Patents

Literature

114results about How to "Not easy to soften" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable

InactiveCN105304203AImprove high temperature resistanceImprove insulation performancePower cables with screens/conductive layersInsulated cablesPower cableEngineering

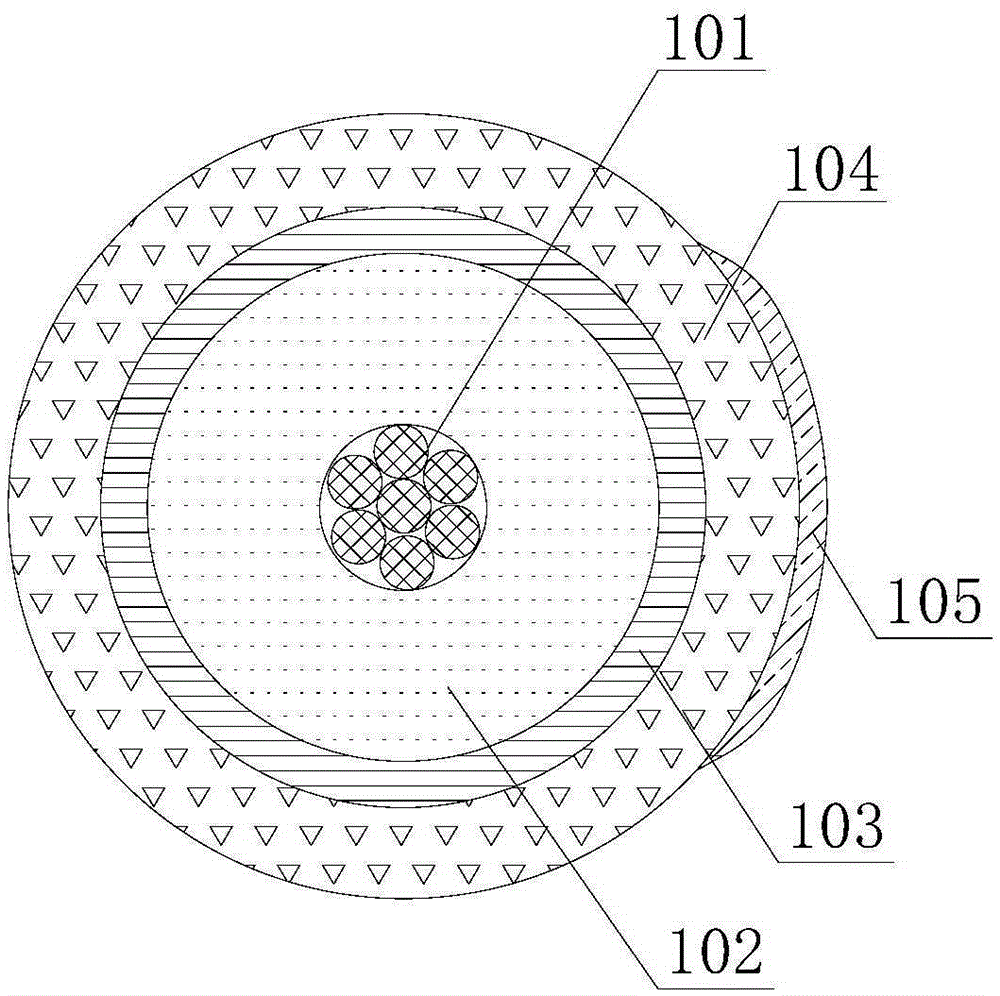

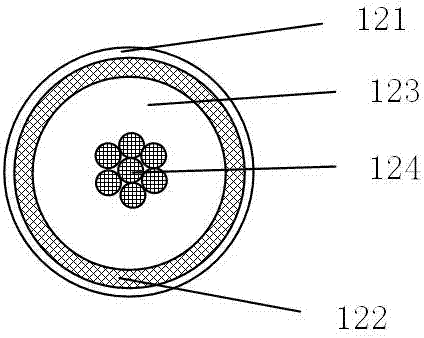

The invention provides a cable and relates to the field of power cables. The cable comprises a wire, a high-temperature-resistant insulated layer, a shielding layer, and a protective layer. The high-temperature-resistant insulated layer, the shielding layer, and the protective layer are all hollow structures. The high-temperature-resistant insulated layer wraps the wire. The shielding layer wraps the high-temperature-resistant insulated layer. The protective layer wraps the shielding layer. The outer surface of the protective layer is equipped with a temperature-sensitive variable-color layer. The cable is not liable to soften and is good in signal shielding effect. The temperature of the outer surface of the wire can be conveniently known and the use safety of the cable is effectively guaranteed.

