Patents

Literature

41results about How to "Achieve processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

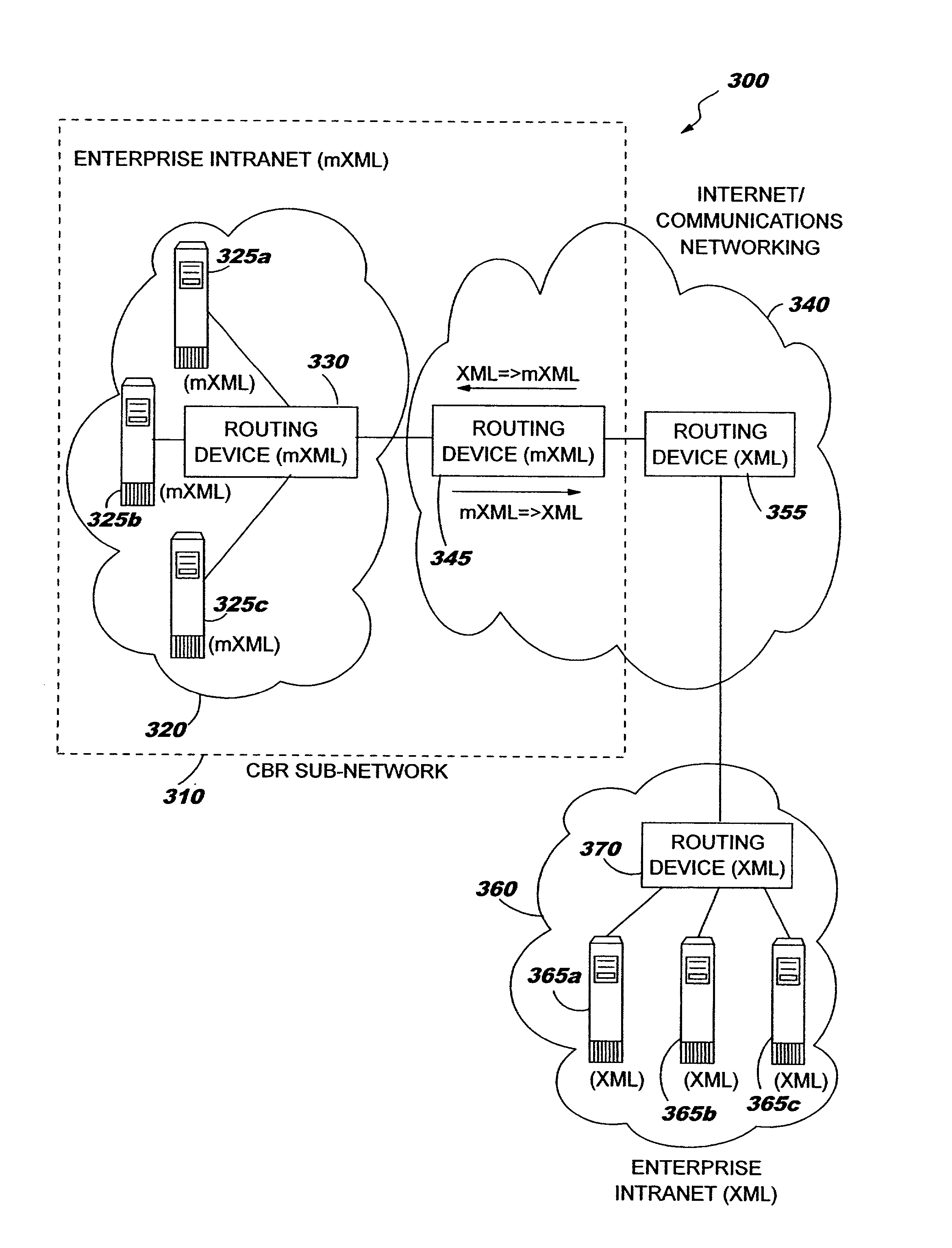

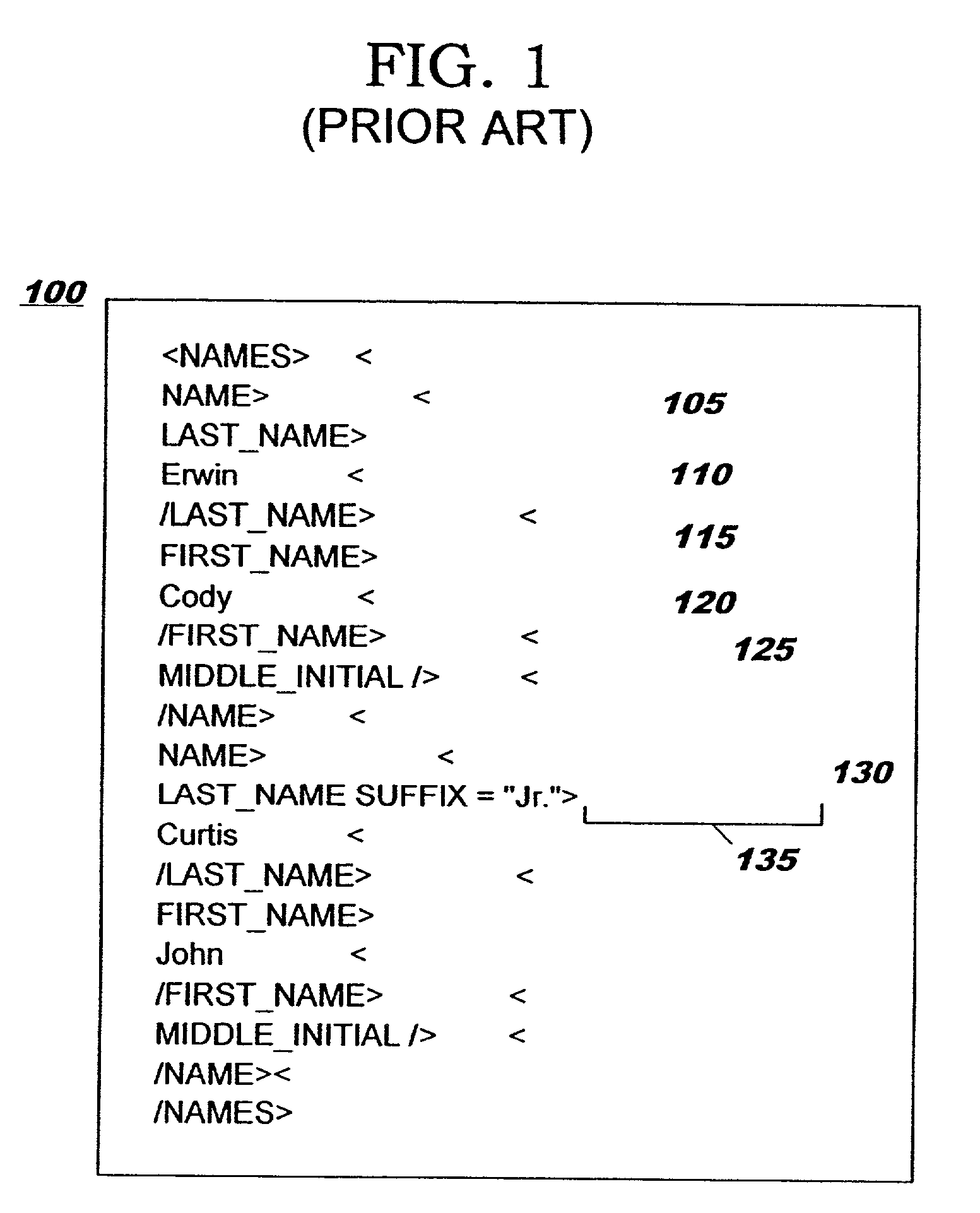

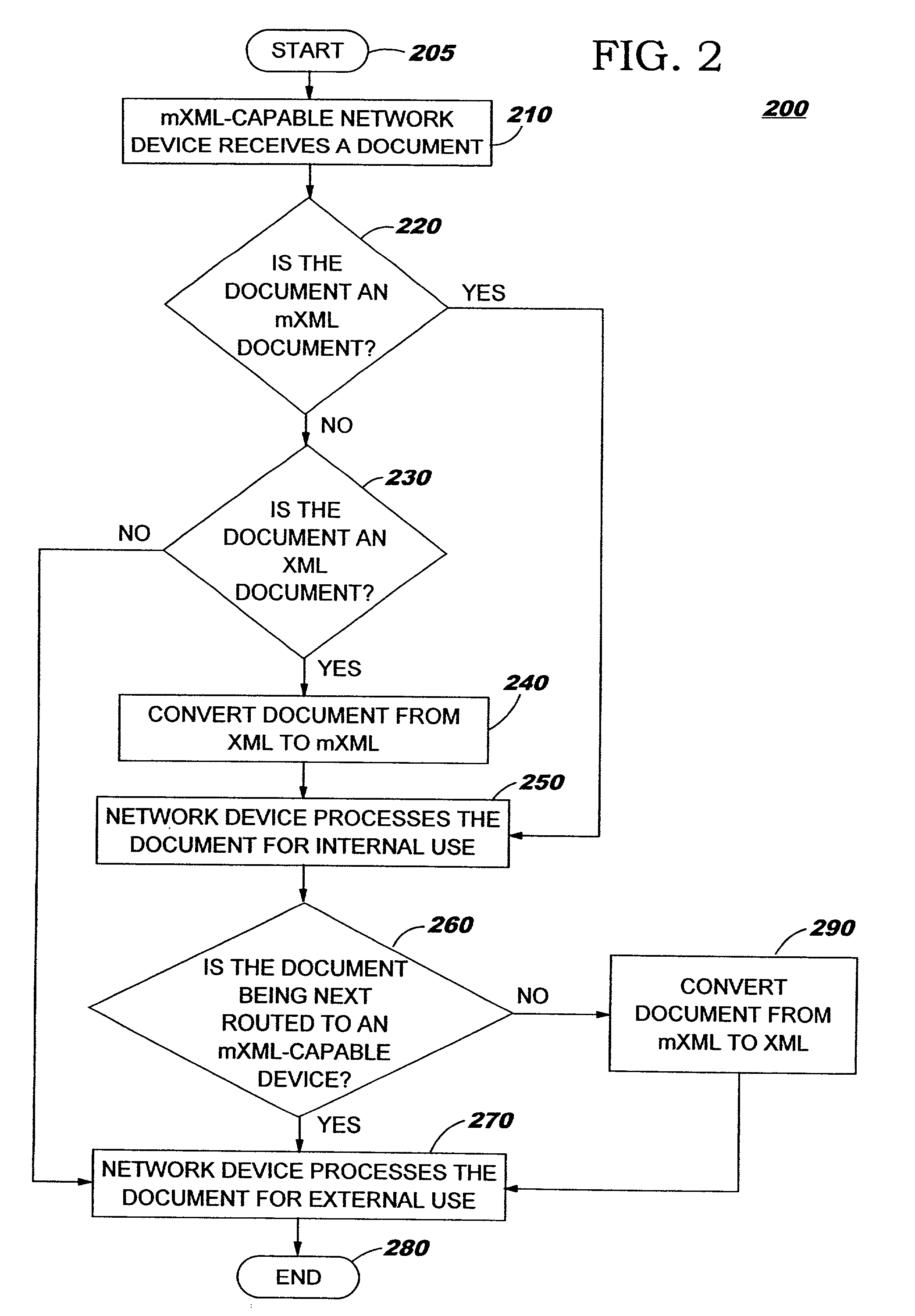

Conversion of documents between XML and processor efficient MXML in content based routing networks

InactiveUS7134075B2Efficient processingImprove performanceNatural language data processingSpecial data processing applicationsSemanticsExtensible markup

A method, system, and computer program product for efficient processing of Extensible Markup Language (XML) documents in Content Based Routing (“CBR”) networks. Specifically, the method involves converting existing XML documents to a machine-oriented notation (“mXML”) which is significantly more compact than XML, while still conveying the content and semantics of the data and the structure of the document. Documents are converted from XML to mXML upon entering a CBR subnetwork and / or upon receipt by an mXML-capable device. The documents are then processed in mXML format. Devices within the inventive system are provided with an awareness of whether target devices or processes are mXML-capable. Documents being routed to a target which is mXML-capable are passed in mXML format while documents being routed to a target which is not mXML-capable are converted to XML before they are passed.

