System and method for fast measuring explosive velocity during deep hole blasting on site

A technology of deep hole blasting and detonation velocity, which is applied in the direction of measuring the time required to move a certain distance, measuring device, fuel test, etc., and can solve problems such as extinguishment and detonation velocity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

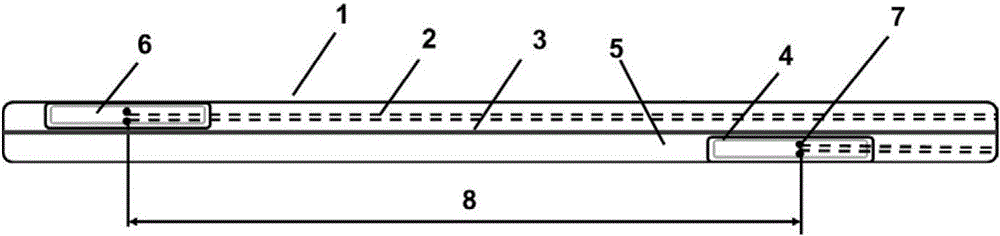

[0037] To quickly measure the detonation velocity of explosives in deep hole blasting on site, it is first necessary to make figure 1 The detonation velocity detection device shown is processed by a network cable 1. The network cable 1 includes four sets of twisted thin wires 2, a cross 3, a shielding layer 4 and a sheath 5. The cross 3 is arranged on In the center of the network cable 1, the four groups of thin wires 2 twisted into a twisted shape are evenly distributed on the cross 3, and the shielding layer 4 wraps the cross 3 and the four groups of thin wires 2 twisted into a twisted shape. The sheath 5 is wrapped on the outside of the shielding layer 4; wherein, each set of twisted thin wires 2 has two, the shielding layer 4 is an aluminum foil shielding layer, and the sheath 5 is a polyvinyl chloride sheath.

[0038]When the detonation speed detection device is being processed, first cut a gap 6 in the sheath 5 of the network cable 1 with a utility knife at a distance of...

Embodiment 2

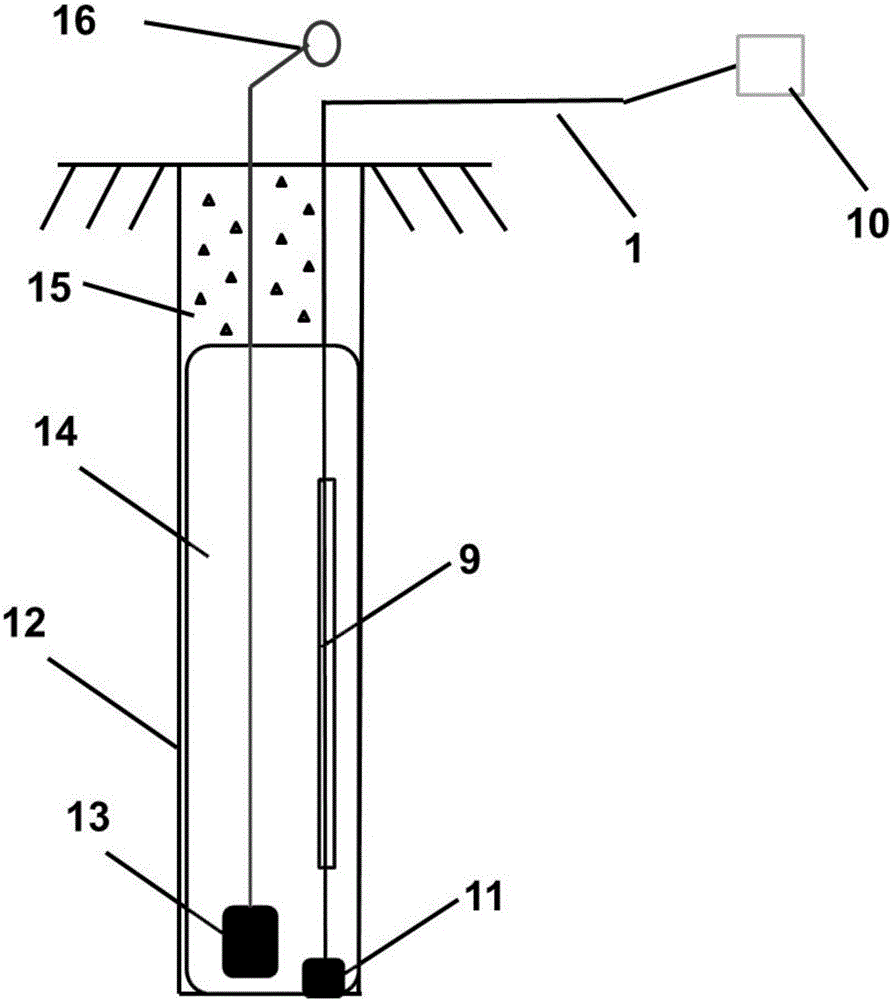

[0042] The system for quickly measuring the detonation velocity of explosives during deep hole blasting in this embodiment uses four sets of twisted thin wires in the network cable to quickly and conveniently process the detonation velocity test probe in the hole, that is, each group of thin wires is cut in the middle to form The detonation velocity test probe in the disconnected state can process four sets of detonation velocity test probes in total. The ionosphere generated during the explosion reaction of the explosive conducts the detonation velocity test probe embedded in the explosive, and changes from the disconnected state to the conductive state. , so as to send a trigger electrical signal; at the same time, use the thin wire group itself as the transmission branch line in the hole of the test signal, use the network cable itself to transmit the main line of the signal outside the hole of the test signal, use the shielding layer to shield the field stray signal, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com