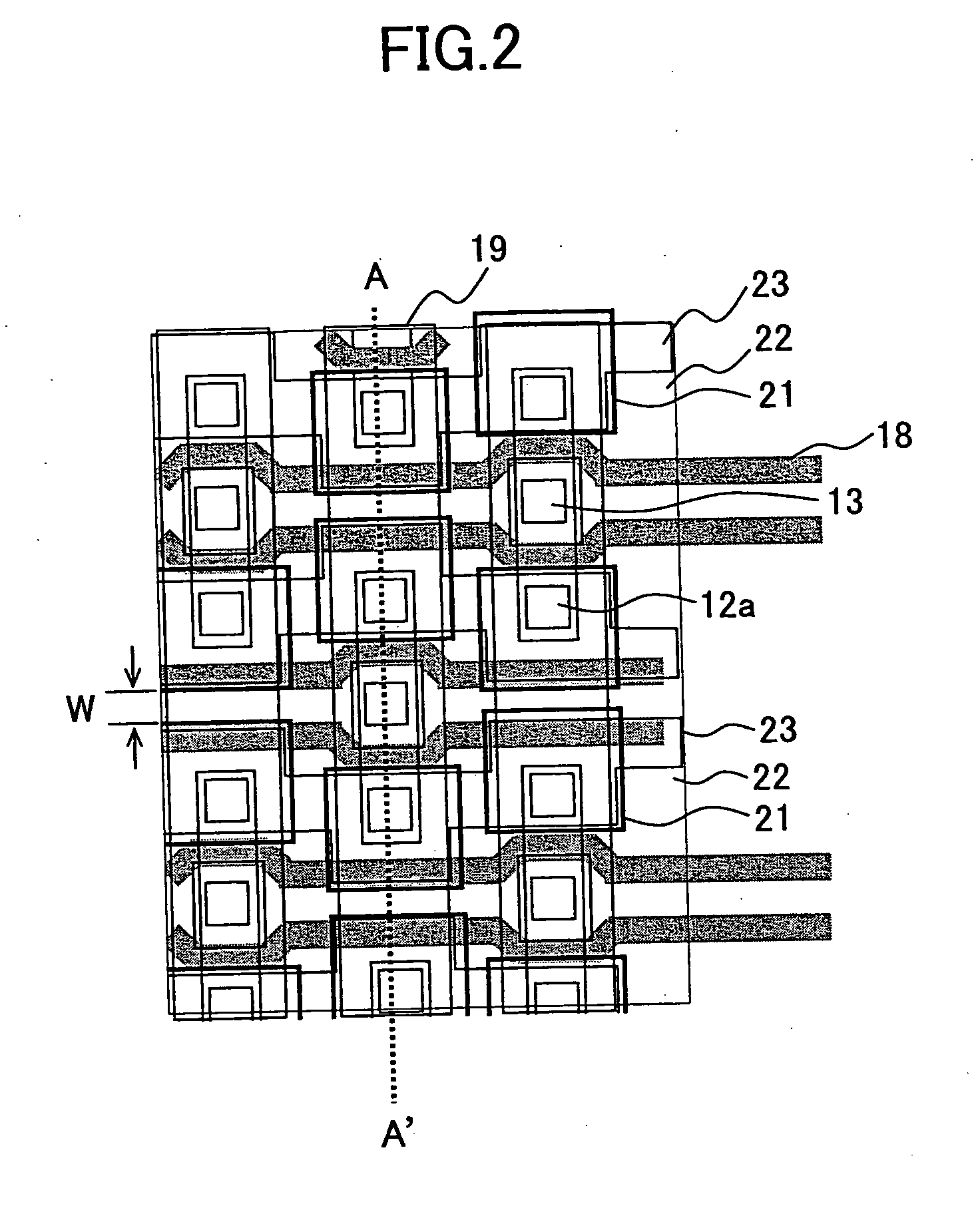

Semiconductor device and fabrication method of a semiconductor device

InactiveUS20050133842A1Improve surfacing efficiencyEliminate degradationSolid-state devicesSemiconductor/solid-state device manufacturingIn planeEtching

In a conventional semiconductor device provided with a conventional stacked type ferroelectric capacitor, there has been caused a problem of capacitor degradation by leakage between an upper electrode and a lower electrode via an etching reside, when the efficiency of utilization of a surface area is increased by decreasing the interval between the capacitors in the in-plane direction of the substrate, as a result of the one-step annealing of the laminated from of lower electrode film / ferroelectric film / upper electrode film. The present invention prevents leakage caused by short circuit between the lower electrode and the upper electrode, by forming plural lower electrodes, forming a ferroelectric film so as to cover the surface and sidewall surface of the lower electrodes and forming an upper electrode on the ferroelectric film so as to oppose with the lower electrodes. Further, as a result of forming the ferroelectric film so as to cover the lower electrodes continuously and by setting the interval between the lower electrodes and the thickness of the ferroelectric film to satisfy a predetermined relationship, the surface of the ferroelectric film is planarized and exposure of the sidewall is suppressed. Thereby, degradation of the capacitor is prevented.

Owner:FUJITSU SEMICON LTD

Self-protection flux-cored wire for strengthening surface of large hot-forging die and production method of self-protection flux-cored wire

ActiveCN107175426AExtended service lifeEasy to processWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a self-protection flux-cored wire for strengthening the surface of a large hot-forging die and a production method of the self-protection flux-cored wire. The flux-cored wire comprises, by mass percentage, 26-30% of chromium, 8-10% of molybdenum, 1.8-3% of tungsten, 1.5-2.5% of nickel, 0.8-1.2% of silicon, 0.6-1.0% of manganese, 0.15-0.3% of niobium, 1.2-1.6% of carbon, not larger than 0.02% of phosphorus, not larger than 0.02% of sulfur and the balance cobalt and impurities. By the adoption of the self-protection flux-cored wire for strengthening the surface of the large hot-forging die, overlaying of the flux-cored wire is conducted on the surface of the working region of a die cavity of the large hot-forging die, the surface strengthened layer is formed, the temperature of the surface layer of the die cavity of the large hot-forging die is below 500-700 DEG C, the wear, deformation and crack are not likely to generate under the extreme working condition that the load is above 40,000 tons, the service life of the large hot-forging die is prolonged by over 10 times, and the manufacturing cost of large forgings is lowered remarkably.

