Patents

Literature

66results about How to "Guaranteed modification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

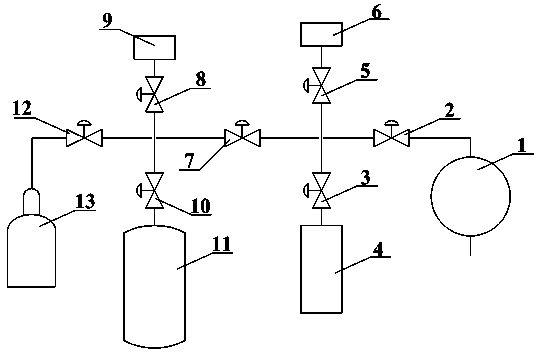

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

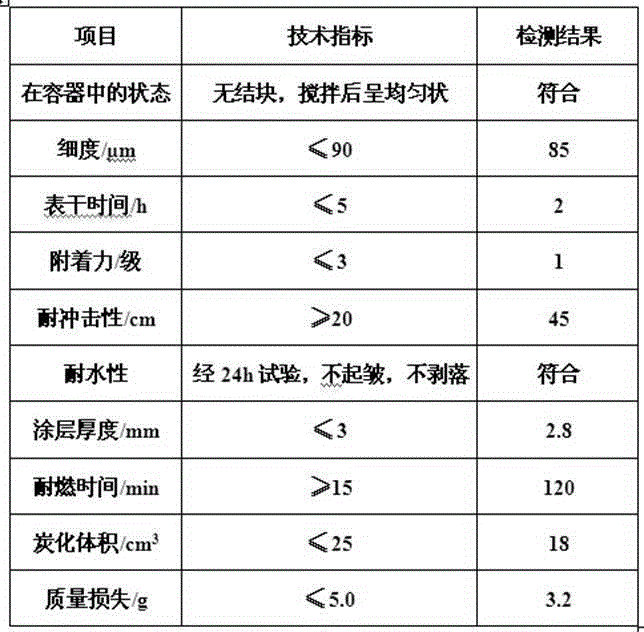

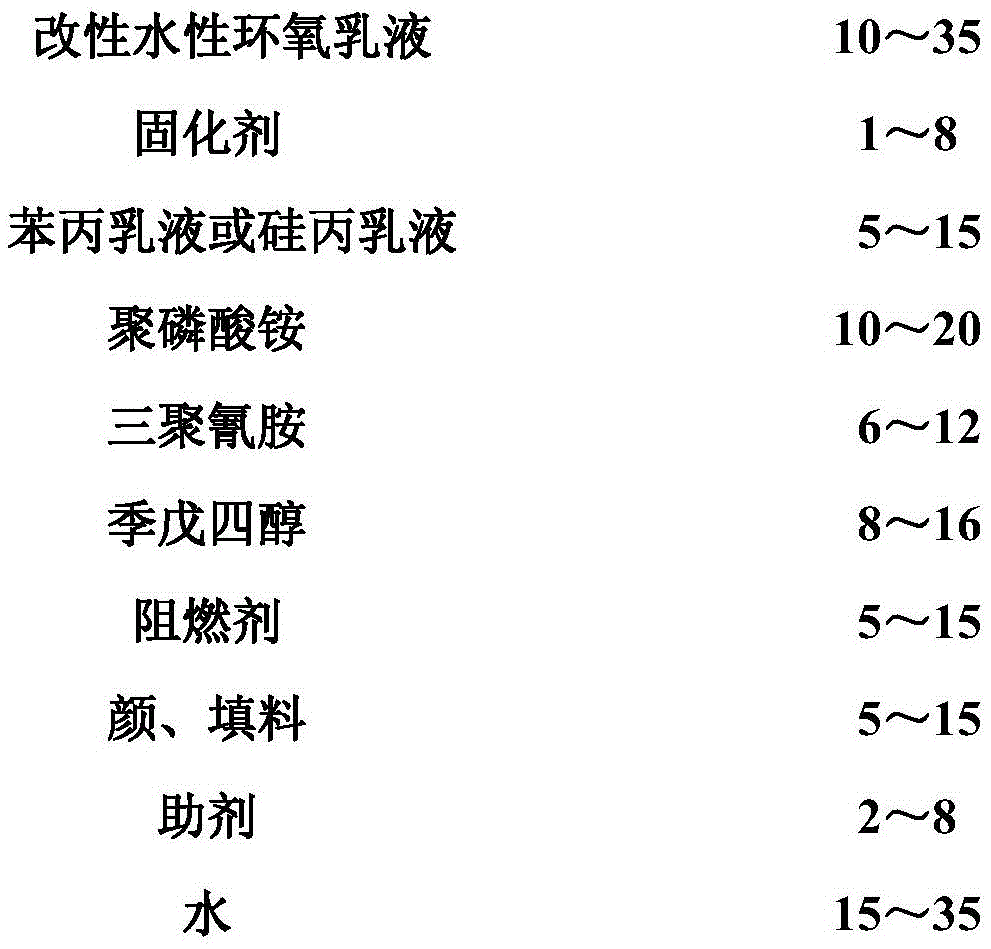

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

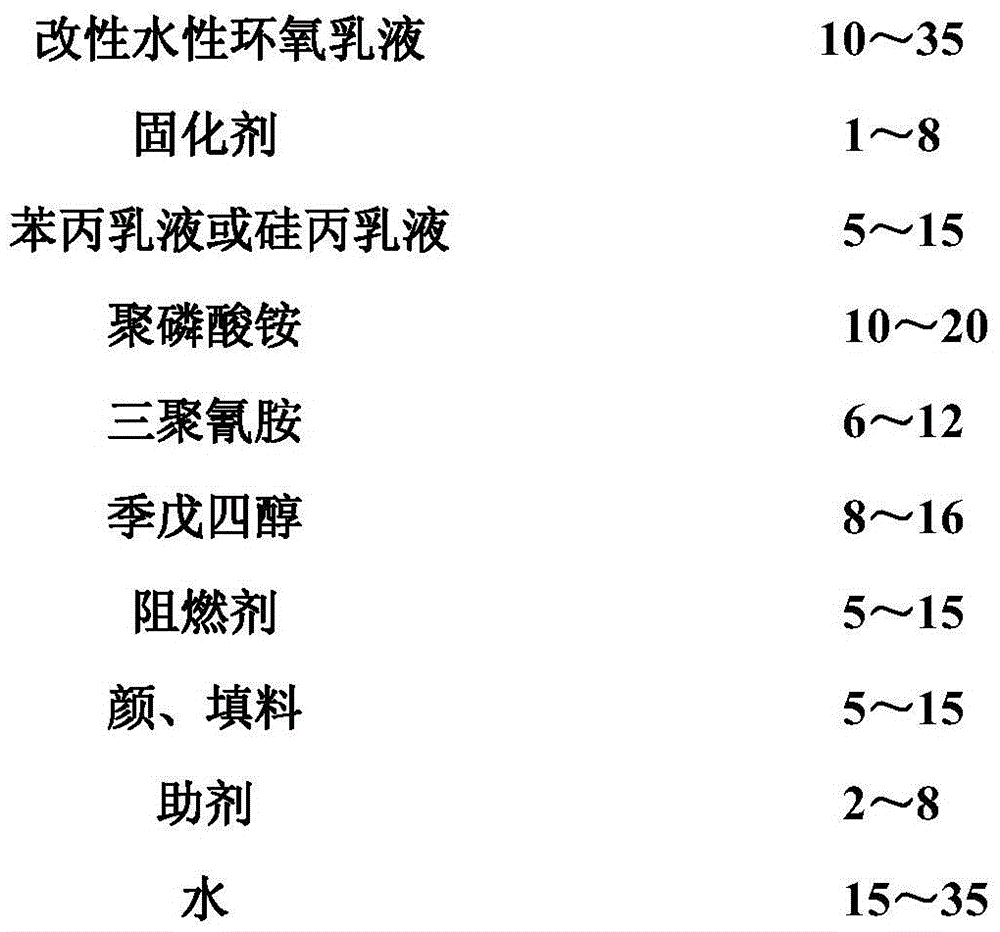

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

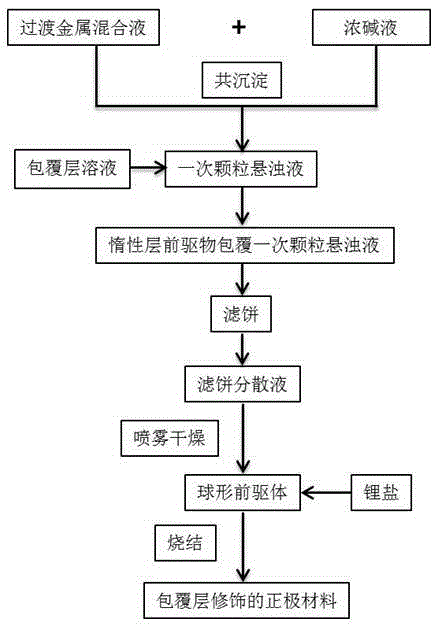

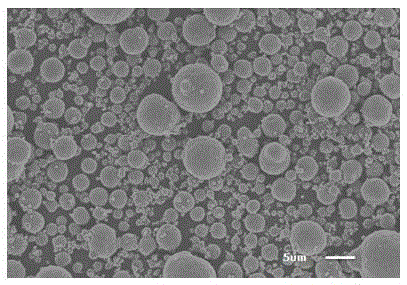

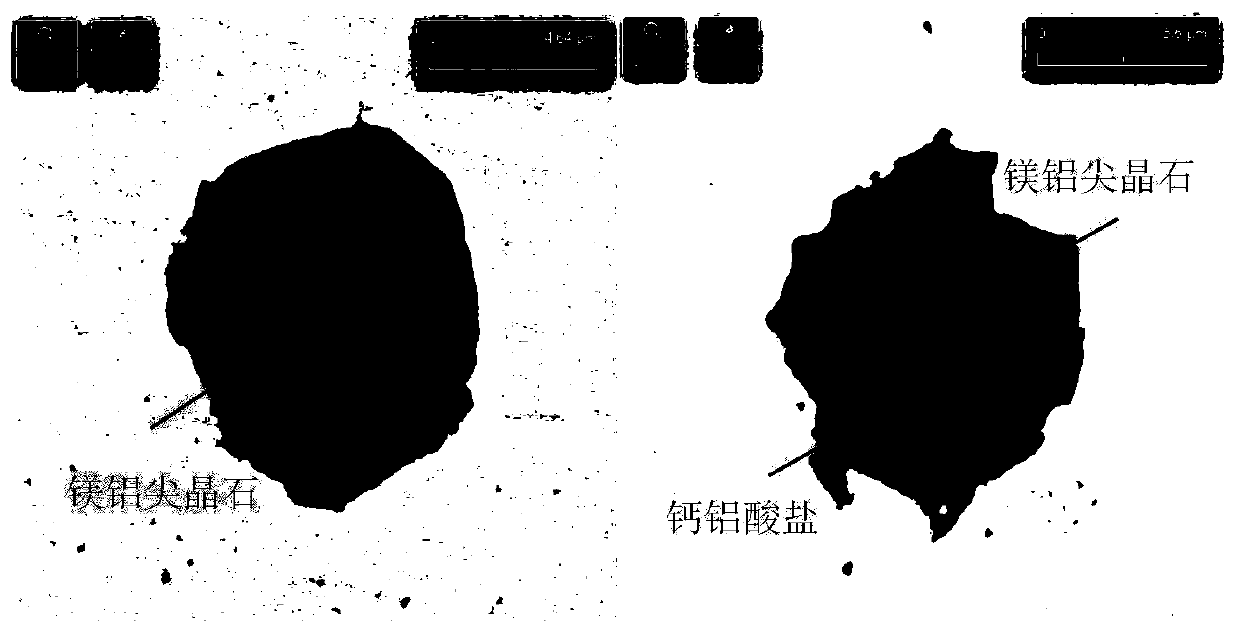

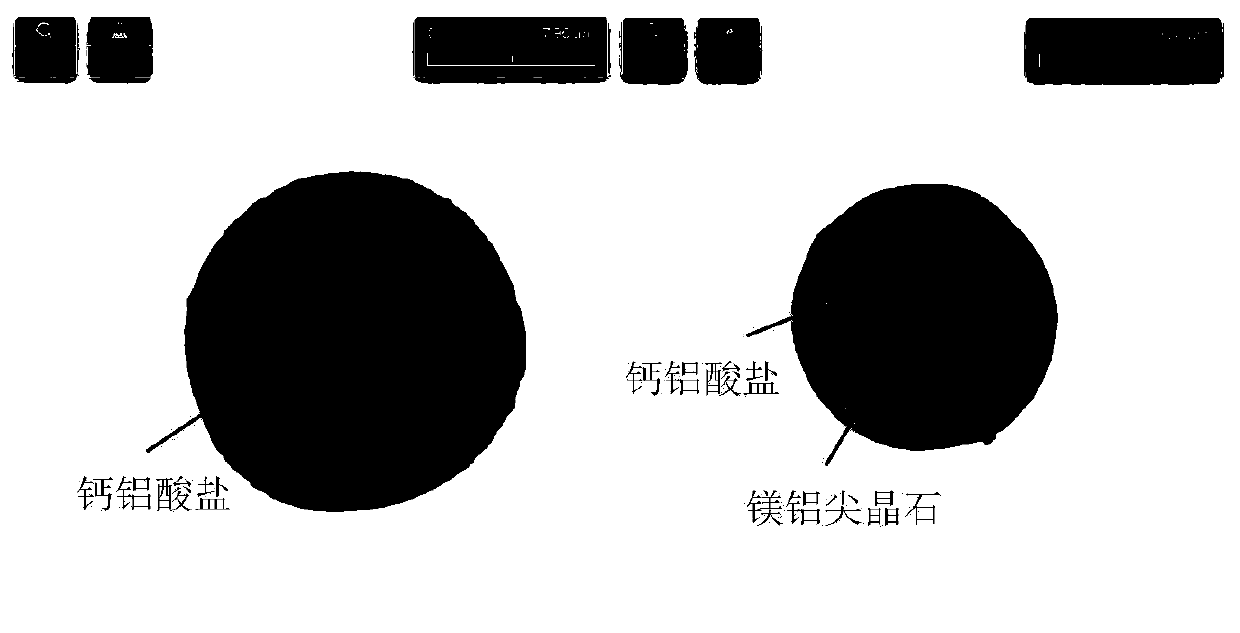

Long-cycle and high-safety power lithium ion battery positive electrode material and preparation method thereof

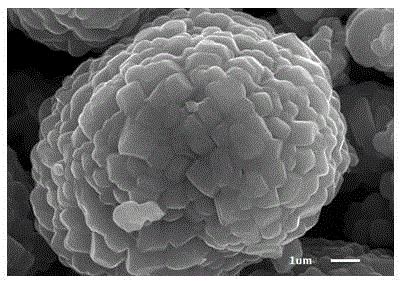

InactiveCN105406056AUniform dispersion and depositionEvenly dispersedCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a long- cycle and high-safety power lithium ion battery positive electrode material and a preparation method thereof. The positive electrode material can be shown as a general formula LiNi<(1-a-b-c)>CoMnM<c>O2.xLiM<1>O<y>, wherein a is greater than 0 and less than 1, b is greater than 0 and less than 1, a+b+c is greater than 0 and less tan 1, x is greater than 0 and less than 0.1, and y is greater than 1 and less than 5; LiNi<(1-a-b-c)>CoMnM<c>O2 is a primary active crystalline particle of the positive electrode material, and is a lithiated composite oxide composed of nickel cobalt manganese and doping element M; and the LiM<1>O<y> is a coating layer coating crystal boundary of the primary active crystalline particle and surface of a polycrystalline secondary particle. The positive electrode material provided by the invention has high stability of crystalline main body, surface and crystal boundary, has good compatibility with electrolyte and is not liable to generate side reaction. The material provided by the invention is used for batteries, has long cycle life, high over-charging resisting capability, good high temperature and high voltage performance and high integral safety, and is particularly suitable for power batteries.

