Patents

Literature

167 results about "Nitroguanidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitroguanidine is an organic compound with the formula (NH₂)₂CNNO₂. It is a colorless, crystalline solid that melts at 232 °C and decomposes at 250 °C. It is very flammable, but has a low impact sensitivity; however, its detonation velocity is high. It is used as a propellant (air bags), fertilizer, and for other purposes.

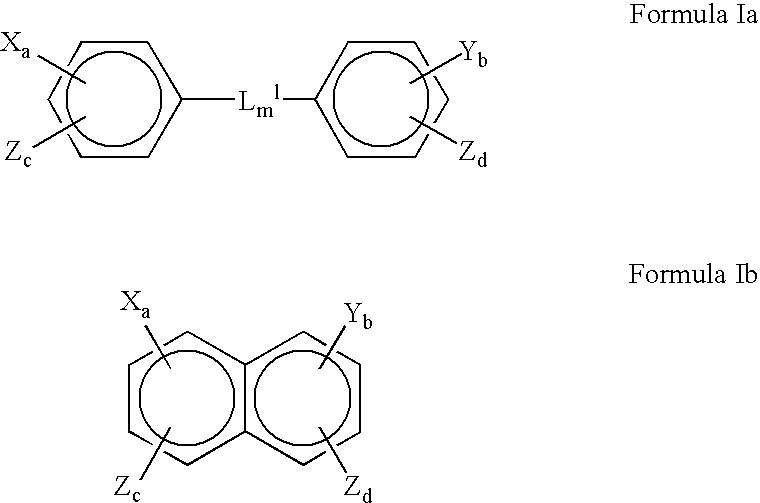

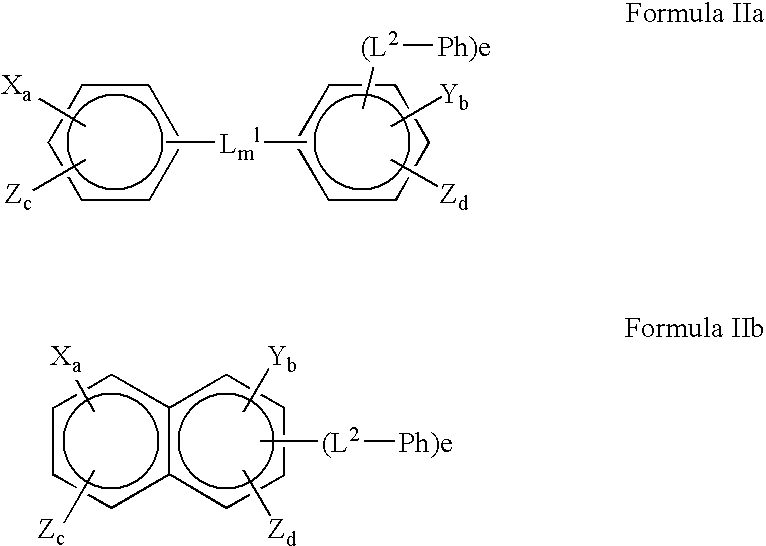

Process for preparing heterocycles

Process for the preparation of heterocycles by reacting 2-substituted acetals of malondialdehyde with a reactant selected from hydroxylamines and their salts, hydrazines and their salts, formamid, amidines and their salts, guanidines and their salts, aminoguanidines and their salts, nitroguanidine and their salts, O-alkyl-isoureas and their salts, O-cycloalkyl-isoureas and their salts, O-aralkyl-isoureas and their salts, O-aryl-isoureas and their salts, S-alkyl-isothioureas, S-cycloalkyl-isothioureas, S-aralkyl-isothioureas, S-arylisothioureas, S-alkyl-isothiouronium salts, S-cycloalkyl-isothiouronium salts, S-aralkyl-isothiouronium salts, S-aryl-isothiuronium salts, thiourea and urea.

Owner:CREANOVA

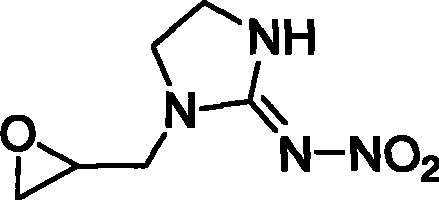

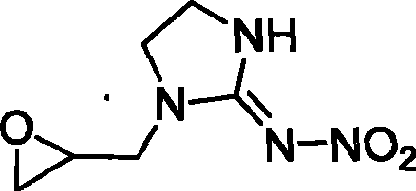

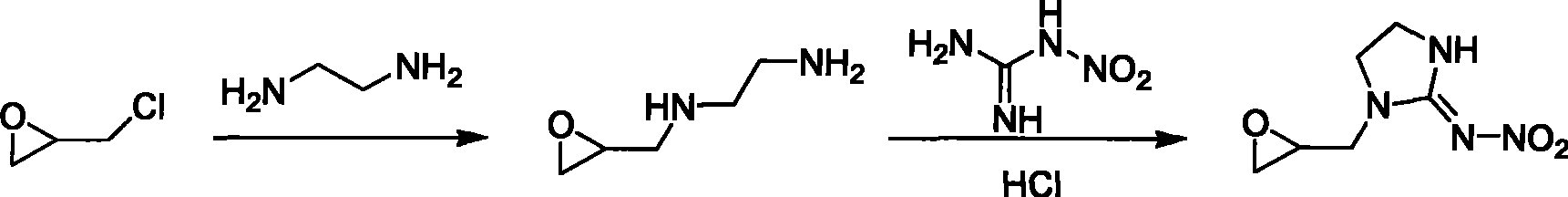

1-(1,2-epoxy propyl)-n-nitroimidazolene amine-2, preparation and use thereof

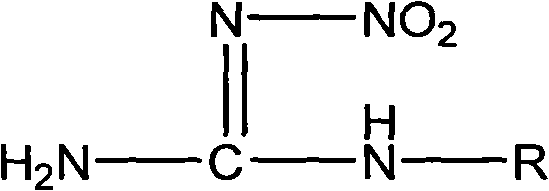

The invention relates to 1-(1,2-epoxypropyl)-N-nitroimidazoline-2-amine which has a structural formula as shown in the picture. A preparation method of the compound comprises the steps of adding ethylenediamine to a reaction container, dropwise adding epoxy chloropropane in the reaction container while stirring, reacting for 2-3h, cooling, and vaporizing out acetonitrile to obtain epoxypropyl ethylenediamine; taking and dissolving nitroguanidine and the epoxypropyl ethylenediamine into water, dropwise adding hydrochloric acid solution while stirring, reacting for 2-3h, cooling, extracting, desolventizing to obtain crude product, and recrystallizating to obtain the product; or adding N-nitroimidazoline, potassium carbonate and organic solvent to the reaction container, heating to 75-81.6 DEG C, dropwise adding epoxy chloropropane in the reaction container after dissolving the N-nitroimidazoline, continuously heating until completing the reaction after dropwise adding, cooling reaction products, filtering, vaporizing filtrate to dry, adding water to residues, extracting by using methylene dichloride, desolventizing to obtain phase product, and recrystallizating by using butanone to obtain the product.

Owner:河北艾林化工科技有限公司

Micro smoke ignition agent for fireworks

The invention discloses a micro smoke ignition agent for fireworks, which consists of potassium perchlorate, carbon powder, nitro-cotton and / or nitroguanidine, a high-energy reducing agent and a detonation agent. The invention has the advantages that: an oxidant adopts a high-oxygen content and high-stability substance, so that the using amount can be controlled and smoke can be reduced; combustibles can release a large amount of heat during combustion, so that a high-temperature substance is generated; therefore, the using amount can be controlled and the smoke can be reduced; and main combustibles adopt high-oxygen content substances, so that the using amount of smoke oxidants can be reduced to the greatest extent. Therefore, only micro smoke is generated during combustion of the ignition agent. Due to the detection result of light transmittance, compared with that of the conventional same-class corresponding products, the produced smoke is reduced by 70 percent. Meanwhile, the configuration of the whole medicament system guarantees ignition performance and stability of the ignition agent, and the safety performance meets the requirement of the national standard.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

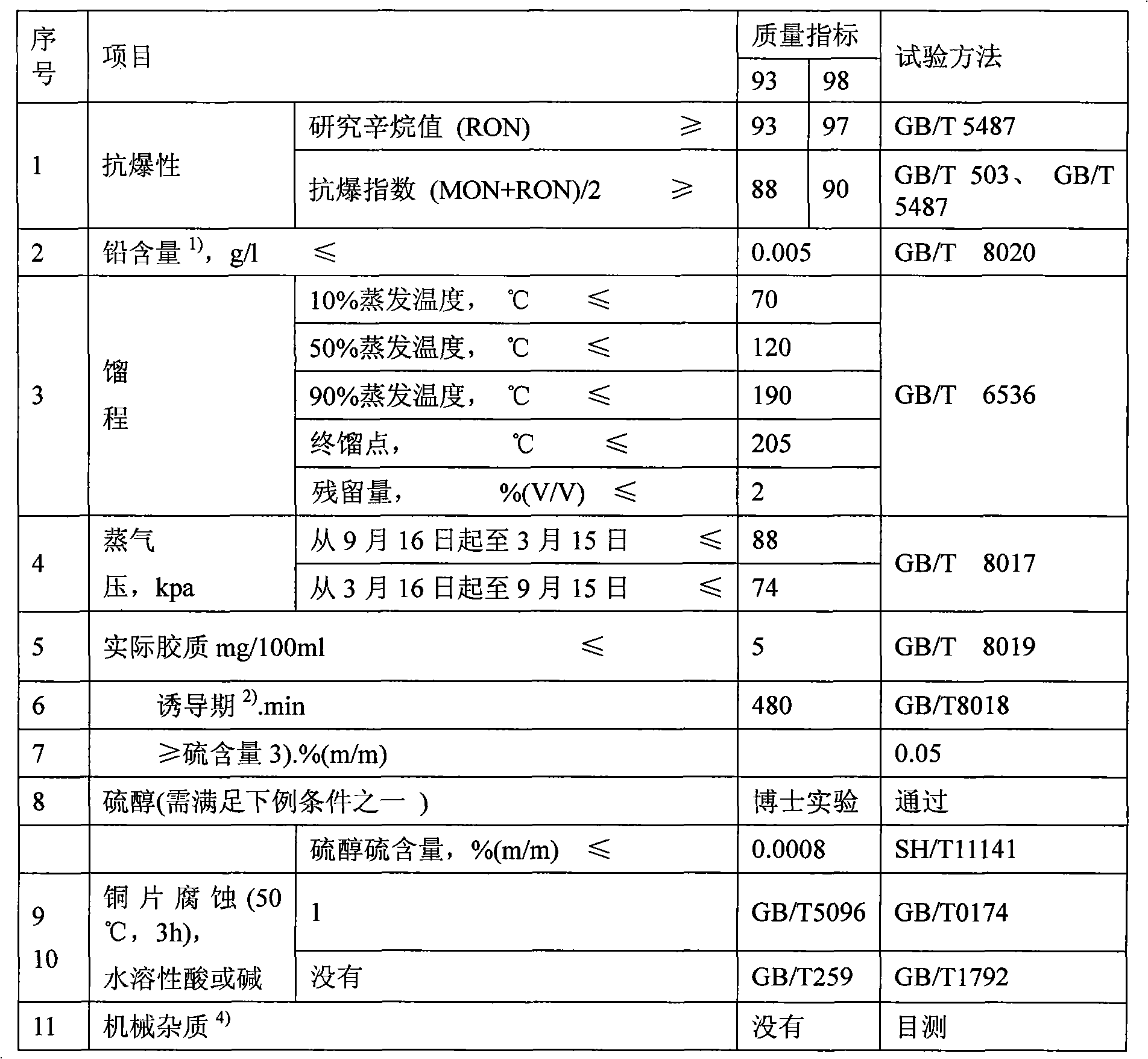

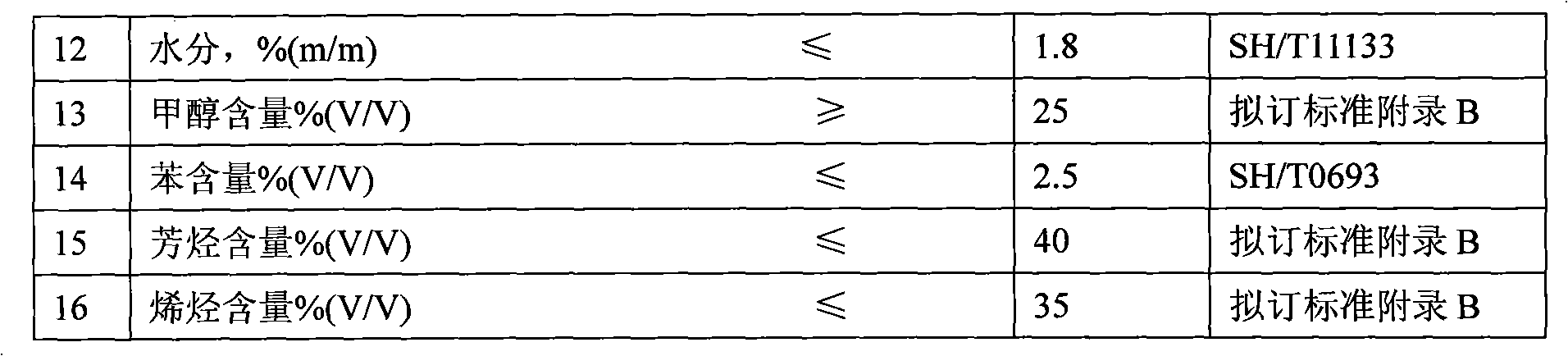

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491AReduce consumptionReduce pollutionLiquid carbonaceous fuelsNew energyLiquid fuel

The invention relates to a liquid fuel, and particularly a liquid carbonaceous fuel of the mixture of hydrocarbons and alcohol ether. The alcohol ether gasoline used in new energy vehicles comprises 25 to 85 percent of gasoline constituents and 15 to 75 percent of alcohol ether-major other chemical raw materials by weight percentage, wherein the components of the alcohol ether-major other chemical raw materials and the weight proportions thereof in the alcohol ether gasoline used in new energy vehicles are as follows: industrial methanol: 10 to 60 percent, n-hexane: 0 to 3 percent, isopropyl chloride: 0 to 1 percent, trichloroethylene: 0 to 1 percent, epichlorohydrin: 0.2 to 3 percent, bromoethanol: 0.2 to 2 percent, isodibutyl ether: 0.5 to 2 percent, ethylene glycol monobutyl ether: 0 to 1 percent, lauric acid : 0.4 to 2 percent, methyl chloroacetate: 0 to 4 percent, isopropyl nitrate: 0.2 to 4 percent, trimethyl phosphate: 0 to 3 percent, nitromethane: 0.1 to 1 percent, nitroethane: 0 to 1 percent, nitroguanidine: 0 to 3 percent, cyclopentadiene: 0 to 4 percent, and n-butylamine: 0 to 1 percent.

