Method for realizing automatic surfacing of ball valve by using novel surfacing equipment

An automatic surfacing and ball valve technology, applied in the field of surfacing, can solve the problems of low surfacing efficiency, welding defects, and high and low inequality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

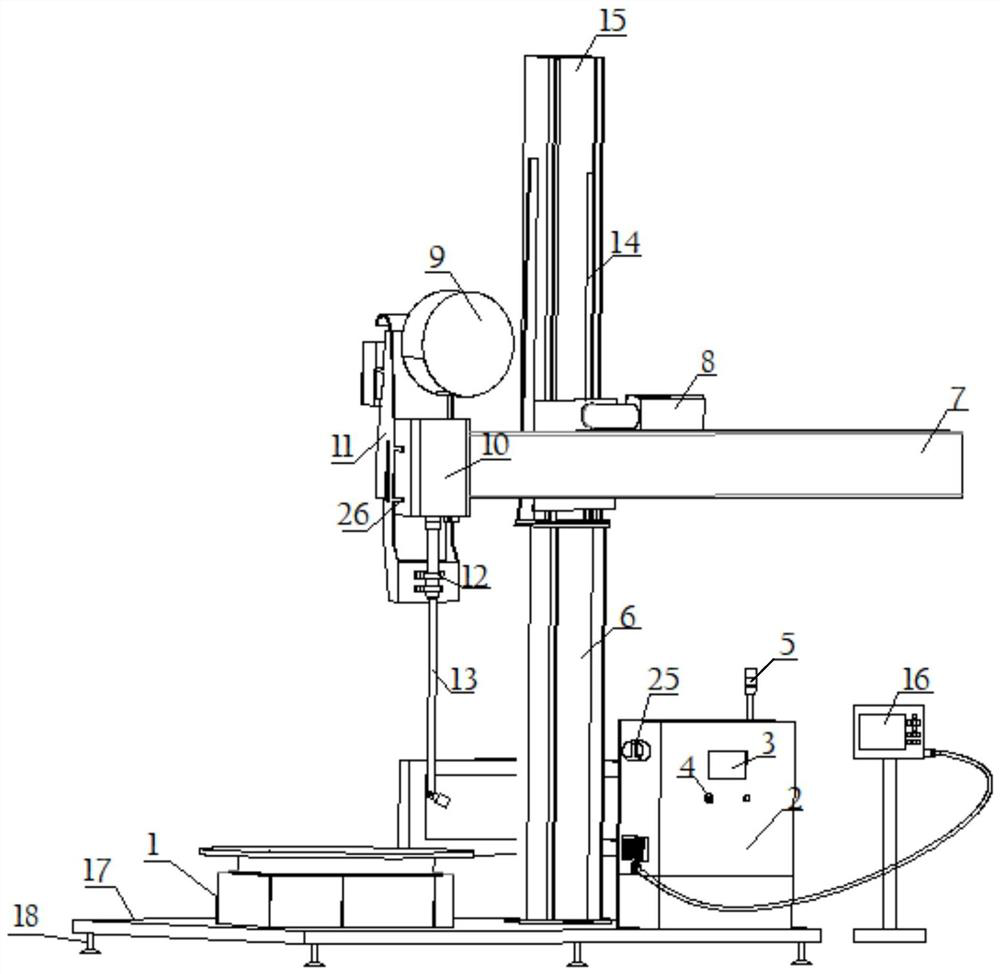

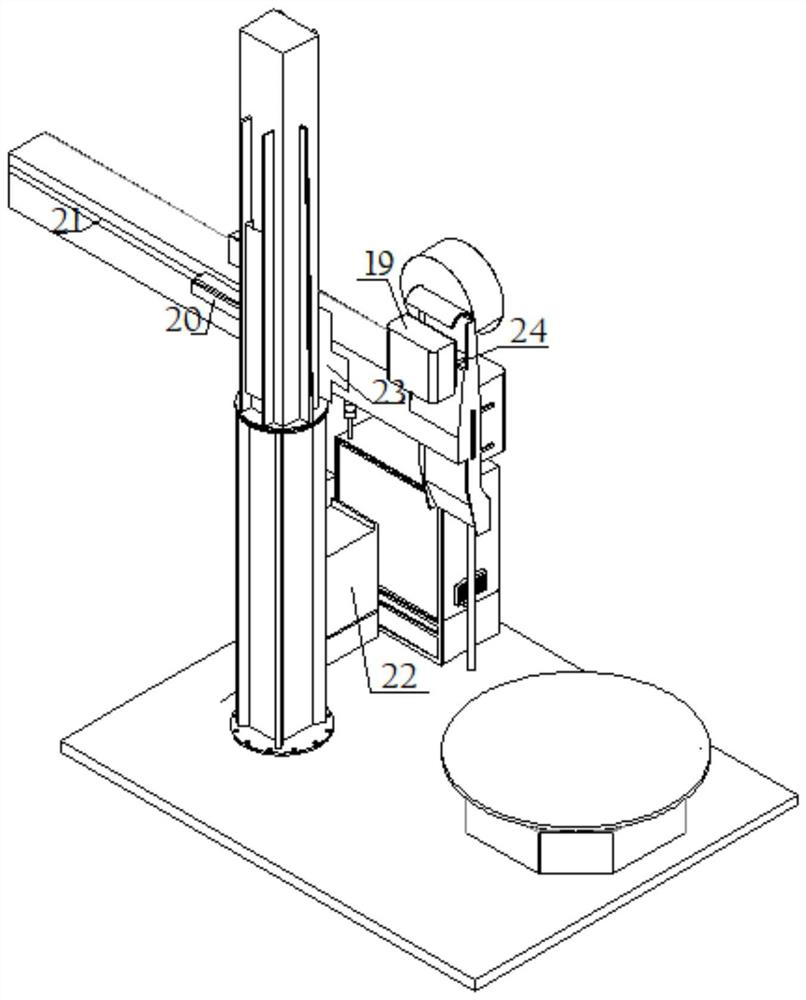

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] A method of using new surfacing equipment to realize automatic surfacing ball valve of the present invention comprises the following steps:

[0035] 1) Place the ball valve on the turntable 1 of the new surfacing equipment;