Owner:HUNAN SOUNDDON NEW ENERGY

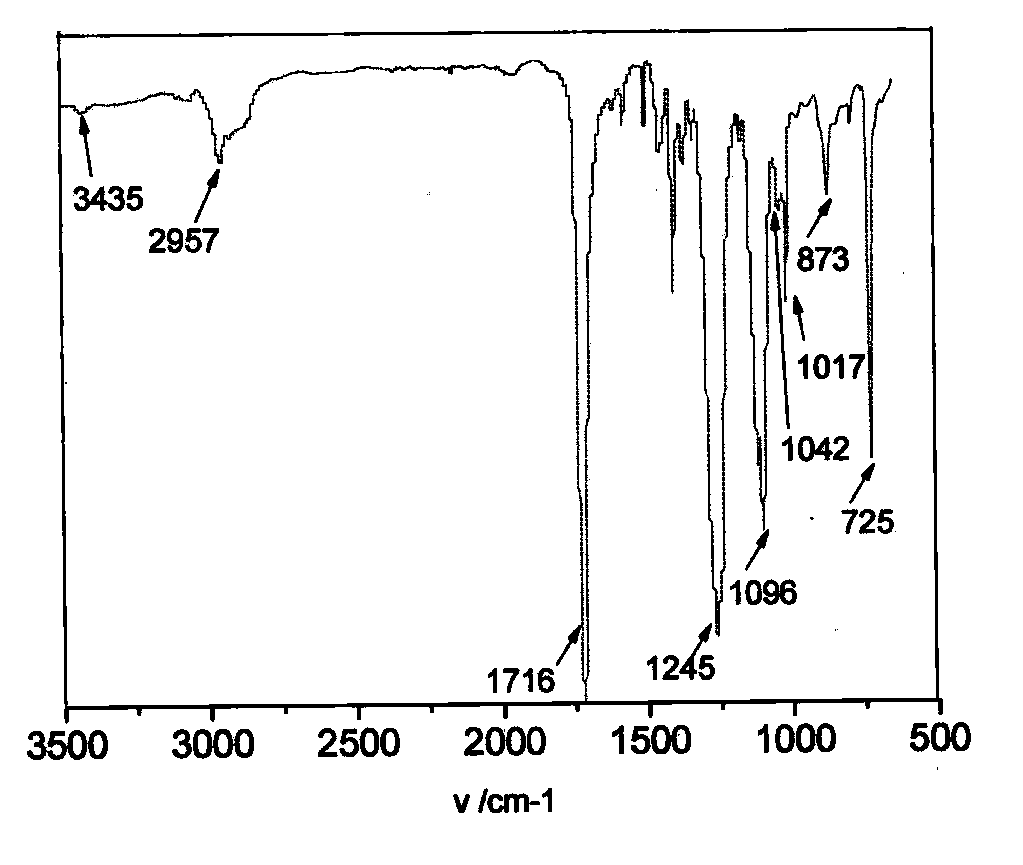

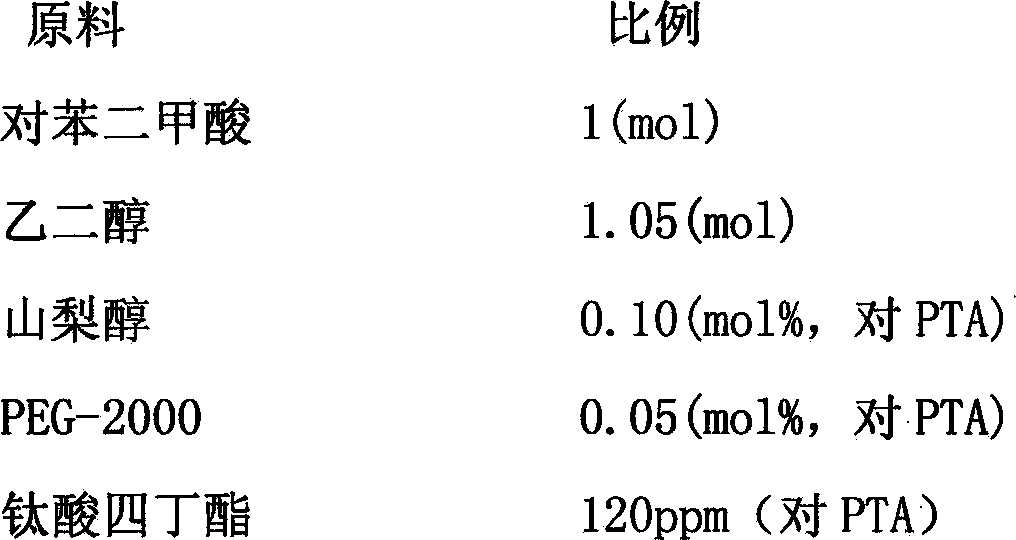

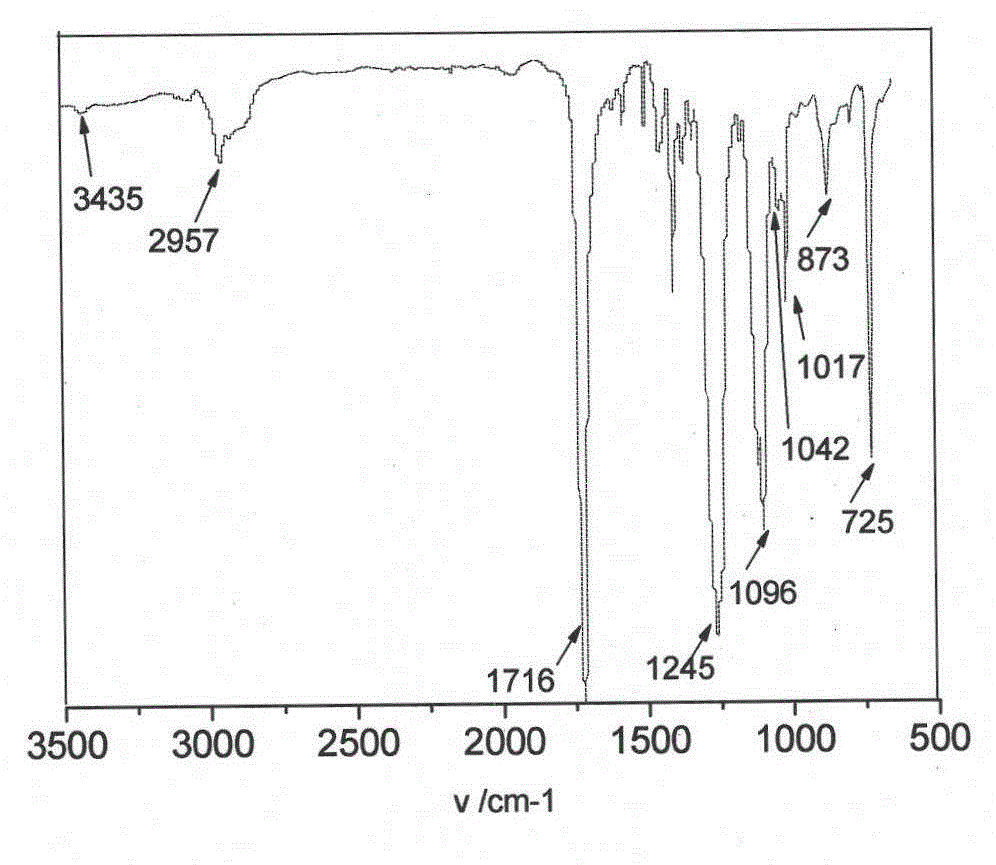

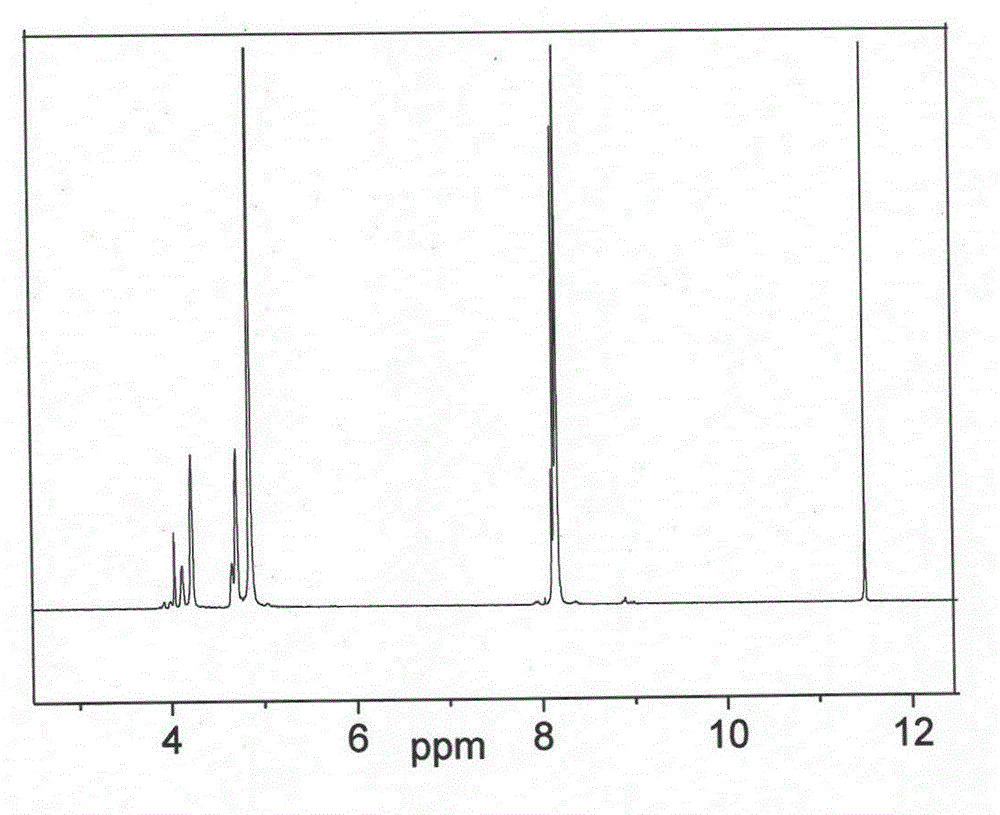

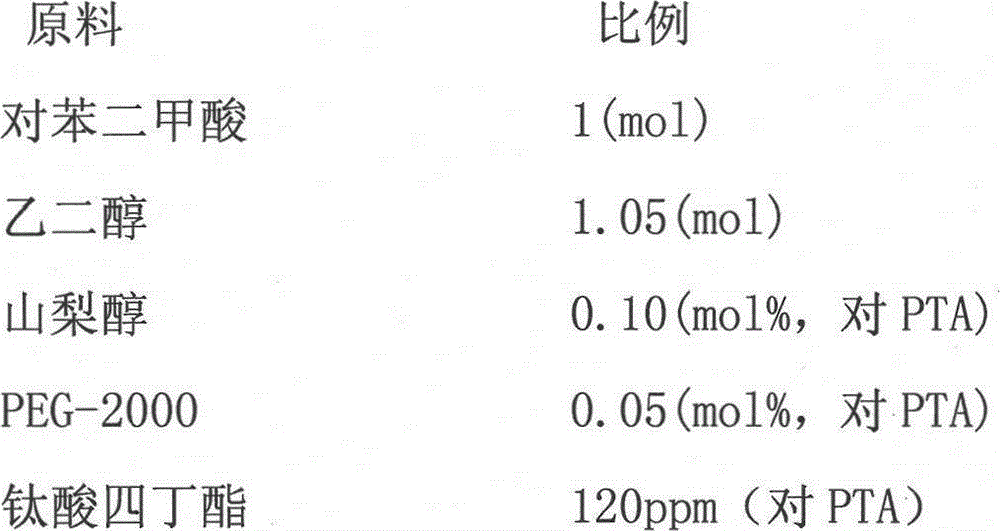

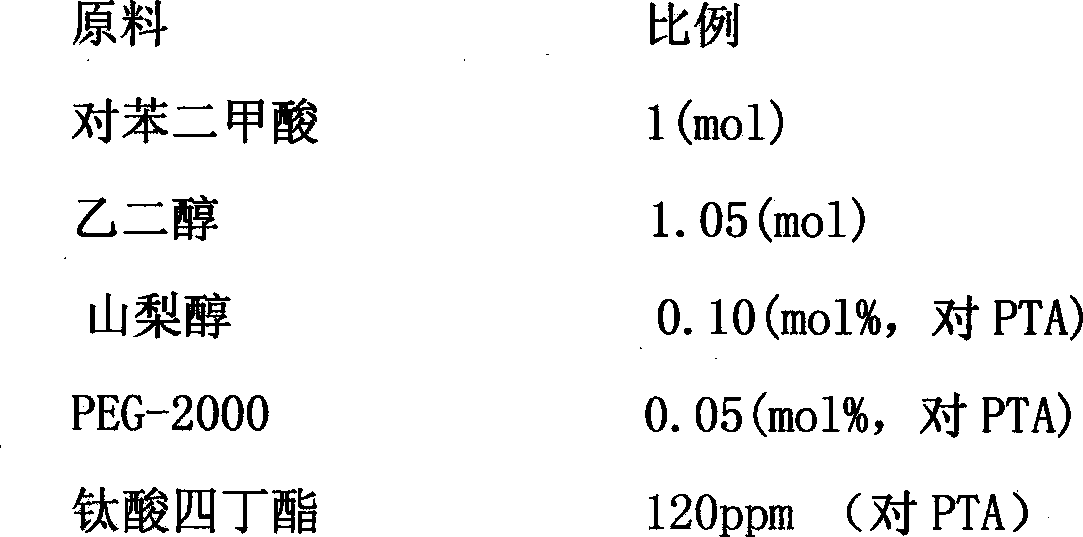

Preparation method for multi-functional hydrophilic polyester fibers

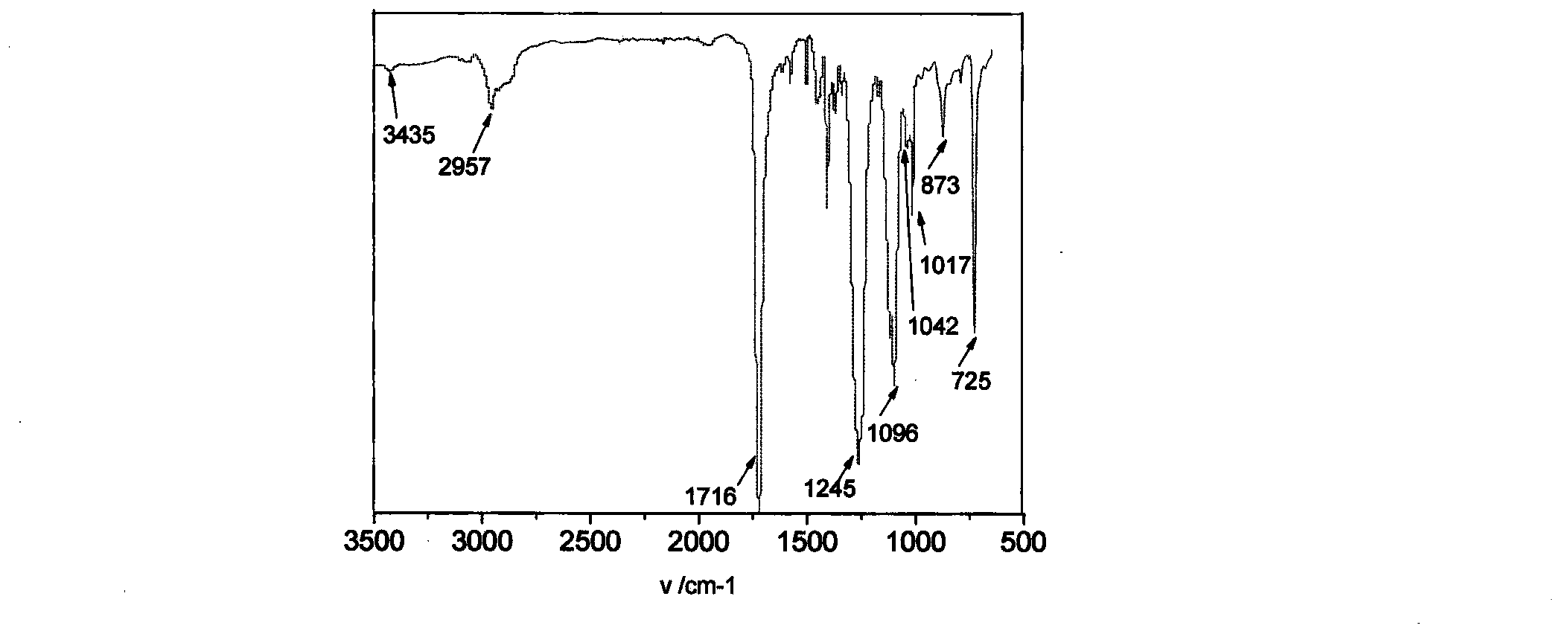

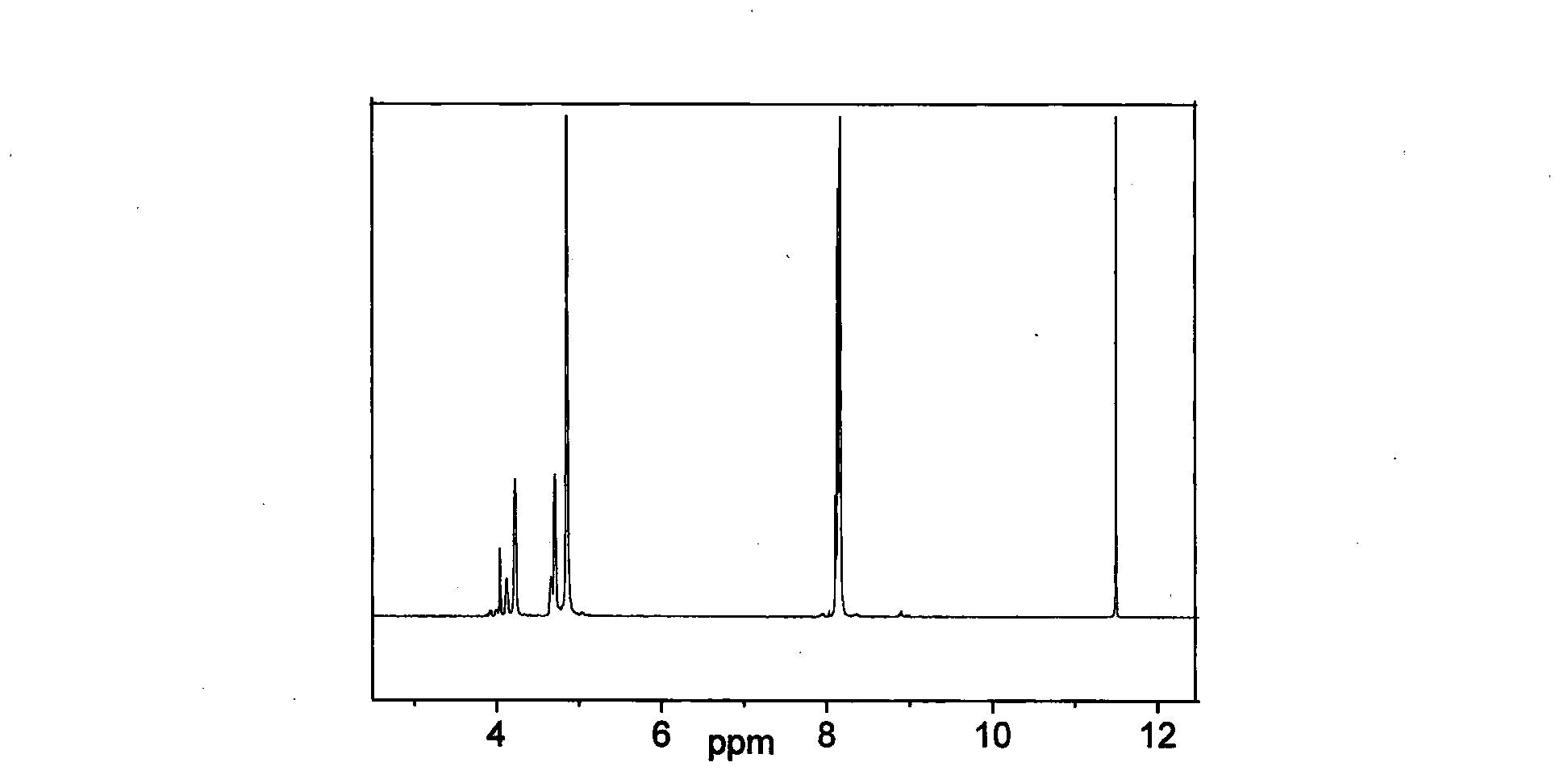

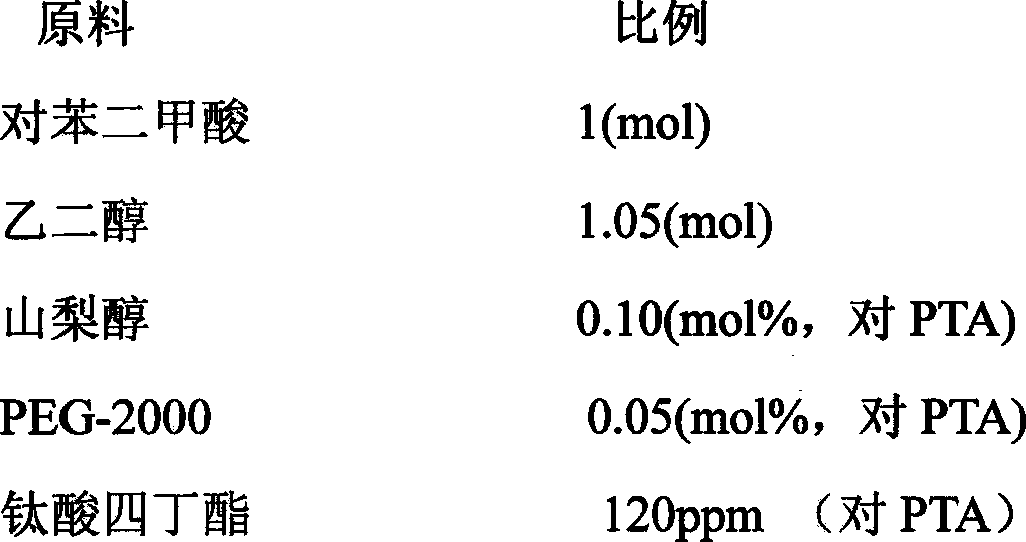

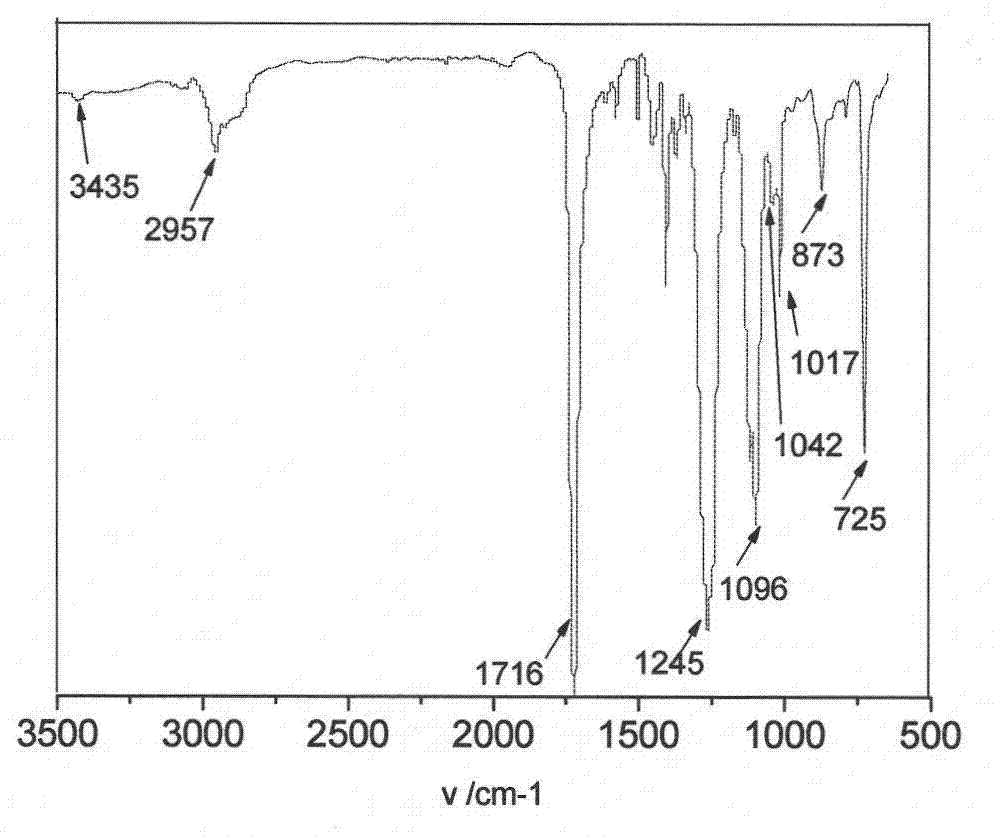

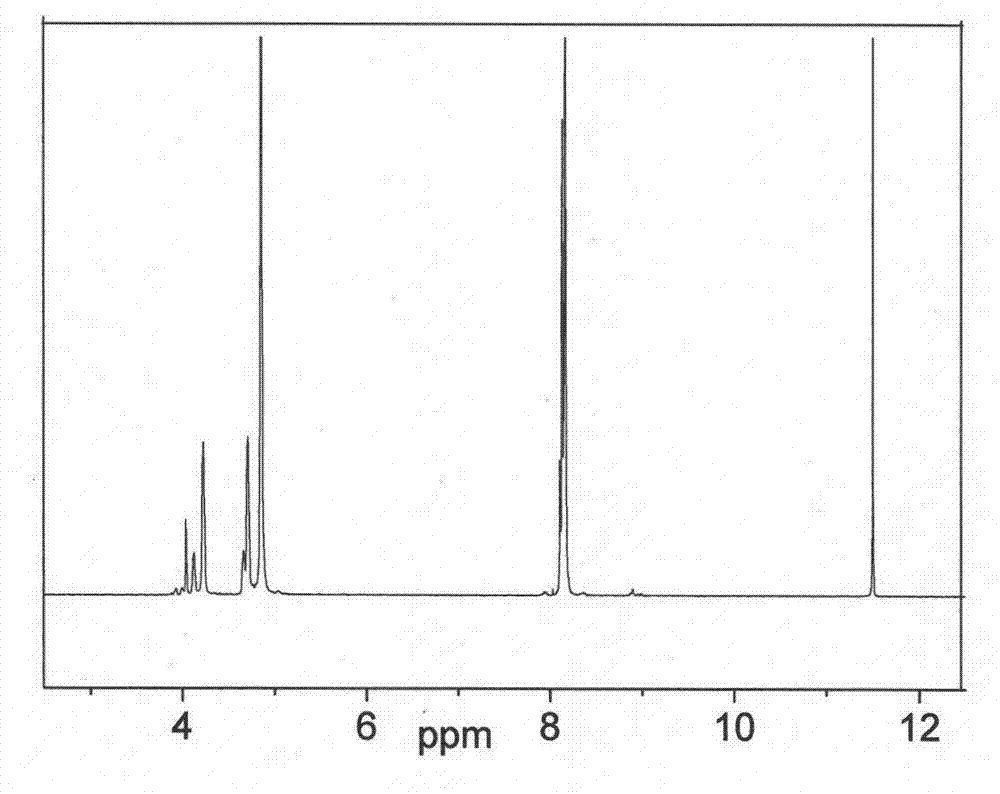

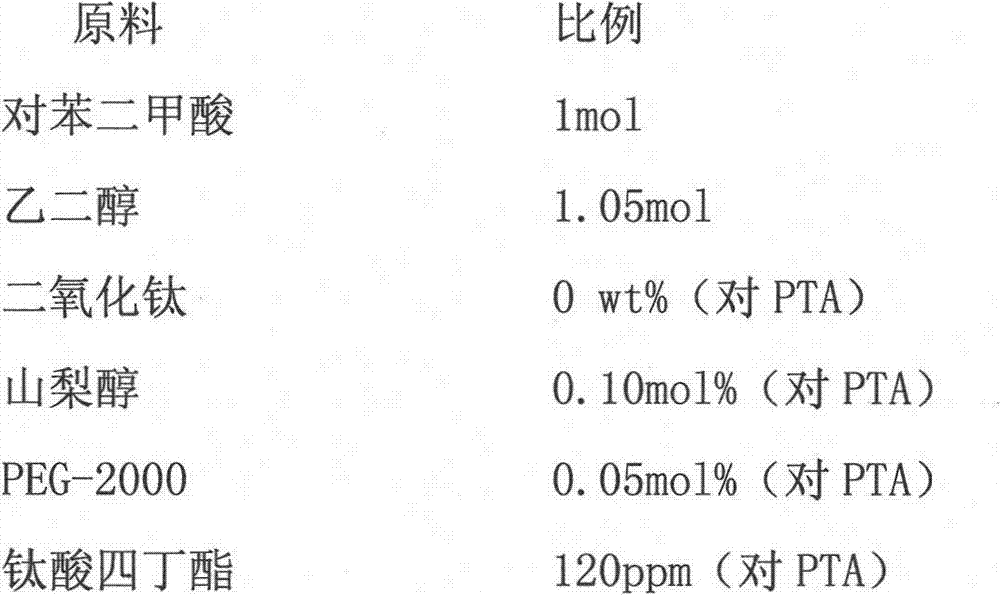

ActiveCN103820878AImprove hydrophilicityNo reactionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyethylene glycolEthylene glycol

The invention provides a preparation method for multi-functional hydrophilic polyester fibers. The method is characterized by specifically comprising the following steps: firstly, mixing terephthalic acid with ethylene glycol to prepare a paste; adding into an esterfying reactor to carry out first esterfying reaction; when the collecting quantity of byproducts reaches 82-95% of a theoretical value, adding sorbitol and polyethylene glycol to carry out second esterfying reaction; after finishing esterfying reaction, performing polycondensation reaction on obtained esterfied products so as to obtain a hydrophilic polyester chip; secondly, preparing nanometer coffee carbon powder; thirdly, preparing nanometer bamboo charcoal powder containing an ultraviolet resistor; fourthly, performing fusing granulation on the nanometer bamboo charcoal powder containing the ultraviolet resistor and the hydrophilic polyester chip so as to obtain functional master batch; fifthly, performing fusing spinning on the functional master batch and the hydrophilic polyester chip so as to obtain the multi-functional hydrophilic polyester fibers. The multi-functional hydrophilic polyester fibers have great hydrophilic performance and continuously have the functions of the ultraviolet resistor and the bamboo charcoal for a long term.

Owner:江苏三联新材料股份有限公司

Hydrophilic polyester fiber containing coffee carbon and preparation method of hydrophilic polyester fiber

ActiveCN103820879AFine structureEffective absorptionMonocomponent polyesters artificial filamentArtifical filament manufactureChemistryPolyester

The invention provides a hydrophilic polyester fiber containing coffee carbon and a preparation method of the hydrophilic polyester fiber. The hydrophilic polyester fiber containing coffee carbon is characterized by comprising a hydrophilic polyester fiber body and nanoscale coffee carbon powder scattered in the hydrophilic polyester fiber body. The hydrophilic polyester fiber containing coffee carbon is good in hydrophilicity, can be used for deodorizing, warming and is dried quickly, and brings touch sensation of enjoying refreshing and comfort to consumers.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