Owner:TIANJIN LANGXING WIRE & CABLE

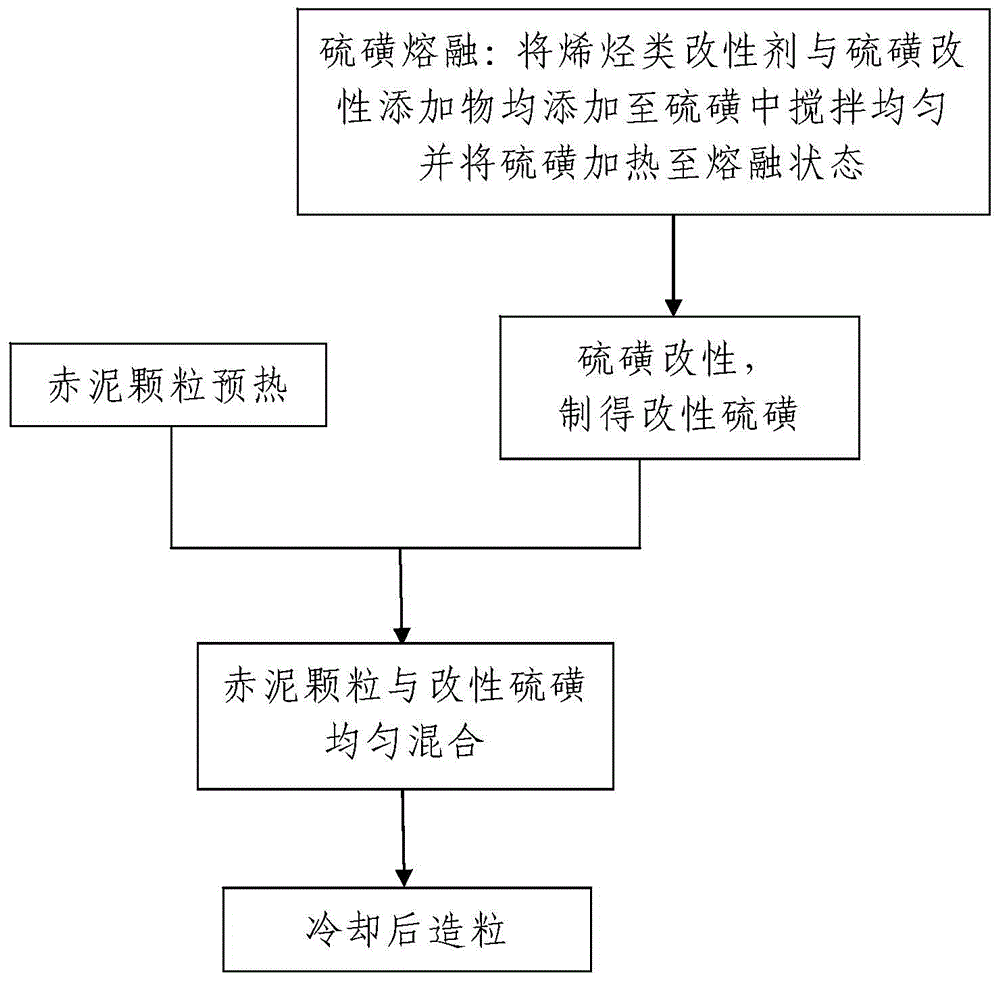

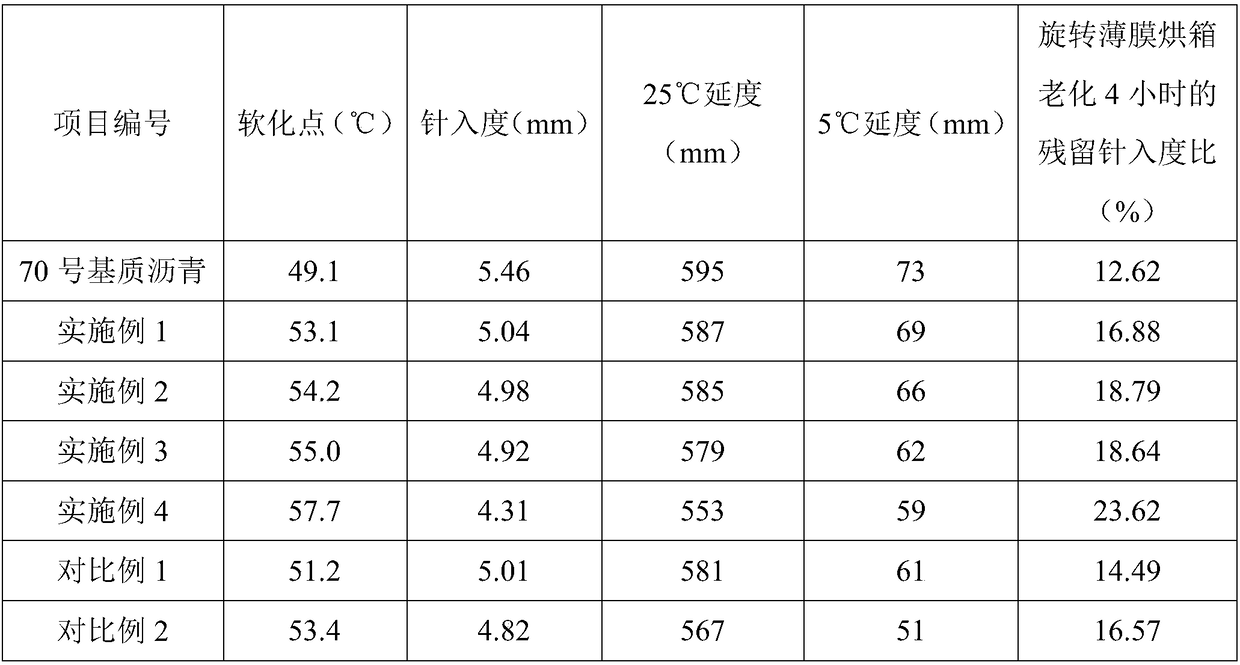

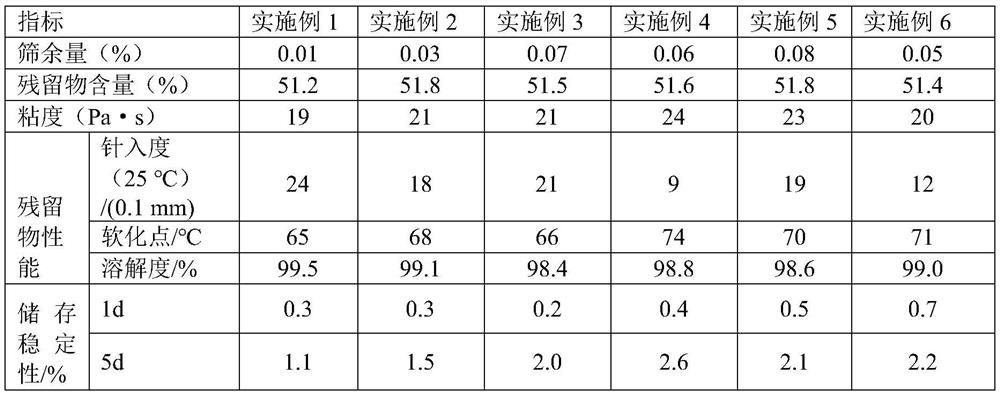

Asphalt modifier and industrial production method and application thereof

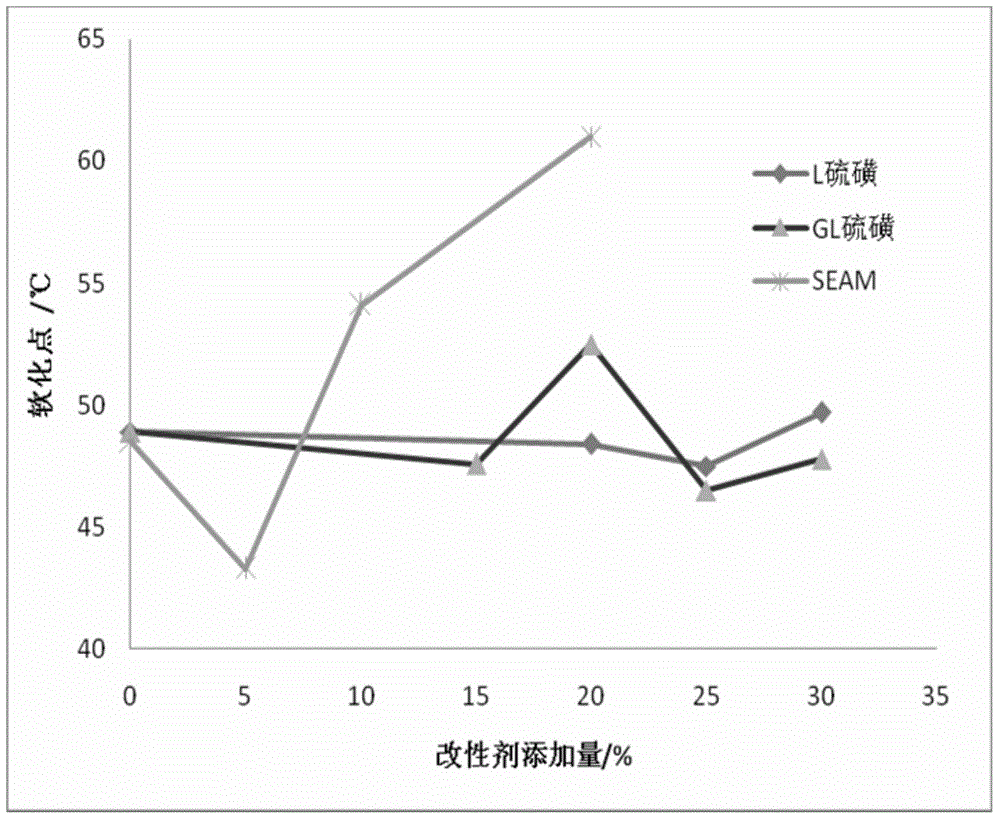

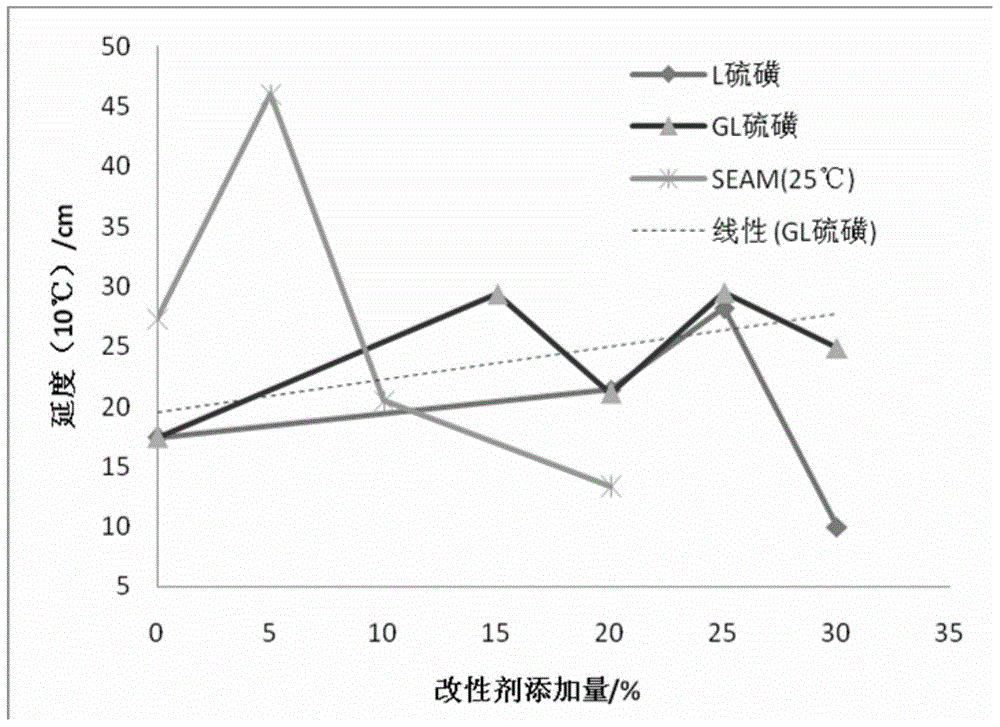

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

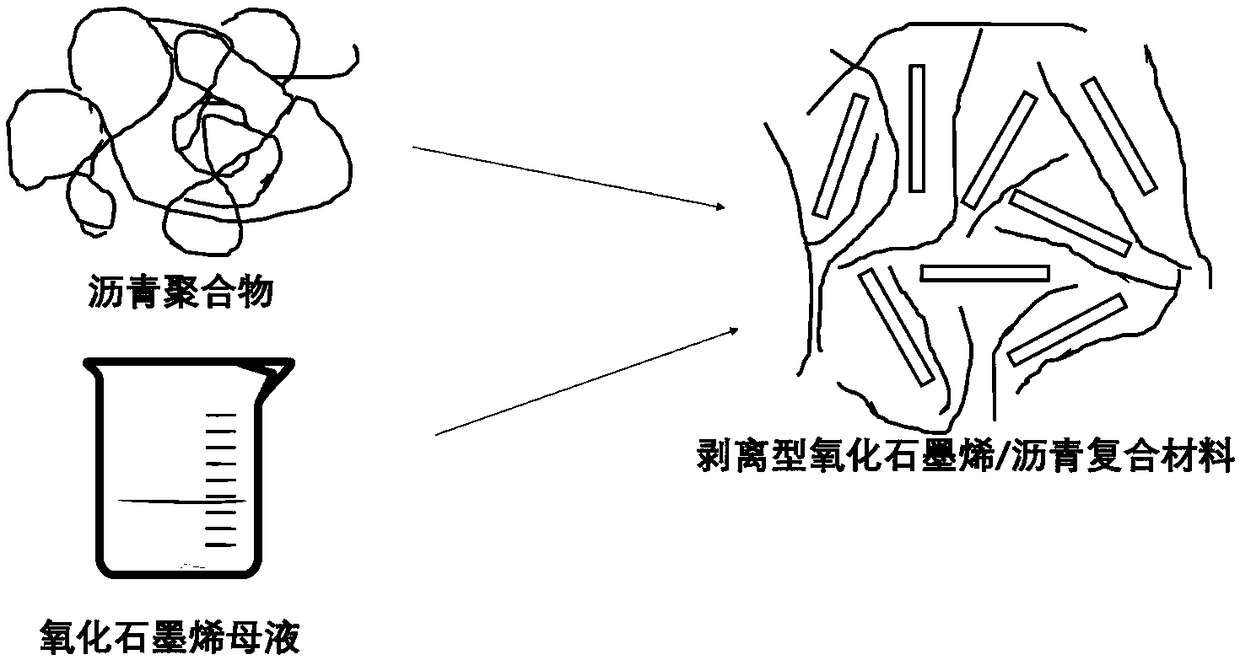

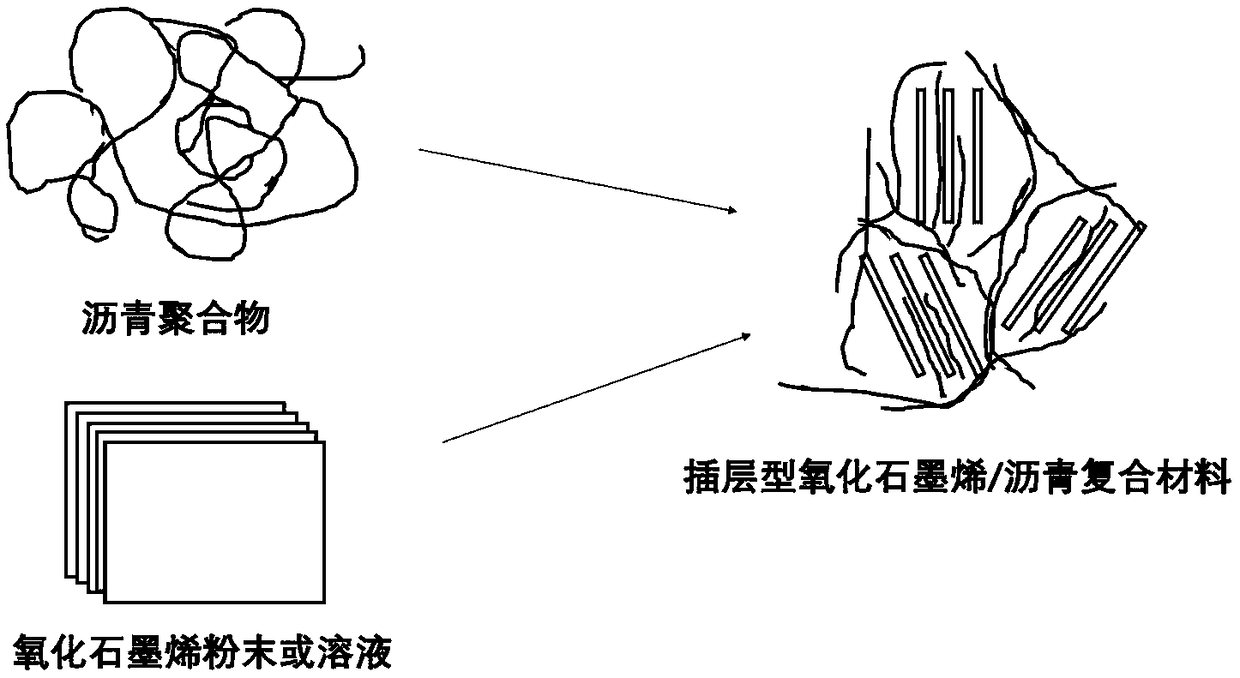

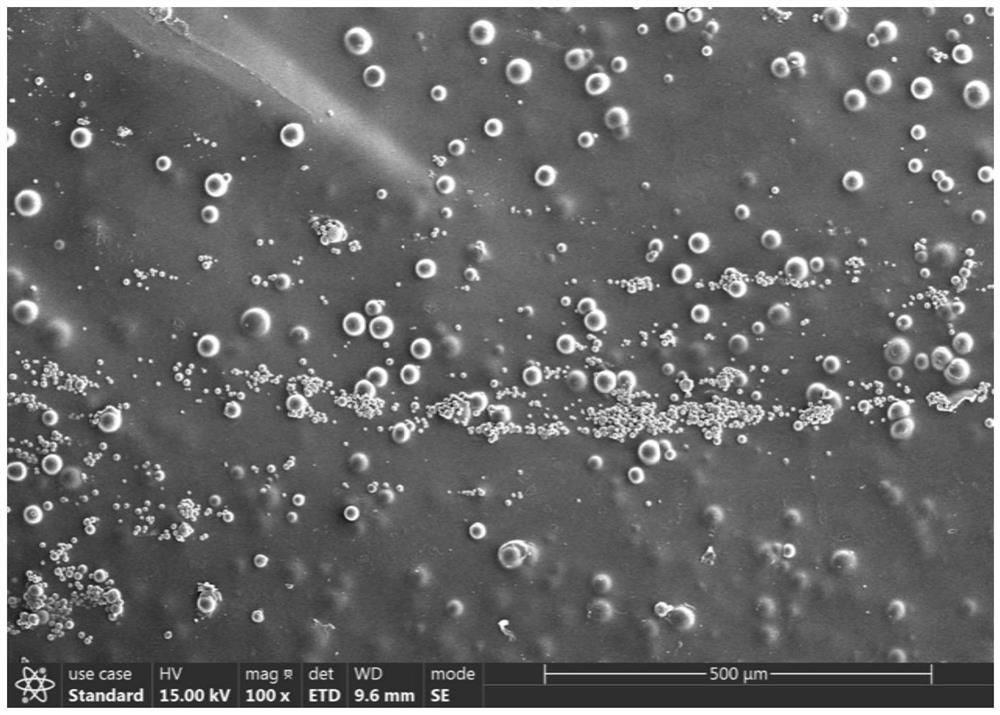

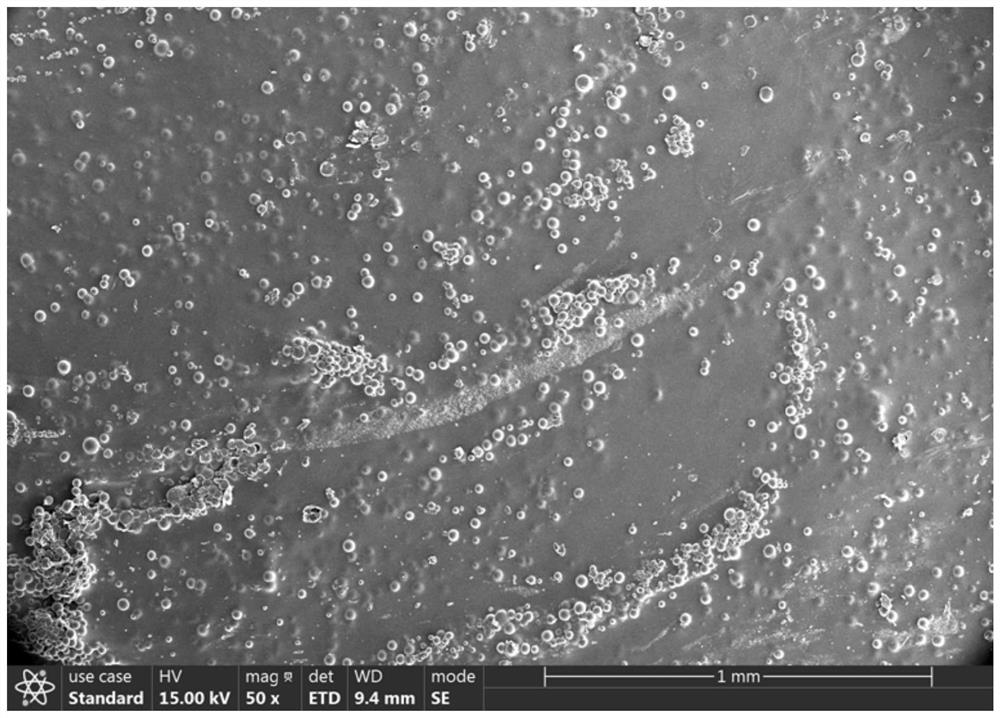

Oxidized graphene modified asphalt and preparation method thereof

The invention provides a preparation method of oxidized graphene modified asphalt. The preparation method includes following steps: slowly adding graphite into mixed acid, and well stirring to obtaina mixed material; during stirring, slowly adding potassium permanganate into the mixed material, and continuously stirring for reaction to obtain an oxidized mixed material; slowly adding hydrogen peroxide into the oxidized mixed material, continuously stirring for reaction to obtain an oxidized mixed solution; cooling the oxidized mixed solution to room temperature, performing ultrasonic treatment, and performing centrifugal separating and washing to obtain oxidized graphene mother liquid; adding the oxidized graphene mother liquid into asphalt, heating to fusion, and shearing to obtain the oxidized graphene modified asphalt. The invention further provides the oxidized graphene modified asphalt prepared by the method. The oxidized graphene modified asphalt is a stripped oxidized graphene / asphalt composite material and has excellent high-temperature stability, low-temperature crack resistance and thermo-oxidative aging resistance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

