Preparation method of bicomponent energetic material core-shell structure

A core-shell structure, two-component technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive composition, etc., can solve the problems of reduced sensitivity, weak adhesion energy and other long-range forces, and difficulty in achieving coating effects, etc. , to achieve the effect of maintaining energy level, reducing friction sensitivity and characteristic drop, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

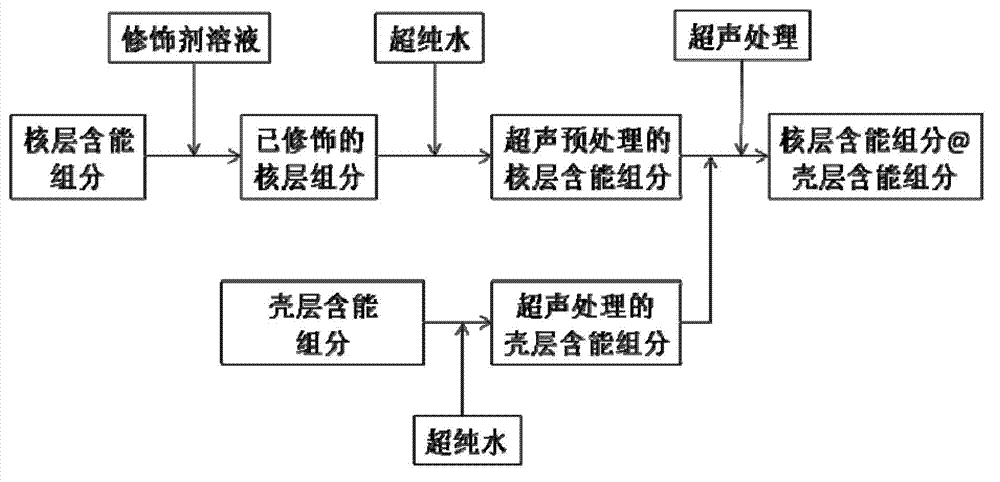

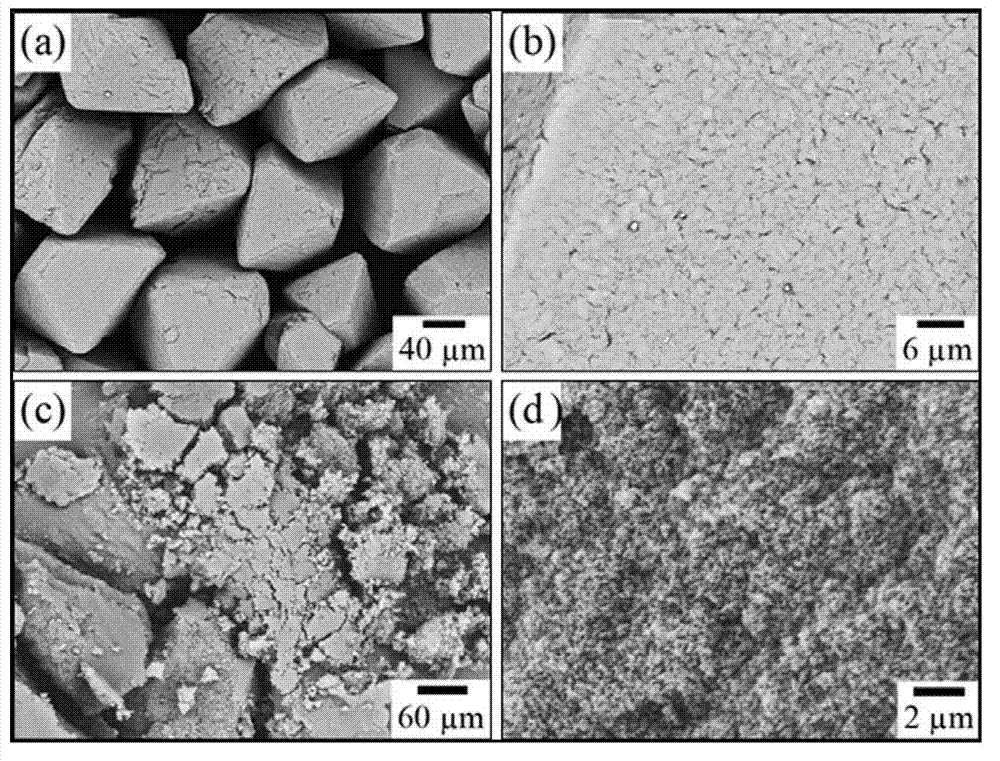

[0028] Such as figure 1 Shown, the preparation process of HMXTATB comprises the following steps in turn:

[0029] (1) At room temperature, add 20 g of HMX with a particle size of about 150 μm into 20 g of Estane’s dichloroethane solution (2% mass fraction), stir at a low speed for 30 minutes, filter, and dry for later use;

[0030] (2) Weigh 1g of the HMX obtained in step (1), add it into 20mL ultrapure water, pretreat it with an ultrasonic wave with a power of 200W and a frequency of 100KHz for 30min, and set aside;

[0031] (3) Weigh 0.18g of nano-sized TATB powder, add it into 10mL of ultrapure water, and use ultrasonic treatment with a power of 240W and a frequency of 40KHz for 30min to make it evenly dispersed;

[0032] (4) Immediately add the TATB suspension obtained in step (3) to the HMX suspension in step (2), treat it with an ultrasonic wave with a power of 200W and a frequency of 100KHz for 15min, filter, and dry to obtain HMX with a core-shell structure and TATB ...