Owner:CHONGQING JIEPIN TECH +2

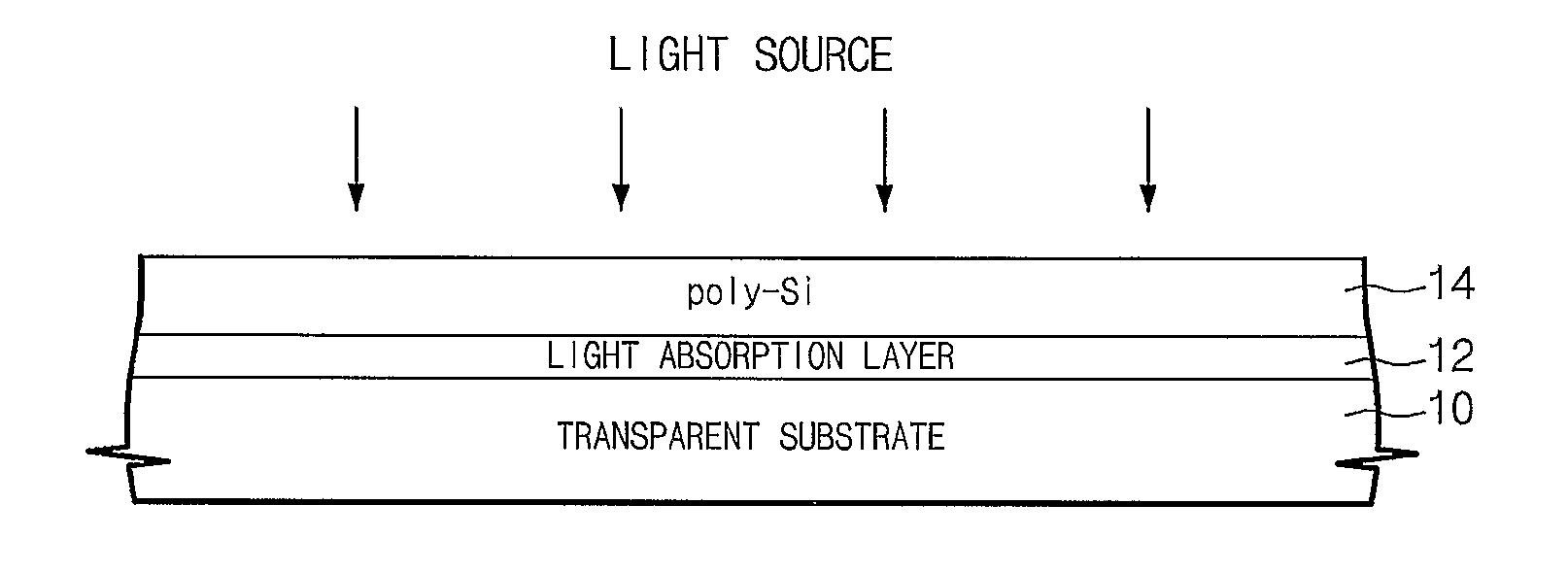

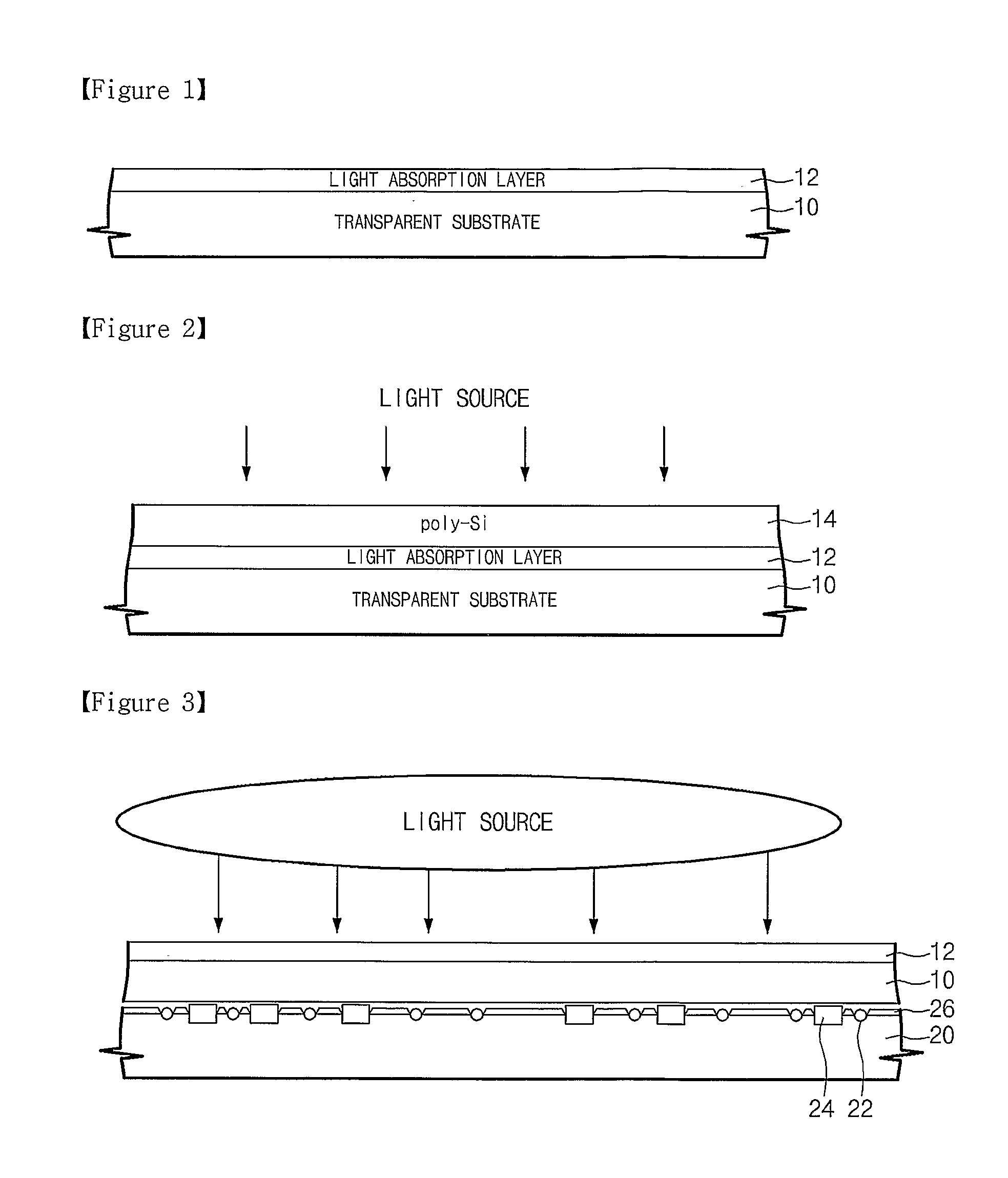

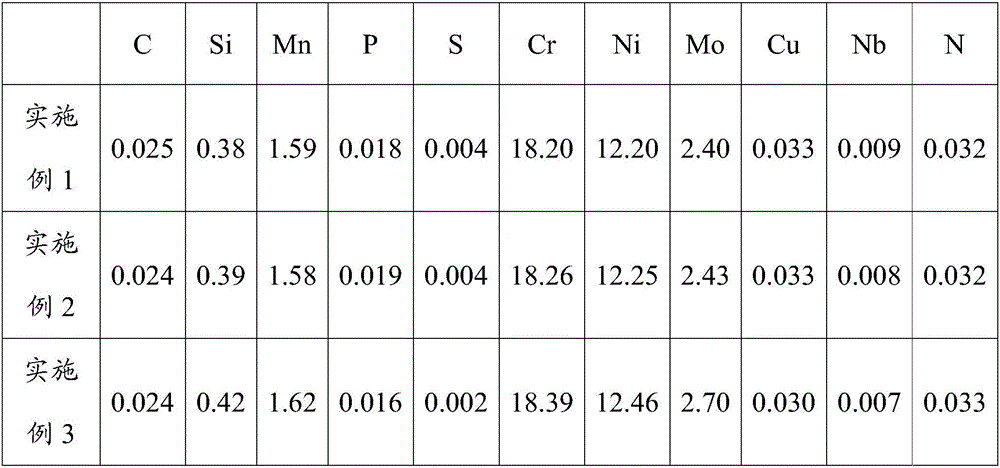

Method and Apparatus For Fabricating Polycrystalline Silicon Film Using Transparent Substrate

InactiveUS20080169468A1Improve surfacing efficiencyOvercome vulnerabilitySolid-state devicesSemiconductor/solid-state device manufacturingIrradiationHeat treated

Provided is a method and apparatus for fabricating a polycrystalline silicon film using a transparent substrate. The method includes forming a light absorption layer on a surface of the transparent substrate; and heating the light absorption layer using irradiation of Rapid Thermal Process (RTP) light source, while depositing the polycrystalline silicon film on the light absorption layer.