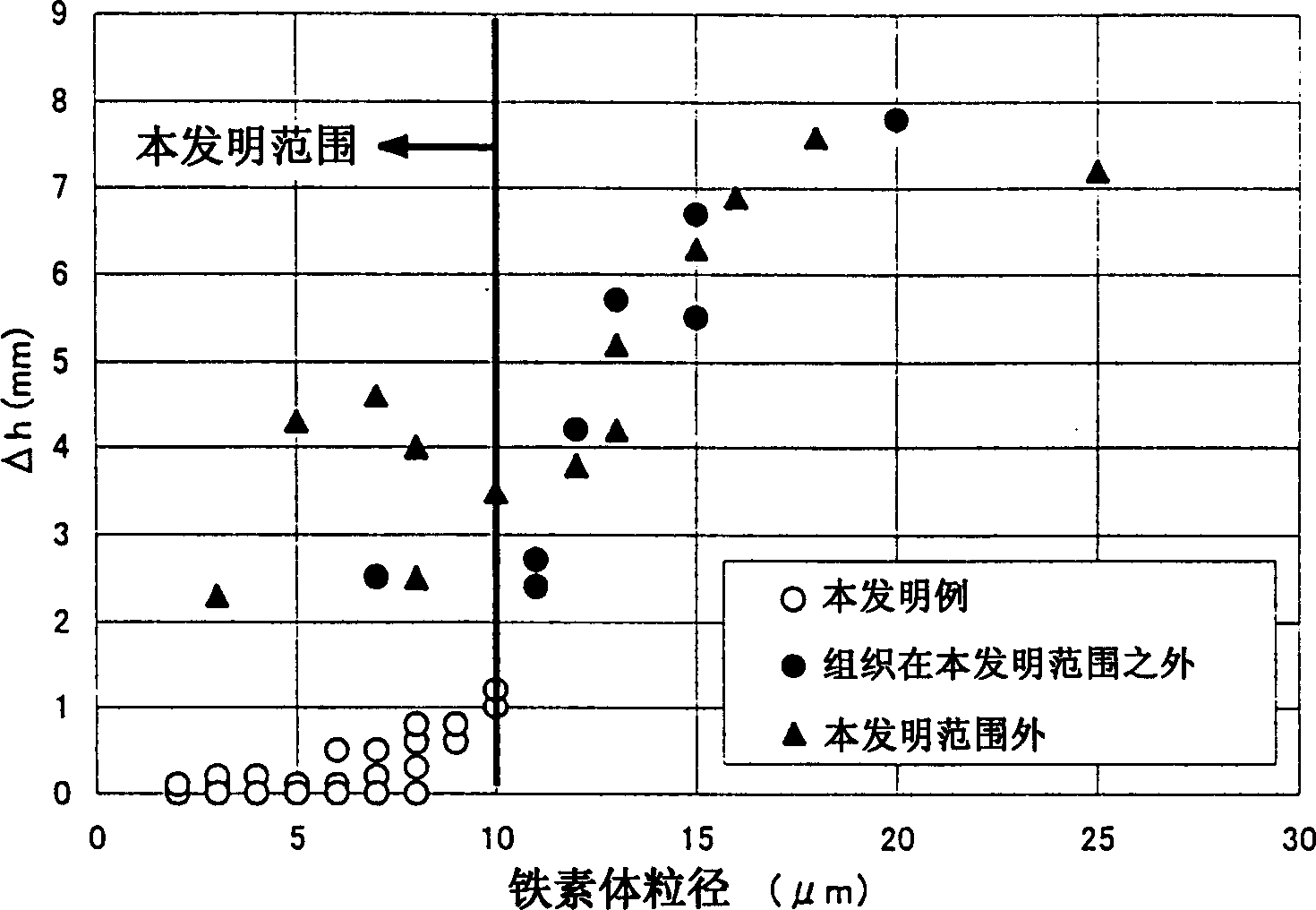

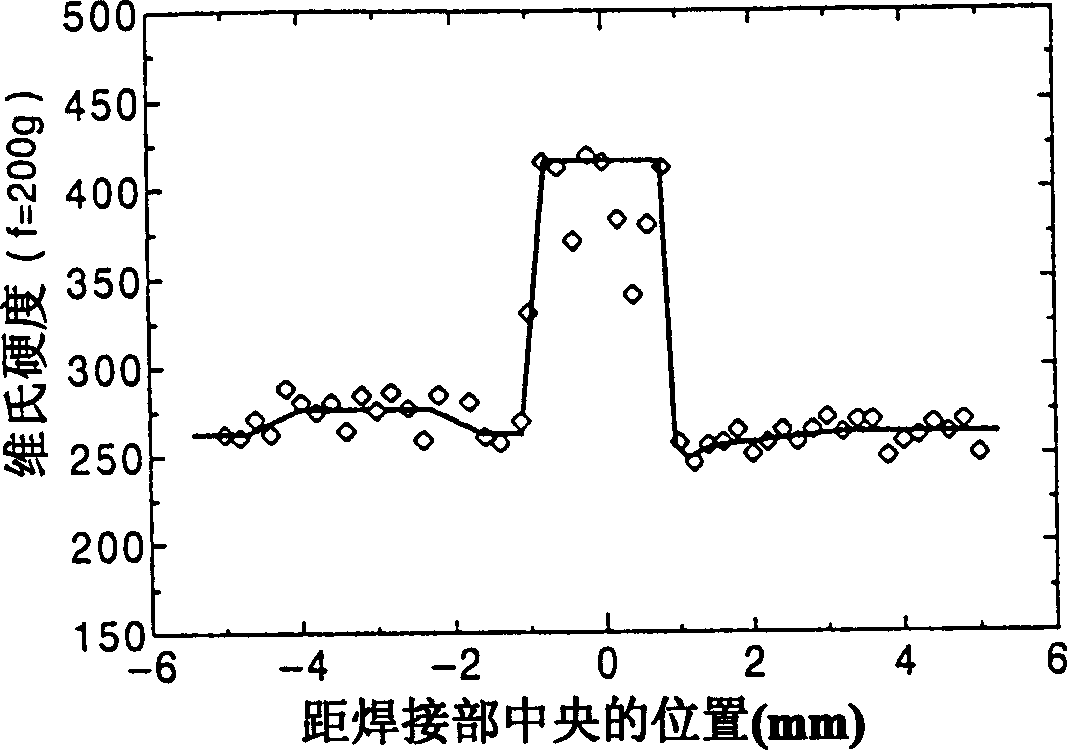

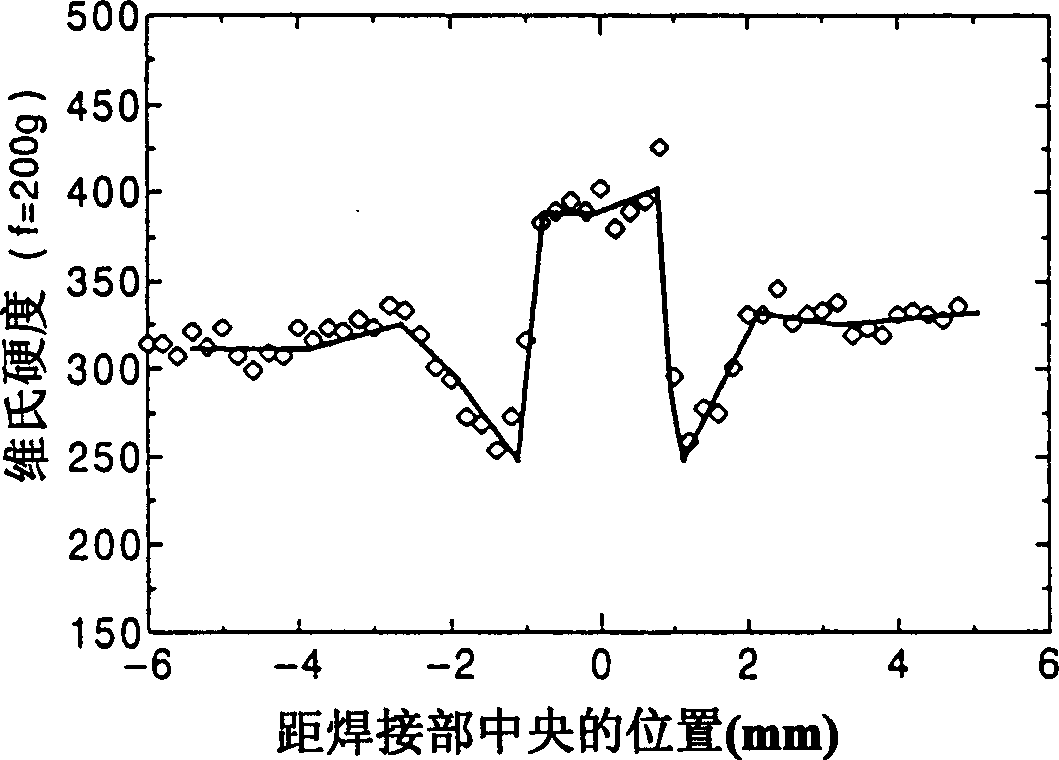

Hot dip zinc plated steel sheet having high strength and method for producing the same

InactiveCN1457371ANot easy to softenEasy to processHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

The invention relates to a high strength hot-dip galvanized steel sheet consisting essentially of 0.03 to 0.25% C, 0.7% or less Si, 1.4 to 3.5% Mn, 0.05% or less P, 0.01% or less S, 0.05 to 1% Cr, 0.005 to 0.1% Nb, by mass, and balance of Fe, and being made of a composite structure of ferrite and secondary phase, and having an average grain size of the composite structure of 10 mu m or smaller. Since the high strength hot-dip galvanized steel sheet of the present invention hardly induces softening at HAZ during welding, it is applicable to structural members of automobiles for Tailor Welded Blanks (TWB).

Owner:JFE STEEL CORP

Method for quickly casting large precision casting based on 3D printing technology

ActiveCN108907095ASimple processing technologyShort production timeAdditive manufacturing apparatusFoundry mouldsSlagDimensional modeling

The invention relates to the technical field of metal molding and casting, in particular to a method for quickly casting a large precision casting based on a 3D printing technology; through combination of a 3D printing and molding technology and a lost foam casting technology, by using special shell type coatings, a casting without the defects of recarburization, pores, slag inclusion or wrinkledskin can be cast, and the requirements of a high grade and complex structure and the precision casting can be met; and the method has the advantage of green, environmental protection and no pollution.The method comprises the steps of three-dimensional modeling, making of a fusible model and a special shell mold, boxing of the shell mold, negative pressure pouring and the like. The method has theadvantages of simple processing technology, no need of developing a mould, short production time, easy regulation and modification, low production cost, green, environmental protection and no pollution, and the molding process can be finished in real time; the requirements of individualization and customization cam be met; high quality products can be made, and massive casting and precision casting are both taken into consideration.

Owner:河南圣得威机械科技有限公司

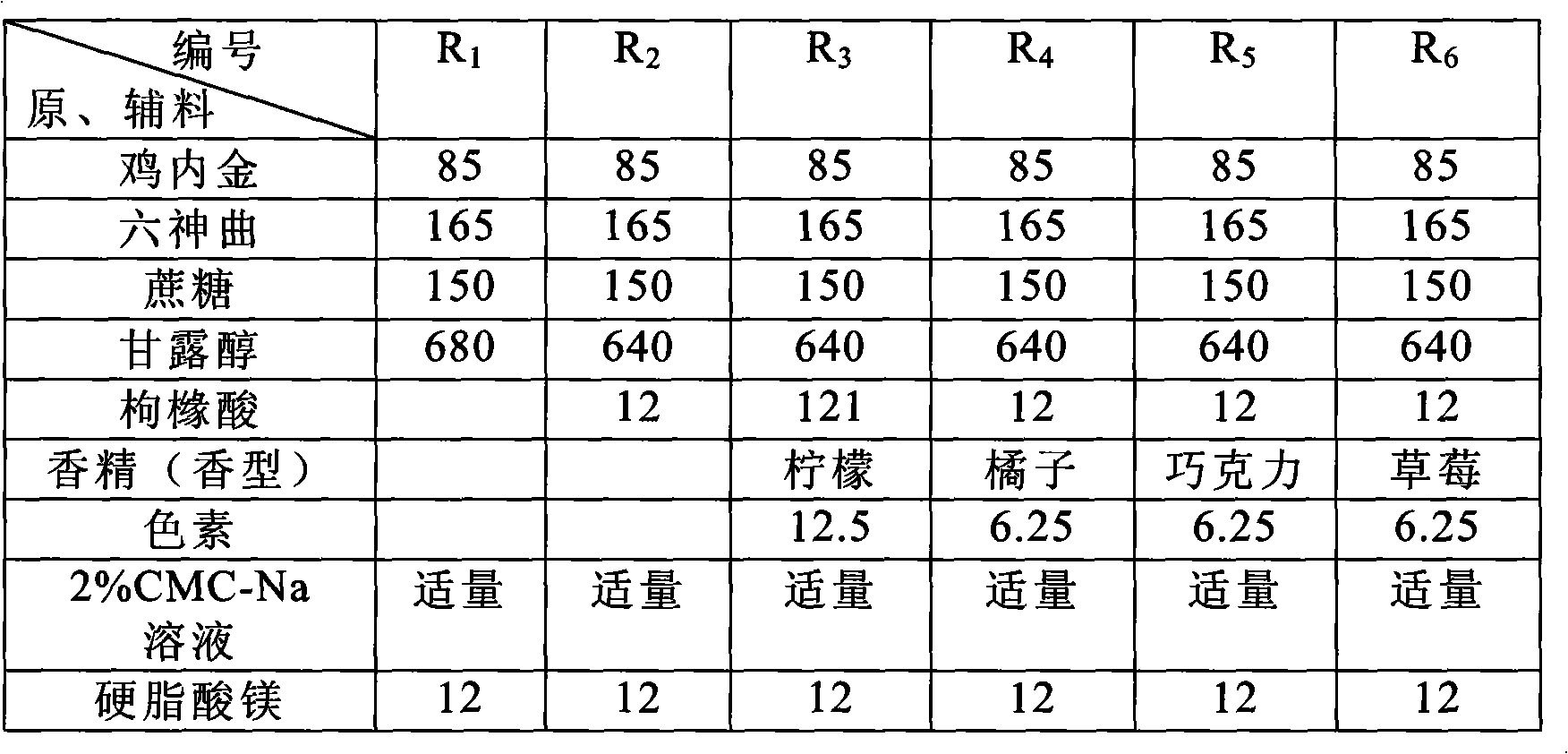

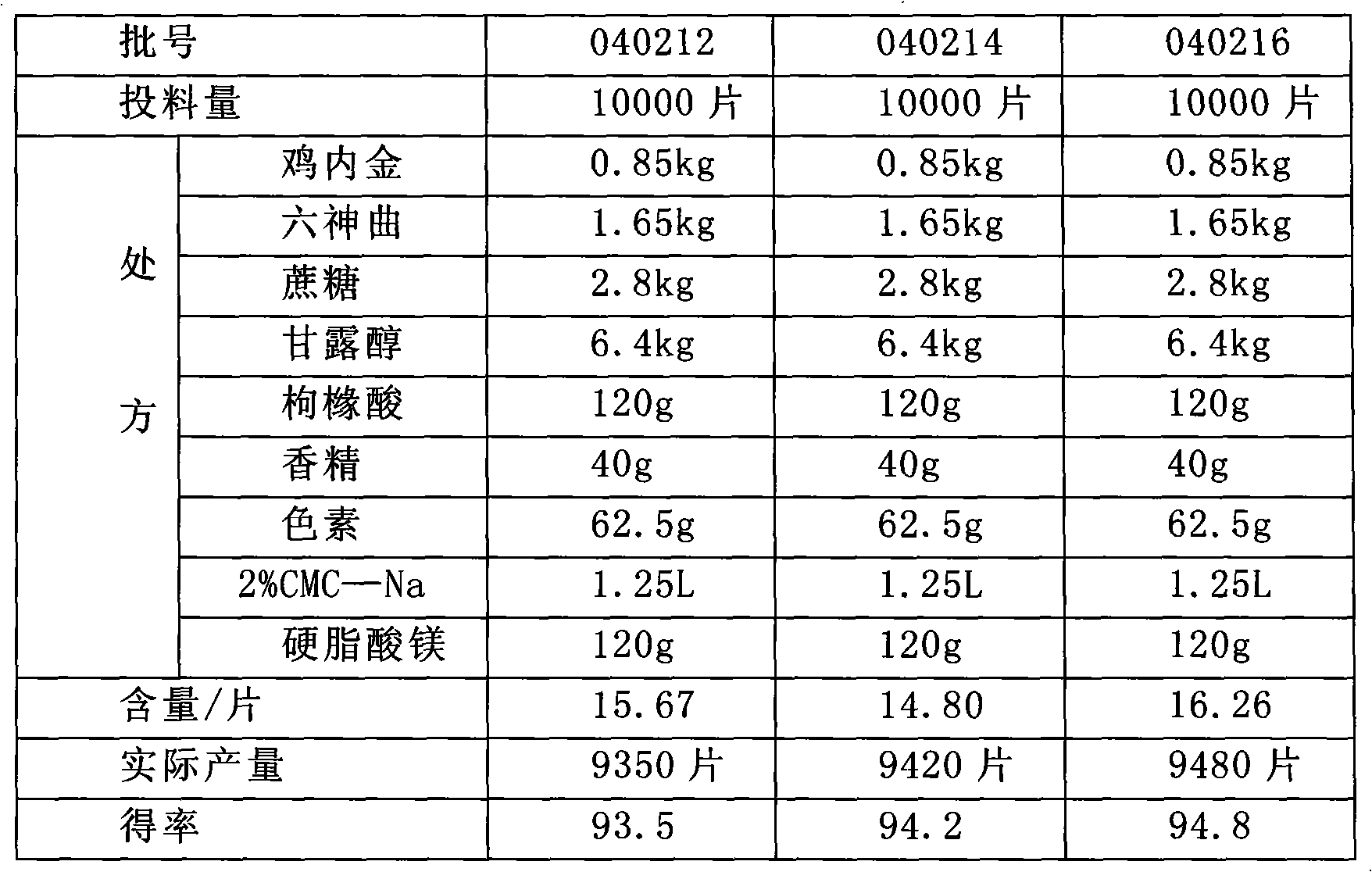

Pediatric compound chicken's gizzard-membrane chewable tablets and preparation method thereof

ActiveCN101940602AMature and reliable technologyAdvanced technologyDigestive systemMammal material medical ingredientsGizzardBioavailability

The invention belongs to the field of Chinese patent medicine preparations and relates to pediatric compound chicken's gizzard-membrane chewable tablets and a preparation method thereof. The pediatric compound chicken's gizzard-membrane chewable tablets comprise the following components in parts by weight: 80-90 parts of chicken's gizzard-membrane, 160-170 parts of medicated leaven, 240-320 parts of first filler, 600-680 parts of second filler, 10-14 parts of flavoring agent, 3-5 parts of fragrance, 6-6.5 parts of pigments, 10-14 parts of lubricant and an appropriate amount of binding agent. The pediatric compound chicken's gizzard-membrane chewable tablets have the advantages of significantly improving the bioavailability and the efficacy, being easily absorbed, having rapid onset of action and being easy to be accepted by children.

Owner:HENAN TALOPH PHARMACEUTICAL STOCK CO LTD

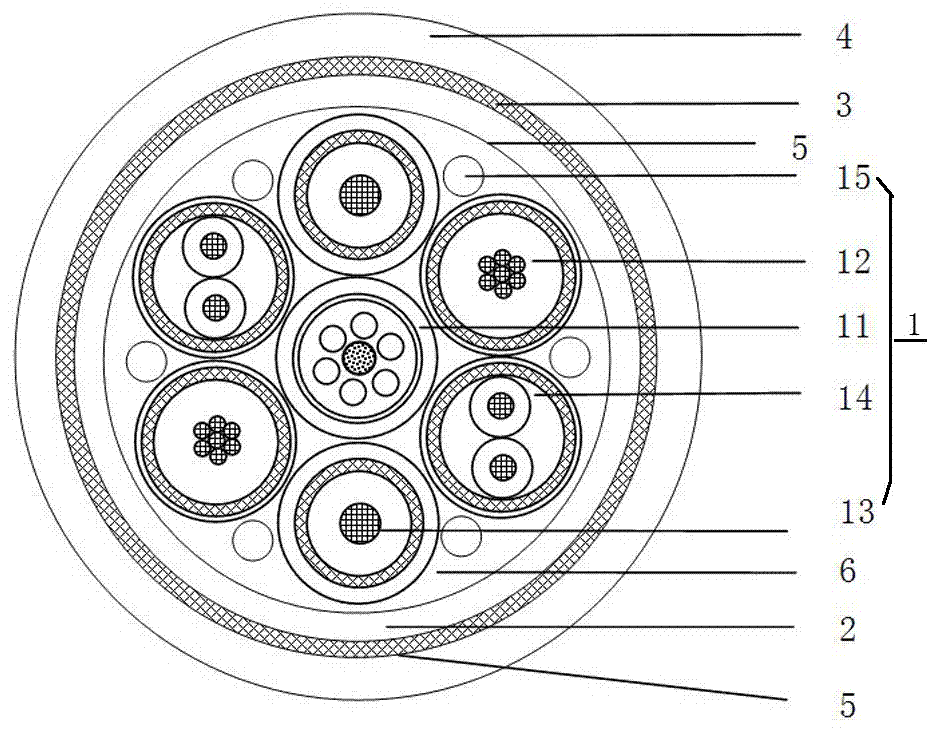

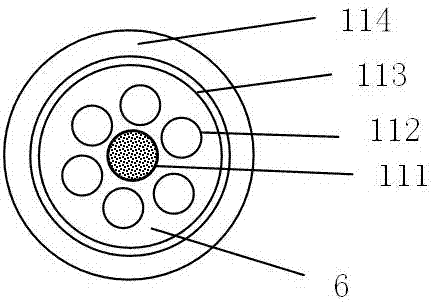

Total cross-section water-stop sealing multi-signal composite cable and preparation technique thereof

