Patents

Literature

286 results about "Detonation velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosive velocity, also known as detonation velocity or velocity of detonation (VoD), is the velocity at which the shock wave front travels through a detonated explosive. The data listed for a specific substance is usually a rough prediction based upon gas behavior theory (see Chapman-Jouguet condition), as in practice it is difficult to measure. Explosive velocities are always faster than the local speed of sound in the material.

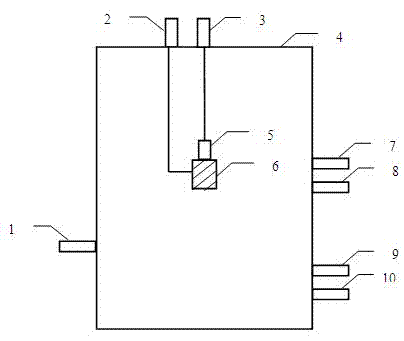

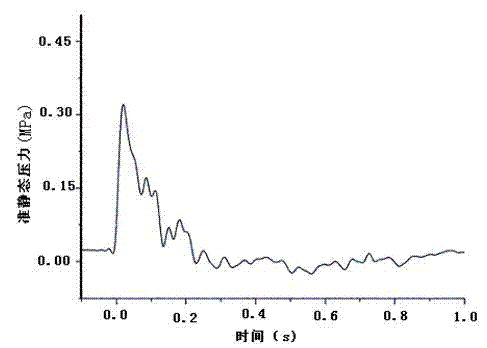

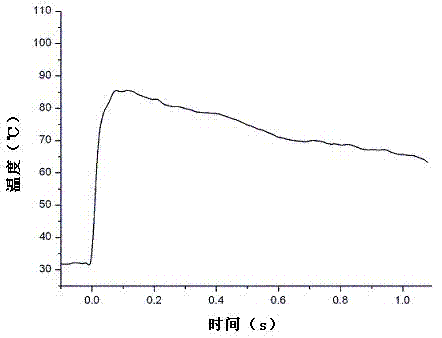

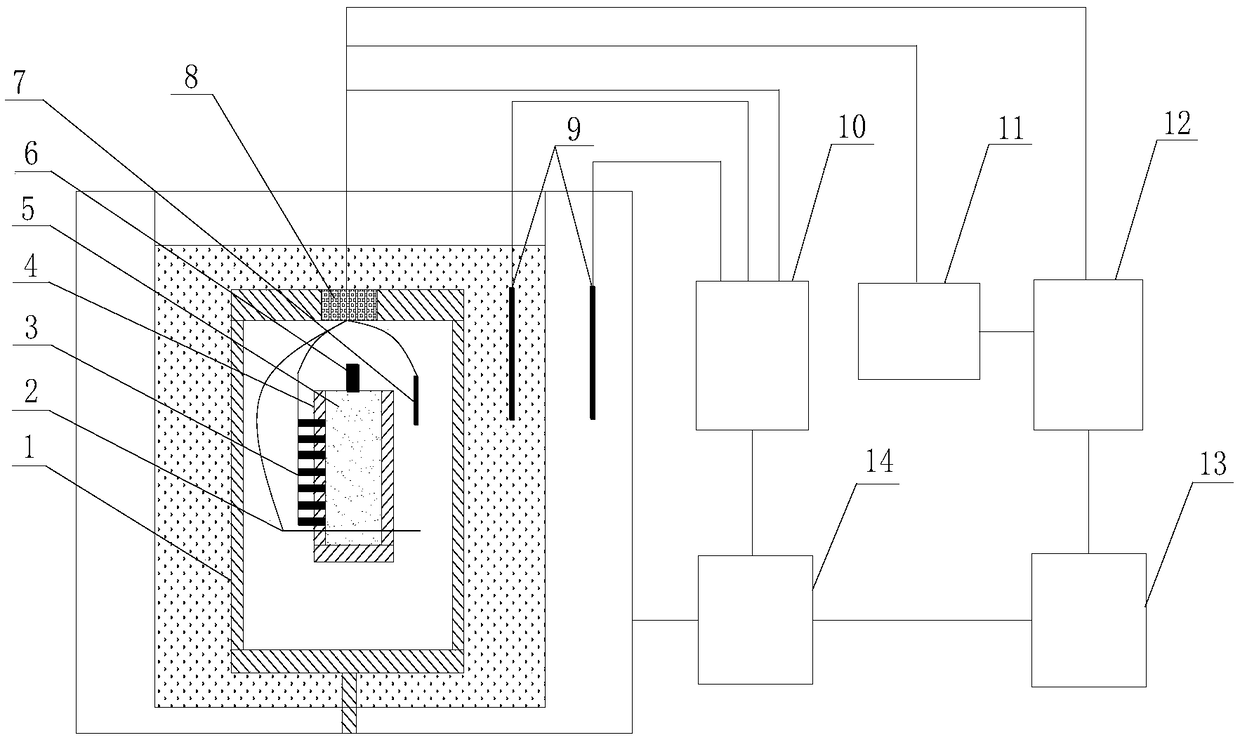

Detonation performance test method for high-energy imploding explosive

InactiveCN102253083AFlexible simulationRealize synchronized measurementsMaterial exposibilityDetonatorExplosive Agents

The invention discloses a detonation performance test method for high-energy imploding explosive. The method is characterized in that: a explosive grain with a detonator is placed in a sealed explosion vessel; quasi-static pressure of the explosive, transient temperature of the explosive, detonation velocity of the explosive and gas components of the explosive are detected; a temperature sensor is arranged on the sealed explosion vessel, and is provided for monitoring the temperature changing in the sealed explosion vessel during the test process, a pressure sensor is arranged on the sealed explosion vessel, and is provided for monitoring the pressure changing in the sealed explosion vessel during the test process; the sealed explosion vessel is further connected with a gas collection andtest system, a firing device, a detonation velocity test device, a mechanical vacuum pump and a gas cylinder. The method is applicable for the performance tests of various imploding explosives, and can be provided for performing laboratory quantitative evaluation to the gas expansion working.

Owner:XIAN MODERN CHEM RES INST

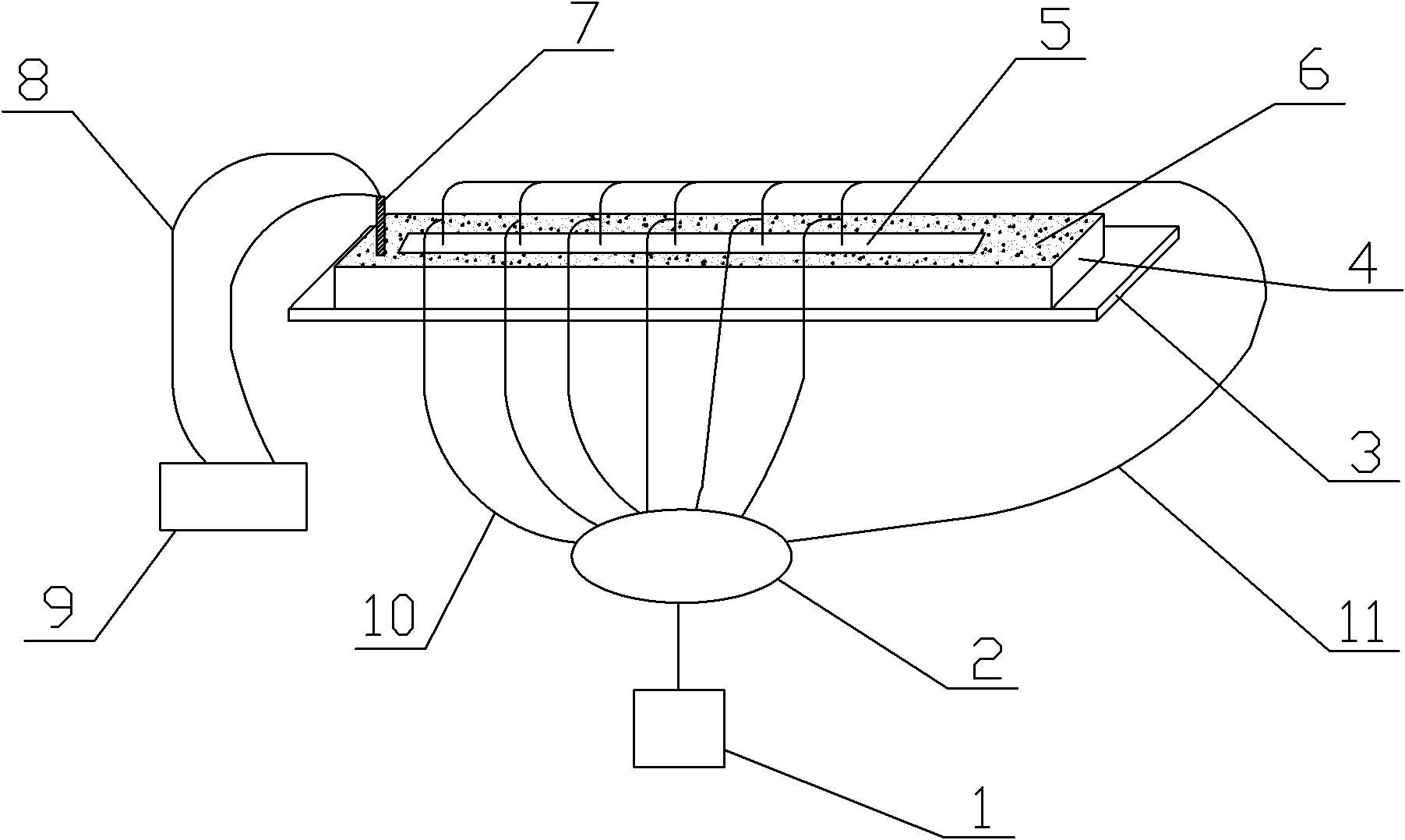

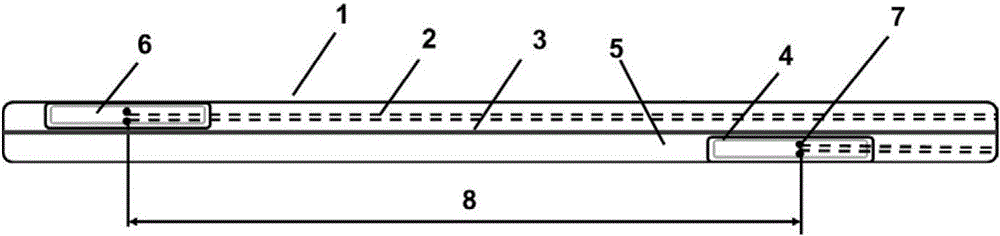

Device and method for measuring detonating velocity of explosive

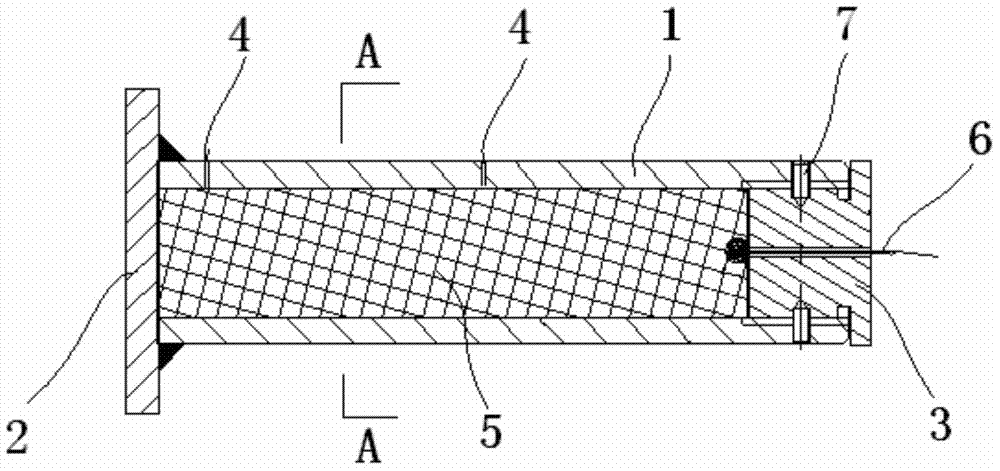

InactiveCN102081104ASimple structureReasonable designLinear/angular speed measurementDetonatorEngineering

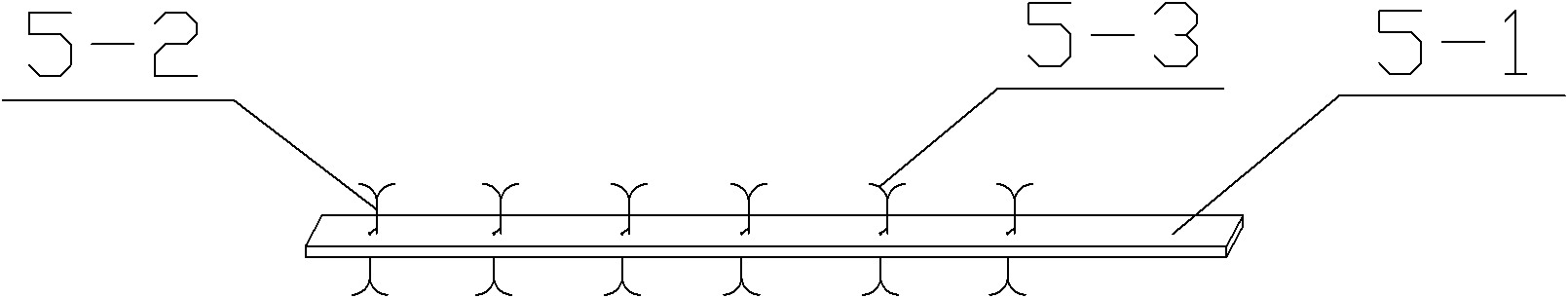

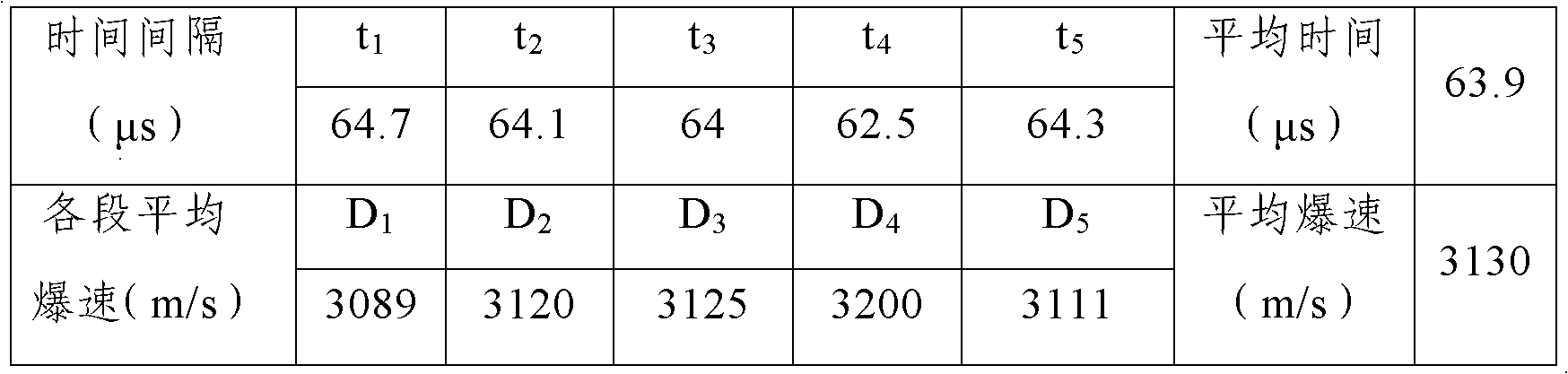

The invention discloses a device for measuring the detonating velocity of explosive. The device comprises a detonating velocity meter, a signal forming circuit connected with the detonating velocity meter, a base plate, an explosive frame arranged on the base plate and used for placing the explosive, a continuous probe arranged on the surface of the explosive, a detonator arranged in the explosive frame, and an exploder connected with the detonator through an explosion initiation line; and the continuous probe consists of a fixed plate, a plurality of supporting objects which are uniformly fixed on the fixed plate in a line, and sensing elements winding on the supporting objects. The invention also discloses a method for measuring the detonating velocity by using the device for measuring the detonating velocity of the explosive. The method for measuring the detonating velocity is simple and practical, and a plurality of groups of data and continuous detonating velocities in the whole explosive detonation are measured, so that the change condition of the detonating velocity is reflected.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Bulked ammonium nitrate explosive with low explosion speed and its prepaing process

InactiveCN1386727ANo pollution in the processLow costNon-explosive/non-thermic compositionsDiluentAmmonium nitrate

A puffed ammonium nitrate explosive with low exploding speed is prepared from ammonium nitrate, surfactant, composite oil, wood powder, and diluent through dissolving ammonium nitrate and surfactant in water, vacuum drying at 110-140 deg.C and -0.085--0.098 MPa vacuity for 5-20 min, mixing with others and cooling. Its advantages are high safety and performance, uniform explosion transmission and low cost.

