A kind of castor oil modified benzoxazine resin and preparation method thereof

A technology of benzoxazine and castor oil, applied in the field of organic polymer materials, can solve the problems of uneven structure, incomplete copolymerization reaction, etc., and achieve the effects of high reactivity, brittleness, and improved dielectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]The invention provides a method for preparing castor oil modified polyurethane benzoxazine composite resin, the preparation steps of which are:

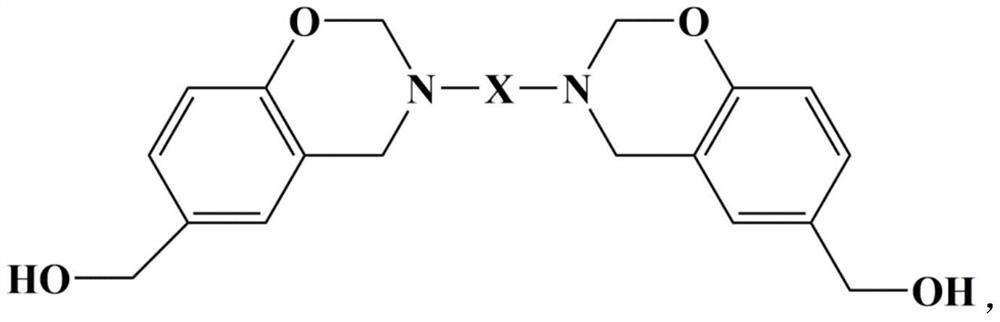

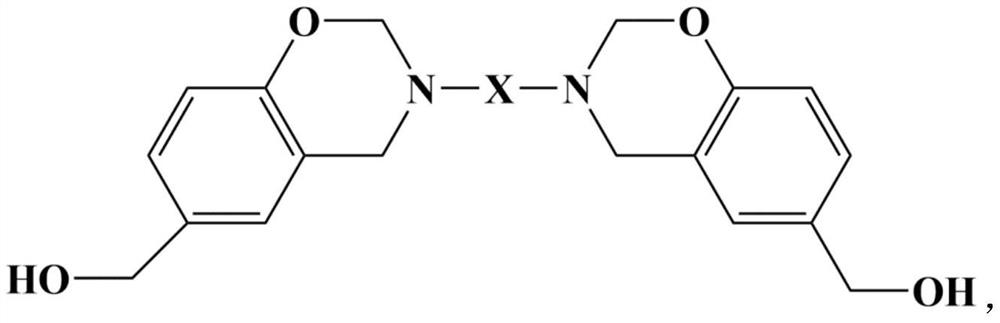

[0029](1) Mix 60ml of toluene with 30ml of ethanol and pour it into a 500ml four-necked flask. Add 9.3g (75mmol) of p-hydroxybenzyl alcohol, 7.4g (37.5mmol) of diaminodiphenylmethane, and 4.5g (150mmol) of formaldehyde in sequence. Add to the flask, stir and mix uniformly at room temperature, then raise the temperature to 60°C, reflux for 12 hours, and stir at 300r / min. After the reaction is completed, the solution is poured into a beaker, and excess cold methanol is added for precipitation, then dried and ground to obtain a yellow powder, which is the DDM-type bis(hydroxymethyl)benzoxazine monomer.

[0030](2) Weigh 2.47g (5mmol) of the benzoxazine monomer prepared in step (1) in 50ml of toluene solution, stir thoroughly to dissolve it, then add 0.93g (1mmol) of castor oil, mix well and heat up to At 110°C, 1.59 g (6.35 mmol) of diphenylm...

Embodiment 2

[0033]The invention provides a method for preparing castor oil modified polyurethane benzoxazine composite resin, the preparation steps of which are:

[0034](1) Mix 60ml of toluene with 30ml of ethanol and pour it into a 500ml four-necked flask. Add 9.3g (75mmol) of p-hydroxybenzyl alcohol, 7.4g (37.5mmol) of diaminodiphenylmethane, and 4.5g (150mmol) of formaldehyde in sequence. Add to the flask, stir and mix uniformly at room temperature, then raise the temperature to 80°C, reflux for 4 hours, and stir at 500r / min. After the reaction is completed, the solution is poured into a beaker, and excess cold methanol is added for precipitation, then dried and ground to obtain a yellow powder, which is the DDM-type bis(hydroxymethyl)benzoxazine monomer.

[0035](2) Weigh 2.47g (5mmol) of the benzoxazine monomer prepared in step (1) in 50ml of xylene solution, stir thoroughly to dissolve, then add 0.93g (1mmol) of castor oil, mix well and raise the temperature At 100° C., 1.07 g (6.35 mmol) of h...

Embodiment 3

[0038]The invention provides a method for preparing castor oil modified polyurethane benzoxazine composite resin, the preparation steps of which are:

[0039](1) Mix 60ml of toluene with 30ml of ethanol and pour it into a 500ml four-necked flask. Add 9.3g (75mmol) of p-hydroxybenzyl alcohol, 7.4g (37.5mmol) of diaminodiphenylmethane, and 4.5g (150mmol) of formaldehyde in sequence. Add it to the flask, stir and mix uniformly at room temperature, then increase the temperature to 70°C, reflux for 10 hours, and stir at 400r / min. After the reaction is completed, the solution is poured into a beaker, and excess cold methanol is added for precipitation, then dried and ground to obtain a yellow powder, which is the DDM-type bis(hydroxymethyl)benzoxazine monomer.

[0040](2) Weigh 2.47g (5mmol) of the benzoxazine monomer prepared in step (1) in 50ml of dimethylformamide solution, stir thoroughly to dissolve, then add 0.93g (1mmol) of castor oil and mix After uniformity, the temperature was raised ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com