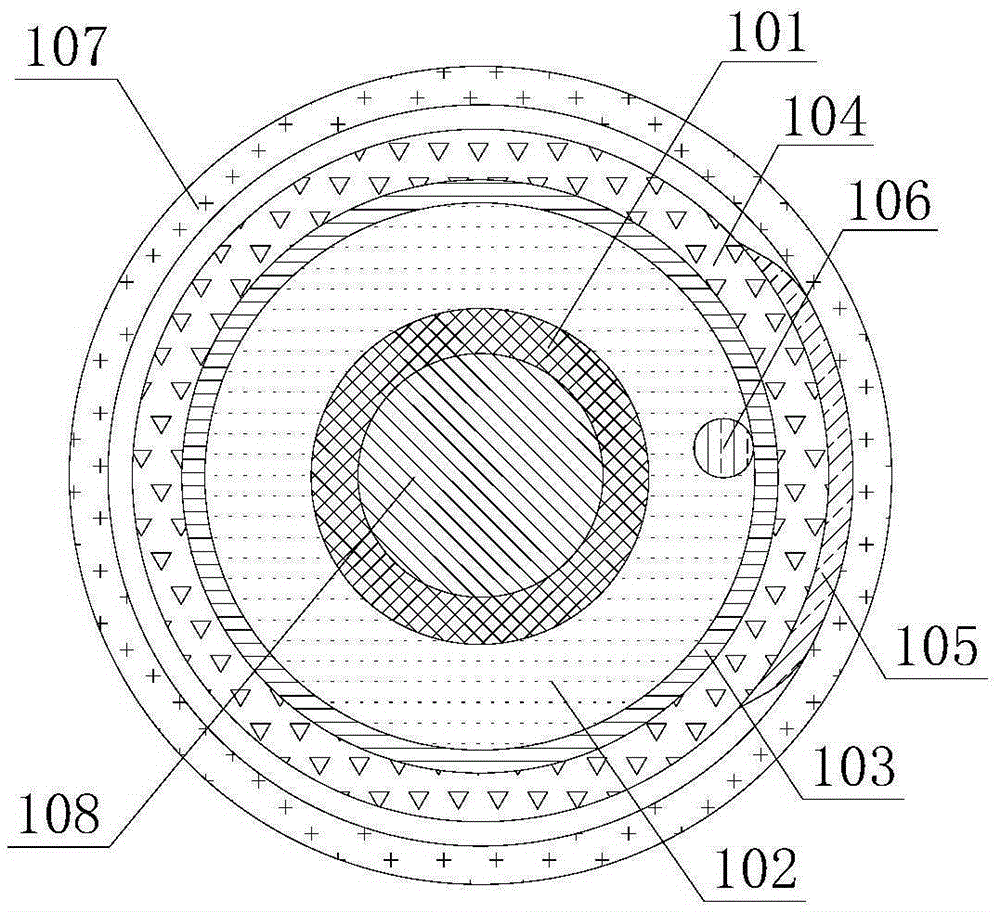

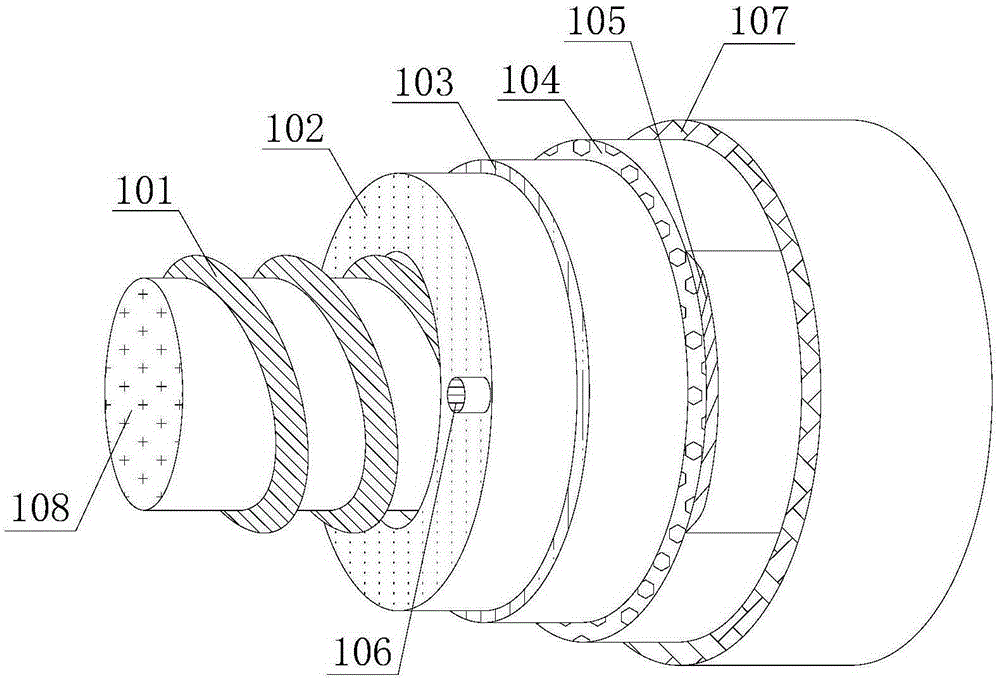

PendingCN107958724ARich varietyLarge transmission capacityNon-insulated conductorsInsulated cablesRadio frequencyCoaxial line

The invention discloses a total cross-section water-stop sealing multi-signal composite cable including a cable core, an inner protection layer, a shielding layer and an outer protection layer. The cable core is externally provided with a wrapping tape. The inner protection layer and the outer protection layer are formed outside the wrapping tape through extrusion. The shielding layer is formed ina braiding manner between the outer protection layer and the inner protection layer. A wrapping tape is also arranged between the shielding layer and the outer protection layer. The cable core is formed by twisting an optical unit, a power line, a coaxial line, a twisting pair and a filler rope in a spiral manner. The twisting gap of the cable core and the gap in the shielding layer are both filled with filler glue. Each of the power line, the coaxial line, the twist pair and the outer protection layer in the composite cable is therein provided with a braided shielding layer, water-resistingand wear-resisting chemical material is adopted for a sheath, and the gaps among the different units are filled with water-stop filler glue. Therefore, the composite cable provided by the invention has a capability of total cross-section high pressure resistance and water leakage prevention. In underwater application, the composite cable can provide optical fibers for transmitting optical signalsand can also provide a power line for transmitting control signals, a coaxial line for transmitting radio frequency signals and a twisting pair for transmitting communication signals. Besides, the composite cable provided by the invention is small in product size, diversified in functions and stable in transmission.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Ceramic grinding ball for cement ball mill, and preparation method thereof

The invention discloses a ceramic grinding ball for a cement ball mill, and a preparation method thereof. The ceramic grinding ball for the cement ball mill comprises the following raw materials in weight percentage: 92-95% of alumina, 0.5%-2% of ferric oxide, 0.8-3% of kaolin, 0.2-2% of silicon carbide, 1.5-2% of titanium dioxide, 0.8-1% of titanium carbide, and 0.3-2% of molybdenum disulfide. According to the technical scheme of the invention, the grinding ball is prepared through the compression moulding and high-temperature sintering process. The preparation method comprises the steps of burdening, ball-milling, spray granulation, ageing in a stock bin, compression processing, high-temperature sintering, powder removing, polishing, finished product drying, and the like. The ceramic grinding ball for the cement ball mill has the advantages of high hardness, high temperature resistance, corrosion resistance, low operation energy consumption, low material consumption, good bonding force, strong impact resistance, shock resistance and detonation resistance. The produced cement is uniform in fineness, reasonable in particle morphology and high in later strength.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

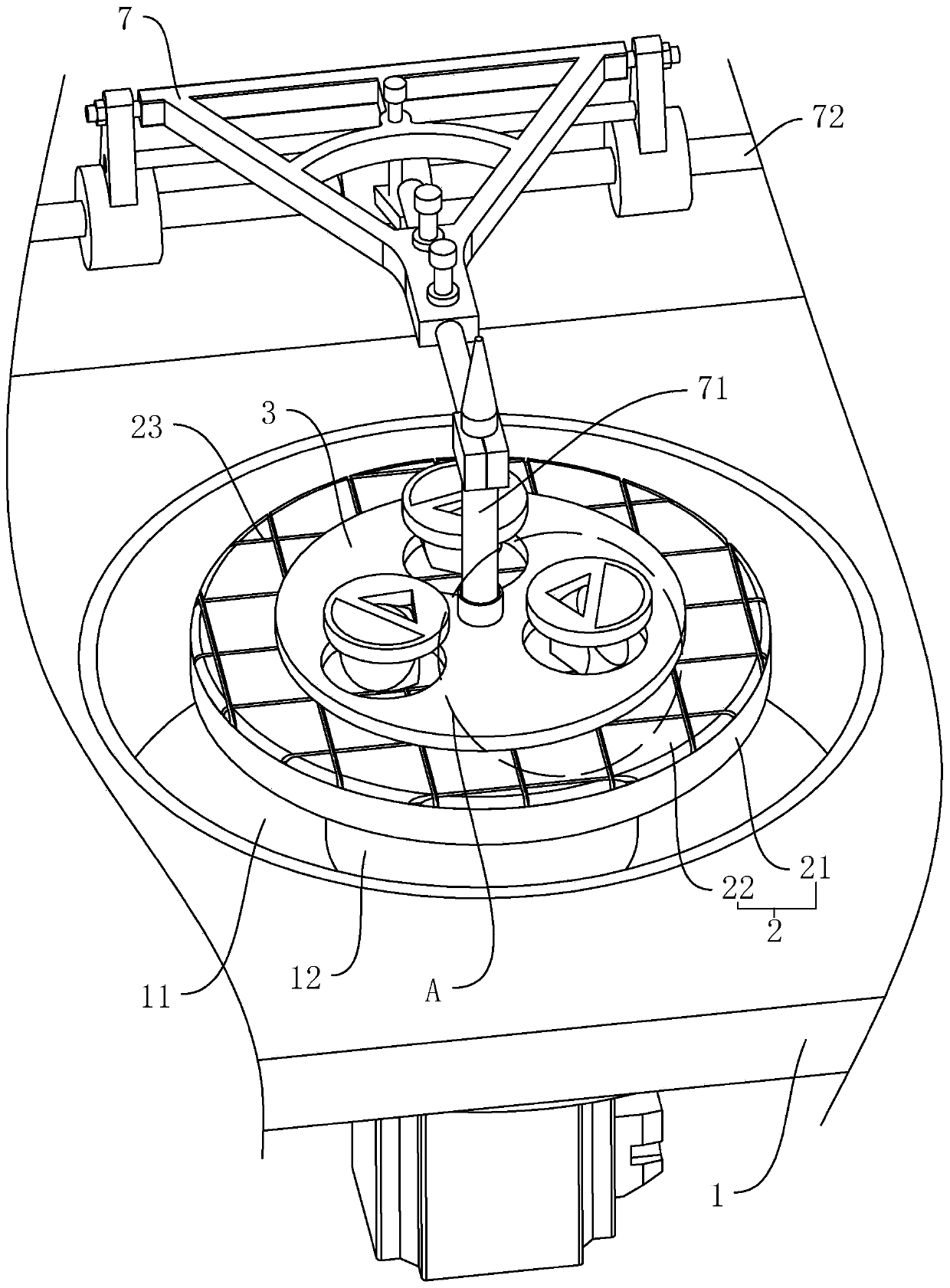

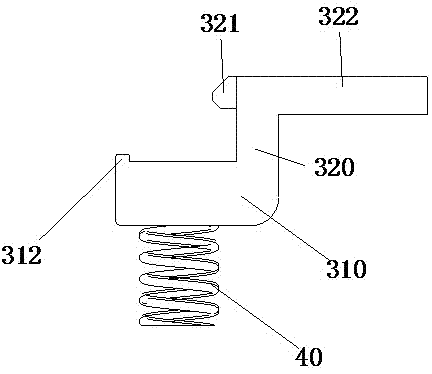

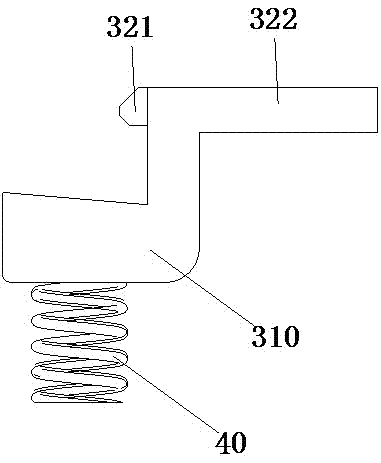

Prism fine polishing device and process

ActiveCN110193763AAvoid softeningNot easy to softenOptical surface grinding machinesEngineeringPrism

The invention discloses a prism fine polishing device, and relates to the technical field of optical lens processing. The prism fine polishing device aims to solve the problems that in a fine polishing process, the temperature is increased, asphalt is softened, and a surface shape of the optical element is not easy to guarantee. According to the technical scheme, the fine polishing device comprises a rack and a polishing assembly, wherein the polishing assembly comprises a polishing solution tank, a rotating main shaft arranged on the top wall of the polishing solution tank, a polishing disc arranged on the top surface of the rotating main shaft and an upper disc attached to the polishing disc; the polishing disc comprises a polishing disc base body and an asphalt polishing module layer, and a plurality of heat dissipation grooves are formed in the asphalt polishing module layer; and the rack is further provided with a spraying component and a pressurizing component for improving the polishing pressure. On one hand, the heat dissipation grooves can dissipate heat to prevent the asphalt from becoming soft, and on the other hand, polishing solution can be uniformly distributed on thepolishing disc; and the polishing solution is sprinkled on the polishing disc through a spray head, so that the heat generated by polishing can be dissipated in time, the asphalt polishing mold layeris not easy to become soft, so that the purpose of improving the precision of the surface shape is achieved.