Owner:陈斌

Gas generating composition

InactiveUS6779464B1Nitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAmmonium perchlorate explosive compositionsNitroguanidinePerchlorate

A gas generating composition is obtained in which an amount of a combustion residue based on a unit amount of a gas generated is reduced.A gas generating composition comprising nitroguanidine, guanidine nitrate or a mixture thereof as a fuel and further an oxidizing agent. The oxidizing agent is a perchloric acid salt, a nitric acid salt or a mixture thereof, and when the oxidizing agent is ammonium perchlorate, a chlorine neutralizer is further incorporated.

Owner:DAICEL CHEM IND LTD

Green process for producing nitroguanidine

InactiveCN101497579AEliminate vacuum distillation recovery processReduce decompositionOrganic chemistryOrganic compound preparationDecompositionFiltration

The invention relates to a green process for producing nitro guanidine, and belongs to the field of chemical engineering. The discontinuous nitrification method is adopted in the invention to prepare the nitro guanidine. The method particularly comprises that: guanidine nitrate is added in concentrated nitric acid while stirring, diluted by water and subjected to decompression and sucking filtration to separate out a crystal, so that the coarse product of the nitro guanidine is obtained; and the coarse product of the nitro guanidine is water-washed for more than four times to obtain the target product. The process is simple and saves the process of the decompression, distillation and recovery of the nitric acid, and the diluent uses water to replace the nitric acid, and the lowest reaction temperature is reduced from 60 DEG C to 30 DEG C, thereby lowering the decomposition of the nitro guanidine in the concentrated nitric acid, and the fastest reaction time is shortened from 3 hours to 20 minutes, and the production efficiency is greatly improved; due to the adoption of the discontinuous method, the prior idle production equipment can be used for production by simple modification; moreover, in the process, the content of the waste nitric acid is more than 45 percent, so that the nitro guanidine can be used as an oxidant and a neutralizer to produce various products such as sodium nitrate, oxalic acid, p-nitrodracylic acid and the like.

Owner:里程

Two-part aqueous metal protection treatment

InactiveUS6902766B1Avoids and reduces blister formationOvercome disadvantagesAdhesive processes with surface pretreatmentAbrasion apparatusOrganic filmElastomer

A two-part metal protection composition includes: an aqueous metal treatment conversion coating component that includes an admixture of an acid and a coating forming component; and an aqueous protective coating component that is applied over metal treated with the aqueous metal treatment conversion coating component and includes an admixture of a blister suppressing agent and an organic film forming protective component. The aqueous metal treatment conversion coating component may contain an accelerator, such as hydroxylamine. In a preferred embodiment, the blister suppressing agent is an organic oxidizing agent that includes one or more of nitroguanidine; aromatic nitrosulfonates, Naphthol Yellow S; and picric acid (trinitrophenol). A method for treating a metallic surface includes: (a) applying an aqueous metal treatment conversion coating component described above; and (b) applying an aqueous protective coating component, described above, to the surface that has at least been partially treated with the aqueous metal treatment conversion coating component. A method for bonding an elastomeric substrate surface to a metallic substrate surface includes: (a) applying an aqueous metal treatment conversion coating component, described above, to the surface; (b) applying an aqueous coating or primer composition, described above, to the surface that has at least been partially treated with the aqueous metal treatment conversion coating component; and (c) applying an adhesive overcoat to effect bonding of the metallic substrate to the elastomeric substrate.

Owner:LORD CORP

Process for producing a gas generating agent

InactiveUS20030030162A1Reliably and stably exhibit propertyPedestrian/occupant safety arrangementLoomsNitroguanidineCopper nitrate

Owner:DAICEL CHEM IND LTD

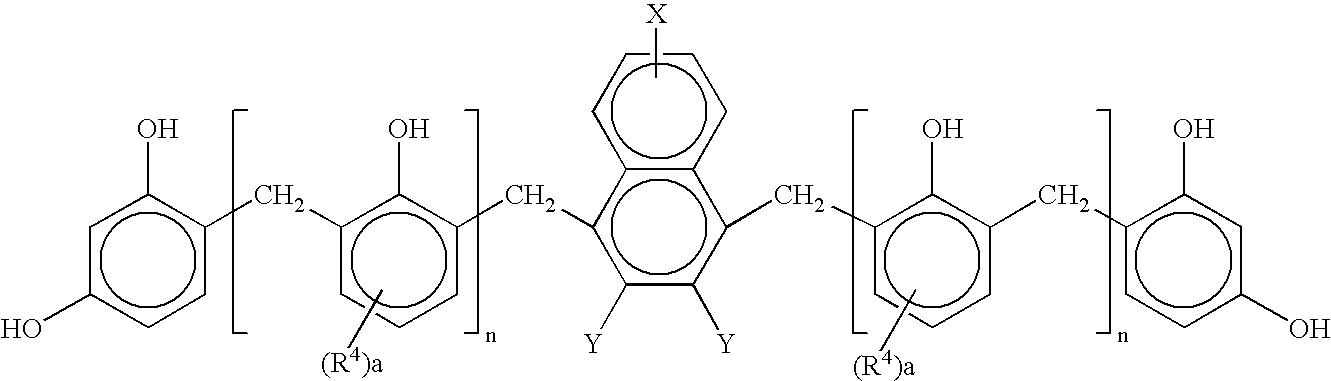

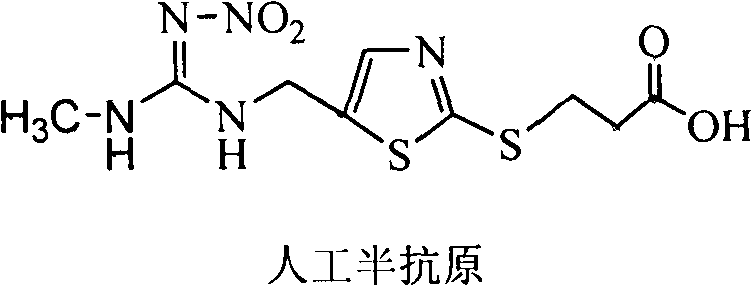

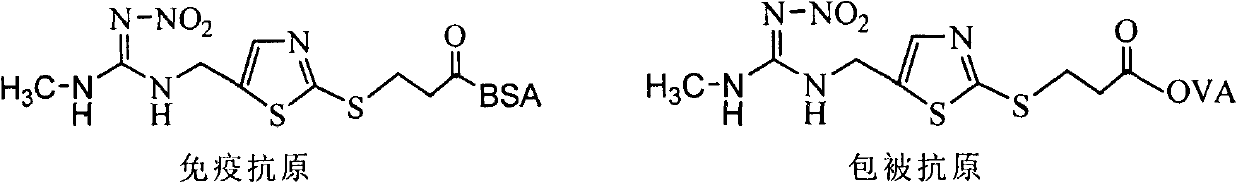

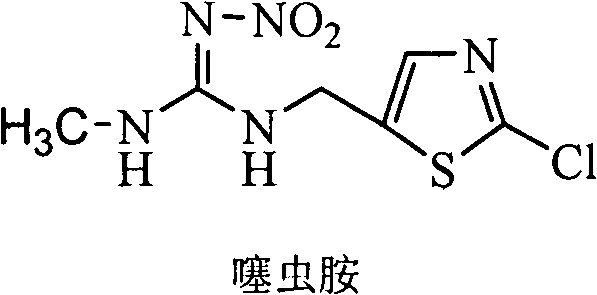

Clothianidin antigen, antibody and application thereof

InactiveCN102875671AHigh analytical capacityReduce analysis costsSerum immunoglobulinsBiological testingPropanoic acidBovine serum albumin

The invention relates to a clothianidin antigen, an antibody and an application thereof, and belongs to the technical field of immunochemistry analysis. The clothianidin antigen and the antibody of the invention are specially used for clothianidin specific polyclonal antibody preparation, enzyme-linked immunoassay (ELISA), and high-sensitivity and rapid detection of clothianidin residues in environment and agricultural products. A hapten is synthesized by substituting a chlorine atom on a thiazole ring of clothianidin, has a chemical name of 3-(5-((3-methyl-2-nitroguanidine)-yl methyl)thiazole-2-mercapto)propionic acid, and is coupled with bovine serum albumin and ovalbumin to prepare an antigen and an envelope antigen. Newzealand white rabbit is immunized by the immunizing antigen to obtain the specific polyclonal antibody of clothianidin. The established ELISA linear scope is 1.1 microgram / L-2 mg / L, and the detection limit is 1.1 microgram / L. The hapten synthetic technology of the invention is simple and feasible, high in antibody specificity, and suitable for detection and on-site monitoring of mass samples in environment and agricultural products.

Owner:NANJING AGRICULTURAL UNIVERSITY

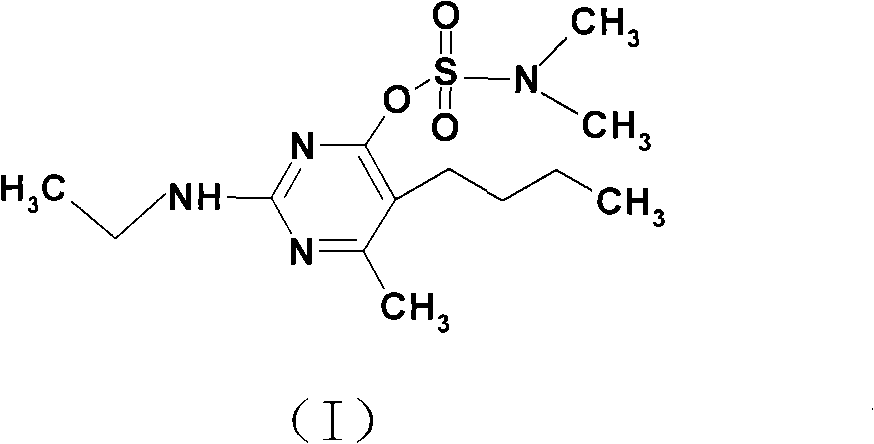

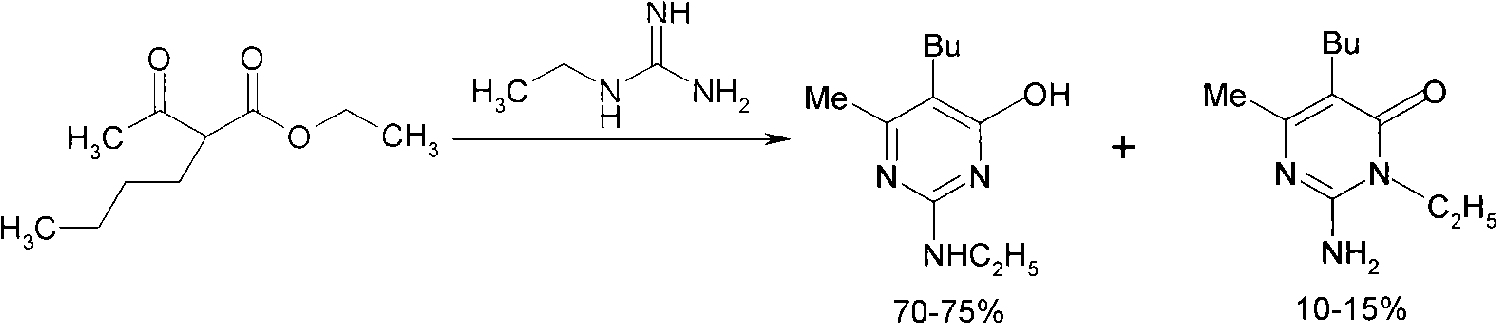

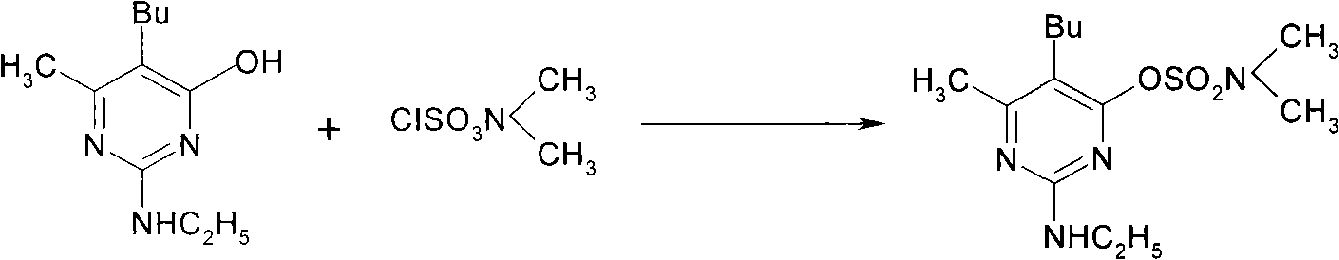

Method for synthesizing 5-nbutyl-2-ethylamido-6-methylpyrimidine-4-dimethyl amine sulfonic acid ester

The invention discloses a method for synthesizing 5- normal-butyl-2- ethide amid-6- methyl pyrimidine-4-based dimethyl amine group sulfonic ester (bupirimate). The method takes nitroguanidine and 2-acetyl group ethyl caproate as raw materials which react under the catalytic action of sodium alcoholate to generate 5- normal-butyl-2-nitryl amine-6- methyl pyrimidine-4- phenol which reacts with ethylamine under catalytic action of Glacial acetic acid; and bupirimate is obtained by the reaction of the 5- normal-butyl-2-nitryl amine-6- methyl pyrimidine-4- phenol and N, N-Dimethylsulfamoyl chloride in the presence of alkalescence. The bupirimate prepared by the synthesizing method has the purity quotient up to 95.4 percent, and the total yield coefficient up to 78.6 percent. The method is mainly used to prepare the bupirimate.

