Patents

Literature

76results about How to "Not prone to chipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of alumina polycrystalline material block

Owner:SHANGHAI UNIV

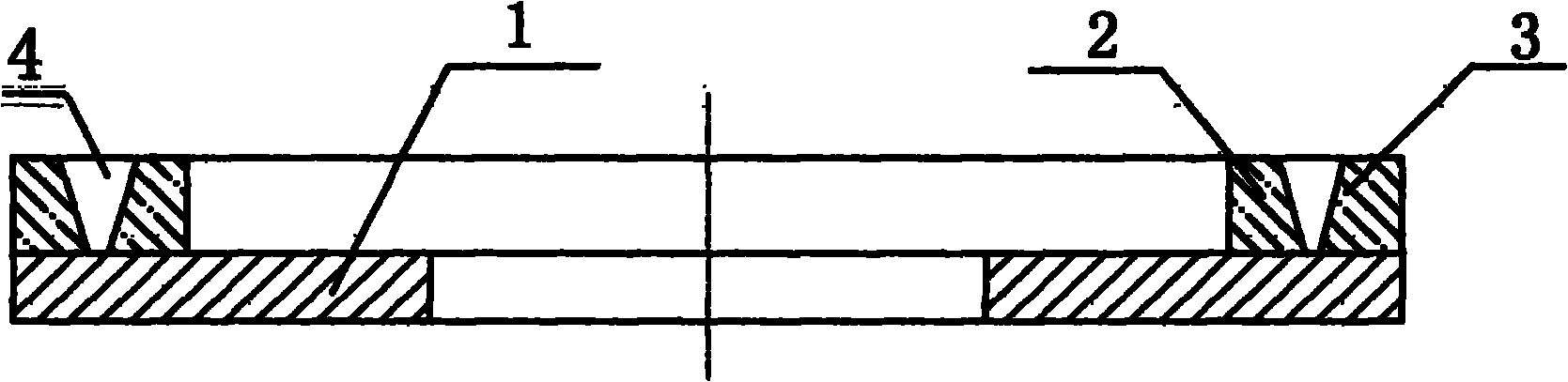

Integrated circuit inverting welding air impermeability packaging structure

ActiveCN103928409AProtect air tightnessGuaranteed air tightnessSemiconductor/solid-state device detailsSolid-state devicesState of artSize change

An integrated circuit inverting welding air impermeability packaging structure comprises a ceramic substrate and a flip chip. The flip chip is fixed on the ceramic substrate through chip protruding points, padding resin is arranged between the chip protruding points, and a metallization layer is arranged around the flip chip. The integrated circuit inverting welding air impermeability packaging structure further comprises a kovar sealing cover plate and a ceramic metallization sealing ring. The ceramic metallization sealing ring is arranged on the ceramic substrate on the outer side of the flip chip, and the resin is packaged between the flip chip and the ceramic metallization sealing ring through the kovar sealing cover plate. A covering metal layer in the prior art is replaced by the kovar sealing cover plate which is made of kovar alloy, and the thickness of the kovar sealing cover plate ranges from 100 microns to 200 microns. When the integrated circuit inverting welding air impermeability packaging structure is used in high-temperature reflow welding packaging chips or chips, very small gaps between the kovar sealing cover plate and the padding resin are enough to relieve the size change, caused by temperature change, of the padding resin, and the air impermeability of packaging is protected.

Owner:JIANGSU PROVINCE YIXING ELECTRONICS DEVICE GENERAL FACTORY

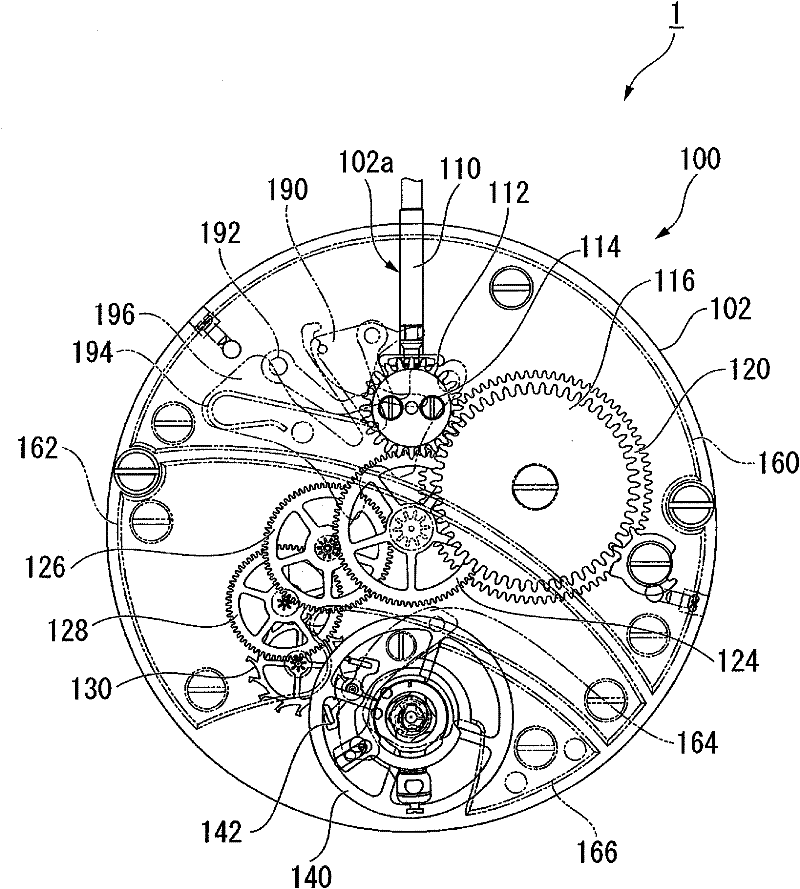

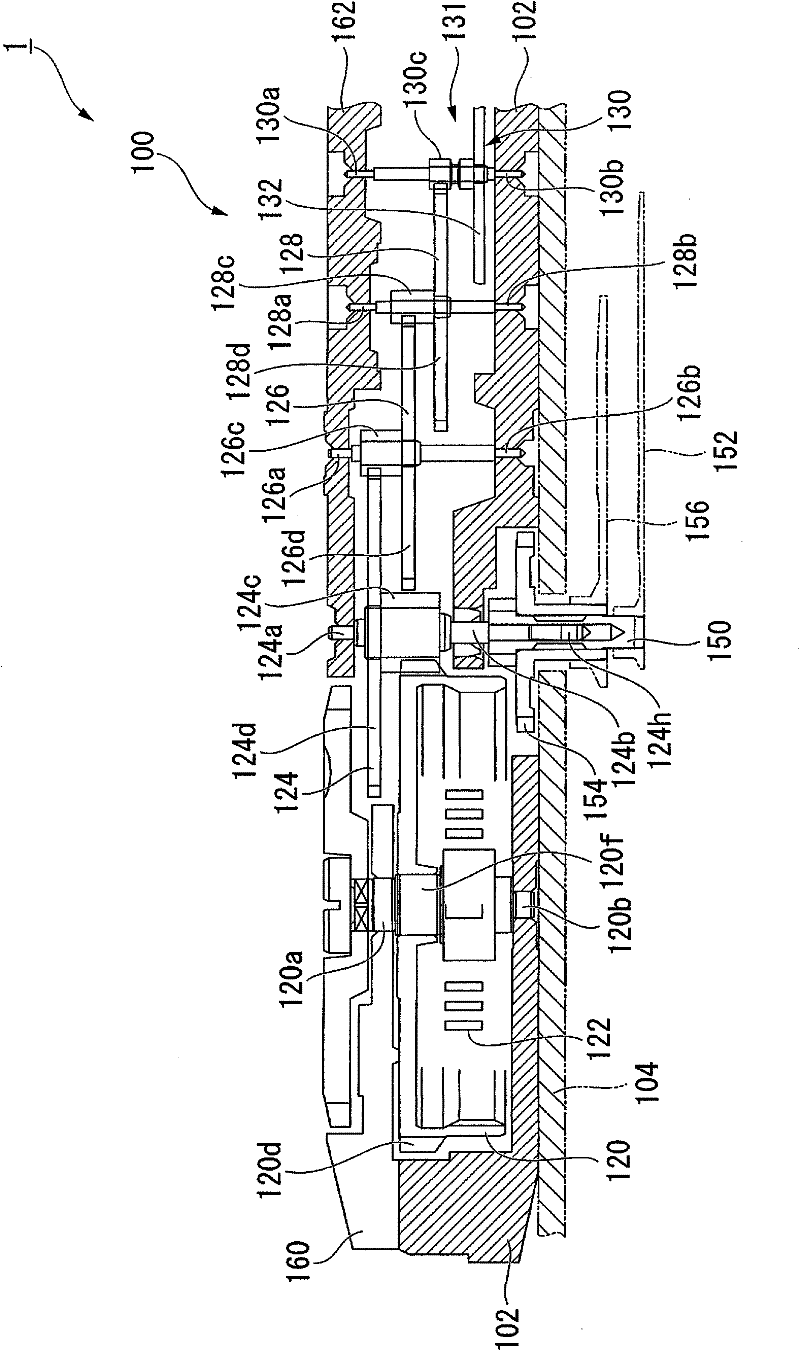

Gear for clock and clock

The invention provides a high-quality gear for clocks and a clock. The gear which can be manufactured with high efficiency thus has a low cost. Meanwhile, the gear has the characteristics of delicacy, high-precision shape, high wear resistance and high working reliability. The gear (130) for clocks comprises a tooth-shaped gear part (132) formed through photoetching. The gear part is made of materials which can survive the photoetching and has higher hardness and toughness than silicon (Si).

Owner:SEIKO INSTR INC

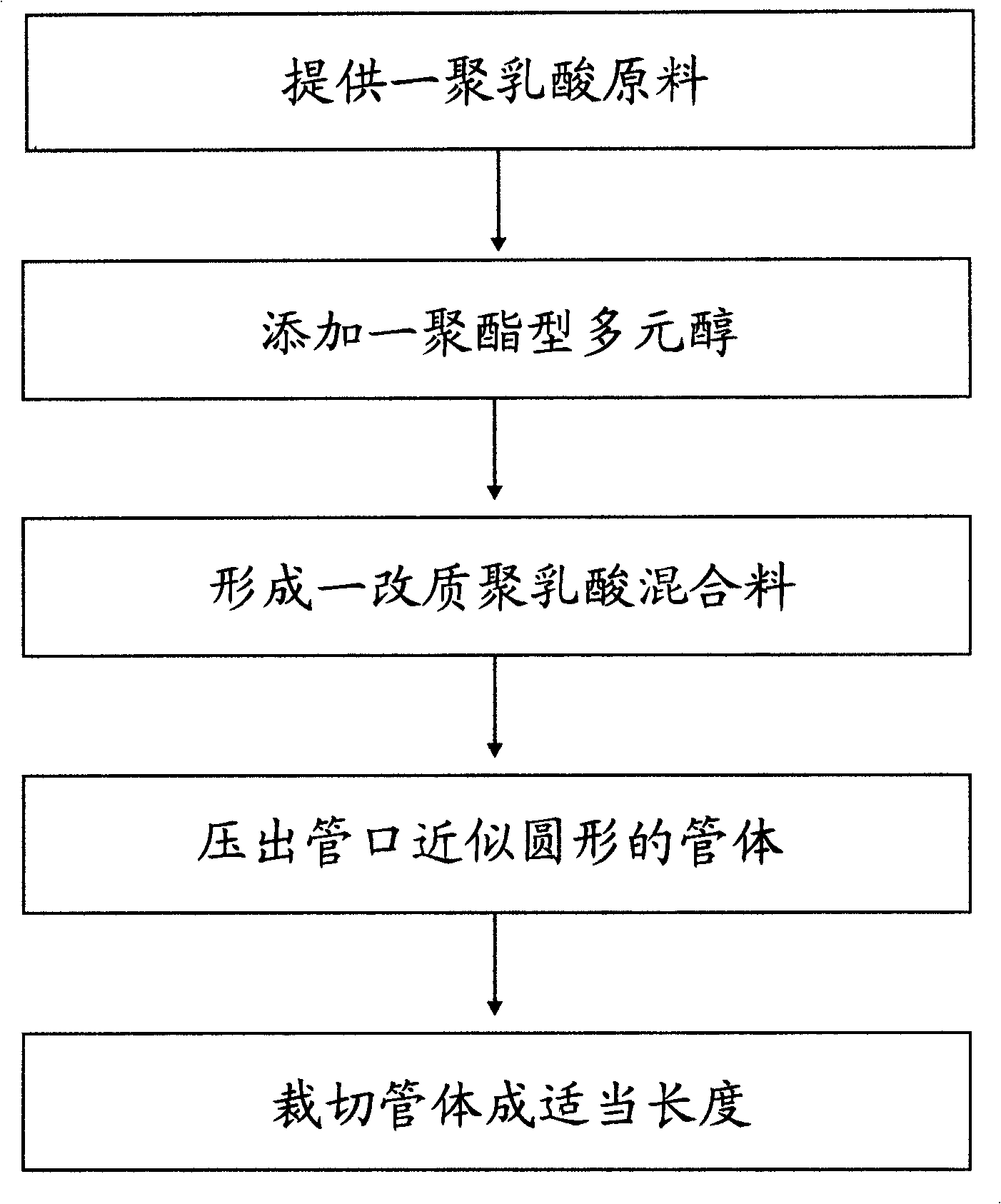

Biofragmentable straw and method for manufacturing same

The invention relates to a biodegradable straw and preparation method thereof, at least comprising: 70-99.9 weight percentage of polylactate and 0.1-30 weight percentage of polyester polyhydric alcohol. The preparation method comprises: providing raw material of polylactate; adding polyester polyhydric alcohol into the raw material to form modified polylactate mix material containing 70-99.9 weight percentage of raw material of polylactate and 0.1-30 weight percentage of polyester polyhydric alcohol; sending the polylactate mix material into an extruder wherein the extruder is in about circular tube; and cutting the tube to a preset length. The biodegradable natural polymer polylactate is used as main component and the polyester polyhydric alcohol is used as modifying agent and the aliphatics longchain and alcohols function group on the polyhydric alcohol structure can increased the impact resistance and flexibility of the finished products.