Owner:苏州奥博特光学科技有限公司

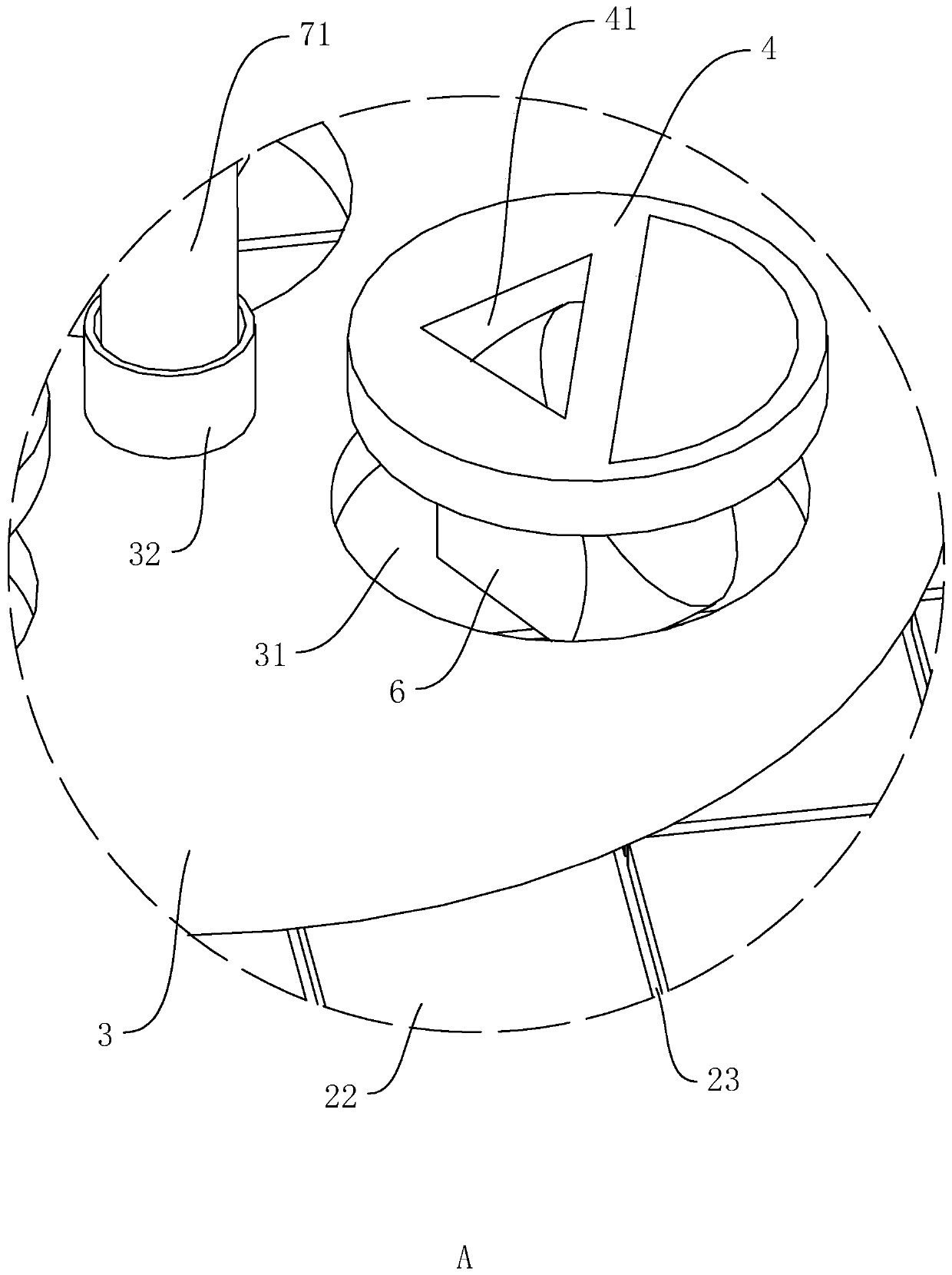

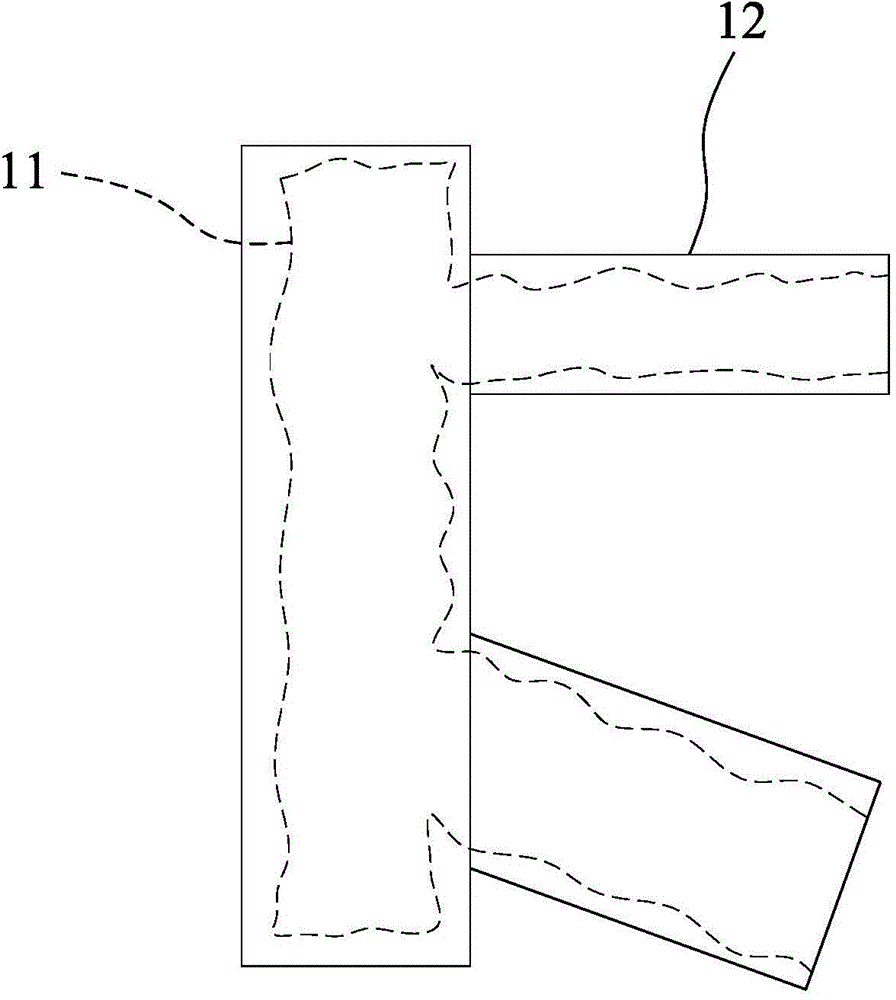

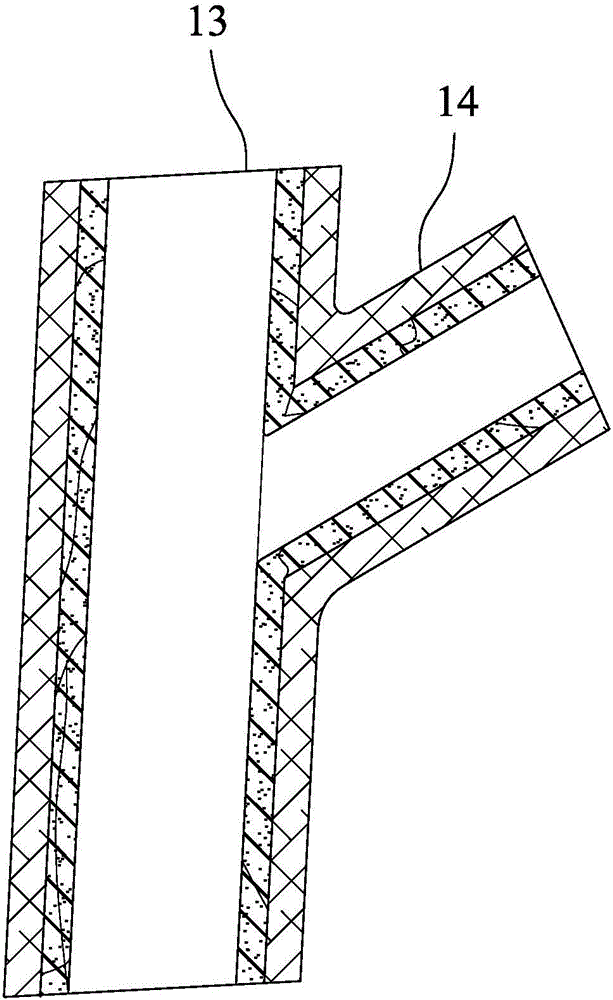

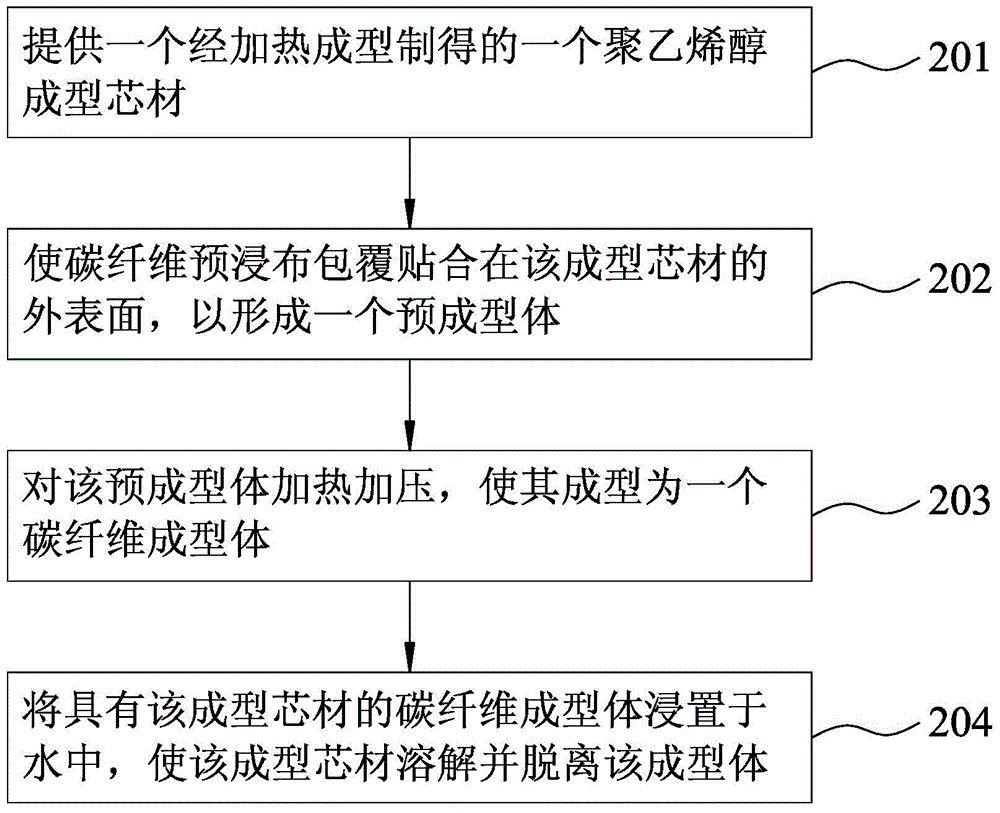

Molding method of carbon fiber material of bicycle

Provided is a molding method of a carbon fiber material of a bicycle. The method includes the steps of providing a temperature that can heat polyvinyl alcohol to be above the melting point of the polyvinyl alcohol, manufacturing a molded core after molding and cooling, making carbon fiber prepreg cloth wrap the whole outer surface of the molded core to form a pre-molded body, heating and pressing the pre-molded body so that the carbon fiber prepreg cloth is hardened and molded, molding the pre-molded body to be a carbon fiber molded body, and immersing the carbon fiber molded body into water and dissolving the molded core therein. The polyvinyl alcohol subjected to heat treatment is selected to serve as a core, can bear heating and pressing during a molding process of carbon fiber, and is not liable to soften or noticeably changes in terms of dimension, so the carbon fiber prepreg cloth can be stably supported. Moreover, the core can be dissolved by water after molding and is separated from the molded body. The manufacturing time is effectively saved.

Owner:APROTECH

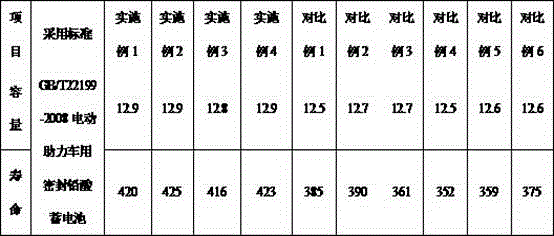

Positive paste mixing technology

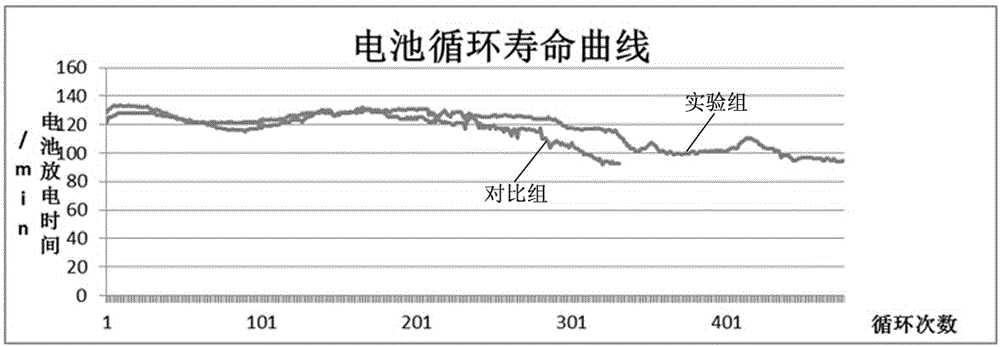

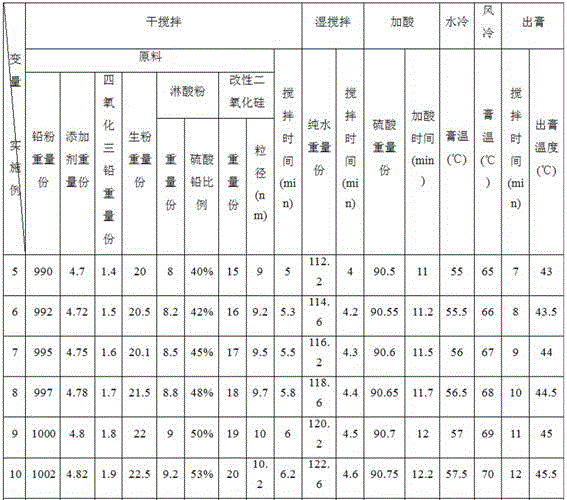

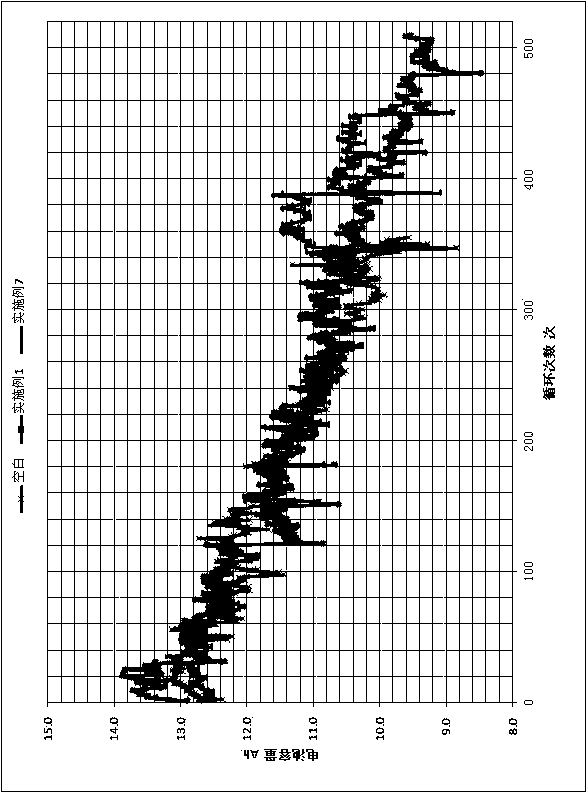

ActiveCN106129338ANot easy to softenExtended service lifeLead-acid accumulator electrodesWater coolingMaterials science

The invention provides a positive paste mixing technology, and relates to the technical field of storage batteries. The positive paste mixing technology comprises the following steps of (1) dry stirring, namely mixing and stirring raw materials for 5-7 minutes; (2) wet stirring, adding pure water and further stirring for 4-5 minutes; (3) acid adding, adding a sulfuric acid and continuously stirring; (4) water cooling, when the temperature of paste is 55-58 DEG C, starting circulating water cooling; (5) air cooling, when the temperature of the paste is 65-75 DEG C, starting air cooling; and (6) paste discharging, wherein the stirring time after acid adding is greater than or equal to 7 minutes, the temperature of the discharged paste is smaller than or equal to 48 DEG C and the density of lead paste when discharged is 4.4-4.5g / cm<3>. The invention provides the positive paste mixing technology. An acid absorption value of a positive electrode generated by the technology is increased; and the positive electrode is not easily softened, so that the service lifetime of the lead-acid storage battery is prolonged.

Owner:济源市万洋绿色能源有限公司

Fukang expandable vaginal suppository, and preparation method and detection method thereof

ActiveCN103520264AGuaranteed effective concentrationPrevent outflowComponent separationSuppositories deliverySolubilityVaginal Suppository

The invention relates to a Fukang expandable vaginal suppository, and a preparation method and a detection method thereof. The expandable suppository comprises active ingredients, a matrix and an expansion carrier. The active ingredients and the matrix form a drug-containing matrix, which is coated on the surface of the carrier. The active ingredients include walnut oil and further include motherwort and radix polygonati officinalis. The additional motherwort and radix polygonati officinalis can improve the curative effect of the Fukang expandable vaginal suppository on symptoms of leukorrhea with reddish discharge and bearing-down pain in lower abdomen; the starch sodium glycolate and walnut oil are prepared into a solid dispersion to improve the solubility of walnut oil and reduce volatilization of walnut oil; the stearic acid palmitic acid glycol ester improve the stability of the suppository; and the dextrin increases cohesiveness of the expandable suppository and is beneficial to forming the expandable suppository. The Fukang expandable vaginal suppository employs six unique technologies, and has beneficial effects of prevention of outflow liquid, high stability, lasting curative effect and prevention of secondary infection.

