Cold handmade soap and preparation method thereof

A cold-process handmade soap and saponification technology, which is applied in the field of daily chemicals, can solve the problems of reducing the quality of precious oils, incomplete local reactions, and mixing in, to increase moisturizing and nourishing effects, solve incomplete saponification reactions, and moderate hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

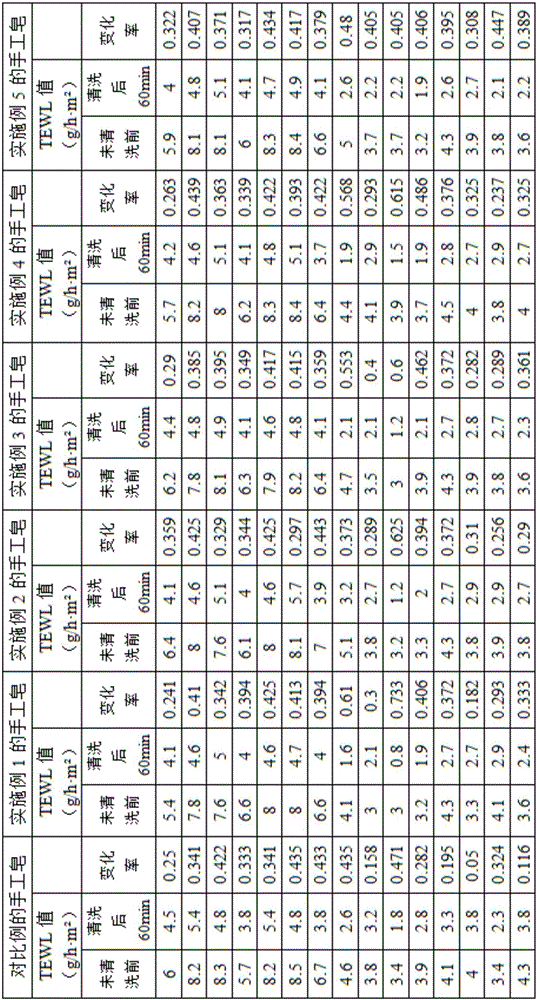

Examples

preparation example Construction

[0030] The preparation method of above-mentioned camellia oil cold process handmade soap comprises the steps:

[0031] S1: Mix camellia oil, palm oil, palm kernel oil, shea butter, castor oil, cupu azu oil, avocado oil, argan oil in proportion, 35-45℃ water bath, 0.08-0.1MPa vacuum degree Heating under the conditions until completely dissolved, stirring and mixing evenly.

[0032] S2: Slowly pour the above sodium hydroxide solution into the mixed vegetable oil under stirring, and carry out saponification reaction for half an hour in a water bath at 35-45° C. and a vacuum of 0.08-0.1 MPa. Wherein, the preparation method of sodium hydroxide solution is: dissolve sodium hydroxide solid in pure water in proportion, wherein, the mass ratio of sodium hydroxide and pure water is 1:1.6-1:2.4, fully stir, and hydrogen The sodium oxide solid is completely dissolved, cooled to about 35-45°C, and set aside.

[0033] S3: Move the reaction liquid in S2 together with the vacuum stirring po...

Embodiment 1

[0039] S1. Take 23 parts of camellia oil, 15 parts of palm oil, 10 parts of palm kernel oil, 3.0 parts of shea butter, 1 part of castor oil, 0.5 parts of cupu azu oil, 12 parts of avocado oil, and 5 parts of argan oil Mix, heat in a 40°C water bath and a vacuum of 0.08MPa until completely dissolved, stir and mix evenly.

[0040] S2. Take 10 parts of sodium hydroxide solid and add 18 parts of pure water to dissolve, and then cool to about 40°C after completely dissolving; Under MPa vacuum condition, carry out saponification reaction for half an hour.

[0041] S3. Transfer the reaction solution in the above steps together with the vacuum stirring pot to an ultrasonic reactor, and perform ultrasonic and saponification reaction for 1 hour under the condition of 100W power and 60KHz frequency.

[0042] S4. When the reaction solution in step S3 is viscous, add 1.5 parts of natural plant essential oil, 0.5 part of natural plant extract, and 0.5 part of jojoba oil, stir well, and mix...

Embodiment 2

[0046] S1. Take 25 parts of camellia oil, 15 parts of palm oil, 9 parts of palm kernel oil, 3.0 parts of shea butter, 1 part of castor oil, 0.5 parts of cupu azu oil, 11.5 parts of avocado oil, and 4 parts of argan oil Mix, heat in a water bath at 42°C and a vacuum of 0.09MPa until completely dissolved, stir and mix evenly.

[0047] S2. Take 9.5 parts of solid sodium hydroxide and add 18 parts of pure water to dissolve, completely dissolve and cool to about 40°C; pour the sodium hydroxide aqueous solution at about 40°C into the mixed vegetable oil under stirring, and put it in a water bath at 40°C, 0.08 Under MPa vacuum condition, carry out saponification reaction for half an hour.

[0048] S3. Move the reaction liquid in the above steps together with the vacuum stirring pot to an ultrasonic reactor, and perform ultrasonic and saponification reaction under the conditions of 110W power and 50KHz frequency for 1.5 hours.

[0049] S4. When the reaction solution in step S3 become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com