Owner:NANJING UNIV OF SCI & TECH

High energy insensitive press-fitting high polymer bonded explosive

ActiveCN107879867AHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Explosive welding method for large-area lead-steel composite board

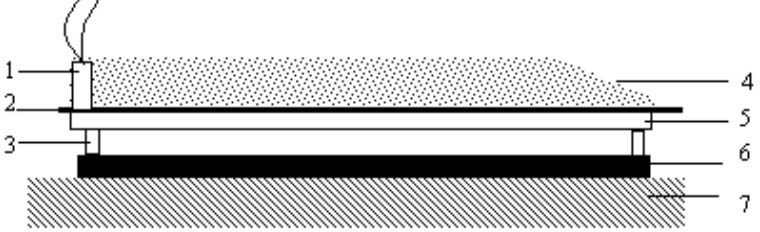

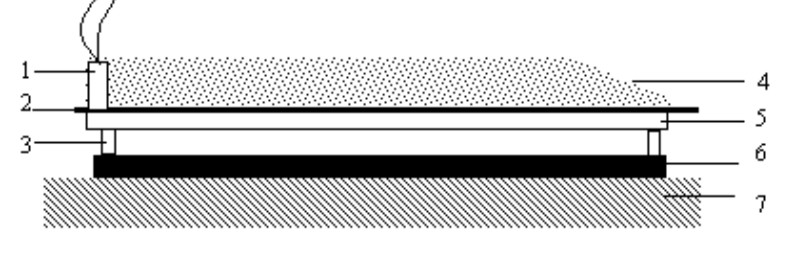

ActiveCN102059445ASolve the problem of too soft and hard to supportFree from burnsWelding/soldering/cutting articlesNon-electric welding apparatusBoundary effectsUltimate tensile strength

The invention discloses an explosive welding method for a large-area lead-steel composite board, in which a base steel board and a composite lead board are adopted. The method comprises the following steps of: adding a high-strength metal board on the surface of the composite lead board, and bonding the composite lead board and the high-strength metal board together with adhesives; and proportioning special explosive as follows: 45-48 parts of expanded ammonium nitrate, 48-51 parts of sodium chloride and 4-6 parts of pearlite, ensuring a detonation velocity range of 1200m / s-1500m / s and adopting slop type explosive distribution at a far end. The method disclosed in the invention realizes the support of the lead board so that the explosive welding of the large-area lead-steel composite board can be implemented; and the method has the advantages of eliminating negative effects of surface burn and boundary effect on explosive composite, ensuring that the lead-steel composite board has the primary composite rate being higher than 98% and higher bond strength.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Energetic ion salts of 1-nitramine-2, 4-dimetridazloe and preparation method thereof

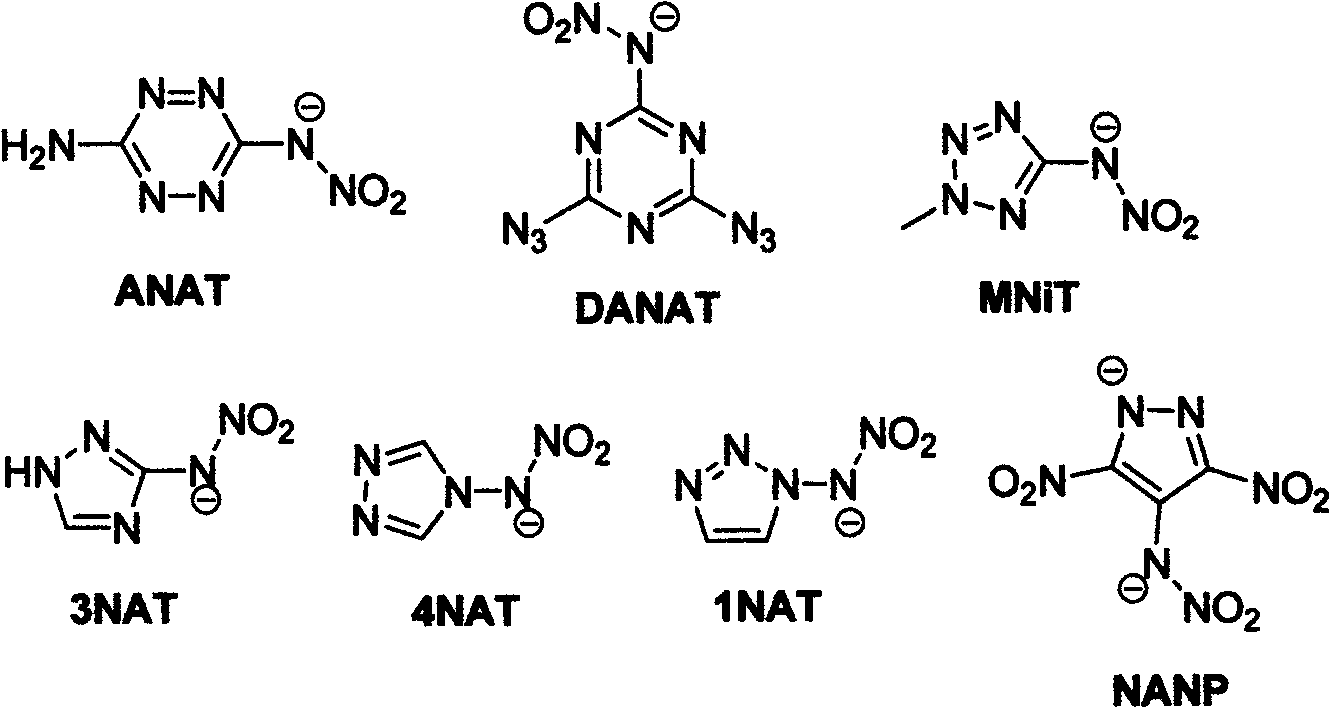

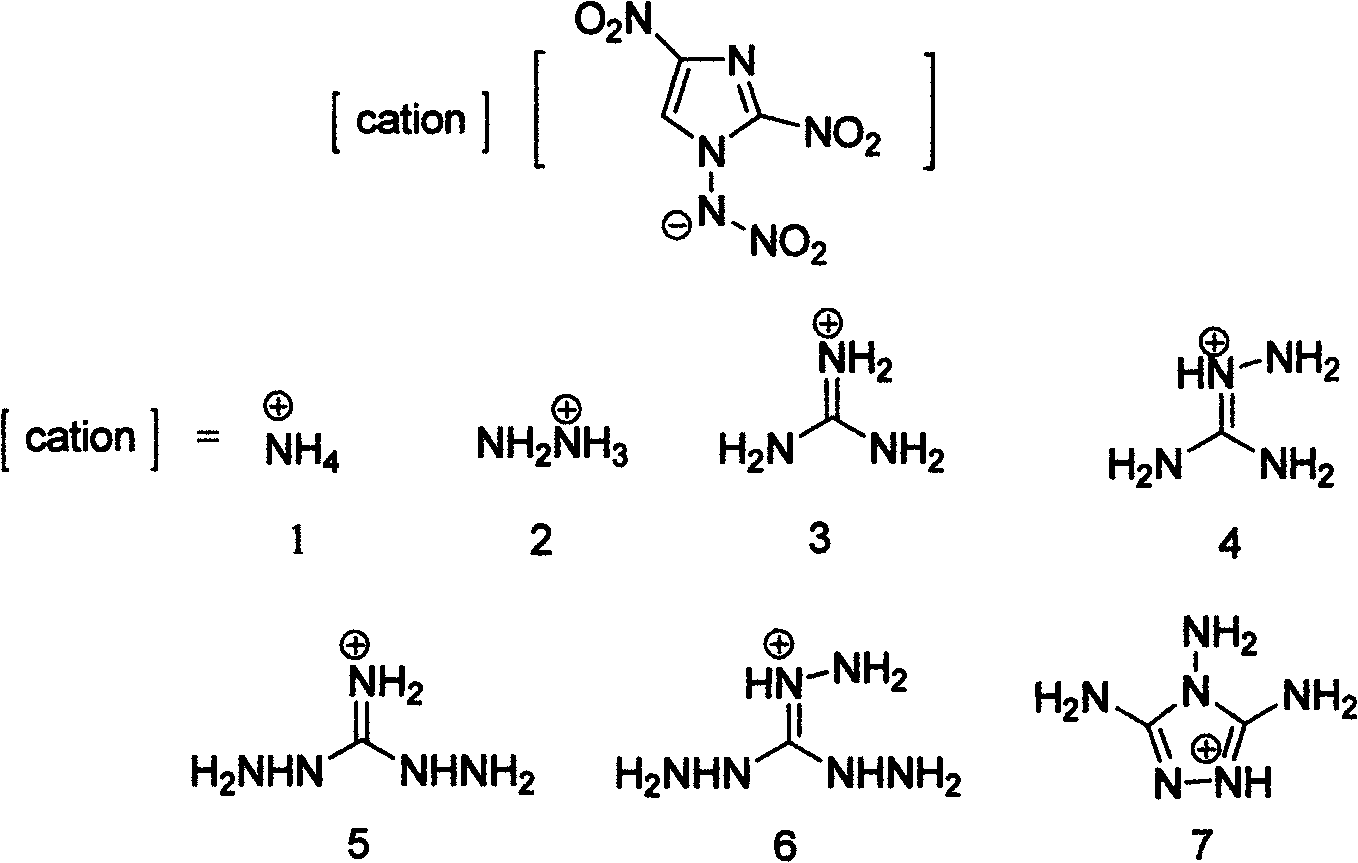

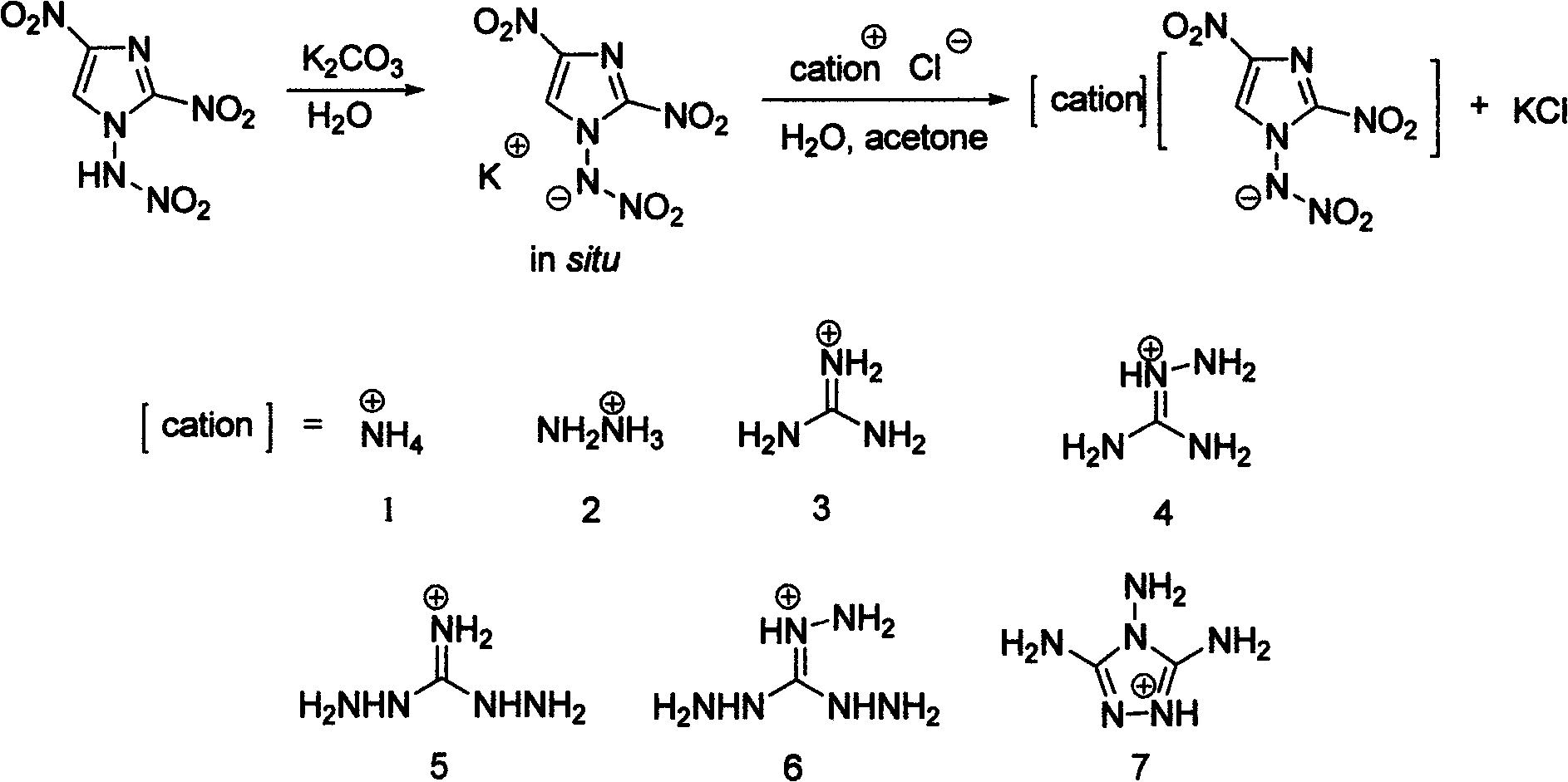

InactiveCN103483264AExcellent detonation speed and pressure performanceThe synthesis method is simpleOrganic chemistryOrganic compound preparationNitroimidazoleHydrazine compound

The invention discloses energetic ion salts of 1-nitramine-2, 4-dimetridazloe and a preparation method thereof, and belongs to the technical field of energetic materials. The synthetic method is as follows: dissolving the 1-nitramine-2, 4-dimetridazloe in deionized water to obtain a pale yellow clear liquid, adding with stirring 0.5 time molar equivalent of potassium carbonate at room temperature for in-situ generation of 1-nitramine-2, 4-dimetridazloe potassium salt, then adding one time molar equivalent of ammonium chloride, hydrazine hydrochloride, guanidine hydrochloride, monoaminoguanidine hydrochloride, diaminoguanidine hydrochloride, triaminoguanidine hydrochloride and 3, 4, 5-triamino-1, 2, 4-triazole hydrochloride, stirring to precipitate a pale yellow solid precipitate, after about 1 hour of reaction, filtering the pale yellow precipitate, further recrystallizing a coarse product by use of an acetone and diethyl ether mixed solvent to obtain a pure product. The synthetic method of the invention is simple, mild in condition and high in yield, and is environmental friendly due to using of the deionized water as a solvent. The density of involved seven salts is 1.70-1.93g cm<-3>, the detonation velocity calculated by EXPLO software is between 8370 and 9209 m s<-1>, the detonation pressure is between 29.3 and 40.5 GPa, the actually measured impact sensitivity is 4-40J, the detonation performance is excellent, and the energetic ion salts are potential energetic materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

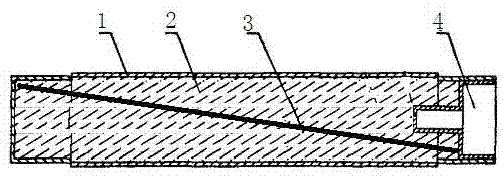

Testing device and method for deflagration to detonation transition

InactiveCN103675194ASimple and fast operationReliable dataChemical analysis using combustionCombustionHigh energy

The invention relates to a testing device and method for deflagration to detonation transition. The device comprises a sample tube, a verification plate and a plug, wherein the sample tube is used for containing a sample to be tested, the verification plate is fixedly installed at one end of the sample tube and used for packaging the sample and detecting whether a perforation is formed in the verification plate or not during combustion of the sample, and the plug is fixedly installed at the other end of the sample tube. The method comprises the steps that the sample is ignited for testing when the sample is packaged in the sample tube, and meanwhile, detonation velocities of the sample between adjacent test holes are tested to obtain at least two groups of detonation velocities; if the perforation is formed in the verification plate, it proves that the sample has the deflagration to detonation transition, or if the detonation velocity of the sample is stable, it proves that the sample has the deflagration to detonation transition, wherein the stability of the detonation velocity of the sample refers to that the standard deviation of at least two groups of detonation velocity values is not more than 35. The device is particularly applicable to deflagration to detonation transition tests of high-energy propellants. Compared with traditional testing methods and devices for the deflagration to detonation transition, the testing device and method have the advantages that two evaluation indicators, namely, the perforation and the stable detonation velocity are adopted, so that the testing efficiency and the data credibility are improved.