Owner:POINT ENG

Corrosion-resistant abrasion-resistant composite metal plate suitable for high-temperature working condition

InactiveCN103192161BImprove corrosion resistanceHeat resistantWelding/cutting auxillary devicesArc welding apparatusComposite plateCarbon steel

The invention discloses a corrosion-resistant abrasion-resistant composite metal plate suitable for a high-temperature working condition, and the corrosion-resistant abrasion-resistant composite metal plate is prepared through the following steps of: obtaining a heat-resistant corrosion-resistant abrasion-resistant composite metal plate blank by taking a low-carbon steel plate or a low-alloy steel plate as a base plate and overlaying a composite layer on the surface of the base plate by adopting a special heat-resistant corrosion-resistant abrasion-resistant overlaying flux-cored wire; and then carrying out seam sealing processing on cracks positioned on the surface of a smoothed composite metal plate blank by using a prepared special seal sealing agent. According to the invention, by preparing the special heat-resistant abrasion-resistant corrosion-resistant overlaying flux-cored wire and overlaying by adopting an open-arc welding process, the deformation of the overlaying composite plate is reduced, the transverse cracks of a welding pass are decreased and uniformly distributed; and the corrosion-resistant property of the composite metal plate is outstandingly enhanced in such a way that the seam sealing agent is effectively permeated into the transverse cracks, so that the service life of the composite metal plate in high temperature and corrosion working conditions is outstandingly prolonged.

Owner:SHANDONG UNIV

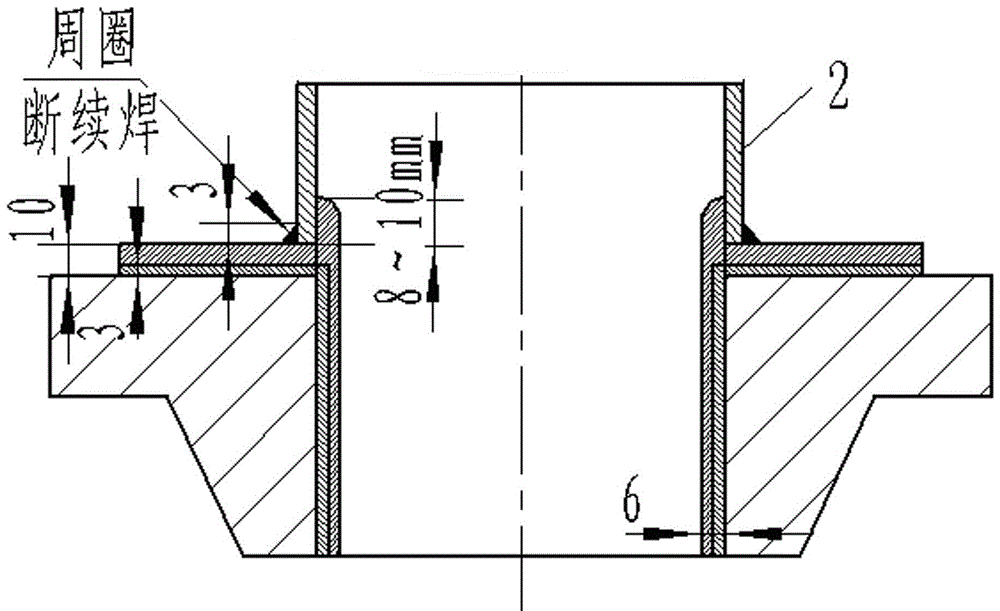

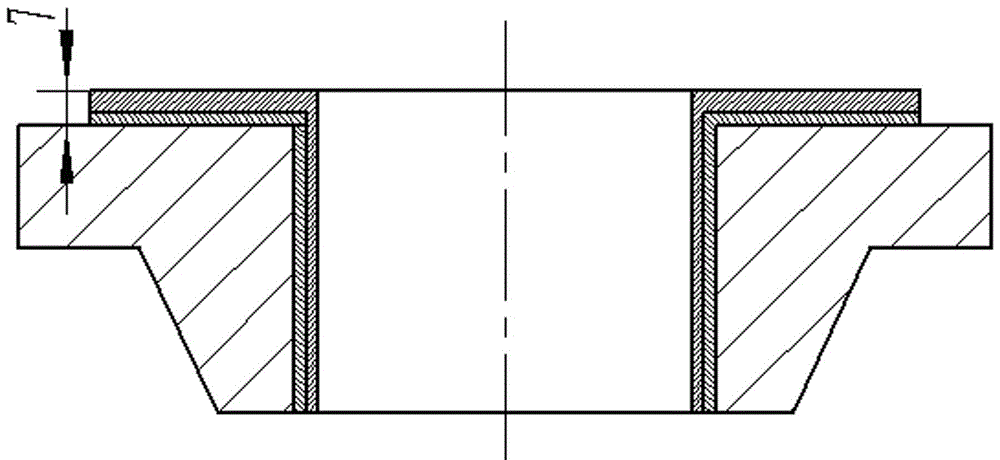

Strip surfacing method for flange of gasification furnace equipment

ActiveCN106180970ARealize automatic surfacingGuarantee the quality of surfacing weldingArc welding apparatusSpot weldingFlange

The invention belongs to the field of strip surfacing, and particularly discloses a strip surfacing method for a flange of gasification furnace equipment. The strip surfacing method for the flange of the gasification furnace equipment comprises the steps: during surfacing of a sealing surface, a baffle ring is subjected to spot welding on the inner wall of the flange; and during the surfacing of the inner surface, a shell ring is subjected to the spot welding on the sealing surface and is used for blocking a flux and for transition surfacing. The effect that the flange of the gasification furnace equipment is accomplished by automatic strip surfacing wholly is realized, the surfacing quality and the appearance forming are ensured, and the surfacing efficiency is improved.

Owner:SHANXI YANG MEI CHEM IND MACHINERY

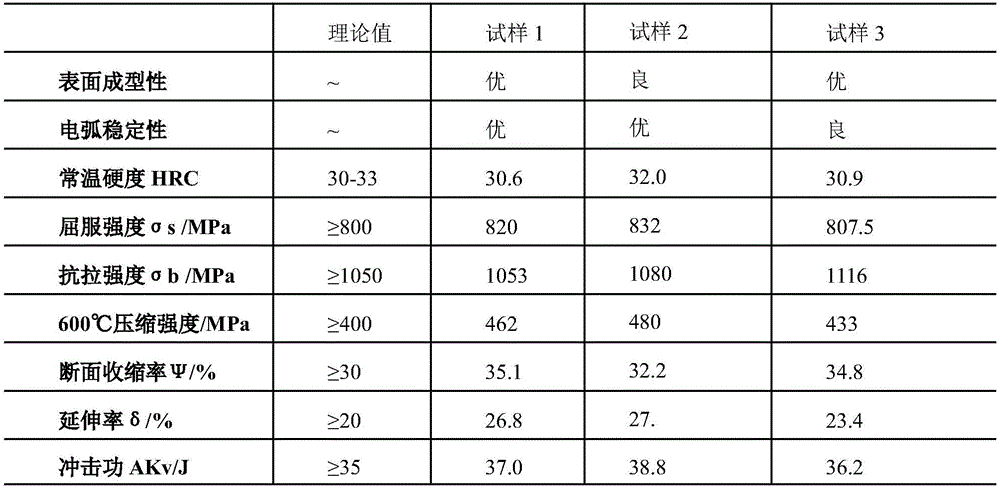

Submerged arc flux-cored wire for Cr13 series universal type build up welding, preparation for submerged arc flux-cored wire and application for submerged arc flux-cored wire