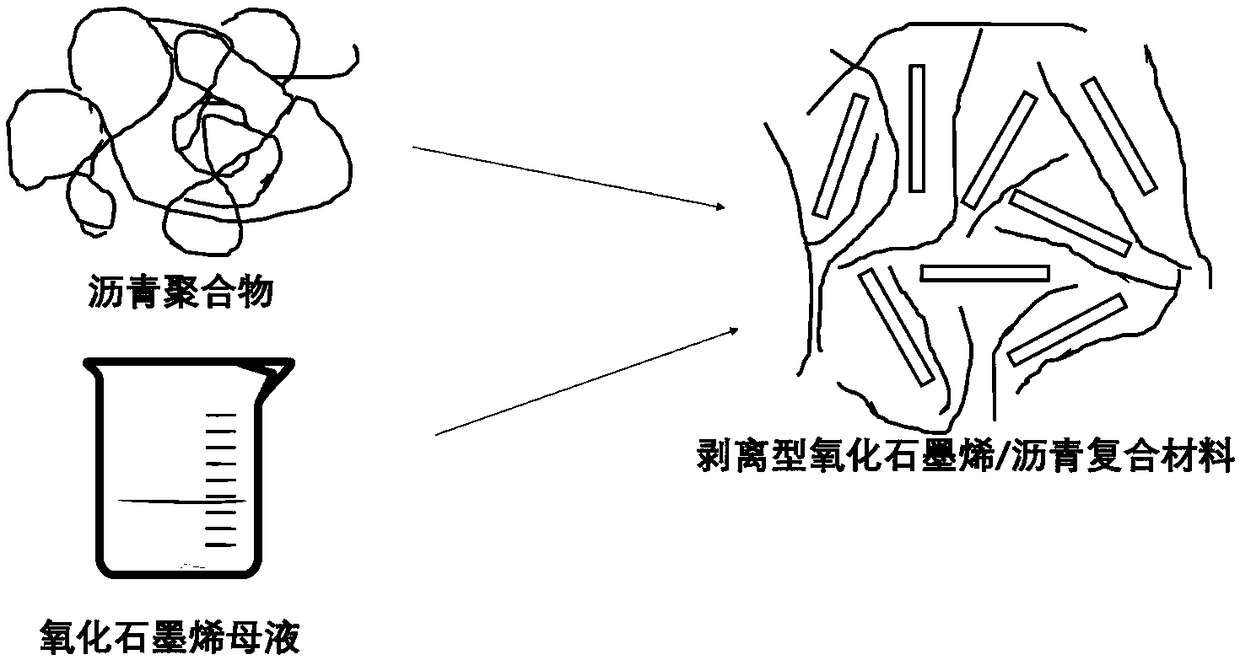

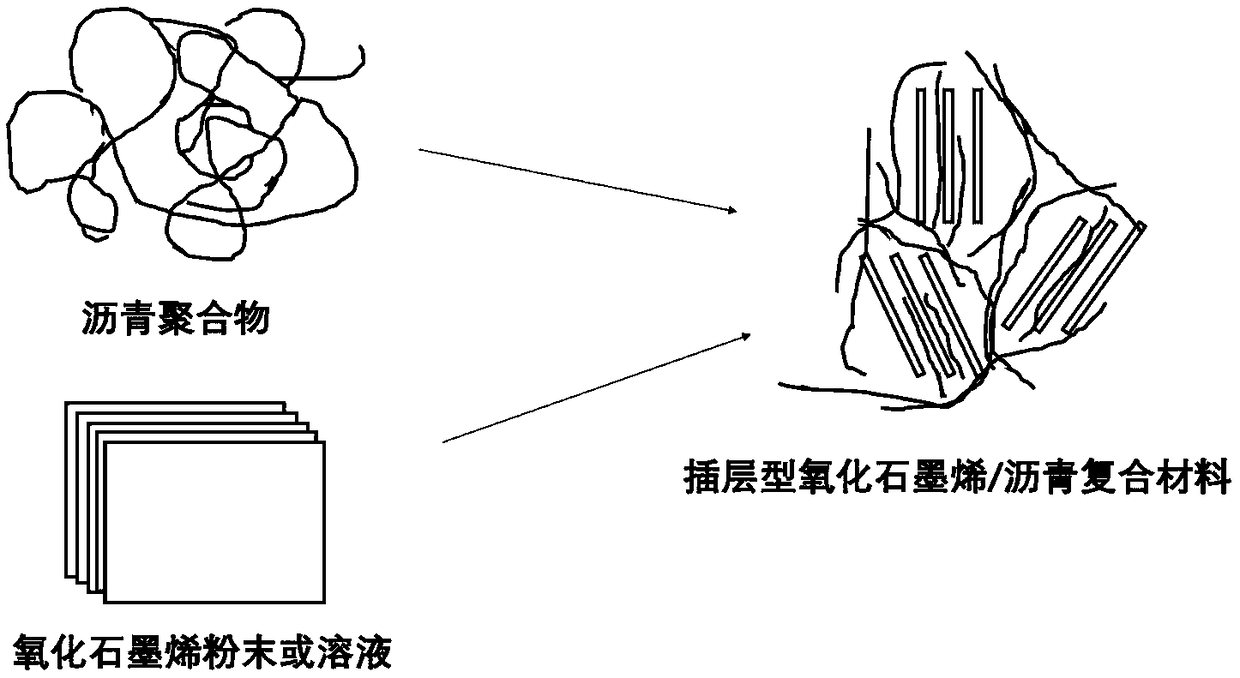

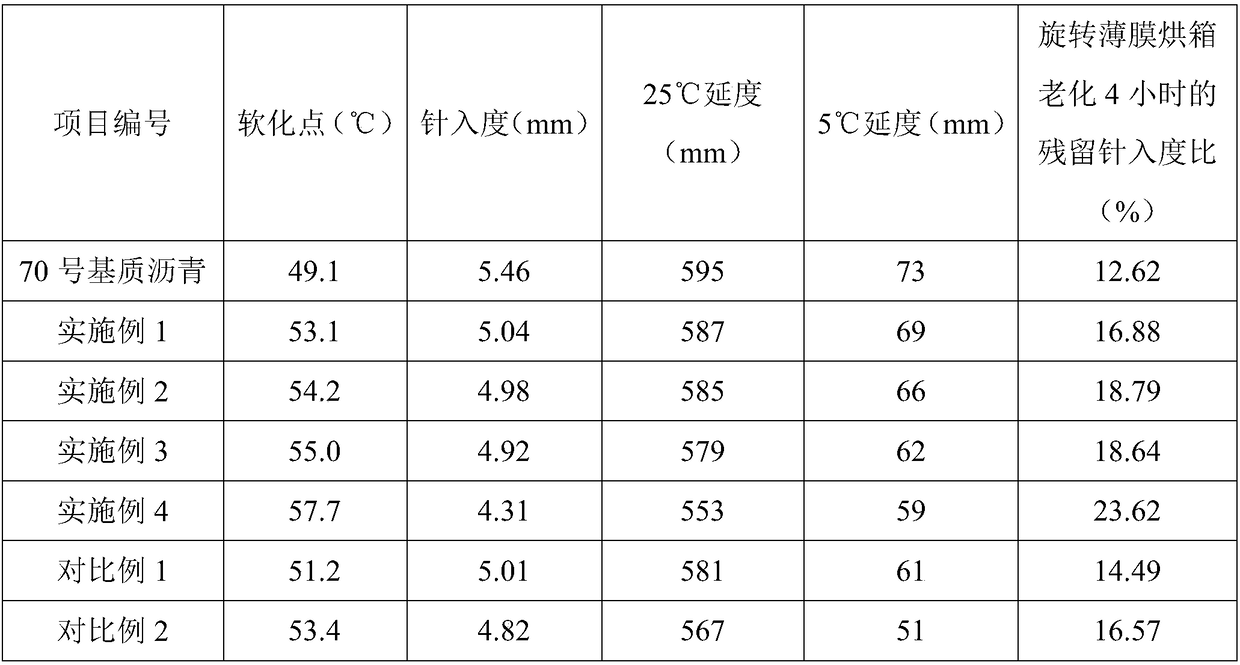

Oxidized graphene modified asphalt and preparation method thereof

The invention provides a preparation method of oxidized graphene modified asphalt. The preparation method includes following steps: slowly adding graphite into mixed acid, and well stirring to obtaina mixed material; during stirring, slowly adding potassium permanganate into the mixed material, and continuously stirring for reaction to obtain an oxidized mixed material; slowly adding hydrogen peroxide into the oxidized mixed material, continuously stirring for reaction to obtain an oxidized mixed solution; cooling the oxidized mixed solution to room temperature, performing ultrasonic treatment, and performing centrifugal separating and washing to obtain oxidized graphene mother liquid; adding the oxidized graphene mother liquid into asphalt, heating to fusion, and shearing to obtain the oxidized graphene modified asphalt. The invention further provides the oxidized graphene modified asphalt prepared by the method. The oxidized graphene modified asphalt is a stripped oxidized graphene / asphalt composite material and has excellent high-temperature stability, low-temperature crack resistance and thermo-oxidative aging resistance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

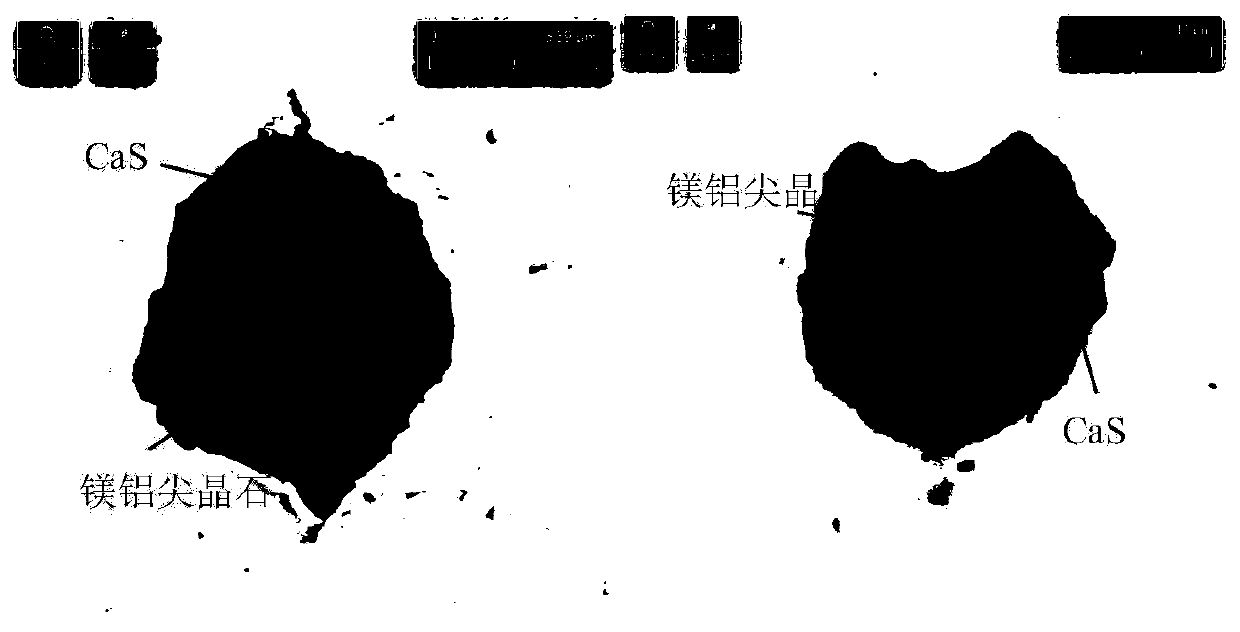

Control method for Ds inclusions of medium carbon sulfur-and-aluminum-containing deoxidized non-tempered steel

The invention discloses a control method for Ds inclusions of medium carbon sulfur-and-aluminum-containing deoxidized non-tempered steel. By adjusting the adding position of S and optimizing multi-component compositions of refined slag and molten steel compositions, on the premise of meeting the requirement of a product for oxygen, the inclusions are converted into a solid phase easy to float upwards, generation of liquid inclusions and CaS is avoided, the vacuum treatment time is further optimized, the removal efficiency of the inclusions, especially the large-particle Ds-type inclusions, inmolten steel is improved, the effect of controlling the Ds-type inclusions in the steel is achieved, and the Ds inclusions in a rolled material can be stably controlled to be 0.5 level or below duringactual production.

