a h 2 Method for preparing carbon-supported PT alloy catalyst by gas-phase thermal reduction

A catalyst, gas-phase technology, applied in the field of electrochemical catalysis, can solve the problem of low utilization rate of Pt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

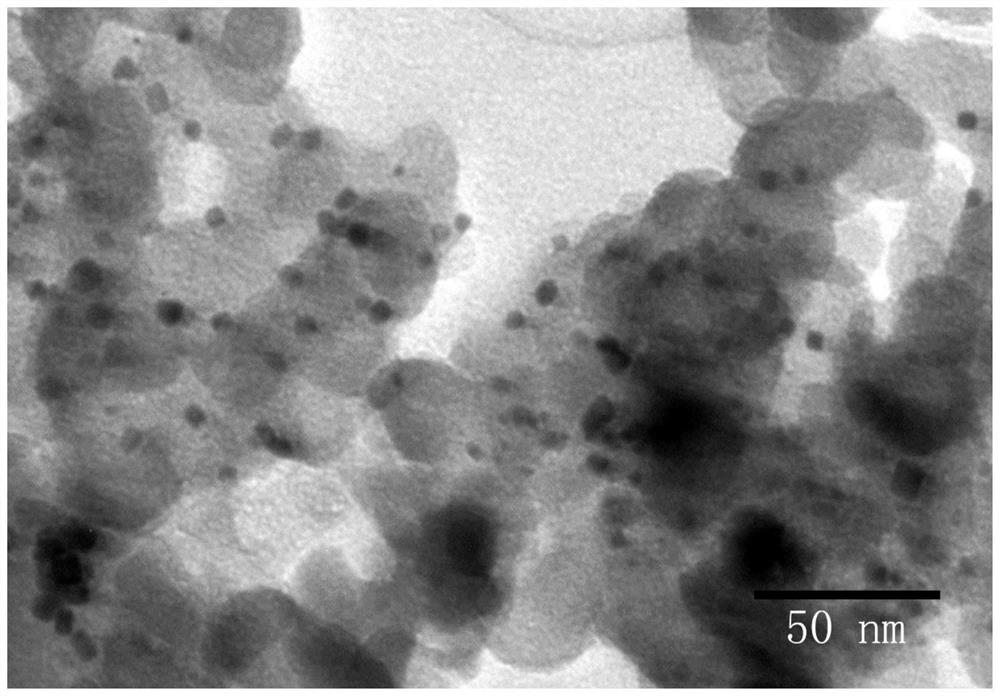

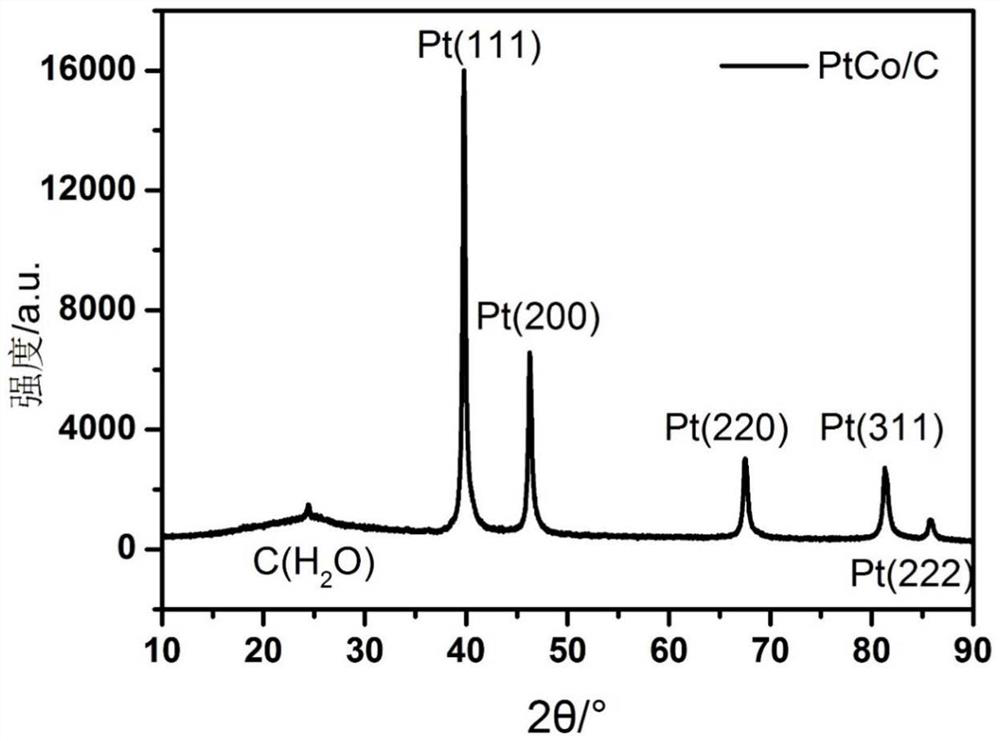

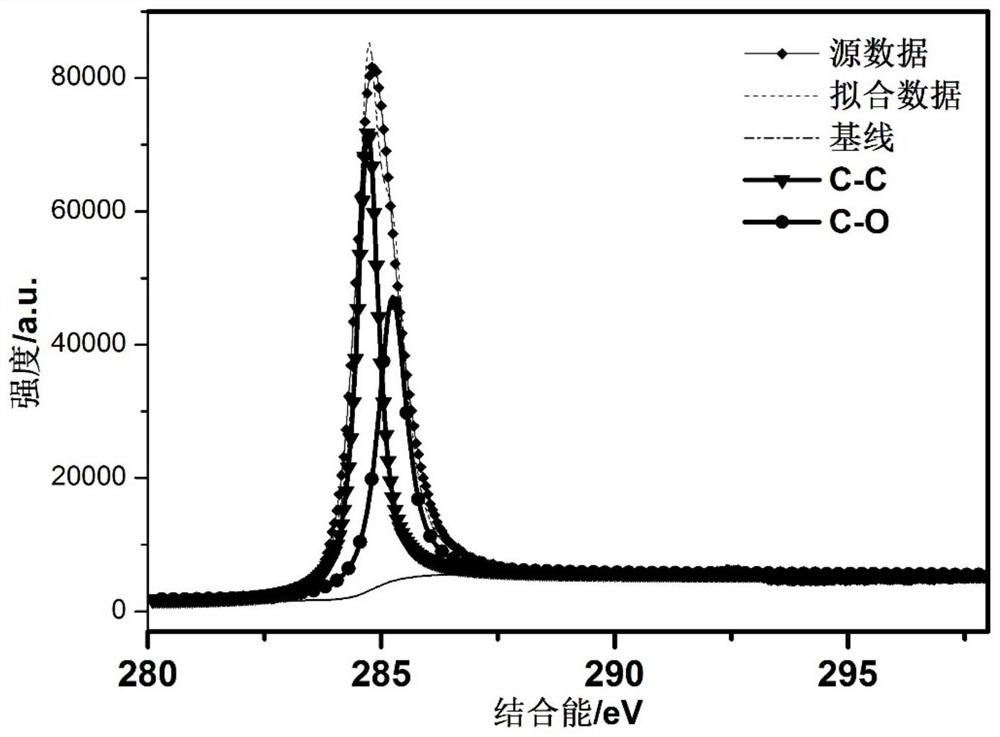

[0059] Take 10mL of 0.017mol / L H 2 PtCl 6 aqueous solution, add 4g NH 4 Cl precipitant, stirred at room temperature for 4 hours to obtain primary sediment A; take 2mL of 0.1mol / L CoCl 2 Solution, add 1g oxalic acid, 4mL deionized water, stir at room temperature for 4h to obtain primary sediment B; mix A and B suspensions, add 50mg carbon powder XC-72 aqueous solution, mix and stir for 4h, centrifuge, dry at 80°C, and h 2 / N 2 (20%) pyrolysis and reduction in the mixed gas, the temperature is 350°C, the time is 4h, the heating rate is 5°C / min, after the reaction is completed, use N 2 Replacement of H in the reactor 2 / N 2 Mixed gas, and take out the sample, so as to obtain the highly active H 2 Pt alloy catalyst prepared by thermal reduction method.

Embodiment 2

[0061] Take 10mL of 0.017mol / L H 2 PtCl 6 aqueous solution, add 4g NH 4 Cl, 4g ammonium carbonate, 10mL deionized water, stirred at room temperature for 4h to obtain the primary sediment A'; take 2mL 0.1mol / L CoCl 2 Solution, add 2g oxalic acid, 1g urea, 15mL deionized water, stir at room temperature for 4h, obtain primary sediment