Owner:WEI MON IND +1

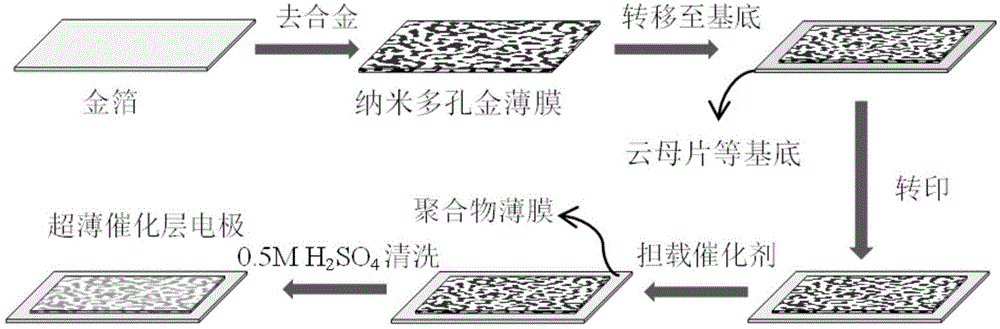

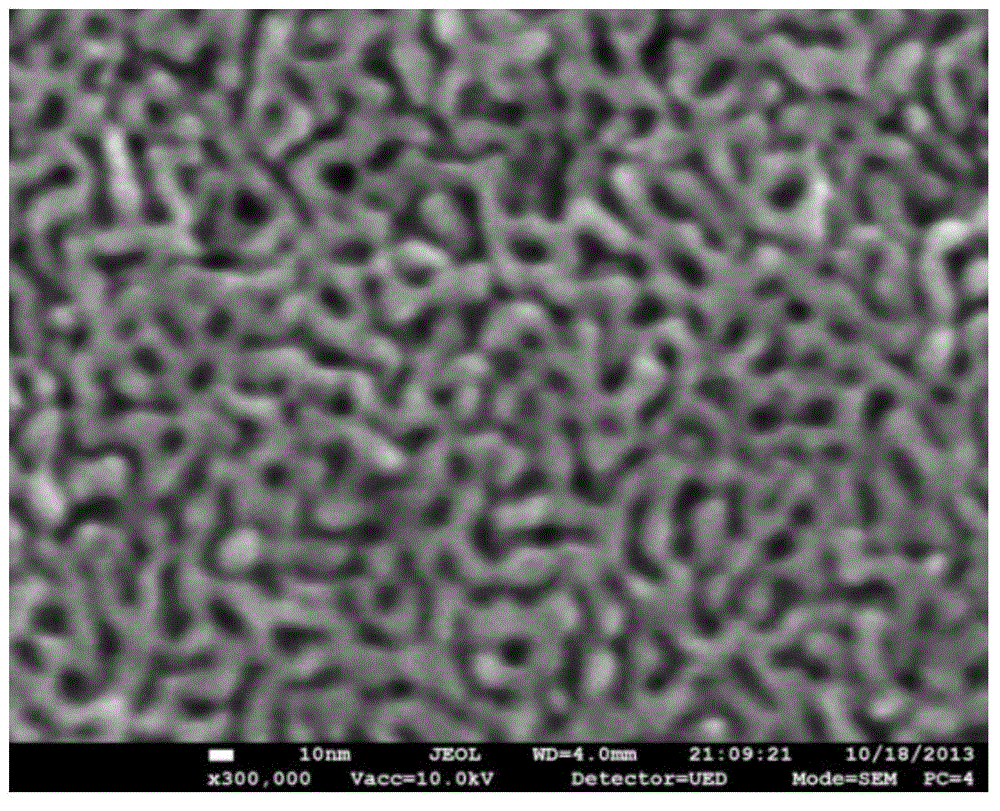

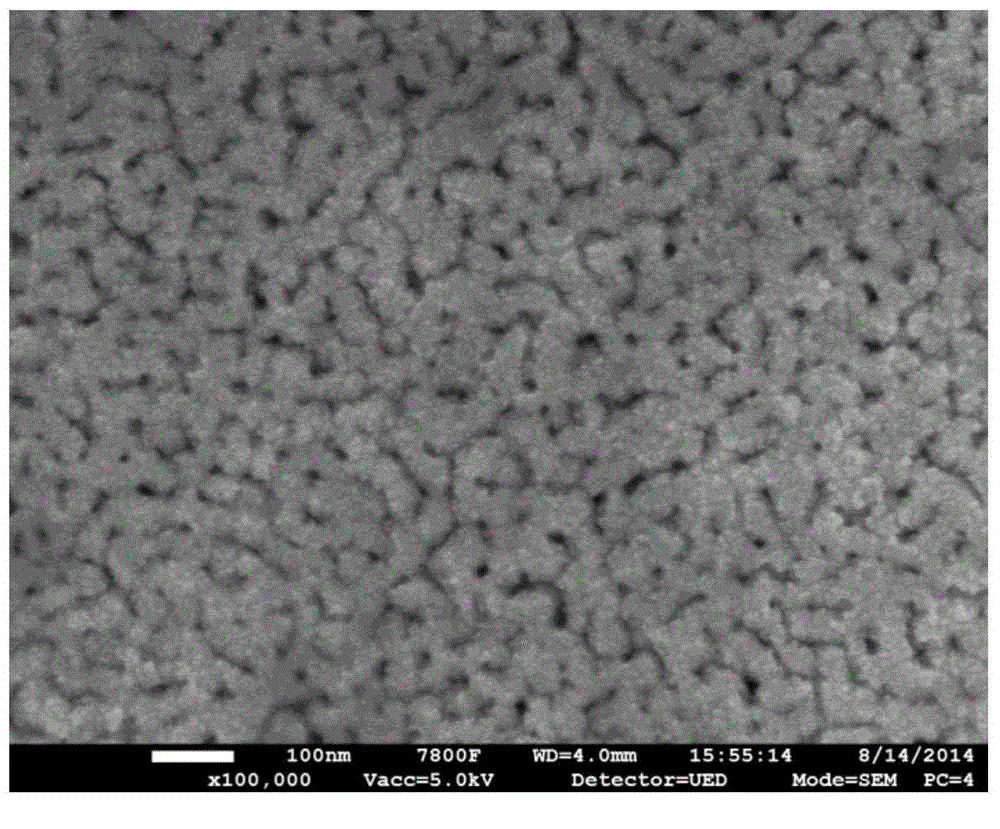

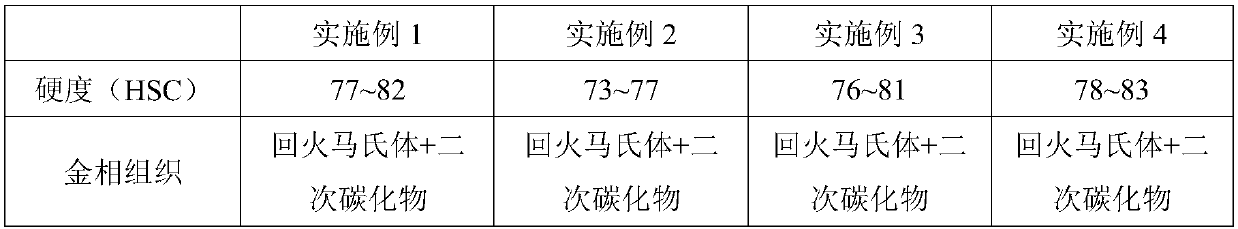

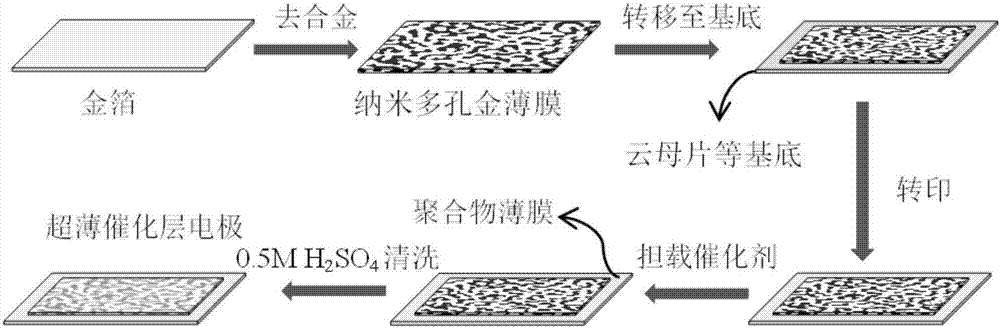

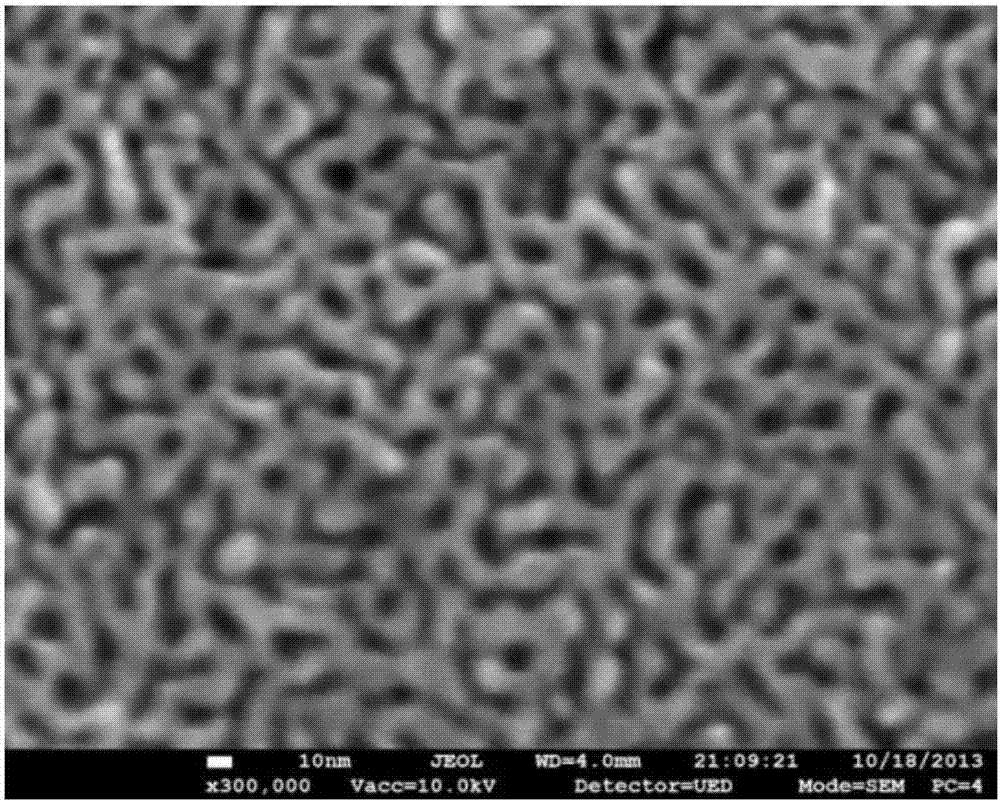

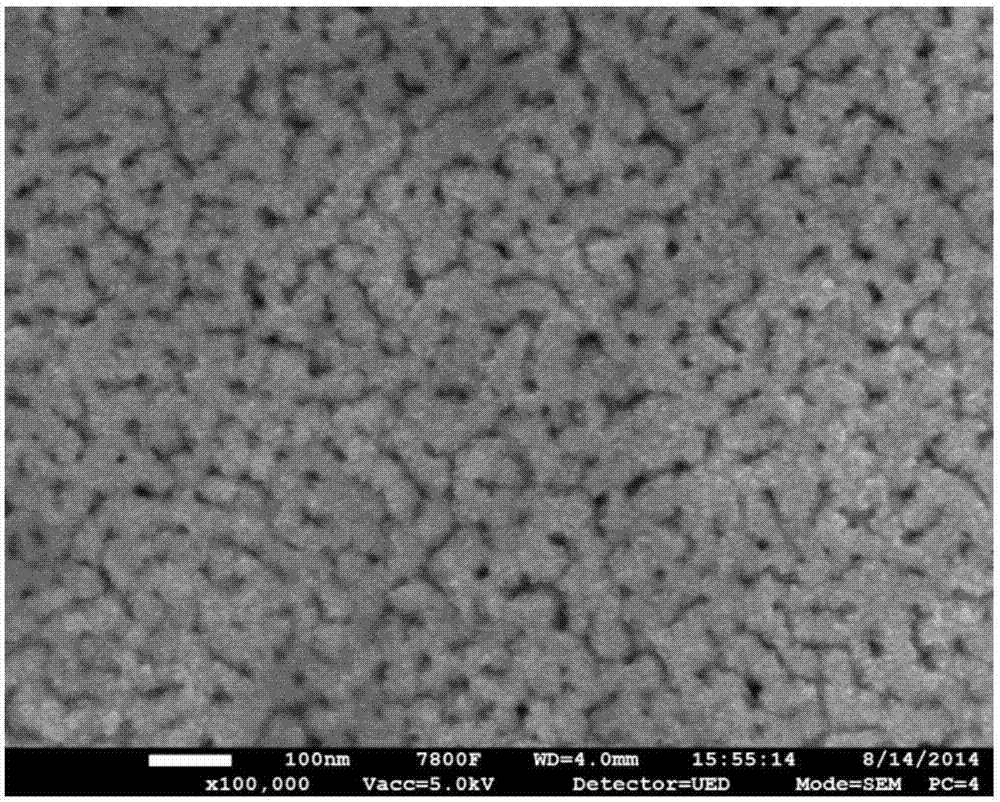

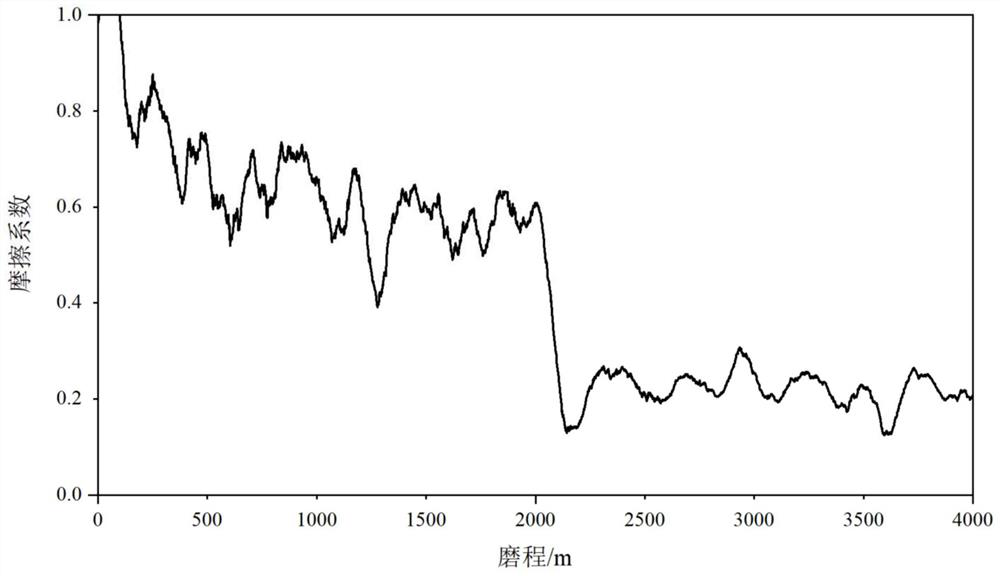

Method for preparing fuel cell thin film electrode by using nanoporous gold

ActiveCN105633420ANot prone to chippingEvenly dispersedCell electrodesElectrochemical responseThin film electrode

The invention provides a method for preparing a fuel cell thin film electrode by using nanoporous gold. The preparation method comprises the following steps of firstly taking a gold foil as a raw material, and obtaining a nanoporous gold thin film through a dealloying method; secondly, transferring the thin film to one side of an ion exchange film; and finally, taking the composite thin film as a support layer and depositing a catalyst by an electrochemical method to form the nanoporous gold thin film electrode. The electrochemical deposition method adopted by the invention has the advantages of environmental friendliness, controllable catalyst loading, easiness in amplification and the like, and the constructed nanoporous gold thin film electrode can be used for a fuel cell, other batteries and other electrochemical reactors.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

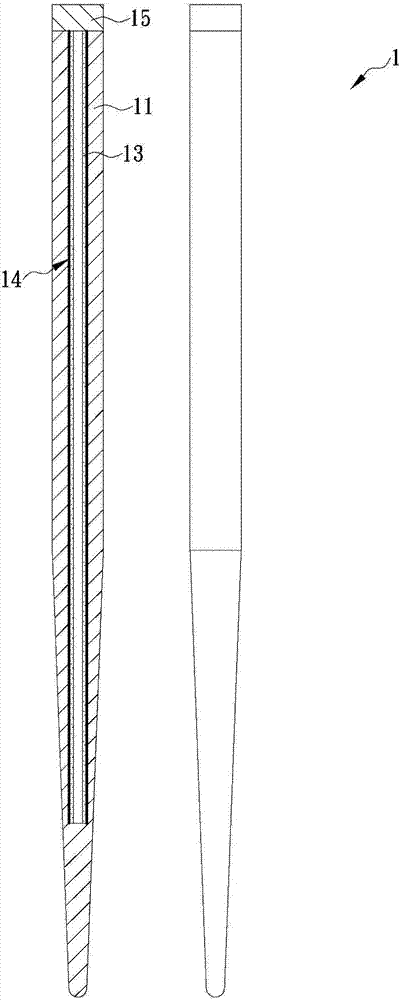

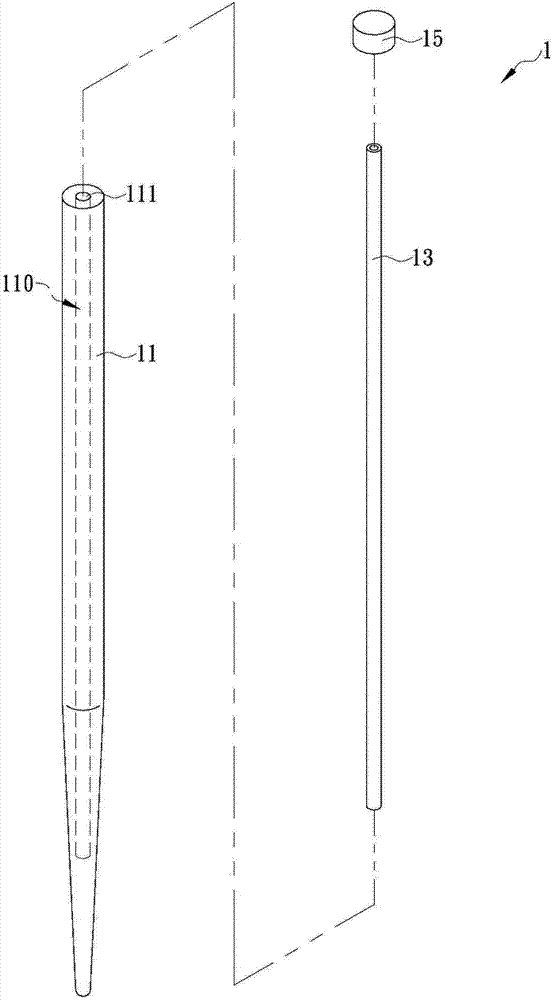

Diamond scribing knife for light filter glass cutting, and preparation method thereof

The invention discloses a diamond scribing knife for light filter glass cutting. The diamond scribing knife is composed of a metal-based matrix and diamond abrasives, and is characterized in that the content in percentage by volume of diamond in the scribing knife is 25-55%, and the particle size is 10-30[mu]m; the metal-based matrix comprises, by mass, 45-59% of copper powder, 25-35% of tin powder, 5-15% of nickel powder, 5-10% of silver powder, 5-15% of zinc powder and 1-10% of graphite. The cutting edge of the scribing knife has a great cutting morphology; the scribing knife has the characteristics of being high in holding force, high in exposure degree, long in life and the like on the premise of meeting the machining quality, has a speed of 12mm / s during test use, and is stable in quality and free from the phenomena of knife breakage and spark in the case of being used in batches. The invention provides a preparation method for the scribing knife simultaneously. The method is more suitable for mixing preparation for raw materials with small particle sizes, beneficial to more uniform formation of blade structures, and also beneficial to stable control for the batch-to-batch quality of blades.

Owner:苏州赛尔科技有限公司

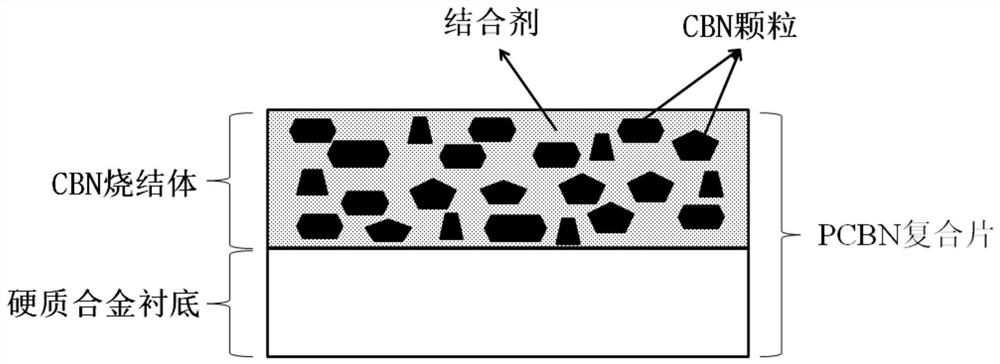

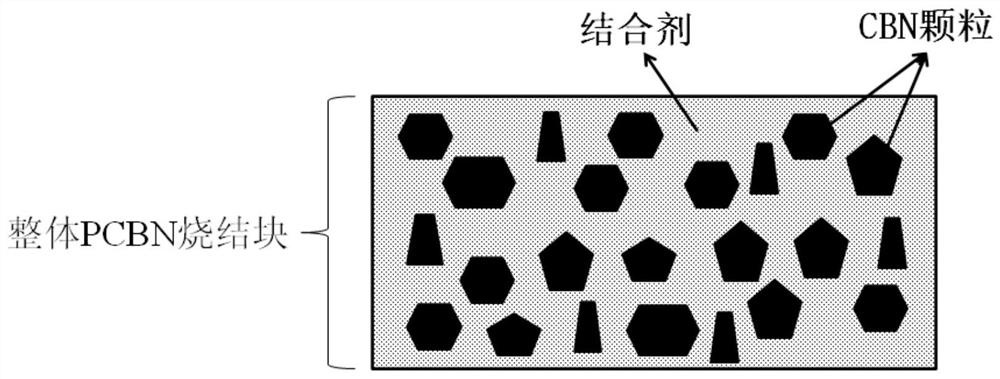

Titanized cubic boron nitride clad sheet and preparation process thereof

ActiveCN108950561ALower surface energyHigh bonding strengthTransportation and packagingVacuum evaporation coatingAlloy substrateBoron nitride

The invention discloses a titanized cubic boron nitride clad sheet and a preparation process thereof. The preparation process of the titanized cubic boron nitride clad sheet includes the steps of 1),surface cobalt removing of a hard alloy substrate; 2), surface titanizing of cubic boron nitride micro-powder; 3), purification of titanized cubic boron nitride micro-powder; 4), mixing preparation ofa cubic boron nitride powder layer; 5), preparation of a composite assembly; and 6), preparation of the clad sheet, wherein the titanized cubic boron nitride clad sheet is obtained. The prepared titanized cubic boron nitride clad sheet meets the machining requirements that an ultra-hard composite tool used in cutting and milling processes has high precision and high efficiency.

Owner:ZHONGNAN DIAMOND CO LTD

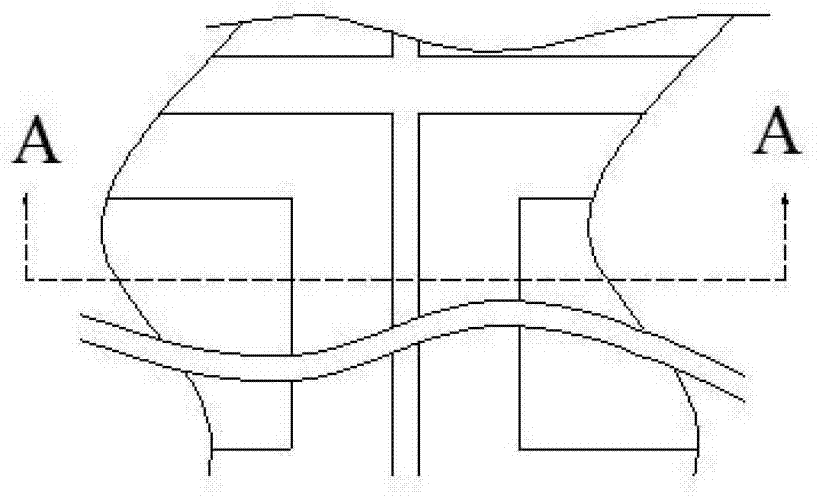

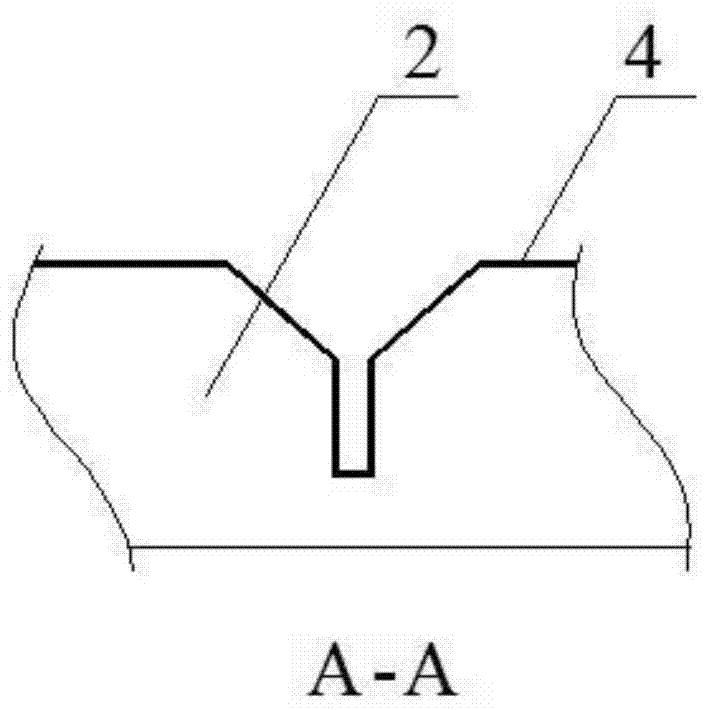

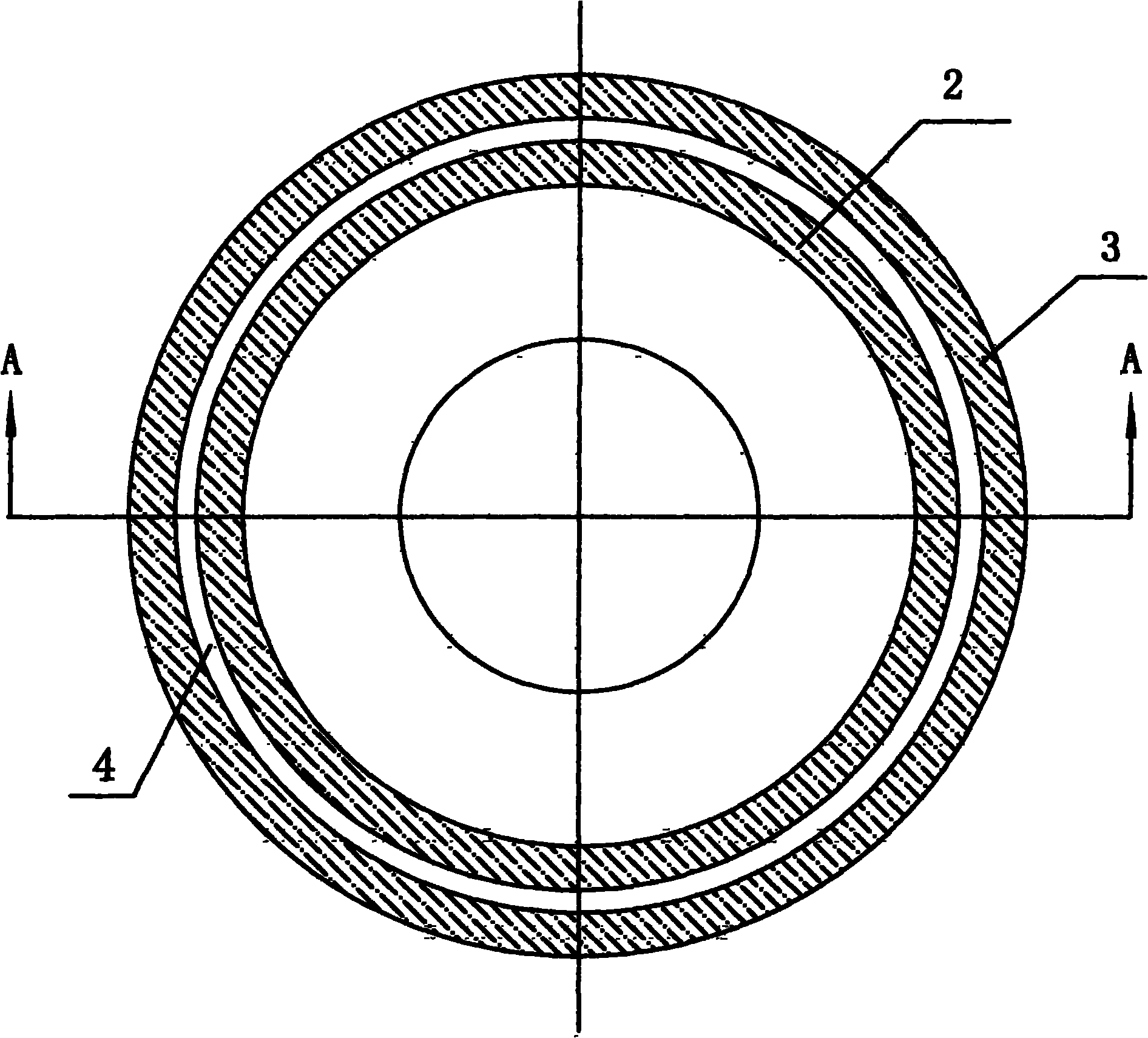

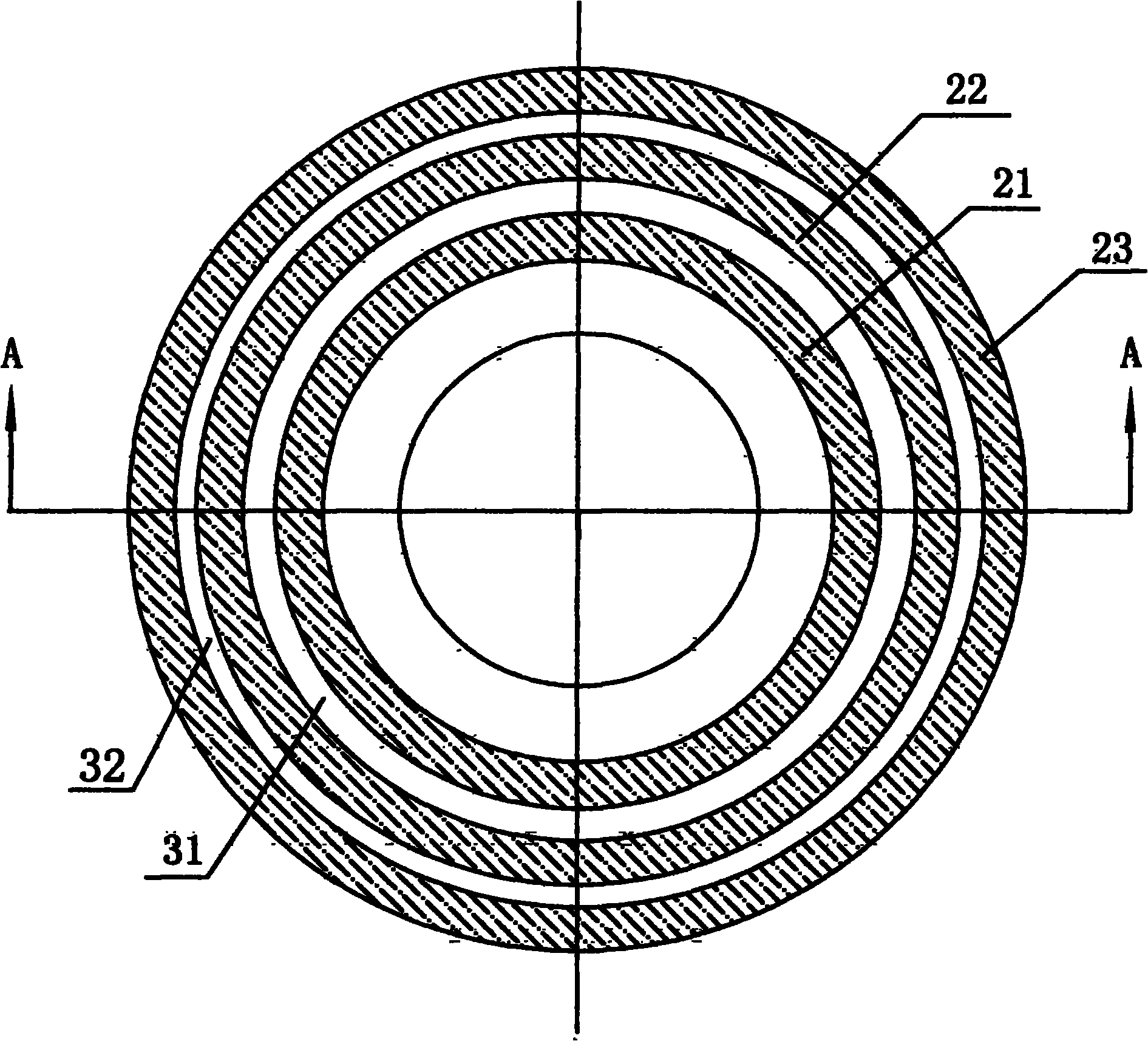

Multi-ring dry grinding wheel for tiles

ActiveCN102059661AEasy to use quantityReduce usageBonded abrasive wheelsEngineeringMachining process

The invention relates to a tool for grinding, in particular to a multi-ring dry grinding wheel applied to ceramic walls and floor tiles. The multi-ring dry grinding wheel comprises a substrate, a plurality of grinding rings and a plurality of circular ring grooves formed between any two adjacent grinding rings of the plurality of grinding rings; the plurality of grinding rings are fixed on the substrate; and the plurality of grinding rings and the plurality of circular ring grooves are concentric circular rings. The multi-ring dry grinding wheel has the advantages of large amount of feed, easiness of heat dissipation, cooling and chip removal and no blocking, can meet requirements of different machining processes, and has the high grinding efficiency and grinding effect.