Embodiment 2

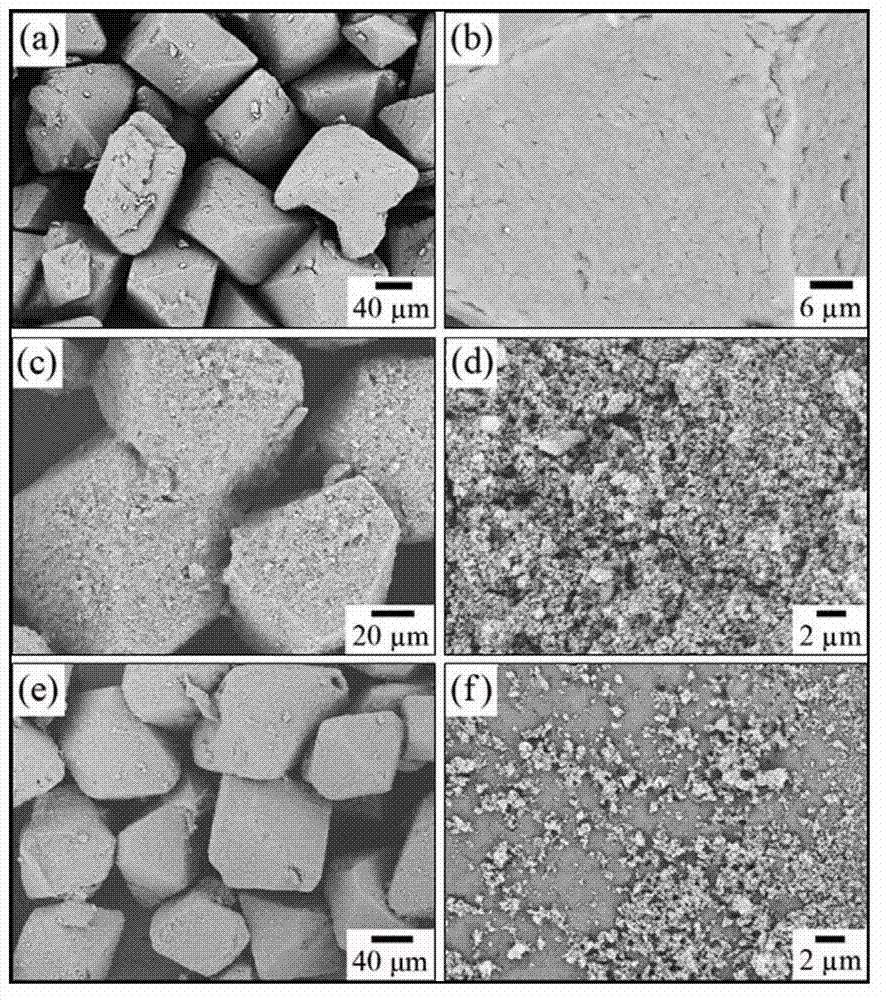

[0042] The preparation of the RDXLLM-105 core-shell structure comprises the following steps in turn:

[0043] (1) Add 20g RDX (particle size about 150μm) into 20g Estane dichloroethane solution (2% mass fraction) at room temperature, stir at low speed for 30min, filter with suction, and dry;

[0044] (2) Weigh 1g of RDX modified by Estane, add it to 20mL ultrapure water, and ultrasonicate for 30min at a power of 200W and a frequency of 100KHz;

[0045] (3) Weigh 0.18g of nanoscale LLM-105 powder, add it to 10mL of ultrapure water, and ultrasonicate for 30min at an ultrasonic power of 240W and a frequency of 40KHz to make it evenly dispersed;

[0046] (4) Add the ultrasonically dispersed LLM-105 suspension to the above-mentioned ultrasonically prepared RDX, continue ultrasonication for 15 minutes under the conditions of power of 200W and frequency of 100KHz, filter, and dry to obtain the core-shell structure of RDXLLM-105.

Embodiment 3

[0048] The preparation of the CL-20ANPZ core-shell structure comprises the following steps in turn:

[0049] (1) At room temperature, add 20g CL-20 (particle size about 150μm) into 20g Estane dichloroethane solution (mass fraction: 2%), stir at low speed for 30min, filter with suction, and dry;

[0050] (2) Weigh 1g of CL-20 modified by Estane, add it into 20mL ultrapure water, and ultrasonicate for 30min at a power of 200W and a frequency of 100KHz;

[0051] (3) Weigh 0.18g of nano-scale ANPZ powder, add it to 10mL of ultrapure water, and ultrasonicate for 30min at an ultrasonic power of 240W and a frequency of 40KHz to make it evenly dispersed;

[0052] (4) Add the ultrasonically dispersed ANPZ suspension to the above ultrasonically prepared CL-20, continue ultrasonication for 15 minutes under the conditions of 200W power and 100KHz frequency, filter, and dry to obtain the CL-20ANPZ core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com