Owner:XIAN MODERN CHEM RES INST

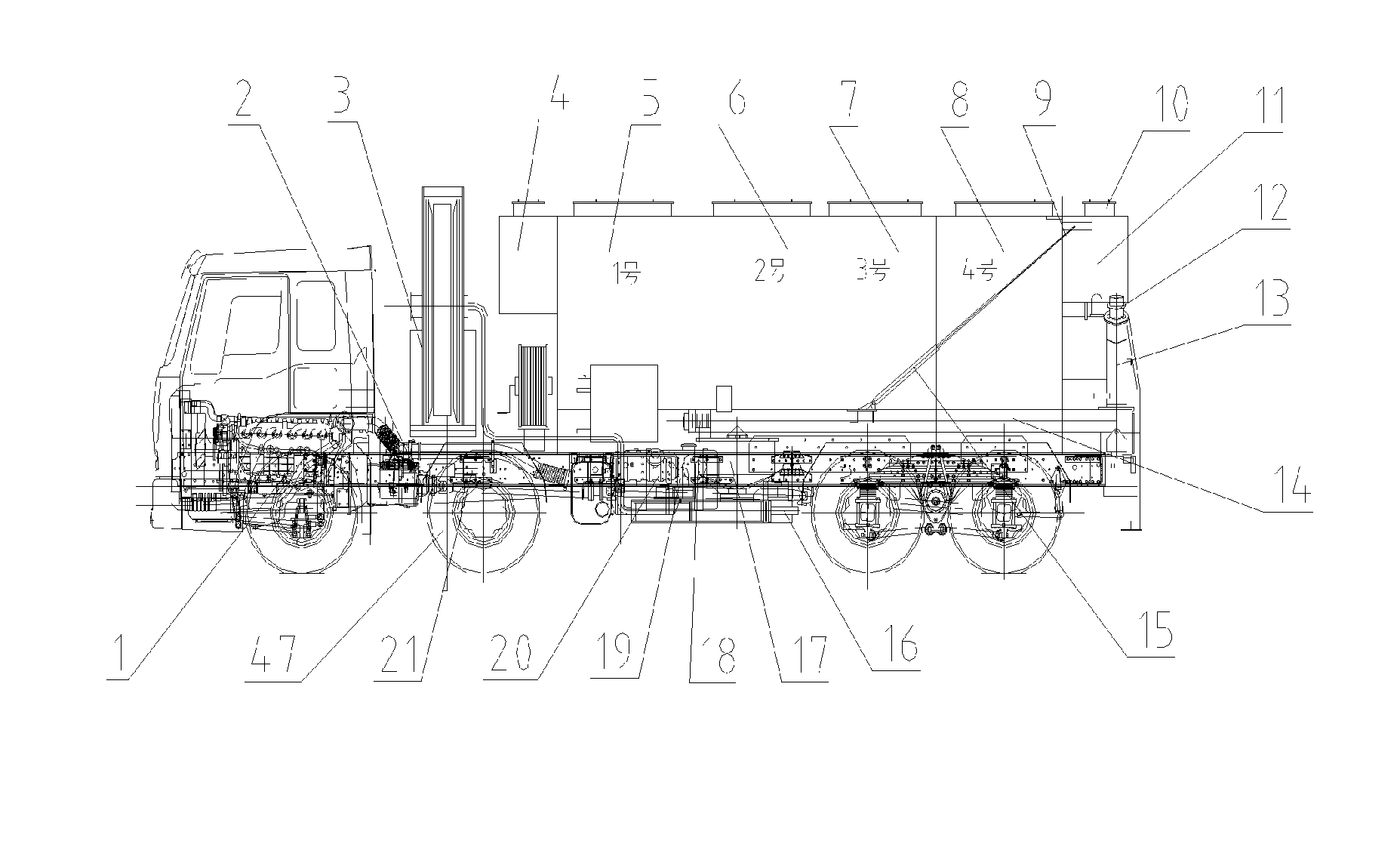

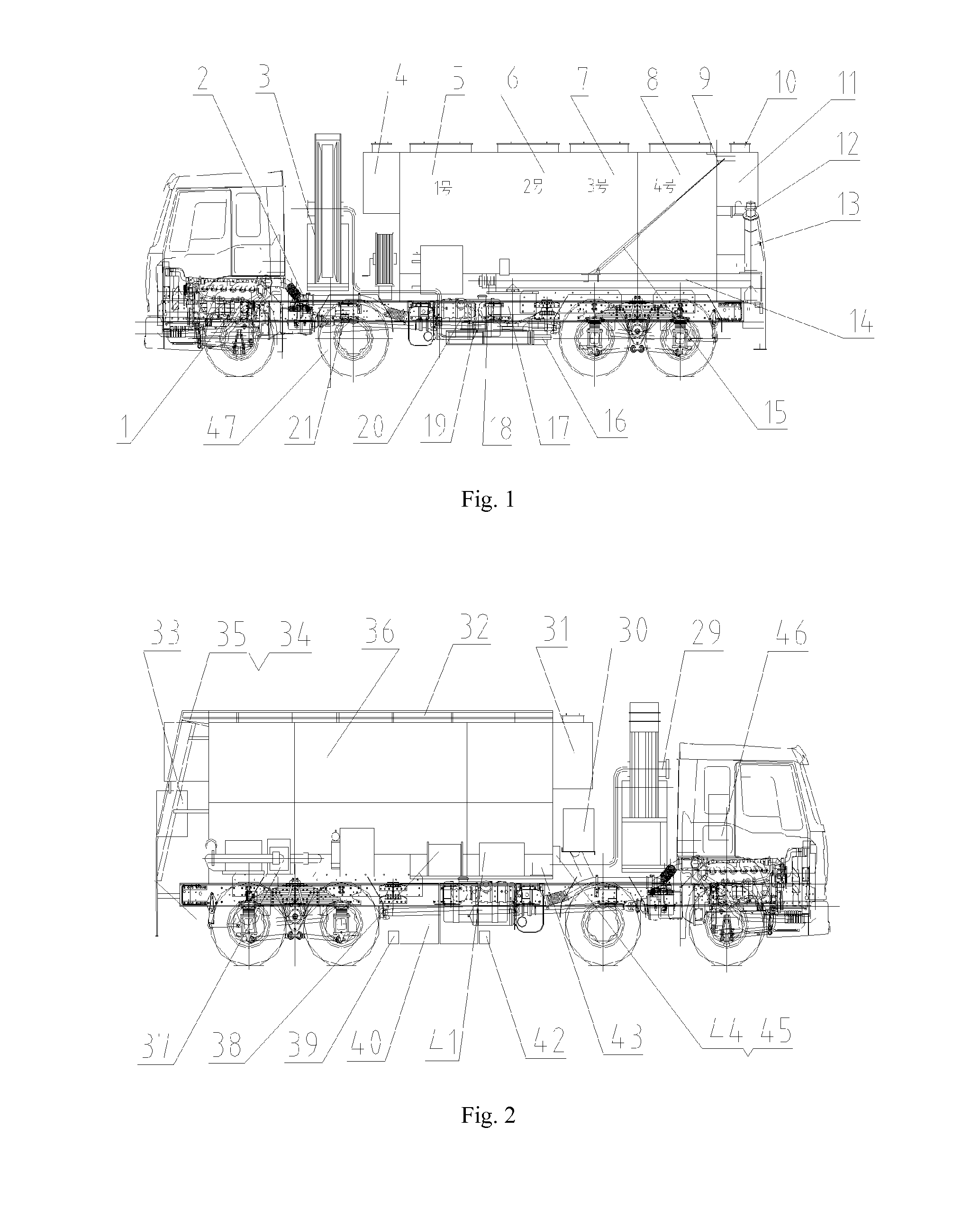

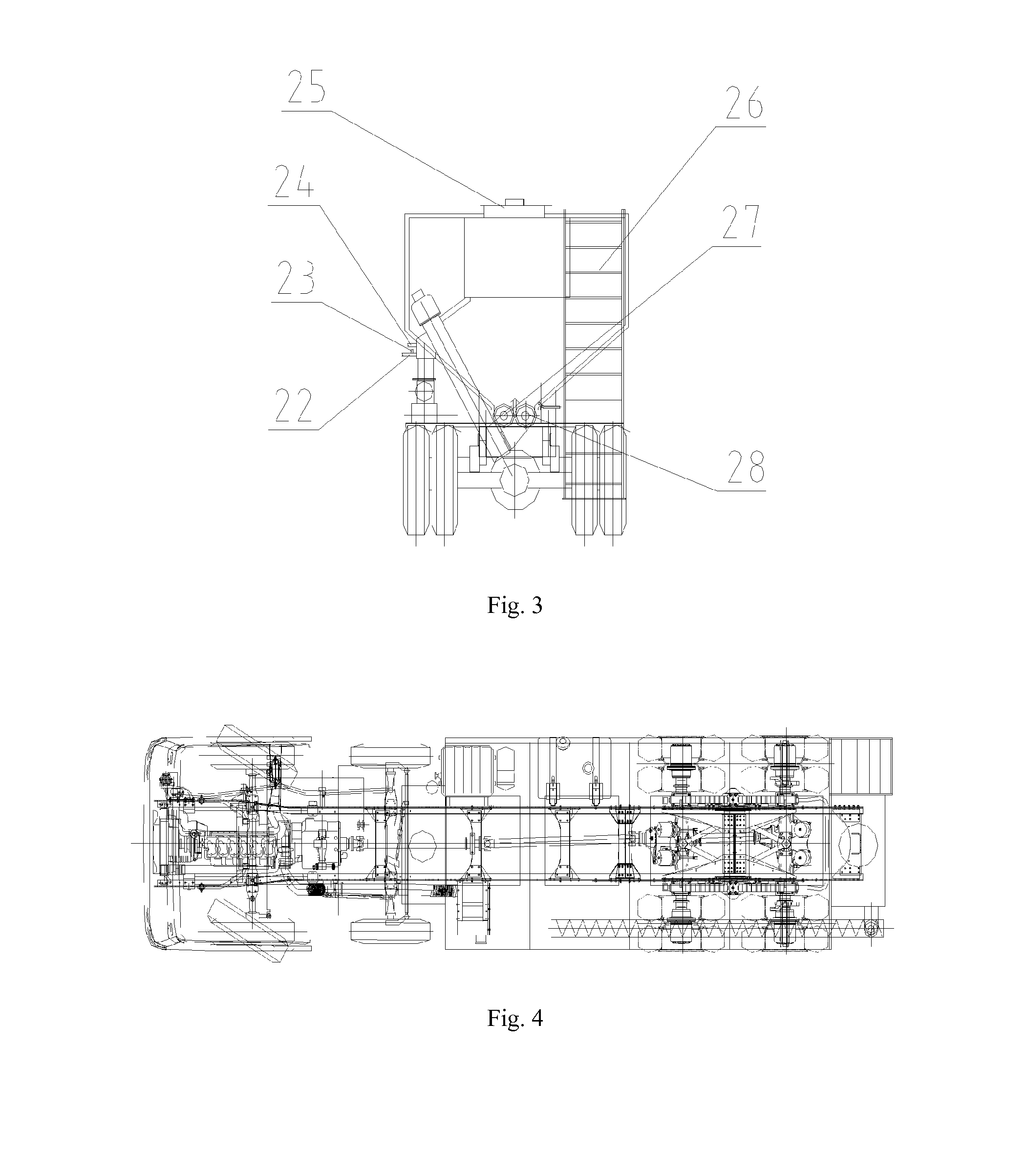

Site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities

ActiveUS20150003186A1Low densityOvercomes shortcomingControlling ratio of multiple fluid flowsTank vehiclesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