[0036] 2) Turn on the main power supply, welding power supply 22, and welding shielding gas. After the equipment starts up and runs stably, enter the workpiece surfacing mode interface on the remote control 16, and select the ball valve surfacing mode;

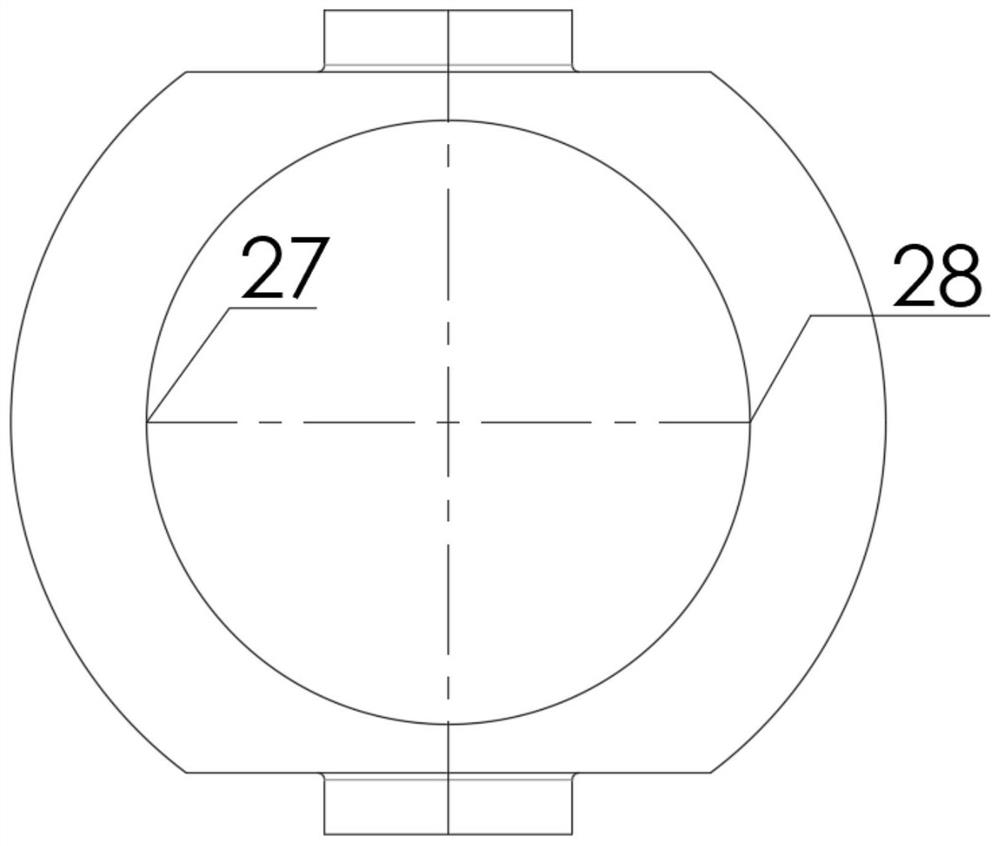

[0037] 3) Use the remote control 16 to control the moving beam 7, move the welding torch 13 to the point on the plane of the connecting end 30 of the ball valve body 29, and rotate the turntable 1 to adjust the welding torch 13 and the valve body 29 to ensure that the welding torch 13 and the valve body 29 at the center of the circle;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com