Owner:珠海市世创金刚石工具制造有限公司

Waste material strip cutting device of electronic component assembling machine

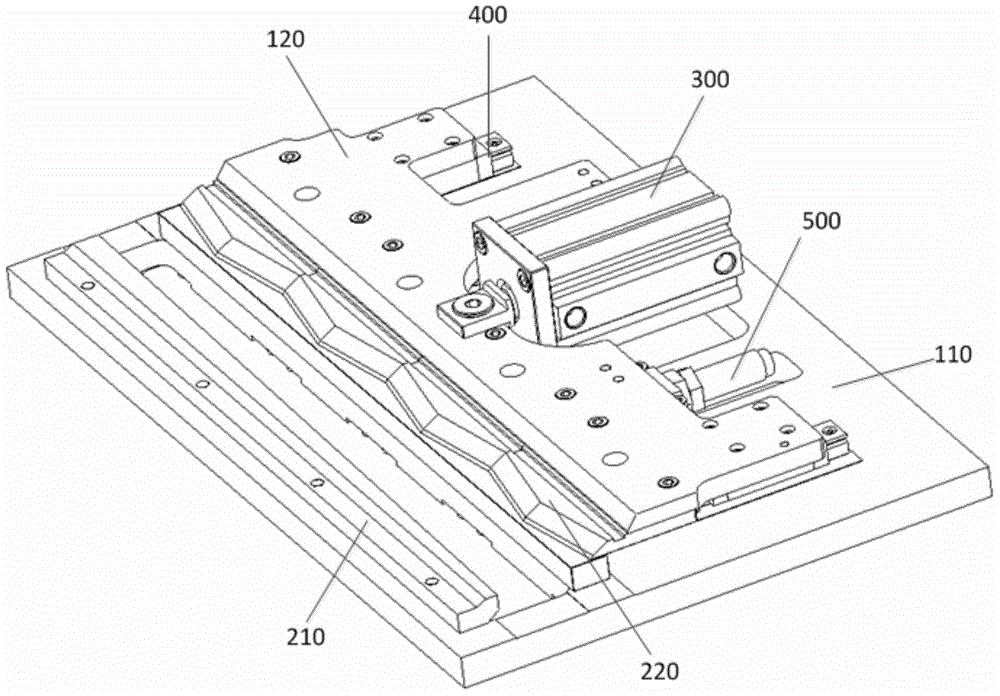

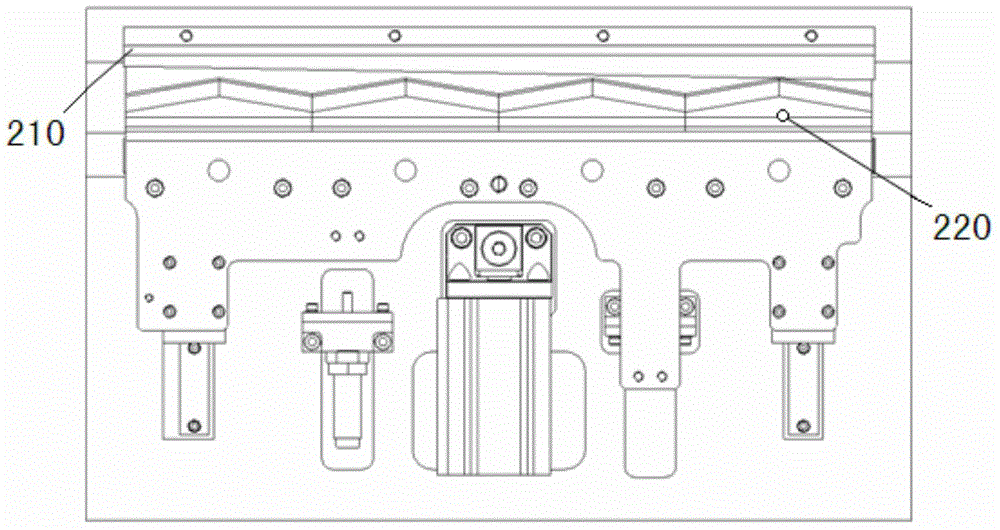

InactiveCN104985246AEasy to replaceCompact structureShearing machinesShearing toolsElectronic componentWaste material

The invention discloses a waste material strip cutting device of an electronic component assembling machine. The device comprises a fixed rack and a movable rack. One end of the fixed rack is provided with a stationary cutter. The middle position of the other end of fixed rack is provided with a drive device. The fixed rack on two sides of the drive device is provided with guiding devices. A limiting device is arranged between the drive device and one of the guiding devices. The movable rack is connected with the drive device. The movable rack is provided with a movable cutter. The movable cutter and the stationary cutter are cooperated. The integrated width of the movable cutter is corresponding to the integrated width of the stationary cutter. The device is compact in structure, good in adaptability, convenient in operation and maintenance, and low in use and maintenance cost. The movable cutter is in a spliced structure, and a strip cutting device can conveniently change blades whose cutting edges are worn, so as to prolong life of the device.

Owner:SHANDONG RIFA TEXTILE MACHINERY

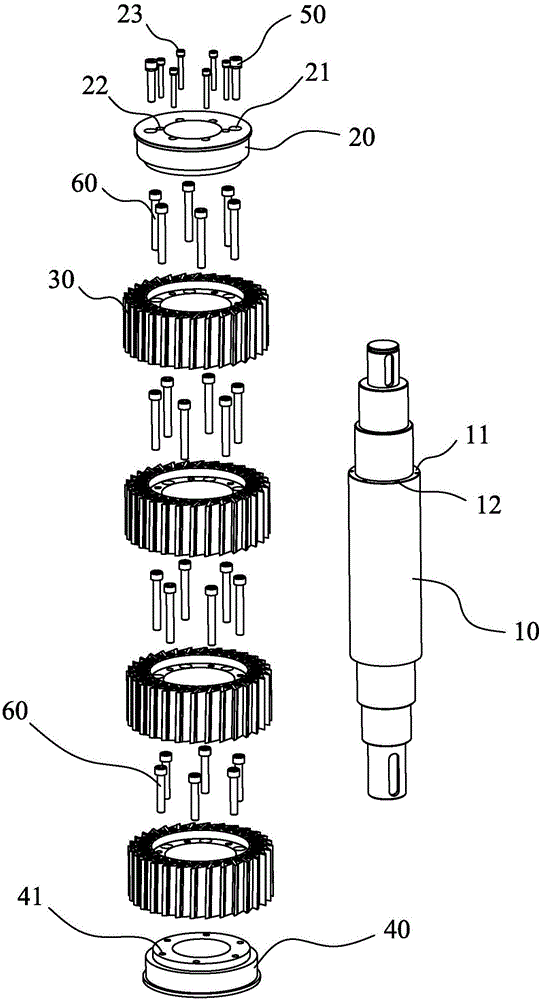

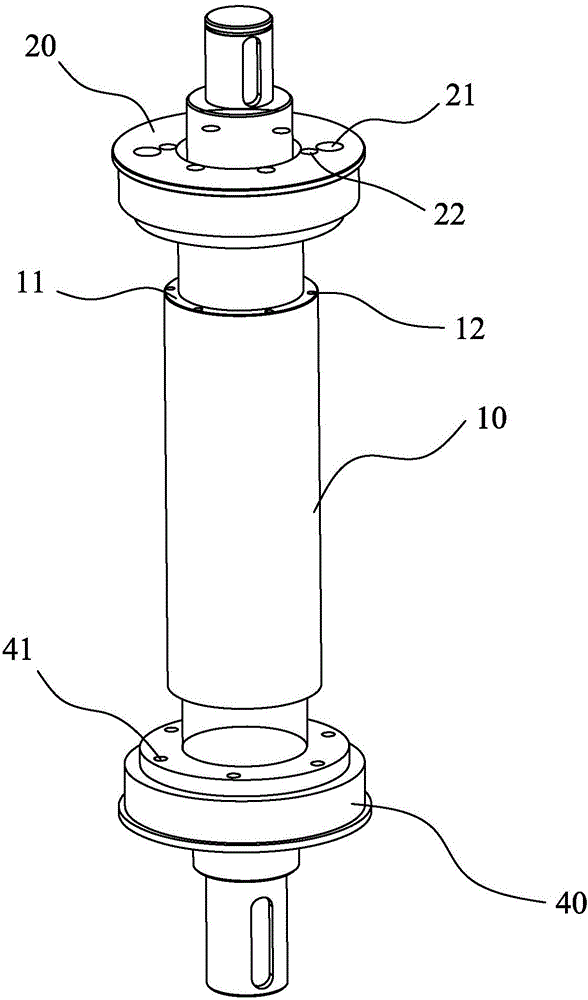

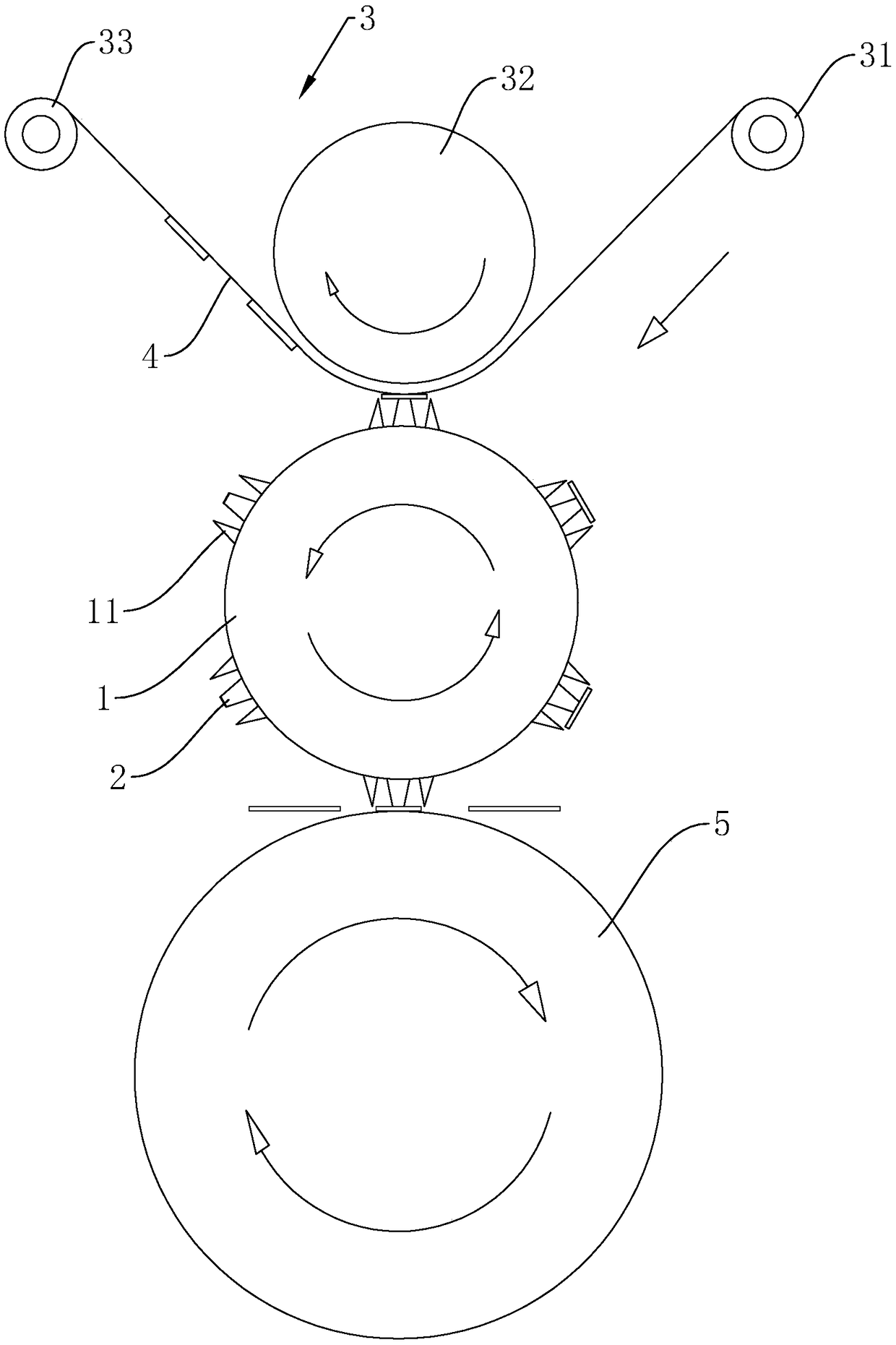

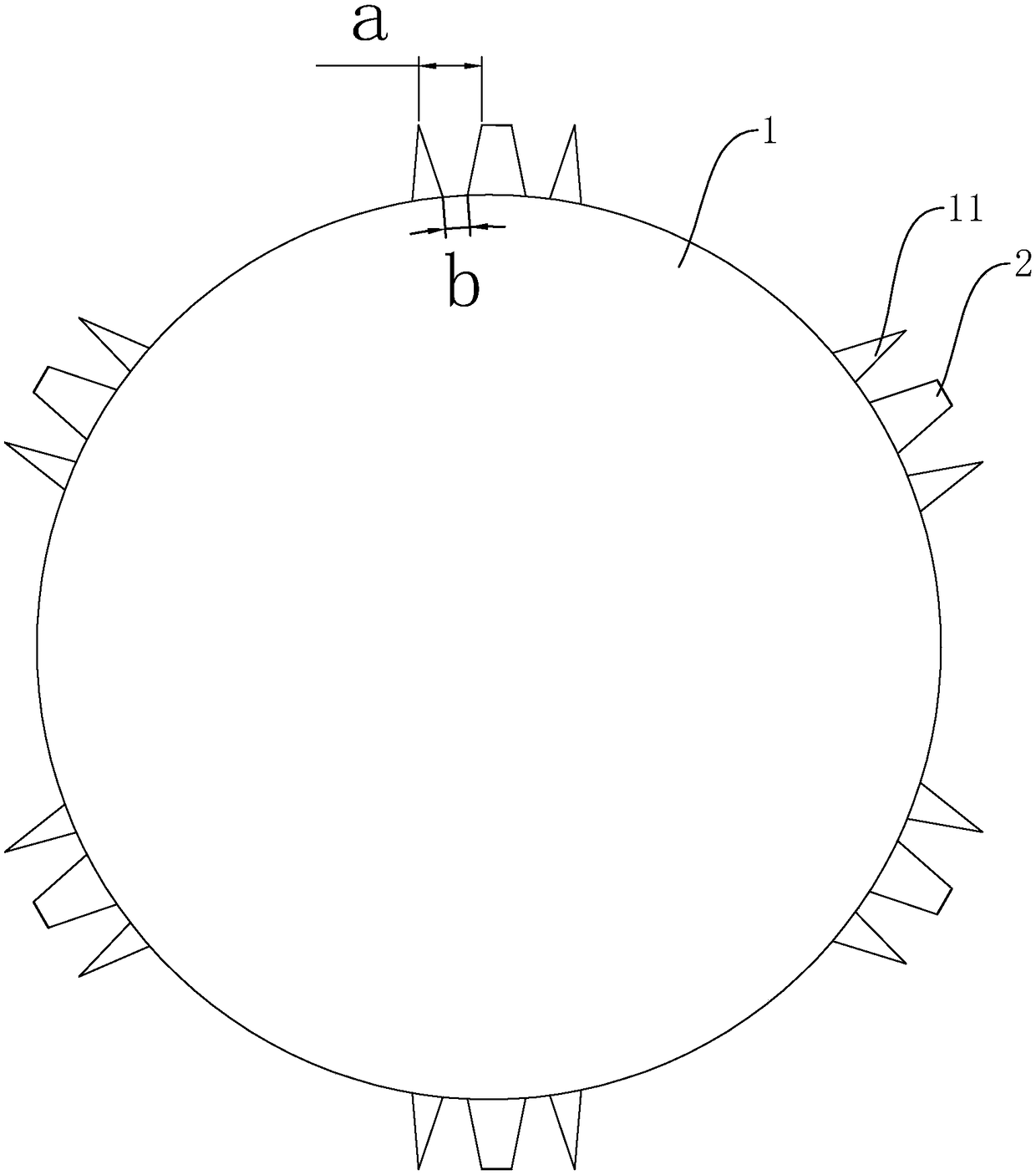

Segmented splicing type granulator hobbing cutter

The invention discloses a segmented splicing type granulator hobbing cutter. The segmented splicing type granulator hobbing cutter comprises a cutter shaft and a plurality of hobbing cutter segments arranged on the outer side of the cutter shaft. Each hobbing cutter segment comprises a cutter ring, short blades detachably fixed to the outer wall of the cutter ring, and locking pieces used for fixing the short blades, wherein the locking pieces are provided with clamping parts, and the short blades are provided with limiting parts corresponding to the clamping parts. A plurality of cutter grooves distributed in the circumferential direction are formed in the outer wall of each cutter ring and axially penetrate the front surface and the rear surface of the corresponding cutter ring, locking holes for containing the locking pieces are formed in the front surface and the rear surface of each cutter ring, one side of each locking hole communicates with the corresponding cutter groove, and the short blades enter the cutter grooves through the clamping parts to be matched with the limiting parts to be detachably fixed into the cutter grooves. The multiple cutter rings penetrate through holes to be detachably connected with threaded holes in a screw joint manner through connecting bolts. The multiple short blades are connected to form long blades. According to the segmented splicing type granulator hobbing cutter, the blades are not prone to breaking, and the service life of the cutter is long; and meanwhile the single blades can be replaced, resource waste is avoided, and the using cost is reduced.

Owner:DONGGUANG HUI RU LAI POWER TECH CO LTD

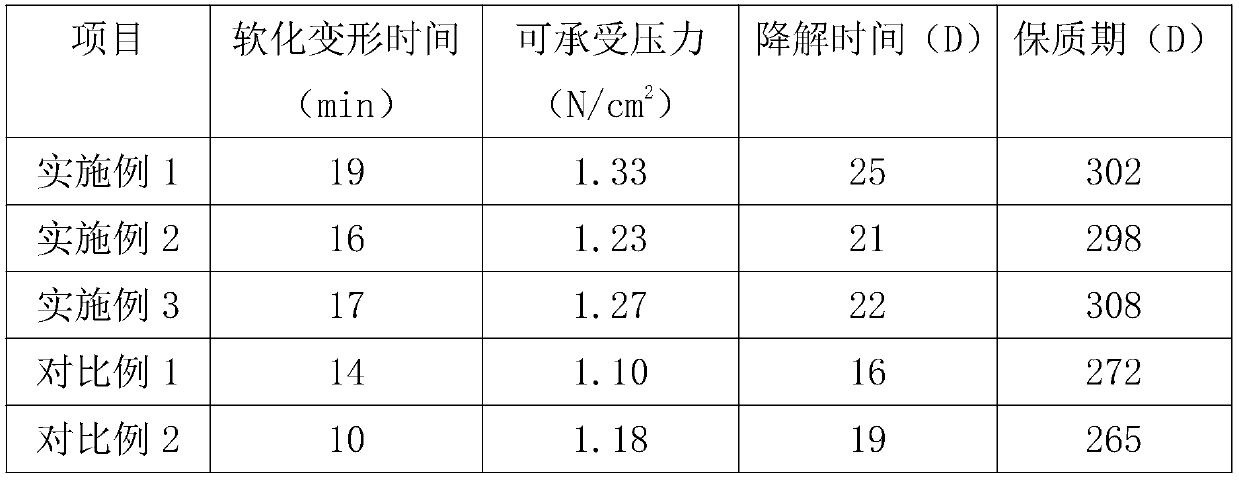

Wheat bran tableware and preparation method thereof

The invention discloses wheat bran tableware and a preparation method thereof, and relates to the technical field of deep processing of wheat. The wheat bran tableware is prepared from the following raw materials: bran dry powder, dietary fibers, modified xanthan gum, corn starch and edible calcium carbonate. The prepared tableware is attractive in appearance and high in practicability, has appropriate hardness and waterproof performance, is good in sensory index, is not liable to cause negative effects such as fracture and fragmentation, can replace common disposable foam tableware, and is safer and more environment-friendly.