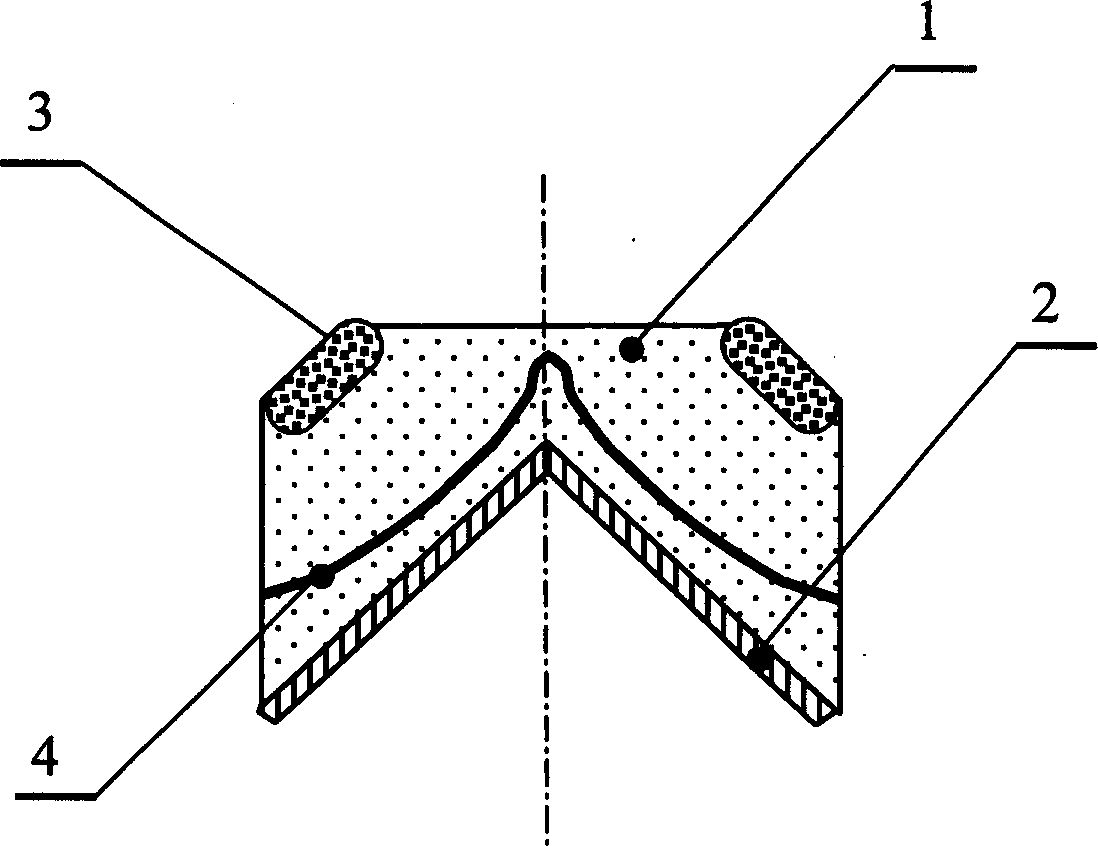

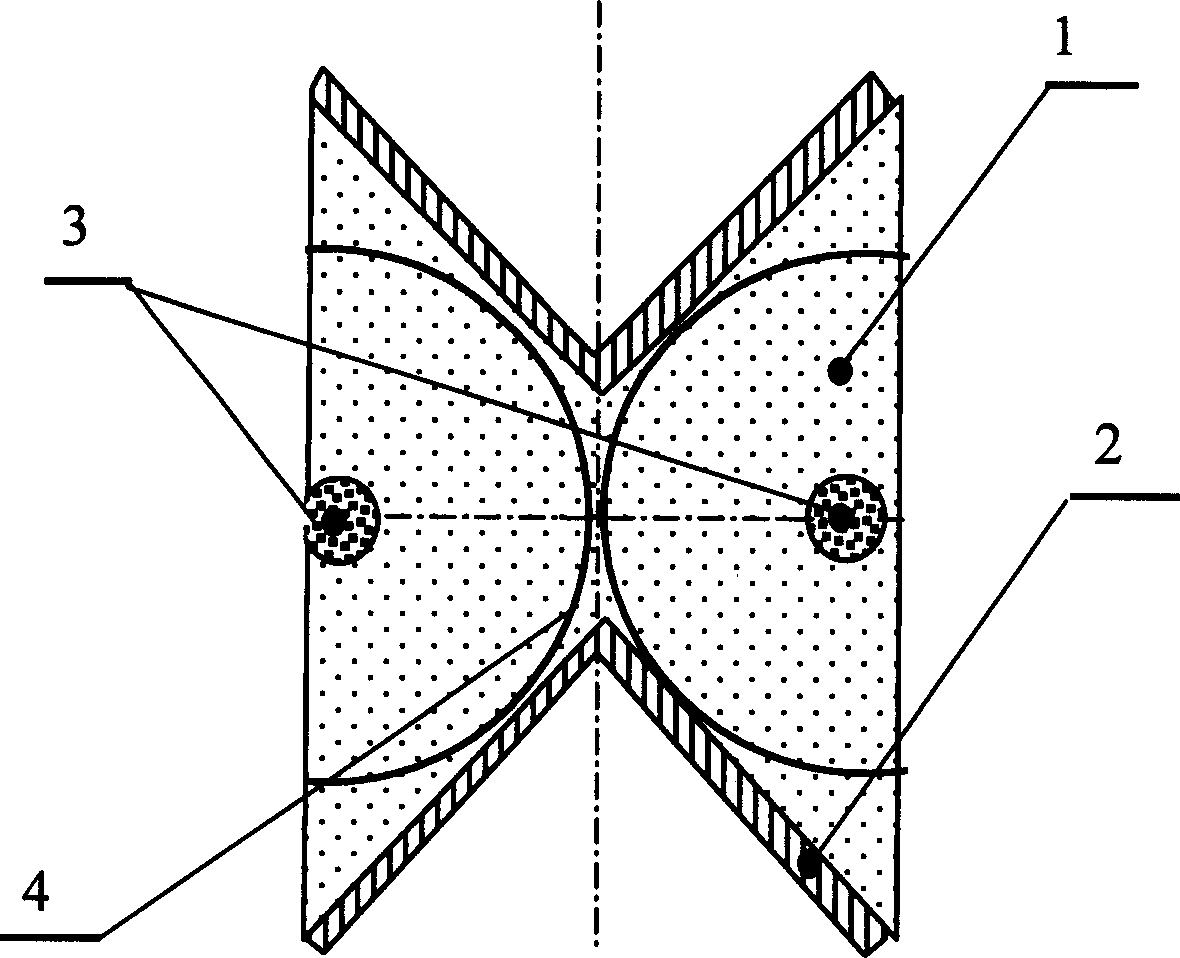

Industrial explosive energy focusing linear type cutter

Low-cost low explosive is used in the invention as main explosive. Two bars of high explosive are used to drive detonation of main explosive. Using dual energy collection effect of detonation wave collected and shaped charge generates strong concourse gas or metal jet flow. Advantages are: enhancing cutting power of low industrial explosive, and possible to reach cutting power of high explosive; main explosive in low cost and safe in use for double face cutter in presplitting, smooth blasting and cutting rock. Detonation direction of main explosive is back to protected face of rock so as to protect face of rock to be reserved.

Owner:DALIAN UNIV OF TECH

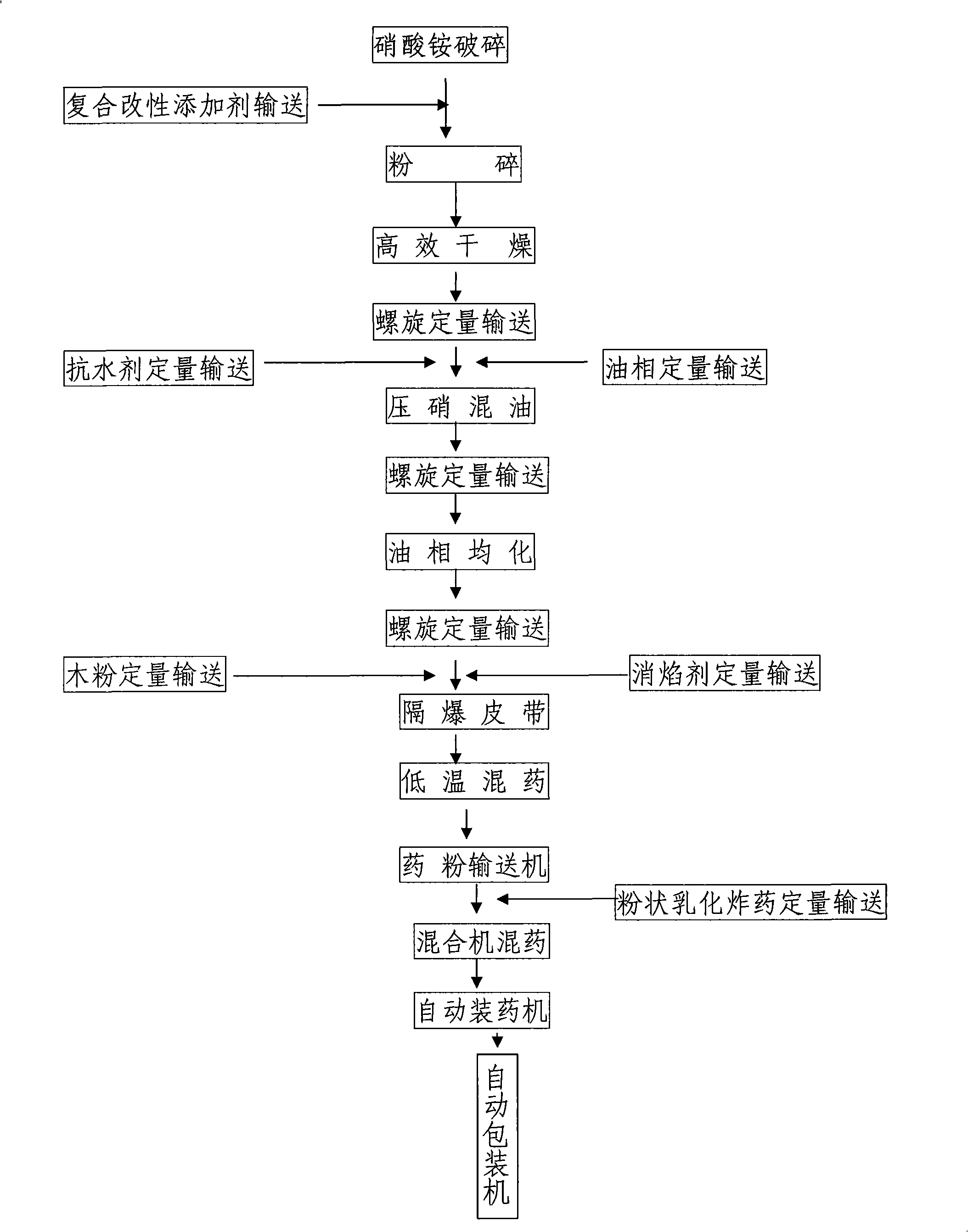

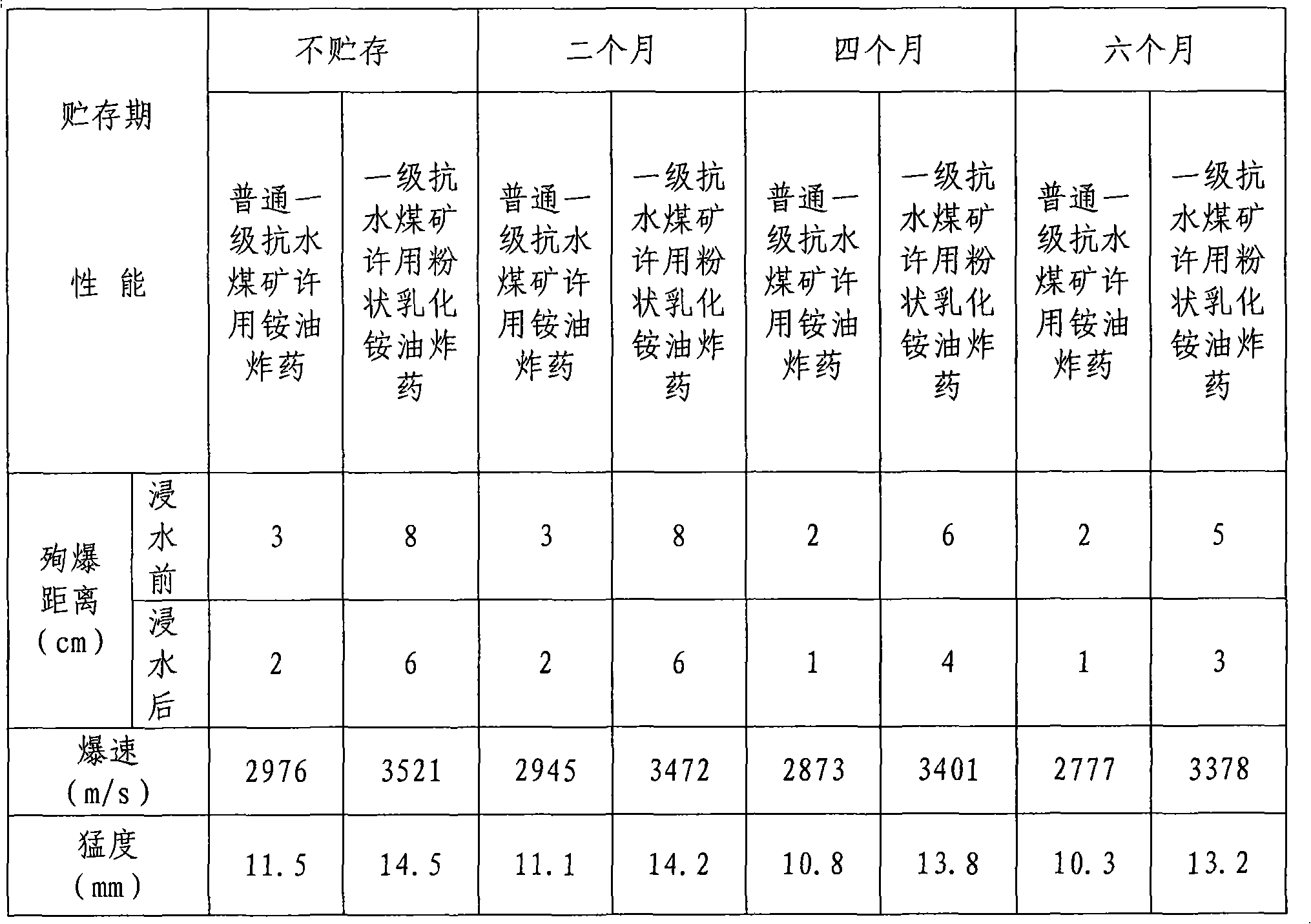

Coal mine admissible powdery emulsifying ammonium nitrate fuel explosive and preparing process thereof

ActiveCN101323552AGood explosive performanceGood storage stabilityExplosive working-up apparatusEmulsion explosiveFuel oil

The invention discloses a powdery emulsion ammonium nitrate fuel oil explosive allowed to be used in coal mines and a preparation technology thereof, which is compounded and prepared by using rock powdery emulsion explosive which has good characteristics of high sensitivity to initiation, high detonation velocity and high explosive grading, to mix with ammonium nitrate fuel oil explosive containing a certain amount of flame inhibitor, wherein, the rock powdery emulsion explosive accounts for 28 percent to 32 percent of the total weight of the explosive and the fire-resistant ammonium nitrate fuel oil explosive accounts for 68 percent to 72 percent of the total weight of the explosive. The rock powdery emulsion explosive is an industrial explosive like powder formed from water-in-oil type latex base material which is sprayed and dried. The rock powdery emulsion explosive can be mixed into ordinary ammonium nitrate fuel oil explosive to replace trinitrotoluene and plays a sensitization role in the explosive to increase the explosive performance of compound explosive. The grade I and the grade II explosive prescriptions of the invention are respectively applicable to the excavating working faces of low-methane rock or low-methane coal beds and mines and the preparation technology thereof is applicable to the discontinuous or continuous automatic production of the powdery emulsion ammonium nitrate fuel oil explosive used in the coal mines.