Owner:XIAN MODERN CHEM RES INST

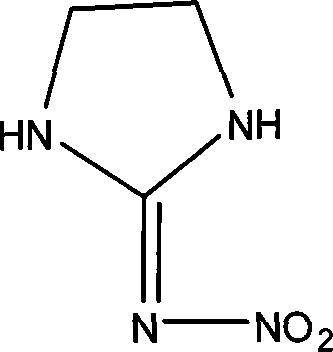

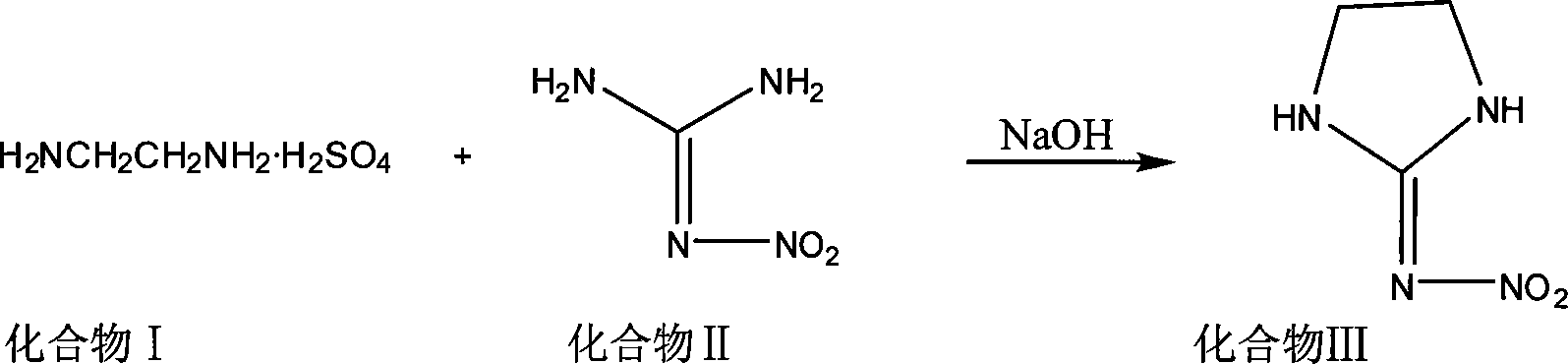

Prepn process of 2-nitro imido imidazolyl alkane

The preparation process of 2-nitro imido imidazolyl alkane belongs to the field of farm chemical intermediate preparing technology. It includes the first reaction between acid and ethylene diamine to obtain ethylene diamine salt, the subsequent reaction between ethylene diamine salt and nitroguanidine, and final filtering and stoving to obtain the 2-nitro imido imidazolyl alkane product. The present invention has the advantages of low material cost, high reaction yield up to 80 % and high product quality, and the product has smelting point of 232-234 deg.c and 2-nitro imido imidazolyl alkane content over 99 %, and is white or yellowish crystal.

Owner:NANTONG TENDENCI CHEM

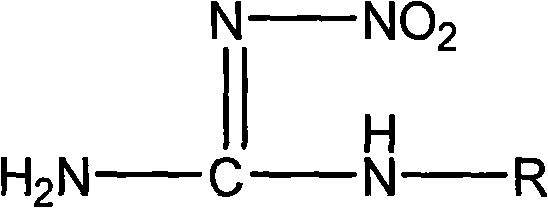

Methyl nitroguanidine and preparation method thereof

InactiveCN101565392ASimple process equipmentEasy to operateOrganic chemistryOrganic compound preparationProcess equipmentNitroguanidine

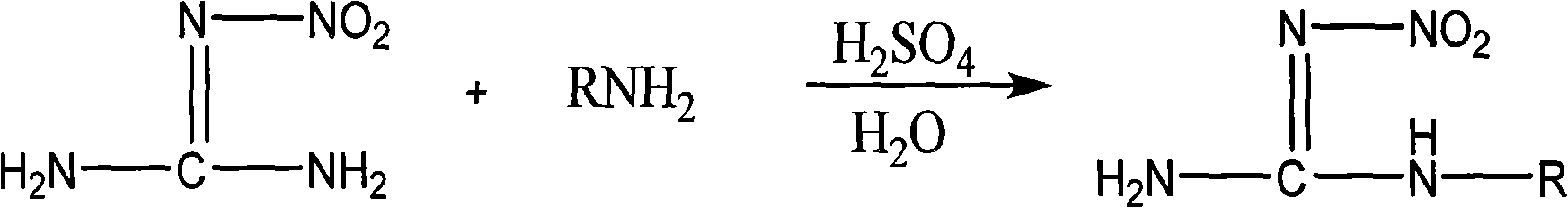

The invention discloses methyl nitroguanidine and a preparation method thereof. Alkyl nitroguanidine is produced by the reaction of nitroguanidine, alkylamine and water under the condition of taking vitriol as a catalyst. The processing equipment is simple in structure and convenient to operate and has high reaction yield after taking the vitriol as the catalyst, little pollution and high product purity of over 98 percent generally.

Owner:NANTONG TENDENCI CHEM

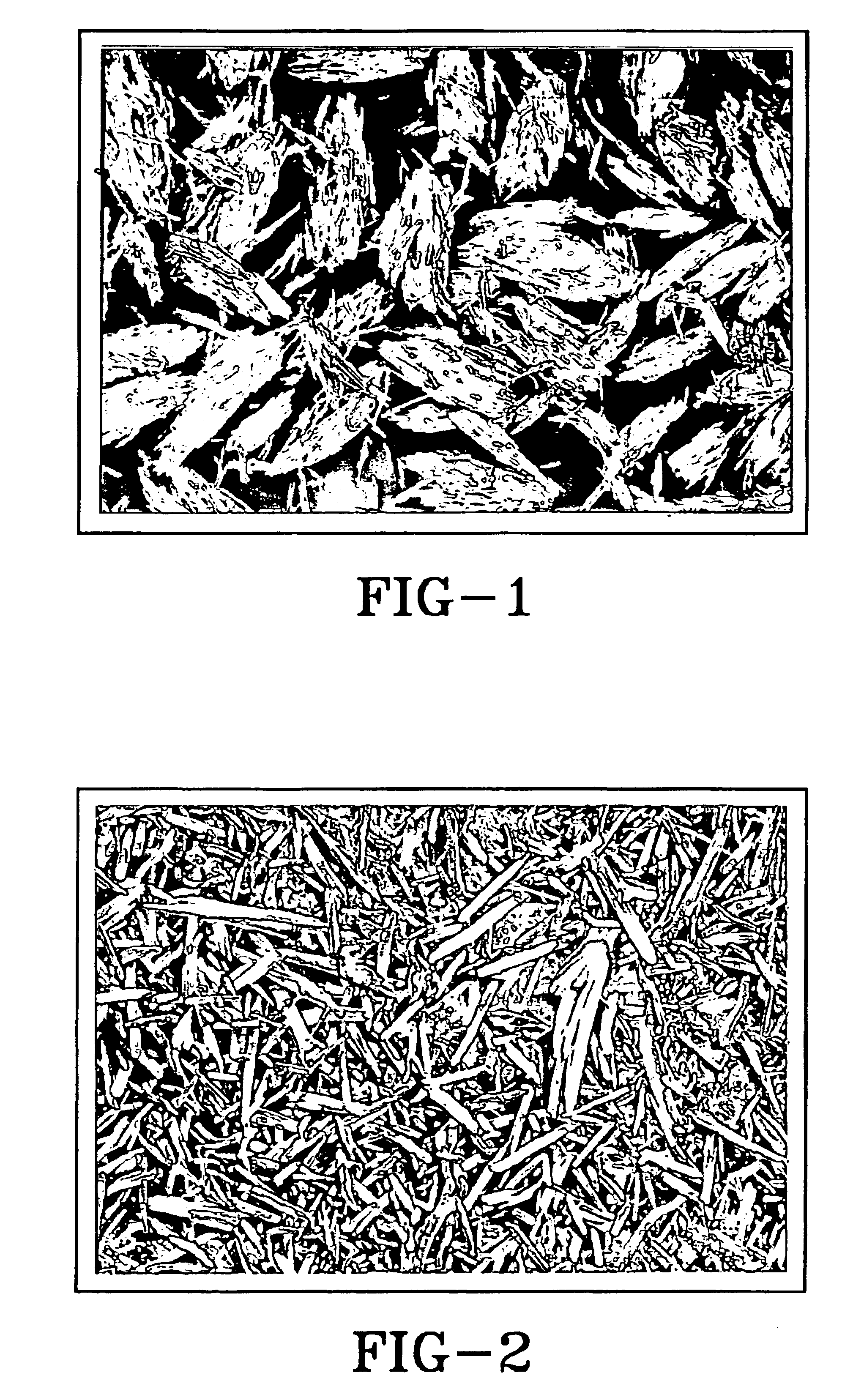

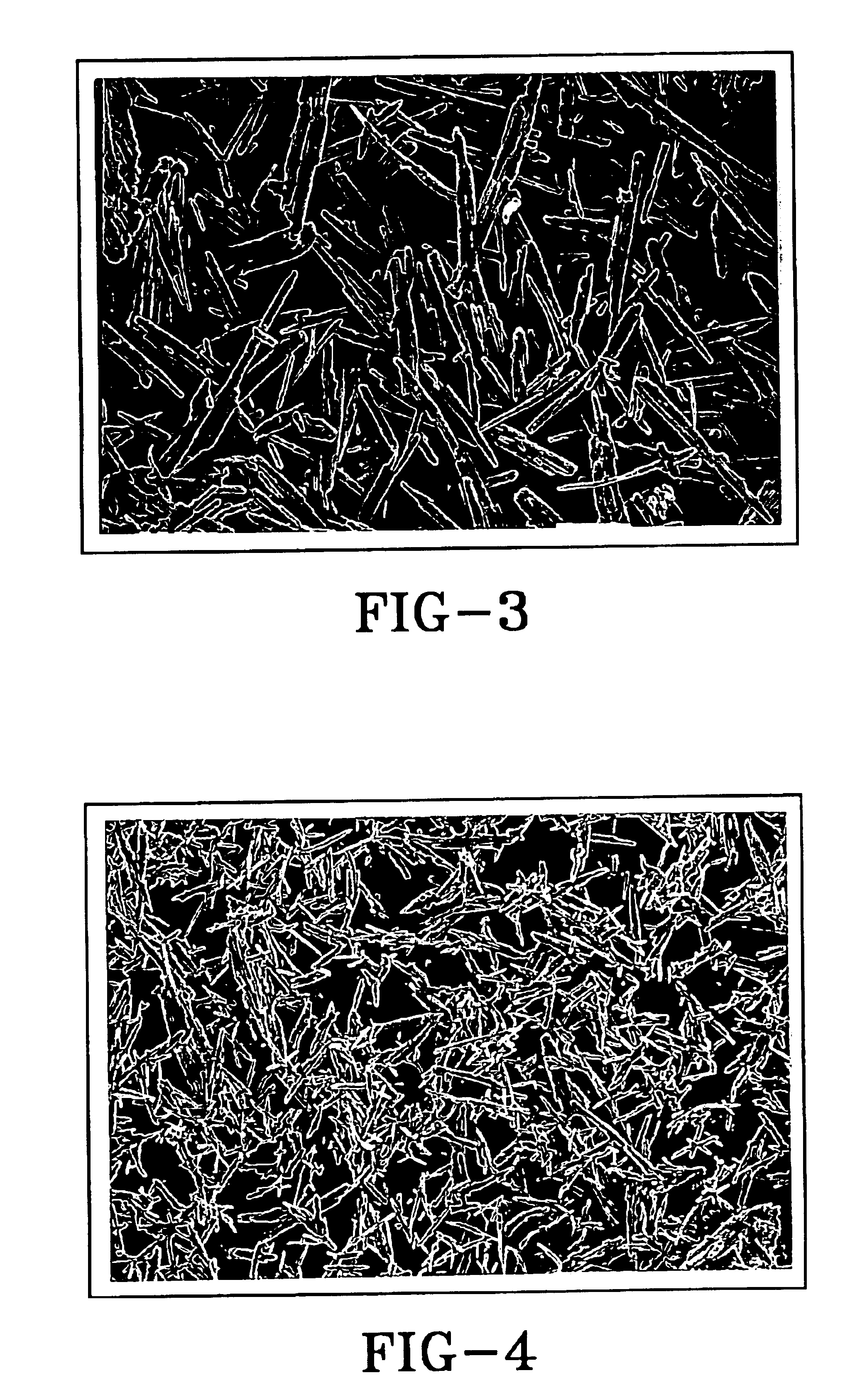

Method of stabilizing the density of gas generant pellets containing nitroguanidine

InactiveUS6887325B2Increase burn rateIncrease surface areaLoomsExplosive working-up apparatusNitroguanidineProduct gas

A non azide gas generant composition of nitroguanidine and an oxidizer such as phase stabilized ammonium nitrate is provided. A gas generant having nitroguanidine and phase stabilized ammonium nitrate has many desirable characteristics such as little production of ash and the production of essentially toxic free exhaust gas. When nitroguanidine is compressed into a pellet it has needle shaped crystals that bend or distort. When the gas generant pellets are subjected to thermal cycling some nitroguanidine crystals will return to their native conformation resulting in pellet growth. To eliminate this pellet growth, nitroguanidine is passed through a vibrating ball mill. The media in the vibrating ball mill pulverizes the nitroguanidine into an amorphous crumb.

