Method for preparing high-energy explosive microcapsules by in-situ polymerization of melamine resin

A high-energy explosive, in-situ polymerization technology, used in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problem of high mechanical sensitivity of high-energy explosives, and achieve the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Weigh 10 g of melamine, 16 g of 40% formaldehyde solution, 24 g of deionized water, and 0.02 g of polyvinyl alcohol to form a mixed solution, and adjust the pH value of the solution to 8-9 with triethanolamine. Heating at 75° C. with a stirring speed of 400 rpm, when the mixture becomes transparent, start timing, and react for 40 minutes to obtain a prepolymer solution.

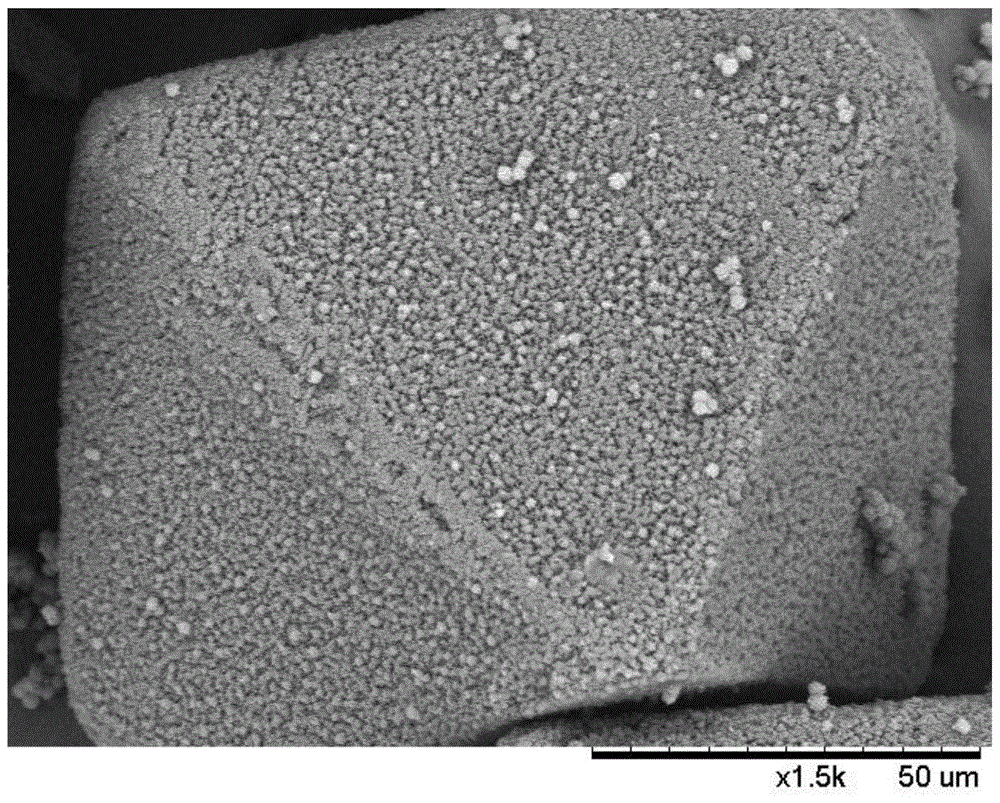

[0032] Step 2: Prepare 200g of 2wt% polyurethane Estane-5703 / 1,2-dichloroethane solution, add 20g of HMX, stir at room temperature for 30min, filter and dry the material to obtain surface-treated HMX explosive.

[0033] Step 3: Take 10g of the treated HMX explosive, add it to 20g of the prepolymer solution prepared in step 1, adjust the pH value of the emulsion to 3-4 with citric acid, control the reaction temperature to 60°C, and the stirring speed to 200rpm, and react for 3h , after filtering, washing and drying, the high-energy HMX explosive microcapsules can be obtained.

[0034] The effec...

Embodiment 2

[0036] Step 1: Weigh 10 g of melamine, 16 g of 40% formaldehyde solution, 24 g of deionized water, and 0.04 g of polyvinyl alcohol to form a mixed solution, and adjust the pH value of the solution to 8-9 with triethanolamine. Heating at 80° C. with a stirring speed of 400 rpm, when the mixture becomes transparent, start timing, and react for 60 minutes to obtain a prepolymer solution.