Owner:LIAONING HONGSHAN CHEM

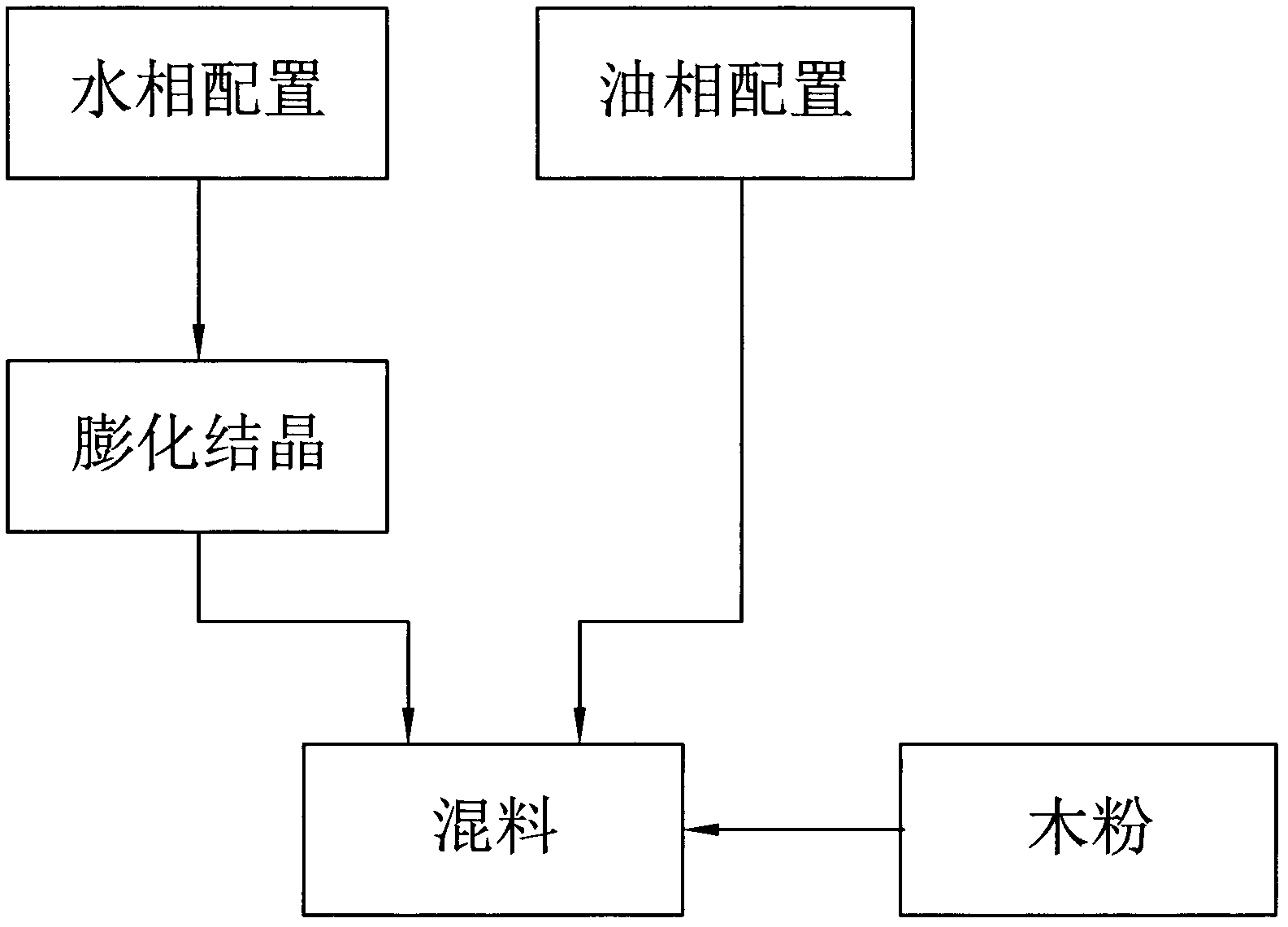

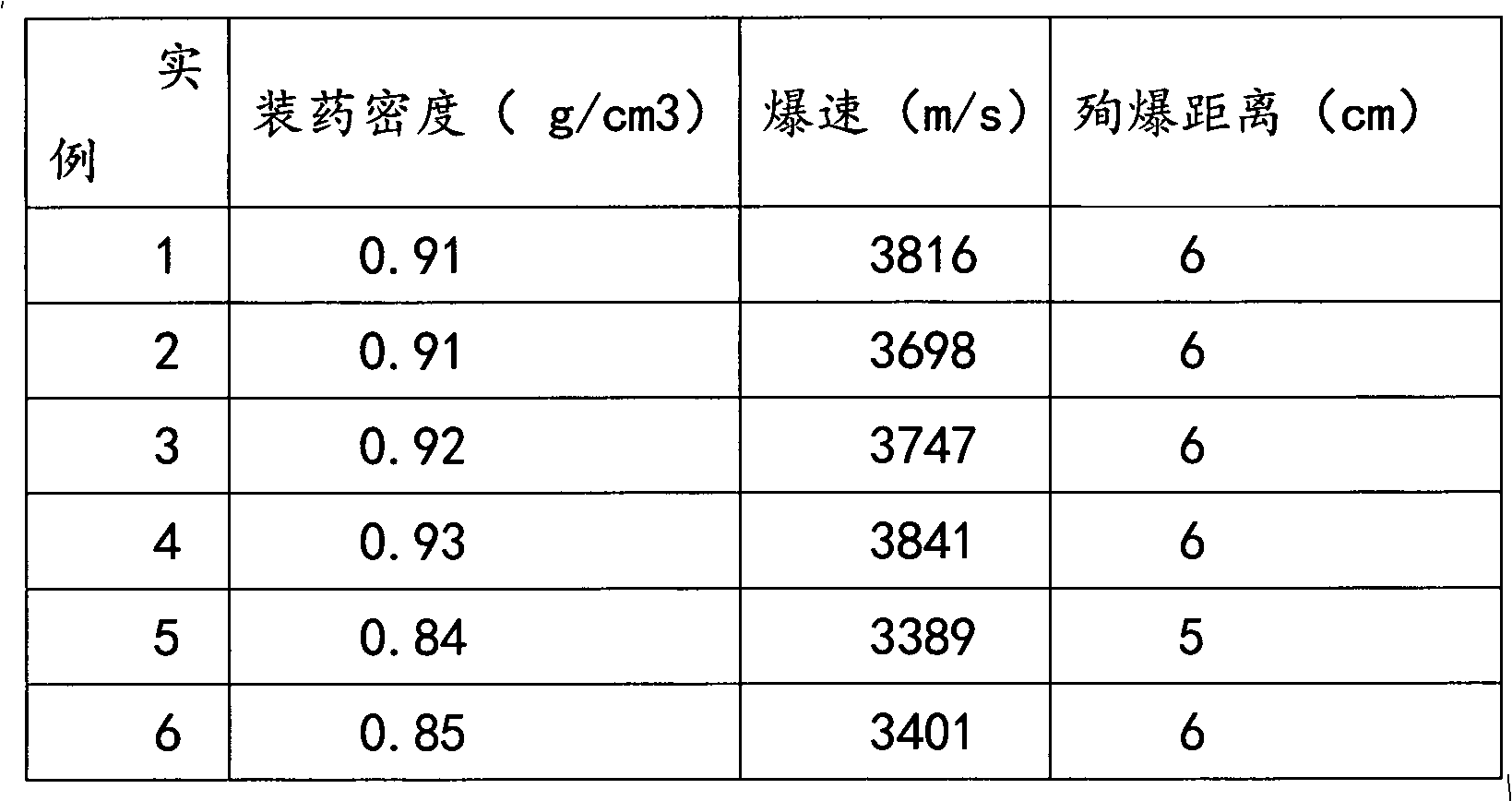

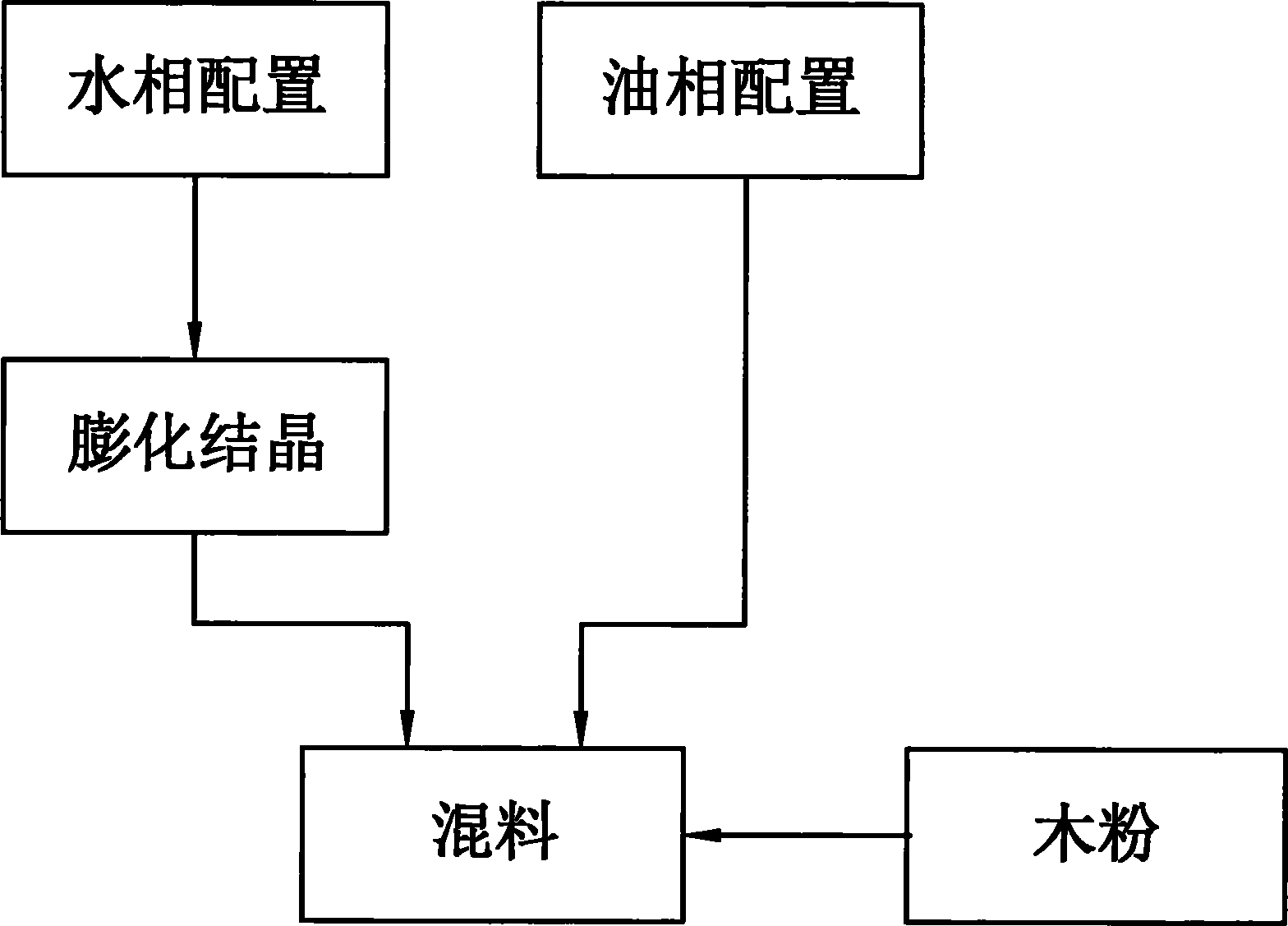

Modified expanded ammonium nitrate explosive and preparation method thereof

The invention relates to a modified expanded ammonium nitrate explosive and a preparation method thereof. The explosive comprises the following main components by weight percent: 85%-93% of ammonium nitrate, 3%-5% of composite oil phase, 0.05%-0.15% of expanding agent and 3%-5% of wood flour; and the explosive also contains 8.9% or less of ammonium nitrate expansion and crystallization modifier. In the production process, a defined amount of ammonium nitrate expansion and crystallization modifier is added to prepare the aqueous phase. Therefore, the aims of reducing the raw material cost and the processing energy consumption can be realized and the performances of the product are much higher than that of the prior art, especially the charge density and explosion velocity are obviously increased. the technical weaknesses of the prior art such as low charge density, poor explosion property and high charge cost can be solved.

Owner:广东南虹化工有限公司

Emulsified powder-like explosive

InactiveCN101024594ALow detonation velocityLow costExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsionDiluent

The invention relates to an emulsion powder explosive that has low detonation velocity. The feature is that it has 80-95 portions emulsion powder explosive, 5-20 portions diluents agent, and 0-10 portions density regulator. It could gain emulsion powder explosive that has 2000-2800m / s low detonation velocity, and density at 0.5-1.0g / cm3. The invention could lower the cost to 10-15% and has no adverse effect to explosive.

Owner:宜兴市阳生化工有限公司

Water gel explosive with low detonation velocity for mining and method for producing same

InactiveCN1884231AAvoid destructionHigh melting pointExplosive working-up apparatusNon-explosive/non-thermic compositionsPolystyreneMethylamine nitrate

The invention discloses a low-exploding slurry explosive and preparing method, which comprises the following parts: 15-30% ammonium nitrate solution, 22-32% methylamine nitrate solution, 8-15% sodium nitrate, 0.8-0.9% sesban powder, 12-15% calcium carbonate, 0.7-3.4% hydrophobic pearlite, 0.3-0.6% polystyrene plastic ball, 0.2-0.4% cross linker and 18-30% composite water resistance grain-sized ammonium nitrate. The preparing method comprises the following steps: preparing ammonium nitrate solution and composite water resistance grain-sized ammonium nitrate (the grain size is 3-5 mm); adding ammonium nitrate solution, methylamine nitrate solution, sodium nitrate, sesban powder, calcium carbonate, hydrophobic pearlite, polystyrene plastic ball, cross linker and composite water resistance grain-sized ammonium nitrate in the mixing tank; blending evenly; loading.

Owner:ANHUI UNIV OF SCI & TECH

Low detonation velocity powdery emulsifying explosive

ActiveCN101423448ALow detonation velocityQuality assuranceExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsion explosiveUltimate tensile strength

The invention relates to a powdery emulsion explosive with low detonation velocity. A rock powdery emulsion explosive, talcum powder and coarse bran are placed into a mixer for fullly stirring to ensure that the mixture is mixed evenly and then is packaged and sold, wherein the bulk density of the rock powdery emulsion explosive is between 0.58 and 0.62 / g.cm<-3>, the detonation velocity is between 3,500 and 3,700 / m.s<-1>, the brisance is between 15 and 17 / mm, the sympathetic detonation is between 9 and 11 / cm, the capacity for work is 360 / ml, and the storage period is 6 months; the bulk density of the talcum powder is between 0.95 and 1.0 / g.cm<-3>, and the grain diameter is 300 meshes; and the bulk density of the coarse bran is between 0.28 and 0.35 / g.cm<-3>, and the grain diameter is between 0.8 and 1mmr. In the invention, the powdery emulsion explosive with low detonation velocity is applied to double metal explosive welding first, which ensures the quality of explosive welding of double metal explosive composite welding and ensures that the double metal explosive welding fully meets the requirement. The powdery emulsion explosive is safe, also has no pollution after the explosion, and has no harm to the health of blasters. The storage period of the powdery emulsion explosive with low detonation velocity can reach more than 180 days, so the powdery emulsion explosive can be mixed by manufacturers without field mixed-making and the labor intensity of the blasters is reduced.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