Owner:安徽雁飞粮油有限责任公司

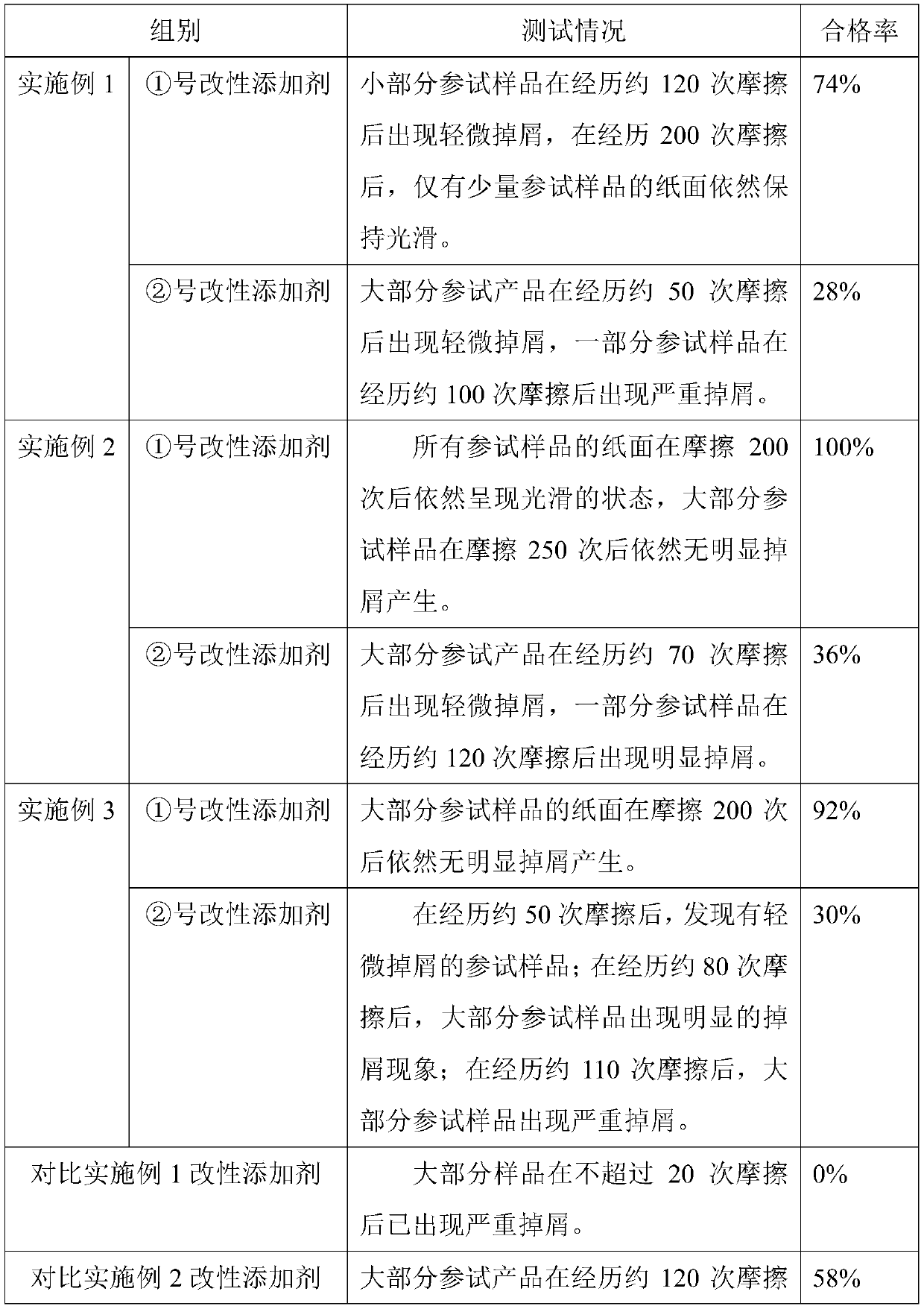

Modified additive for paper pulp molded products, preparation method and application thereof

ActiveCN110670407ASave time and costSave equipment costNon-fibrous pulp additionPaper coatingMolded pulpFiber

The invention provides a modified additive for pulp molded products, which comprises 8-10% of cationic starch and 5-7% of gloss oil according to mass percentage. The modified additive of the paper pulp molded product prepared by the invention is applied to the surface of the paper pulp molded product, the modified additive penetrates into the inside of the paper pulp molded product from the outside to the inside, a layer of dense oil wax film can be formed on the surface of the paper pulp molded product, the adhesive force of fibers, fillers on the surface and the inside of the product and among the fibers, fillers and each other are effectively improved, the fibers on the surface of the paper can be better combined without generating chips easily, and the abrasion resistance of the paperpulp molded product is obviously improved.