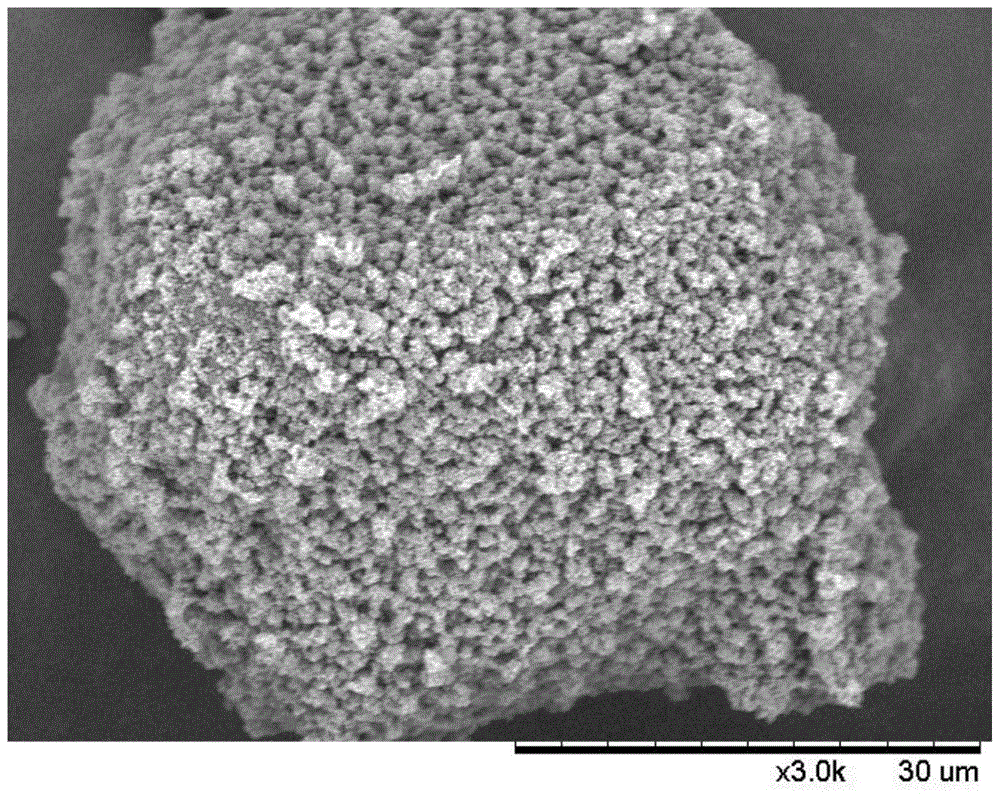

[0037] Step 2: Prepare 200 g of 1 wt % polyurethane Estane-5703 / 1,2-dichloroethane solution, add 20 g of RDX, stir at room temperature for 30 min, filter and dry the material to obtain surface-treated RDX explosive.

[0038] Step 3: Take 10g of the treated RDX explosive, add it to 30g of the prepolymer solution prepared in step 1, adjust the pH of the emulsion to 3-4 with dilute hydrochloric acid, control the reaction temperature to 70°C, and the stirring speed to 250rpm, and react for 3 hours , after filtering, washing and drying, high-energy RDX explosive microcapsules can be obtained.

[00...

Embodiment 3

[0041]Step 1: Weigh 8 g of melamine, 12 g of 40% formaldehyde solution, 24 g of deionized water, and 0.02 g of polyvinylpyrrolidone to prepare a mixed solution, and adjust the pH value of the solution to 8-9 with sodium hydroxide. Heating at 70° C. with a stirring speed of 450 rpm, when the mixture becomes transparent, start timing, and react for 100 minutes to obtain a prepolymer solution.

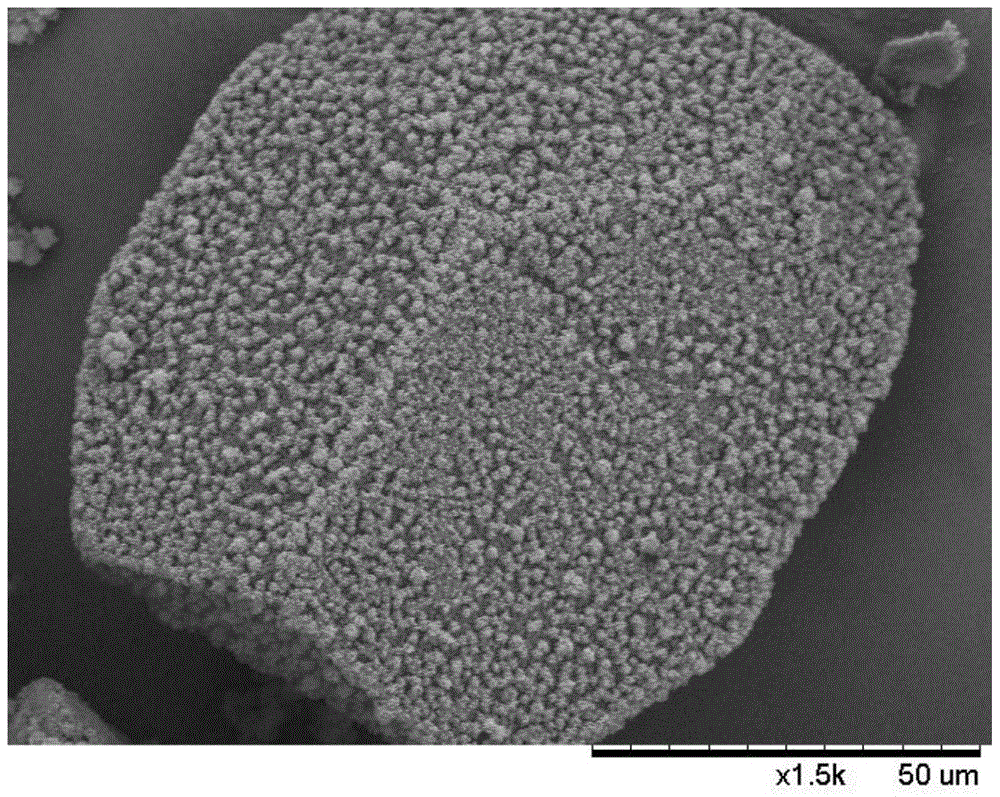

[0042] Step 2: Prepare 100g of polyurethane Estane-5703 / 1,2-dichloroethane solution with a concentration of 1.5wt%, add 10g of CL-20, stir at room temperature for 50min, filter and dry the material to obtain surface-treated CL -20 Dynamite.

[0043] Step 3: Take 5g of the treated CL-20 explosive, add it to 15g of the prepolymer solution prepared in step 1, adjust the pH value of the emulsion to 3-4 with citric acid, control the reaction temperature to 65°C, and the stirring speed to 400rpm, React for 1.5 hours, filter, wash and dry to obtain high-energy CL-20 explosive microcapsules.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com