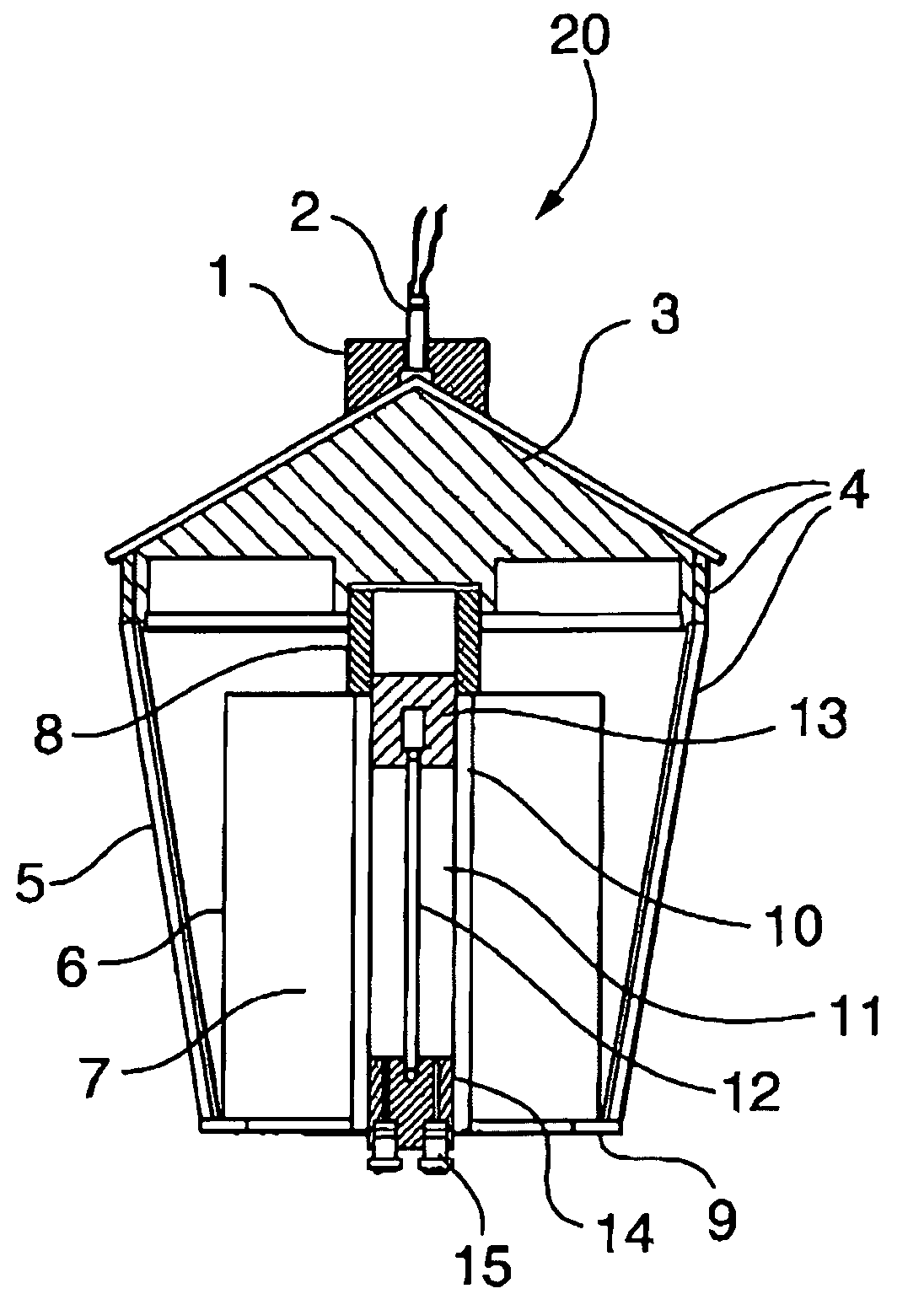

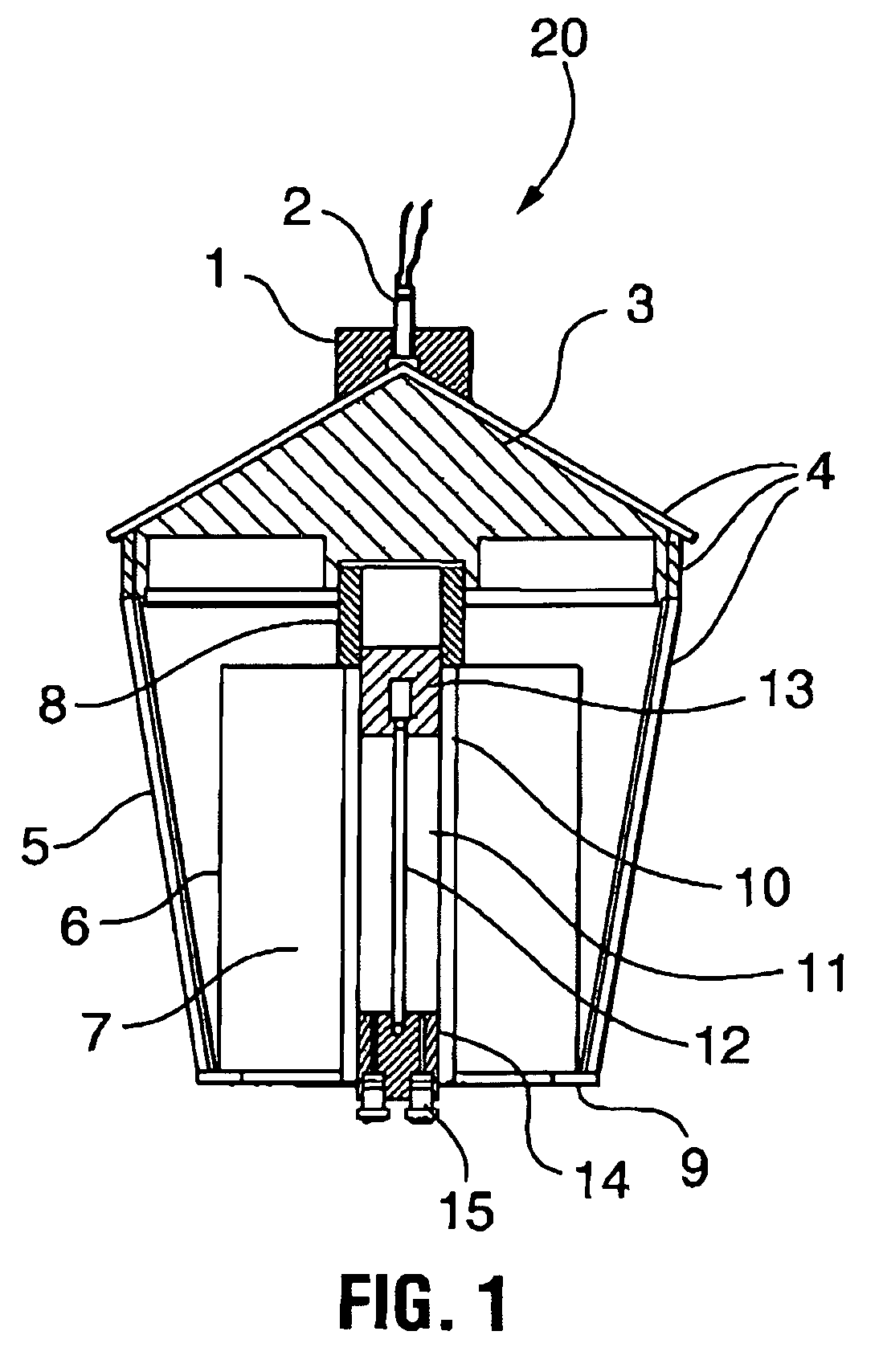

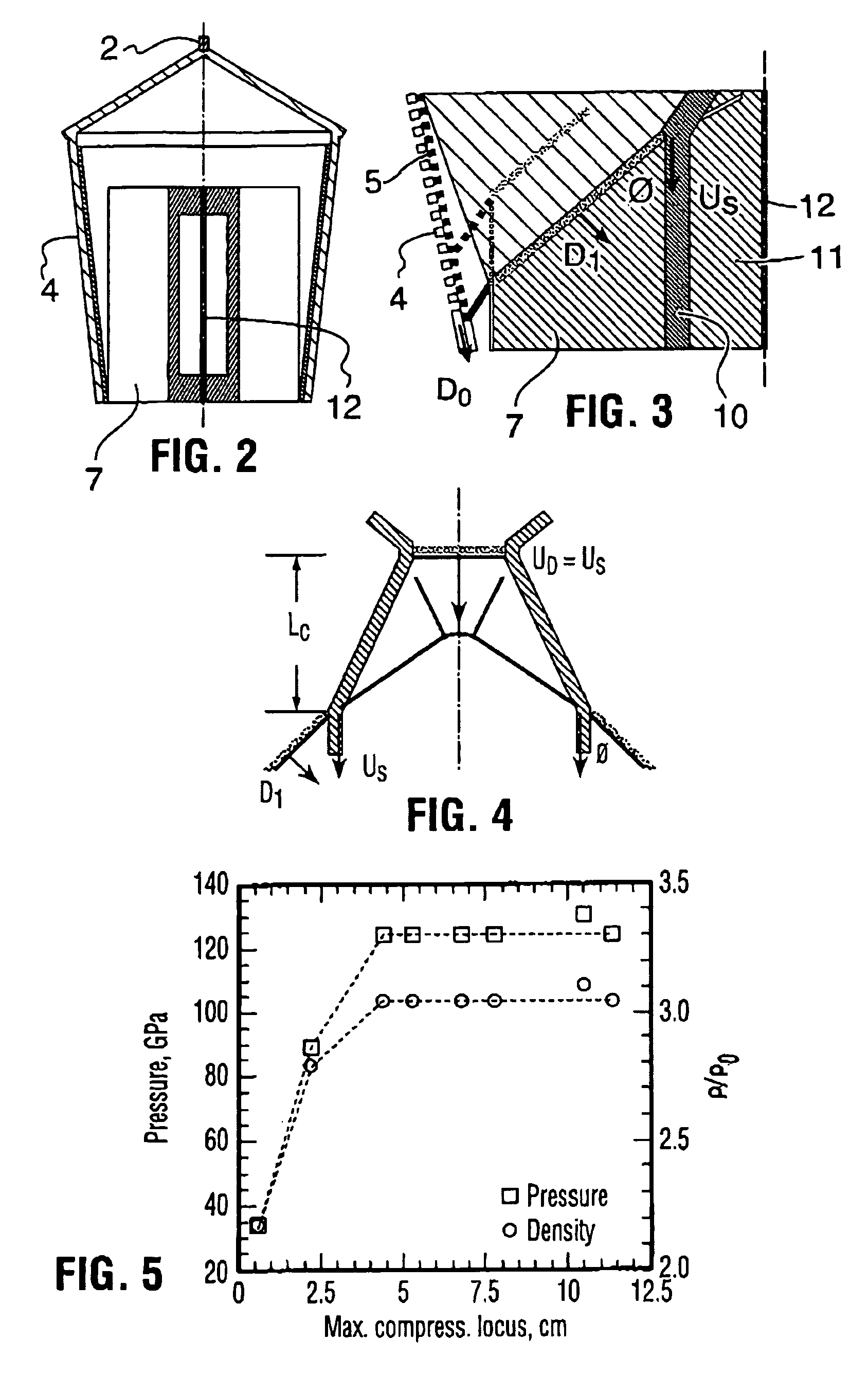

Super compressed detonation method and device to effect such detonation

ActiveUS7513198B2Improve propertiesHigh energyExplosive chargesAmmunition projectilesShock waveDelayed time

A method and apparatus are provided for detonation of a super-compressed insensitive energetic material by cylindrical implosion followed by an axial detonation to a detonation velocity several times that of TNT and a detonation pressure in excess of ten times that of TNT. The device provides a conical metal flyer shell within which is disposed a cylindrical anvil surrounded by explosive. The anvil retains an insensitive energetic material to be compressed and detonated. A first detonation of explosive by impact of the flyer shell generates a reverberating oblique shock wave system for sample compression. Axial detonation of the compressed sample through any length of a sample is achieved following the principal of matching the axial velocity and compression time of the oblique shock wave system to the detonation velocity and induction delay time of the compressed sample. The method and apparatus are also applicable to enhancing the effect of anti-armour and anti-hard-target munitions. The apparatus is also applicable to inert sample compression to the megabar range without using the axial detonation.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

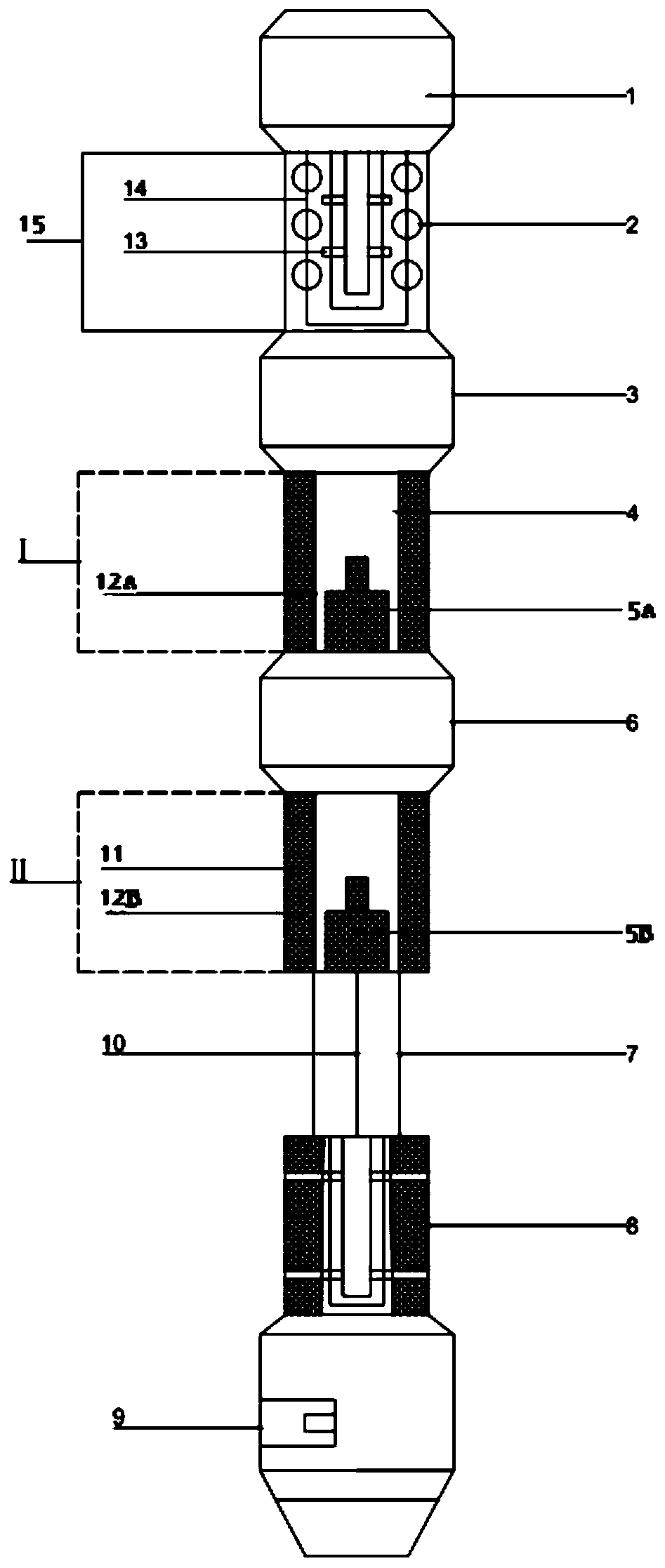

Multi-pulse combined fracturing device for perforation of coalbed methane reservoir

PendingCN109915080AOrderly and rapid extensionAchieve security isolationFluid removalEngineeringDeflagration

The invention relates to a multi-pulse combined fracturing device for perforation of coalbed methane reservoir, comprising a percussion initiator; the lower part of the percussion initiator is connected with a perforating barrel; the perforating barrel is internally provided with a frame type ammunition rack, and perforating bullets are loaded on the frame type ammunition rack; the perforating bullets are isolated from low-explosive-velocity liquid explosive by means of capsules, so that the low-explosive-velocity liquid explosive can be safely detonated; the lower part of the composite perforator is connected with a detonation convertor, the lower part of the detonation convertor is connected with a first-stage propulsion device, a central aluminum pipe is positioned in the center of thefirst-stage propulsion device, the lower part of the central aluminum pipe is connected with a delay ignition device, and the lower part of the delay ignition device is connected with a second-stage propulsion device; when the temperature of the outer wall of the central aluminum pipe reaches the ignition point of a propellant, a great deal of high-temperature and high-pressure gas produced by thepropellant acts on the coalbeds in a pulse loading way, thus enabling cracks to rapidly extend; the lower part of the second-stage propulsion device is connected with a connecting rod, a detonating cord is arranged in the connecting rod, the lower part of the connecting rod is connected with a perforator, and the perforator is connected with a pressure measurement tail plug, so that the deflagration pressure change of gunpowder in a fracturing process is reflected; the multi-pulse combined fracturing device has the advantages of treating the multiple coalbeds at a time, and being high in energy utilization rate and cost-saving.

Owner:XI'AN PETROLEUM UNIVERSITY

Low-detonation velocity anfo explosive and preparation method thereof

The invention relates to a low-detonation velocity anfo explosive and a preparation method thereof. The low-detonation velocity anfo explosive comprises 77-88 parts of modified powdery anfo explosive, 10-20 parts of porous granulated ammonium nitrate and 2-3 parts of polystyrene foam plastic microballoon, wherein the modified powdery anfo explosive mainly comprises 74.54-84.66 parts of crystallized ammonium nitrate, 0.15-0.26 part of modifying agent and 2.31-3.08 parts of compound oil phase; and the compound oil phase comprises 1.71-2.12 parts of paraffin, 0.58-0.86 part of rosin and 0.02-0.06 part of Span 80 emulsifying agent. The preparation method comprises the following steps of: mixing the crystallized ammonium nitrate and the modifying agent, crushing and drying; and then mixing with the compound oil phase; finally adding the porous granulated ammonium nitrate and the polystyrene foam plastic microballoon and uniformly mixing to obtain the low-detonation velocity anfo explosive with the density less than 0.55g / cm<3> and the detonation speed less than 2,600m / s. The explosive has the advantages of favorable particle flowability, convenience for filling into a blast hole, low detonation velocity, low density and capability of meeting the requirements for using the explosive on smooth surface blasting and presplitting blasting of mines, highways, railways and open-air deep-hole slopes.

Owner:HUAINAN SHUNTAI CHEM

Locale vehicle made emulsification blasting agent underwater demolition

The invention relates to a field vehicle-made emulsion explosive suitable for underwater blasting, belonging to a technical field for preparing the emulsion explosive. The emulsion explosive is mainly prepared by applying water-phase materials of ammonium nitrate, sodium nitrate and perchlorate water; oil-phase materials of emulsifier and diesel oil; density modifier of glass or plastic hollow bead; and dry powder of coarse aluminum powder and fine aluminum powder. Compared with traditional emulsion explosive, the field vehicle-made emulsion explosive of the invention has the advantages of high detonation velocity, big power and good water-resistant performance; the emulsion explosive is beneficial to solve the problem that the existing emulsion explosive is unsuitable for underwater blasting; the emulsion explosive has high application value in a large-scale underwater blasting project.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD +1

Low detonation velocity powdery emulsion explosive for explosive welding

The invention discloses a low detonation velocity powdery emulsion explosive for explosive welding, which is prepared by mixing the following components by weight percentage: 60-85% of powdery emulsion explosive and 15-40% of at least one of talcum powder and expanded perlite. Water content of the talcum powder is not greater than 0.5wt% and content of the talcum powder with fineness of 40 meshes is 70-85wt%. Water content of the expanded perlite is not greater than 0.5wt% and bulk density of the expanded perlite is 40-60kg / m<3>. Density of the low detonation velocity powdery emulsion explosive for explosive welding is 0.6-0.85g / cm<3>. The low detonation velocity powdery emulsion explosive for explosive welding has the advantages of easy production, stable performance, greater brisance and good explosive welding effect.