Owner:ZENITH STEEL GROUP CORP

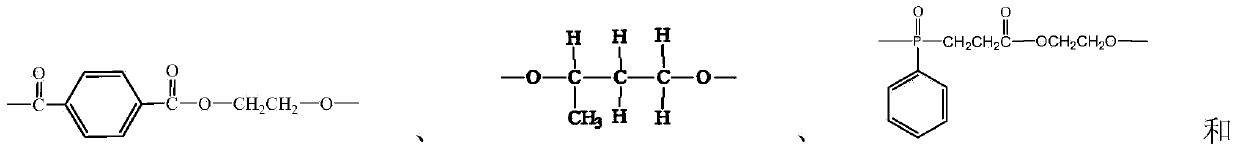

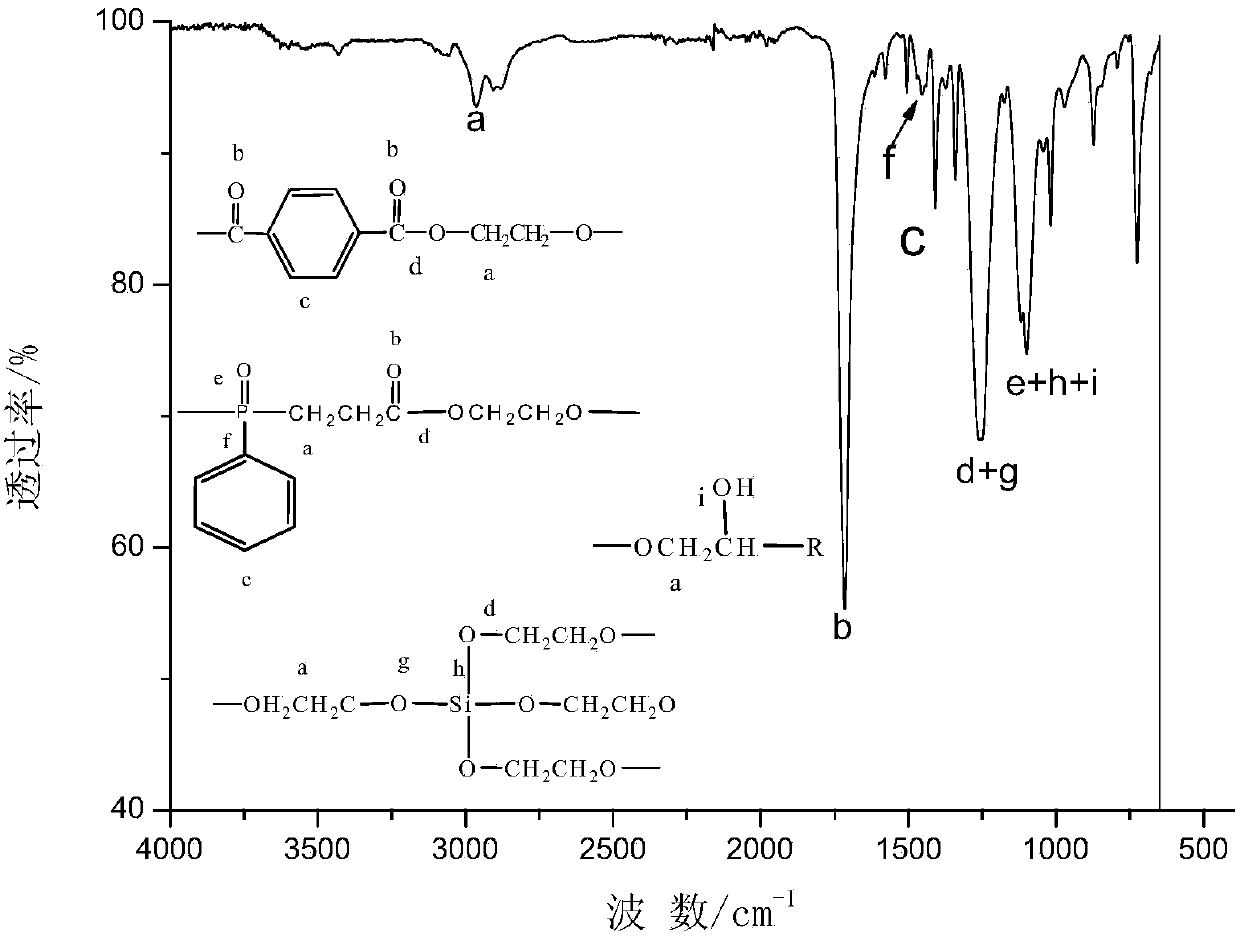

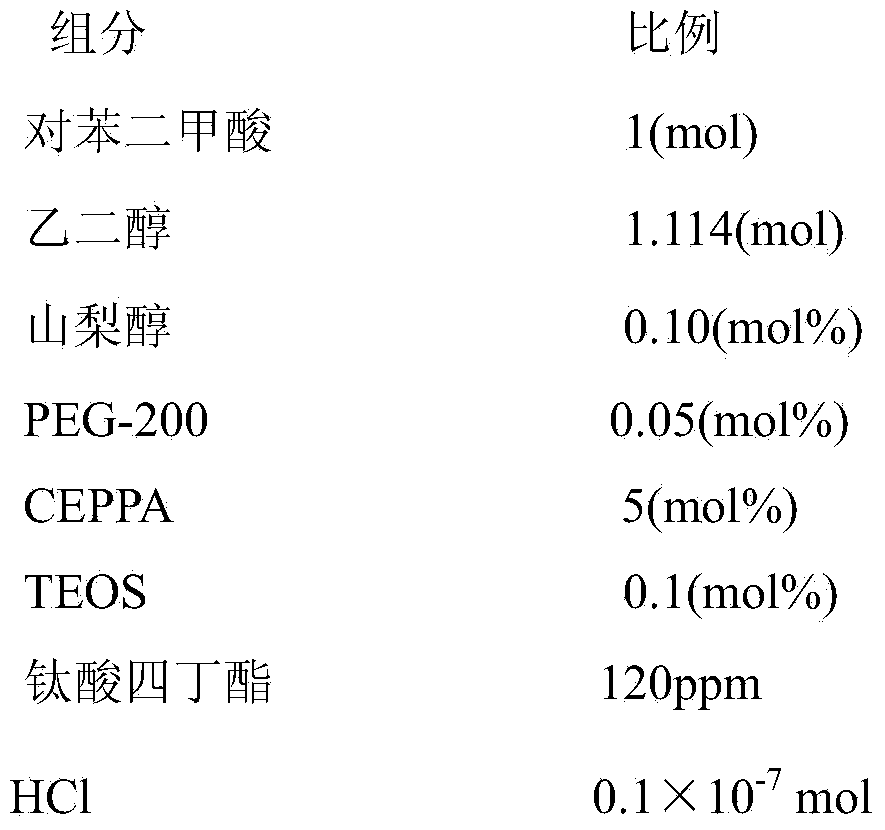

Preparation method of high-hydrophilicity flame-retardant polyester fiber

ActiveCN103628173AImprove hydrophilicityNo reactionArtificial filament heat treatmentMonocomponent copolyesters artificial filamentPolyesterPolymer science

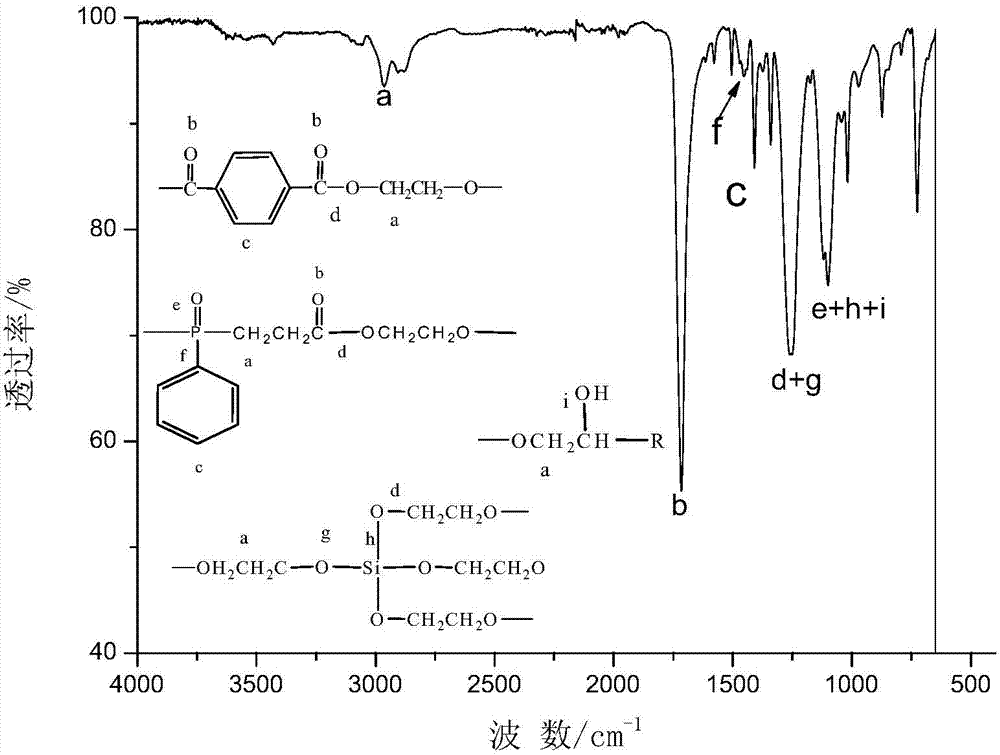

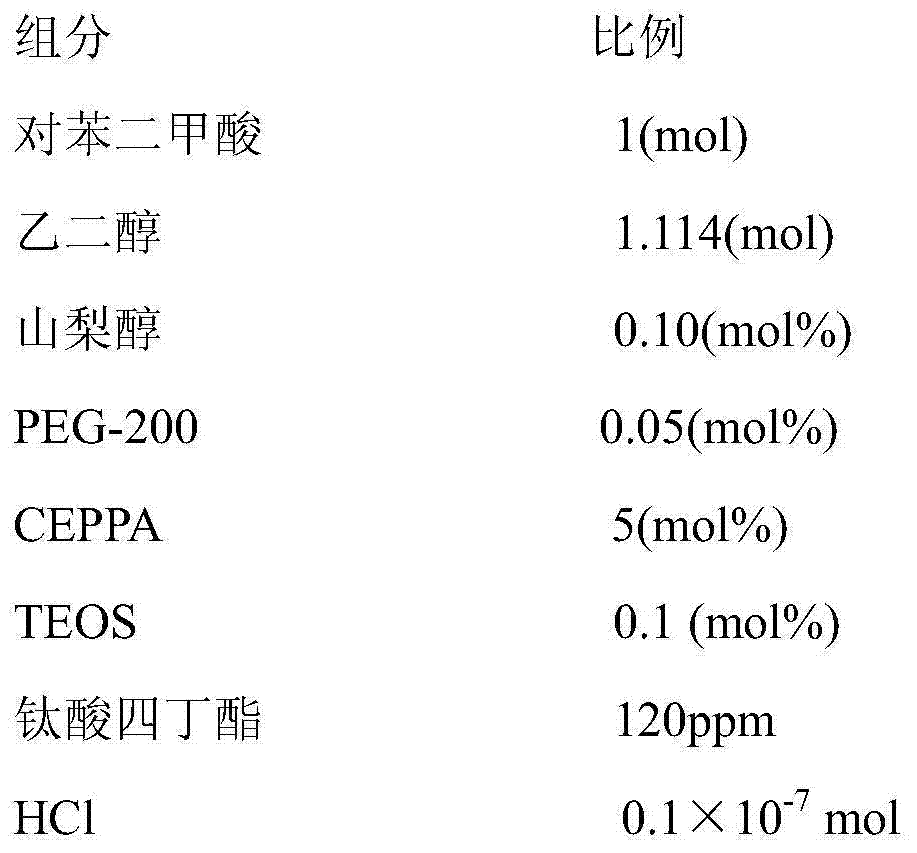

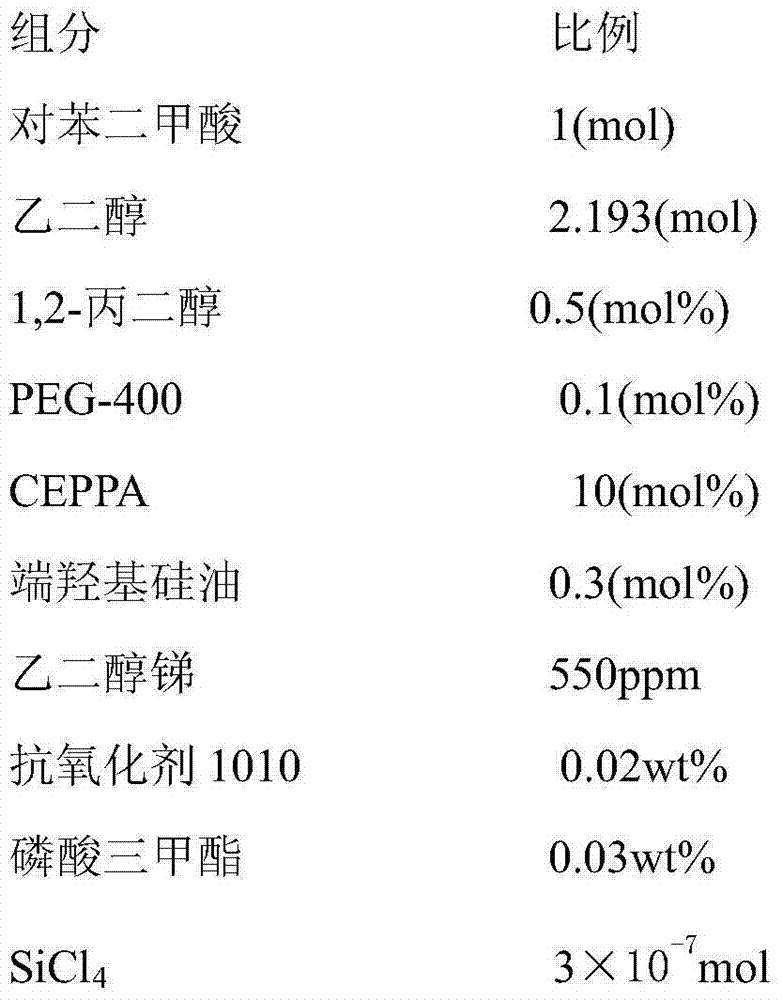

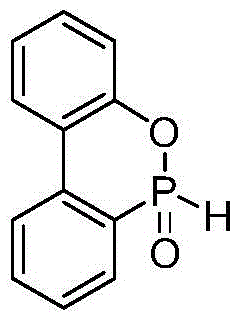

The invention relates to a preparation method of high-hydrophilicity flame-retardant polyester fiber, which comprises the steps of (1) enabling a copolymer flame retardant to react with polyalcohol to obtain CEPPA (carboxethyl phenylphosphinic acid)-polyalcohol; (2) enabling hydroxyl-terminated siloxane to react with ethylene glycol in the presence of a catalyst to obtain a hydroxyl-terminated siloxane-ethylene glycol solution; (3) preparing slurry, and adding the prepared slurry into an esterification reaction kettle to perform a first esterification reaction; (4) when the quantity of the collected byproducts reaches 82-95% of the theoretical value, adding polyalcohol, sodium sulfo bis(hydroxyethyl) isophthalate (SIPE) and polyethylene glycol (PEG) to perform a second esterification reaction; (5) after the esterification reaction, adding the products obtained by the steps (1) and (2) into a reaction kettle, and after the condensation polymerization reaction, performing melt spinning to obtain the high-hydrophilicity flame-retardant polyester fiber. The limit oxygen index of the polyester fiber prepared by the method provided by the invention is over 30%, the moisture regain is 0.6-2.0%, and the fiber has relatively high moisture regain and is comfortable to wear.

Owner:DONGHUA UNIV

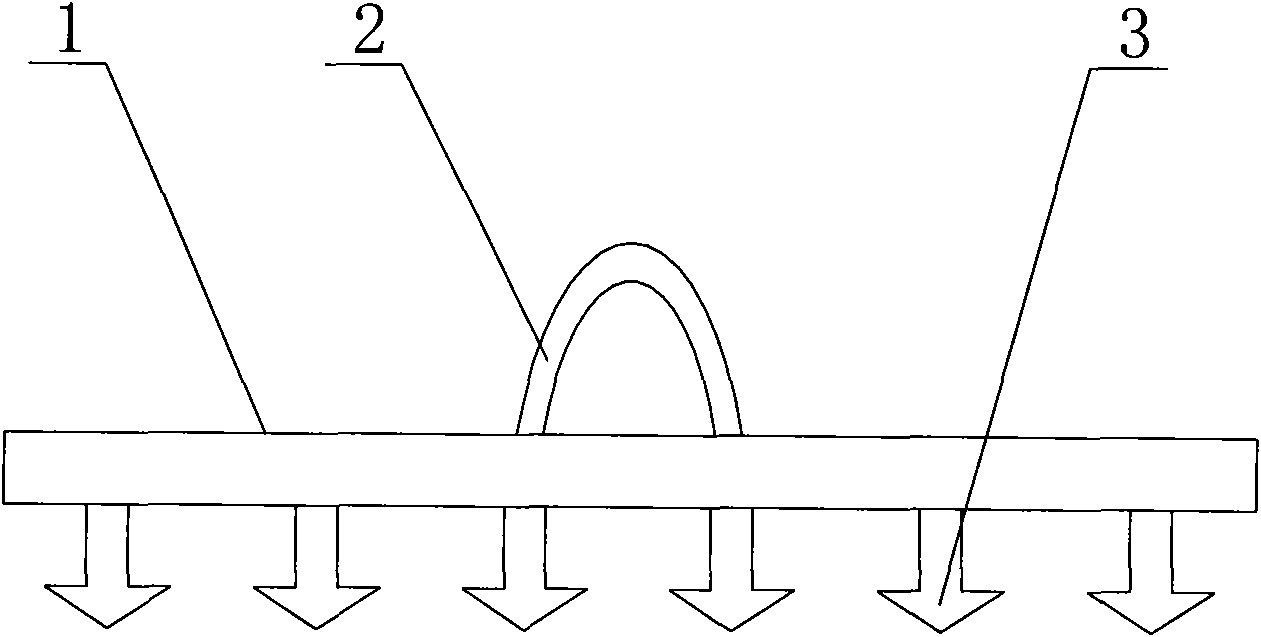

Air purification filter paper containing attapulgite clay and preparation method of air purification filter paper

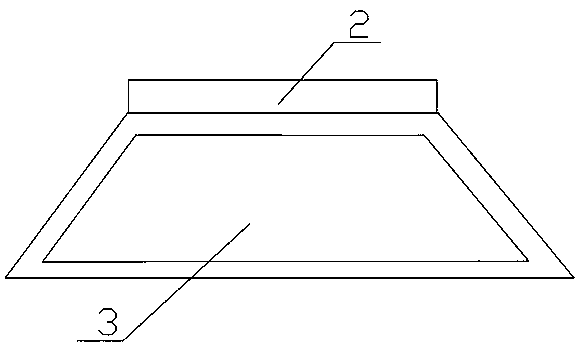

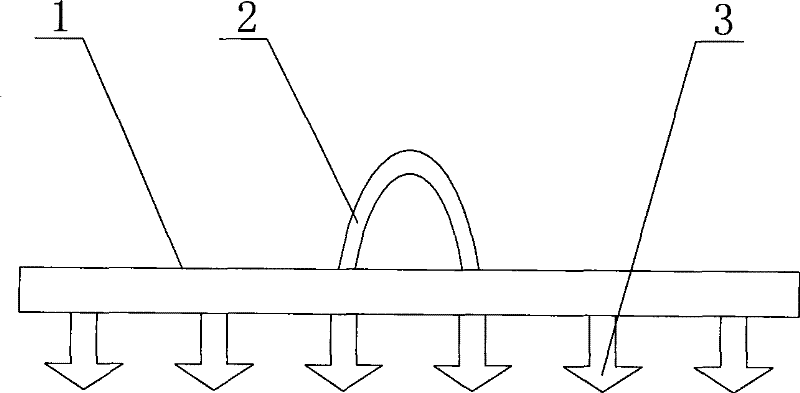

InactiveCN107012741ATightly boundFully infiltratedWater-repelling agents additionPaper coatingAir filtrationGlass fiber

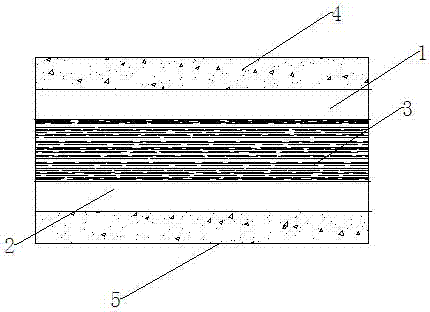

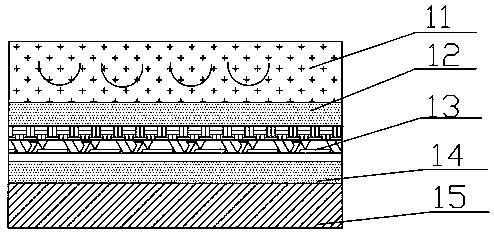

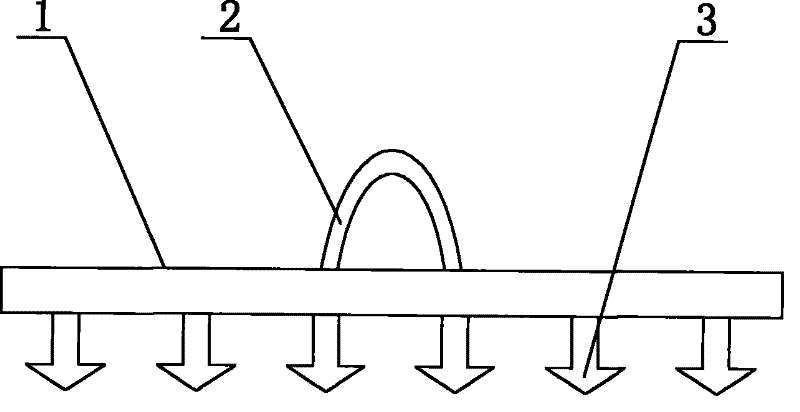

The invention belongs to the technical field of air purification filter material processing and provides an air purification filter paper containing attapulgite clay and a preparation method of the air purification filter paper. The filter paper comprises an upper glass fiber layer (1) and a lower glass fiber layer (2), wherein an antibacterial layer (3) is arranged between the upper glass fiber layer (1) and the lower glass fiber layer (2); a glue spray layer (4) is compounded on the upper surface of the upper glass fiber layer (1); a glue dipping layer (5) is compounded on the lower surface of the lower glass fiber layer (2); and the antibacterial layer (3) is prepared from a quaternary ammonium salt, halogenated amine, chitosan and modified attapulgite clay. Through adding the attapulgite clay, an air filter membrane has relatively high adsorbability, thereby adsorbing bacteria in air.