ActiveCN103612024AStable and uniform hardnessImprove surfacing efficiencyArc welding apparatusWelding/cutting media/materialsIron powderFerromolybdenum

The invention discloses a submerged arc flux-cored wire for Cr13 series universal type build up welding, preparation for the submerged arc flux-cored wire and application for the submerged arc flux-cored wire. The flux-cored wire comprises a cover and an encapsulated flux-cored core wire, wherein the weight of the flux-cored core wire accounts for 35-36% of the total weight; and the flux-cored core wire comprises the following components in percentage by weight: 2.8-6% of high carbon ferro-chrome, 2.5-3.5% of micro-carbon ferro chrome, 11-13% of chromium metal, 2-3.6% of nickel powder, 1.5-2% of ferro-molybdenum, 2.8-4.5% of mid-carbon ferromanganese, 1-5.4% of ferrotitanium and the balance iron powder. The submerged arc flux-cored wire for the Cr13 series universal type build up welding is high in build up welding; the hardness of a build up welding layer is stable and uniform (the hardness deviation is smaller than or equal to HRC 3); and welding technological properties are excellent.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

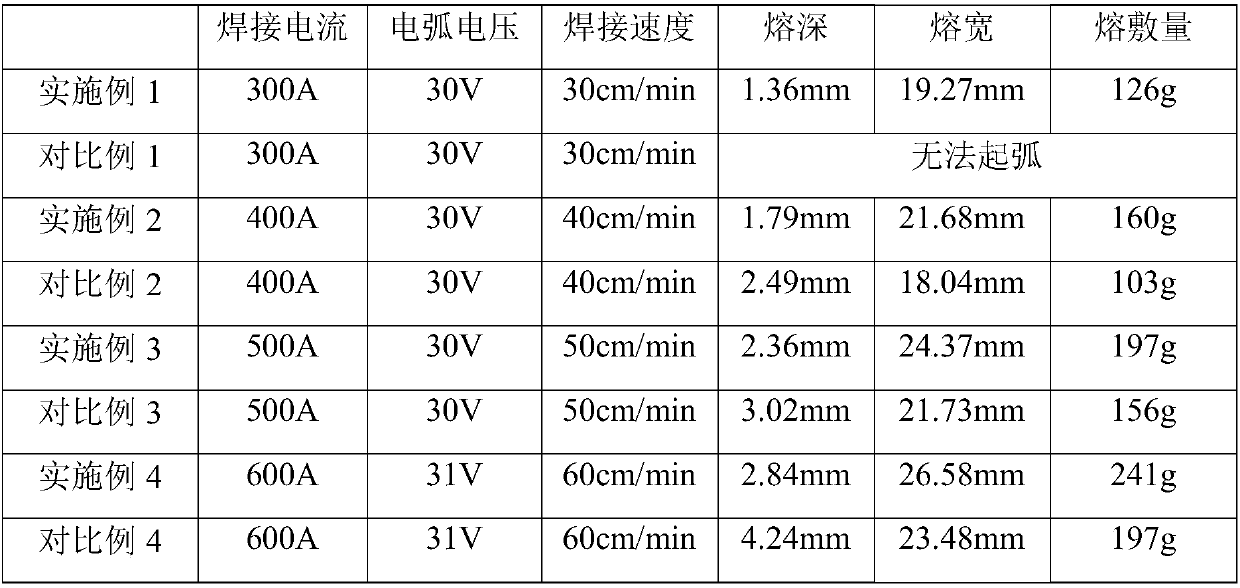

Thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method

The invention discloses a thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method. The method comprises the following steps that a weldingwire is used for winding six fine welding wires around one center welding wire to be spiraled into a spiral structure; and the prepared welding wire is fed into a welding area of a submerged-arc automatic trolley through a wire guide pipe and is connected with a welding power source to transmit welding current, the submerged-arc automatic trolley can move along the joint of a base material, meanwhile, a flux is applied to the welding area in an assisted mode until surfacing is completed. According to the method, the rotation motion of the welding arc is further driven under the action of mechanical rotation generated during feeding of the spiral-shaped single wires, a liquid molten pool is forced to carry out fluid motion perpendicular to the fusion depth direction so as to reduce the convection motion of the metal in the molten pool to the bottom, so that the heat inside the molten pool is conducted in the width direction of a weld joint, then the melting amount of the root of the molten pool is reduced, and a welding bead is enabled to be expanded in the width direction. According to the process method, the cable type welding wire shallow fusion depth with the diameter of 6.0 mmand wide-bead submerged-arc automatic surfacing are achieved, extremely high surfacing efficiency is realized, meanwhile, the welding cost can be further reduced.

Owner:NANJING INST OF TECH

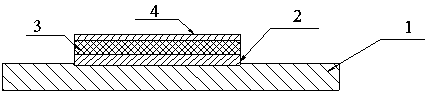

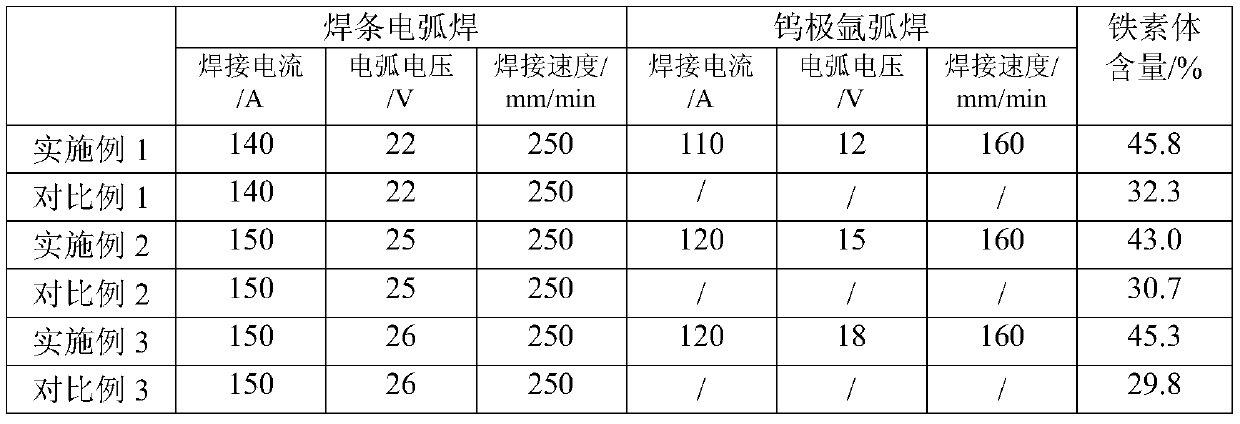

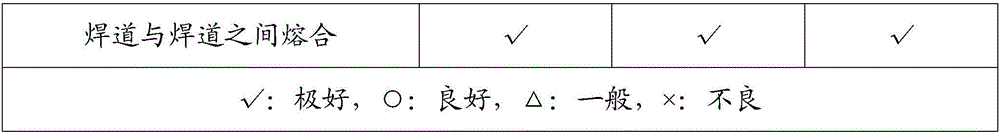

Phase proportion control method for surfacing welding of two-phase corrosion resistant layer on surface of carbon steel

ActiveCN110449692AIncreased ferrite contentImprove corrosion resistanceArc welding apparatusManufacturing cost reductionDouble phase