Owner:KEY SAFETY SYST

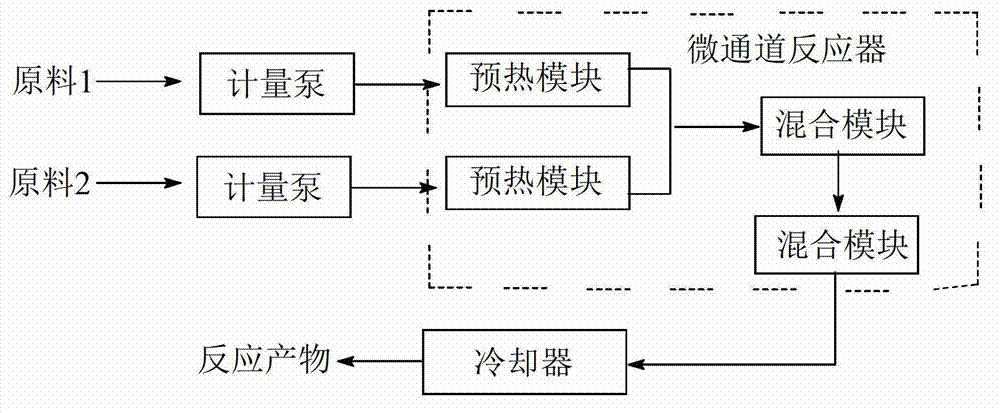

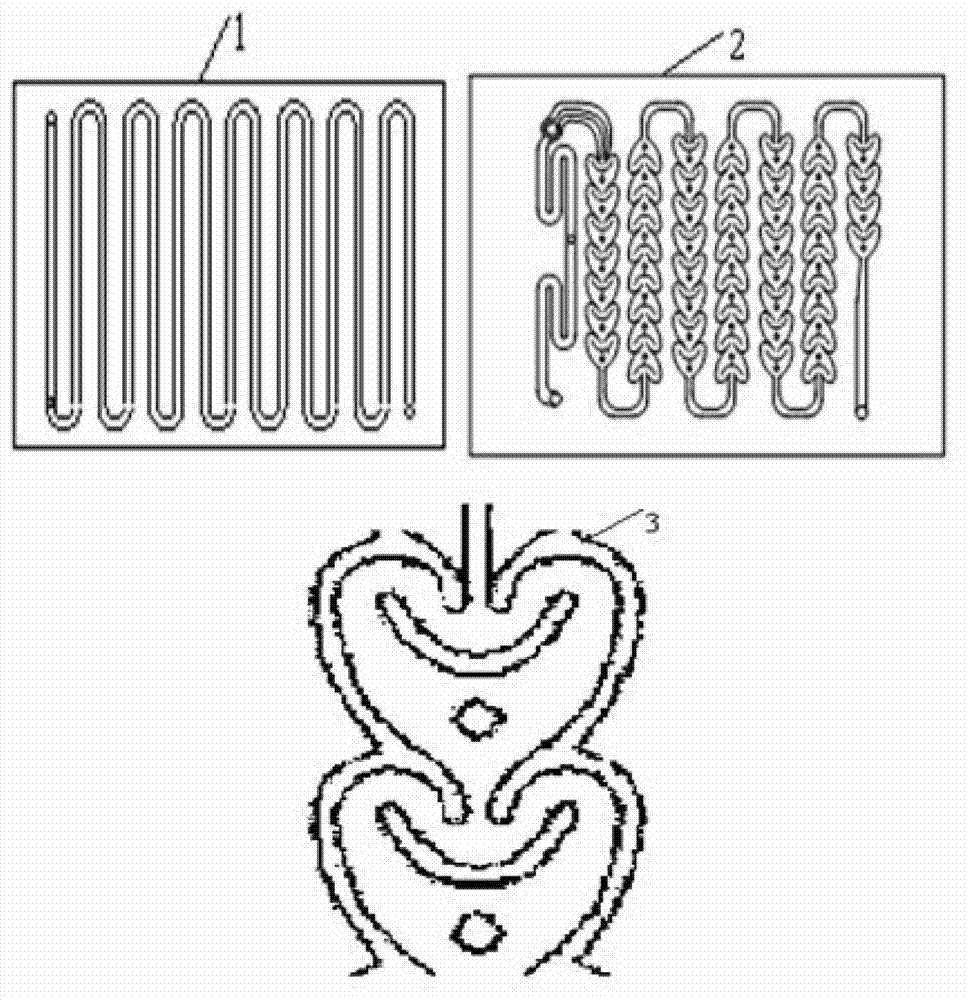

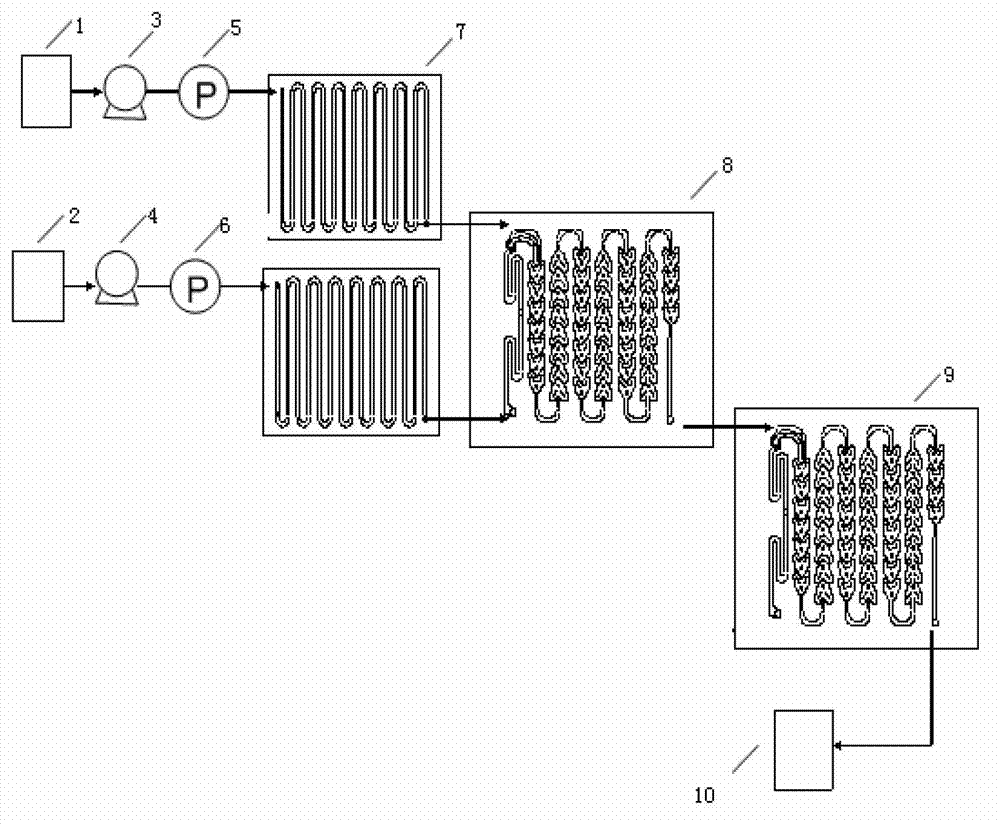

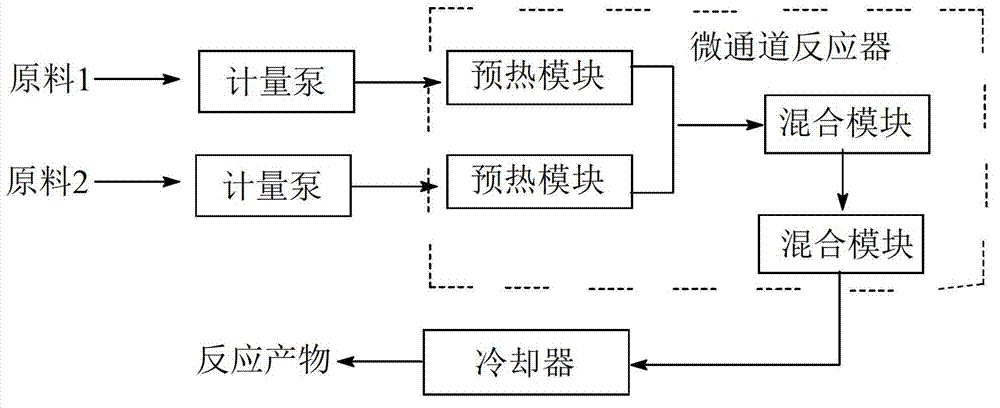

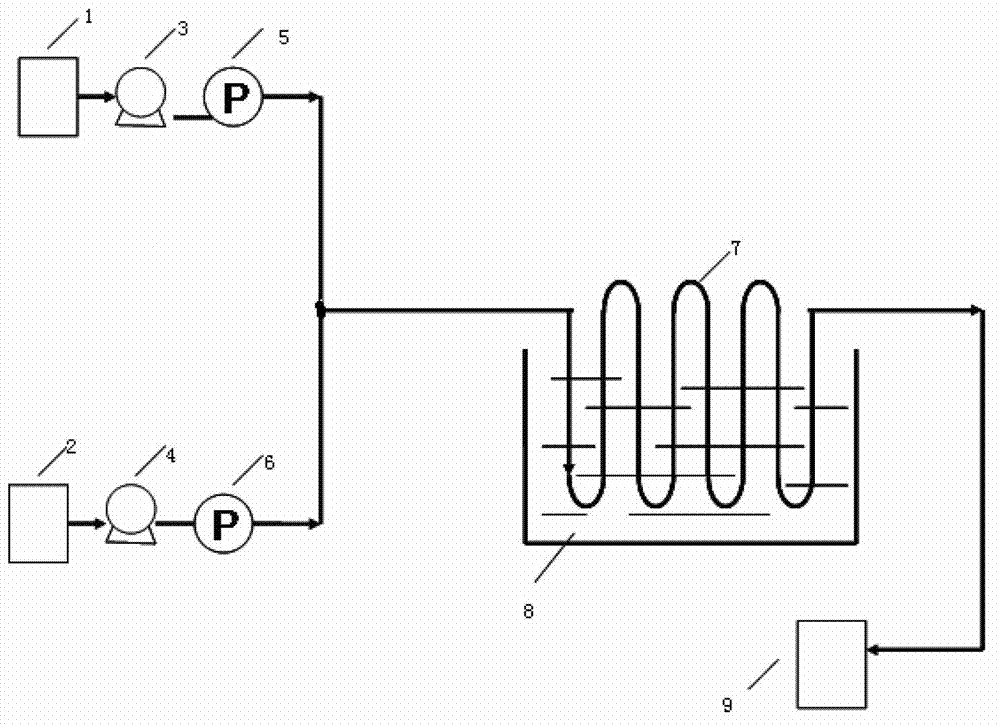

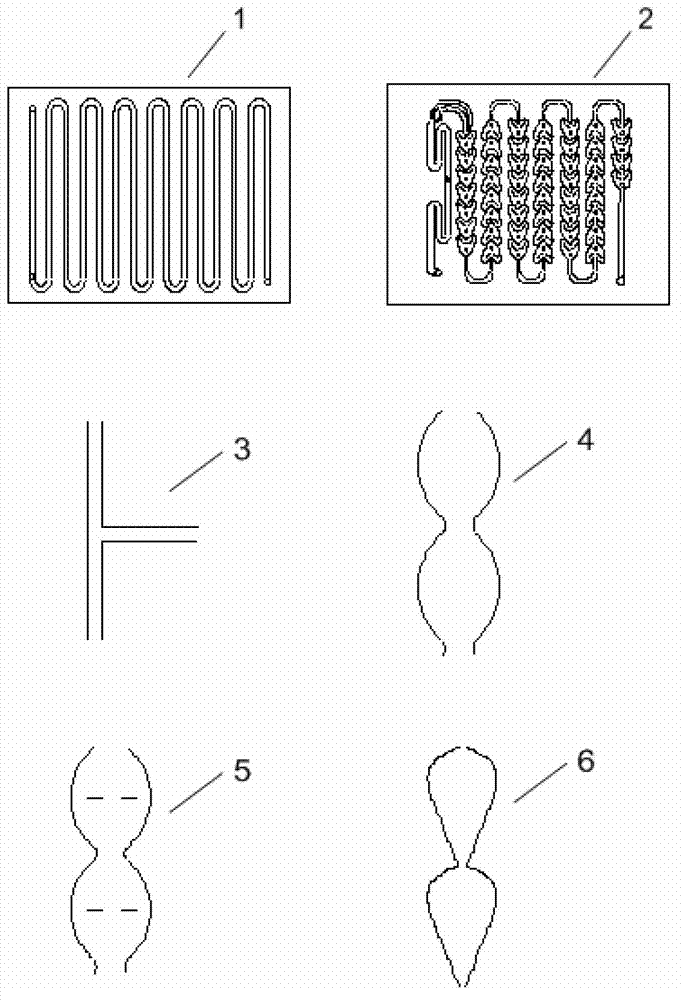

Method for preparing nitroguanidine by adopting micro-channel reactor

ActiveCN103172546AShort reaction timeImprove reaction efficiencyOrganic chemistryOrganic compound preparationNitroguanidineOrganic synthesis

The invention relates to a method for preparing nitroguanidine by adopting a micro-channel reactor, belonging to the technical field of organic synthesis applications. The mehtod is a new process for synthesizing nitroguanidine by taking a sulfuric acid solution of guanidine sulfate and nitric acid as raw materials and performing nitrification and dehydration in the Corning micro-channel reactor within a short reaction time from tens of seconds to a few minutes. Materials are introduced into the Corning micro-channel reactor through a metering pump, a nitroguanidine product is obtained by preheating, mixing, reaction and post-treatment, and the method has the advantages of simplicity, convenience and safety in operation, high yield and continuous production of the nitroguanidine product; and in addition, by adopting the process, the environmental pollution can be greatly reduced. The yield of the product according to the method disclosed by the invention is 90-93%, and the melting point of the product is 230-232 DEG C.

Owner:CHANGZHOU UNIV

Production technology of nitroguanidine

The invention discloses a production technology of nitroguanidine. The nitroguanidine serves as a raw material, a nitroguanidine crude product is obtained after sulfuric acid dehydration, ice water hydrolysis and liquid ammonia neutral reaction, and ammonium sulfate in filtrate is recycled through multiple-effect evaporation. The technology has the advantages that the prepared nitroguanidine has a molar yield higher than 95% and a content larger than 97%, and three wastes seldom exist.

Owner:NANTONG TENDENCI CHEM

Gas generating composition

InactiveUS6190474B1Pedestrian/occupant safety arrangementNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAlkaline earth metalManganese

A gas generating composition having a low combustion temperature and a low heat of combustion at the time of burning and therefore enabling downsizing of gas generators themselves, which comprises as the essential components nitroguanidine and an oxidizing agent comprising (a) nitrates or nitrites of alkali metals or alkaline earth metals, (b) oxides or multiple oxides of metals selected from among copper, cobalt, iron, manganese, nickel, zinc, molybdenum and bismuth, or a mixture of the components (a) and (b).

