Thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method

A technology of automatic surfacing welding and process method, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of narrow melting width and large penetration depth of single-wire submerged arc welding, so as to increase the welding bead melting width and current The effect of high density and low welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

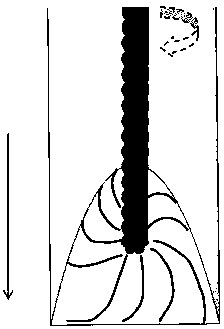

Image

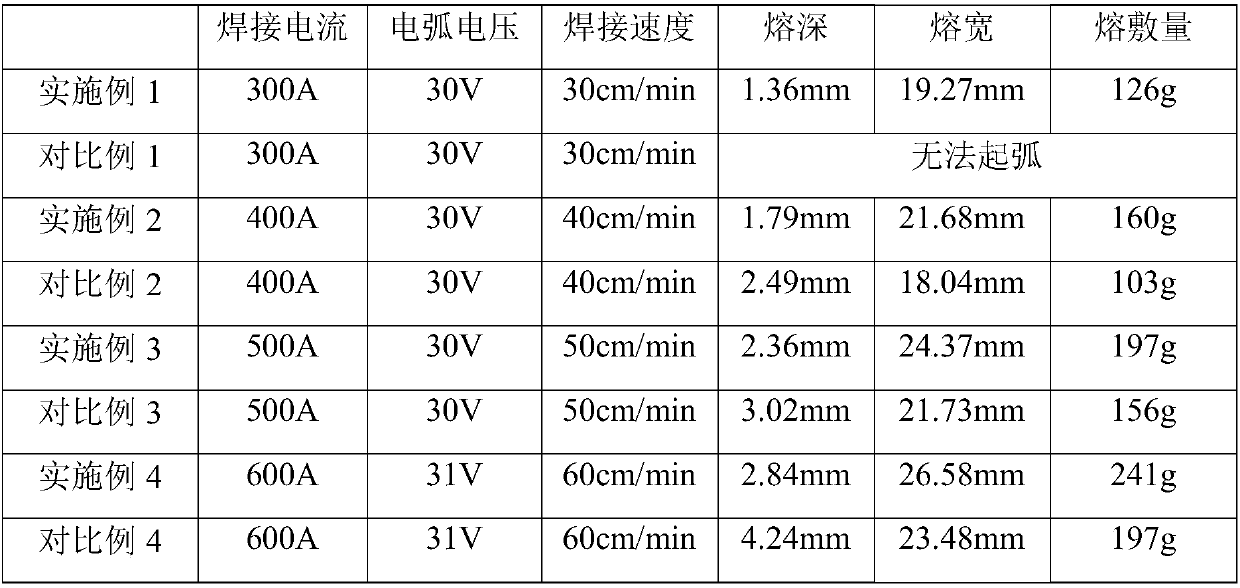

Examples

Embodiment 1

[0029] (1) Welding wire preparation: choose 7 solid welding wires with a diameter of 2.0mm, take 1 as the central welding wire, and the remaining 6 are tightly wound around the central welding wire in a spiral shape to form a cable-type thick welding wire; the cable-type thick welding wire The diameter is 6.0mm, and the solid welding wire adopts the submerged arc cable welding wire whose specification is 316L stainless steel;

[0030] (2) Base metal pretreatment: grind and derust the base metal, then degrease with alcohol cleaning agent, and finally rinse with water and blow dry; perform welding work within 24 hours of pretreatment;

[0031] (3) Preheating: Preheat the base metal at 90°C; heat and dry the flux at 200°C for 2 hours; the flux is SJ101 sintered flux;

[0032] (4) Overlay welding: Send the welding wire prepared in step (1) into the welding area of the submerged arc automatic trolley through the guide wire tube, connect the welding power source to transmit the we...

Embodiment 2

[0035] (1) Welding wire preparation: choose 7 solid welding wires with a diameter of 2.0mm, take 1 as the central welding wire, and the remaining 6 are tightly wound around the central welding wire in a spiral shape to form a cable-type thick welding wire; the cable-type thick welding wire The diameter is 6.0mm, and the solid welding wire adopts the submerged arc cable welding wire whose specification is 316L stainless steel;

[0036](2) Base metal pretreatment: grind and derust the base metal, then degrease with alcohol cleaning agent, and finally rinse with water and blow dry; perform welding work within 24 hours of pretreatment;

[0037] (3) Preheating: Preheat the base metal at 95°C; heat and dry the flux at 180°C for 2 hours; the flux is SJ101 sintered flux;

[0038] (4) Overlay welding: Send the welding wire prepared in step (1) into the welding area of the submerged arc automatic trolley through the guide wire tube, connect the welding power supply to transmit the wel...

Embodiment 3

[0041] (1) Welding wire preparation: choose 7 solid welding wires with a diameter of 2.0mm, take 1 as the central welding wire, and the remaining 6 are tightly wound around the central welding wire in a spiral shape to form a cable-type thick welding wire; the cable-type thick welding wire The diameter is 6.0mm, and the solid welding wire adopts the submerged arc cable welding wire whose specification is 316L stainless steel;

[0042] (2) Base metal pretreatment: grind and derust the base metal, then degrease with alcohol cleaning agent, and finally rinse with water and blow dry; perform welding work within 24 hours of pretreatment;

[0043] (3) Preheating: Preheat the base metal at 90°C; heat and dry the flux at 200°C for 2 hours; the flux is SJ101 sintered flux;

[0044] (4) Overlay welding: Send the welding wire prepared in step (1) into the welding area of the submerged arc automatic trolley through the guide wire tube, connect the welding power source to transmit the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com