Chuck body and mechanical pencil

A chuck and component technology, applied in mechanical pencils, printing, writing utensils, etc., can solve problems such as inability to use, and achieve high retention and damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same component in a drawing.

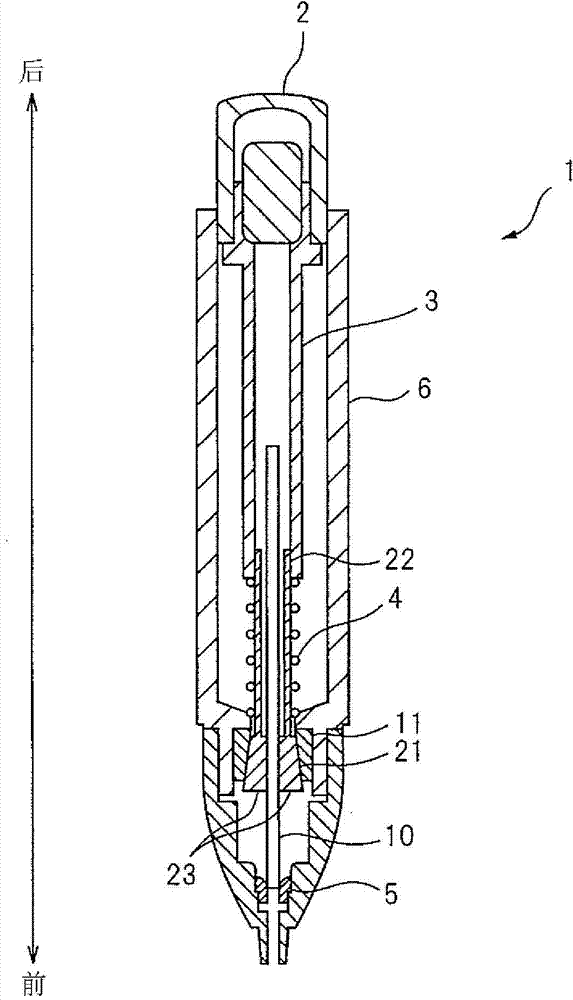

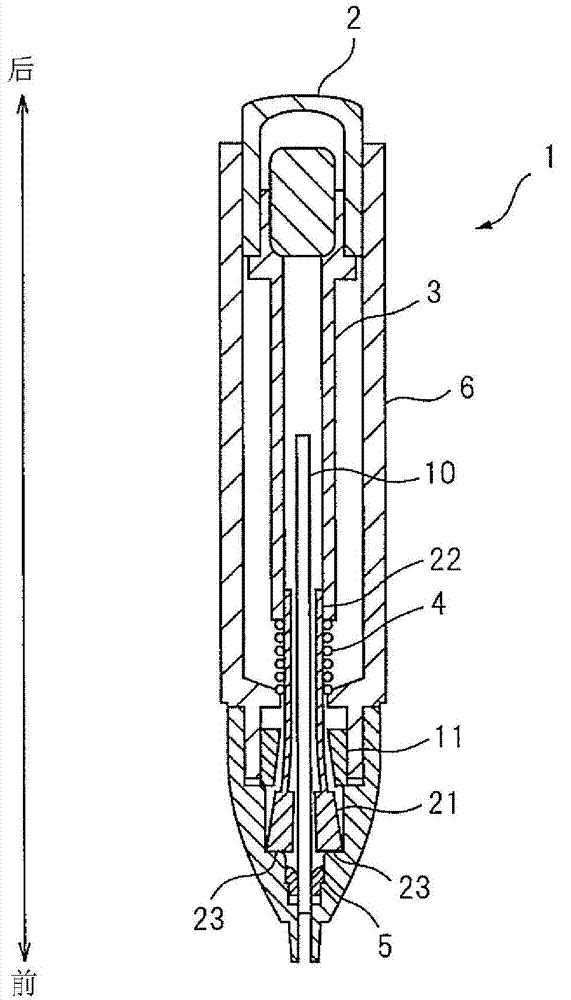

[0035] initial reference figure 1 and figure 2 A structure in which the lead 10 is drawn out in the mechanical pencil 1 will be briefly described.

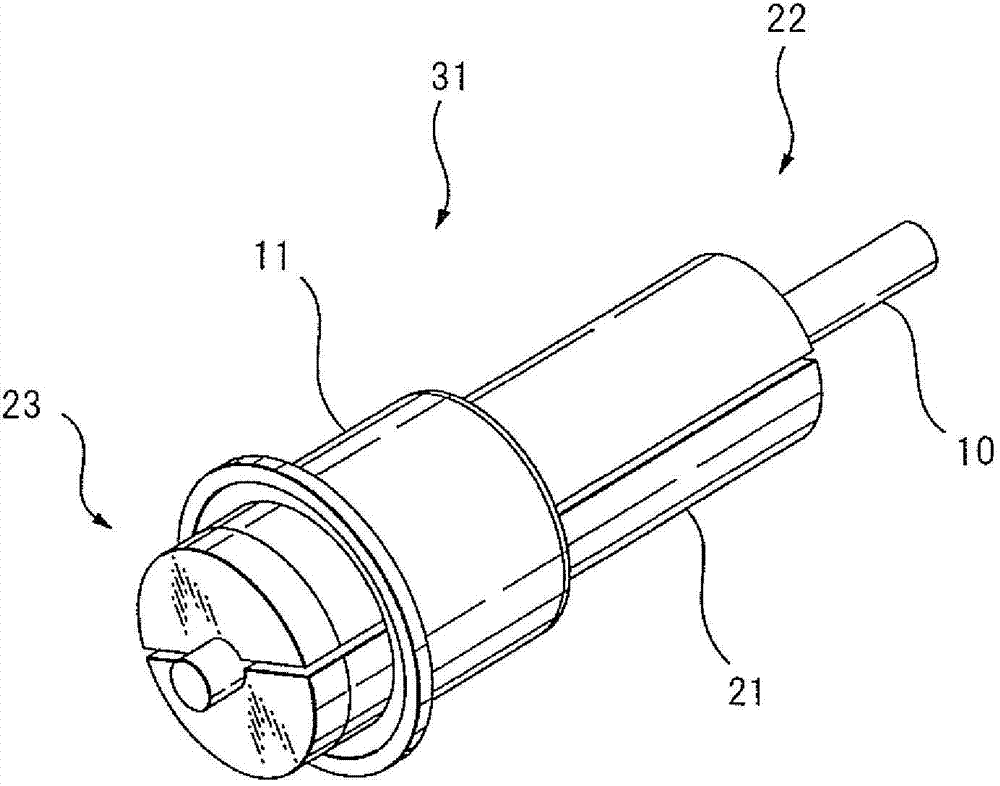

[0036] figure 1 and figure 2 It is a side sectional view of the mechanical pencil 1 of the present invention. The mechanical pencil 1 has a structure capable of releasing the core 10 , and includes a push part 2 , a core case 3 , a fastener 11 , a chuck 21 , a spring 4 and a holding body 5 . The push part 2 is engaged with the core case 3 . The collet 21 has a fitting end portion 22 fitted to the core case 3 and a split end portion 23 capable of entering and withdrawing from the fastener 11 in the longitudinal direction. Such as Figure 4 As shown, the split end portion 23 of the collet 21 is configured to protrude from the fastener 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com