The invention discloses a phase proportion control method for surfacing welding of a two-phase corrosion resistant layer on the surface of carbon steel. The phase proportion control method comprises the following specific steps that a transition isolation layer, a filling layer and a cover layer are sequentially arranged on a base material through surfacing welding; the high-nickel ultra-low carbon austenitic deposited metal is adopted as the transition isolation layer; high-chromium and high-nickel stainless steel electrode is adopted for large-current and high-efficiency arc surfacing welding to form the filling layer, namely the super alloyed anti-corrosion surfacing welding layer of an austenite-ferrite double-phase structure; the interlayer temperature is controlled to be 120 DEG C orlower in the process of surfacing welding; small-current gas shielded tungsten arc welding is adopted for cover surface surfacing welding to form the cover layer; the post weld heat treatment is notneeded after surfacing welding is finished; and the penetrant inspection is carried out 24 hours after welding, and the ferrite content is measured through a ferrite tester. According to the weldingmethod, two-phase structure corrosion-resistant surfacing welding layer with approximately equal proportion can be formed, and heat treatment is not needed after welding so that the machining technology can be simplified, and the manufacturing cost can be reduced.

Owner:NANJING INST OF TECH

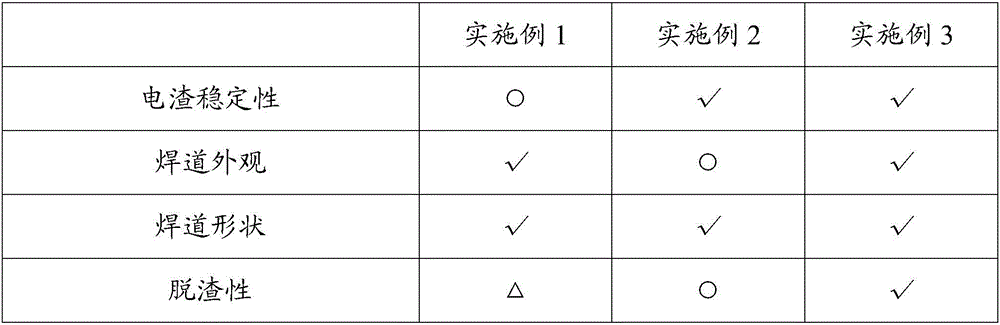

Sintering flux used for stainless steel high-speed electro-slag strip surfacing and preparation method for same

InactiveCN106514053AImprove surfacing efficiencyGood welding performance and mechanical propertiesWelding/cutting media/materialsWelding/soldering/cutting articlesSlagSintering

The invention discloses a sintering flux used for stainless steel high-speed electro-slag strip surfacing and a preparation method for the same. The sintering flux is made of 6-10 parts by weight of SiO2, 0.5-1 part by weight of MgO, 16-20 parts by weight of Al2O3, 65-85 parts by weight of CaF2, 2-4 parts by weight of CaO and 0.5-2 parts by weight of MnO. The preparation method comprises the steps that all the constituent power materials of the sintering flux are mixed according to proportion ratios, so a first mixed materials is obtained; a binder which occupies 15-20% of the weight of the first mixed material is added, and the mixture is mixed, stirred and pelleted, so that a second mixed material is obtained; and the second mixed material is successively processed by low-temperature baking of 100-200 DEG C and high-temperature sintering of 600-800 DEG C, so the sintering flux can be obtained after screening. The sintering flux disclosed by the invention has the advantages that surfacing efficiency is twice the surfacing efficiency of common electro-slag strip surfacing during the same period, and the sintering flux has god welding technological performance and mechanical properties.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

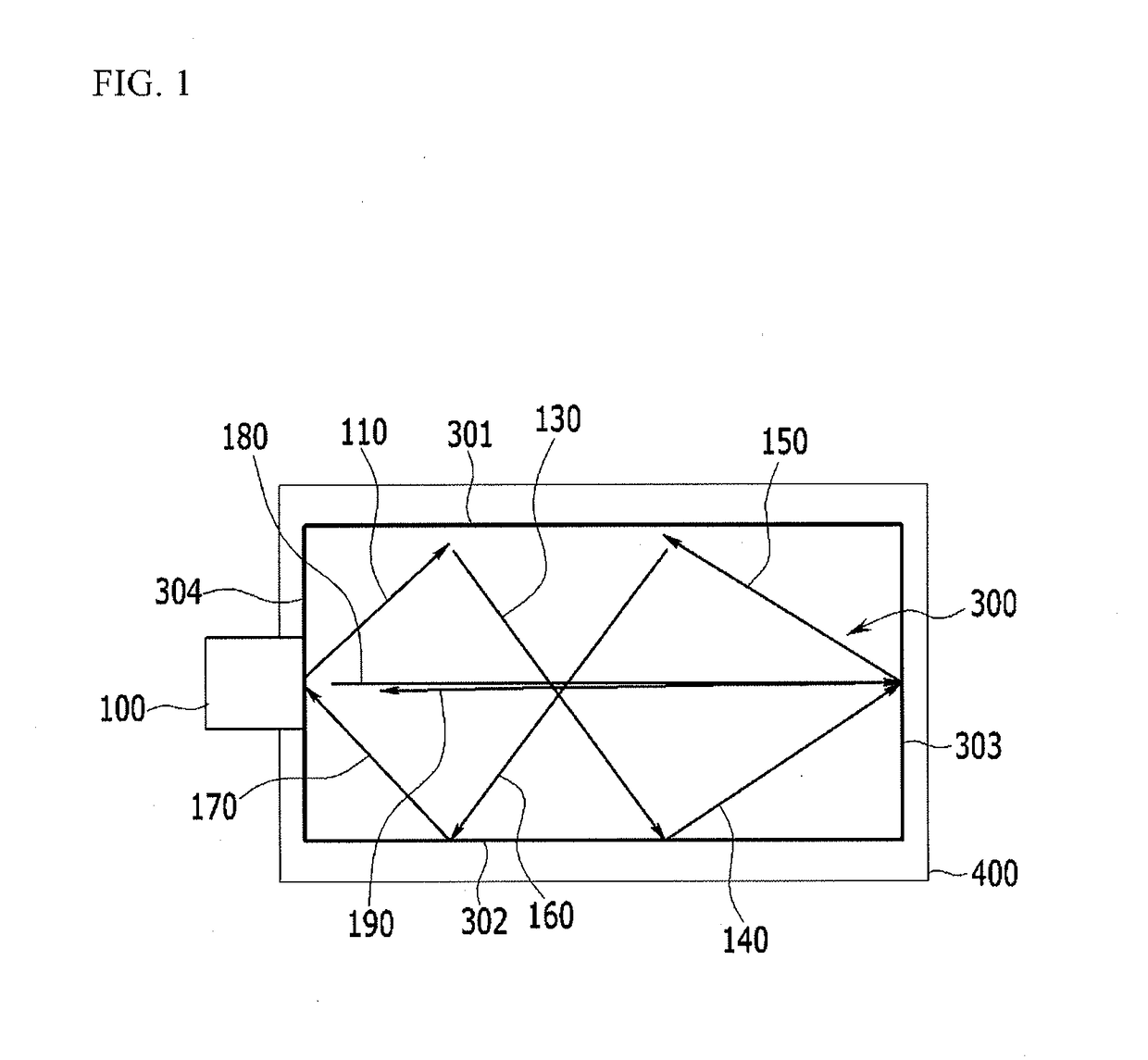

Surface lighting module and surface lighting source device for a vehicle using the same

InactiveUS20170368989A1Improve surfacing efficiencyImprove marketabilityPlanar light sourcesMechanical apparatusLight guideEffect light

A surface lighting module may include: a light source configured to emit light; a main reflection part configured to reflect light emitted from the light source; a light guiding part that is provided at an upper portion of the main reflection part and spreads light reflected from the main reflection part to have a surface shape; and a lateral reflection part that is attached to a lateral surface of the light guiding part and reflects light leaking to the lateral surface of the light guiding part.

