A spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst and its preparation method and use

A carbon-supported cobalt-based, nitrogen-doped technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low methanol oxidation catalytic performance, high cost and low life of platinum-based catalysts, and achieve excellent stability and resistance The effect of methanol performance, good ORR catalytic activity, and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] According to the first embodiment provided by the present invention, a spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst is provided.

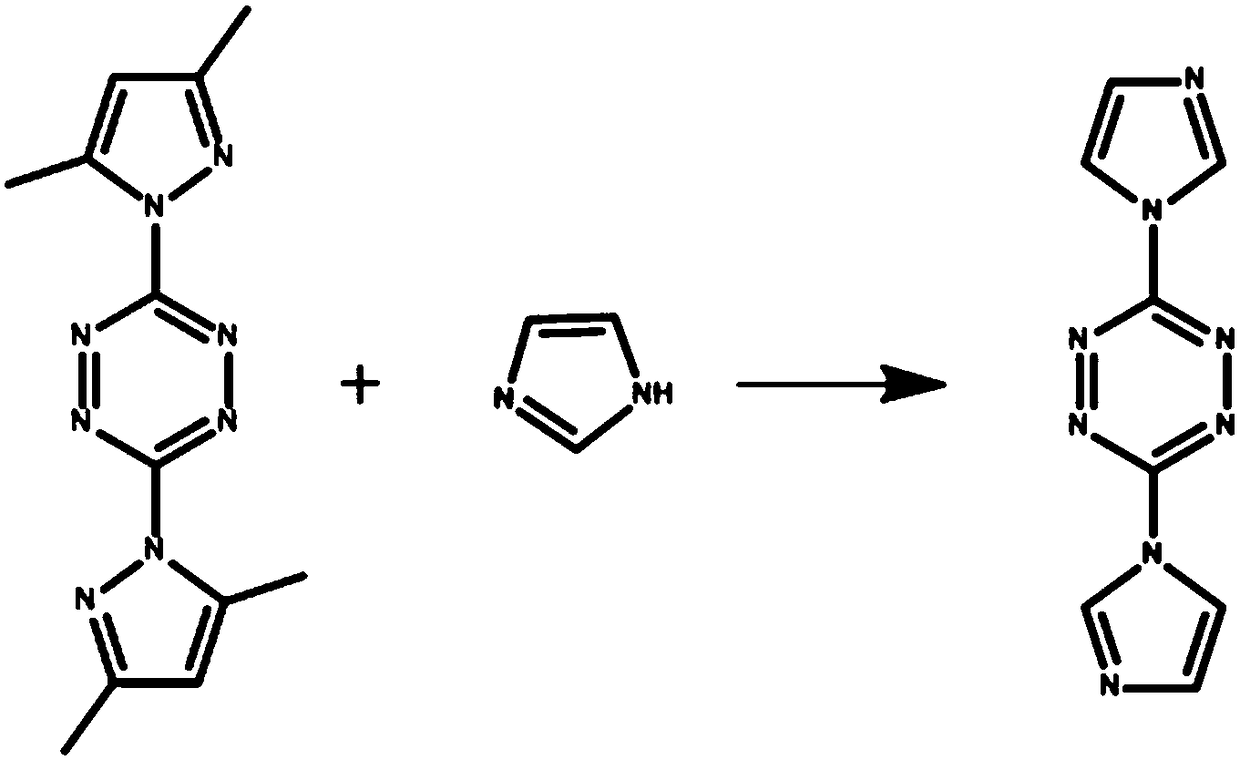

[0047] A spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst is prepared by the following preparation method: first synthesize 3,6-bis(3,5-dimethylpyrazole)-1,2 through guanidine nitrate, 4,5-tetrazine (BT), then add imidazole to 3,6-bis(3,5-dimethylpyrazole)-1,2,4,5-tetrazine (BT) to synthesize 3,6- Bis(imidazolyl)-1,2,4,5-tetrazine (DT) ligand, followed by 3,6-bis(imidazolyl)-1,2,4,5-tetrazine (DT) with transition metal Cobalt ions are coordinated to form a cobalt-based zeolite imidazolate framework coordination polymer (CoDT-ZIF), and then the spherical nitrogen-doped carbon-supported cobalt is prepared by high-temperature pyrolysis of the cobalt-based zeolite imidazolate framework coordination polymer (CoDT-ZIF) based (Co-N / C) oxygen reduction catalysts.

[0048] In the p...

Embodiment 1

[0070] A preparation method of a spherical nitrogen-doped carbon-supported cobalt-based oxygen reduction catalyst, the method comprising the following steps:

[0071] (1) Preparation of 3,6-bis(3,5-dimethylpyrazole)-1,2,4,5-tetrazine (BT): 3,6-bis(3,5 -Dimethylpyrazole)-1,2,4,5-tetrazine (BT);