Owner:DAICEL CHEM IND LTD

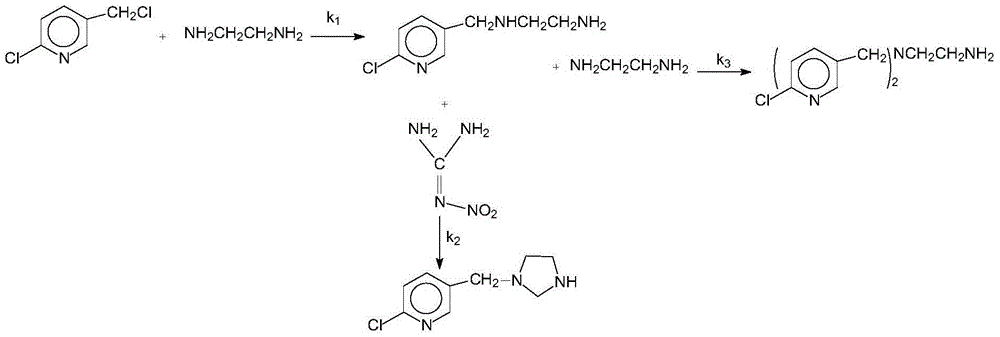

Method for synthesizing imidacloprid employing cascade reaction

The invention discloses a method for synthesizing imidacloprid employing cascade reaction. The method comprises the following steps: with 2-chlorine-5-chloromethyl pyridine, ethidene diamine and guanidine nitrate as raw materials, mixing 2-chlorine-5-chloromethyl pyridine, ethidene diamine and guanidine nitrate with a certain amount of solvent ethanol; adding a little of ionic liquid as a catalyst, controlling the pH value of the reaction process to be about 6 with a little of hydrochloric acid; heating, warming, and slowly dropwise adding a certain amount of ethidene diamine, reacting, heating for a certain period of time, stopping heating, and cooling to a room temperature; and purifying and drying to obtain an imidacloprid product. Due to adoption of one-pot cascade reaction, an intermediate product 2-degree amine is high in activity, and easily forms a heterocyclic ring together with nitroguanidine; byproducts can be prevented; and the high-purity imidacloprid is synthesized. Compared with an original two-step technology, the method for preparing the imidacloprid disclosed by the invention is simple in reaction step; the yield and the purity of the product are greatly improved; the yield reaches more than or equal to 95%; the purity of a reaction product through gas chromatography reaches more than or equal to 90%.

Owner:JIAXING UNIV

Continuous crystallization process for preparing nitroguanidine through nitric acid method

InactiveCN104860849AEmission reductionNo importOrganic chemistryOrganic compound preparationNitroguanidineFiltration

The invention relates to a continuous crystallization process for preparing nitroguanidine through a nitric acid method. The process is applied to continuous crystallization for preparing single-compound explosive nitroguanidine and belongs to the technical field of preparation processes of explosives and powder. According to the process disclosed by the invention, the nitroguanidine is dissolved in a nitric acid solution, the synthetic process is optimized by virtue of a micro-tube reactor, the requirement of the reaction system on the nitric acid concentration is reduced, and the product yield is improved. A continuous crystallizer and a filter are arranged behind the micro-tube reactor, the continuous crystallization and filtration process is established, the manual operation is reduced, and the production efficiency of the product is improved; and moreover, with the adoption of ultrasonic oscillating and washing, the washing frequency is reduced, and wastewater emission is reduced. The process disclosed by the invention has the advantages of simplicity, high continuity, high product yield, small wastewater emission amount and the like and is particularly suitable for continuous crystallization for preparing single-compound explosive nitroguanidine.

Owner:XIAN MODERN CHEM RES INST

Gas generating composition

ActiveUS20130340900A1Pedestrian/occupant safety arrangementNitrated explosive compositionsHigh resistancePolyethylene oxide

Provided is a gas generating composition with a low combustion temperature, good ignition ability, and a high heat resistance.The gas generating composition includes: (a) a fuel; (b) an oxidizing agent including a basic metal nitrate; (c) a basic metal carbonate; and (d) a binder. The fuel of the component (a) includes melamine cyanurate (MC) and nitroguanidine (NQ), with a ratio (MC / NQ) of contents of MC and NQ being within a range of 0.3 to 1.5. The binder of the component (d) is one or two or more selected from: (d-1) starch, etherified starch, methyl cellulose, hydroxyethyl methyl cellulose, hydroxypropyl methyl cellulose, and hydroxyethyl cellulose; (d-2) poly(vinyl alcohol), polyvinyl ether, polyethylene oxide, polyvinyl pyrrolidone, and polyacrylamide; (d-3) guar gum, etherified guar gum, and tamarind gum.

Owner:DAICEL CHEM IND LTD

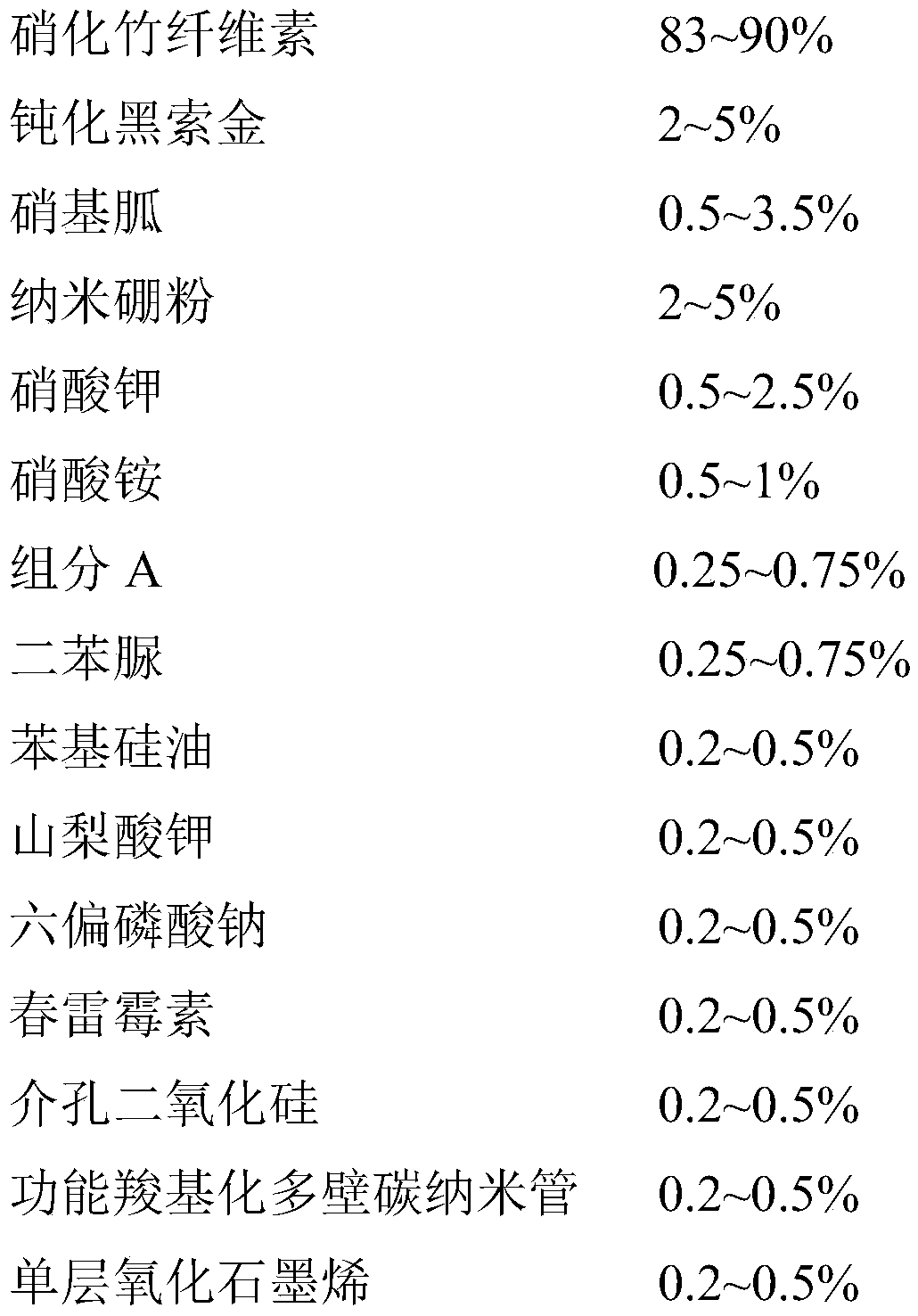

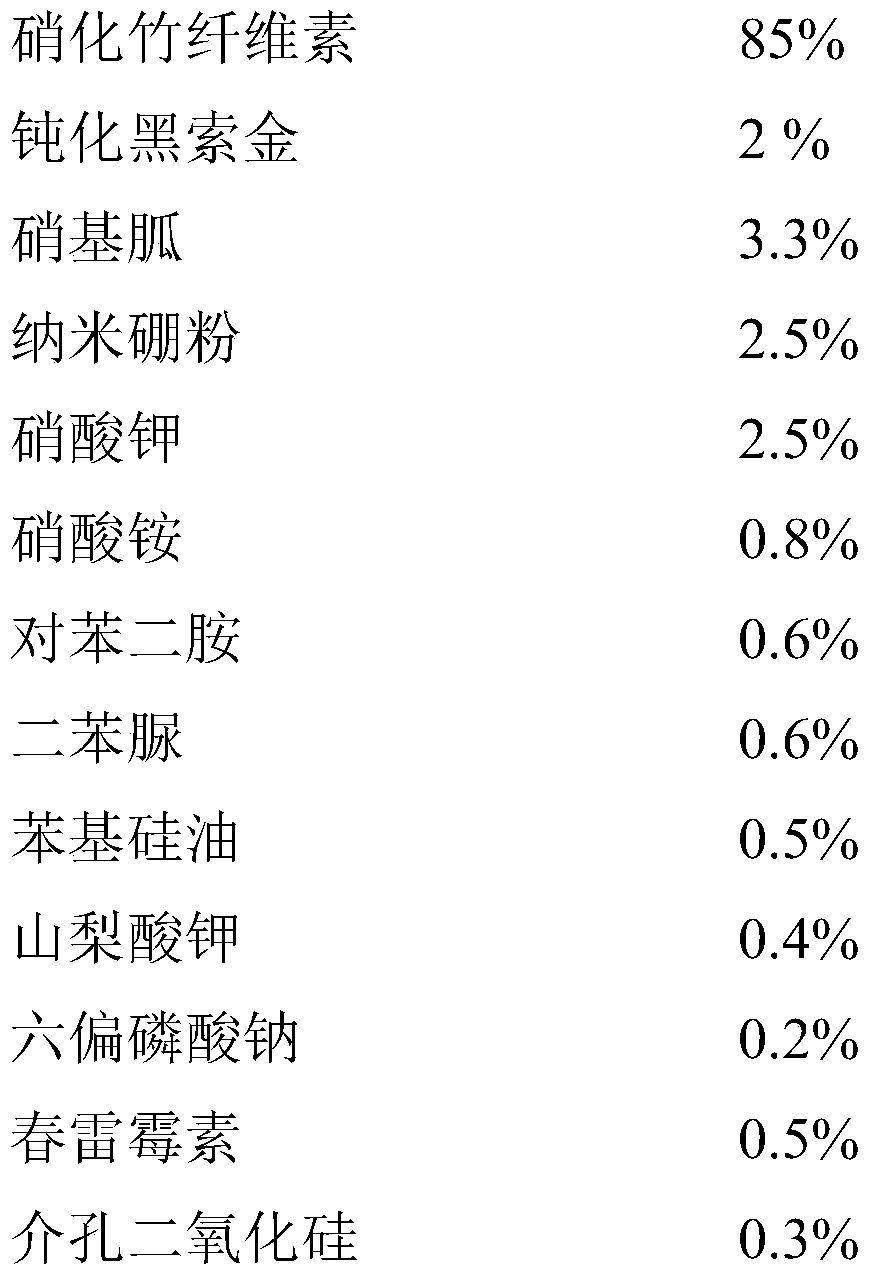

Multifunctional smoke-free non-sulfur firecracker propellant and preparation method thereof

InactiveCN110937966AHigh launch heightMeet the requirements of environmentally friendly pyrotechnic agentsExplosivesSODIUM METAPHOSPHATECellulose

The invention relates to a multifunctional smoke-free non-sulfur firecracker propellant and a preparation method thereof and belongs to the field of environment-friendly pyrotechnic compositions. Thefirecracker propellant includes: nitro-bamboo cellulose, passivated hexogen, nitroguanidine, nano boron powder, KNO3, NH4NO3, a component A, diphenyl urea, phenyl silicone oil, potassium sorbate, sodium hexametaphosphate, kasugamycin, meso-porous SiO2, functional carboxylated multiwall carbon nanotubes, and single-layer graphene oxide. The firecracker propellant is high in launch height during setting off, is smoke-free and residue-free, satisfies the demand of environment-friendly pyrotechnic compositions and is improved in comprehensive performances such as moisture absorption, corrosion resistance, antistatic effect thereof on the basis of ensuring normal performances of the firecracker propellant.