Owner:HYUNDAI MOTOR CO LTD

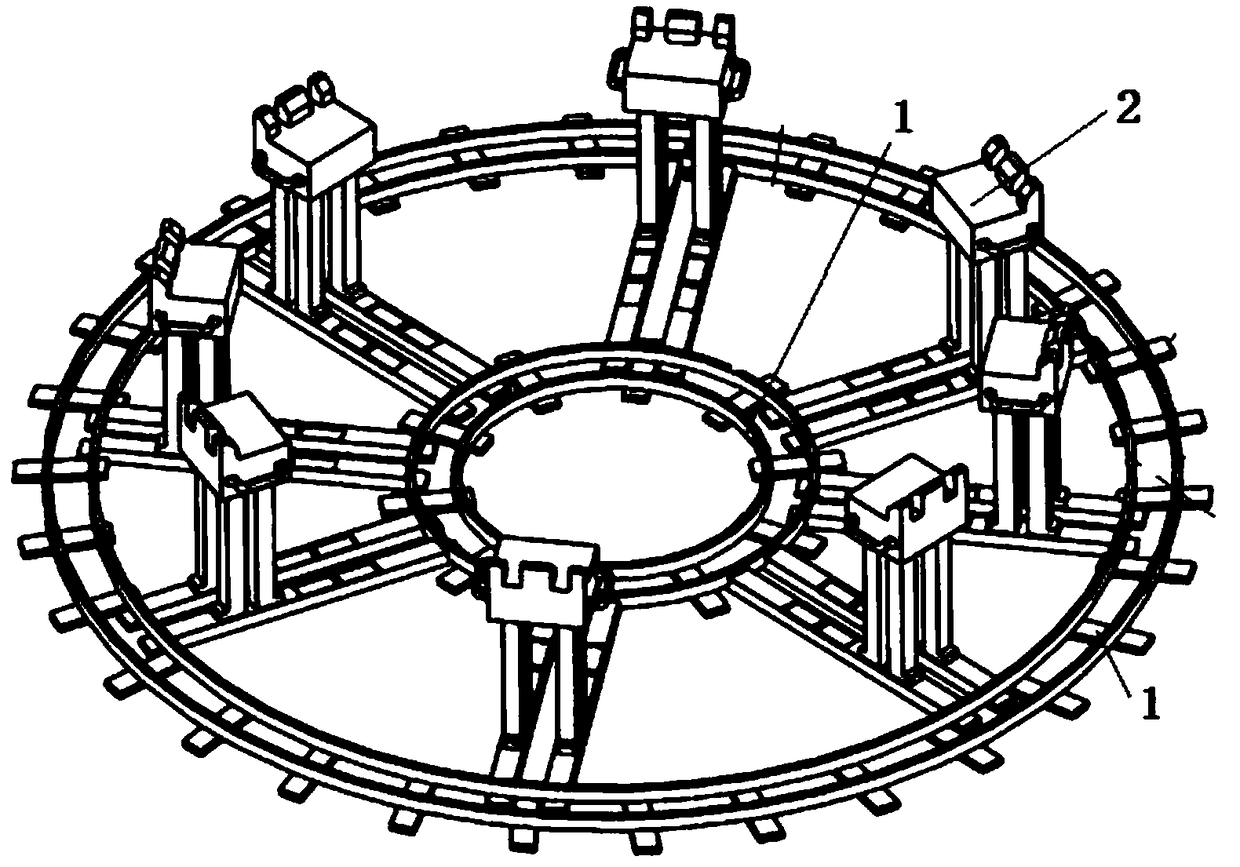

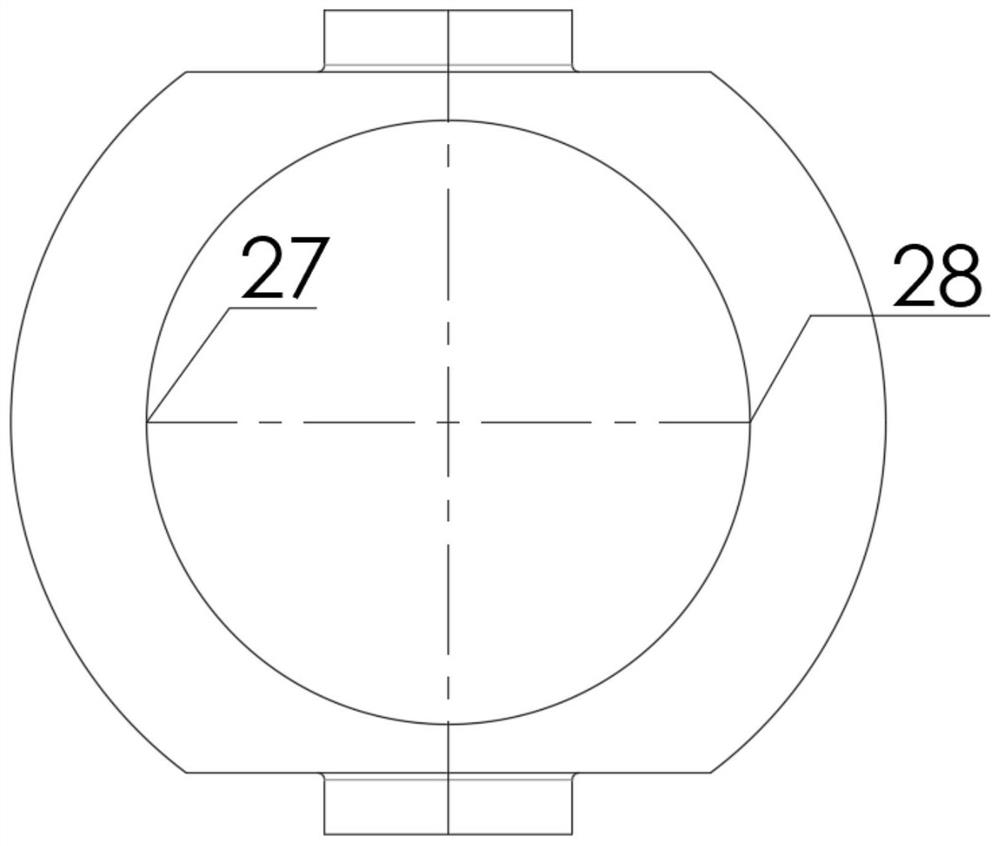

Surfacing technology for ring-type workpiece

InactiveCN108746935AQuality improvementImprove surfacing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRing type

The invention provides a surfacing technology for a ring-type workpiece, and relates to the technical field of welding. The technical problems that in the prior art, manual welding is low in welding efficiency and large in labor intensity are solved. The surfacing technology for the ring-type workpiece comprises the following steps that S1, a surfacing device moves along a predetermined track in the circumferential direction of a to-be-welded piece or autorotates, and each time the surfacing device moves along the predetermined track in the circumferential direction or autorotates, distribution of one or more weld beads on the corresponding area of a to-be-surfaced area of the to-be-welded piece is completed by a welding device; and S2, the step S1 is executed repeatedly until all the weldbead distribution is completed, and thus surfacing treatment on the to-be-surfaced area is achieved. The surfacing technology is used for improving the surfacing efficiency, reducing the labor intensity and improving the surfacing quality.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