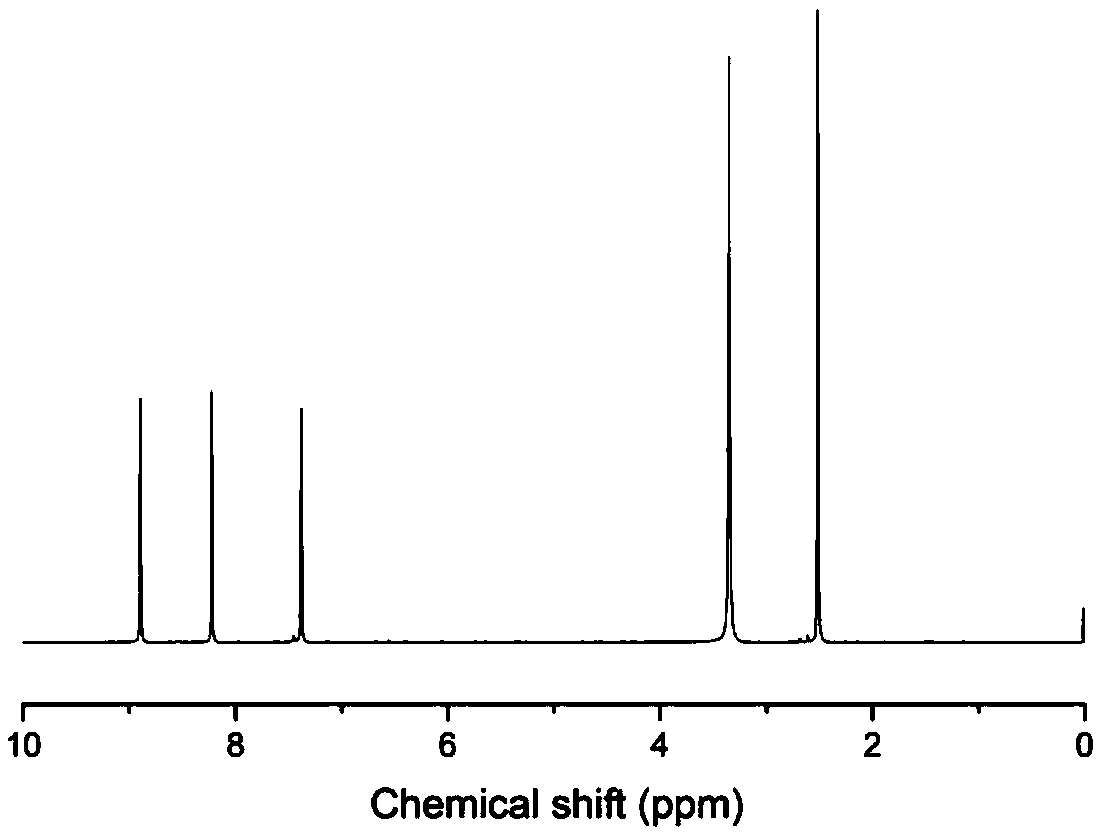

[0072] (2) Preparation of 3,6-bis(imidazolyl)-1,2,4,5-tetrazine (DT) ligand: 3,6-bis(3,5-dimethylpyrazole)-1 , 2,4,5-tetrazine (BT) is loaded into the reactor, imidazole is added, heated for a period of time, cooled, filtered, and dried to obtain 3,6-bis(imidazolyl)-1,2,4, 5-tetrazine (DT) ligand;

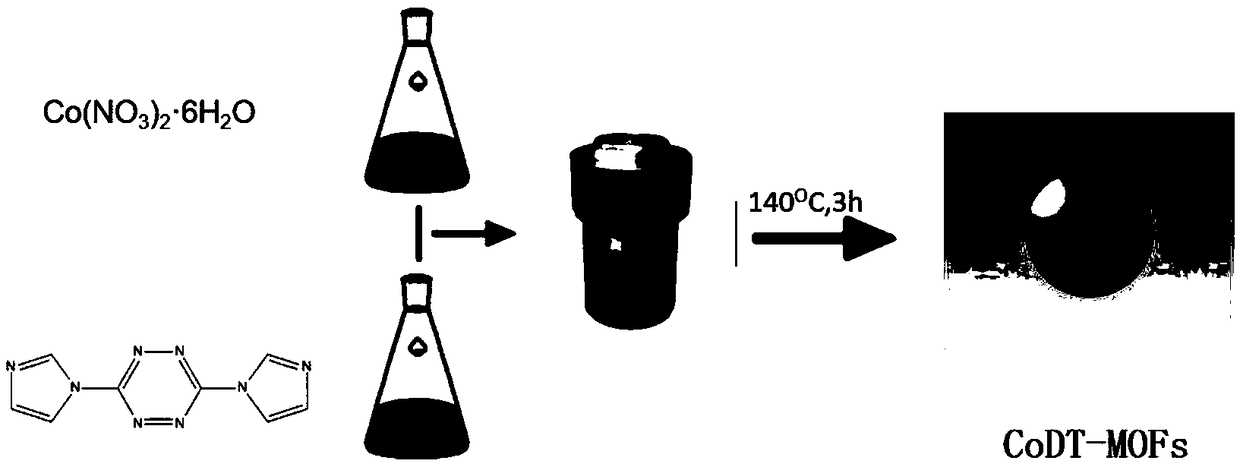

[0073] (3) Preparation of cobalt-based zeolite imidazolate framework coordination polymer (CoDT-ZIF): 3,6-di(imidazolyl)-1,2,4,5-tetrazine (DT) ligand was dissolved in organic Add cobalt nitrate hexahydrate to the solvent, heat and react for a period of time after dispersion, filter with suction after cooling, and wash to obtain a brown solid, which is the cobalt-based zeolite imidazolat...

Embodiment 2

[0076] Preparation of 3,6-bis(3,5-dimethylpyrazole)-1,2,4,5-tetrazine (BT):

[0077] Dissolve 6.11g of guanidine nitrate in 50ml of dioxane solution, add 6.26g of hydrazine hydrate, heat to 110°C, and reflux for 4h, filter to obtain a white solid, then dissolve the white solid in water, add 15.02g of Acetylacetone, heated to 70°C for 4 hours, filtered, washed with water and dried to obtain 3,6-bis(3,5-dimethylpyrazole)-1,2,4,5-tetrazine (BT) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com