Owner:哈尔滨田美药业股份有限公司

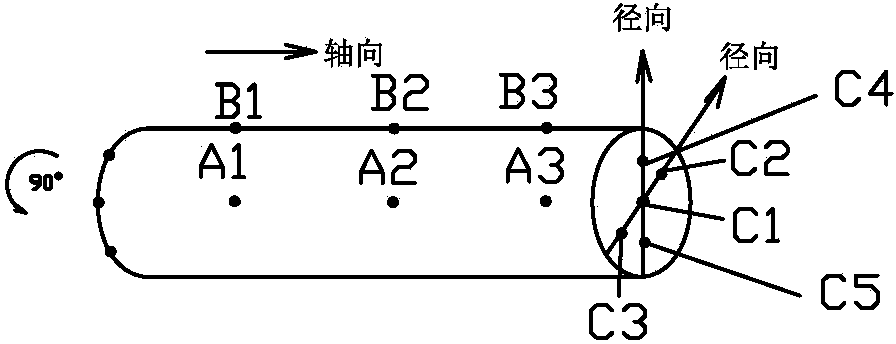

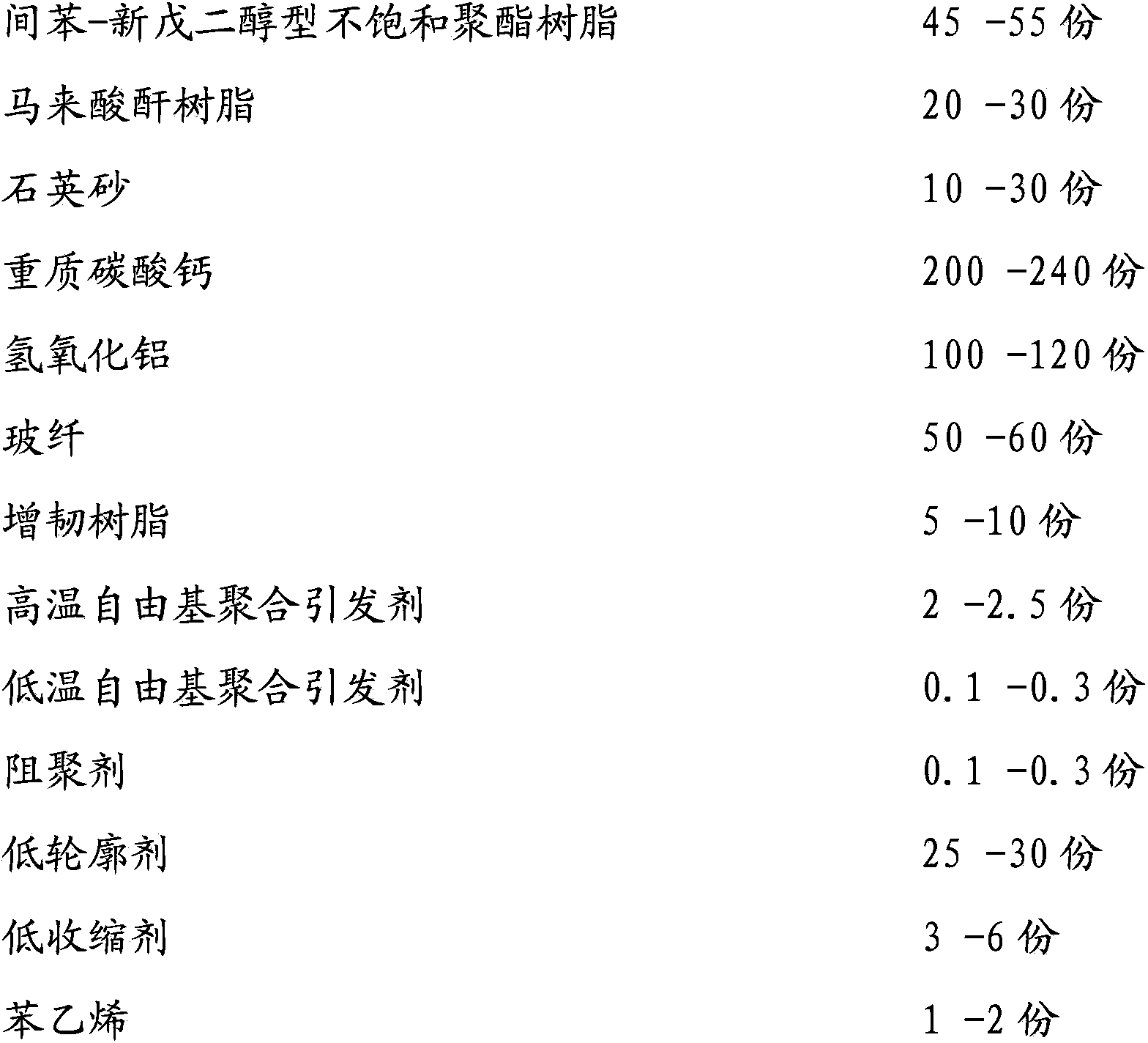

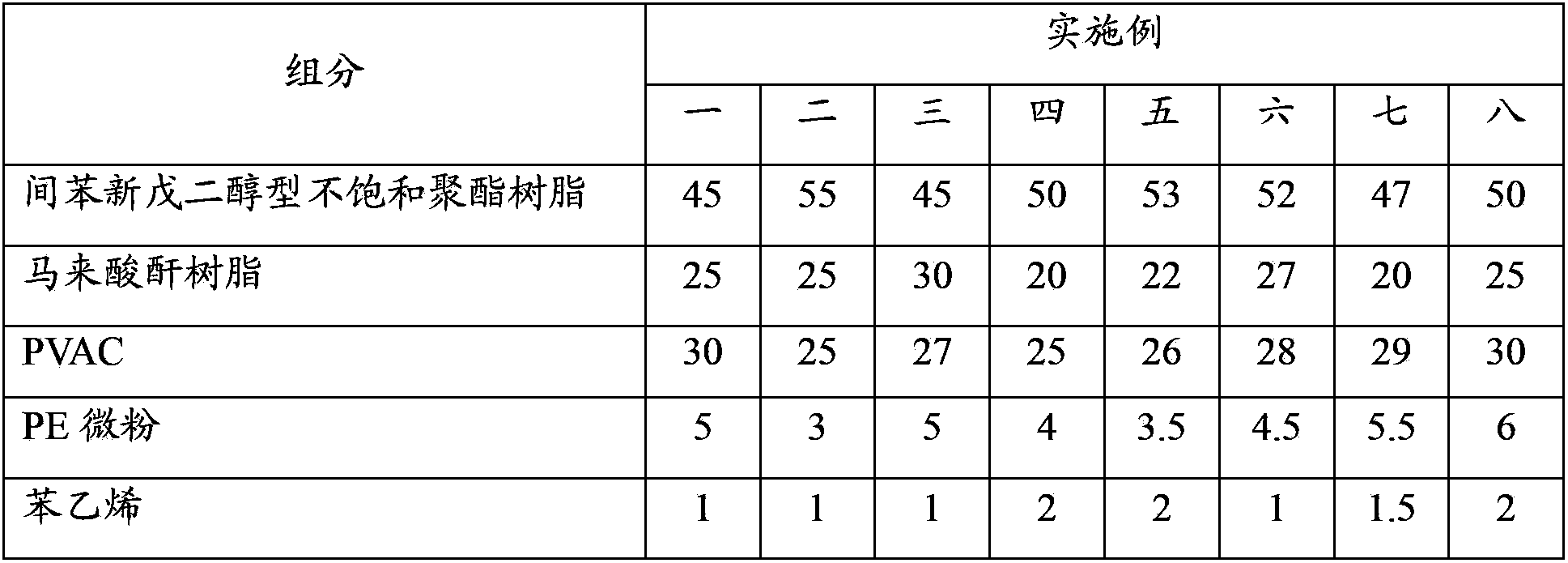

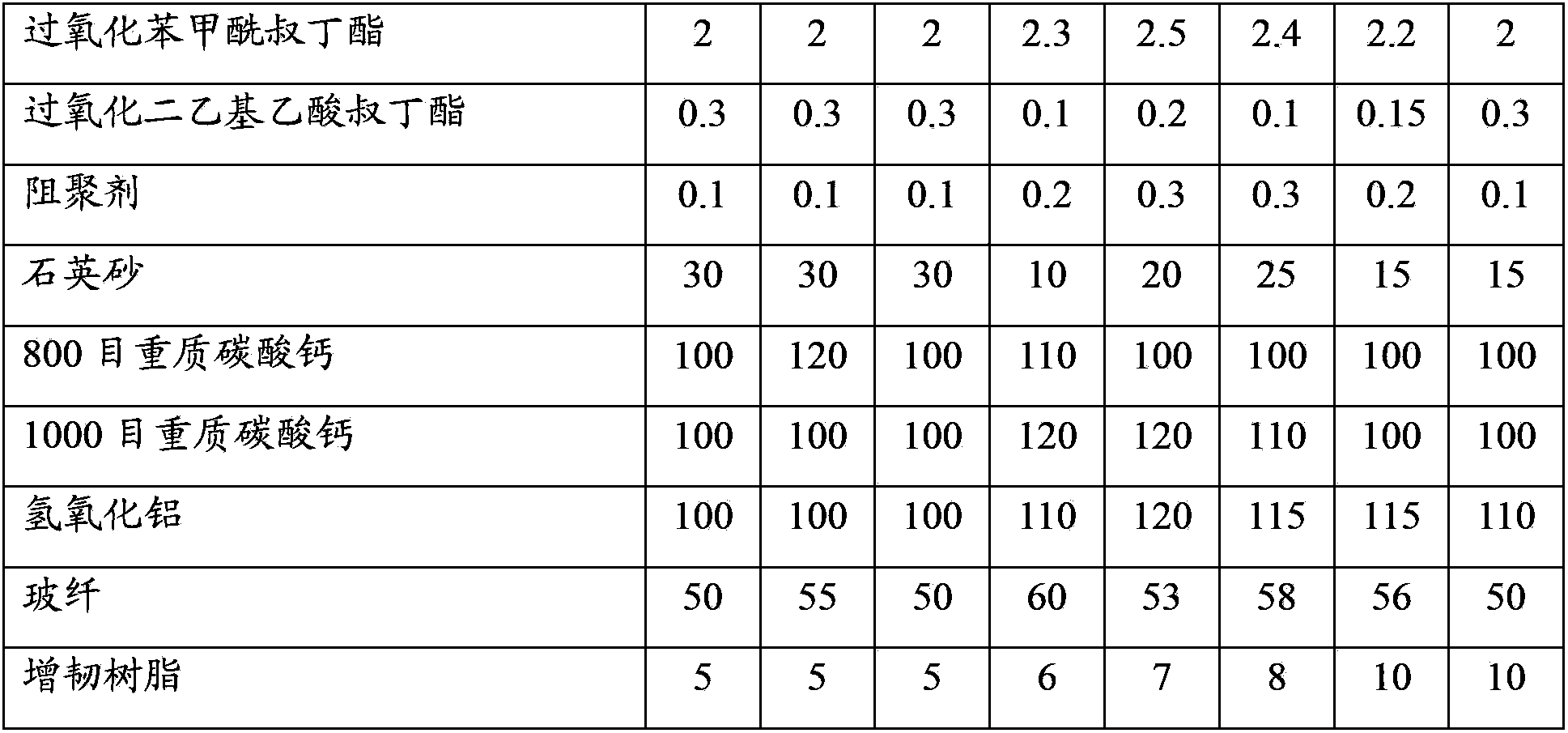

Unsaturated polyester molding compound

InactiveCN103570883AGood formabilityImprove the processing environmentPlastic/resin/waxes insulatorsCross-linkChemical structure

The present invention relates to an unsaturated polyester molding compound, particularly to an unsaturated polyester molding compound adopted as a double insulation material for an electric tool. The unsaturated polyester molding compound comprises, by weight, 45-55 parts of an isophthalic-neopentyl glycol type unsaturated polyester resin, 20-30 parts of a maleic anhydride resin, 10-30 parts of quartz sand, 200-240 parts of heavy calcium carbonate, 100-120 parts of aluminium hydroxide, 50-60 parts of glass fiber, 5-10 parts of a toughening resin, 2-2.5 parts of a high temperature free radical polymerization initiator, 0.1-0.3 part of a low temperature free radical polymerization initiator, 0.1-0.3 part of a polymerization inhibitor, 25-30 parts of a low profile agent, 3-6 parts of a low shrinkage agent, and 1-2 parts of styrene. The unsaturated polyester molding compound has the following advantages that: formability of the unsaturated resin is adopted, the functional filler and the special additive are matched, and the glass fiber is added to reinforce, such that the novel special functionality composite material relying on excellent forming ability of the unsaturated resin is achieved; and the chemical structure of the product is a cross-linking network structure, and the heat distortion temperature of the product is 273 DEG C and is about 25 DEG C higher than the heat distortion temperature of the conventional material, such that the product can achieve excellent thermal strength property when being used for high power electric mallets, electric breakers and the like, wherein the previous material does not have the excellent thermal strength property.

Owner:SHANGHAI ZAOJIE COMPOSITE TECH CO LTD

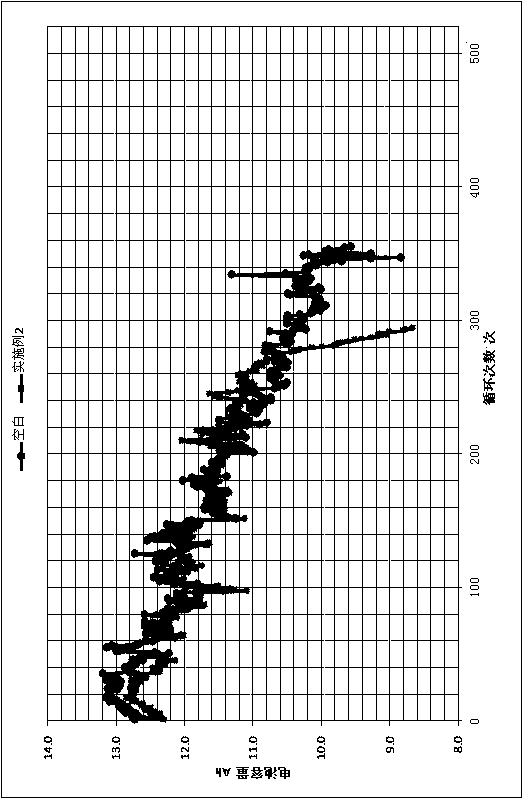

Lead-acid storage battery negative electrode lead paste

ActiveCN104253274AStable structureNot easy to softenLead-acid accumulator electrodesSulfuric acidPhosphate

The invention relates to a lead-acid storage battery negative electrode lead paste comprising the following components by mass: 3%-15% of sulfuric acid, 5%-20% of water, 0.05%-2% of short fiber, 0.05%-2% of lignin, 0.05%-2% of humic acid, 0.05%-2% of barium sulfate, 0.01-10% of phosphate, 0.1-1% of C, and balance of lead powder. Through addition of the phosphate harmless to a negative electrode into the negative electrode, the phosphate slowly dissolves out the battery using process, and diffuses to a positive electrode to promote alpha PbO2 generation and overcome the softening of a positive electrode plate.

Owner:CHAOWEI POWER CO LTD

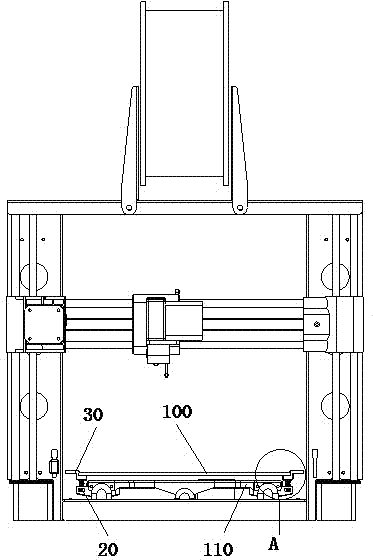

3D printer printing platform

InactiveCN104842558AEasy to disassembleOvercoming the impact on molding qualityAdditive manufacturing apparatusComputer printing3d printer

Owner:FUZHOU ZHANXU ELECTRONICS

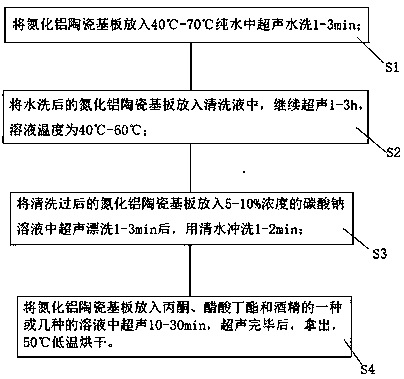

A black edge cleaning method of aluminum nitride ceramic substrate for rail transit chip packaging

InactiveCN109065458AImprove rigidityNot easy to softenSemiconductor/solid-state device detailsSolid-state devicesSodium carbonateBlack edge

A method for clean a black edge of an aluminum nitride ceramic substrate for packaging a rail transit chip comprise placing an aluminum nitride ceramic substrate at 40 DEG C, and cleaning that aluminum nitride ceramic substrate at 40 DEG C, wherein the aluminum nitride ceramic substrate is cleaned at 40 DEG C, wherein the aluminum nitride ceramic substrate is clean at 40 DEG C, and the aluminum nitride substrate is cleaned at 40 DEG C. Ultrasonic washing in pure water at 70 DEG C for 1-3min; Put the washed aluminum nitride ceramic substrate into the cleaning solution, and continue ultrasonic 1-3h, the solution temperature is 40 DEG C-60 DEG C; placing the cleaned aluminum nitride ceramic substrate in a 5-10% sodium carbonate solution for ultrasonic risining for 1 to 3 minutes,, washing with clean water for 1-2min; The aluminum nitride ceramic substrate was placed in one or more solutions of acetone, butyl acetate and alcohol to ultrasound 10-30 min, after that ultrasound is finished, take out, and drying at low temperature of 50 DEG C. The invention can effectively clean the black edge of the aluminum nitride ceramic substrate caused by the laser, and does not damage the surface ofthe aluminum nitride ceramic substrate.