Owner:佛山市顺德区文达创盈包装材料科技有限公司

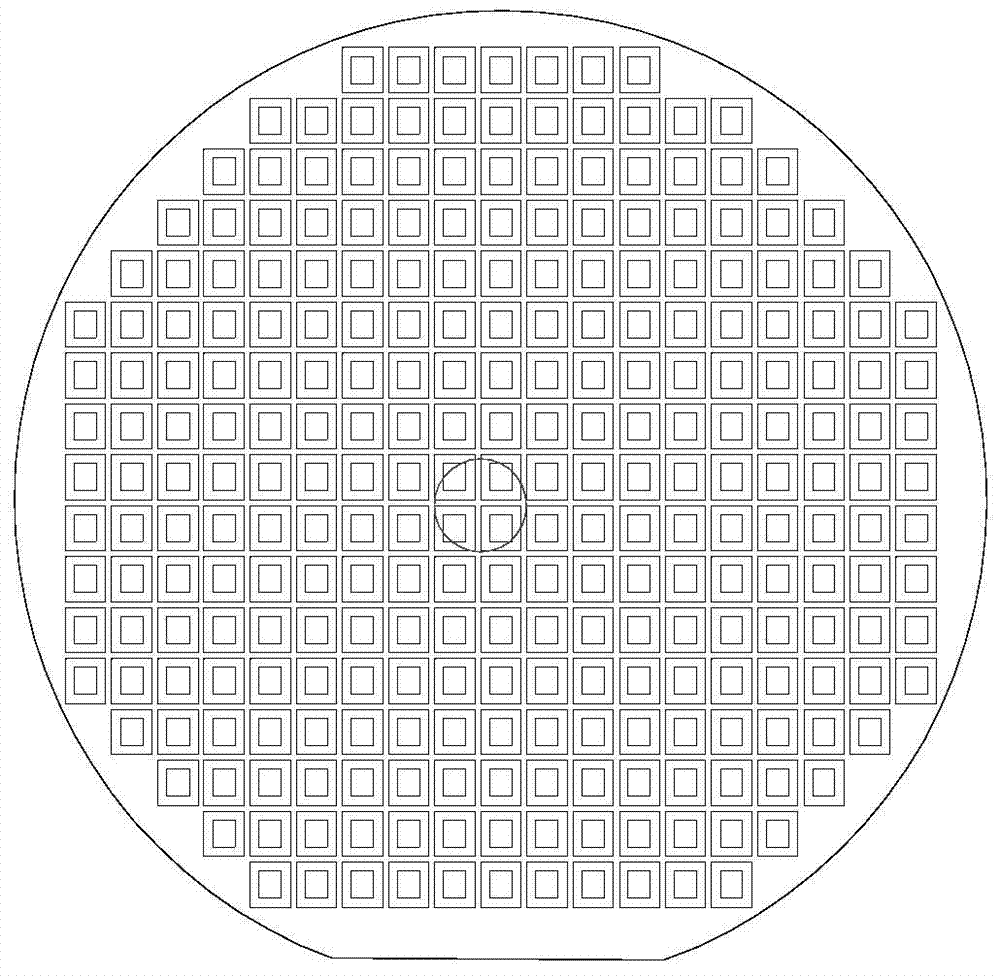

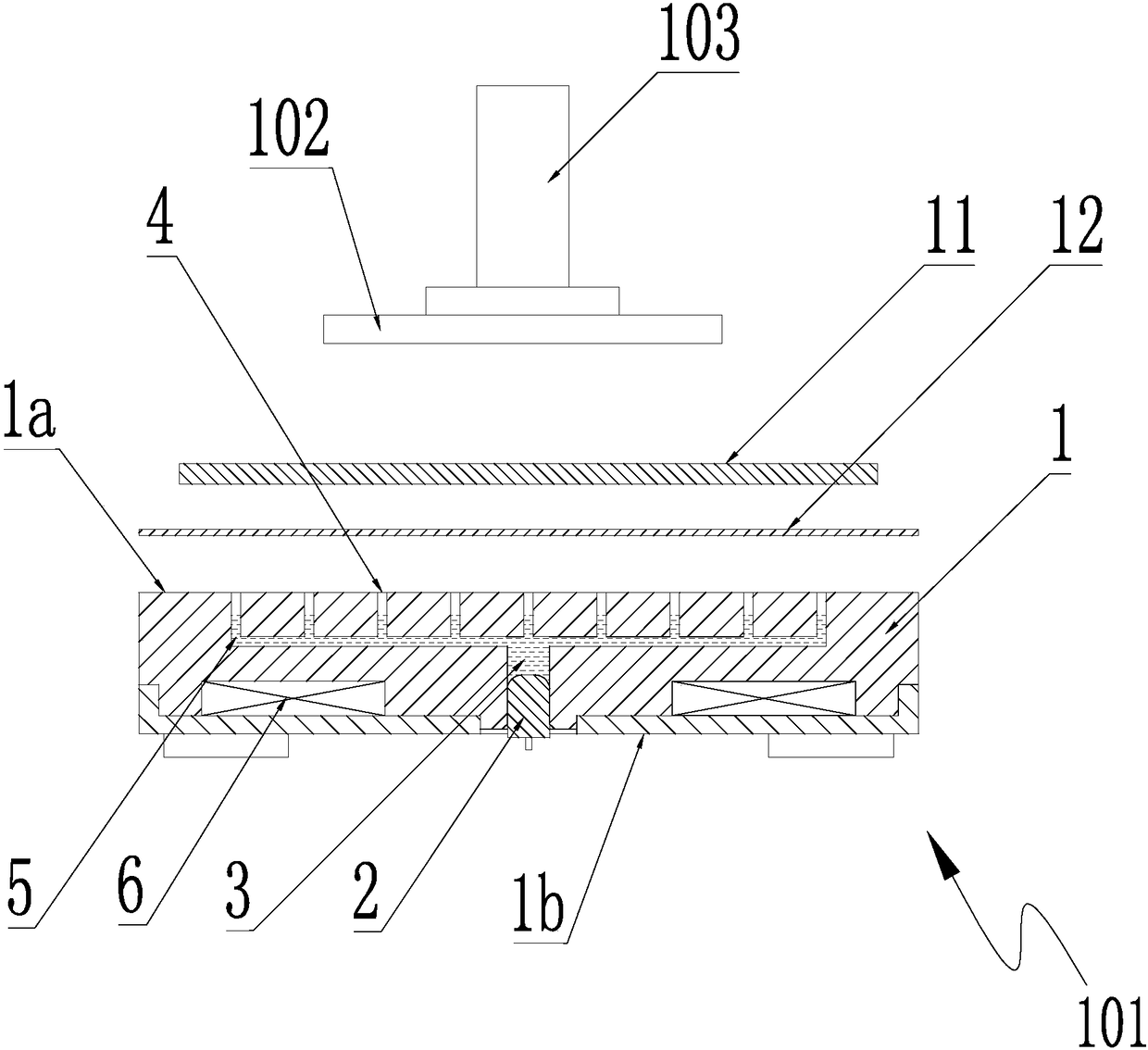

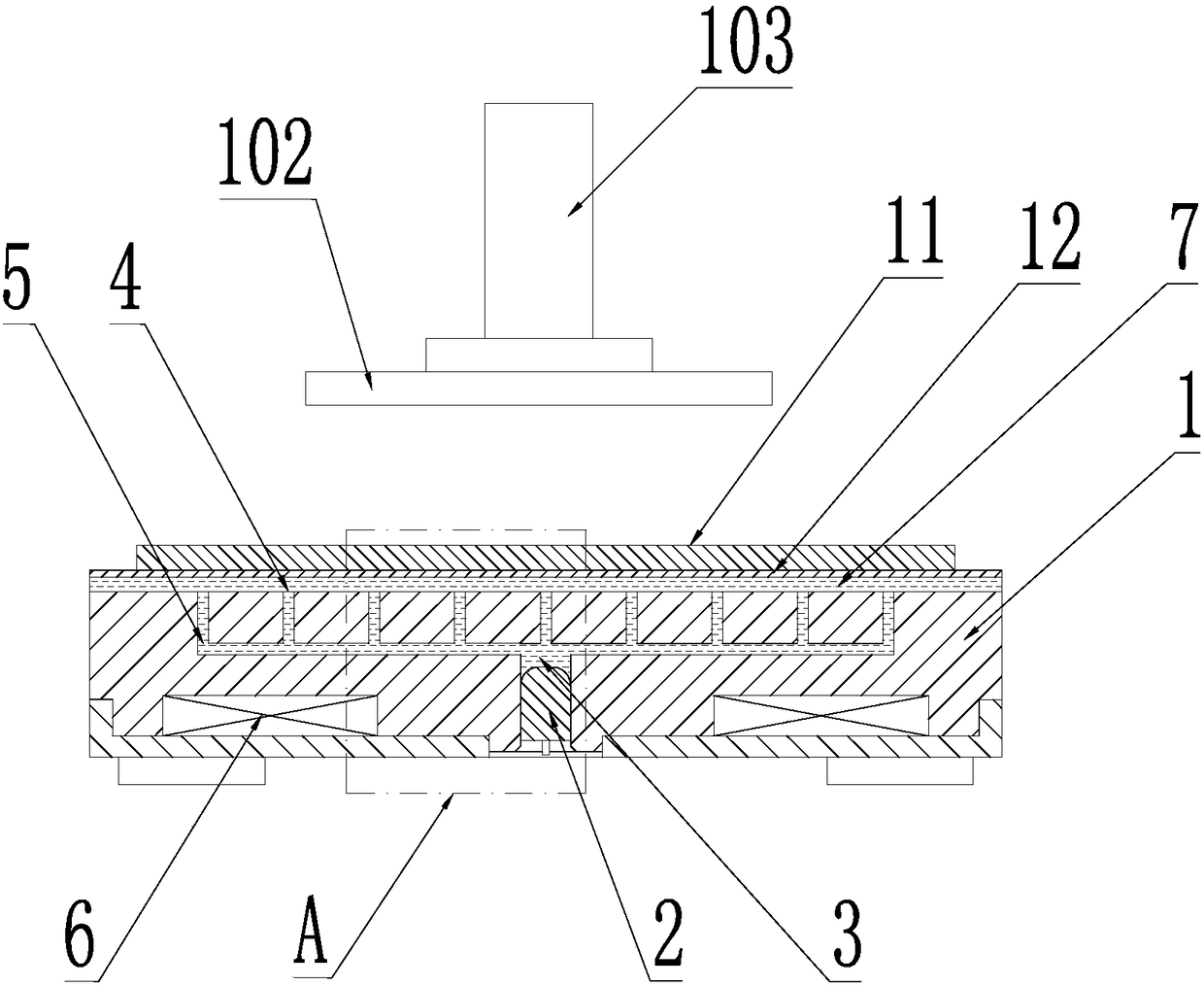

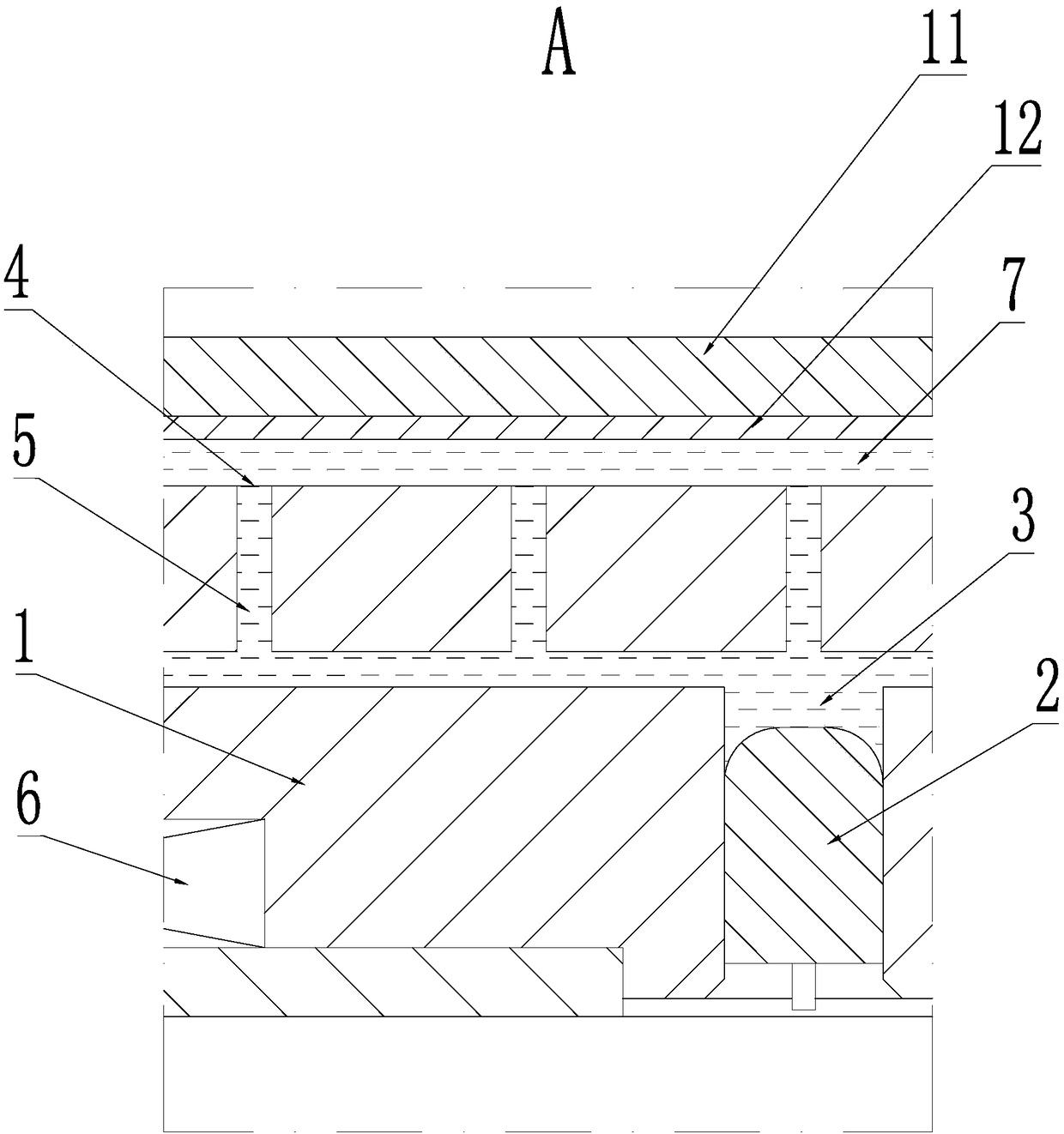

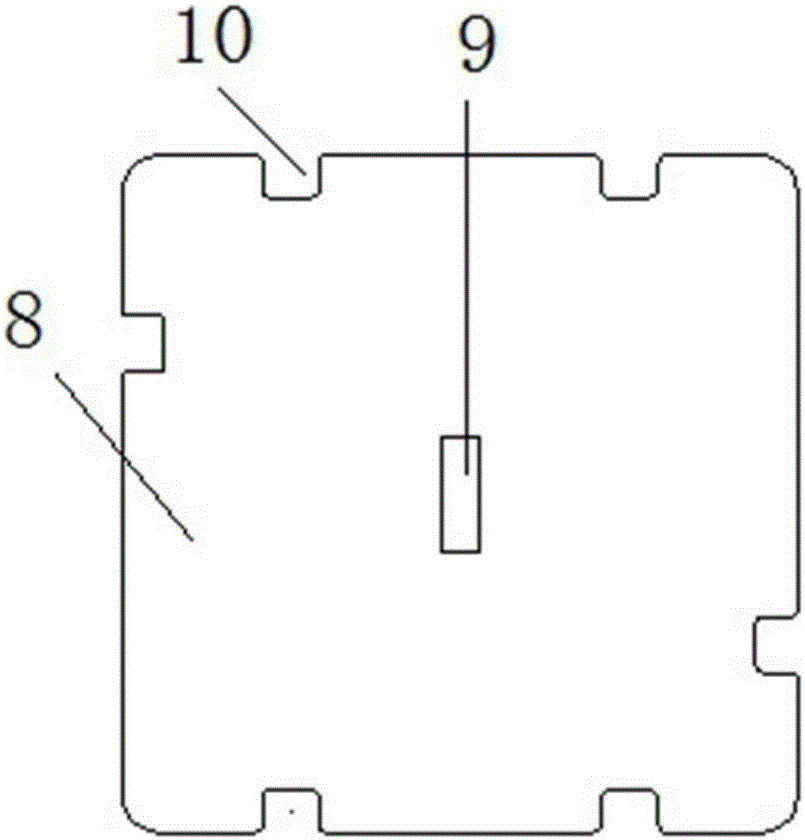

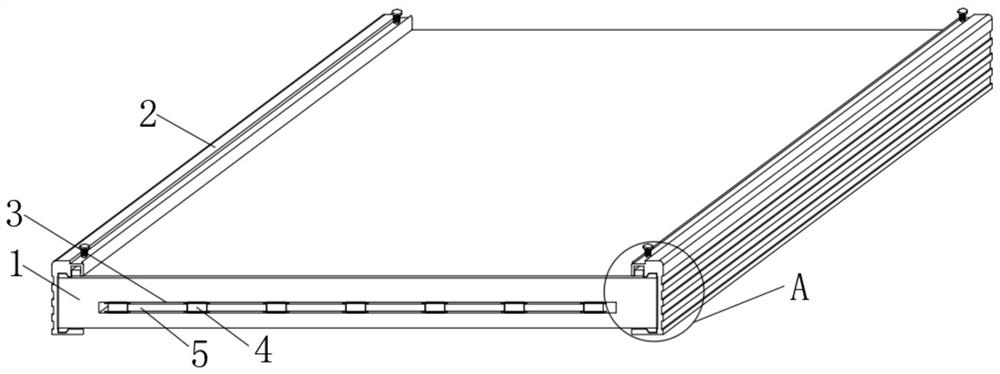

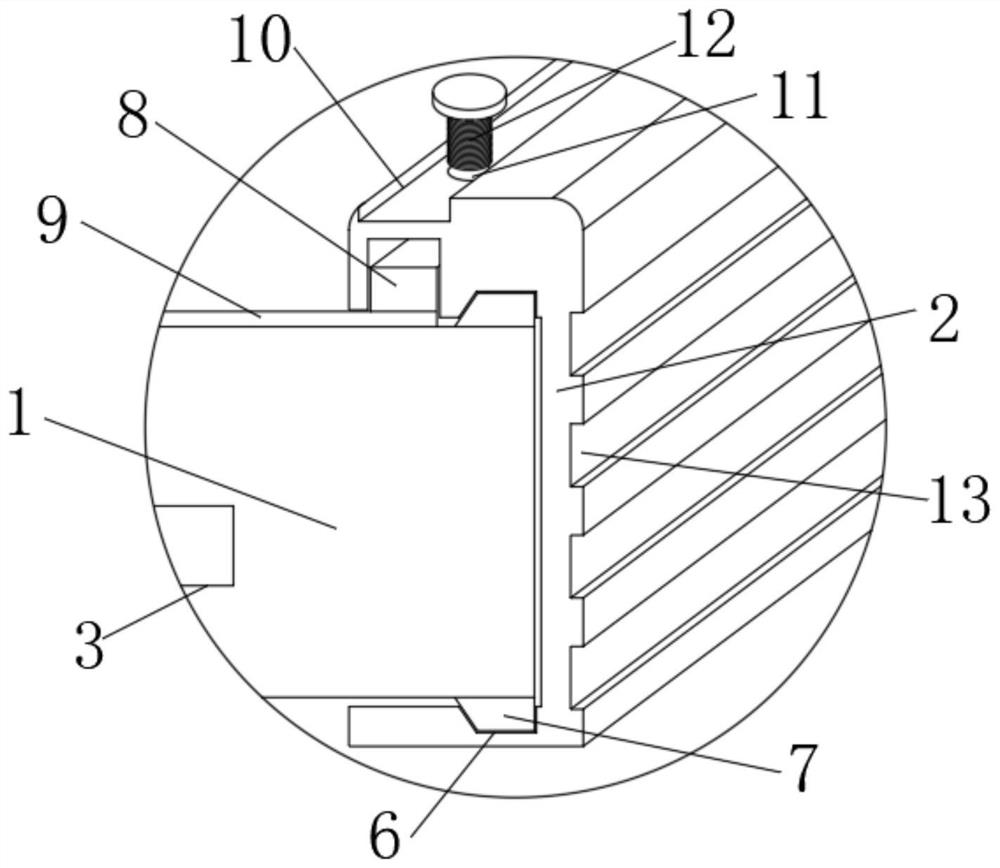

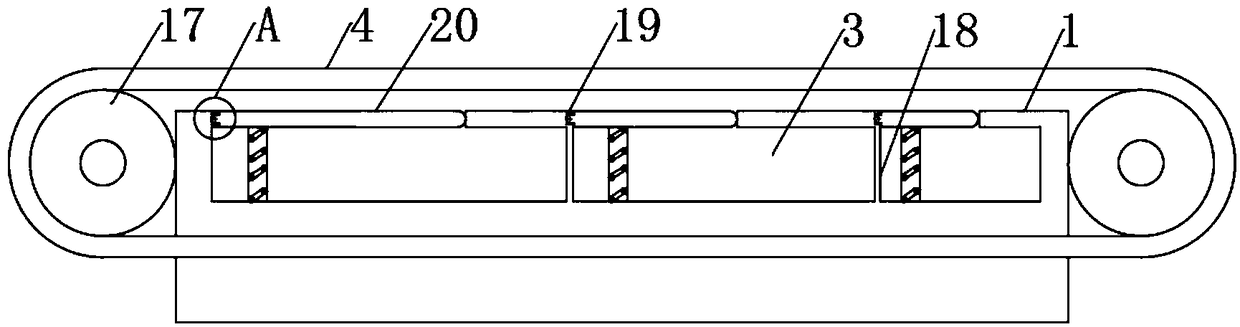

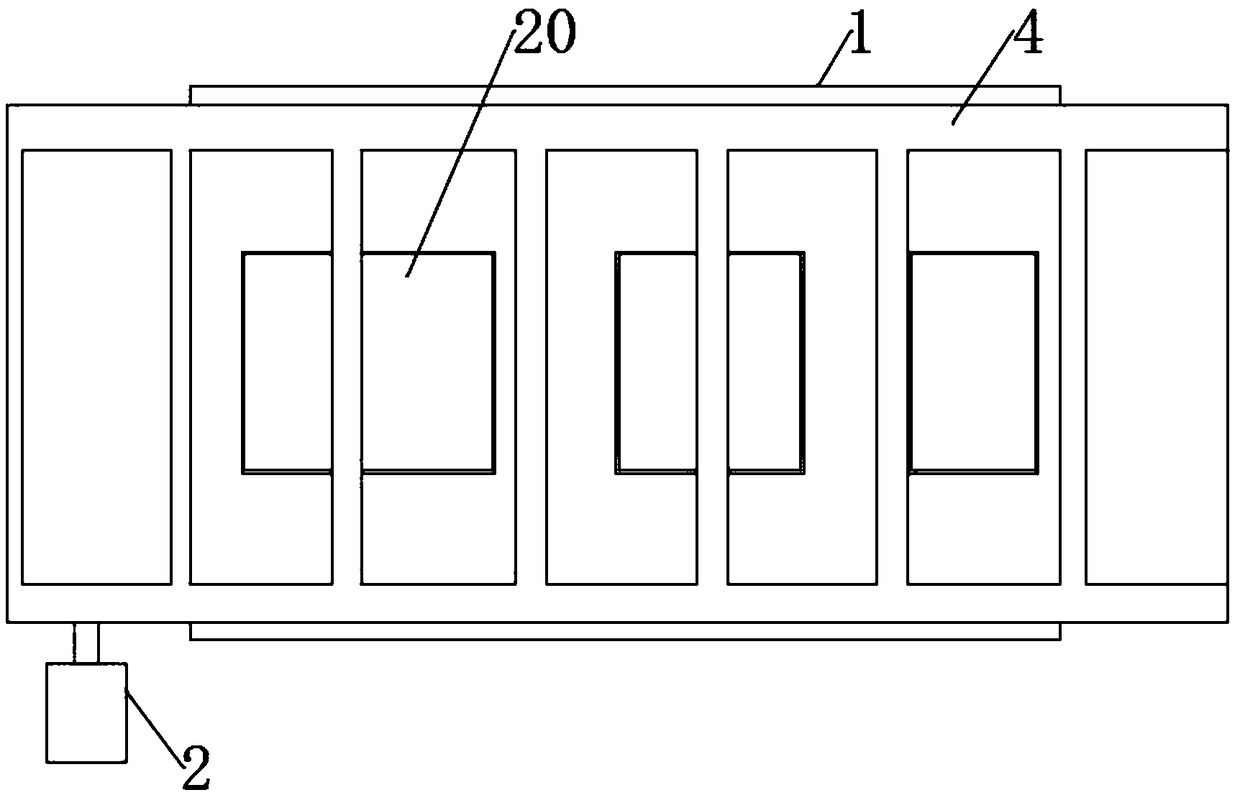

Machine tool for processing wafer surface

ActiveCN108550535ANot prone to chippingThe process of unbonding is simple and convenientSemiconductor/solid-state device manufacturingEngineeringMachine tool

The invention discloses a machine tool for processing a wafer surface. The machine tool comprises a workpiece mounting table and a carrier which is detachably mounted on the workpiece mounting table.A millstone is arranged above the carrier. The millstone is mounted on the driving shaft of the machine tool and rotates along with the driving shaft of the machine tool. The millstone comprises a disc-shaped body. The central position of the lower end surface of the body is provided with a mounting trough. The mounting trough is internally provided with a sub-millstone. The lower end surface of the body is provided with a plurality of liquid feeding troughs which are uniformly distributed along the circumferential direction of the mounting trough. The liquid feeding troughs are used for accommodating mortar. In the inner wall of the liquid feeding trough, an inside wall which corresponds with the opposite direction of a body rotation direction is in transition connection with the lower end surface of the body. The machine tool for processing the wafer surface can satisfy a requirement for strength after wafer bonding and furthermore realizes quick and reliable wafer de-bonding process. The machine tool has advantages of high efficiency, high product qualified rate and low processing cost.

Owner:游精学

Aperture turning tool for grinding wheel finish machining and machining method thereof

InactiveCN110961663ASolve root problemsSolve the problem that the tool cannot be clamped on the CNC lathe latheTurning toolsTurning machinesTool bitEngineering

The invention discloses an aperture turning tool for grinding wheel finish machining and a machining method thereof, and relates to the technical field of a turning tool. The cutter comprises a main cutter body, wherein a first chamfering slope is arranged on one surface of the main cutter body, a clamping block is fixedly connected with the position, corresponding to the first chamfering slope, of the main cutter body, internal threads are formed on a bottom surface of the clamping block, blade assemblies are installed between opposite surfaces of the clamping block and the main cutter body,the blade assembly comprises a double-head cutter bar, a through hole is formed on one surface of the double-head cutter bar, and second chamfering slopes are arranged on two sides of the double-headcutter bar. The turning tool is advantaged in that 30-degree included angle design of a diamond composite blade and design of a right-leaning type main cutter body are adopted, a problem of back chipping when a blind hole is machined by a machining person can be effectively solved, an abrasion mode of the tool is changed into post-abrasion through the design, moreover, the cutting force and the turning temperature of the tool bit are effectively reduced through the design, and an edge breakage phenomenon is not likely to happen in the grinding wheel machining process.

Owner:辽宁程瑞砂轮有限公司

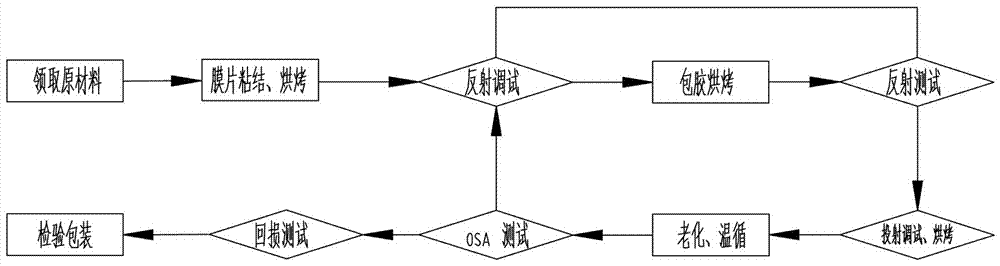

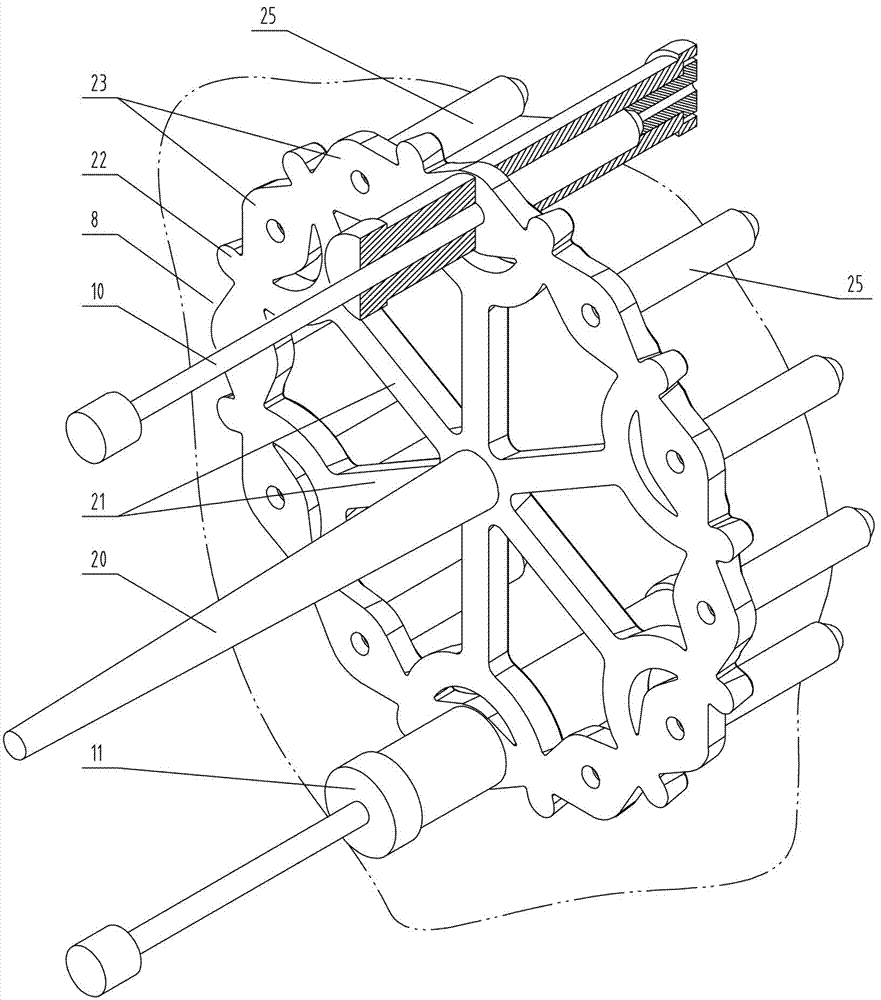

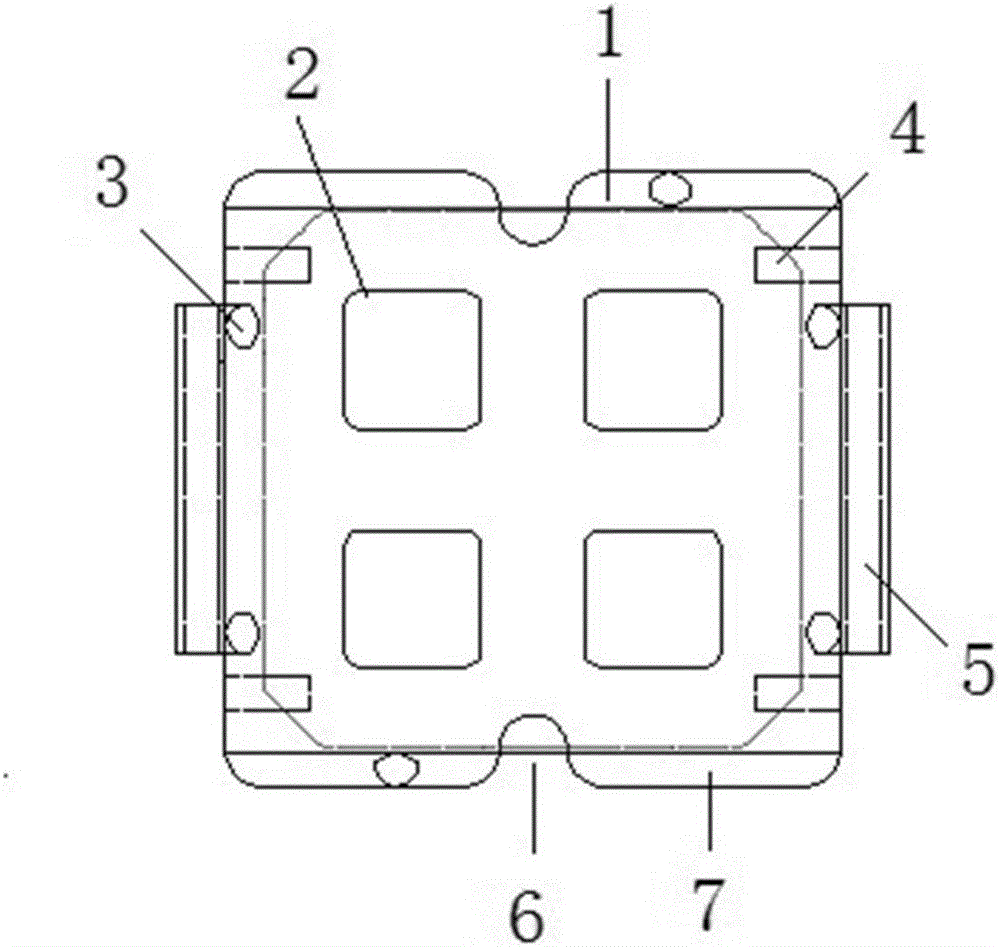

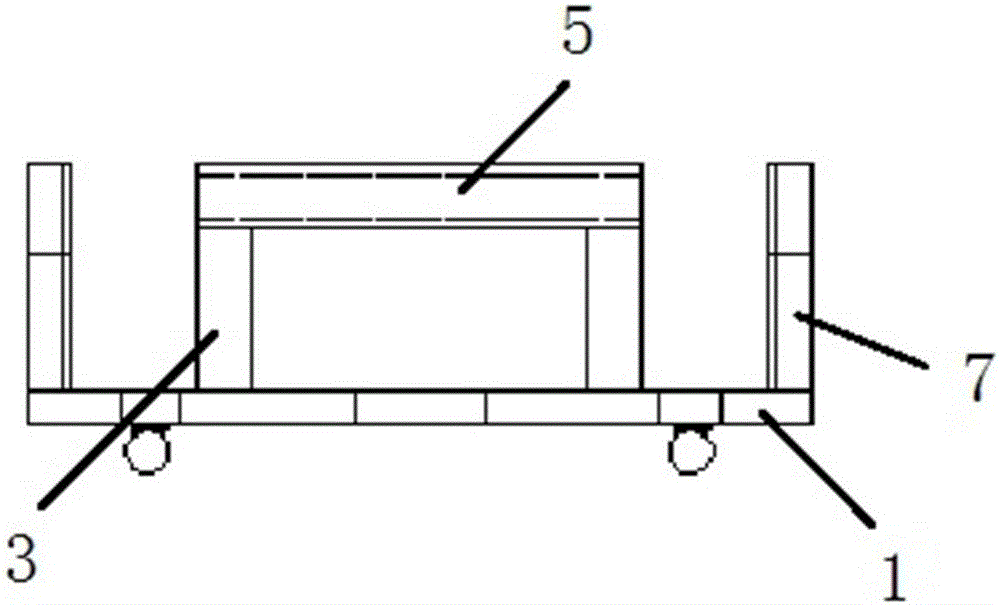

All-ceramic wavelength division multiplexer and production method thereof

ActiveCN107162589ASimple production processHigh energy consumptionOptical light guidesFiberMultiplexer

The invention provides an all-ceramic wavelength division multiplexer and a production method thereof; the all-ceramic wavelength division multiplexer has a sleeve, a single-core fiber collimator and a double-core fiber reflector are mounted in the sleeve, all the sleeve of the wavelength division multiplexer, a sleeve of the single-core fiber collimator and a sleeve of the double-core fiber reflector are of ceramic, a single insert core of the single-core fiber reflector is a circular microporous ceramic insert core, and a double insert core of the double-core fiber reflector is a special-deformed microporous ceramic insert core; the defect that a traditional glass wavelength division multiplexer is fragile and difficult to process is overcome; the process of the all-ceramic wavelength division multiplexer of the invention is simple, high in production efficiency and low in manufacture cost, and the all-ceramic wavelength division multiplexer has the advantages of low insertion loss, high echo loss, good reliability and the like and is easier to process, lower in cost, better in uniformity, less prone to ambient influence and higher in reliability as compared with traditional glass wavelength multiplexers; the wavelength multiplexer produced by using the method has transmission insertion loss of 0.35 dB and below.

Owner:黄石晨信光电股份有限公司

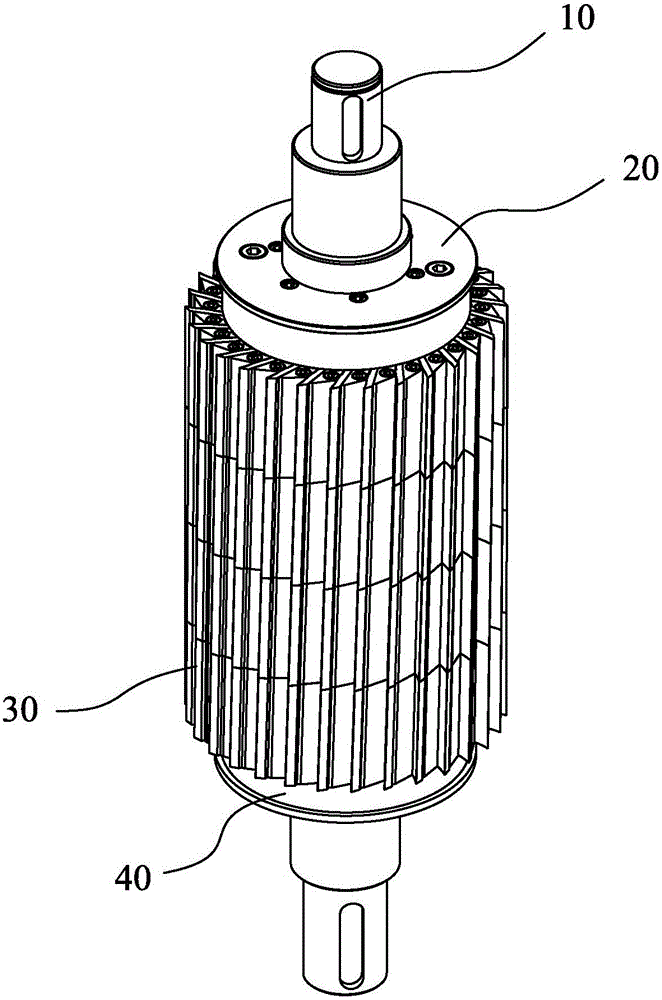

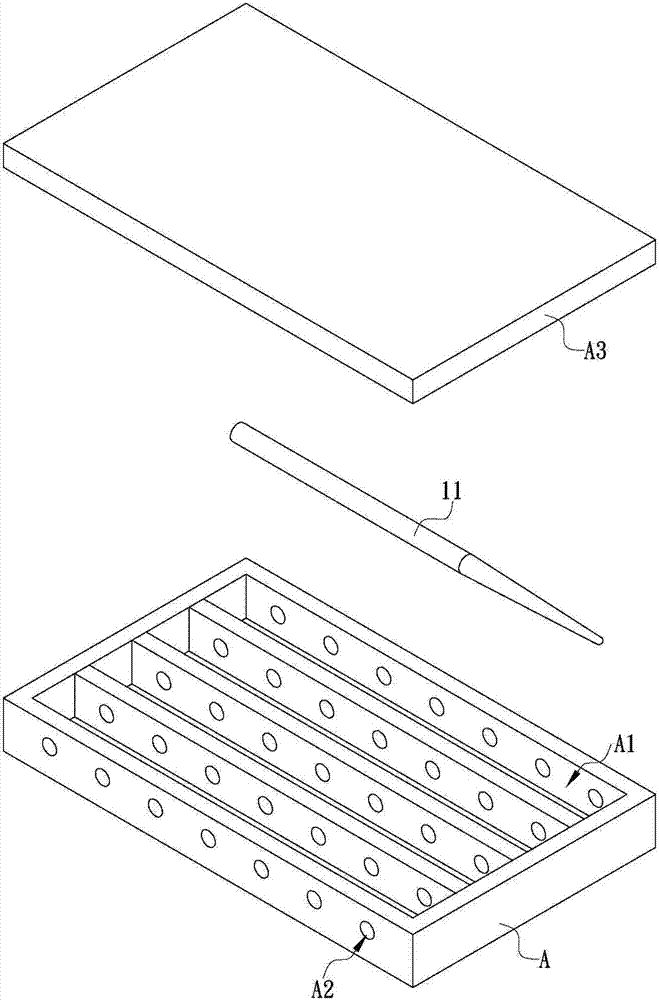

Stackable high-temperature annealing technology

ActiveCN106257625AEasy to operateShort time consumingSemiconductor/solid-state device manufacturingQuartzMaterials science

