Double-groove type indexable cutting blade

A technology of cutting blades and double-sided grooves, which is applied in the direction of cutting blades, turning equipment, tool holder accessories, etc., can solve the problems of adhesion and wear between cutting blades and chips, affecting the surface processing quality of workpieces, and reducing the life of cutting blades. Achieve good cutting effect, stable clamping, balance sharpness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

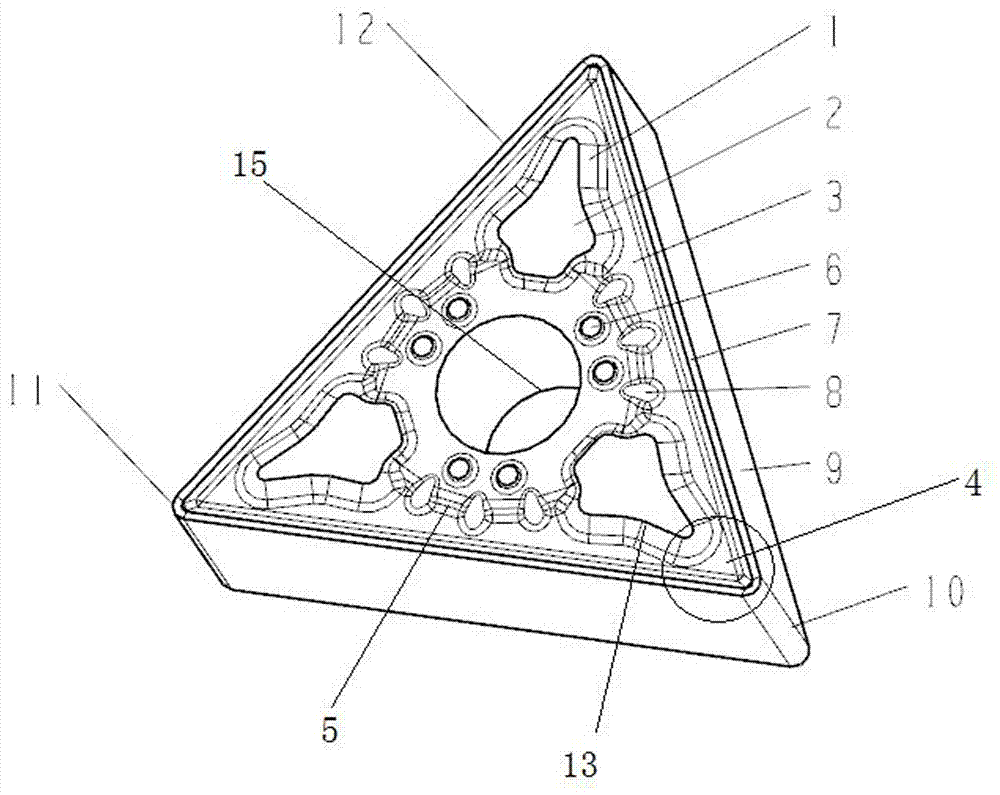

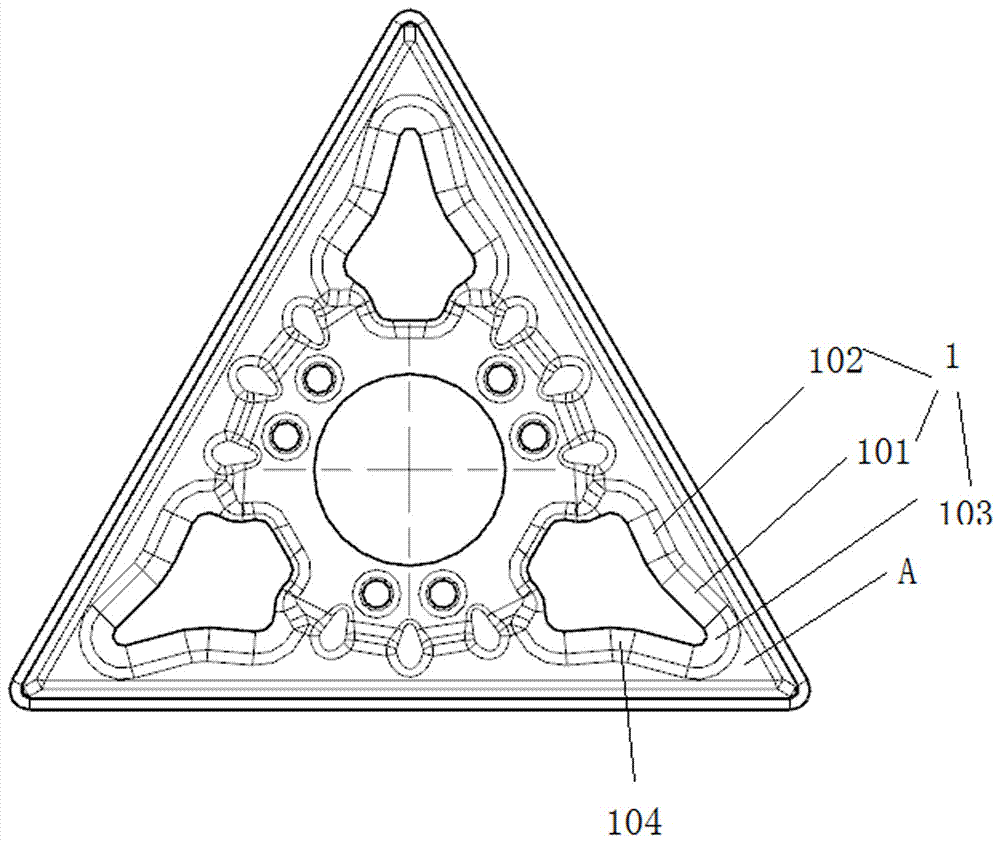

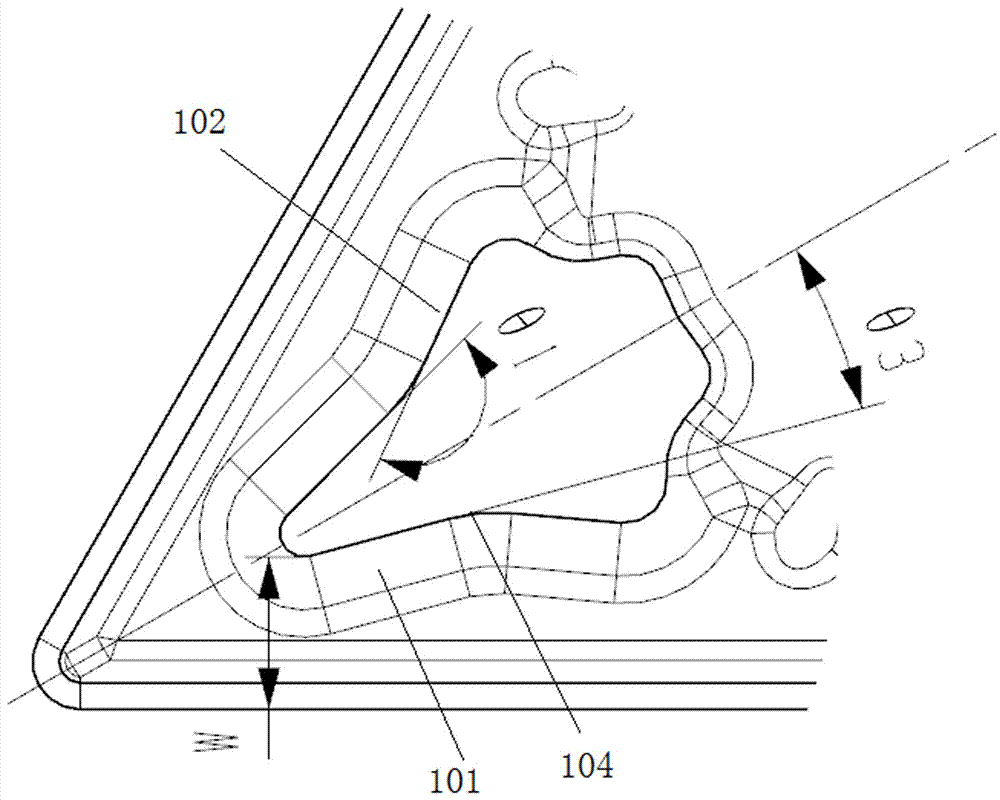

[0036] Such as Figure 1~Figure 4 As shown, this embodiment provides a double-sided groove type indexable cutting insert. The insert body includes an upper surface, a lower surface, a side surface and a cylindrical surface connecting adjacent sides. The center of the cutting insert is provided with a central hole for installation and positioning. 15, the upper surface includes a bottom plane 3, a positioning surface 2 protruding from the bottom plane 3 along the circumferential direction of the central hole 15, a positioning boss 6 and a cutting unit 4; wherein, the positioning surface 2 is arranged near the vertex A of each polygon position; the positioning boss 6 is arranged between the adjacent positioning surfaces 2 along the circumferential direction of the center hole 15; the slope between the positioning surface 2 and the bottom plane 3 is the chip sweeping surface 1, and the chip blocking surface 1 is symmetrical along the bisector of the angle A of the top angle arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com