Owner:ANHUI XIANGKE CHEM IND CO LTD

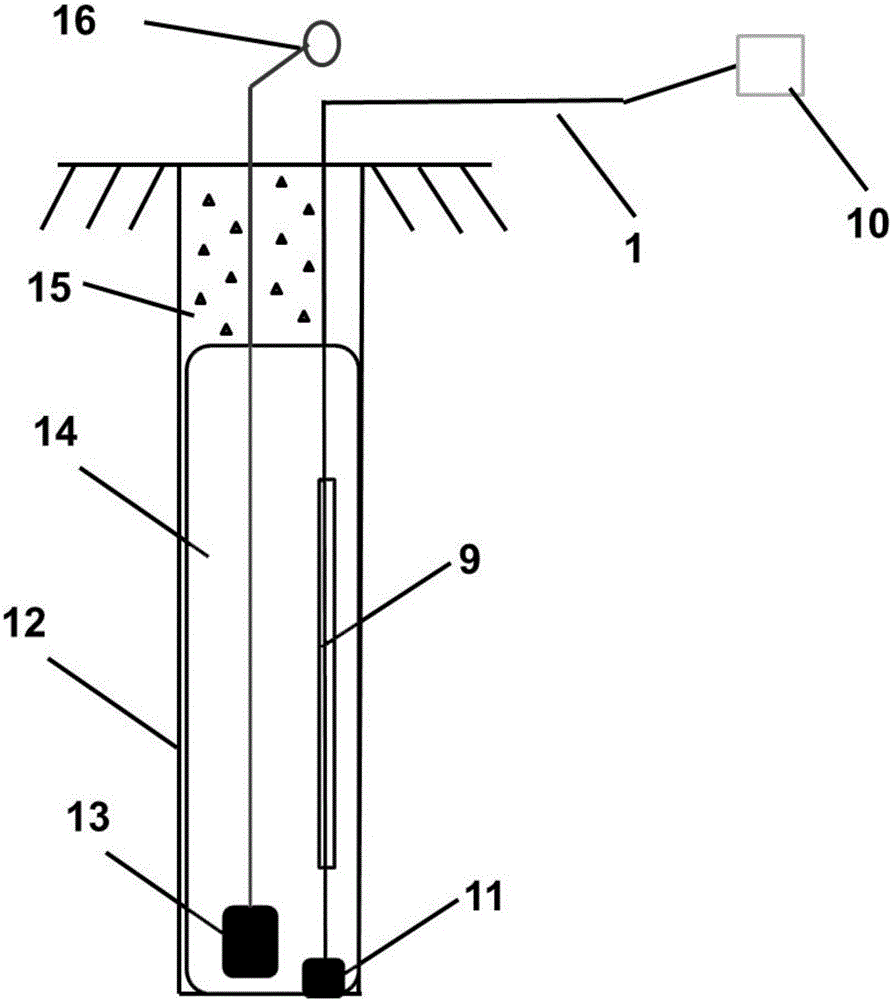

System and method for fast measuring explosive velocity during deep hole blasting on site

ActiveCN105866464ADetonation gainEasy to processFuel testingDevices using time traversedFast measurementClassical mechanics

The invention discloses a system and method for fast measuring explosive velocity during deep hole blasting on site. The system comprises an explosive velocity detecting device, a priming device, explosive and stemming which are placed in a blast hole, one end of the explosive velocity detecting device is connected with a multi-section explosive velocity instrument, the other end of the explosive velocity detecting device is connected with a balance weight, the multi-section explosive velocity instrument is placed in a safe region outside the blast hole, and the balance weight is placed at the bottom of the blast hole and pulled straightly; the distance between the priming device and the bottom of the blast hole is smaller than that between the explosive velocity detecting device and the bottom of the blast hole, the explosive velocity detecting device, the balance weight and the priming device are embedded in the explosive, and the stemming is located on the explosive. The phenomenon that an ionized layer is generated in the explosion reaction process of the explosive, explosive velocity detecting probes embedded in the explosive are connected and changed into the connected state from the disconnected state, a triggering electric signal is emitted out, and the distance between the two adjacent explosive velocity detecting probes is divided by time difference of the corresponding triggering signal to obtain explosive velocity of the explosive in the blast hole.

Owner:HONGDA MINING IND

Special low-detonation velocity explosive for explosive welding

InactiveCN104072322AHigh intensityHigh detonation velocityNon-explosive/non-thermic compositionsPrillEmulsion explosive

The invention relates to a special low-detonation velocity explosive for explosive welding, and the special low-detonation velocity explosive comprises the following components in percentage by weight: 55-65% of powdery emulsion explosive, and 34-45% of calcium carbonate particles; the powdery emulsion explosive is no.2 powdery emulsion explosive; the fineness of the calcium carbonate particles is 80-120meshes; the moisture of the calcium carbonate particles is not higher than 0.5wt%; the 55-65% of powdery emulsion explosive and 34-45% of calcium carbonate particles are evenly mixed. By adding and evenly mixing the powdery emulsion explosive with calcium carbonate particles, the explosive is higher in explosive grading, stable to detonate, within the range of explosion combination expection for the explosive velocity, easy to produce, uniform in mixing of all components, good in flow property, moderate in density, convenient to store and transport, and capable of meeting the demands of various metal composite materials on explosive welding technology. The special low-detonation velocity explosive can be widely popularized and applied to all explosive welding production enterprises.

Owner:HUBEI JINLAN SPECIAL METAL MATERIAL

High-density high-explosion-speed water gel explosive seismic charge and preparation method thereof

Owner:淮北矿业控股股份有限公司 +1

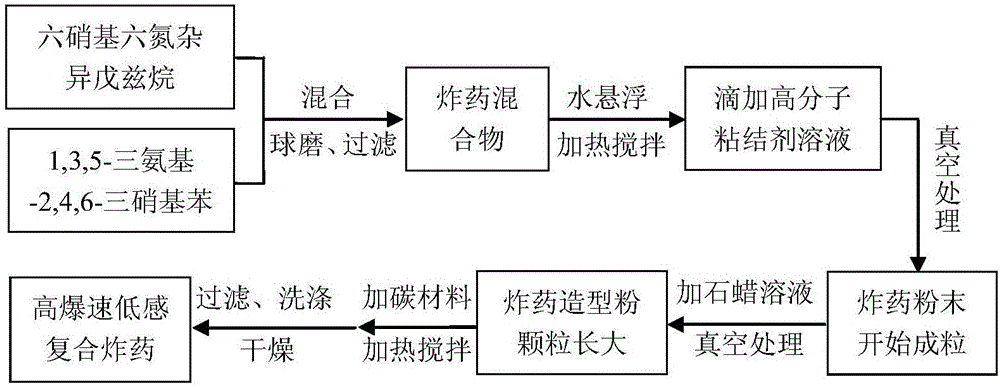

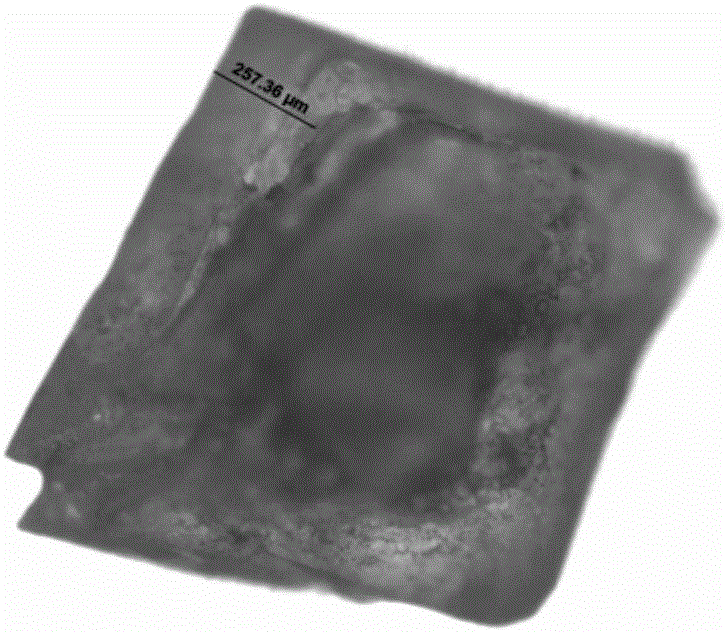

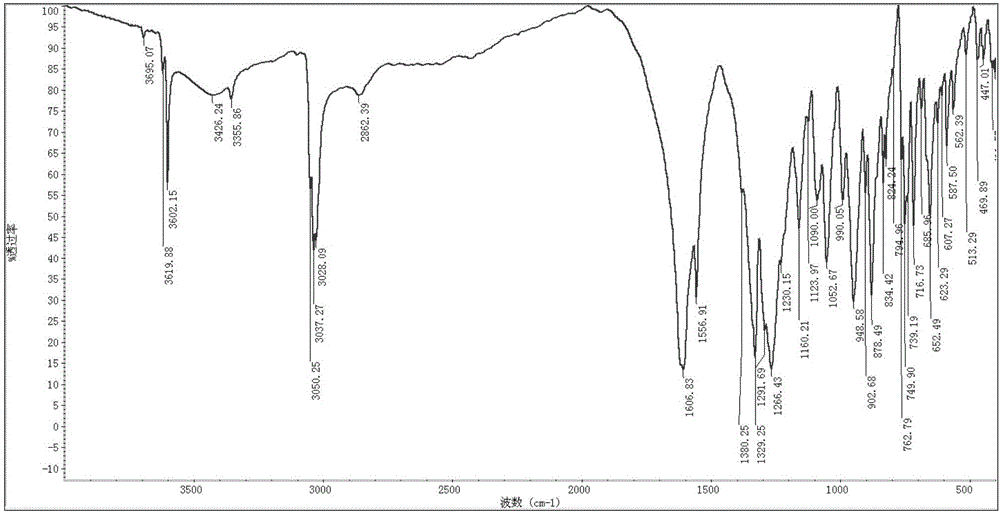

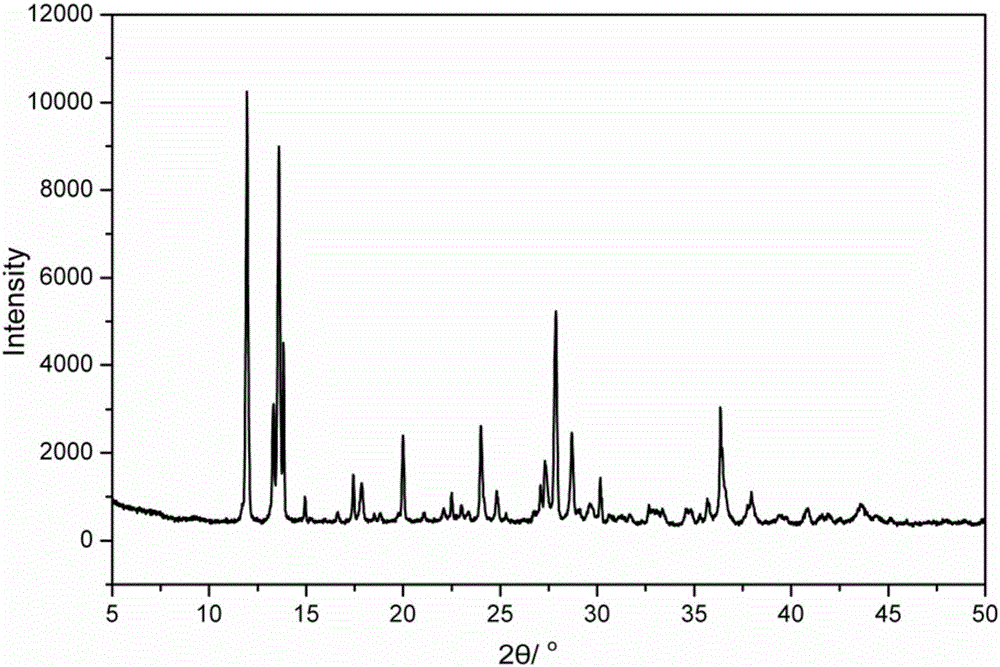

High-detonation-velocity low-sensitivity composite explosive and preparation method thereof

InactiveCN106220458ASolve the technical problem of high mechanical sensitivityLow impact sensitivityExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityAdhesive

The invention discloses a high-detonation-velocity low-sensitivity composite explosive and a preparation method thereof. The preparation method comprises the following steps: weighing hexanitro-hexaaza-isopentaisowurtzitane and 1,3,5-triamino-2,4,6-trinitrobenzene, adding deionized water, a surfactant and zirconium oxide milling balls, carrying out mechanical ball milling by using a planetary ball mill, filtering, washing with deionized water, and drying to obtain an explosive mixture; adding deionized water into the explosive mixture, stirring, heating, dropwisely adding a high-polymer adhesive solution, and carrying out vacuum treatment; dropwisely adding a paraffin solution while keeping heating, stirring and vacuum treatment; and adding a carbon material, stirring, filtering the material, carrying out deionized washing, and drying to obtain the high-detonation-velocity low-sensitivity composite explosive. The high-detonation-velocity low-sensitivity composite explosive can effectively implement the explosive detonation velocity of up to 9000 m / s or above, and the impact sensitivity and friction sensitivity are respectively less than 10%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Subjective-objective explosive with high crystal density and preparation method of subjective-objective explosive

ActiveCN106831278AImprove thermal stabilityAchieve stabilizationNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingCell cavityHydroxylamine

The invention discloses a preparation method of a subjective-objective explosive with high crystal density. The preparation method comprises the following steps: respectively preparing a fresh hydroxylamine solution and a CL-20 explosive solution, mixing the two solutions, oversaturating the solutions by using a recrystallization technique, driving cocrystallization of CL-20 with hydroxylamine, thereby obtaining the subjective-objective explosive crystal which is highly ordered in molecular accumulation, is periodically arranged and prepared through cocrystallization of CL-20 with hydroxylamine. The invention further discloses the subjective-objective explosive with high crystal density. The molecular ratio of the subjective-objective explosive with high crystal density is 2:1, the hydroxylamine is embedded into unit cell cavities of CL-20, then the crystal density of the explosive can be up to 2.0g.cm<-1> or greater, relatively good thermal stability can be achieved, and meanwhile stable preparation of the hydroxylamine is achieved. The subjective-objective explosive prepared by using the preparation method has the potential of increasing air release quantity, increasing the detonation velocity and the detonation pressure and improving comprehensive properties of explosives, and has wide application prospects in advanced weapon payloads and rocket propellants.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

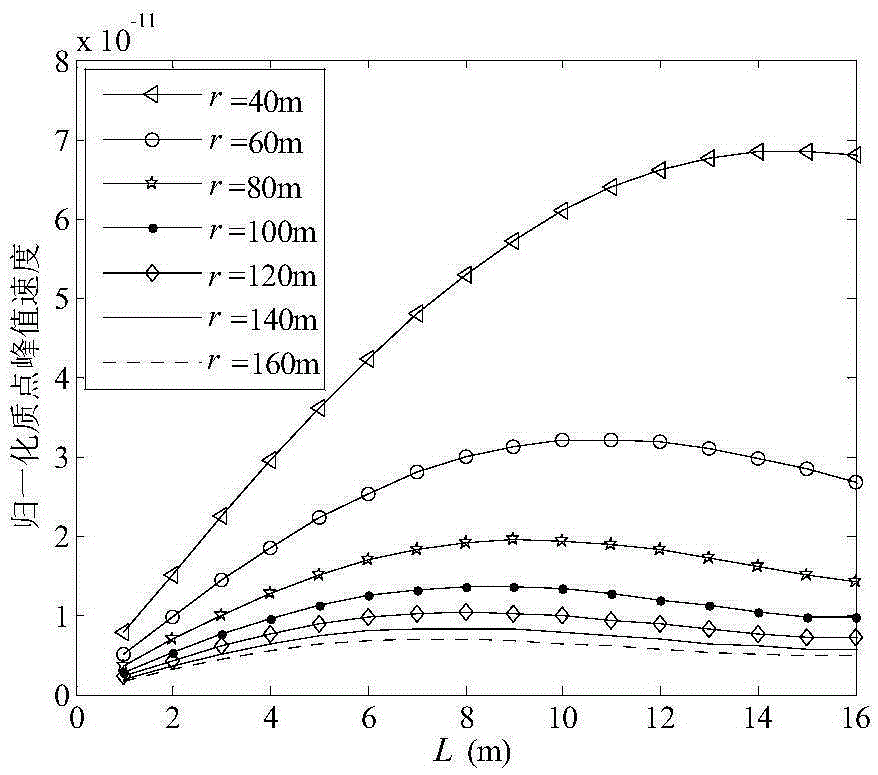

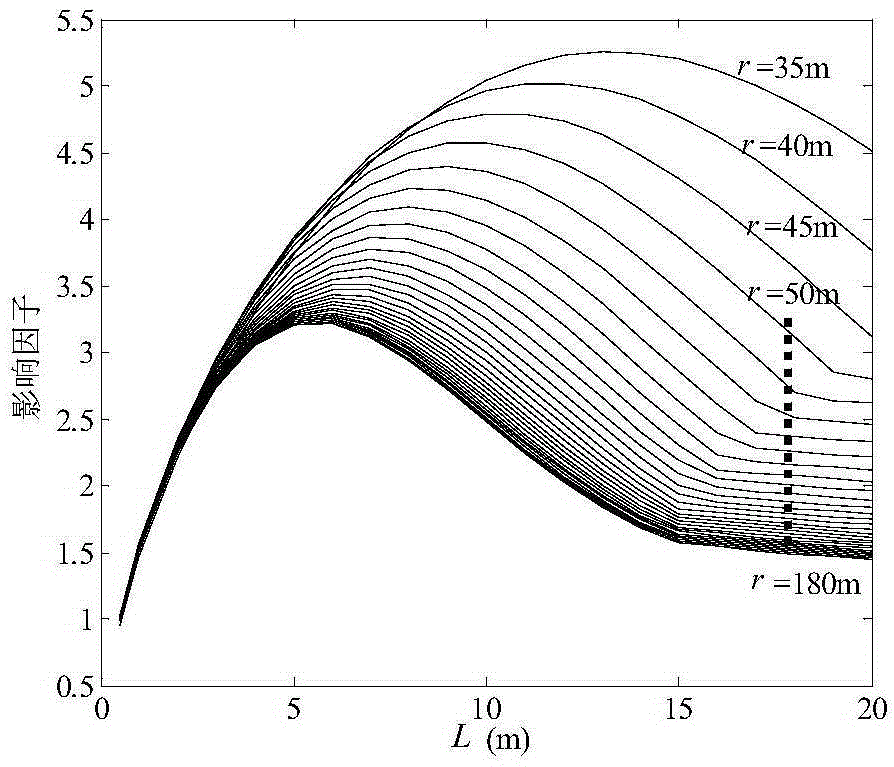

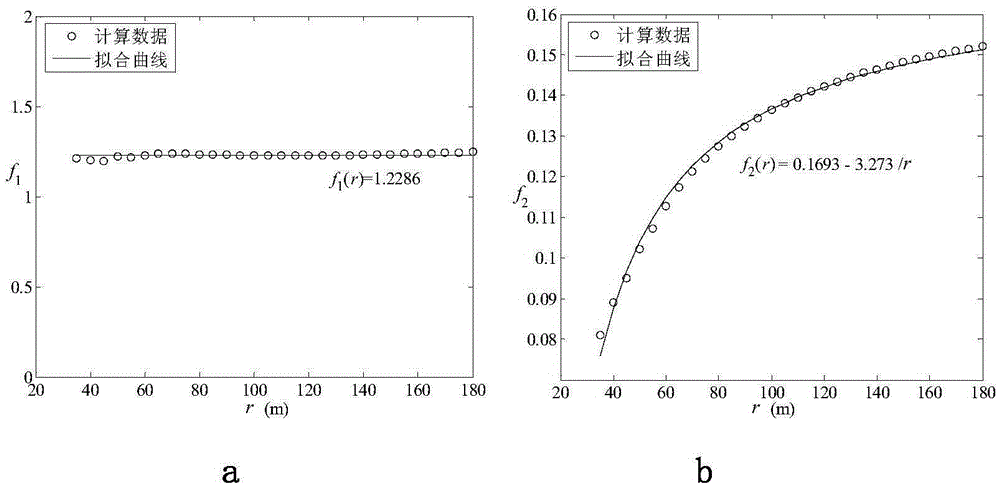

Prediction method for peak particle vibration velocity of column charge blasting

ActiveCN105389415AFacilitate discussionDescribe wellGeometric CADSpecial data processing applicationsPredictive methodsPeak value