The invention discloses a stackable high-temperature annealing technology. The technology comprises the following specific operation steps that 1, etched silicon wafers are stacked in order and put into a quartz sheet frame for annealing; 2, the silicon wafers on the quartz sheet frame are covered with a quartz cover plate and pressed, and the quartz sheet frame is fed into a high-temperature diffusion-oxidation furnace; 3, annealing is conducted by increasing and stabilizing the temperature of a furnace tube of the high-temperature diffusion-oxidation furnace; 4, temperature decreasing and discharging from the furnace are conducted, wherein the temperature of the furnace tube of the high-temperature diffusion-oxidation furnace is decreased, and the quartz sheet frame is discharged from the furnace. The stackable high-temperature annealing technology has the advantages that the surfaces of the stacked silicon wafers are isolated from air, and therefore the problems existing in a thermal oxidation technology are effectively solved; operation is easy, the consumed time is short, and quantity production is easy to achieve; meanwhile, the yield is high, the battery piece efficiency is significantly improved, the problems such as edge breakage, corner faults, hidden cracks and fragments in the loading and unloading process of the silicon wafers can be effectively solved, the loading and unloading time is shortened, the quality of battery pieces is improved, and the qualified rate of the battery pieces is increased.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

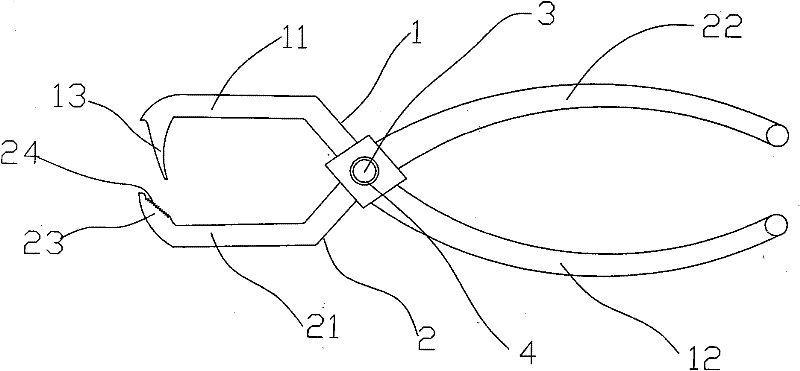

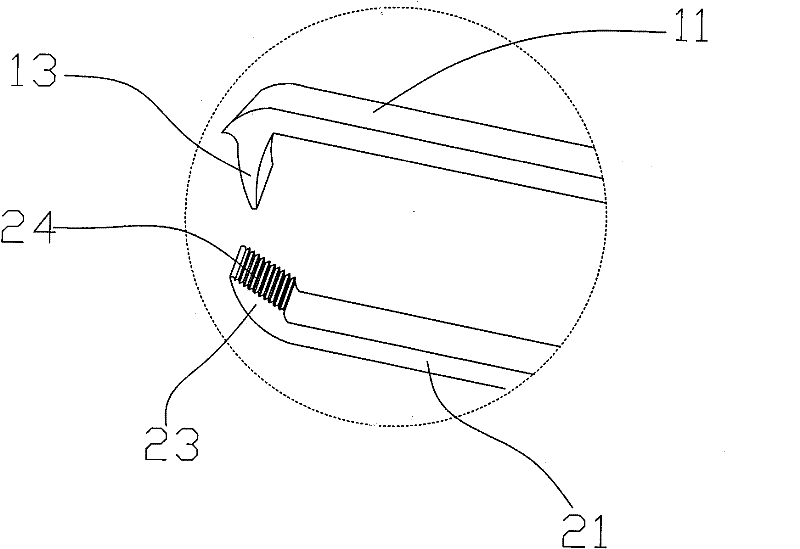

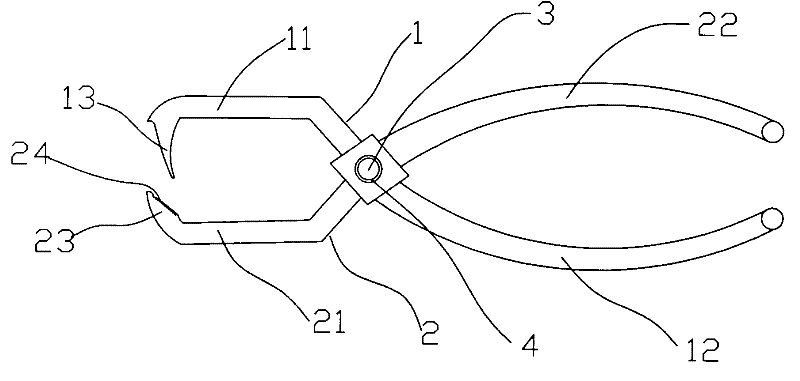

Dark tea cutting tool

The invention discloses a cutting tool used for cutting brick tea or compressed tea such as dark tea. The cutting tool is manufactures with high-quality steel with hardness greater than HB 200, and is designed as an effort-saving lever according to the lever principle. A major cutter is provided on the top of an upper cutting tool arm. The cross section of the major cutter is in a V shape. A cutting edge of the major cutter is transversely positioned, and is connected with the upper cutting tool arm, forming a T shape. The cutting edge of the major cutter is slightly withdrawn, forming an arc with the cutting tool arm. A vice cutter is arranged on the top of a lower cutting tool arm, with a cross section of an inverted V shape. The vice cutter is connected with the lower cutting tool arm, forming a T shape. The cutting edge of the vice cutter extends outwards. The inward surface of the vice cutter is provided with grabbing teeth. Clearances are reserved between the major cutter edge and the vice cutter edge. With the technical scheme of the present invention, the brick tea or the compressed tea can be cut easily, and can be prevented from crushing.

Owner:田恒

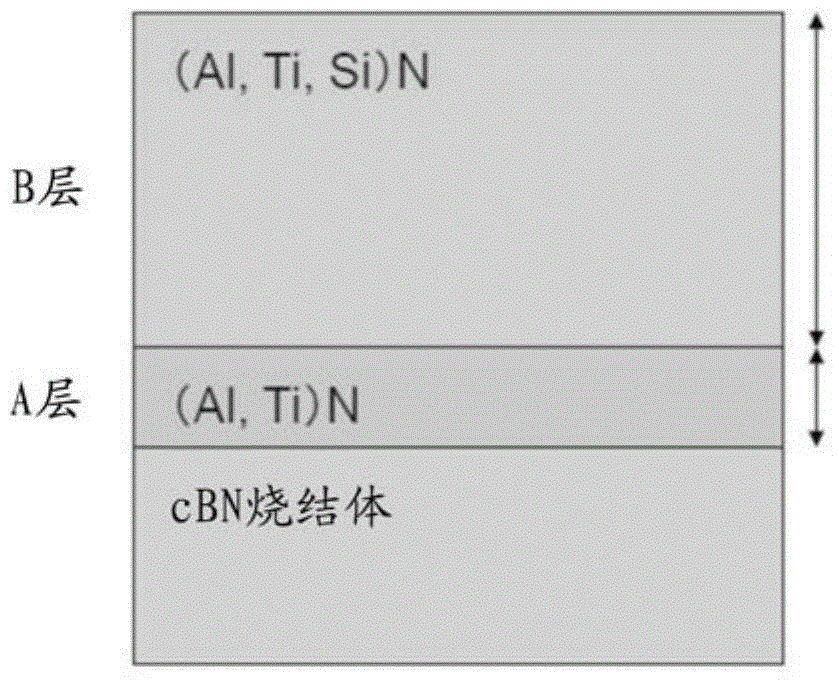

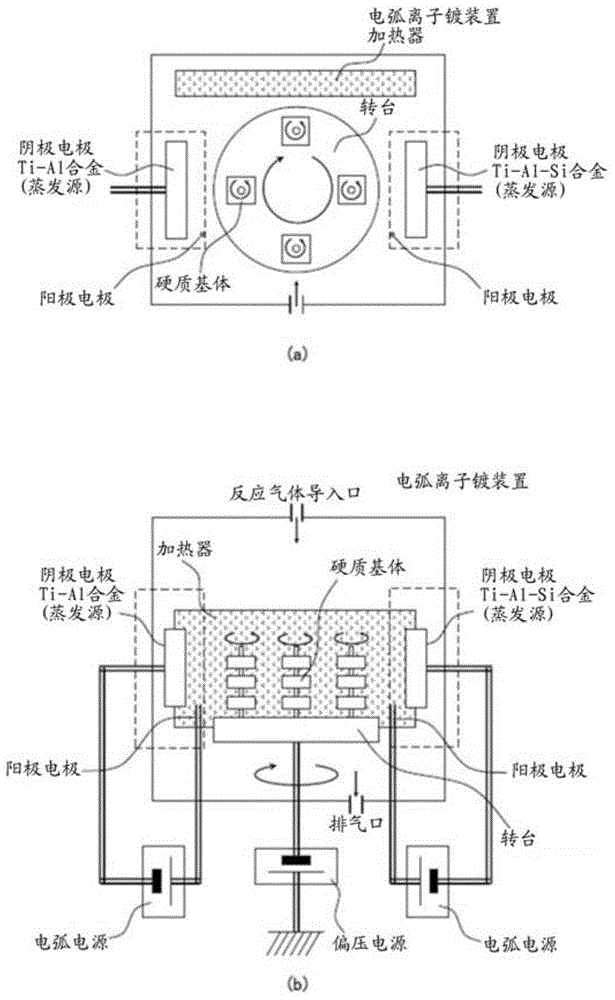

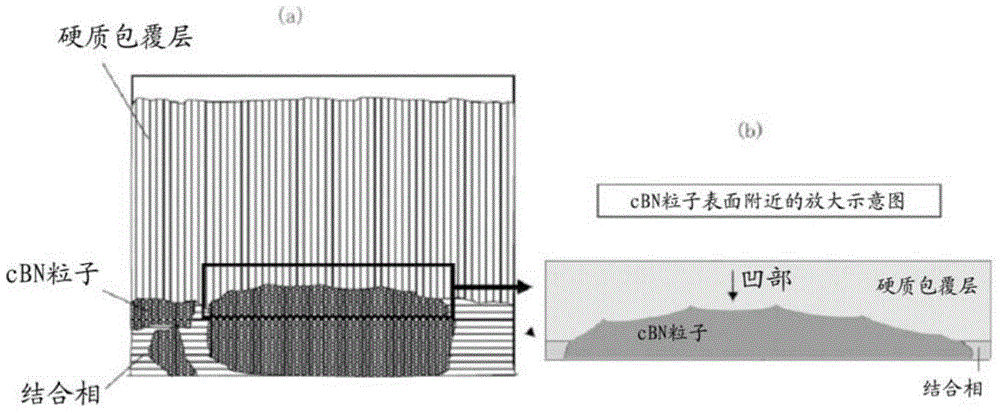

Surface coating cutting tool with excellent chipping resistance

ActiveCN104668597AImprove adhesionIncrease the areaTransportation and packagingMilling cuttersHardnessBoron nitride

The invention provides a surface coating cutting tool with excellent chipping resistance. The tool is a cBN sintered body cutting tool which maintains long-term excellent cutting performance and will not break when cutting high-hardness steel that needs high load cutting conditions during a high-speed cutting process. A hard coating layer of the surface coating cutting tool is formed by an A layer formed on the surface of a tool base body and a B layer arranged thereon. The A layer contains Ti1-aA1aN, wherein 0.3<=a<=0.7. The B layer contains Ti1-b-cA1bSicN, wherein 0.3<=b<=0.7, and 0.01<=c<=0.1. On the back blade surface of the tool base body, spherical recesses are formed on surfaces of cubic boron nitride particles that contact the hard coating layer.

Owner:MITSUBISHI MATERIALS CORP

Binding method for magnetic material before inner-round dissection

ActiveCN1929055AReduce entryAdhesive protectionInductances/transformers/magnets manufactureNon solventWater soluble

This invention discloses one binding method for cut inner circle of magnetic materials, which comprises the following steps: adding one layer of non solvent and non evaporated organic liquid on the magnetic materials surface; then distributing magnetic materials for glue. Due to the one layer of non solvent organic liquid for glue, when in circle cutting, its work liquid cannot destroy magnetic materials surface adhesive intensity.

Owner:SINO MAGNETICS TECH

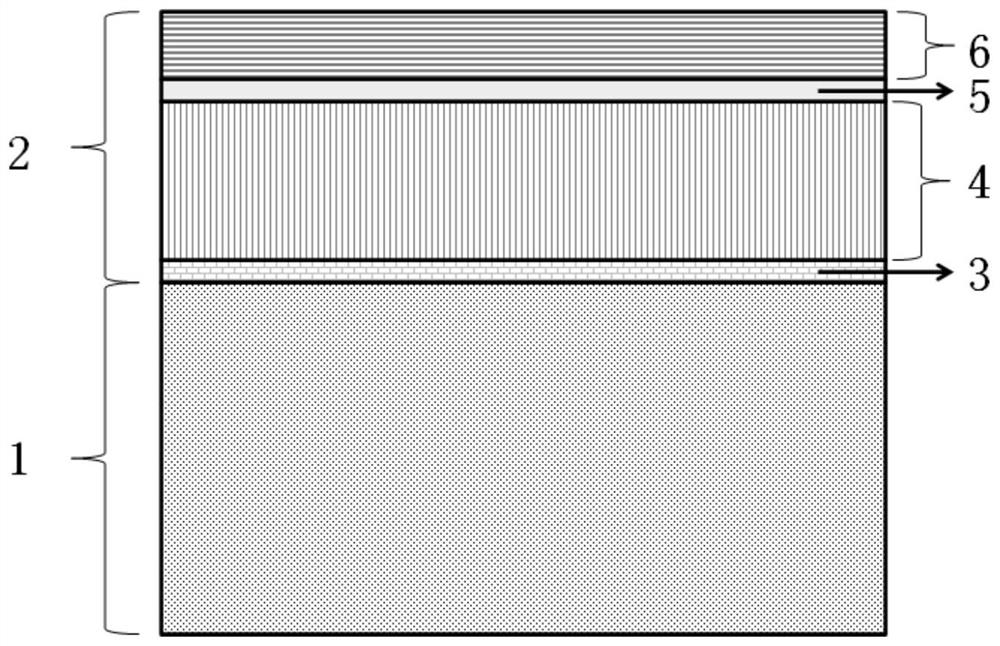

Composite coating PCBN cutting tool and preparation method thereof

ActiveCN111910172AImprove wear resistanceHigh bonding strengthVacuum evaporation coatingSputtering coatingChemical vapor depositionBonding strength

The invention discloses a composite coating PCBN cutting tool and a preparation method thereof. The cutting tool comprises a PCBN tool base body and a composite coating applied to the PCBN tool base body, the composite coating comprises a coating A located on the inner layer and a coating B located on the outer layer, wherein the coating A at least comprises an AlxTi1-xCyN1-y coating prepared through a low-pressure chemical vapor deposition method, and the coating B at least comprises a Ti1-a-bAlaMebN coating prepared by adopting a physical vapor deposition method; and the preparation method comprises the following steps of preparing the PCBN tool base body, depositing the AlxTi1xCyN1y coating by adopting a low-pressure CVD process, and depositing the Ti1-a-bAlaMebN coating by adopting a PVD process. The cutting tool has the advantages of being good in bonding strength between the coating and the base body, high in abrasion resistance, excellent in tipping resistance and the like, theservice life of the tool is long, and stability is good.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

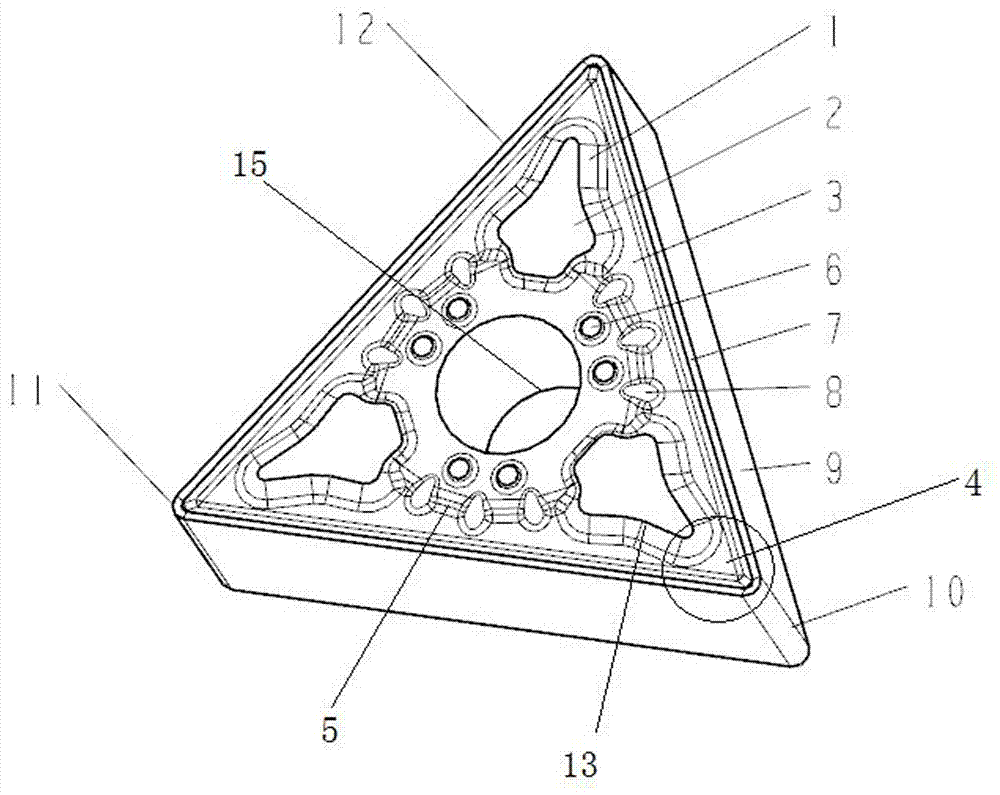

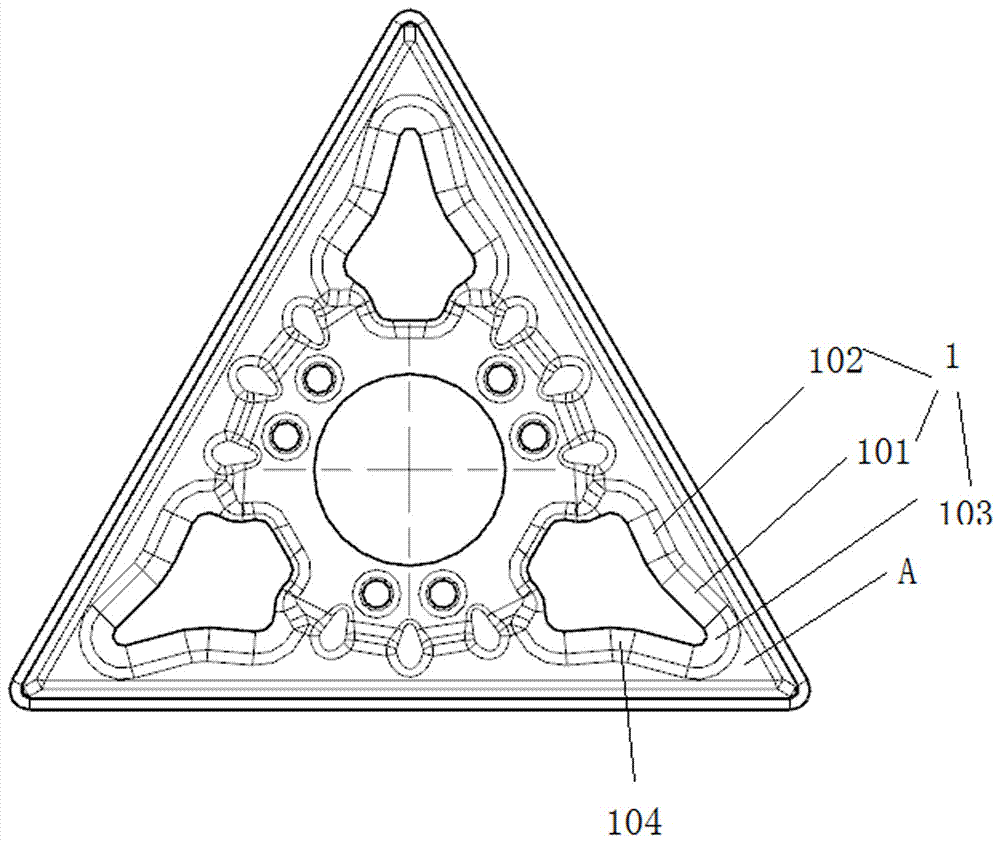

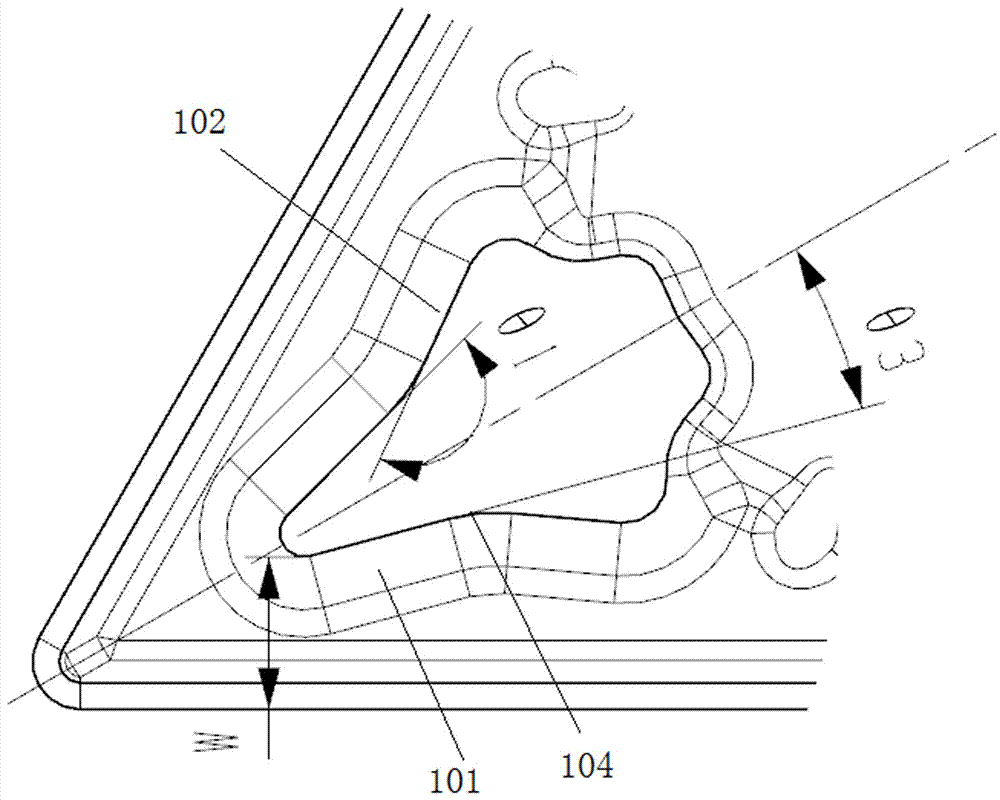

Double-groove type indexable cutting blade

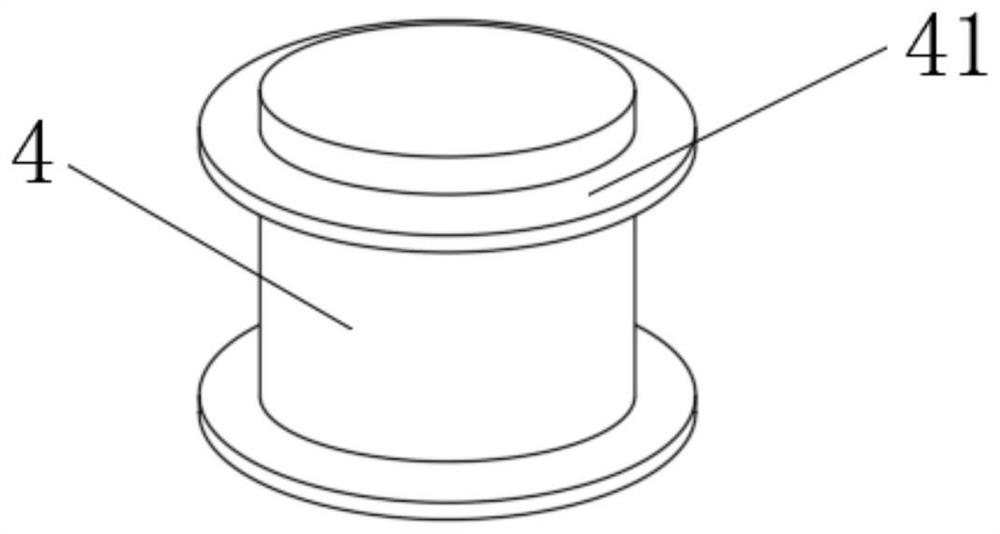

PendingCN107363276AGuaranteed StrengthNot prone to chippingCutting insertsTurning toolsPhysicsTriacontagon

