A core-shell type composite explosive prepared by surface seed adsorption-induced growth and its preparation method

A technology of core-shell type and explosives, which is applied in the direction of explosives processing equipment, explosives, explosives composite components, etc., can solve the problems of high mechanical sensitivity of high-energy nitramine explosives, achieve controllable coating content, solve the problem of excessive mechanical sensitivity and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

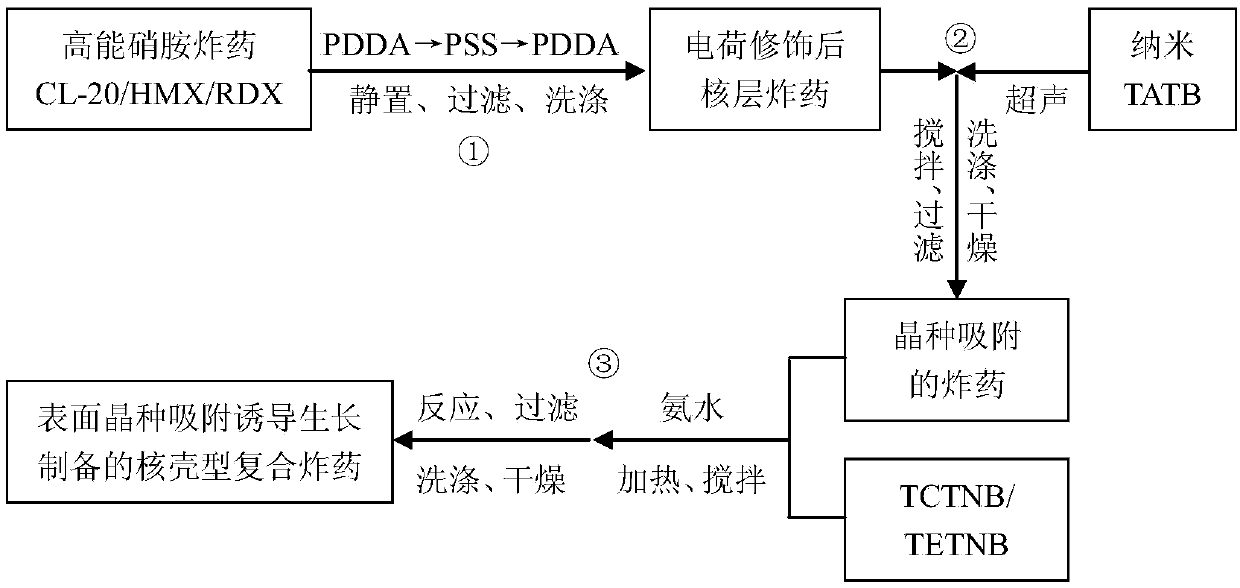

Method used

Image

Examples

Embodiment 1

[0030] Step (1): take 20g of CL-20 explosives, disperse it in 120g concentration of 0.2% PDDA solution, let stand for 1h, filter, wash with deionized water, then immerse in 120g concentration of 0.2% PSS solution, After standing for 1 hour, filtering, and washing with deionized water, immerse again in 120 g of PDDA solution with a concentration of 0.2%, let stand for 1 hour, filter, wash with deionized water, and dry to obtain a nuclear layer explosive modified by surface charge;

[0031] Step (2): Disperse 1g of nanoscale powdery TATB explosive in 100g of water, apply 100kHz ultrasonic treatment for 10min to obtain a uniform suspension, and then apply the surface charge modified nuclear layer nitramine explosive obtained in step (1) Add to the suspension, stir at 200rpm for 30min, let stand for 5min, filter the material, wash with deionized water, and dry to obtain the seed crystal adsorption explosive.

[0032] Step (3): The seed crystal adsorption explosive obtained in step...

Embodiment 2

[0035] Step (1): take 100g of CL-20 explosives, disperse it in 450g concentration of 0.5% PDDA solution, let stand for 1h, filter, wash with deionized water, then immerse in 450g concentration of 0.5% PSS solution, After standing for 1h, filtering, and washing with deionized water, immerse again in 450g of PDDA solution with a concentration of 0.5%, let stand for 1h, filter, wash with deionized water, and dry to obtain the nuclear layer explosive after surface charge modification;

[0036] Step (2): Disperse 10g of nanoscale powdery TATB explosive in 1000g of water, apply 80kHz ultrasonic treatment for 30min to obtain a uniform suspension, and then apply the surface charge modified nuclear layer nitramine explosive obtained in step (1) Add it into the suspension, stir at 250rpm for 15min, let stand for 15min, filter the material, wash with deionized water, and dry to obtain the seed crystal adsorption explosive.

[0037] Step (3): The seed adsorption explosive obtained in step...

Embodiment 3

[0040] Step (1): Take 10g of HMX explosives, disperse it in 400g concentration of 0.05% PDDA solution, let stand for 1.5h, filter, wash with deionized water, then immerse in 400g concentration of 0.05% PSS solution, static After standing for 1.5h, filtering, and washing with deionized water, immerse again in 400g of PDDA solution with a concentration of 0.05%, let stand for 1.5h, filter, wash with deionized water, and dry to obtain the nuclear layer explosive after surface charge modification;

[0041] Step (2): Disperse 0.8g of nanoscale powdery TATB explosive in 200g of water, apply 50kHz ultrasonic treatment for 15min to obtain a uniform suspension, and then apply the surface charge-modified nuclear layer nitramine obtained in step (1) Add explosives to the suspension, stir at 600 rpm for 45 minutes, let stand for 10 minutes, filter the material, wash with deionized water, and dry to obtain explosives adsorbed by seeds.

[0042] Step (3): adding the seed adsorption explosiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com