Owner:江西吉润花炮新材料科技有限公司

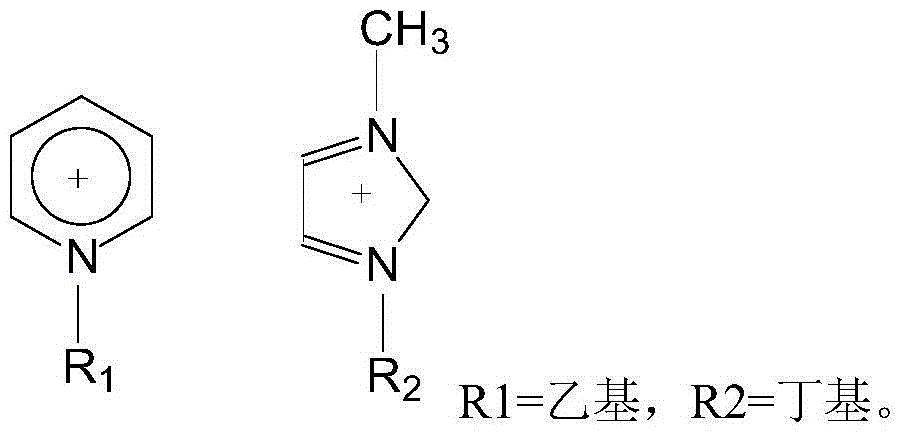

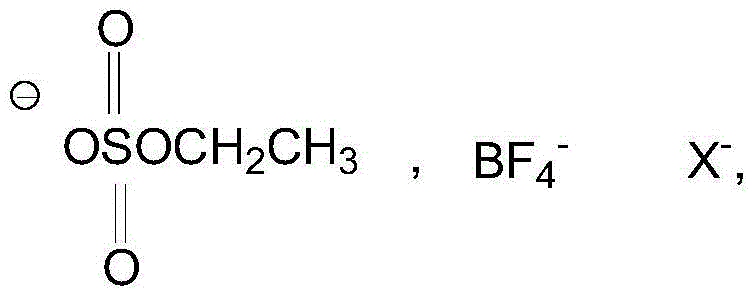

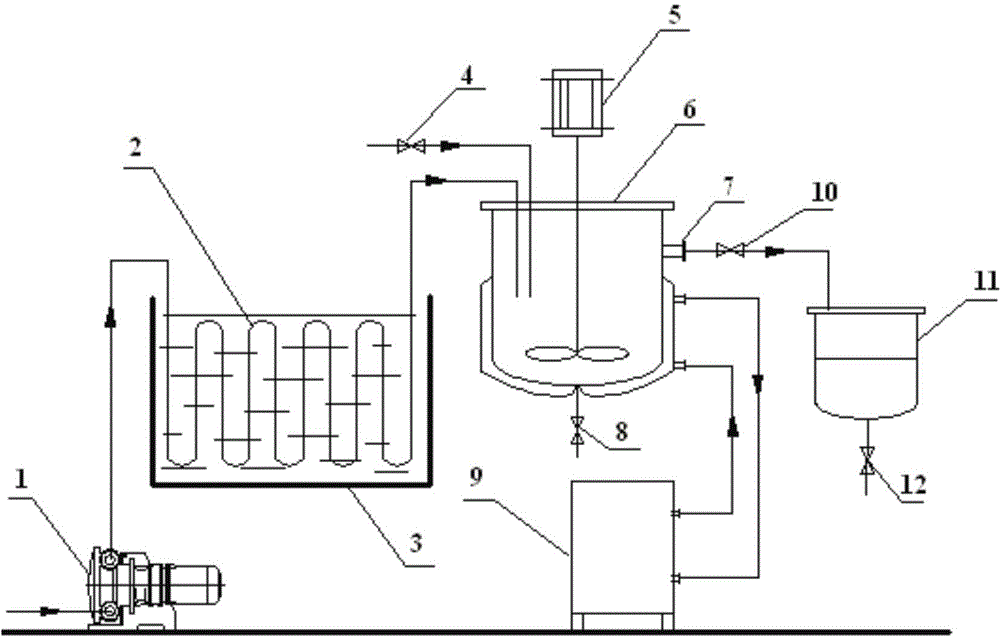

Method for acidizing and dewatering guanidine nitrate to prepare nitroguanidine in continuous flow micro-channel reactor

ActiveCN103193682AShort reaction timeImprove reaction efficiencyOrganic chemistryOrganic compound preparationNitroguanidineOrganic synthesis

The invention discloses a method for acidizing and dewatering guanidine nitrate to prepare nitroguanidine in a continuous flow micro-channel reactor, belongs to the technical field of organic synthesis application, and is a new technology of taking guanidine nitrate water solution and concentrated sulfuric acid as materials in the continuous flow micro-channel reactor, and synthesizing the nitroguanidine within the reaction time from dozens of seconds to a few minutes. The materials are led to the continuous flow micro-channel reactor through a metering pump, and the dewatered product nitroguanidine is finally obtained by pre-heating, mixing, and reacting. The method is simple and safe to operate; high-yield continuous production of the nitroguanidine becomes possible; the technology is small in environmental pollution; the yield of the product disclosed by the invention is 80-85%; and the melting point is 230-232 DEG C.

Owner:CHANGZHOU UNIV

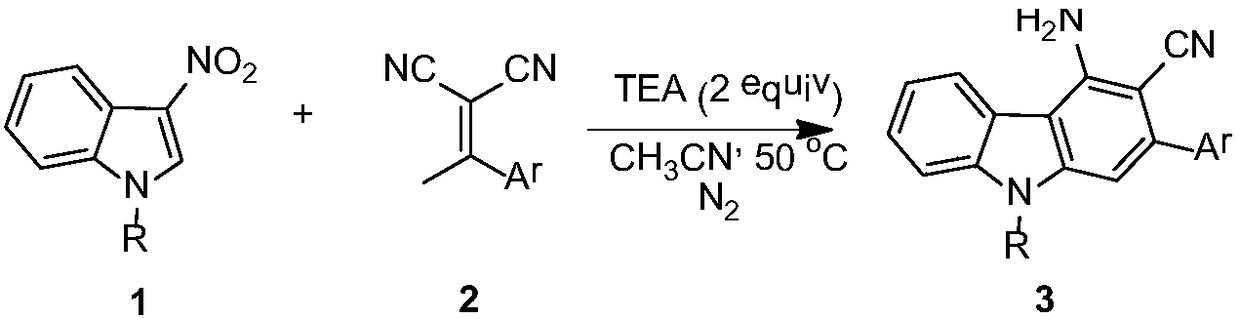

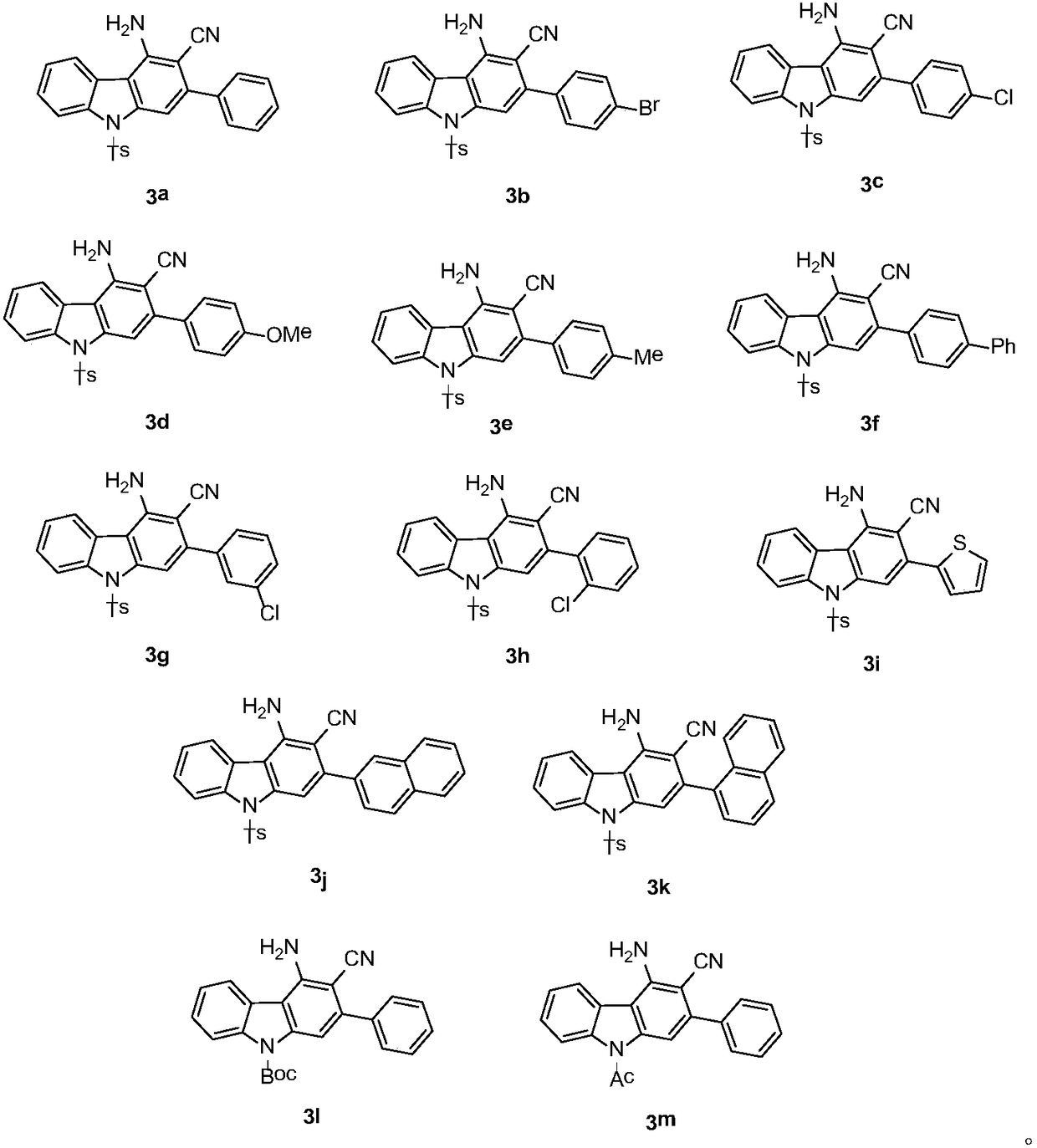

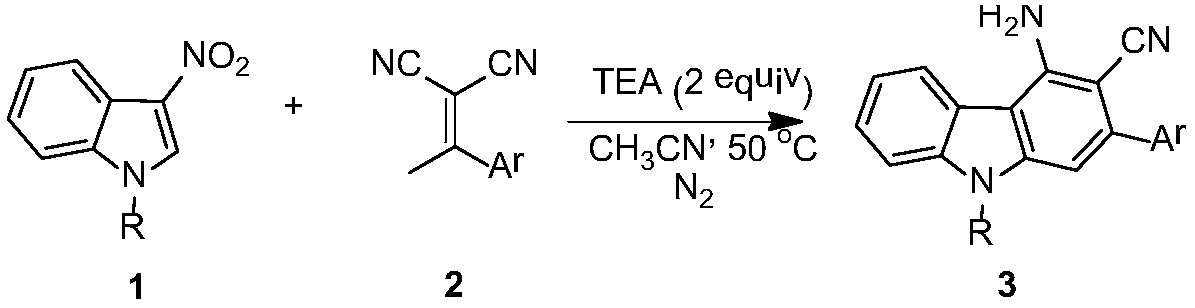

Method for preparing disubstituted 4-aminocarbazole compound

The invention discloses a method for preparing a disubstituted 4-aminocarbazole compound. The method comprises the steps of with a 3-nitroguanidine compound and a 2-(1-arylethylidene)malononitrile compound as the raw materials and acetonitrile as a solvent, reacting at 50 DEG C for 6-24 hours in a nitrogen protection system, so as to synthesize a target compound. The synthetic method is simple, efficient, relatively high in yield and mild in conditions and has good application prospects.

Owner:TAIZHOU UNIV

Gas generating composition

ActiveUS20130319586A1Pedestrian/occupant safety arrangementNitrated explosive compositionsPolyethylene oxideGuar gum

Provided is a gas generating agent with a low combustion temperature and good ignition ability. The gas generating agent includes: (a) a fuel; (b) an oxidizing agent including a basic metal nitrate; (c) a basic metal carbonate; and (d) a binder (not including a component selected from starch, etherified starch, methyl cellulose, hydroxyethyl methyl cellulose, hydroxypropyl methyl cellulose, hydroxyethyl cellulose, guar gum, etherified guar gum, tamarind gum, poly(vinyl alcohol), polyvinyl ether, polyacrylamide, polyethylene oxide, and polyvinyl pyrrolidone). The fuel of the component (a) includes melamine cyanurate (MC) and nitroguanidine (NQ), with MC / NQ (ratio of contents) of being within a range of 0.20 to 1.50.

Owner:DAICEL CHEM IND LTD

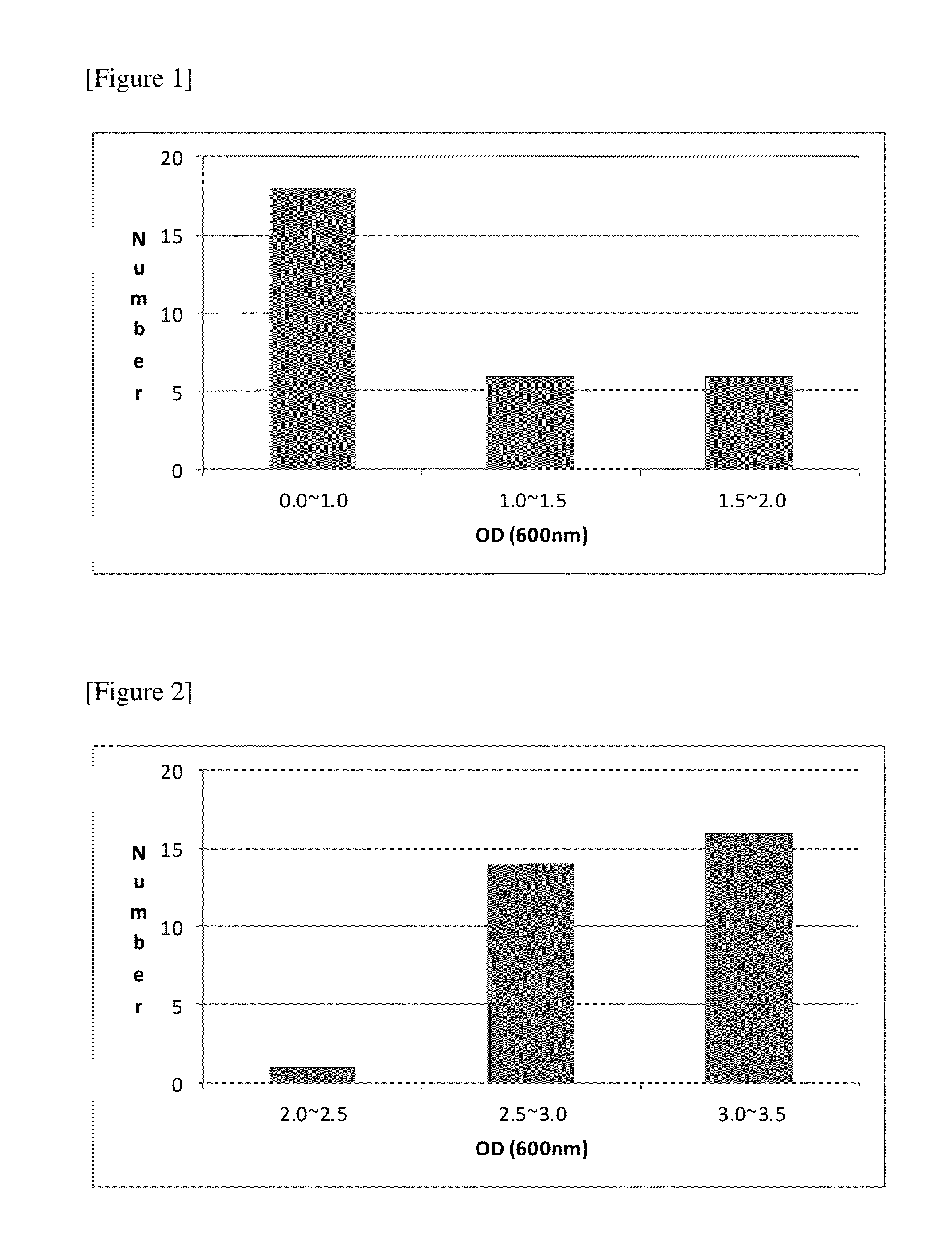

Hyphomicrobium sp. microorganism and method of producing pyrroloquinoline quinone using the same

InactiveUS20160160250A1Improve productivitySimple processBacteriaUnicellular algaeMicroorganismNitroguanidine

Provided are a Hyphomicrobium sp. mutant strain SWB-P91 (KCTC12695BP) having high productivity of pyrroloquinoline quinone, and a method of producing a Hyphomicrobium sp. mutant strain SWB-P91 (KCTC12695BP), which includes inducing mutation by treating a Hyphomicrobium sp. parent strain with N-methyl-N′-nitro-N-nitroguanidine (NTG) and UV rays, and culturing the mutant strain in a medium and selecting a mutant strain with high productivity of pyrroloquinoline quinone. Also, provided is a method of mass-producing pyrroloquinoline quinone, which includes culturing a Hyphomicrobium sp. mutant strain, SWB-P91 (KCTC12695BP), adsorbing pyrroloquinoline quinone in a fermenting culture solution from the fermenting culture solution using an adsorption resin, detaching the adsorbed pyrroloquinoline quinone with an eluent; and recovering pyrroloquinoline quinone by vacuum-evaporating the detached pyrroloquinoline quinone solution.