The invention discloses a prediction method for peak particle vibration velocity of column charge blasting. On the basis of existing spherical charge blasting vibration theory and stress wave superposition principle, axial detonation velocity influence of charge blasting is considered; a column charge is decomposed into a short column charge with the axial length of d; blasting vibration characteristics of the short column charge are mainly obtained through an Heelan solution; a theoretical solution of blasting vibration of a long column charge is compared with a Sadaovsk formula; and a length influence factor of the charge is introduced in the Sadaovsk formula to calculate the peak particle vibration velocity of column charge blasting. According to the method, the influence of the charge length in column charge blasting on the peak particle vibration velocity is considered, an attenuation relationship of the peak velocity along with a horizontal distance is given out, and the prediction and control of column charge blasting vibration can be realized; and corresponding charge length capable of maximizing the peak particle velocity can be obtained through a calculation model, so that the column charge blasting design can be subjected to peak velocity safety evaluation.

Owner:HUAQIAO UNIVERSITY

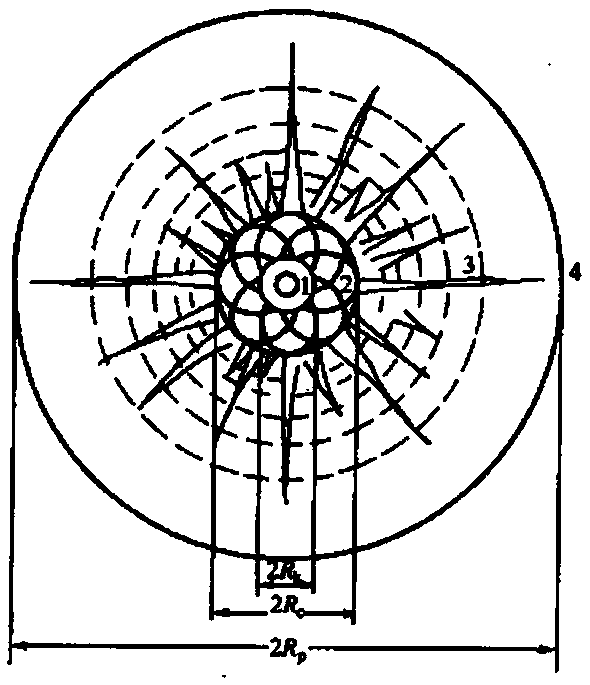

Method for determining blasting action area of cylindrical charge in rock

The invention discloses a method for determining a blasting action area of a cylindrical charge in rocks. The method comprises the following steps: according to the characteristic data of the following rocks and explosives before and after the cylindrical charge is exploded in rocks, namely the radius of a blast hole, the compressive strength of the rocks, the tensile strength of the rocks, the density of the rocks, the density of the explosives, the detonation velocity of the explosives, the longitudinal wave velocity and the Poisson's ratio of the rocks, bringing the above characteristic data into the formula I-1, formula I-2, formula I-3, calculating to obtain the blasting action area of the cylindrical charge in rocks, namely the radius of an enlarged cavity, the radius of a crushing area and the radius of a rupture area, which are respectively marked as r1, r2 and r3. According to the method, the enlarged cavity, the crushing area and the rupture area with rock mass destruction characteristics can be obtained through a model of a single column-shaped charge acting area in rocks. The compound structure is shown in the description.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Explosive detonation velocity test method

ActiveCN104764899ASimple and fast operationHigh measurement accuracyDevices using time traversedEngineeringTime difference

An explosive detonation velocity test method accurately measures the explosive detonation velocity by using a detonating module, a time measurement module, a signal conversion device, a detonating component, a detonation transmission cap and detonating tubes. The explosive detonation velocity test method is characterized in that the detonating module, the time measurement module and the signal conversion device are sequentially connected with one another, and the detonating module denotes the first detonating tube and the second detonating tube simultaneously, wherein an explosive volume to be tested connects the second detonating tube and the third detonating tube through the detonating component and the detonation transmission cap; the time measurement module records time, and the explosive detonation velocity can be obtained according to the length of the explosive volume and a time difference. The explosive detonation velocity test method has the advantages that the operation is simple and convenient, the measurement accuracy is high, and the explosive detonation velocity test method is capable of being applied to measuring the detonation velocity at a construction site and making up for defects of an existing method.

Owner:铜陵雷鸣双狮化工有限责任公司

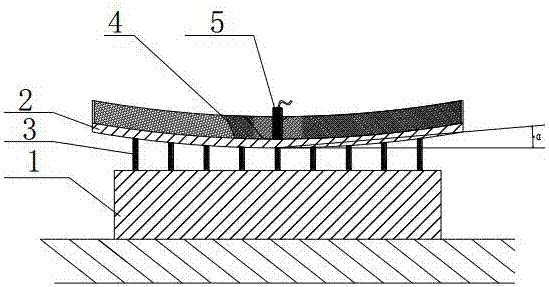

Large-area composite plate explosive welding production process

InactiveCN106964892AAvoid bulgingAvoid disjointWelding/soldering/cutting articlesMetal working apparatusDetonatorComposite plate

The invention discloses a large-area composite plate explosive welding production process. The process includes the following steps of (1), splice welding, annealing and leveling, specifically, a composite plate is subjected to splice welding, a base plate is subjected to annealing, and the base plate and the composite plate are subjected to leveling correspondingly; (2) polishing; (3), coating of a protection layer, specifically, the surface of the composite plate obtained in step (2) is manually coated with the protection layer, wherein the thickness of the protection layer is 0.5-1.5 mm; (4), arrangement of clearance columns, specifically, the composite plate is placed on the base plate, a plurality of clearance columns are arranged between the composite plate and the base plate, and the installation angle alpha between the clearance columns arranged in the middle and the clearance columns arranged on the periphery ranges from 0.7 degrees to 2 degrees; (5) arrangement of an explosive frame, specifically, the explosive frame is arranged on the circle along the edge of the composite plate, and low-detonation-velocity explosives are uniformly distributed in the explosive frame; (6) inserting of a detonator, detonation and completing of welding; and (7), post-processing. By means of the large-area composite plate explosive welding production process, the problem that when the large-area composite plate is produced in an explosive welding manner, non-combination and the like are caused due to the fact that an air layer between the base plate and the composite plate is not discharged timely can be effectively solved.

Owner:嘉峪关天源新材料有限责任公司

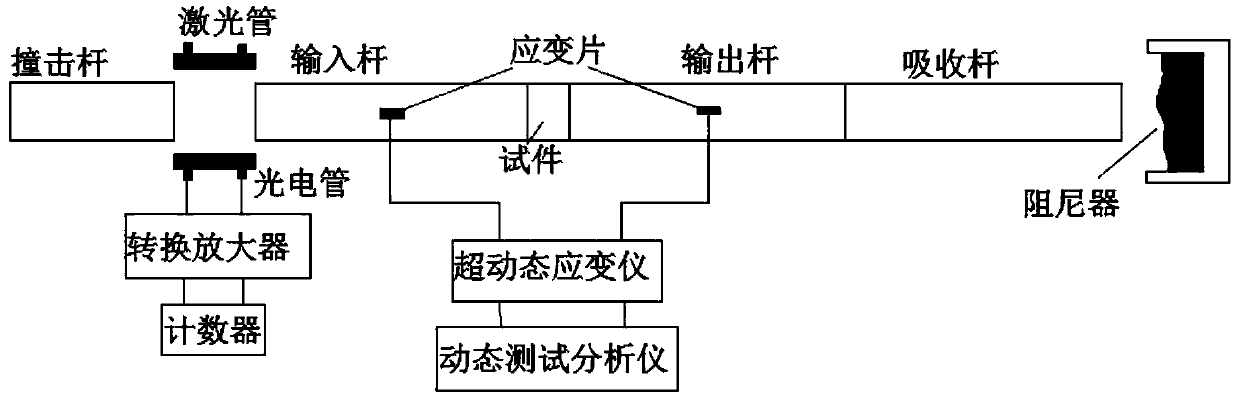

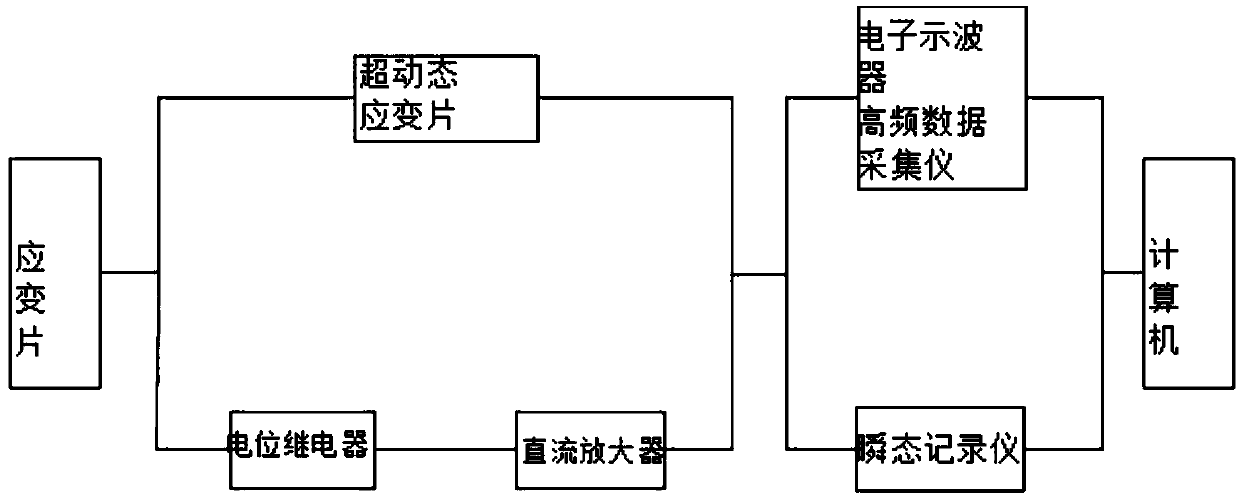

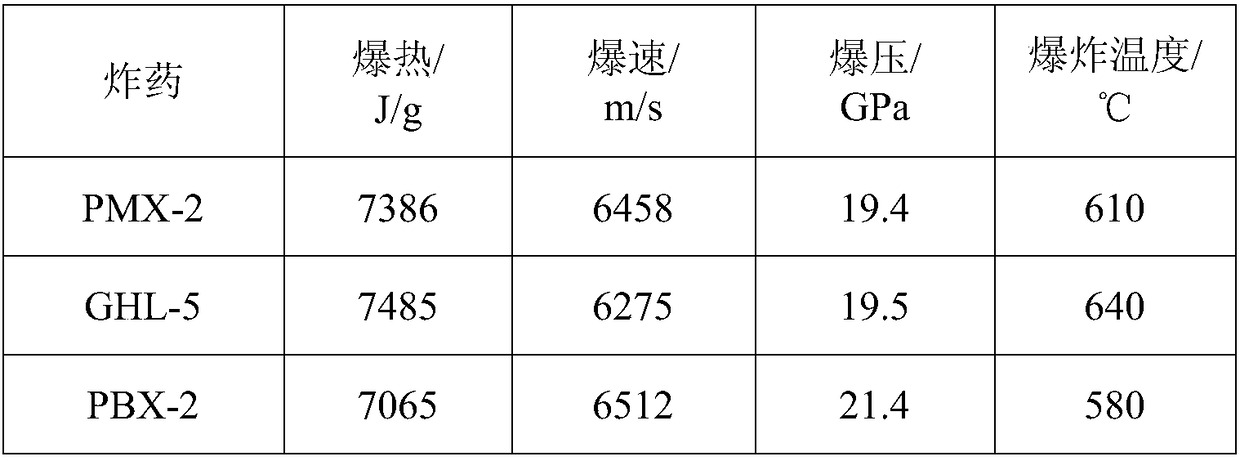

Multi-parameter synchronous measurement method for detonation performances of condensed-phase high explosives

ActiveCN108981503AShort measuring cycleImprove measurement efficiencyAmmunition testingTemperature controlEngineering

The invention discloses a multi-parameter synchronous measurement method for detonation performances of condensed-phase high explosives. In the method, a temperature sensor, an optical fiber probe anda manganese copper piezoresistance sensor are all mounted in an explosion chamber; the explosion chamber is externally provided with a heat measurement system; through once experiment, the synchronous measurement of the detonation velocity, the detonation heat, the detonation pressure and the detonation temperature of explosives is realized; a grain is mounted in an inert shell; the optical fiberprobe is mounted in a positioning hole of the shell; the manganese copper piezoresistance sensor is embedded in the grain; the temperature sensor is mounted in the explosion chamber; and platinum resistors are distributed in inner and outer barrels of the heat measurement system for temperature measurement and temperature control. The method is suitable for synchronous measurement of multiple detonation performance parameters of low-dose condensed-phase high explosives; and through once experiment, the detonation velocity, the detonation heat, the detonation pressure and the detonation temperature of the explosives can be measured, so that the comprehensive evaluation of the detonation performances of the explosives is achieved.

Owner:XIAN MODERN CHEM RES INST

Gel type emulsion explosive and preparation thereof

InactiveCN101328099AImprove intrinsic safetyImprove securityExplosive working-up apparatusLow speedEmulsion explosive

The invention discloses a gel-type emulsion explosive and a method for preparing the same. The explosive is prepared by 75%-86% of ammonium nitrate, 4%-7% of emulsifier-compound grease, 0.5%-4% of crystal modifier and water balance, different models of coal permissible products are prepared by adding 3%-7% of flame reducer into the explosive. When preparation, the ammonium nitrate, crystal modifier, water and flame reducer are mixed, heated and dissolved to form an oxidant water solution as an aqueous phase solution, the emulsifier-compound grease is heated to form a combustible agent solution as an oil phase solution, the aqueous phase solution and oil phase solution are pumped into an open type emulsifier for emulsification after accurate measurement and are sensitized to finished products in a low speed mixing device by means of a belt device. The explosive energy of the product can be released to a maximum extent, the density can reach 1.4g / cm<3>, the explosion strength can reach 360ml and the detonation velocity can reach 6500m / s.

Owner:耿一平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com