Owner:WUXI TIANYANG ELECTRONICS

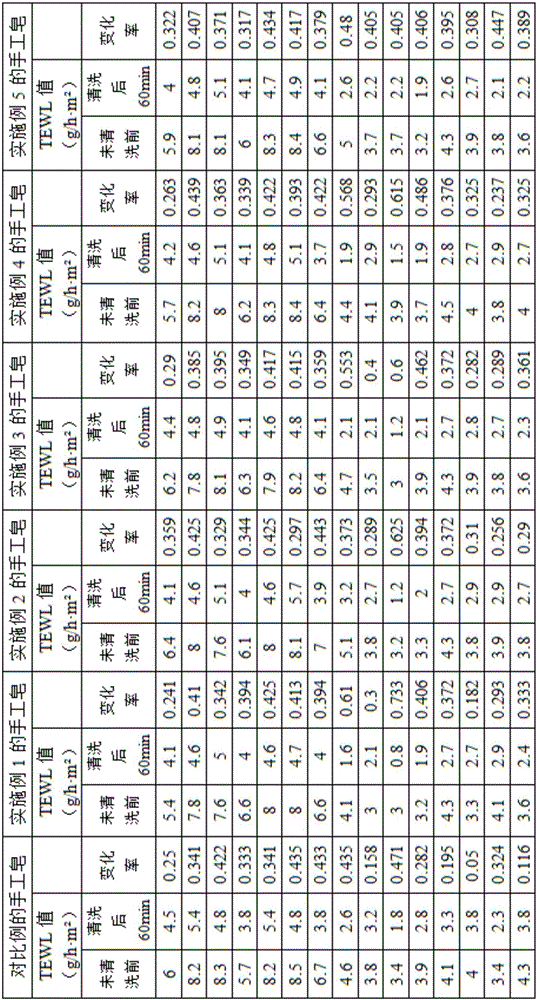

Cold handmade soap and preparation method thereof

InactiveCN106753921AModerate hardnessNot easy to softenShaping soapSkin careAdditive ingredientJojoba oil

The invention relates to the technical field of daily chemical products, and specifically discloses cold handmade soap and a preparation method thereof. The cold handmade soap is prepared from the following components: 20 to 25 parts of camellia oil, 13 to 16 parts of palm oil, 10 to 12 parts of palm kernel oil, 2.5 to 3.0 parts of shea butter, 1 to 1.5 parts of castor oil, 0.5 to 1 part of jojoba oil, 0.5 to 1 part of cupuacu butter, 10 to 12 parts of avocado oil, 3 to 5 parts of argan nut oil, 1.5 to 2.0 parts of natural plant essential oil, 0.5 to 1.5 parts of natural plant extract, 18 to 22 parts of water and 9 to 11 parts of sodium hydroxide. The cold handmade soap disclosed by the invention is obtained through a special preparation method, and not only can nutritional ingredients in plant oil be reserved to the maximum, but also the technical problem that local saponification in a preparation method of existing cold handmade soap is incomplete can be solved.

Owner:江西神州通油茶科技有限公司

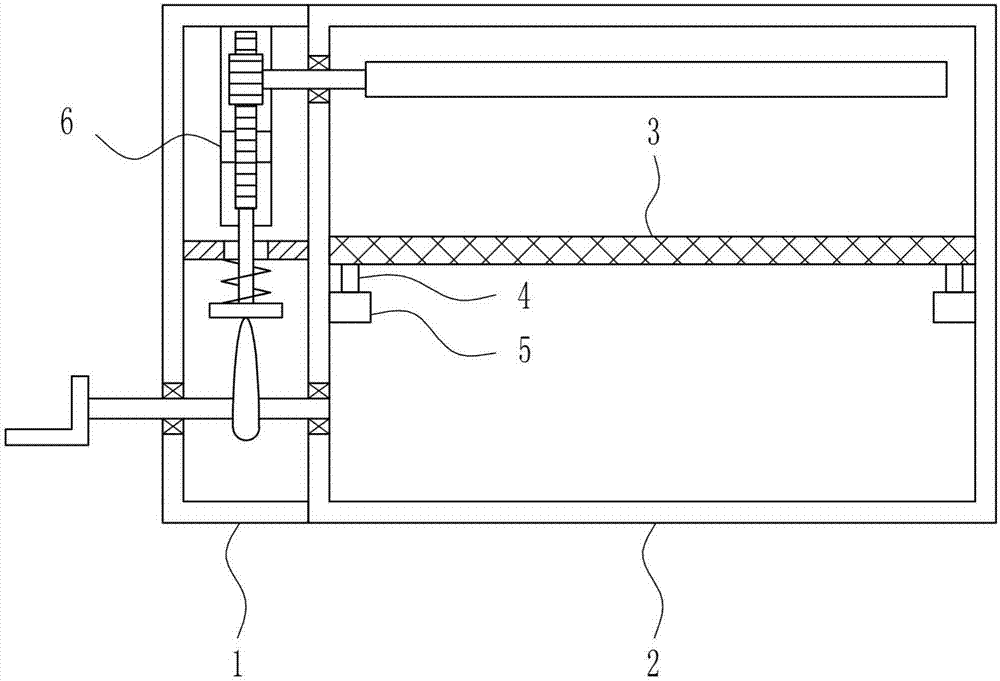

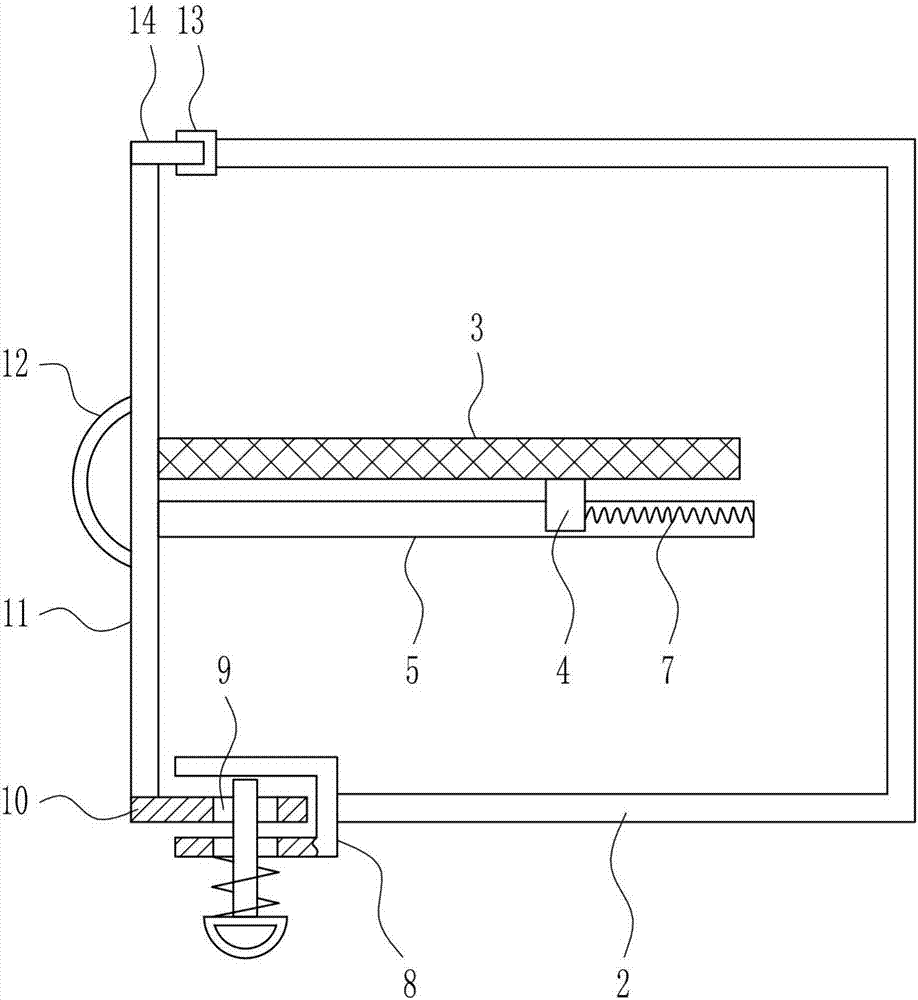

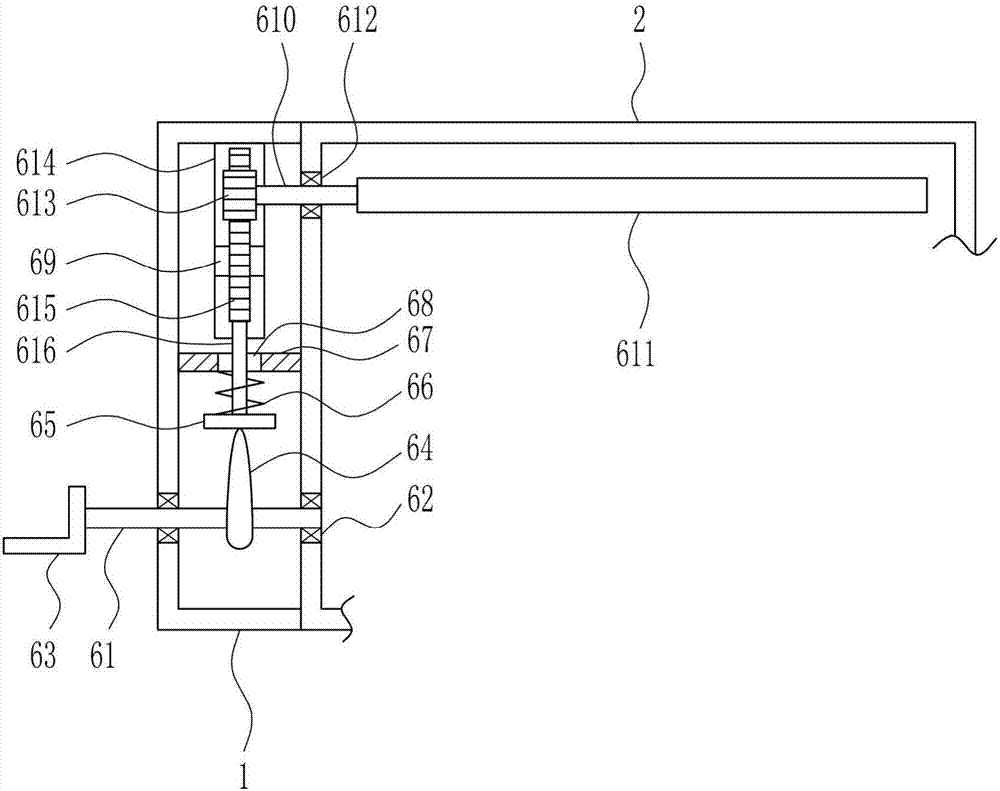

High-efficiency baking and shaping device for vamp

The invention relates to a baking and shaping device, and particularly relates to a high-efficiency baking and shaping device for a vamp. The invention aims at solving the technical problem to provide the high-efficiency baking and shaping device for the vamp; the device has the advantages of quick baking speed and uniform heating. In order to solve the technical problem, the invention provides thesuch a high-efficiency baking and shaping device for the vamp. The high-efficiency baking and shaping device comprises a fixing groove, a working box, a placing net, a first sliding block, first sliding rails, a rocking heating device, a first spring, a fixing device, a fixing rod, a baffle plate, a first pull ring and the like, wherein the left side of the working box is connected with the fixing groove; the rocking heating device is arranged in the fixing groove; the right side of the rocking heating device is connected with the working box; a left wall and a right wall in the working box are symmetrically connected with the first sliding rails. By using the high-efficiency baking and shaping device, the effects that the baking speed is quick and the heating is uniform are achieved; a rotating rod is artificially rocked with a hand to make a heating plate radiate heat to bake and shape the vamp; the fixing device is used for making the baffle plate more stable; meanwhile, an air heater swings upwards, downwards, leftwards and rightwards.

Owner:浙江天宏鞋业有限公司

Preparation method of vehicle brake block

InactiveCN101158381AEnsure driving safetySimple production processFriction liningMass ratioMetallurgy

A making method for a brake shoe of an automobile relates to a making method of the brake shoe of the automobile. The method comprises the following steps: (1) the silica powder is crushed to the fineness of 1200 grids; (2) the silicon nitride is crushed to the fineness of 1600 grids; (3) the milled silica and silicon nitride powder is uniformly mixed according to the mass ratio of 1: 0.05-0.10 and heated to 1200 DEG C; the heated powder is poured into a die (50cm multiplied by 50cm multiplied by 20cm) under the pressure of 10MPa; the pressure is maintained until the temperature of the powder reduces to 700 DEG C, and the temperature keeps reducing naturally to get the product which is the raw material of the inorganic automobile brake shoe; (4) the obtained raw material is processed to suitable shape in order to get the final products according to the requirement of the design of the automobile brake. The invention has simple production process and low manufacture cost, and can be widely generalized; the brake shoe resists high temperature and is not easy to be softened, which can ensure the driving safety of the automobile.

Owner:SHENYANG JIANZHU UNIVERSITY

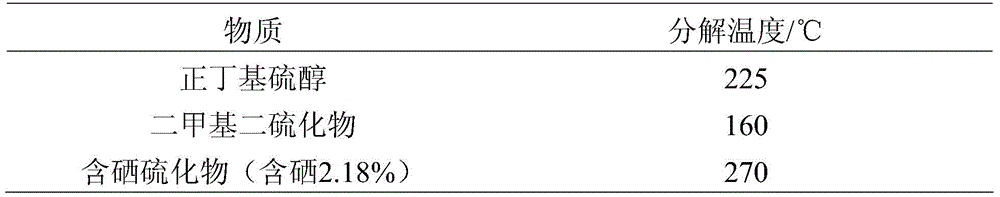

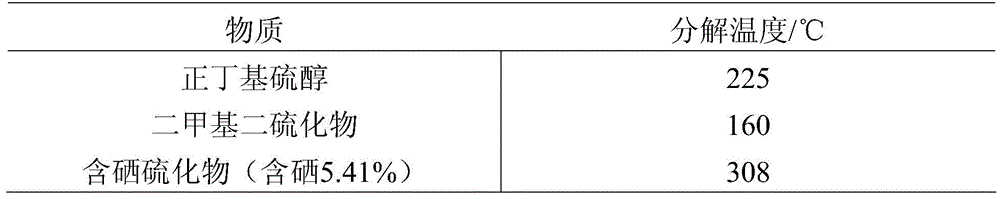

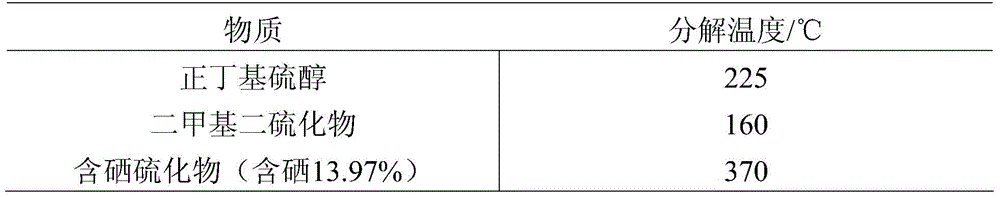

Vulcanizing agent containing selenium and preparing method and application thereof

The invention belongs to the field of rubber materials, and particularly relates to a vulcanizing agent containing selenium and a preparing method and application thereof.After sulfur is mixed with selenium powder, the catalyst strong base solution is added, then reaction with gas-state olefin lasts for 180-360 min at 245-250 DEG C, and then the vulcanizing agent containing selenium is obtained.The vulcanizing agent containing selenium is prepared by replacing the sulfur elementary substance with sulfur homdogy matter, the preparing method is easy to operate and low in cost, and industrial production can be achieved easily.The vulcanizing agent containing selenium is not softened easily at high temperature, heat stability is high, and chemical stability is high.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Casting method for casting high-end large precision castings

ActiveCN108889907AAvoid pollutionNot suitable for cracking the shellFoundry mouldsFoundry coresSlagLost-foam casting

The invention relates to the technical field of lost foam casting, in particular to a casting method for casting high-end large precision castings. The casting method adopts a special shell mold, cancast high-quality castings without defects like recarburization, pores, slag inclusion and skin wrinkling, can meet high-grade, complex-structure and precision casting requirements and is environment-friendly and pollution-free. The casting method includes steps: making a mold, coating the surface of a blank mold with shell mold paint, drying, melting the mold to make a shell, boxing the shell mold, and pouring at negative pressure. The casting method has the advantages of being capable of casting the high-quality castings without the defects like recarburization, pores, slag inclusion and skin wrinkling and meeting high-grade, complex-structure and precision casting requirements and being environment-friendly and pollution-free.