Owner:SUNGWUN BIO CO LTD

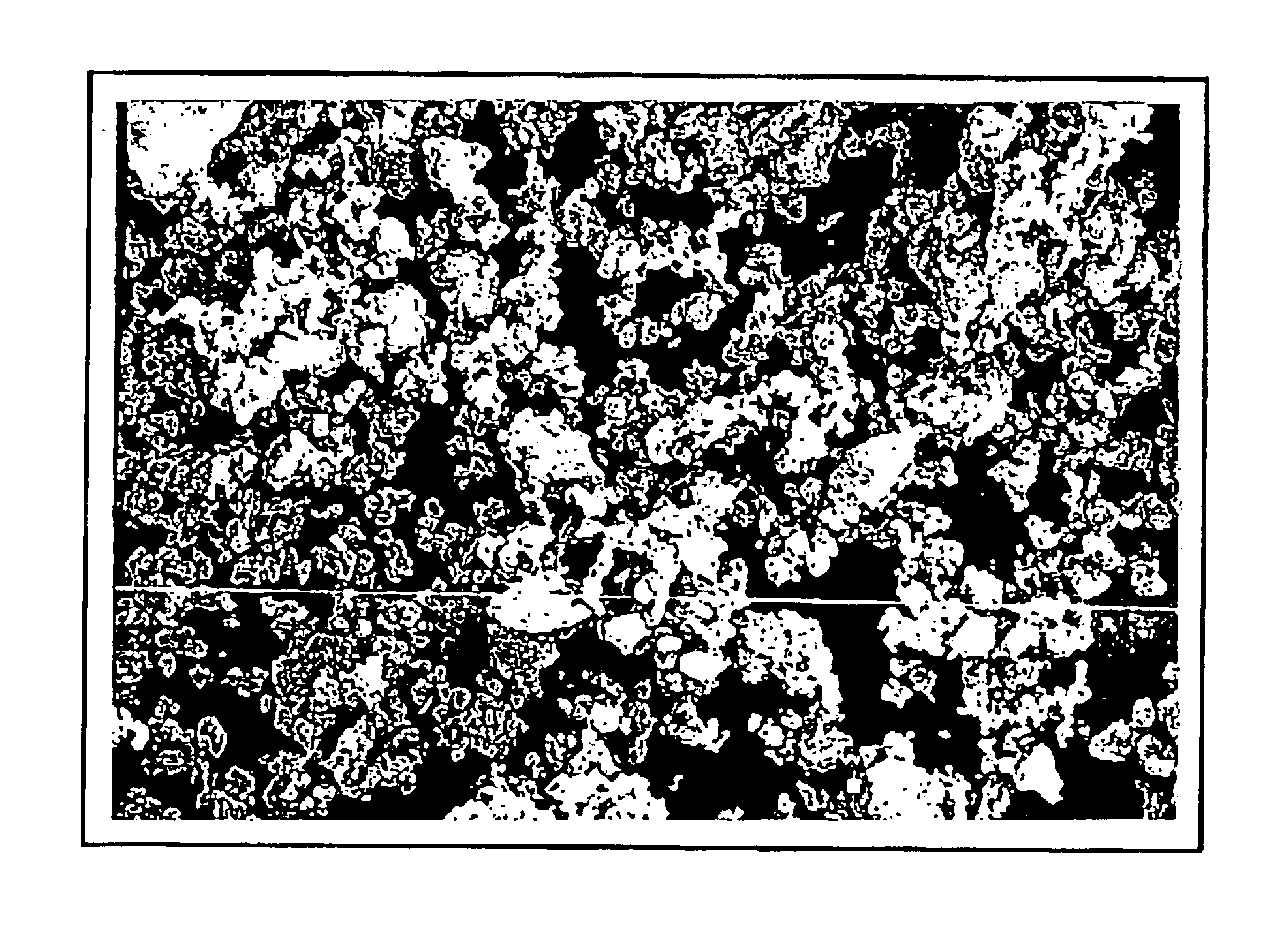

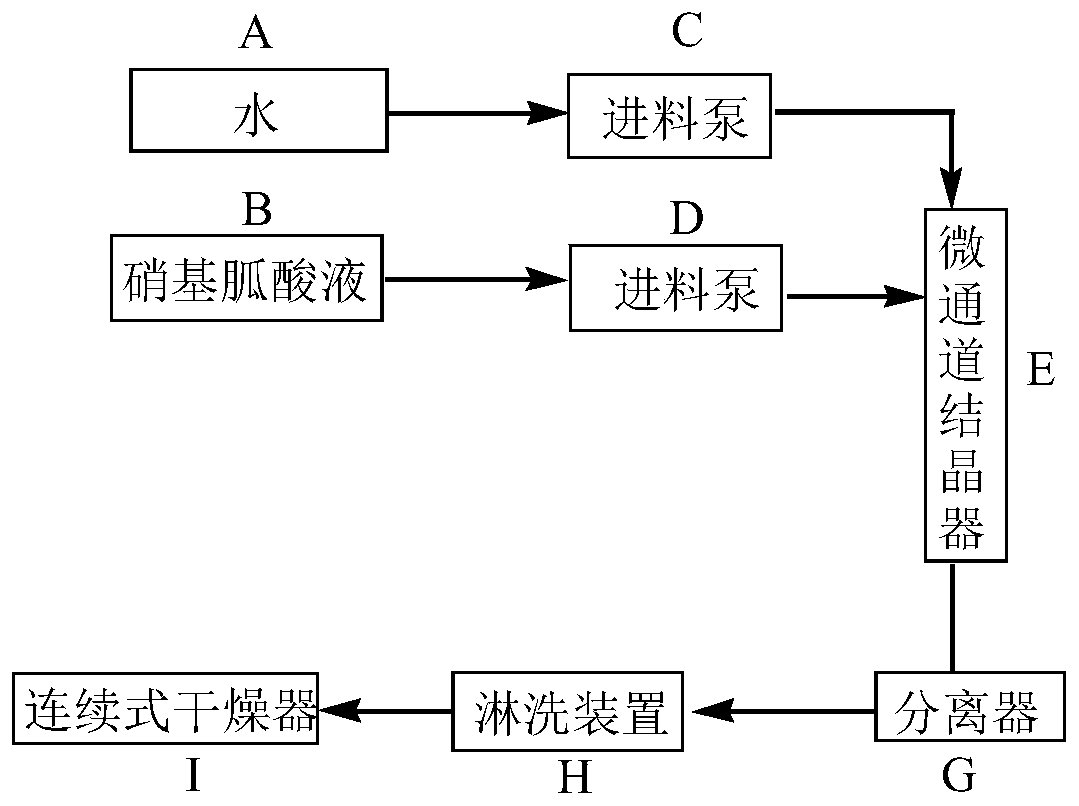

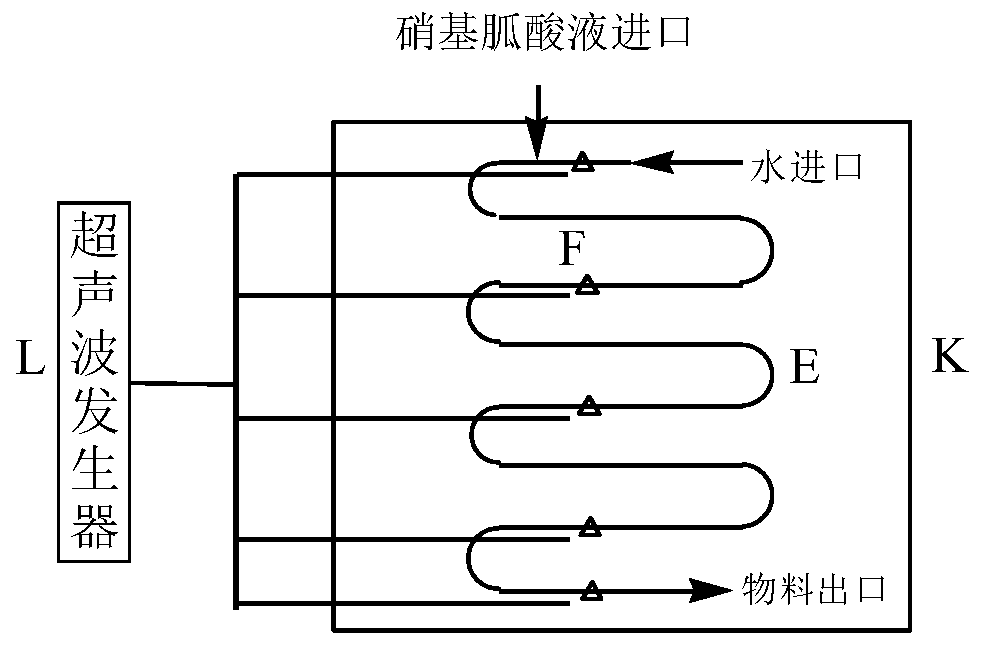

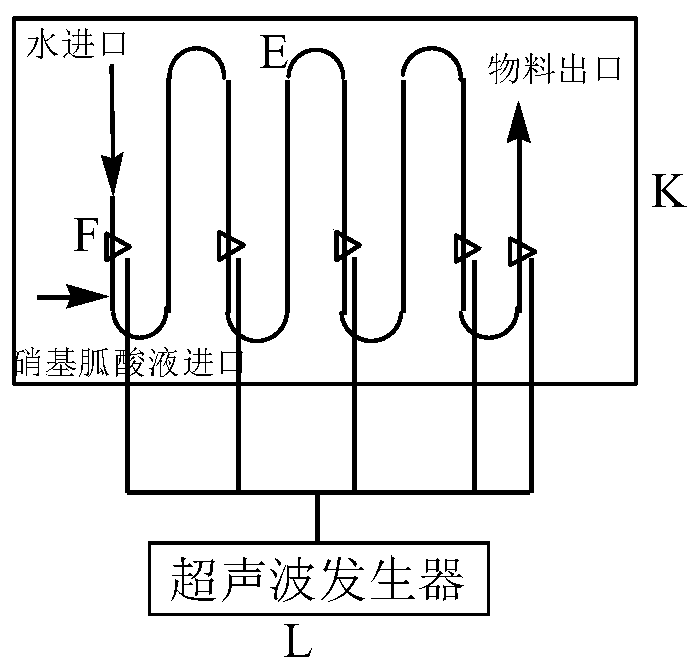

Nitroguanidine crystal and microchannel crystallization process and device of nitroguanidine

ActiveCN110204461AWith operational continuityReaction conditions are easy to controlOrganic chemistryVibration crystallizationNitroguanidinePhysical chemistry

The invention discloses a nitroguanidine crystal and a nitroguanidine microchannel crystallization process and device. After water, concentrated nitric acid and guanidine nitrate react, a nitroguanidine acid solution is obtained and is respectively fed into a microchannel crystallizer in a continuous mode for crystallization, ultrasonic treatment is carried out in the crystallization process, anda crystallized product is separated, washed and dried to obtain the high-purity spherical nitroguanidine crystal, wherein the mass fraction of nitroguanidine in the nitroguanidine acid solution is 25%-50%, the input flow rate of the nitroguanidine acid solution is 100-300 mL / min, the input flow rate of water is 150-400 mL / min, and the ultrasonic power of ultrasonic treatment is 1000-1800 W. The nitroguanidine microchannel crystallization process and the nitroguanidine microchannel crystallization device have the advantages of continuous operation, simple and controllable reaction conditions, high reaction safety and the like, and can be directly applied to actual production.