The invention discloses a double-groove type indexable cutting blade, which is provided with a polygonal blade body. The indexable cutting blade comprises a bottom plane (3), positioning surfaces (2) protruding out of the bottom plane (3) and distributed along the circumference of a center hole (15), and cutting units (4), wherein the positioning surface (2) is close to a vertex angle A of each polygon; each cutting unit (4) is arranged at each vertex angle A of a polygon, and comprises a cutting edge and a chip blocking surface (1). Through reasonably designing the cutting units, the cutting blade has high sharpness and enhanced strength; when the cutting blade is in use, a phenomenon of tipping does not occur easily, the life of the cutting blade is prolonged, and the quality of a cut workpiece is guaranteed. The cutting blade is effectively applied to the semifinishing and roughing of a stainless steel material, the cutting blade is clamped stably, the heat dissipation performance is good, the sharpness and strength of a cutting edge are guaranteed, and the chip curling, chip breaking and chip discharge can be realized perfectly.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

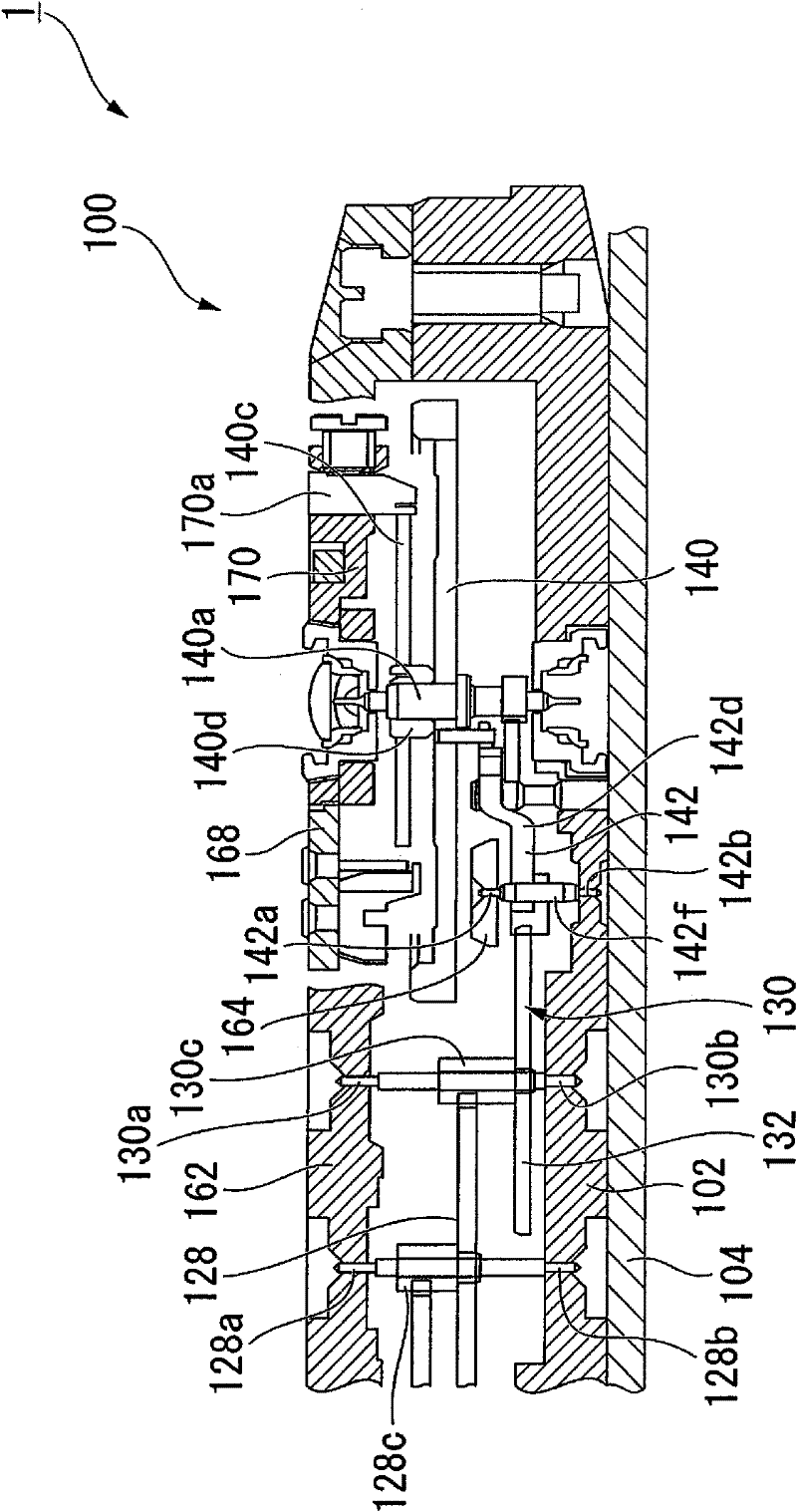

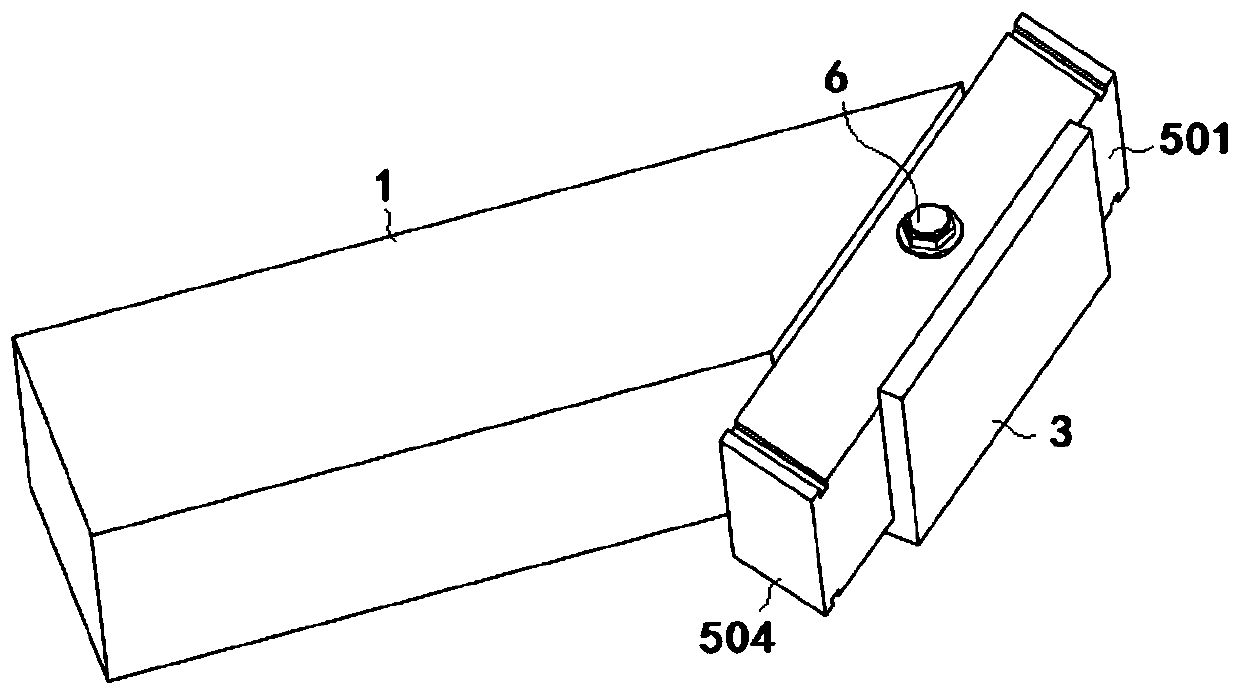

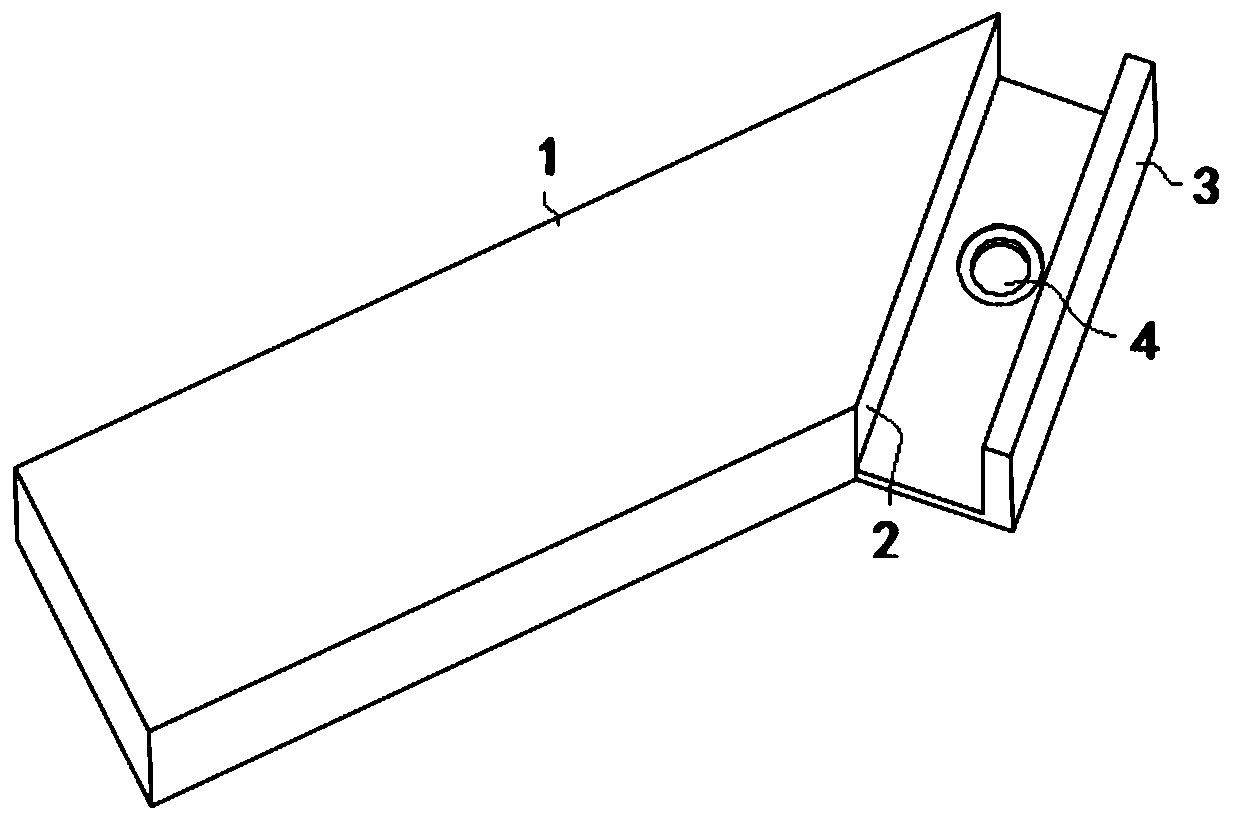

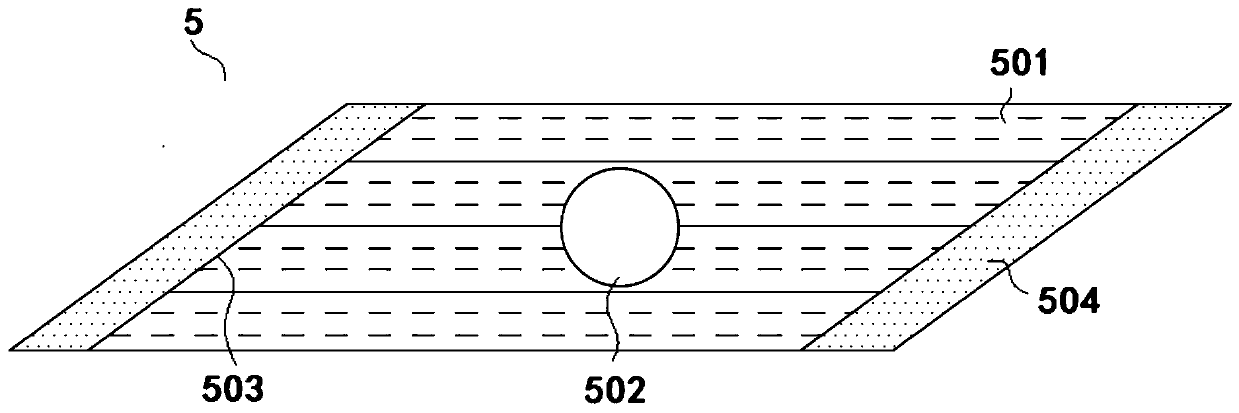

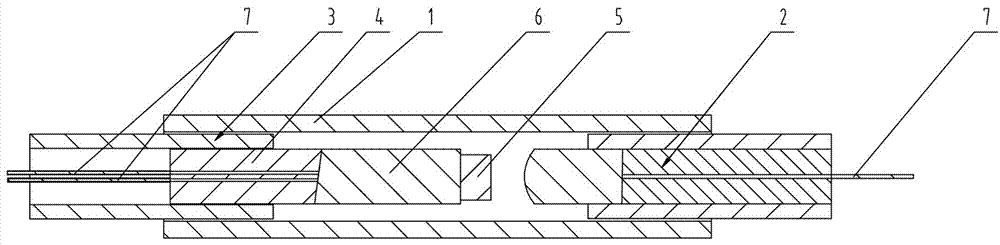

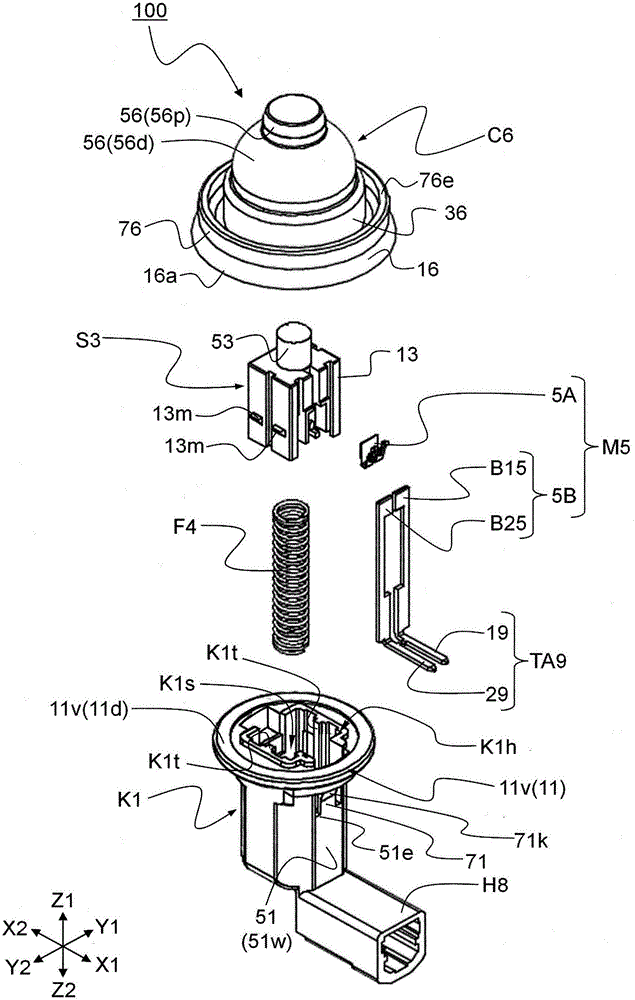

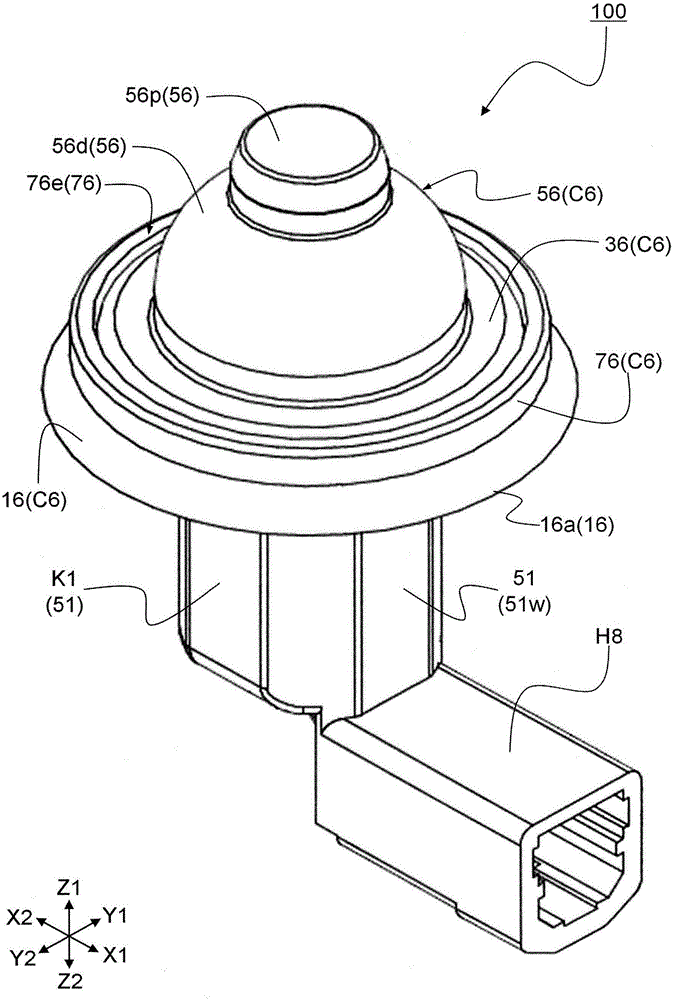

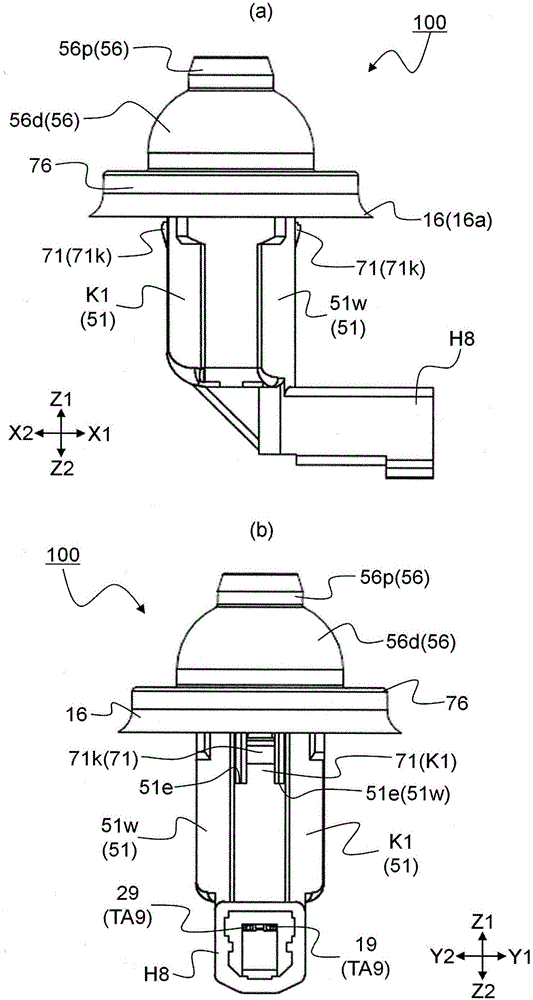

Electrical component

The present invention provides an electrical component having a simple structure and a waterproof structure. The electric component (100) is characterized by including a housing (K1) formed with an opening (K1h), an operable member (S3) which is operative, a detecting mechanism (M5) for detecting operation of the operating member and cover member (C6) formed of materials having water resistance and elasticity. The electrical component is mounted on a mounted portion (500) having a mounting hole allowing a housing to be inserted. The housing has a flange portion (11v) formed by projecting outwardly from an outer edge of the housing. The cover member having a base portion (16) formed in a plate shape, a cylindrical portion (36) extending from an inner edge of the base portion and being elastically deformable and a cover portion (56) for closing the cylindrical portion. The outer shape of the cylindrical portion is smaller than the outer shape of the flange portion in a state before the cover member is attached to the housing, and the cylindrical portion is fitted along the outer shape of the flange portion when the cover member is fitted to the housing.

Owner:ALPS ALPINE CO LTD

Tableware with strengthening structure and preparation method thereof

InactiveCN107440443AHigh hardnessAvoid breakageCeramic shaping apparatusTablewaresHardnessEngineering

The invention relates to a tableware with a reinforced structure and a preparation method thereof, comprising two tableware bodies and two reinforcement components, wherein each of the tableware bodies is a columnar body made of ceramic material, and the top ends are respectively extended inward to form an accommodating space The hardness of each reinforcement component is greater than the hardness of each tableware body, and its part or whole is positioned in each of the accommodating spaces, and an adhesive layer is provided on the outer edge of each of the reinforcement components and the inner wall of the accommodating space of each of the tableware bodies In this way, in the process of using the tableware by the user, the overall stress of the tableware can be increased by means of these strengthening components, avoiding the breakage of the tableware due to improper application of force or collision by the applicator, and greatly improving the convenience of use sex.