Owner:SOLVE AIR HEFEI

High-hydrophilic flame-retardant polyester and preparation method thereof

The invention relates to high-hydrophilic flame-retardant polyester and a preparation method thereof. The flame-retardant polyester comprises terephthalic acid, polyatomic alcohol, a copolymerization fire retardant and hydroxyl-terminated siloxane. The preparation method comprises the steps as follows: 1), the copolymerization fire retardant is reacted with the polyatomic alcohol, so that a reaction product CEPPA-polyatomic alcohol is obtained; 2), the hydroxyl-terminated siloxane is reacted with ethylene glycol under the effect of a catalyst, so that a hydroxyl-terminated siloxane-ethylene glycol solution is obtained; 3), a slurry is prepared, and the prepared slurry is added to an esterification reaction kettle for first esterification reaction; 4), when the collection amount of a by-product reaches 82%-95% of a theoretical value, the polyatomic alcohol, 5-sodium sulfo bis(-hydroxyethyl) isophthalate (SIPE) and PEG (polyethylene glycol) are added, and second esterification reaction is performed; and 5), after the esterification reaction, products obtained in the step 1) and the step 2) are added to the reaction kettle, and condensation polymerization is performed, so that the high-hydrophilic flame-retardant polyester is obtained. The high-hydrophilic flame-retardant polyester has a higher flame-retardant function and a higher hydrophilic function.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

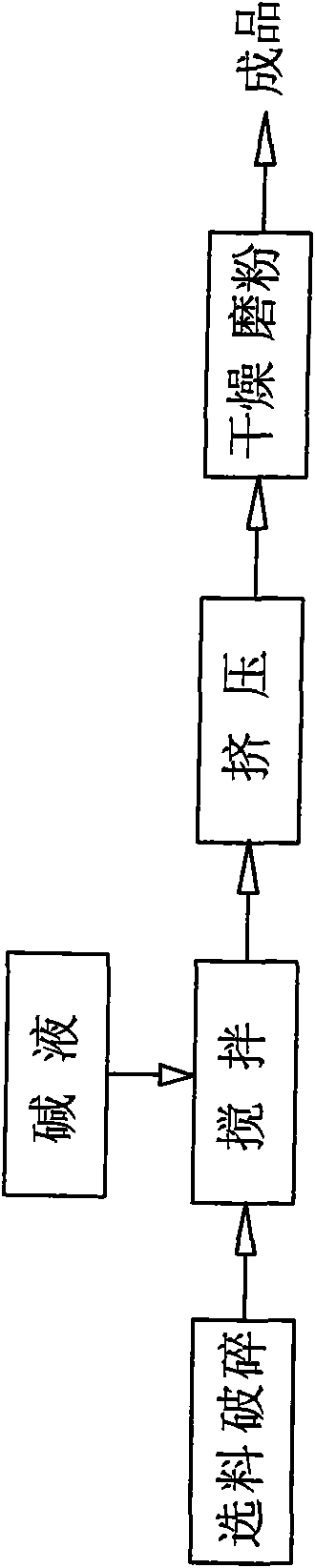

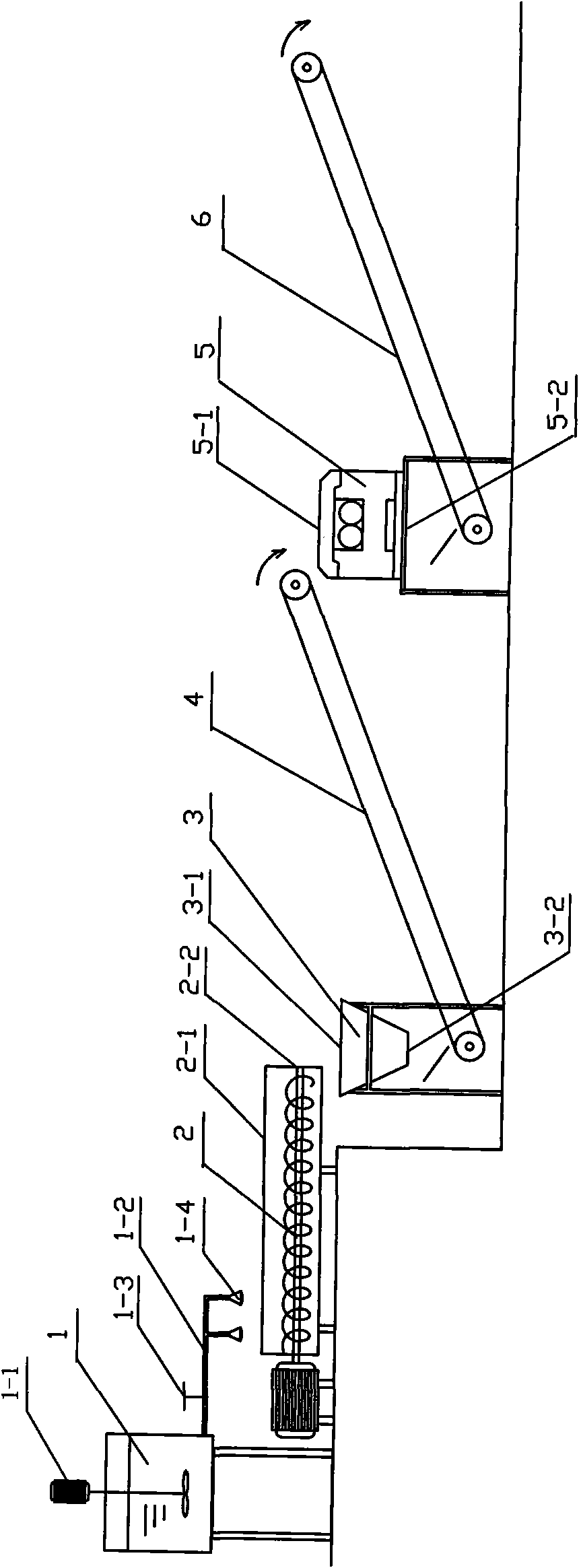

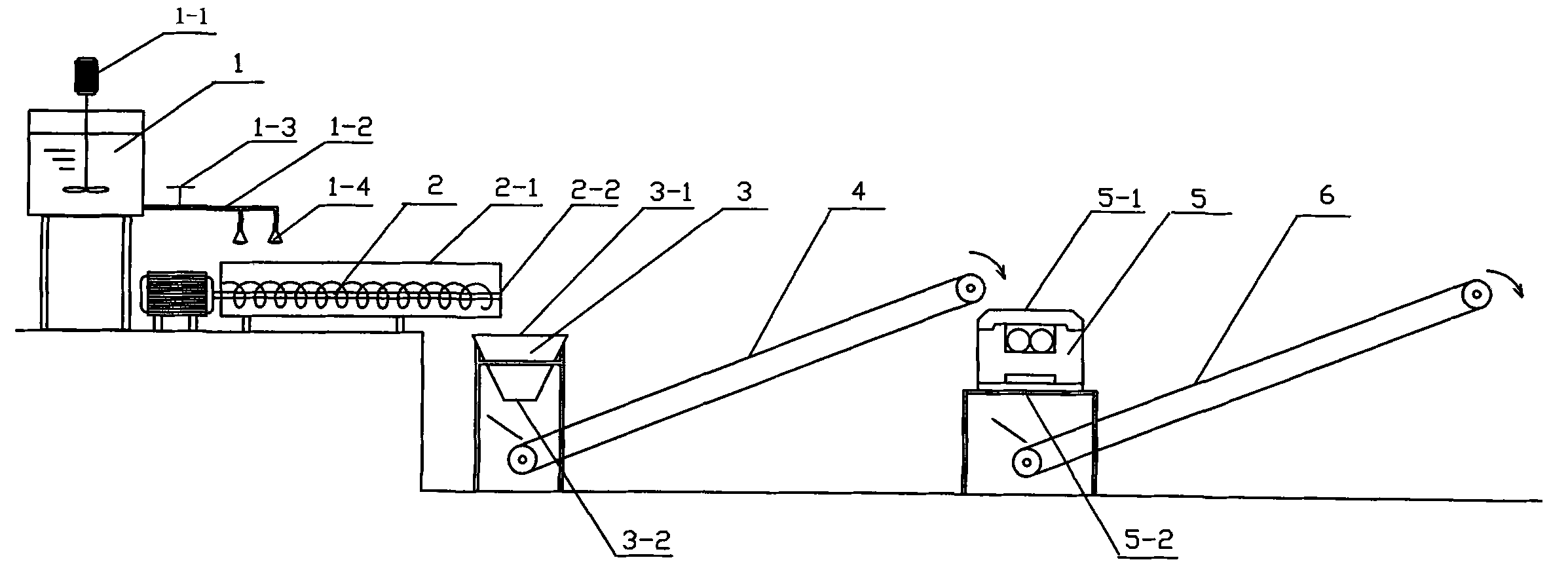

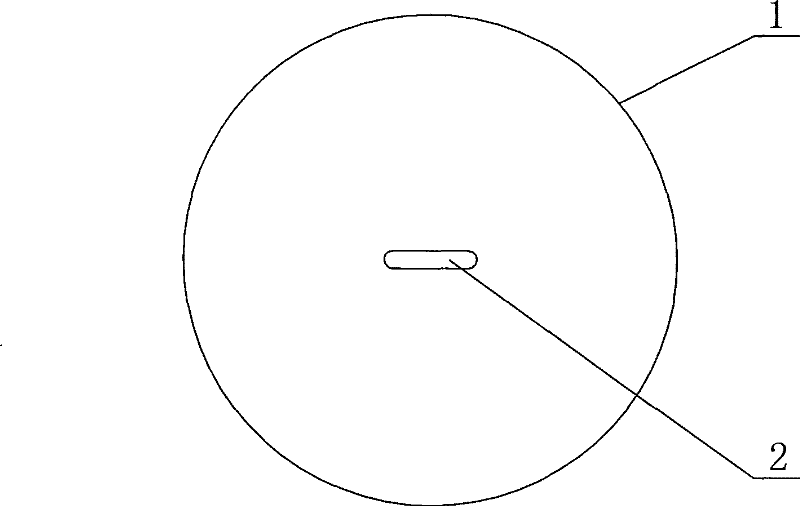

Cheto-type bentonite sodium modification method and device thereof

The invention discloses a Cheto-type bentonite sodium modification method and a device thereof. The modification method comprises processes such as material selection, alkali adding and mixing, forcible extrusion, drying, pulverization and the like. The modification device comprises an alkali solution barrel, a double-screw agitator, a silo, a belt conveyor and an open mill. The core of the invention is that the open mill used in the rubber industry is used as a main modification device. The open mill is provided with a gearbox which is able to provide enough extrusion force and two differential-speed opposite-rotating steel rolls. After material enters the two rolls, the material receives the strong extrusion force and the shear force generated by the two rolls. Bentonite is instantly extruded, kneaded, delaminated and modified. Compared with the existing modification method and device, the method and the device have obvious advantages and are particularly suitable for the sodium modification of Cheto-type bentonite.

Owner:中国非金属矿工业有限公司 +1

New method for modifying top dross in steel ladle of rimmed steel

ActiveCN101684510AGuaranteed modification effectReduced (FeO) contentManufacturing convertersCarbon steelDross

The invention relates to a liquid steel secondary refining method for steelmaking, in particular to a new method for modifying the top dross in a steel ladle of rimmed steel. The method is achieved bystirring the top dross by adopting a mechanical stirring way to promote the contact and reaction of a modifier and the top dross and react, wherein the modifier comprises the main components as follows in parts by weight: 30-70 parts of CaO and 70-30 parts of Al. The method is suitable for aluminum killed low carbon steel with the carbon content of 150-500ppm or aluminum killed ultralow carbon steel with the carbon content less than 60ppm. Compared with the prior art, the invention effectively ensures the modifying effect of the top dross of the rimmed steel and lowers the FeO content in steel slag to below 4 percent and can be used for producing steel for cold-rolled sheets with high cleanliness.

Owner:ANGANG STEEL CO LTD

Preparation method of antistatic hydrophilic polyester fiber

ActiveCN102926023BImprove hydrophilicityNo reactionMonocomponent copolyesters artificial filamentPolymer sciencePolyethylene glycol

Owner:中国化学纤维工业协会

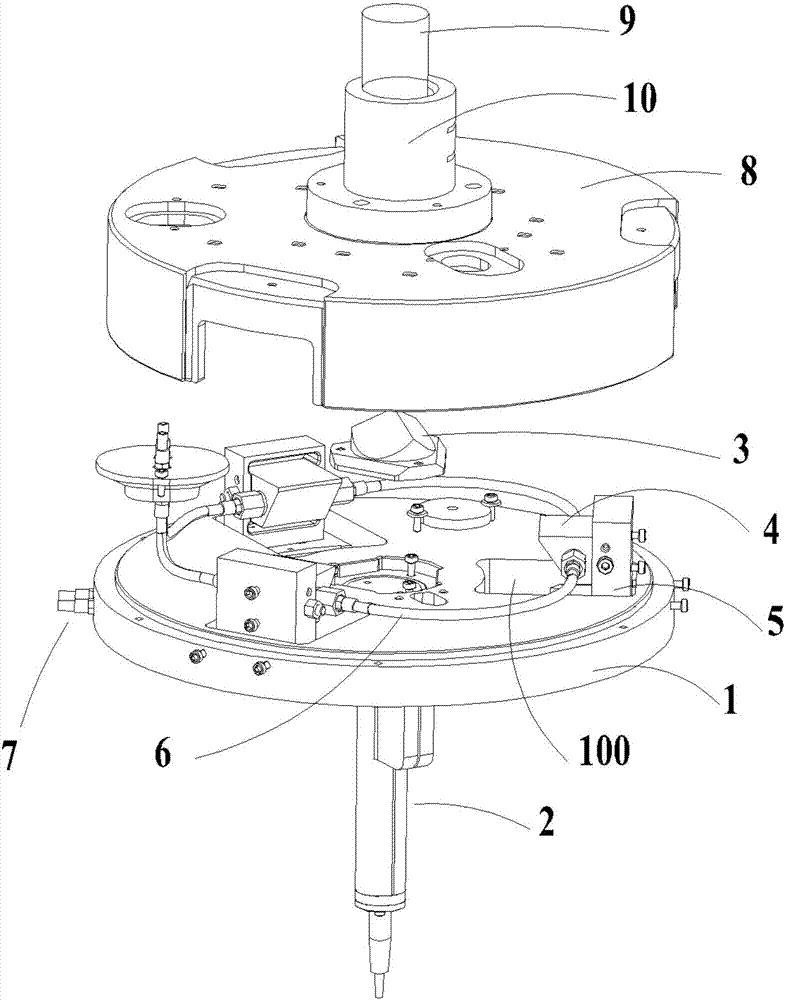

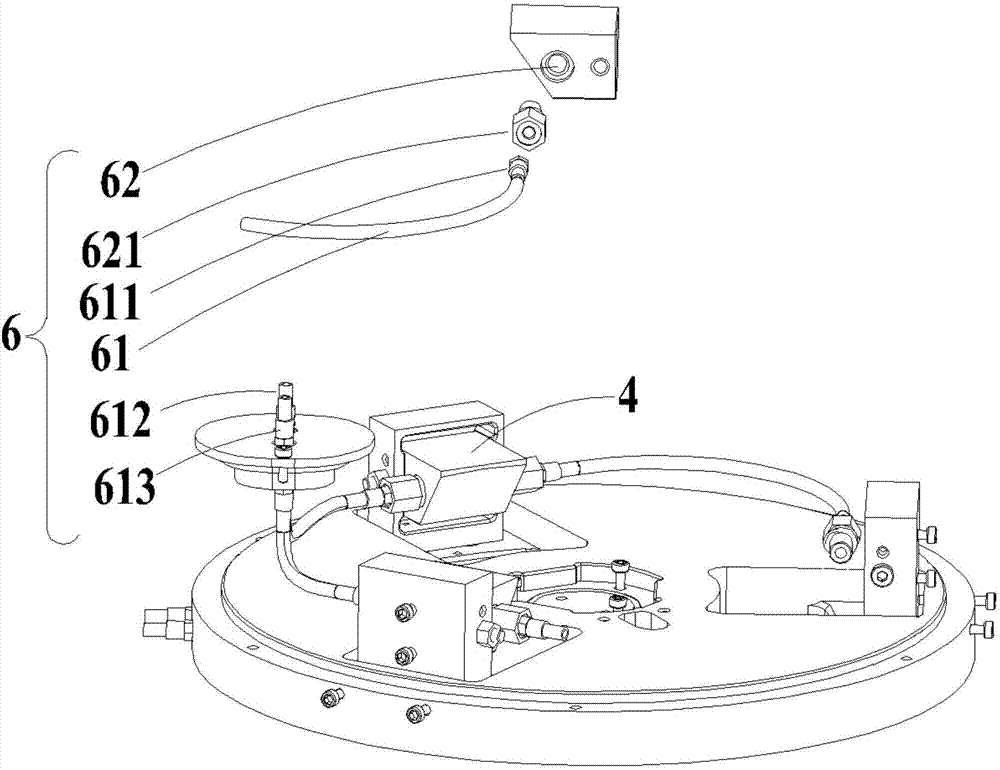

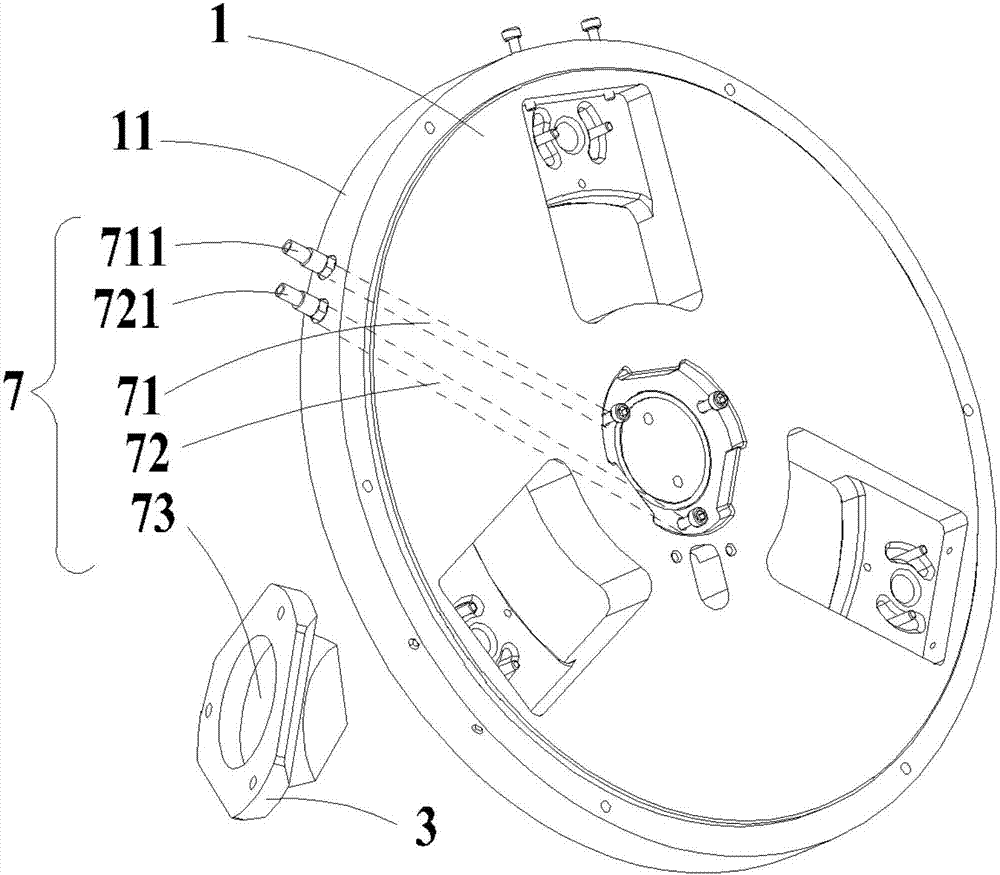

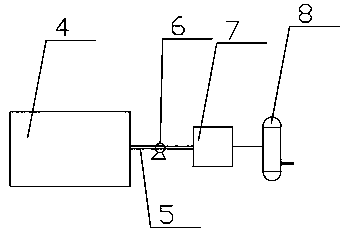

Laser cladding device

ActiveCN107217257ASmall thermal deformationGuaranteed modification effectIncreasing energy efficiencyMetallic material coating processesBeam splitterLight beam

The invention relates to a laser cladding device. The laser cladding device comprises a supporting base and a nozzle which is located below the supporting base. The supporting base is provided with a spectroscope and at least two reflection focus lenses. The spectroscope receives an incident beam and reflects the incident beam into a reflection beam, and the reflection focus lenses receive the reflection beam and convert the reflection beam into focused beams. The supporting base is further provided with a first cooling system and a second cooling system, wherein the first cooling system is used for enabling a cooling medium to circularly flow so as to cool the reflection focus lenses, and the second cooling system is used for enabling the cooling medium to circularly flow so as to cool the spectroscope. The laser cladding device is provided with two independent water path systems, water or cooling liquid at different temperatures is input to the spectroscope and the reflection focus lenses according to the heat on the spectroscope and the heat on the reflection focus lenses, the purpose of respective cooling is achieved, a relatively-good cooling effect is achieved, the service life of the spectroscope and the reflection focus lenses is prolonged, thermal deformation of the focus lenses and the spectroscope is reduced, and the modification or repairing situation of a cladded base body is guaranteed.