A nickel-based self-fluxing hardfacing flux-cored welding wire for plasma surfacing

InactiveCN106271208BGood self-fluxingReduce manufacturing costPlasma welding apparatusWelding/cutting media/materialsIron powderHardness

The invention belongs to the field of welding materials, and particularly relates to a nickel-based self-fluxing hard-facing flux-cored wire for plasma surfacing. The flux-cored wire comprises all elemental components including, by weight, 0.3% to 1.0% of carbon, 14% to 19% of chromium, 3.5% to 5.0% of silicon, 3.0% to 4.5% of boron, 0% to 6% of iron and the balance nickel. The wire is prepared through the following method: a certain amount of chromium powder, boron powder, nickel powder and silicon and iron powder are weighed and sufficiently stirred to be evenly mixed, a Ni80Cr20 stainless steel strip bent into a U shape is filled with the mixed powder, curling and opening sealing are carried out, the strip is drawn down to the diameter of 2.0 stage by stage through a wire drawing machine, and the flux-cored wire is obtained. The nickel-based self-fluxing hard-facing flux-cored wire has the beneficial effects of being low in production cost, good in self-fluxing, high in surfacing efficiency, high in cladding rate and the like, and is suitable for plasma surfacing; a surfacing layer is large in combination strength and high in hardness and has the extremely high hard-faced wear resistance, abrasive particle wear resistance and erosive wear resistance properties.

Owner:WUHAN UNIV OF TECH

Double-coated electrode and preparation method thereof

ActiveCN111730240APrevent breakdownEasy to useWelding/cutting media/materialsCoatingsAdhesiveGraphite

The invention discloses a double-coated electrode and a preparation method thereof. The double-coated electrode comprises an inner coating, an outer coating and two core wires; the inner coating is located between the two core wires, and the graphite content of the inner coating is 4% below the critical graphite content at which the electrode can be broken through; the outer coating wraps the twocore wires parallel to each other, and the content of graphite in the outer coating is 10-15%; and the interval between the two core wires is 0.8-2.0 mm, and the two coatings are bonded through an adhesive. The invention provides the electrode containing the inner and outer coating structures, by arranging the two coatings different in graphite content, the situation that electrode breaking through may occurs because that the two core wires are electro-conductive is avoided, and normal use of the electrode is ensured. The electrode provided by the invention is high in overlaying efficiency, safe and capable of saving energy, the overlaying hardness is high, and the abrasion weight loss is greatly decreased.

Owner:QILU UNIV OF TECH

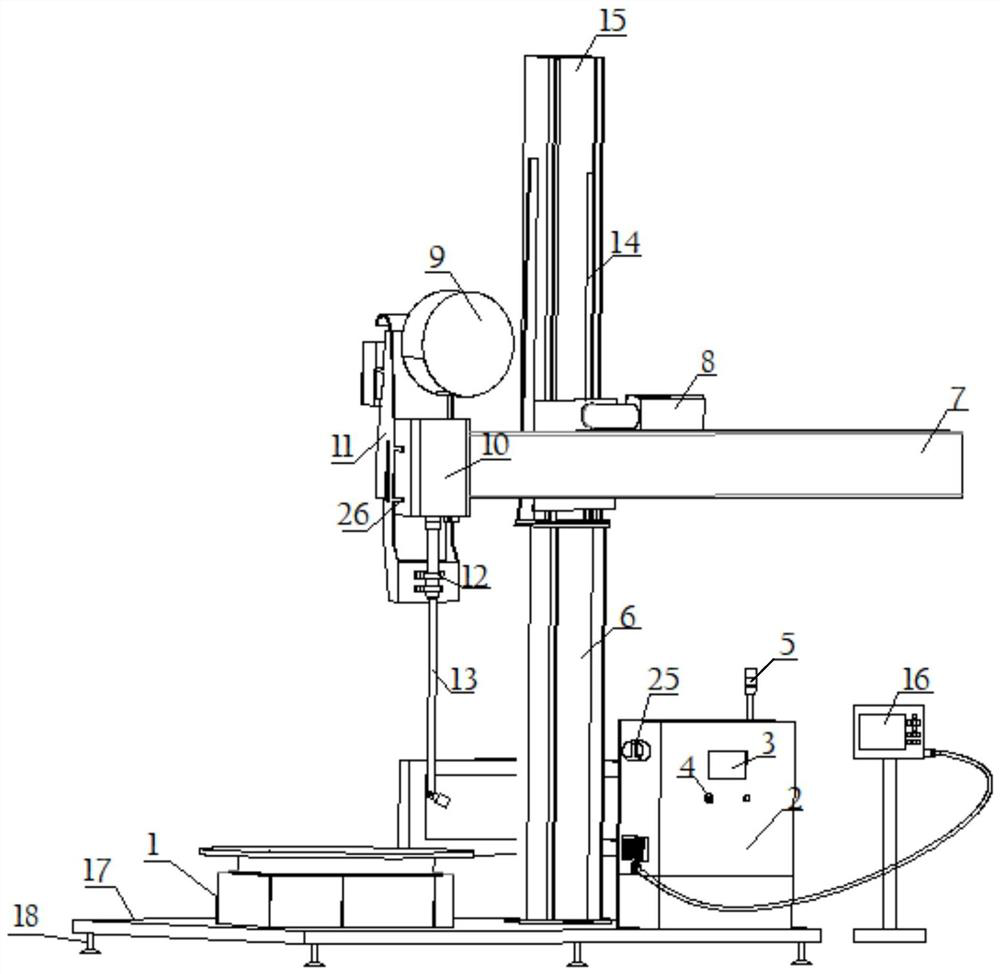

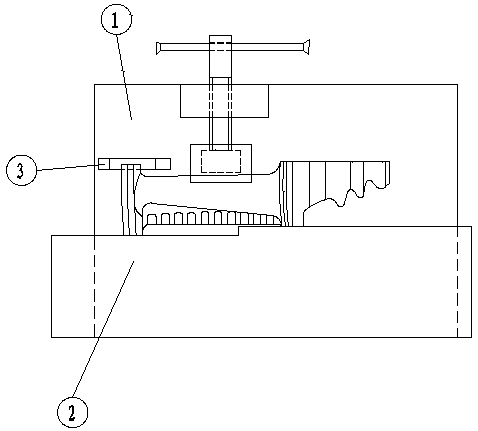

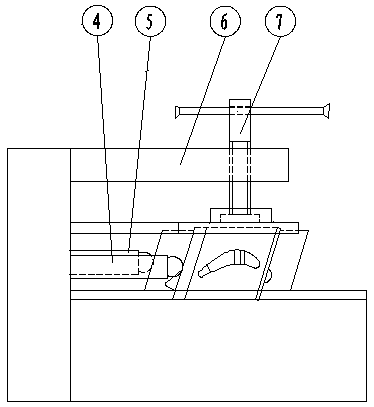

Method for realizing automatic surfacing of ball valve by using novel surfacing equipment

ActiveCN111822817AArc starting and extinguishing are neat and smoothReduce welding defectsWelding accessoriesWelding defectIndustrial engineering

The invention discloses a method for realizing automatic surfacing welding of a ball valve by using novel surfacing welding equipment. For a ball valve that needs surfacing welding, the sizes of different areas are inputted to the novel compact type equipment to implement programming setting; and after ball parameters are set, a welding gun on the equipment is used for correcting the roundness ofa workpiece to make sure that the ball valve and the welding gun that is positioned on the surfacing welding equipment are at the concentric positions. According to the method disclosed by the invention, in a surfacing welding process, the equipment can automatically avoid a ball channel, realizes orderly and smooth arc start and arc blowout, reduces welding defects and improves the surfacing welding efficiency.