Owner:JULIYA

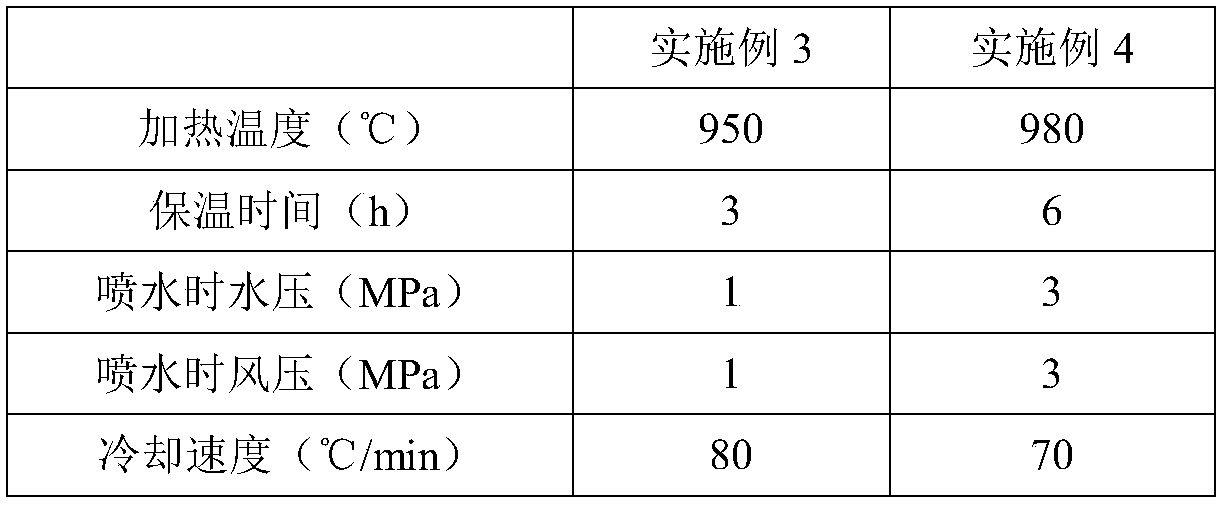

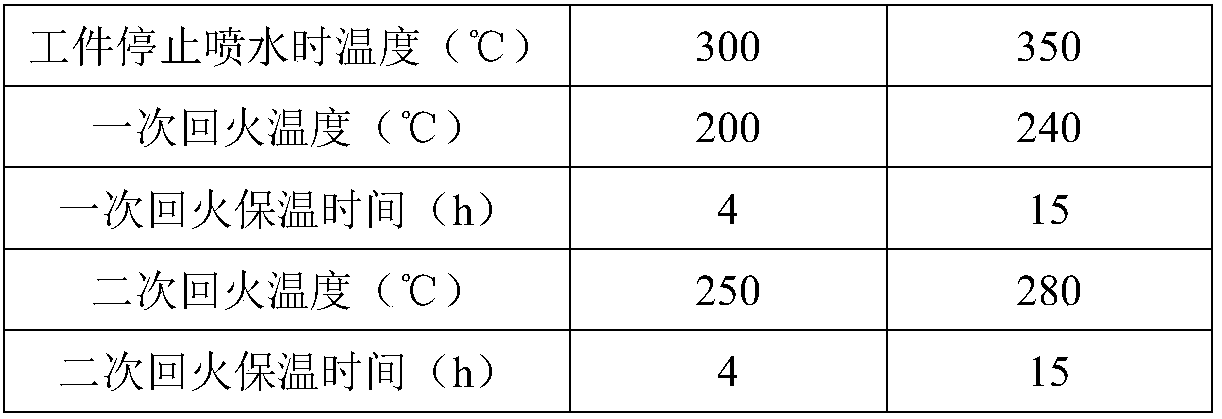

Heat treatment method for shear blade

InactiveCN109576457AReduce cooling rateImprove hardness and uniformityFurnace typesHeat treatment furnacesQuenchingHardness

The invention discloses a heat treatment method for a shear blade, and belongs to the technical field of mechanical blade machining. The method comprises the following steps that A, a blank is prepared according to chemical components and content in technological requirements; B, the blank is subjected to isothermal spheroidization and rough machining to obtain a workpiece; C, the workpiece is subjected to water spraying and blowing quenching treatment, and after the workpiece is cooled to certain temperature, water spraying is stopped, and blowing continues to be carried out; and E, the workpiece is subjected to tempering treatment, and the shear blade is obtained. By means of the method, the cooling speed of the workpiece can be decreased, the hardness and uniformity of the shear blade can be improved, the product deformation is reduced, and the problem that cracks are likely to be produced in the using process is solved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

A preparation method of nanoporous gold for fuel cell thin-layer electrodes

ActiveCN105633420BNot prone to chippingEvenly dispersedCell electrodesElectrochemical responseThin film electrode

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Mold cutting roller device with waste discharging function

InactiveCN109434954ANot prone to chippingExtended service lifeMetal working apparatusPulp and paper industryScrap

The invention discloses a mold cutting roller device with a waste discharging function, and belongs to the field of mold cutting rollers. The mold cutting roller device comprises a cutting roller bodyand a plurality of cutting edges arranged on the surface of the cutting roller body. A waste extracting block is arranged between every two adjacent cutting edges and on the cutting roller body. Theheight of the waste extracting blocks is less than that of the cutting edges. A plurality of pattern grooves used for pasting waste are formed in the end faces, away from the cutting roller body, of the waste extracting blocks. Waste pasting assemblies used for pasting the surfaces of the pattern grooves are arranged above the cutting roller body. The mold cutting roller device has the effects that waste produced in mold cutting can be pasted, other pasting materials are matched to automatically discharge the waste to protect the cutting edges.

Owner:苏州中航盛世刀辊制造有限公司

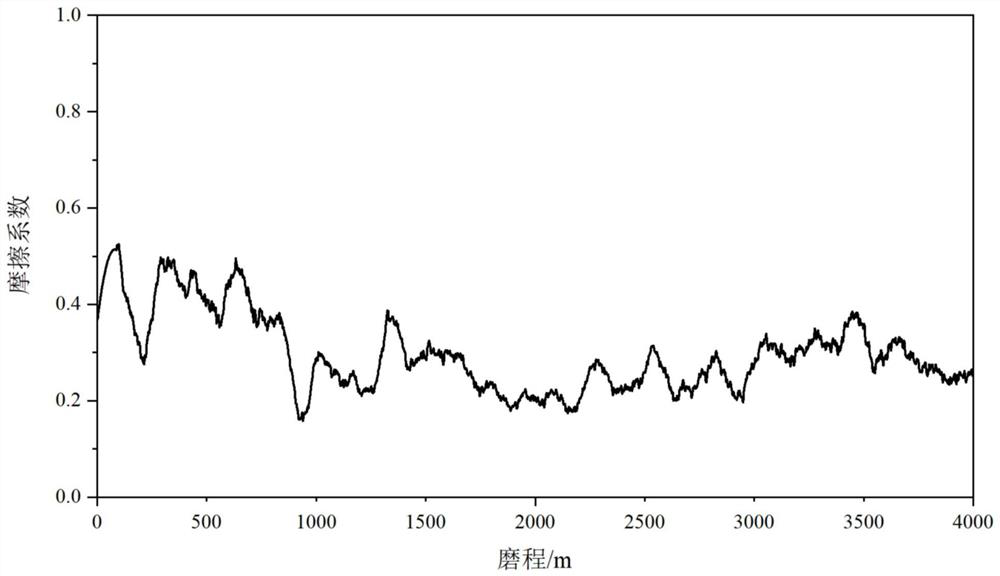

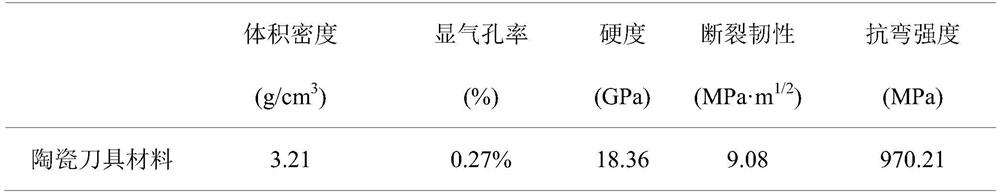

Green and environment-friendly ceramic cutter material and preparation method thereof

PendingCN113896541AImprove fracture toughnessHigh strengthMetal working apparatusSilicon nitrideMagnesium

The invention provides a green and environment-friendly ceramic cutter material and a preparation method thereof. The preparation method comprises the following steps of 1, taking 87-89wt% of silicon nitride, 2-4wt% of nano lignin, 9-11wt% of magnesium oxide and 9-11wt% of yttrium oxide, uniformly mixing, and drying to obtain mixed powder, wherein the nano lignin is extracted from poplar, 2, mixing the mixed powder with absolute ethyl alcohol, and grinding to obtain uniformly mixed slurry, 3, drying the mixed slurry obtained in the step 2 to obtain uniformly mixed composite powder, and 4, loading the composite powder obtained in the step 35 into a mold and conducting hot pressing sintering under the protection of the nitrogen atmosphere, wherein the sintering temperature ranges from 1700 DEG C to 1800 DEG C, the pressure ranges from 30 MPa to 40 MPa, the heat preservation and pressure maintaining time ranges from 30 min to 60 min, heat preservation is conducted for 30 min to 40 min when the temperature is increased to 800 DEG C to 850 DEG C, and the green and environment-friendly ceramic cutter material is obtained. The used raw materials are green, the preparation method is simple, the prepared cutter can achieve low friction coefficient and wear rate without using a cutting fluid, and the fracture toughness is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Flame-retardant medium-high density fiberboard

InactiveCN111959066AImprove fire performanceAvoid glitchesSynthetic resin layered productsPaper/cardboard layered productsFiber layerPolymer chemistry

The invention relates to the technical field of plates. The invention discloses a flame-retardant medium-high density fiberboard. The density fiberboard comprises a density fiberboard body, protectiveframes are arranged on the two sides of the density fiberboard body, a mounting groove is formed in the middle of the density fiberboard body, a plurality of supporting columns are fixedly connectedto the mounting groove at equal intervals, a water absorption plate is arranged between the two supporting columns, sliding strips are slidably connected into grooves in the top ends of the inner sides of the protective frames, the bottom ends of the two sliding strips are fixedly connected with a protective layer, and the density fiberboard body is composed of a wear-resistant paper layer, a waterproof layer, a first flame retardant layer, a first reinforcing layer, a wood fiber layer, a second reinforcing layer and a second flame retardant layer. According to the flame-retardant medium-highdensity fiberboard, the fireproof performance of the fiberboard is improved, obvious flame-retardant treatment can be performed on open fire, so that the side edges of the fiberboard are protected, itis guaranteed that the waterproof performance of the fiberboard is good, the situation that the fiberboard is rotten due to water absorption is avoided, and the service life of the fiberboard is prolonged.

Owner:宋红刚

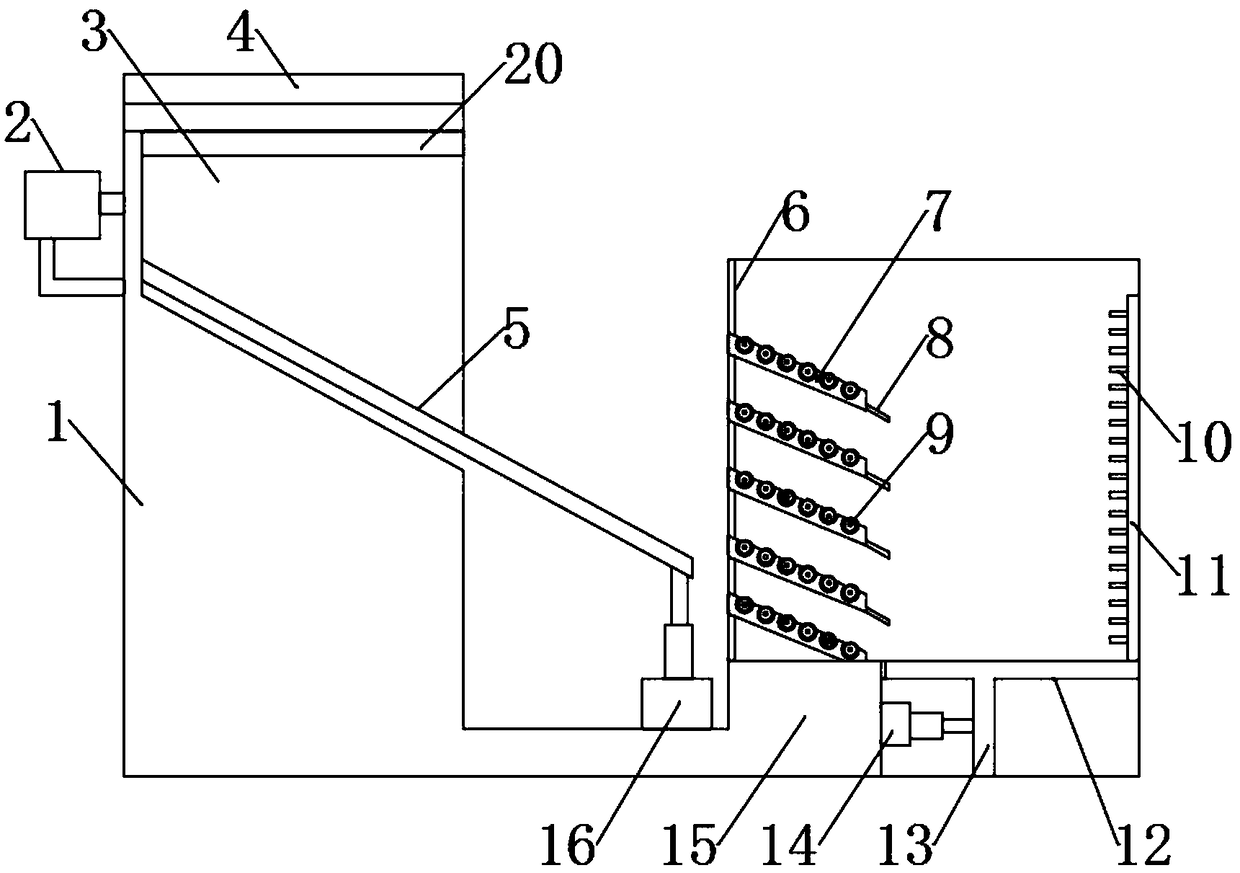

Dish washing robot with function of automatic dish placement

InactiveCN108836225AAvoid collisionNot prone to chippingTableware washing/rinsing machine detailsCleaning equipmentSlide plateEngineering

The invention discloses a dish washing robot with a function of automatic dish placement. The dish washing robot comprises a conveying table, a conveying plate and a dish placement box, wherein the conveying table is arranged on the left side of the dish placement box; a conveying cavity is formed in the upper end of the conveying table; partitions are arranged in the conveying cavity; multiple openings are formed in the upper surface of the conveying table above the conveying cavity and arranged between the adjacent partitions. Dishes slide on a base through buffer plates, mutual collision oftwo corners of the dishes during stacked placement is prevented by rubber strips and rubber pads on the left side and the right side above the base, the dishes are not prone to breakage or damage, the probability of accidents is low, and safety is higher; the dishes with different specifications can be separated in different conveying cavities by sliding plates with different specifications on the conveying table, so that the dish washing robot can automatically classify and place the dishes when cleaning the dishes with different specifications, manual classification is not needed, dish placement is fully automatic, cleaning and dish placement efficiency is improved, and the dish washing robot is suitable for being popularized.

Owner:谭雅文

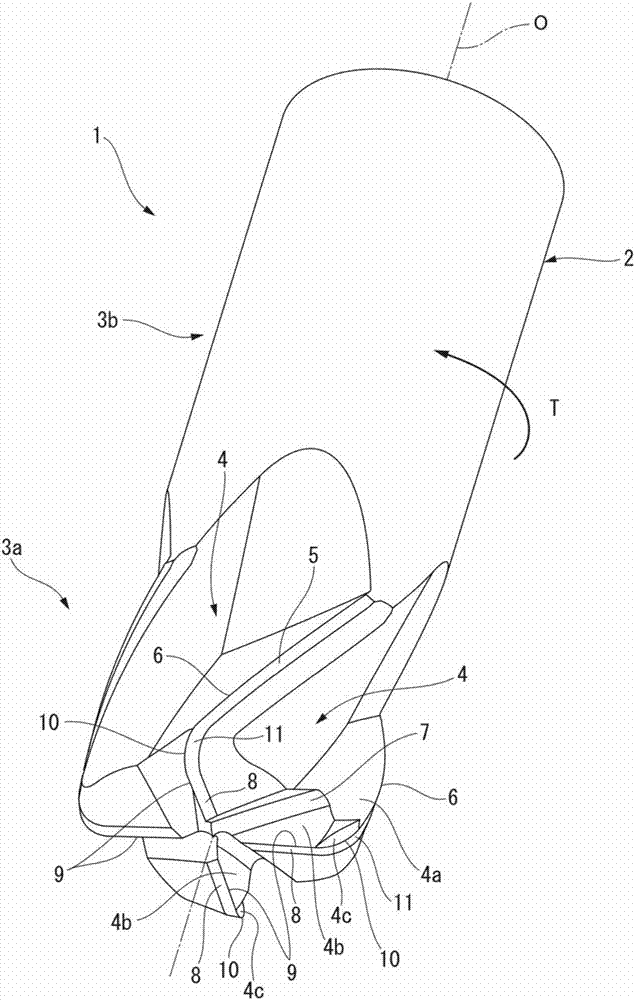

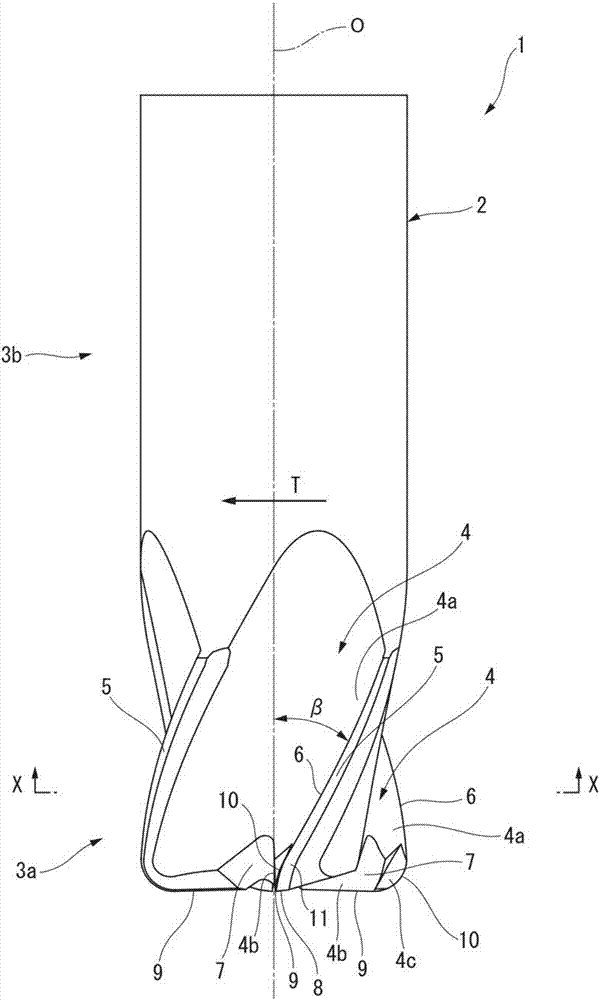

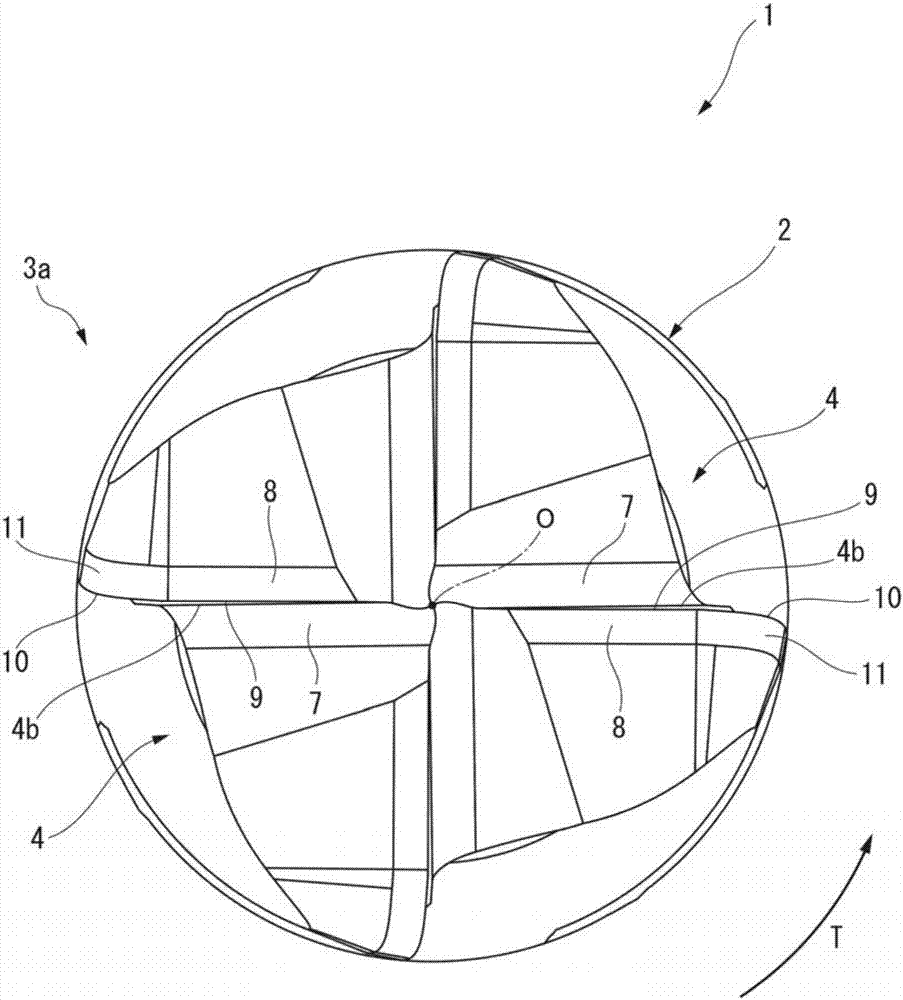

Radius end mill, ball end mill, and end mill

InactiveCN107000080AAchieve processing efficiencyHigh strengthMilling cuttersWorkpiecesMilling cutterEngineering

The present invention is provided with: a ceramic end mill main body (2); chip discharge grooves (4) formed in an outer periphery of the end mill main body (2); outer peripheral cutting edges (6) formed at intersecting ridge lines between wall surfaces which face in a tool rotation direction (T), in the chip discharge grooves (4), and an outer peripheral surface of the end mill main body (2); base cutting edges formed at intersecting ridge lines between the wall surfaces in the chip discharge grooves (4) and a tip end surface of the end mill main body (2); and corner cutting edges which are located in tip end outer peripheral portions of the end mill main body (2), connect the outer ends of the base cutting edges with the tip ends of the outer peripheral cutting edges (6), and are formed in the shape of convex curved lines which have a convexity facing toward the tip end outer peripheral side of the end mill main body (2). From among the outer peripheral cutting edges (6), the base cutting edges and the corner cutting edges, a radial rake angle (angle alpha) of at least the outer peripheral cutting edges (6) is set to a negative angle. The radial rake angle (angle alpha) of the outer peripheral cutting edges (6) is between -20 deg and -10 deg.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com