Owner:SUZHOU UNIV

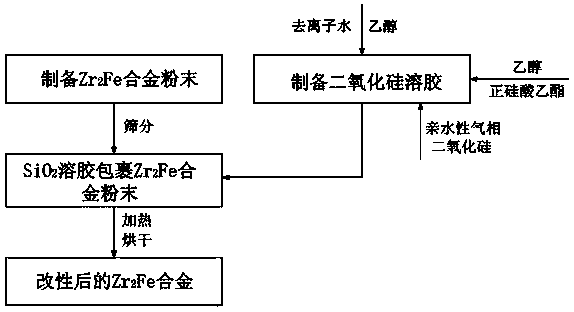

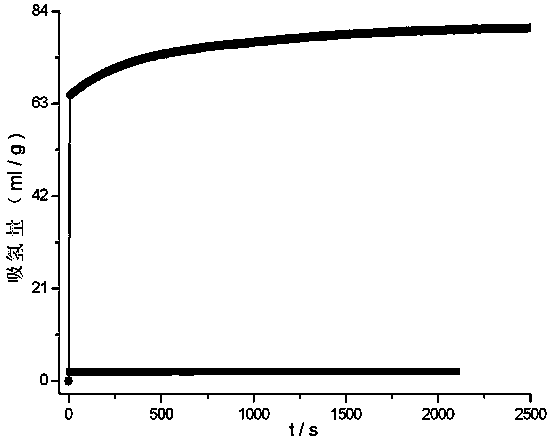

Method for enhancing air poison resistance of Zr2Fe alloy

The invention discloses a method for enhancing air poison resistance of Zr2Fe alloy. The method for enhancing the air poison resistance of the Zr2Fe alloy includes steps: S1, simultaneously loading Zr2Fe alloy particles and stainless steel balls into a stainless steel vacuum ball milling tank, and connecting the stainless steel vacuum ball milling tank with a hydrogen storage performance test system; S2, pumping gas out of the stainless steel vacuum ball milling tank, and inflating the stainless steel vacuum ball milling tank with argon gas; S3, performing ball milling on the Zr2Fe alloy particles; S4, inflating the stainless steel vacuum ball milling tank with the argon gas, and passivating the Zr2Fe alloy particles; S5, placing the stainless steel vacuum ball milling tank into a glove box, controlling air inflow of air, and exposing Zr2Fe alloy powder to air; S6, sieving the Zr2Fe alloy powder; S7, preparing silicon dioxide sol; S8, adding the Zr2Fe alloy powder into the silicon dioxide sol and stirring the Zr2Fe alloy powder so as to form cream; S9, heating and drying the cream. The method for enhancing the air poison resistance of the Zr2Fe alloy solves the problem that the Zr2Fe alloy is poor in air poison resisting ability, strengthens use stability of the Zr2Fe alloy, and prolongs use life of the Zr2Fe alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

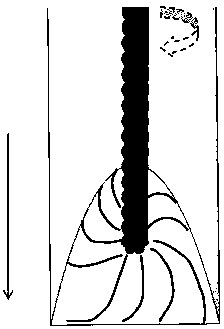

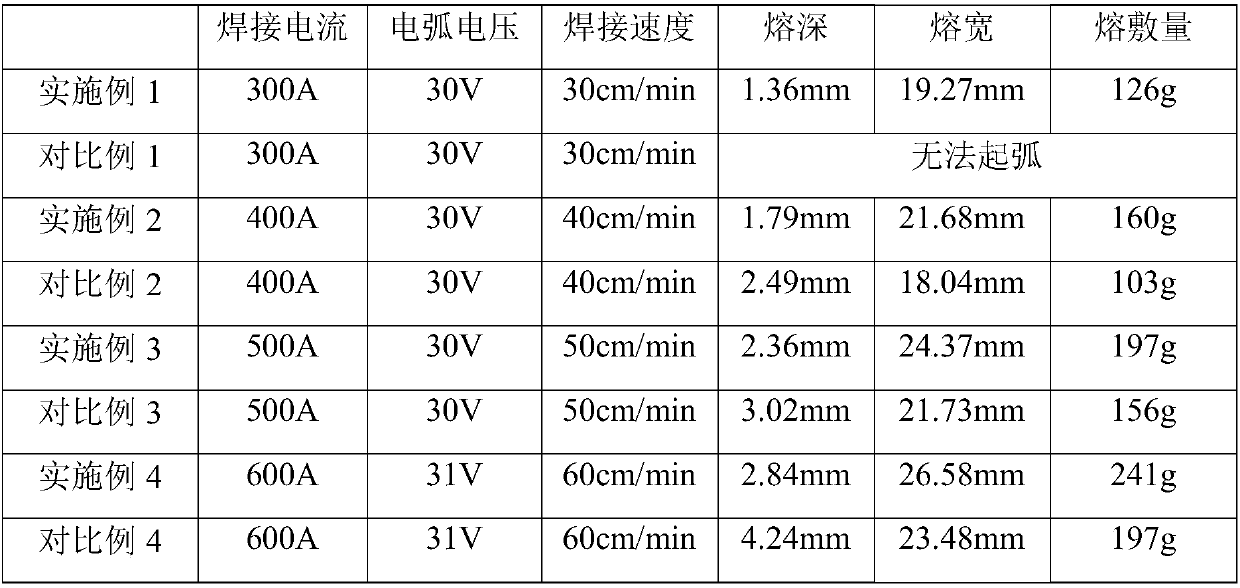

Thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method

The invention discloses a thick-wire single-power-source shallow-fusion-depth high-efficiency submerged-arc automatic surfacing process method. The method comprises the following steps that a weldingwire is used for winding six fine welding wires around one center welding wire to be spiraled into a spiral structure; and the prepared welding wire is fed into a welding area of a submerged-arc automatic trolley through a wire guide pipe and is connected with a welding power source to transmit welding current, the submerged-arc automatic trolley can move along the joint of a base material, meanwhile, a flux is applied to the welding area in an assisted mode until surfacing is completed. According to the method, the rotation motion of the welding arc is further driven under the action of mechanical rotation generated during feeding of the spiral-shaped single wires, a liquid molten pool is forced to carry out fluid motion perpendicular to the fusion depth direction so as to reduce the convection motion of the metal in the molten pool to the bottom, so that the heat inside the molten pool is conducted in the width direction of a weld joint, then the melting amount of the root of the molten pool is reduced, and a welding bead is enabled to be expanded in the width direction. According to the process method, the cable type welding wire shallow fusion depth with the diameter of 6.0 mmand wide-bead submerged-arc automatic surfacing are achieved, extremely high surfacing efficiency is realized, meanwhile, the welding cost can be further reduced.

Owner:NANJING INST OF TECH

High-performance SBS modified emulsified asphalt and SBS latex, and preparation methods thereof

ActiveCN111019366AHigh solid contentGood storage stabilityBuilding insulationsPolymer scienceBitumen emulsion

The invention provides a high-performance SBS modified emulsified asphalt and an SBS latex, and preparation methods thereof. The high-performance SBS modified emulsified asphalt is prepared from matrix asphalt, a modifier, the SBS latex, an emulsifier, a stabilizer, hydrochloric acid and water; and the SBS latex is prepared from SBS with the model of T6302, SBS with the model of D1101, n-pentane,dimethylformamide, stearamidopropyl dimethylamine, dioctyldodecyl lauroyl glutamate and water. The prepared modified emulsified asphalt is high in solid content and stable in performances; the storagestability is high, and the 5d storage stability is far lower than the standard requirement index; and the high-low temperature performance of evaporation residues is excellent. The solid content of the prepared SBS latex can reach 40-50%, and the storage stability of the SBS latex can reach one month or more, so it can be guaranteed that the modified emulsified asphalt prepared in the later period has excellent high and low temperature performances.

Owner:CHANGAN UNIV

Modified corn straw composite fiber reinforced friction material and its preparation method

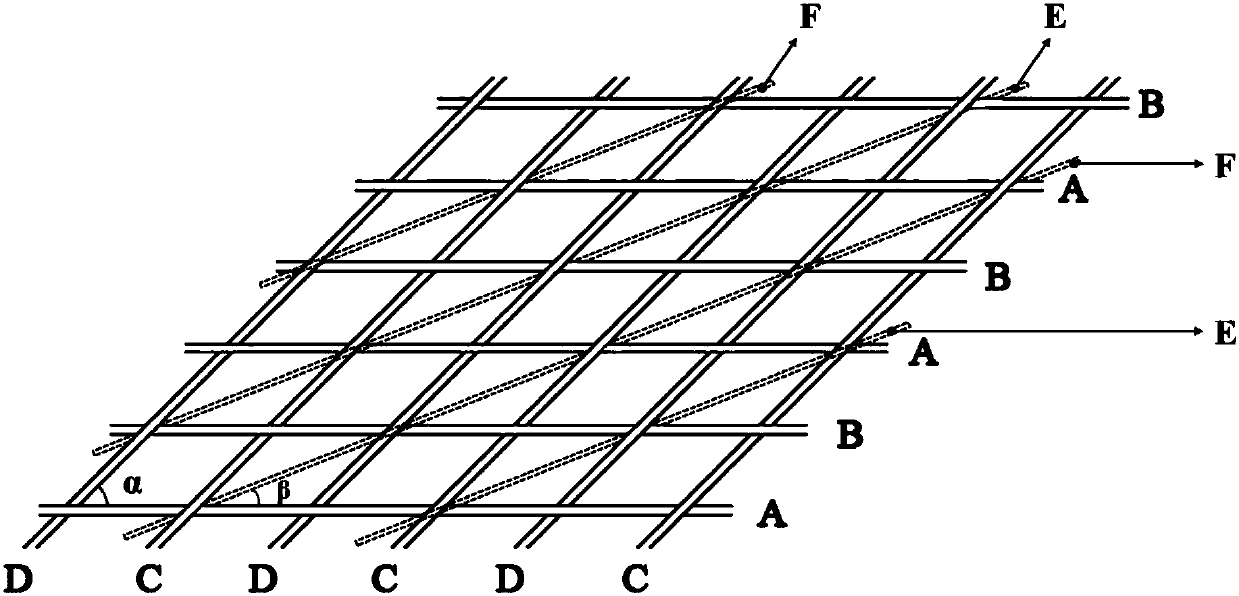

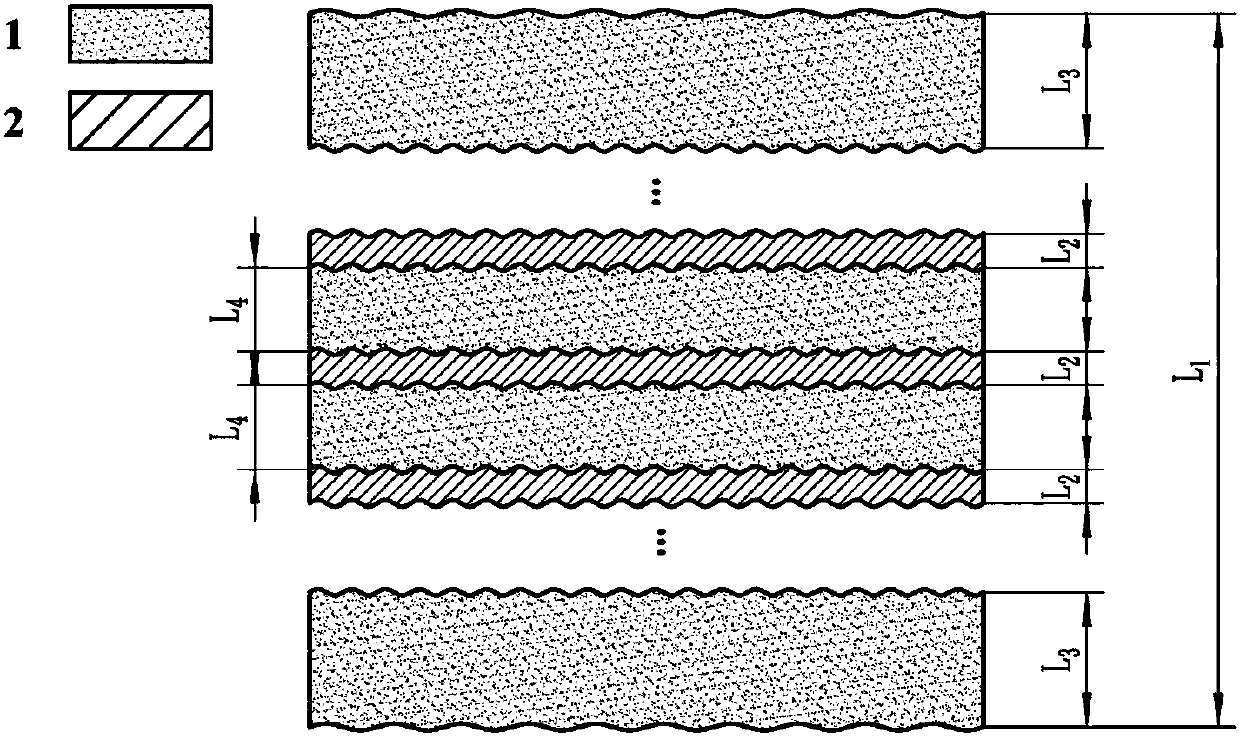

ActiveCN107828373AWidely distributedLow costOther chemical processesPhysical treatmentAramidHybrid fibre

The invention discloses a modified corn straw composite fiber reinforced friction material and its preparation method, and belongs to the technical field of a brake friction material. The brake friction material is composed of a composite fiber interweaving structure layer and a filler layer, wherein the composite fiber interweaving structure la is formed by interweaving, aligning and combining the modified corn straw fiber and the mixed fiber; the mixed fiber is composed of modified aramid fiber and modified polybenzoxazole fiber; by comprehensively using the advantageous performance of everyfiber, the thermal stability and wear resistance of the friction material are enhanced while the production cost is reduced; by adopting the alternative alignment method of the composite fiber interweaving structure layer and the filler layer, the uniformity of the fiber dispersion, the combination property with base material, and the effectiveness of using as a friction material enhancer are guaranteed. The invention provides a friction material featured by low friction factor, low wear rate, good thermal recession resistance, strong shearing resistance, small brake noise, strong environmentprotection property, low cost, high comprehensive performance cost, and others.

Owner:JILIN UNIV

Step releasing type solidifying stabilizing remediating method for heavy metal polluted soil

ActiveCN108637008ALow priceWon't penetrateContaminated soil reclamationPolluted soilsHeavy metals pollution

The invention relates to a step releasing type solidifying stabilizing remediating method for heavy metal polluted soil. The method comprises the steps of (1) preparing a step releasing control agent;(2) treating the heavy metal polluted soil by a medicine; (3) stacking the polluted soil after medicine treating; and detecting for inspection and acceptance; and (4) backfilling the heavy metal polluted soil into a planned backfilling area after passing the inspection. According to the method, the heavy metal can be efficiently stabilized for a long time; the cost is low; the effect is good; andthe heavy metal can be released by steps.

Owner:HEBEI YUHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

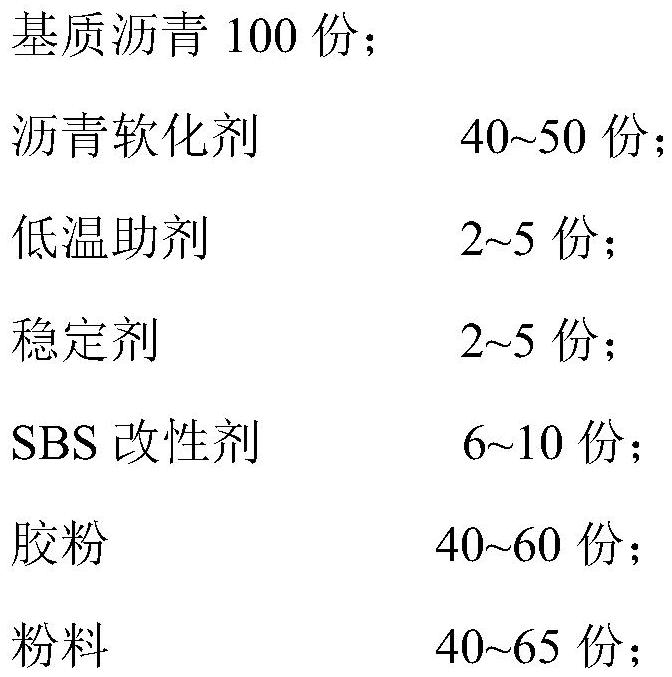

Modified asphalt coating material with excellent high and low temperature performance, waterproof roll and preparation method thereof

ActiveCN113389058AGood high and low temperature performanceMeet waterproof requirementsSynthetic resin layered productsConstructions elementsSorbitanFatty acid

The invention discloses a modified asphalt coating material with an excellent high and low temperature performance. The modified asphalt coating material with the excellent high and low temperature performance comprises the following components in parts by weight: 100 parts of matrix asphalt; 40 to 50 parts of an asphalt softener; 2 to 5 parts of a low-temperature auxiliary agent; 2 to 5 parts of a stabilizer; 6 to 10 parts of an SBS modifier; 40 to 60 parts of rubber powder; and 40 to 65 parts of powder. The low-temperature auxiliary agent is one or a mixture of more of castor oil, epoxidized soybean oil, industrial white oil and tea tree oil; and the stabilizer is one or a mixture of more of short glass fiber, long glass fiber and fatty acid sorbitan. The modified asphalt coating material provided by the invention has excellent ultra-high temperature resistance and ultra-low temperature resistance, is more aging-resistant, is more suitable for being applied to coiled materials of waterproof engineering in an extreme environment, and is low in cost and easy to popularize, and the adopted components do not harm the environment and human health. The invention also discloses a preparation method of the coating material, a waterproof roll using the coating material and a preparation method of the waterproof roll.