Owner:河南圣得威机械科技有限公司

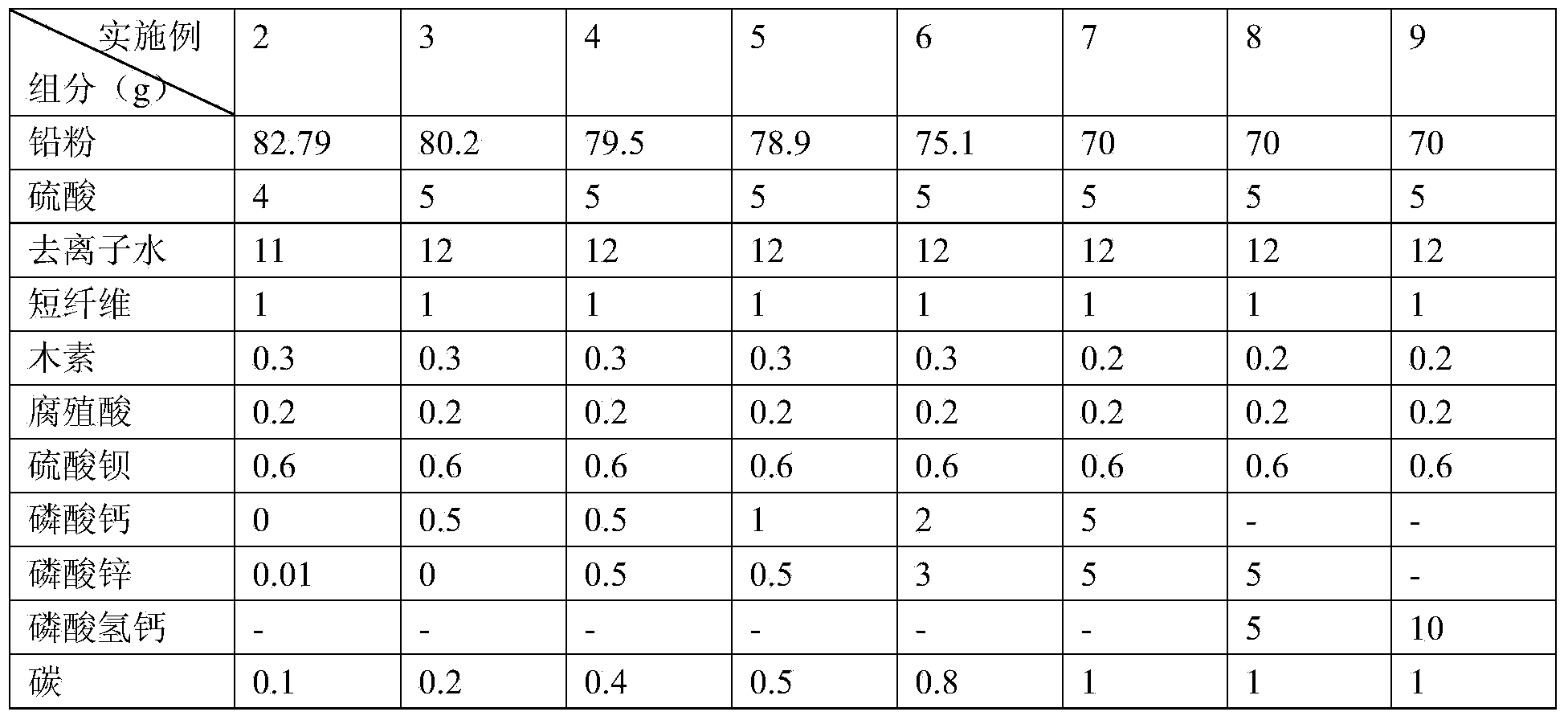

Positive lead paste for lead-acid storage battery and preparation method of positive lead paste

ActiveCN106654257AImprove conductivityAvoid decompositionLead-acid accumulatorsCell electrodesCalcium biphosphateMaterials science

The invention relates to a storage battery material and a preparation method thereof, in particular to positive lead paste for a storage battery and a preparation method of the positive lead paste. The positive lead paste is prepared from the following components in parts by weight: 75-85 parts of lead powder, 5-10 parts of red lead, 0.5-1 part of calcium phosphate, 5-10 parts of dilute sulfuric acid, 0.2-0.3 part of graphene oxide, 0.5-1.5 parts of EDTA-2Na and 10-20 parts of deionized water; and the calcium phosphate, the graphene oxide and the EDTA-2Na are added at the same time, so that the formation effect on the battery is not affected, the capacity of the battery is improved in the using process of the battery, the problem of softening of a later pole plate of the battery is effectively solved and the service life of the battery is prolonged.

Owner:TIANNENG GRP HENAN ENERGY TECH

Injection gel composite microsphere and preparation method thereof

PendingCN114796602AHigh biosecurityLess side effectsPharmaceutical delivery mechanismTissue regenerationSodium hyaluronateChemistry

The invention belongs to the technical field of medical materials, and particularly relates to an injection gel composite microsphere and a preparation method thereof. The injection gel composite microsphere comprises a component A, a component B, silk fibroin, an anesthetic and a salt solution, the component A is prepared from sodium hyaluronate, collagen, recombinant collagen, chitosan or bacterial cellulose; and the component B is a polycaprolactone or polylactic acid derivative degradable material. The injection gel composite microsphere provided by the invention has a long-acting shaping effect; meanwhile, when the gel is sterilized by adopting a damp and hot high-pressure steam sterilization method, the microspheres are not easy to soften at high temperature, and the form can be well maintained; and no bubble is generated after packaging, no additive is required to be additionally introduced, and the biological safety is high.

Owner:成都迪康中科生物医学材料有限公司

Casting method for rapid casting of large precision castings based on 3D printing technology

ActiveCN108907095BSimple processing technologyShort production timeAdditive manufacturing apparatusFoundry mouldsMetal formingProcess engineering

The invention relates to the technical field of metal molding and casting, in particular to a method for quickly casting a large precision casting based on a 3D printing technology; through combination of a 3D printing and molding technology and a lost foam casting technology, by using special shell type coatings, a casting without the defects of recarburization, pores, slag inclusion or wrinkledskin can be cast, and the requirements of a high grade and complex structure and the precision casting can be met; and the method has the advantage of green, environmental protection and no pollution.The method comprises the steps of three-dimensional modeling, making of a fusible model and a special shell mold, boxing of the shell mold, negative pressure pouring and the like. The method has theadvantages of simple processing technology, no need of developing a mould, short production time, easy regulation and modification, low production cost, green, environmental protection and no pollution, and the molding process can be finished in real time; the requirements of individualization and customization cam be met; high quality products can be made, and massive casting and precision casting are both taken into consideration.

Owner:河南圣得威机械科技有限公司

Making method of improved filter bag mouth

InactiveCN101920145AConsistent materialNot easy to softenDispersed particle filtrationEngineeringSpring steel

The invention relates to a making method of an improved filter bag mouth. The method comprises the following steps of: making a concave pad by using cloth for making a filter bag; attaching the concave pad to a spring steel sheet to make a synthetic piece; fording filter bag material cloth to wrap the synthetic piece; and stacking the skirts of two layers of filter bag material cloth at one end of the synthetic piece outside the filter bag mouth to be sewed together. By improving the concave pad material and the sewing method of the filter bag mouth, the filter bag mouth can resist aging, softening and dust, and has lower and stable dust discharge amount of tail gas dust; and the filter bag hardly falls in use and has long service life and decreased making cost.

Owner:宜兴市泰清环保设备有限公司

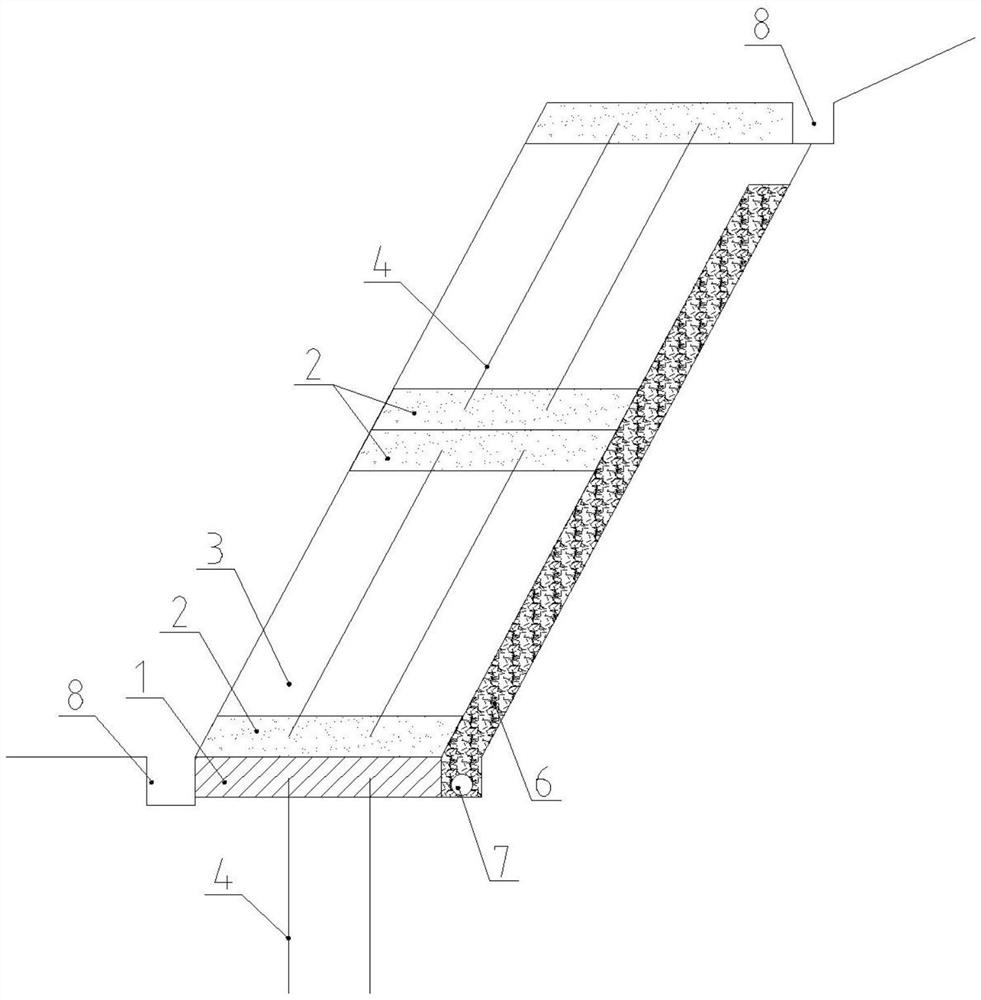

Slope reinforcing retaining wall and construction method thereof

ActiveCN111827312AEasy constructionImprove stabilityArtificial islandsExcavationsSoil scienceSoil cement

The invention discloses a slope reinforcing retaining wall and a construction method thereof. The retaining wall comprises a concrete cushion and a plurality of unit structural layers formed by a backfill soil layer entraining a concrete soil layer above the concrete cushion. The inclination angle of each unit structural layer is consistent with the grade of the slope. A plurality of hollow steelpipes vertically pressed unto a soil body downward are arranged on the concrete cushion. The hollow steel pipes of same inclination angle are arranged in the unit structural layers. Two ends of the hollow steel pipes are restrained and fixed by concrete soil layers. A base structure of the retaining wall is relatively high in bearing capacity and unlikely to soften and permeate. The unit structural layers are stable structural bodies and have the characteristics of isolating water and being unlikely to soften. The inclination angle of the retaining wall can be arranged relatively steeply, so that the cost of filling engineering is saved. A soil material of the retaining wall is fully taken from an excavated natural soil body, so that the engineering cost can be saved. The slope reinforcingretaining wall is particularly suitable for south region with limited sites for reinforced design of the slope and high perennial rainfall frequency.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

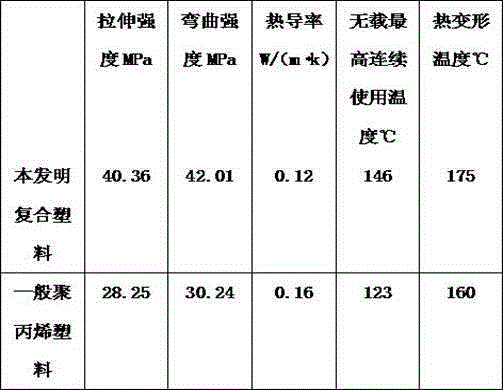

Modified compound plastic

InactiveCN105237874AImprove structural performanceGood weather resistancePolymer sciencePolypropylene

The invention discloses a modified compound plastic, which is made from components: polypropylene, thermoplastic styrene-butadiene rubbers, attapulgite, silicon powder, phenolic resins, bentonite, sodium acrylate, aluminium nitride, dispersants, plasticizers and heat stabilizers. The modified compound plastic is steady in quality and excellent in mechanical and physical chemical properties, and has excellent adaptive efficiency. The modified compound plastic can improve structure performance and enhances weather resistance by adding the treated attapulgite. The modified compound plastic enables plastic components to be more uniform by mixing and pretreating the phenolic resins and the aluminium nitride, and enables organization structures to be more firm. The modified compound plastic can enhance plastic texture by adding the treated silicon powder, and is not easy to soften. The polypropylene and the sodium acrylate are mixed to add into a twin-screw extruder firstly, can improve integration of the polypropylene and other components, improve structure quality, and prolong service life.

Owner:QUANJIAO XIANGRUI PLASTIC

Tellurium-containing vulcanizing agent, and preparation method and application thereof

The invention belongs to the field of rubber materials, and particularly relates to a tellurium-containing vulcanizing agent, and a preparation method and application thereof. The preparation method comprises the following steps: mixing sulfur and tellurium powder, adding a catalyst strong alkali solution, and carrying out reaction with gas olefins at 480-490 DEG C for 180-360 minutes, thereby obtaining the tellurium-containing vulcanizing agent. The tellurium with the same family as sulfur is used instead of the sulfur simple substance to prepare the tellurium-containing vulcanizing agent. Thus, the preparation method is simple to operate and low in cost, and can easily implement industrial production. The tellurium-containing vulcanizing agent has the advantages of low softening tendency at high temperature, favorable heat stability and favorable chemical stability.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Wheel-sticking-free emulsified asphalt and preparation method thereof

ActiveCN112266622AHigh softening pointNot easy to softenBuilding insulationsBitumen emulsionRoad surface

The invention discloses wheel-sticking-free emulsified asphalt and a preparation method thereof, which relate to the technical field of pavement asphalt materials, and solve the problem that an existing emulsified asphalt material adheres to a tire of a construction vehicle. The wheel-sticking-free emulsified asphalt material is prepared from the following components in parts by mass: 30-60 partsof matrix asphalt, 0.5-5 part of an emulsifier, 5-15 parts of a modifier and 30-60 parts of water, wherein the modifier comprises sulfonated asphalt powder. According to the technical scheme providedby the invention, the softening point of the emulsified asphalt can be increased, so that the emulsified asphalt is not easy to soften, and the emulsified asphalt is difficult to adhere to a construction wheel.

Owner:HEBEI PROVINCIAL COMM PLANNING & DESIGN INST +1

High-temperature grease composition and preparation method thereof

InactiveCN104371816AImprove work performanceEasy to prepareLubricant compositionWork performanceDithiophosphoric acid

The invention relates to a high-temperature grease composition and a preparation method thereof. The composition comprises animal grease, polyurea, organic dye, sulfurized isobutylene, molybdenum disulfide, phenylenediamine, hexadecylamine, calcium oxide and phosphorodithioate. The preparation method of the grease composition provided by the invention has the advantages of simpleness and reasonable ratio of raw materials; the composition has good high temperature performance. Polyurea, organic dye and sulfurized isobutylene are used as thickeners to make little change of grease under the condition of temperature change, so as to meet the usage requirement in high temperature; the addition of molybdenum disulfide, phenylenediamine, hexadecylamine, calcium oxide and dithiophosphate improves the work performance of the grease under high temperature conditions, so that the grease is not easy to soften under high temperature condition.

Owner:WUXI FEITIAN GREASE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com