Owner:西安万德能源化学股份有限公司

Arthrobacter for producing beta-fructofuranosidase and application of arthrobacter

ActiveCN106148243AImprove the ability to convert into lactulose oligosaccharidesIncrease vitalityBacteriaMicroorganism based processesBiotechnologyNitroso

The invention relates to arthrobacter for producing beta-fructofuranosidase and application of the arthrobacter. The Arthrobacter sp. BLCY-004 is preserved in the China General Microbiological Culture Collection Center on August 16th, 2016, the address is the Institute of Microbiology, Chinese Academy of Sciences, No. 3, No.1 Yard, Beichen West Road, Chaoyang District, Beijing, and the preservation number is CGMCC No. 12855. The arthrobacter is separated from soil, the high-producing strain of high-producing beta-fructofuranosidase is obtained by means of mutagenic treatment technologies such as ultraviolet mutagenesis, nitrosoguanidine mutagenesis and the like and is named as BLCY-004, the enzyme activity reaches 1100U / ml and is improved by more than 50% as compared with that of conventional beta-fructofuranosidase, the capacity that sucrose is converted into lactosucrose can be highly improved by applying the arthrobacter to production of lactosucrose, and production cost is lowered significantly.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

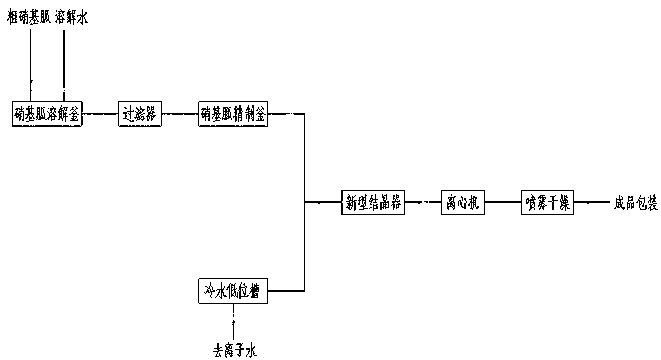

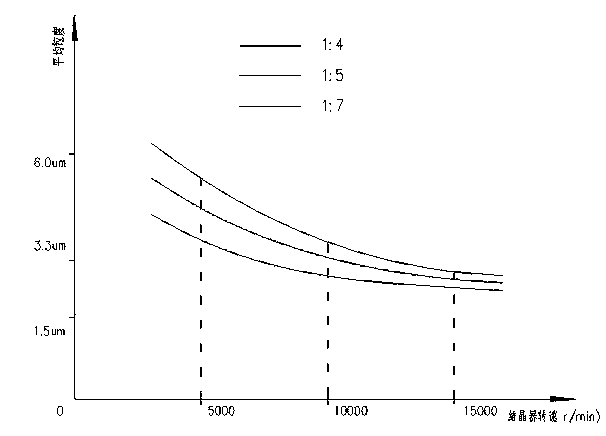

Process for continuously preparing superfine nitroguanidine

ActiveCN102702034AReduce the amount of mother liquorReduce wasted waterOrganic chemistryOrganic compound preparationRefluxNitroguanidine

The invention relates to a process for continuously preparing superfine nitroguanidine. The process comprises the following steps of: adding nitroguanidine and deionized water into a dissolving kettle in a ratio of 1:7, heating the nitroguanidine and deionized water to reach a reflux state, and performing refluxing to completely dissolve the nitroguanidine; filtering a nitroguanidine solution to remove mechanical impurities, and adding the filtered solution into a nitroguanidine refining kettle; mixing the refined nitroguanidine and cooling water, controlling the ratio of the nitroguanidine to the water to be 1:4-1:7, adding a mixture into a crystallizer, and thus obtaining the superfine nitroguanidine with the particle size range of 2 to 6 micrometers; and performing centrifugal dewatering, washing, drying, water content and acidity regulating, and packaging on the crystallized superfine nitroguanidine to obtain a finished superfine nitroguanidine product.

Owner:NANTONG TENDENCI CHEM

Pyrotechnic composition generating clean gases with low levels of nitrogen oxides, and pellets of such a composition

InactiveUS6024811ARaise the ratioReduce the ratioAmmonium perchlorate explosive compositionsPressure gas generationEpoxyAmmonium nitrate

The present invention relates to gas-generating pyrotechnic compositions. The compositions according to the invention contain a small amount of epoxy binder, stabilized ammonium nitrate, optionally potassium perchlorate or an organic oxidant containing nitrogen and, characteristically, a reactive organic nitrogen compound selected from nitroguanidine, guanidinium nitrate and oxamide. This reactive nitrogen compound may advantageously be combined with cupric oxide. The compositions according to the invention produce nitrogen-rich gases with very low levels of nitrogen oxides, and find their preferred application in the form of pellets as pyrotechnic charges in gas generators for pyrotechnic extinguishers, for devices designed to inflate external structures or for devices designed to protect the occupants of a motor vehicle.

Owner:SNPE MATERIAUX ENERGETIQUES

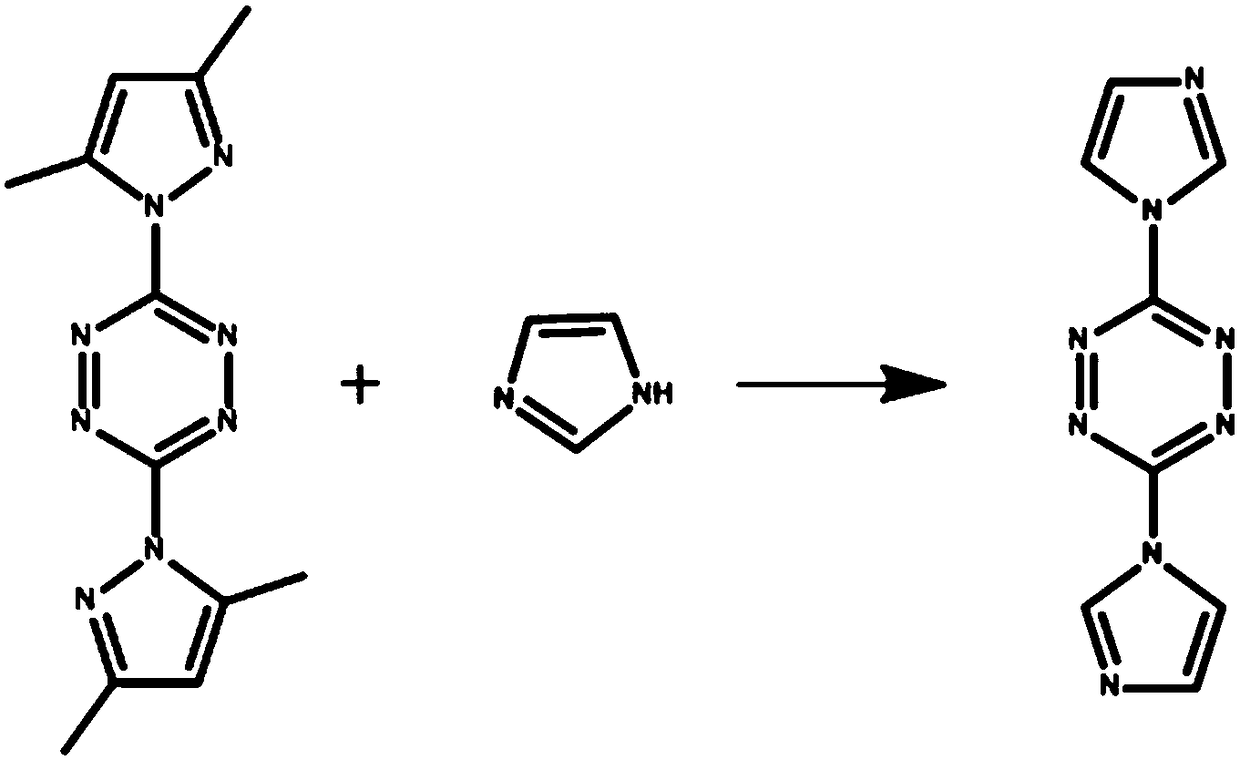

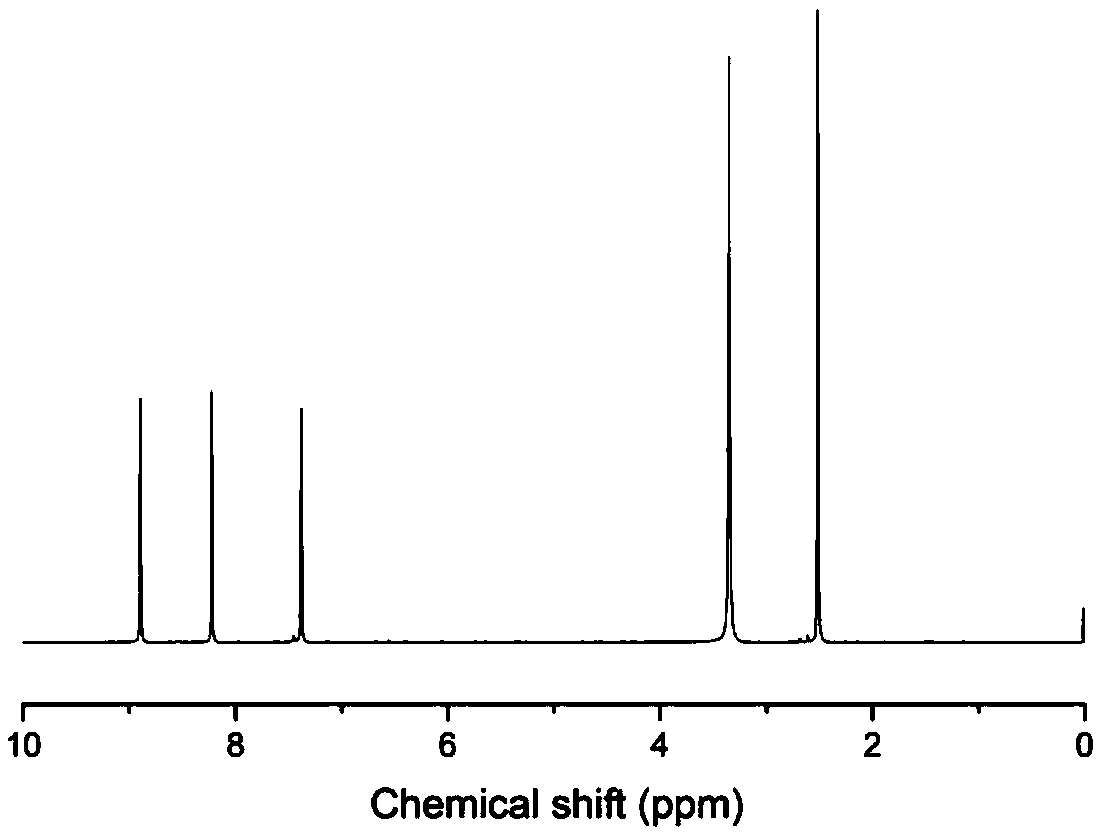

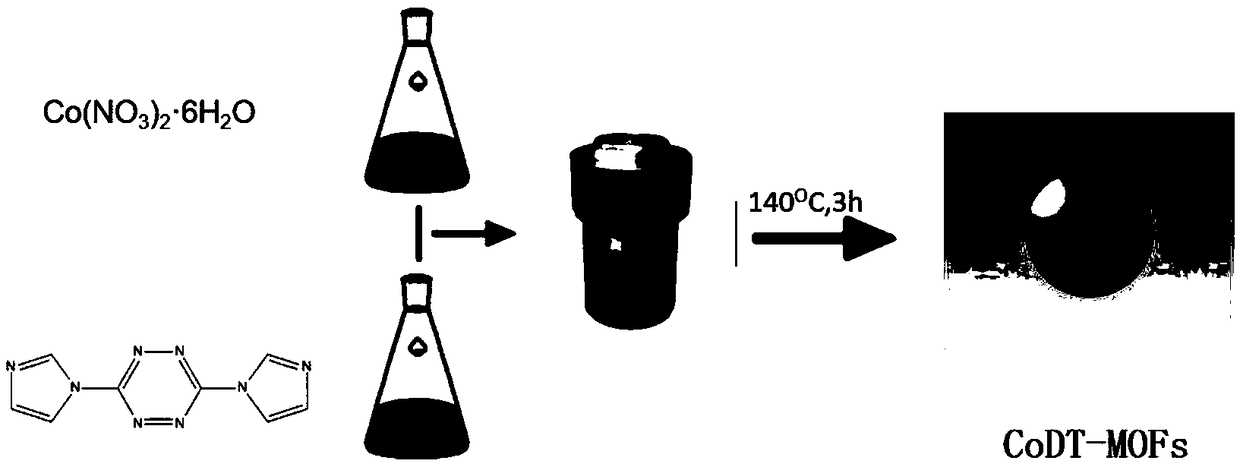

A spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst and its preparation method and use

ActiveCN109192996AORR catalytic activity is goodLarge specific surface areaCell electrodesNitrogen dopedOxygen reduction

The invention provides a spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst, which is prepared by the following preparation methods: firstly, synthesizing 3, 6-dimethyl-3-nitroguanidine by guanidine nitrate; secondly, synthesizing 3, 6-dimethyl-3-nitroguanidine by guanidine nitrate; finally, synthesizing 3, 6-dimethyl-3-nitroguanidine by guanidine nitrate. Bis (3, 5-dimethylpyrazole)-1, 2, 4, 5-Tetrazine (BT), and 3, 6-Bis (3, 5-dimethylpyrazole)-1, 2, 4, 5-Imidazole is added into tetrazine (BT) to synthesize 3, 6-Bis (imidazolyl)-1, 2, 4, 5-Tetrazine (DT) ligand,and then 3, 6-Bis (imidazolyl)-1, 2, 4, 5-Tetrazine (DT) coordinated with transition metal cobalt ion to form cobalt-based zeolite imidazolium ester framework coordination polymer (CoDT ZIF), and then pyrolyzed cobalt-based zeolite imidazolium ester framework coordination polymer (CoDT ZIF) to prepare spherical nitrogen doped carbon supported cobalt (Co N / C) oxygen reduction catalyst. The preparation method of the catalyst is simple, the cost is low, and the catalyst has extremely rich active sites, which is conducive to promote the practical application of fuel cells.

Owner:XIANGTAN UNIV

Continuous synthetic method of nitroguanidine

InactiveCN105152984AIncrease contentHigh yieldOrganic chemistryOrganic compound preparationNitroguanidineRetention time

The invention relates to a continuous synthetic method of nitroguanidine. The method comprises the steps that guanidine nitrate and concentrated sulfuric acid are used as raw materials to respectively flow into a reaction kettle formed by serially connecting three reaction kettles with openings formed in the side surfaces according to a molar ratio of 1: 2, by controlling the material flow rate, the temperature of each synthetic kettle and the material reaction retention time, and feeding reaction is continuously carried out by virtue of the overflow of materials after the reaction, wherein the content of a finished product is 98.0 percent to 98.5 percent, and the comprehensive yield is 85 percent to 95 percent. By adopting the method for continuously synthesizing the nitroguanidine, the content and yield of the product are remarkably increased, the problems that an additional device is needed in a conventional intermittent reaction and leakage appears in a transferring process can be avoided, the operation intensity is greatly alleviated, and the production efficiency is greatly improved.

Owner:NANTONG TENDENCI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com