B'; mix A' and B' suspensions, add 50mg carbon powder XC-72 aqueous solution, mix and stir for 4h, centrifuge , dried at 80°C, in H 2 / N 2 (20%) pyrolysis and reduction in the mixed gas, the temperature is 350°C, the time is 4h, the heating rate is 5°C / min, after the reaction is completed, use N 2 Replace the H in the reaction furnace 2 / N 2 Mixed gas, and take out the sample, so as to obtain the highly active H 2 Pt alloy catalyst prepared by thermal reduction method.

Embodiment 3

[0063] Electrochemical tests were performed in a three-electrode system to characterize the oxygen reduction activity of the catalysts. The electrolyte solution of this system is 0.1mol L -1 HClO 4 , the counter electrode is a Pt sheet electrode, the reference electrode is a saturated calomel electrode, and the cyclic voltammetry test electrolyte solution is N 2 Saturation, the test system is Gamry3000; ORR test solution is O 2 saturation. Preparation of the catalytic layer of the rotating disk electrode membrane: 40% Pt / C catalyst: 5 mg catalyst, 2.5 mL isopropanol, ultrasonication; add 50 μL of 5wt% Nafion solution, ultrasonication, take 3.2 μL of the above dispersed slurry and coat it on a rotating disk electrode The disc electrode surface, as the working electrode. Due to the low loading of PtCo / C catalyst, preparation of membrane catalyst layer: 5mg catalyst, 2.5mL isopropanol, ultrasonication; add 50μL of 5wt% Nafion solution, ultrasonication, take 10μL of the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com