Special composite oil phase for emulsion explosive and preparation method thereof

An emulsion explosive and composite oil phase technology, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of low performance of emulsion explosives, short storage period, and fast decay of detonation ability, etc. The effect of good milk forming effect, long storage period and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: According to the following formula (percentage by weight) as the oil phase material, the AE-HLC continuous emulsion explosive production line of Shandong Tianbao Chemical Co., Ltd. was used as the platform to carry out the production line test, and the explosive produced was No. 2 rock emulsion explosive. Produced by EL20-1 emulsion explosive automatic charging machine Standard roll products, the packaging material is ordinary wax paper rolls.

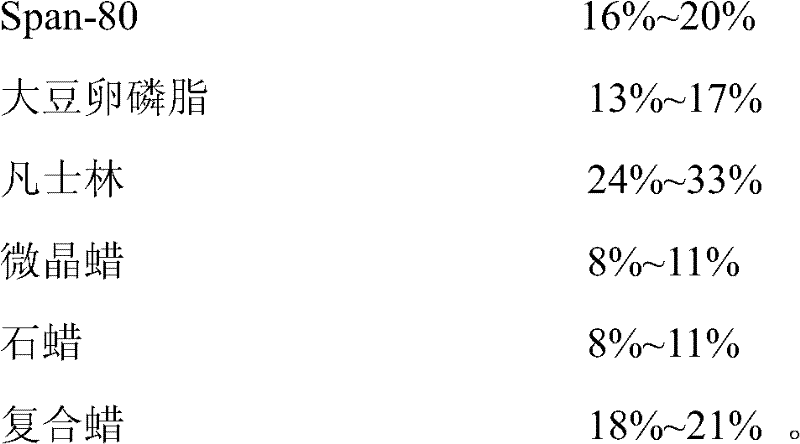

[0022] Oil phase material formula:

[0023]

[0024] The measured drug density is 1.18g / cm -3 , the initial performance is: detonation velocity: 5700m / s; detonation: ≥ 8cm; intensity: 19.3mm; the performance changes tested under natural storage conditions are shown in Table 1.

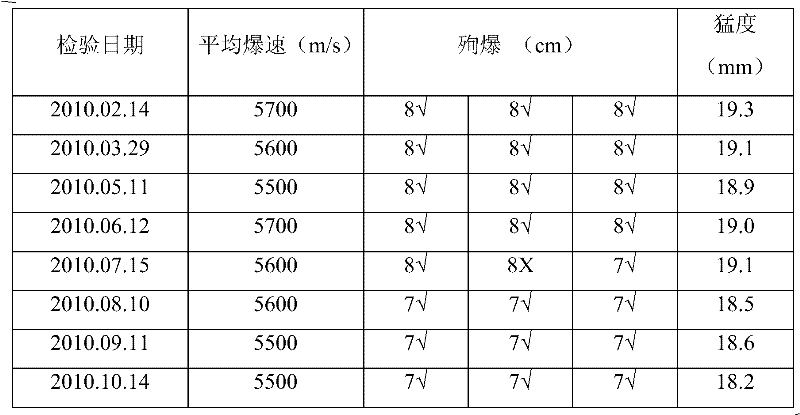

[0025] Table 1, under the natural storage condition, implement the performance change of explosive product in 1 example

[0026]

[0027]

[0028] Note: Production date: 2010.02.13

Embodiment 2

[0029] Example 2: According to the following formula (percentage by weight) as the oil phase material, the AE-HLC continuous emulsion explosive production line of Shandong Tianbao Chemical Co., Ltd. was used as the platform to carry out the production line test, and the explosive variety produced was No. 2 rock emulsion explosive. Produced by EL20-1 emulsion explosive automatic charging machine Standard roll products, the packaging material is ordinary wax paper rolls.

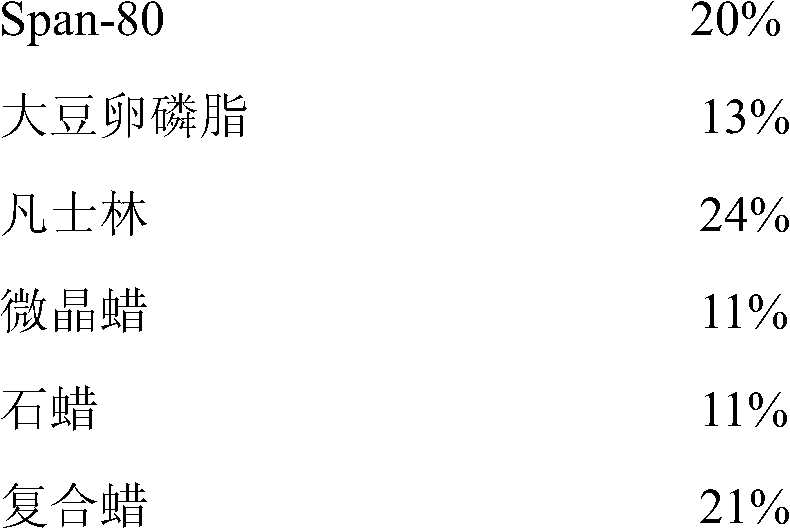

[0030] Oil phase material formula:

[0031]

[0032] The measured drug density is 1.19g / cm -3 , the initial performance is: detonation velocity: 5400m / s; detonation: ≥ 8cm; intensity: 18.0mm; the performance changes tested under natural storage conditions are shown in Table 2.

[0033] Under table 2, natural storage condition, the performance change of explosive product in embodiment 2

[0034]

[0035]

[0036] Note: Production date: 2010.02.19

Embodiment 3

[0037] Example 3: According to the following formula (percentage by weight) as the oil phase material, the AE-HLC continuous emulsion explosive production line of Shandong Tianbao Chemical Co., Ltd. was used as the platform to carry out the production line test, and the explosive produced was No. 2 rock emulsion explosive. Produced by EL20-1 emulsion explosive automatic charging machine Standard roll products, the packaging material is ordinary wax paper rolls.

[0038] Oil phase material formula:

[0039]

[0040] The measured drug density is 1.18g / cm -3 , the initial performance is: detonation velocity: 5600m / s; detonation: ≥ 8cm; intensity: 18.4mm; the performance changes tested under natural storage conditions are shown in Table 3.

[0041] Under table 3, under natural storage condition, the performance change of explosive product in embodiment 3

[0042]

[0043]

[0044] Remarks: Production date: 2010.03.06

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rate | aaaaa | aaaaa |

| Fierceness | aaaaa | aaaaa |

| Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com