Owner:福建科顺新材料有限公司 +1

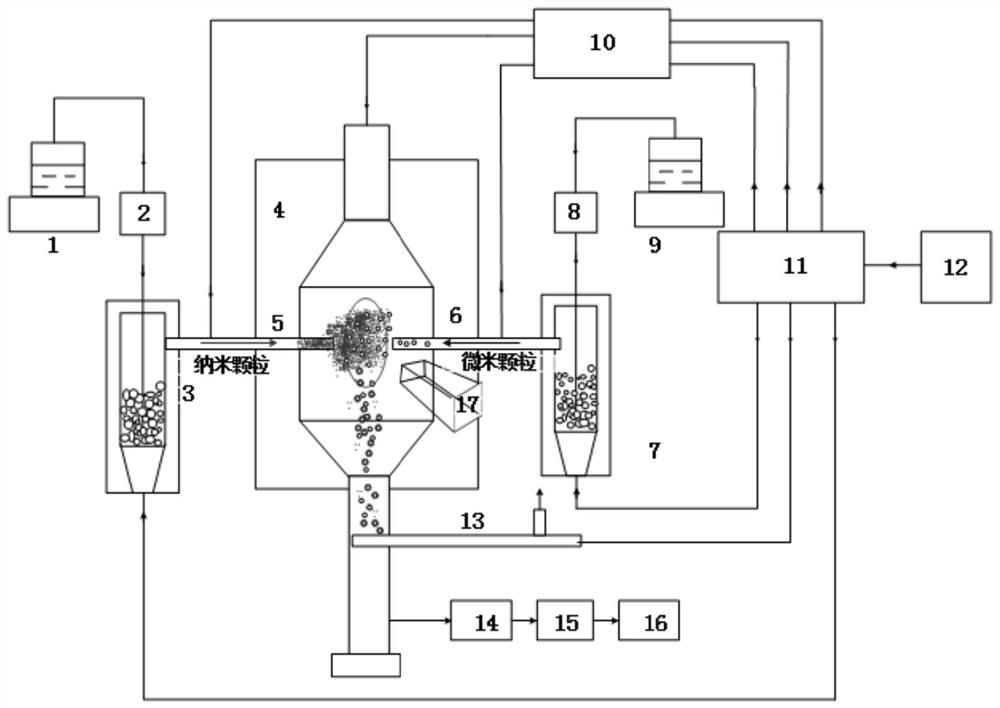

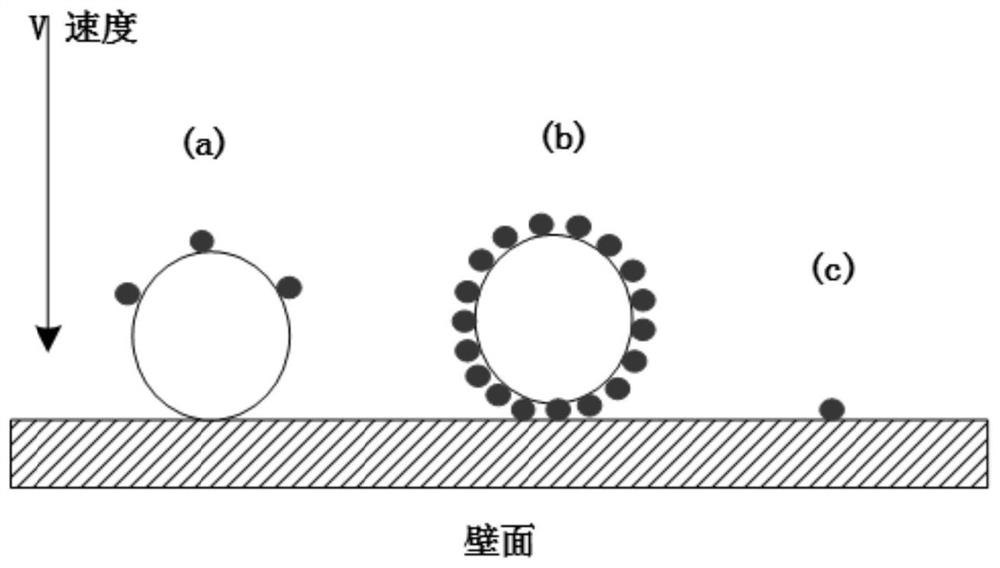

Device and method for regulating and controlling fly ash deposition layer based on impinging stream technology

The invention discloses a device and method for regulating and controlling a fly ash deposition layer based on an impinging stream technology, and belongs to the technical field of ash deposition prevention and control. The device for regulating and controlling the fly ash deposition layer based on the impinging stream technology comprises a high-temperature hearth, a nano-particle spraying systemand a fly ash spraying system, the nano-particle spraying system and the fly ash spraying system are used for spraying nano-particles and micron fly ash into the high-temperature hearth correspondingly, and the spraying directions of the nano-particle spraying system and the fly ash spraying system are oppositely arranged. According to the method for regulating and controlling the fly ash deposition layer, nano-particles are introduced into the high-temperature hearth, so that the surface of coal-fired fly ash is coated with the nano-particles, the surface viscosity of the coal-fired fly ashcan be effectively reduced, the structure and composition of the fly ash deposition layer are regulated and controlled, and finally the purpose of remarkably solving the ash deposition problem is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of preparation method of multifunctional hydrophilic polyester fiber

ActiveCN103820878BImprove hydrophilicityNo reactionMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer scienceSpinning

The invention provides a preparation method for multi-functional hydrophilic polyester fibers. The method is characterized by specifically comprising the following steps: firstly, mixing terephthalic acid with ethylene glycol to prepare a paste; adding into an esterfying reactor to carry out first esterfying reaction; when the collecting quantity of byproducts reaches 82-95% of a theoretical value, adding sorbitol and polyethylene glycol to carry out second esterfying reaction; after finishing esterfying reaction, performing polycondensation reaction on obtained esterfied products so as to obtain a hydrophilic polyester chip; secondly, preparing nanometer coffee carbon powder; thirdly, preparing nanometer bamboo charcoal powder containing an ultraviolet resistor; fourthly, performing fusing granulation on the nanometer bamboo charcoal powder containing the ultraviolet resistor and the hydrophilic polyester chip so as to obtain functional master batch; fifthly, performing fusing spinning on the functional master batch and the hydrophilic polyester chip so as to obtain the multi-functional hydrophilic polyester fibers. The multi-functional hydrophilic polyester fibers have great hydrophilic performance and continuously have the functions of the ultraviolet resistor and the bamboo charcoal for a long term.

Owner:江苏三联新材料股份有限公司

Construction process of cement modified soil

InactiveCN110565618AImprove mixing uniformityGuaranteed modification effectIn situ soil foundationSoil preservationSocial benefitsSoil treatment

The invention relates to the technical field of expansive soil treatment processes, in particular to a construction process of cement modified soil. The construction process mainly comprises the following steps: first, the expansion level of an expansive soil material is tested, and a physical property test and a compaction test are carried out on the cement modified soil subjected to filling replacement; second, after the property of the cement modified soil is detected, regulated and controlled, mixing and filling preparation is conducted; third, operation construction is conducted through mechanical equipment; 4, the construction quality of the cement modified soil for filling construction is subjected to quality control and detection; and fifth, real-time detection and timed maintenance are conducted. The construction process is used for improving expansive soil and the construction quality of a channel section and a construction section to ensure the cement modifying effect of theexpensive soil and the filling quality of the modified soil material, by regulating construction data to standard parameters, the functions of high water content quick decreasing, ultra-large soil mass breaking, cement mixing uniformity improving and the like can be quickly realized, meanwhile construction operation is efficient and easy, the quality is controllable, construction is reliable, thecost is saved, and the construction process has obvious social benefits and economic benefits.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

A water-based ultra-thin intumescent fireproof coating for steel structures and preparation method thereof

ActiveCN104130671BImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsWater basedEmulsion

The invention discloses a water-based ultra-thin intumescent fireproof coating for steel structures and a preparation method thereof, belonging to the technical field of fireproof coatings. The composition and mass percent of the fireproof coating are: modified water-based epoxy emulsion: 10 ~ 35 ;Hardener: 1 ~ 8 ;Styrene acrylic emulsion or silicone acrylic emulsion: 5 ~ 15 ; Ammonium polyphosphate: 10 ~ 20 ;Melamine: 6 ~ 12 ; Pentaerythritol: 8 ~ 16 ; Flame retardant: 5 ~ 15 ; Color, filler: 5 ~ 15 ;Auxiliary: 2 ~ 8 ;water: 15 ~ 35 . The invention has the characteristics of low raw material cost, simple preparation process, environmental protection and the like.

Owner:沈阳泰丰化工有限公司

New method for modifying top dross in steel ladle of rimmed steel

ActiveCN101684510BGuaranteed modification effectReduced (FeO) contentManufacturing convertersSteelmakingLiquid steel

The invention relates to a liquid steel secondary refining method for steelmaking, in particular to a new method for modifying the top dross in a steel ladle of rimmed steel. The method is achieved by stirring the top dross by adopting a mechanical stirring way to promote the contact and reaction of a modifier and the top dross and react, wherein the modifier comprises the main components as follows in parts by weight: 30-70 parts of CaO and 70-30 parts of Al. The method is suitable for aluminum killed low carbon steel with the carbon content of 150-500ppm or aluminum killed ultralow carbon steel with the carbon content less than 60ppm. Compared with the prior art, the invention effectively ensures the modifying effect of the top dross of the rimmed steel and lowers the FeO content in steel slag to below 4 percent and can be used for producing steel for cold-rolled sheets with high cleanliness.

Owner:ANGANG STEEL CO LTD

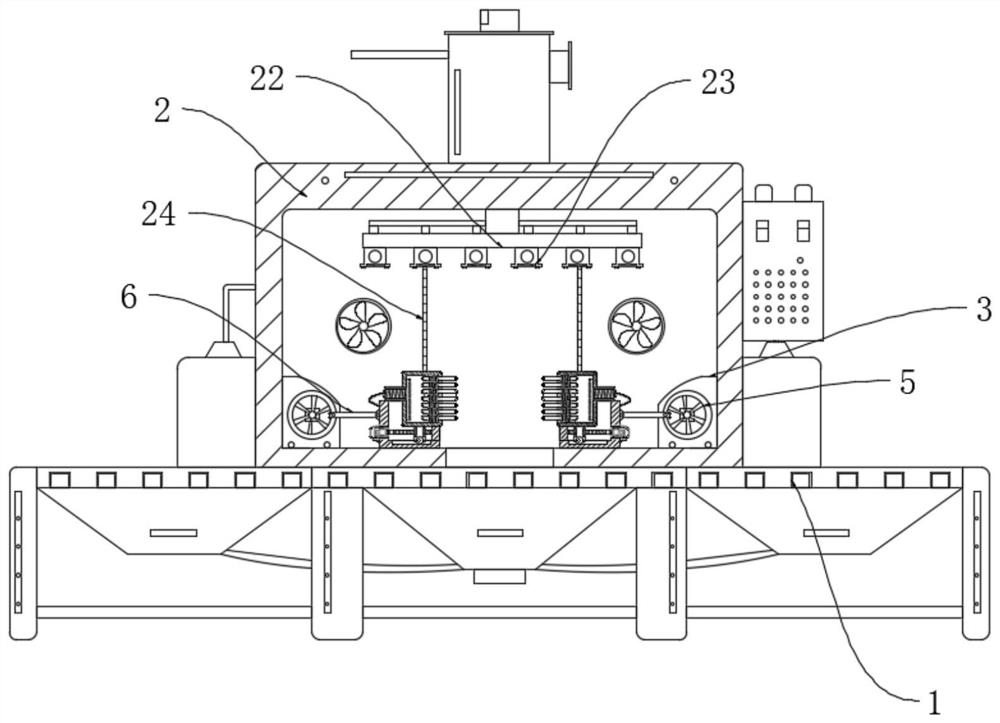

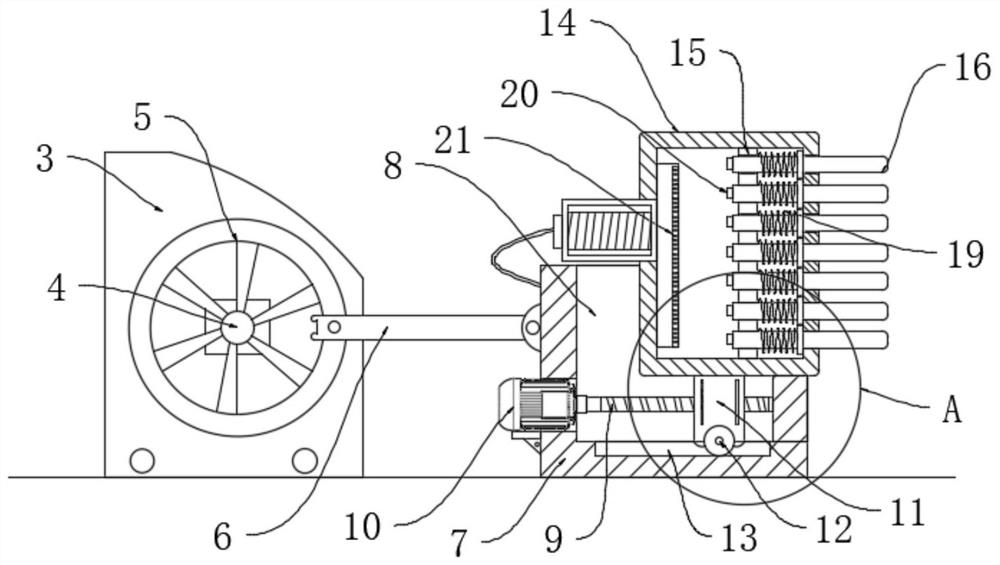

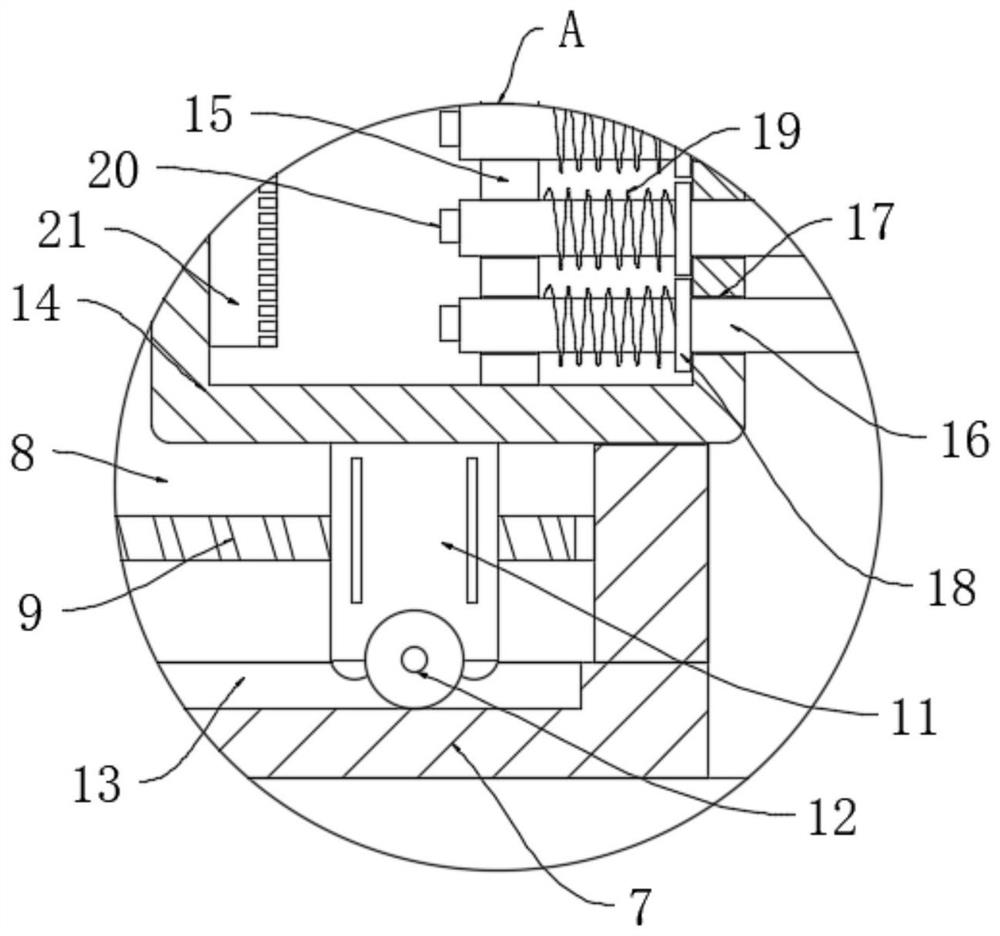

Multi-specification type aluminum profile sand blasting equipment

ActiveCN112847151AReduce shockAvoid deformationAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDrive shaft

The invention relates to the technical field of processing of materials and particularly relates to multi-specification type aluminum profile sand blasting equipment. The multi-specification type aluminum profile sand blasting equipment comprises a base, wherein a sand blasting box is fixedly mounted on the base; base tables are fixedly mounted in the sand blasting box; a driving shaft is rotatably mounted on each base table; a rotating wheel is fixedly mounted on each driving shaft; a connecting rod is rotatably connected with each rotating wheel; each connecting rod is rotatably connected with a sliding seat; a limiting groove is formed in each sliding seat; a screw is rotatably mounted in each limiting groove; each screw is connected with a servo motor and is in threaded connection with a nut seat; a caster is rotatably mounted on each nut seat and is movably connected with the interior of a guide groove; a double-sided clamping mechanism is designed in the sand blasting box in allusion to aluminum profile workpieces; two clamping blocks are mainly used as main clamping parts; and flexible limiting mechanisms are formed on the clamping blocks through clamping columns which are arranged and mounted, so that the multi-specification type aluminum profile sand blasting equipment can be perfectly attached with the surface shapes of the workpieces and can adaptively fix different specifications of aluminum profiles.

Owner:广西扬力铝业有限公司

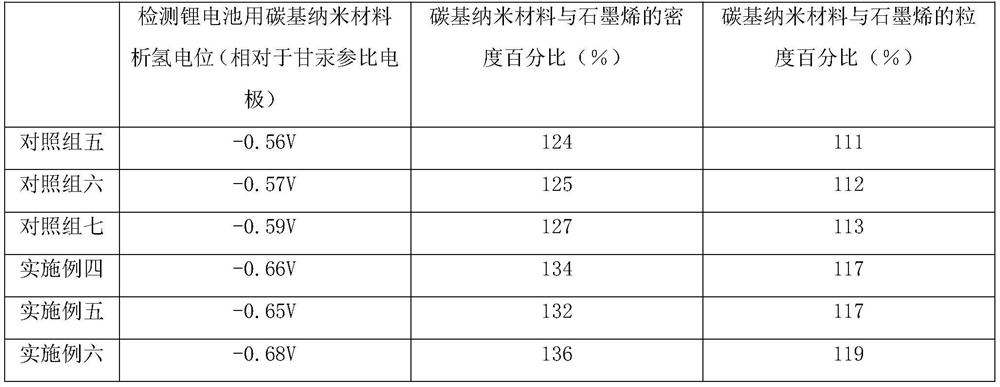

Carbon-based nano material for lithium battery and preparation method of carbon-based nano material

ActiveCN113889612ALower hydrogen evolution potentialHigh densityCell electrodesElectrolytic agentCarbon based nanomaterials

The invention discloses a carbon-based nano material for a lithium battery and a preparation method of the carbon-based nano material, and particularly relates to the technical field of lithium battery materials, and the carbon-based nano material comprises electrolytic graphene and an inhibitor. The surface of the carbon material can be effectively modified, the hydrogen evolution potential of the carbon material can be effectively reduced, and the density and granularity of the carbon-based nano material for the lithium battery can be effectively improved, so that the electrochemical behavior of the carbon material in an electrolyte is improved, and meanwhile, the combination effect between the carbon material and a negative plate active substance is enhanced; the carbon material cannot fall off in the working process of the battery; zinc nitrate, silver nitrate and bismuth nitrate pentahydrate are subjected to microwave hydrothermal irradiation treatment in an alkaline environment, nano-zinc oxide, nano-silver oxide and nano-bismuth oxide can be effectively synthesized, the nano-zinc oxide, nano-silver oxide and nano-bismuth oxide are compounded to the surface of water-soluble graphene, the surface of the water-soluble graphene is modified, and the hydrogen evolution inhibition effect of the carbon-based nano material for the lithium battery can be effectively enhanced.

