High-detonation-velocity low-sensitivity composite explosive and preparation method thereof

A technology of high detonation velocity and explosives, which is applied in the direction of explosives processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., which can solve the problems of decreased energy of explosives, high mechanical sensitivity of high-energy explosives, and poor desensitization effect And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

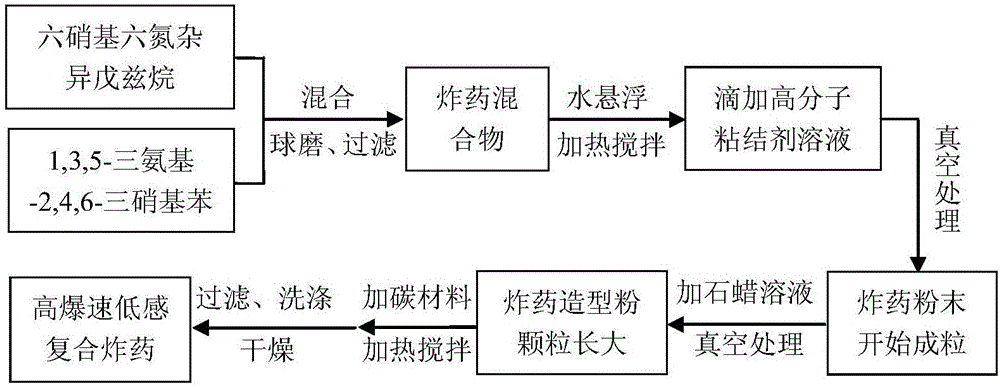

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 91g of hexanitrohexaazpentazane, 4g of 1,3,5-triamino-2,4,6-trinitrobenzene, 190g of deionized water, 0.1g of polyvinyl alcohol, add Zirconia ball milling beads were mechanically milled for 30 minutes at 150 rpm using a planetary ball mill, filtered, washed with deionized water, and dried to obtain an explosive mixture;

[0033]Step 2: Add 100 g of deionized water to the above-mentioned explosive mixture, stir at 300 rpm for 15 minutes to form an explosive suspension, heat to 50° C., and add dropwise a polymer bonding agent with a concentration of 4 wt % made of 3 g of polyurethane Agent solution, apply vacuum treatment for 15min, the vacuum degree is 300mbar, and the explosive powder begins to granulate. Then add dropwise a paraffin solution with a concentration of 8 wt % prepared from 1 g of paraffin wax, and keep heating at 50° C., stirring at 300 rpm and vacuum treatment at 300 mbar for 5 min. Add 1g of colloidal graphite, stir for 5 minutes, filter t...

Embodiment 2

[0036] Step 1: Weigh 86g of hexanitrohexaazaisopentazane, 10g of 1,3,5-triamino-2,4,6-trinitrobenzene, 190g of deionized water, polyoxyethylene sorbitan Add 0.1 g of monolaurate, add zirconia ball milling beads, use a planetary ball mill to perform mechanical ball milling at 500 rpm for 30 minutes, filter, wash with deionized water, and dry to obtain an explosive mixture;

[0037] Step 2: Add the above explosive mixture to 280g of deionized water, stir at 800rpm for 15min to form an explosive suspension, heat to 70°C, add dropwise a polymer viscous solution with a concentration of 1wt% made of 3g of ethylene-vinyl acetate copolymer. Binder solution, apply vacuum treatment for 15min, the vacuum degree is 60mbar, and the explosive powder starts to granulate. Then add dropwise a paraffin wax solution with a concentration of 4 wt% prepared by 0.5 g paraffin wax, and keep heating at 70° C., stirring at 800 rpm and vacuum treatment at 60 mbar for 5 min. Add 0.5 g of graphene, stir ...

Embodiment 3

[0040] Step 1: Weigh 180g of hexanitrohexaazisopentazane, 10g of 1,3,5-triamino-2,4,6-trinitrobenzene, 380g of deionized water, octylphenol polyoxyethylene Add 0.2 g of ether, add zirconia ball milling beads, use a planetary ball mill to perform mechanical ball milling at 400 rpm for 30 minutes, filter, wash with deionized water, and dry to obtain an explosive mixture;

[0041] Step 2: Add the above explosive mixture to 350g of deionized water, stir at 500rpm for 15min to form an explosive suspension, heat to 65°C, add dropwise a polymer solution with a concentration of 6wt% made of 4g of fluororubber, and apply vacuum treatment After 15 minutes, the vacuum degree was 240mbar, and the explosive powder began to granulate. Add dropwise a solution with a concentration of 2 wt% prepared from 1 g of paraffin, and keep heating at 65° C., stirring at 500 rpm and vacuum treatment at 240 mbar for 5 min. Add 1 g of colloidal graphite, stir for 5 minutes, filter the material, wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Detonation velocity | aaaaa | aaaaa |

| Detonation velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com