Owner:福尼斯(南京)表面工程技术有限公司

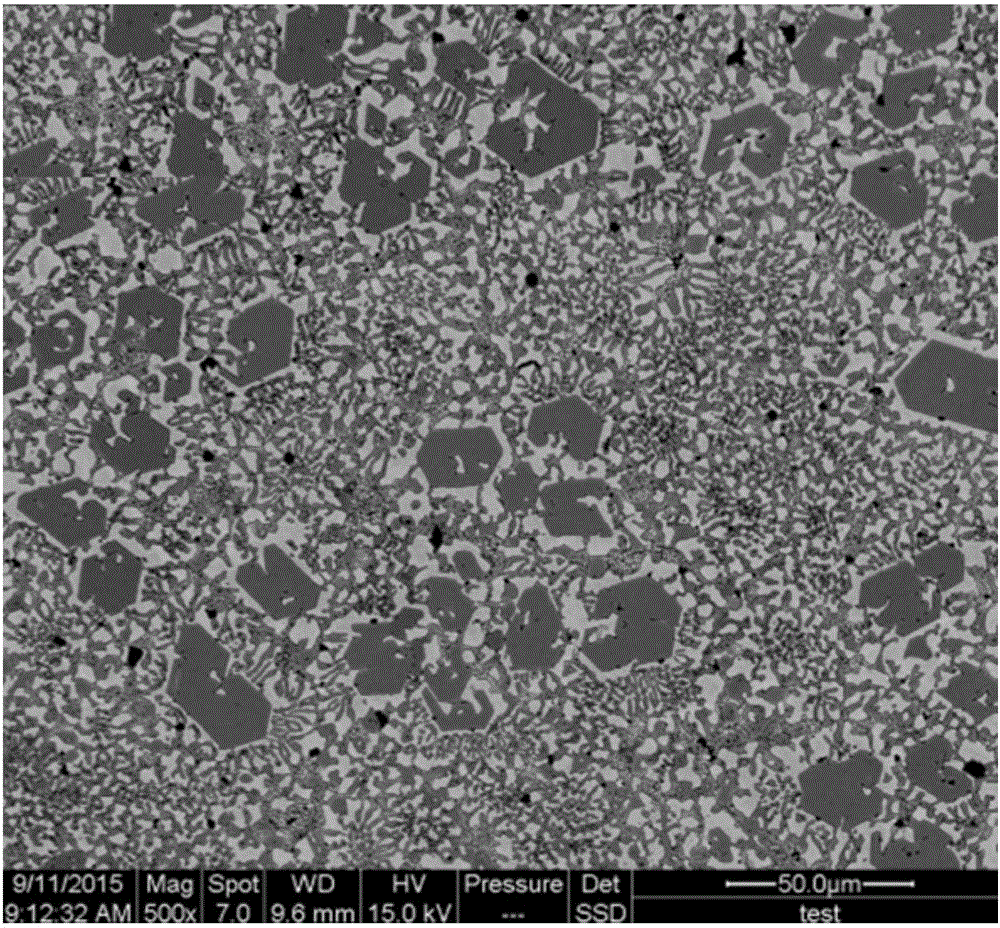

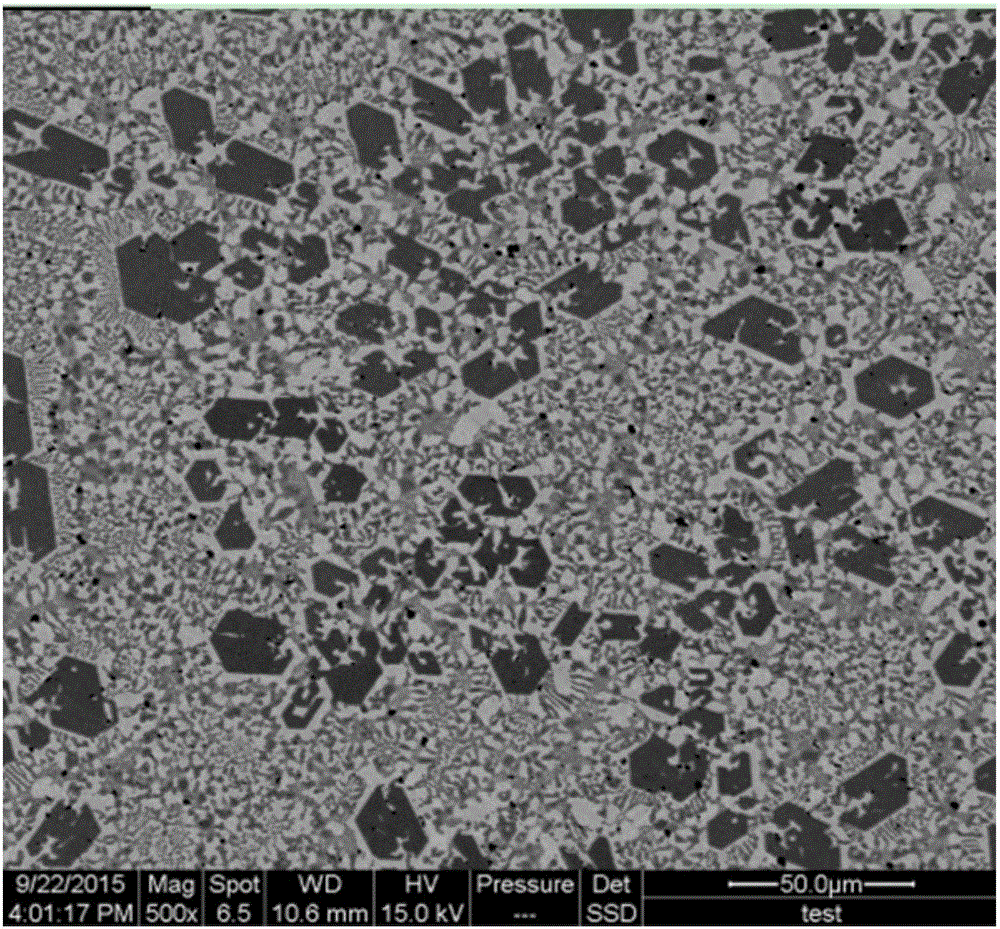

Welding scheme for crown wear-resistant block of single crystal turbine blade

The invention provides a welding scheme for a crown wear-resistant block of a single crystal turbine blade and relates to the technical field of non-traditional machining. According to the welding scheme, welding current is adjusted to be 30-45 A, the amount of argon is adjusted to be 8-12 L / min, and the crown part of the blade fixed on a fixture is subjected to surfacing for 1-5 s; then the surfacing effect is checked, whether an alloy is full, whether a corner R is provided with holes and whether a welding part has crack defects are checked, and blades with defective appearance are removed;hardness of substrates of an accumulation layer and a surfacing position, crystalline phase structure of the substrates in the surfacing position, welding quality and depth of a fusion layer at a weldjoint are subjected to metallographic inspection. The condition of falling of the wear-resistant block after welding can be solved, repeated brazing caused by falling of the wear-resistant block during brazing is avoided, so that production time is saved, cost is saved, qualification rate of argon arc welding surfacing is high, machining quality is guaranteed, and production efficiency is improved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com