Owner:江苏华清能源科技有限公司

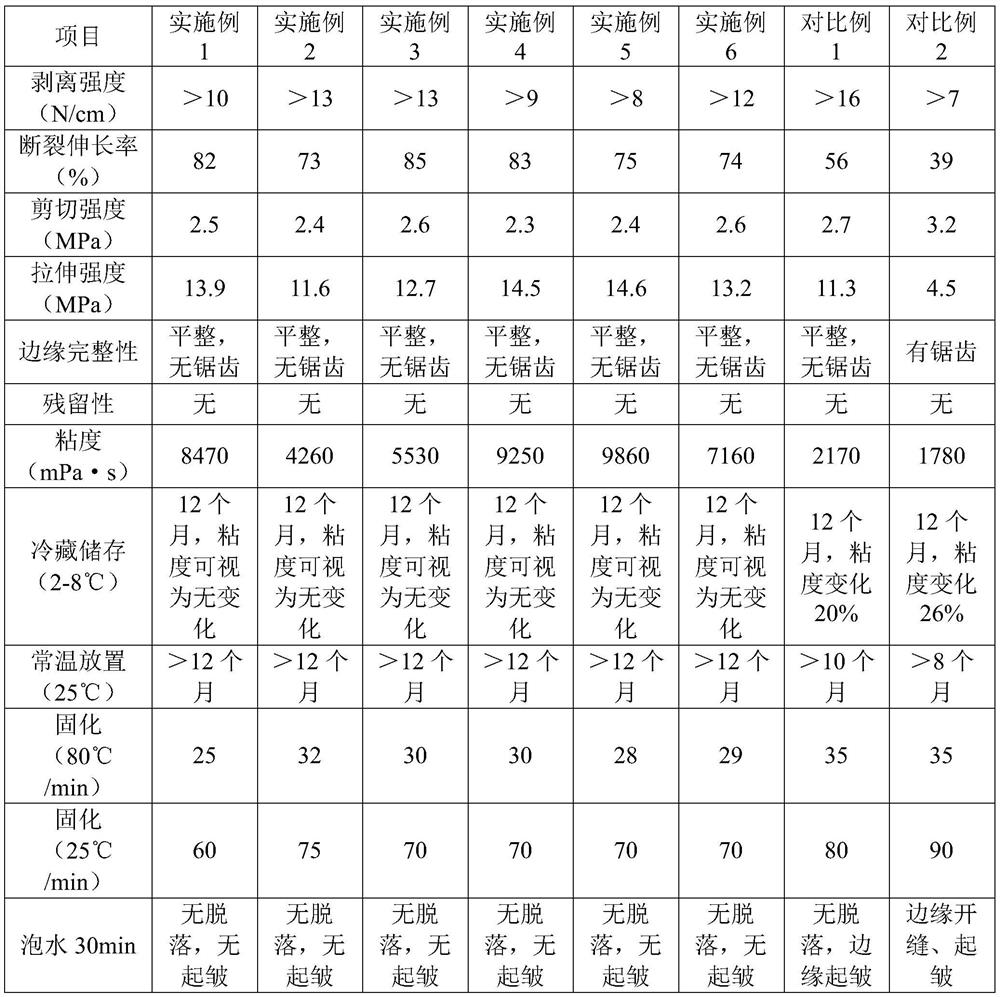

Low-temperature thermosetting waterborne peelable adhesive and preparation method thereof

PendingCN113621337AEasy to peelIncrease brightnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides a low-temperature thermosetting waterborne peelable adhesive and a preparation method thereof. The peelable adhesive comprises the following components: 50-70 parts of waterborne polyurethane resin, 3-7 parts of a silane coupling agent, 3-7 parts of nano graphene, 1-2 parts of a dispersing agent, 1-5 parts of a film-forming agent, 0.1-1 part of a wetting agent, 1-1.5 parts of a defoaming agent, 0.5-2 parts of a thickening agent, 0.3-0.5 part of color paste and 20-40 parts of filler. The preparation method comprises the following steps: weighing the raw materials; diluting the thickening agent and preparing a nano graphene dispersion liquid; uniformly mixing the nano graphene dispersion liquid and the waterborne polyurethane for three times, sequentially adding the silane coupling agent, the film-forming agent, the wetting agent, the defoaming agent, the color paste, the thickening agent and the filler, and uniformly stirring to obtain the low-temperature thermosetting waterborne peelable adhesive. The low-temperature thermosetting waterborne peelable adhesive is curable at low temperature, good in flexibility, good in adhesive force, peelable and capable of adapting to CNC operation, and the preparation method is simple and environmentally friendly.

Owner:广州亦盛环保科技有限公司

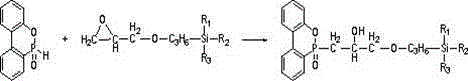

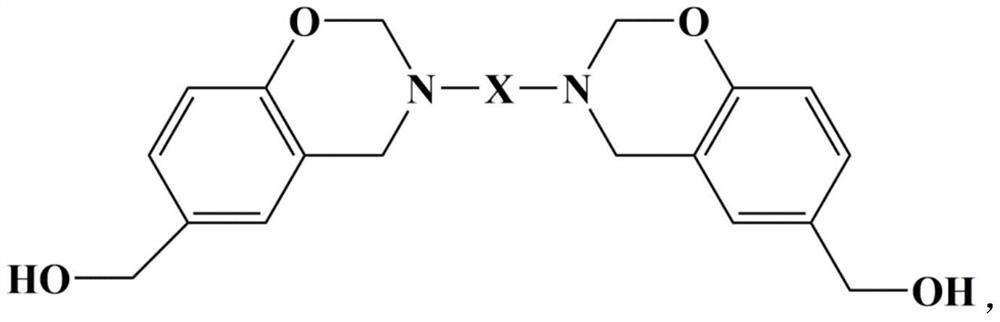

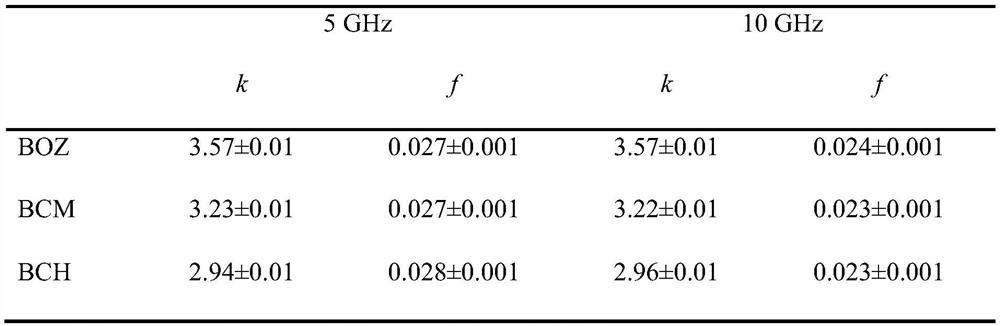

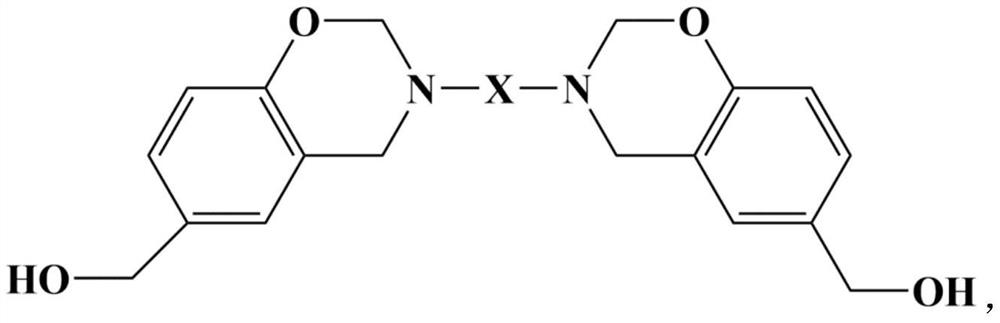

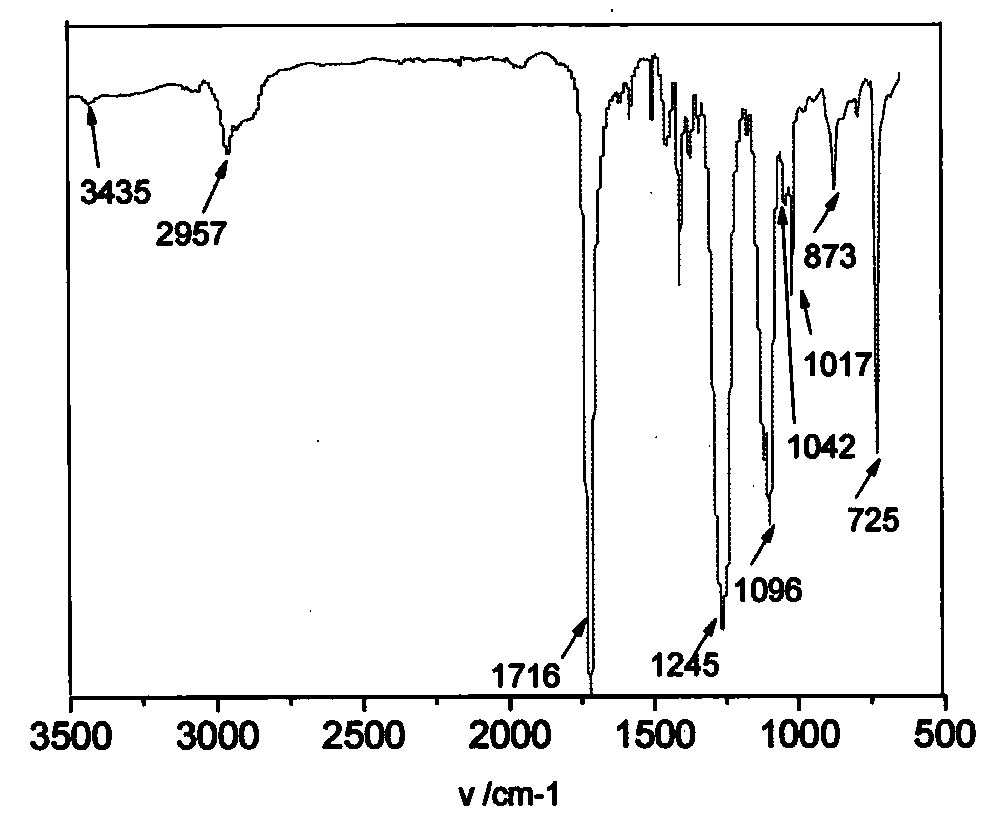

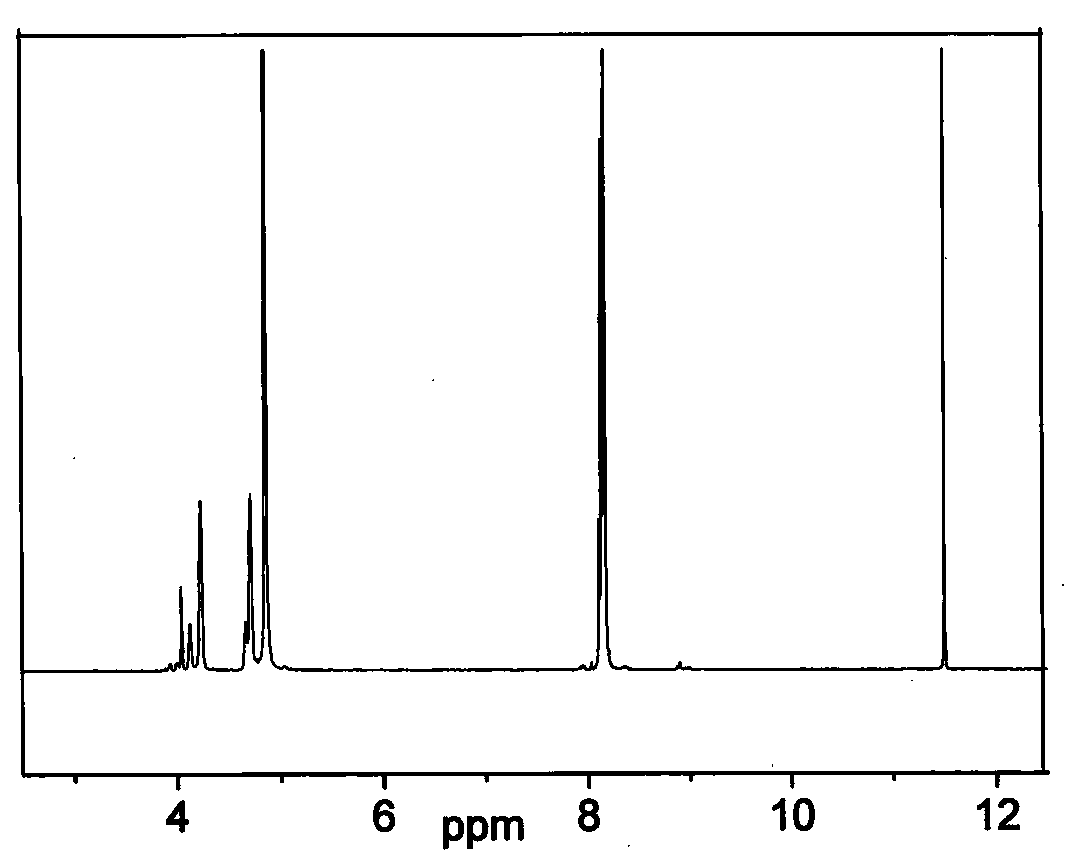

A kind of castor oil modified benzoxazine resin and preparation method thereof

ActiveCN108102072BIncomplete copolymerizationInhomogeneous copolymerizationPolymer sciencePrepolymer

The invention relates to a castor oil modified benzoxazine resin and a preparation method thereof. A castor oil-modified benzoxazine resin is obtained by cross-linking and solidifying after one-step reaction of diisocyanate, castor oil and bismethylol benzoxazine monomer. Preparation: mix castor oil and bis-hydroxymethyl benzoxazine monomers in a solvent evenly, according to the cyanate group in diisocyanate and the total hydroxyl groups in castor oil and bis-hydroxymethyl benzoxazine monomers The amount of the diisocyanate is 1:1 molar ratio, the diisocyanate is slowly added dropwise to the reaction solution to react, and after cooling, a castor oil-based polyurethane benzoxazine prepolymer is obtained; the obtained prepolymer solution is solidified to obtain a castor oil modified benzoxazine resins. The method introduces the natural renewable resource castor oil as a raw material to prepare the modified benzoxazine resin, which has good compatibility, flexibility and excellent dielectric performance, and the synthesis process is simple.

Owner:淮北绿洲新材料有限责任公司

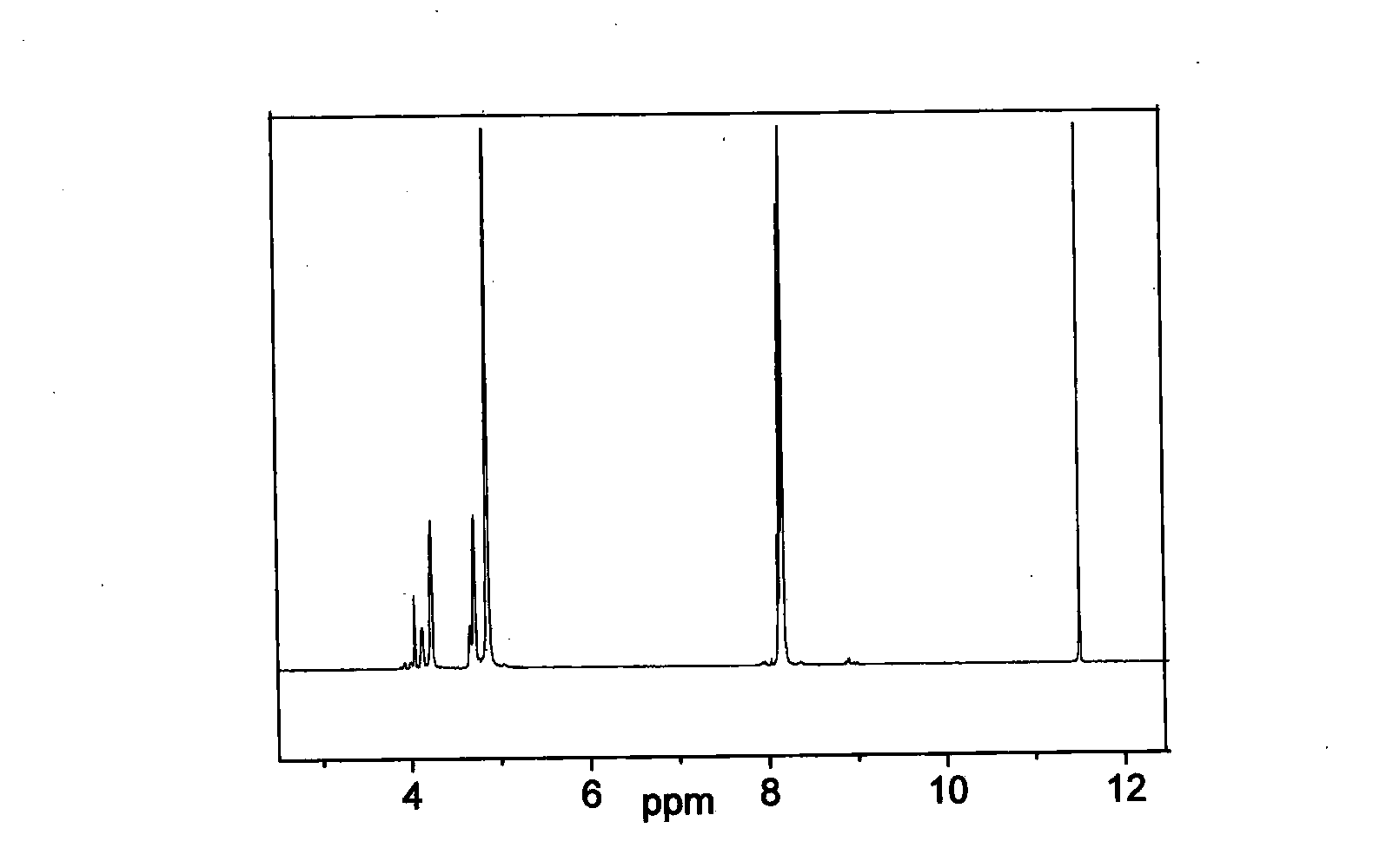

Hydrophilic polyester and preparation method thereof

ActiveCN102924701BImprove hydrophilicityShort stayMonocomponent copolyesters artificial filamentPolyesterCrystal structure

The invention provides a hydrophilic polyester and a preparation method of the hydrophilic polyester. The hydrophilic polyester is characterized in that the molecular chain comprises two chain segments like -COC6H4COOCH2CH2O- and -COC6H4COOCH2CH(OH)CH(OH)CH(OH)CH(OH)CH2O- with a quantitative proportion of 100:0.1-2.0; the intrinsic viscosity is 0.50-0.85g / dl and the melting temperature is 210-265 DEG C. The introduction of the hydrophilic groups into the polyester macromolecular chain and the change of the polyester crystal structure by increasing an amorphous zone are beneficial to the enterance of the water molecules, thereby increasing the hydrophilicity of the polyester, and the surface contact angle of the polyester chip is 40-65 degrees. The spun fiber has higher moisture regain rate and can be used for underwear, sporting suit, liner and the like. The method provided by the invention applys trace additive for the modification of the polyester, the additive has a few effects on the polymerization process, polyester quality and spinnability owing to the small addition amount. The obtained polyester has good modification effect and is especially suitable for melt direct spinning. The method provided by the invention reduces the development cost of the product and is easy to realize industrial production.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com