Owner:IBM CORP

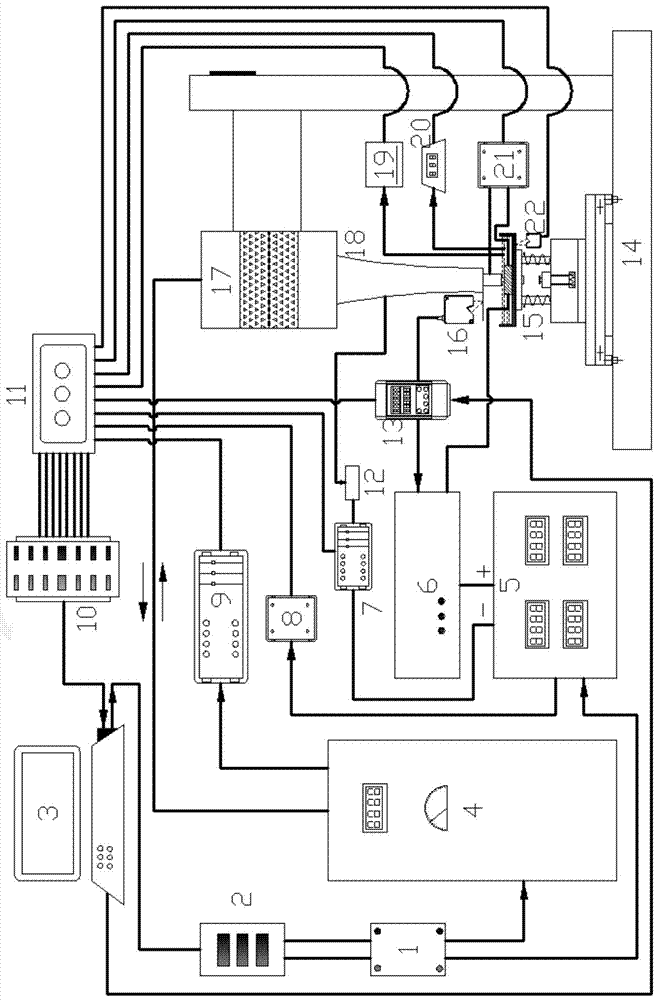

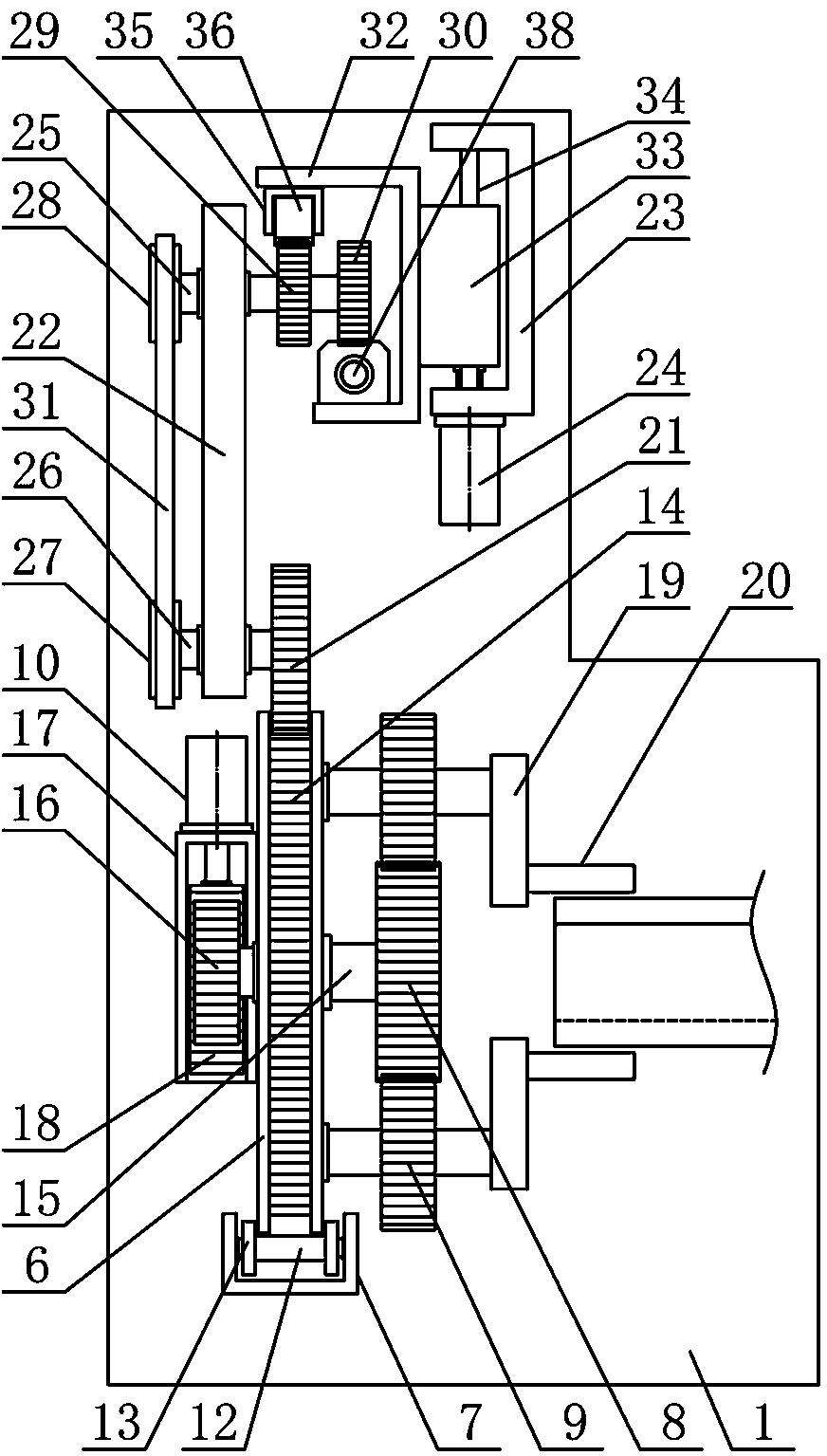

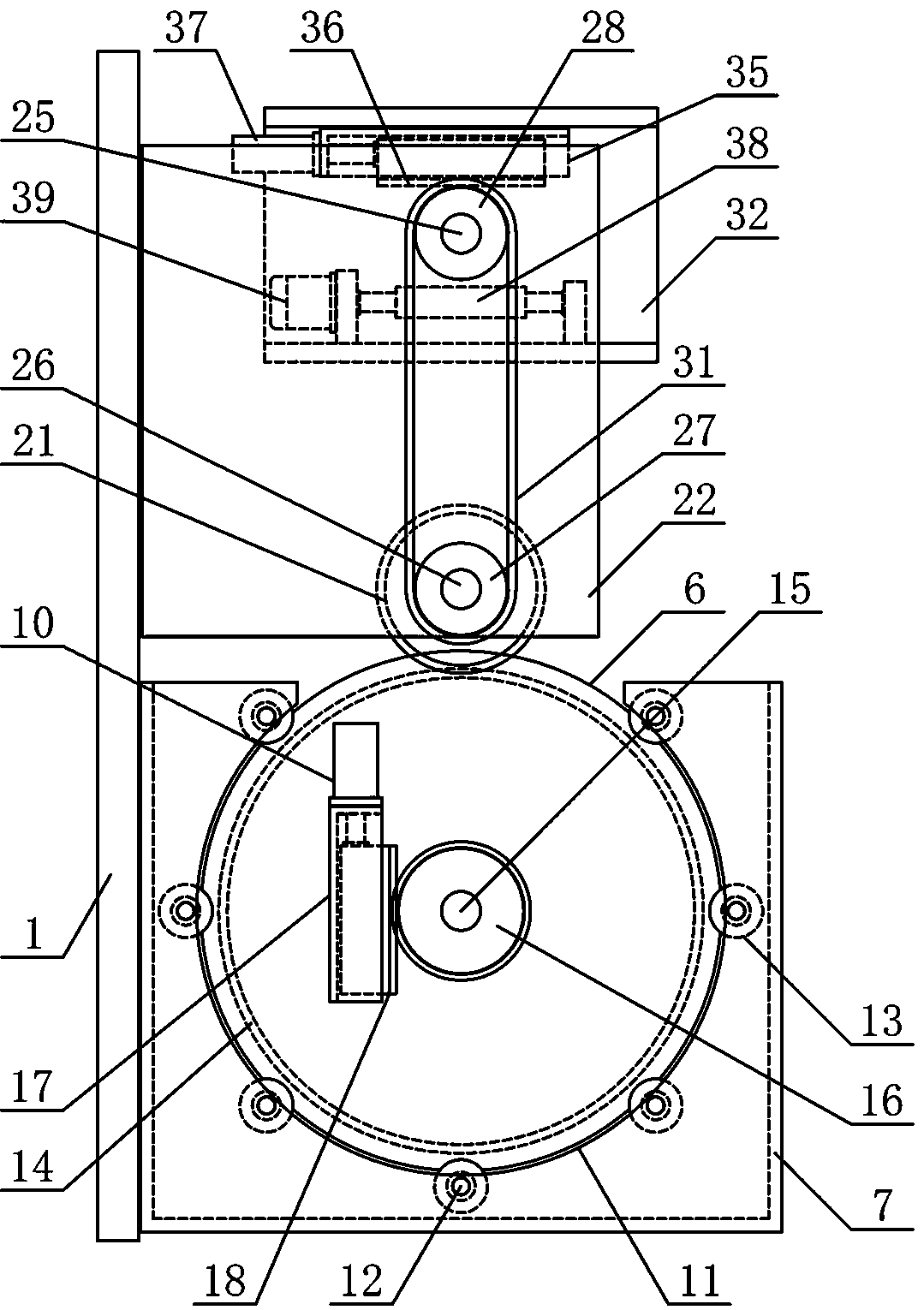

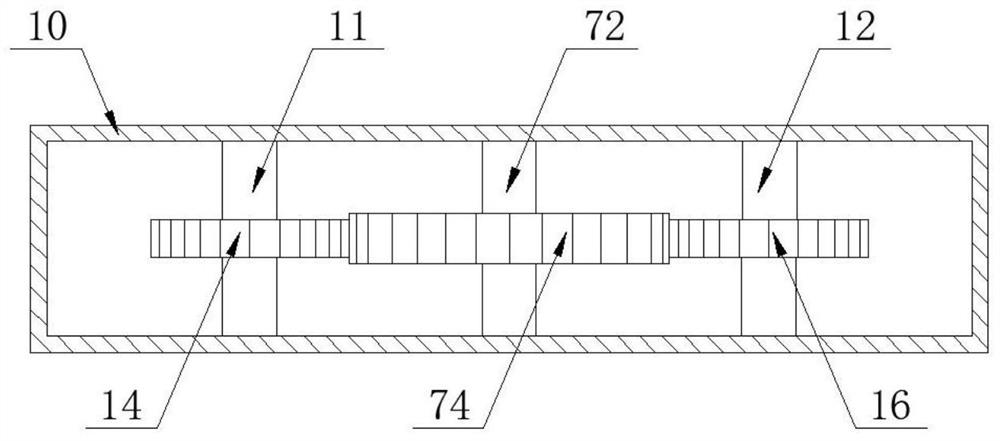

Ultrasonic combined electric machining technology real-time optimizing control system and control method thereof

InactiveCN104722866AHigh productivity requirementsStable processing parametersMechanical vibrations separationElectric circuitsControl signalState parameter

The invention discloses ultrasonic combined electric machining technology real-time optimizing control system and a control method thereof. An ultrasonic power supply is connected with a first current sensor and a transducer, a computer is connected with a synchronous data acquisition card, and the synchronous data acquisition card collects all machining parameter data, acquired by the first current sensor, a voltage sensor, a second current sensor and a laser micro displacement sensor probe, of a machining workpiece; the machining workpiece is placed on a magnetic levitation workbench, a tool electrode is fixed on the lower end face of an amplitude changing rod, the upper end of the amplitude changing rod is connected with the transducer, the positive electrode of a pulse power supply is connected with a synchronous chopper which receives chopping control signals given by a laser micro displacement sensor controller, the synchronous chopper is connected with the machining workpiece, working liquid is filled between the machining workpiece and the electrode, the electrode is connected with the second current sensor through a current-limiting resistor, the second current sensor is connected with the negative electrode of the pulse power supply, and the voltage sensor is connected with the output end of the pulse power supply. The ultrasonic combined electric machining technology real-time optimizing control system and the control method thereof have the advantages of being capable of obtaining vibration displacement, temperature, and voltage state parameters in real time.

Owner:YANGZHOU UNIV

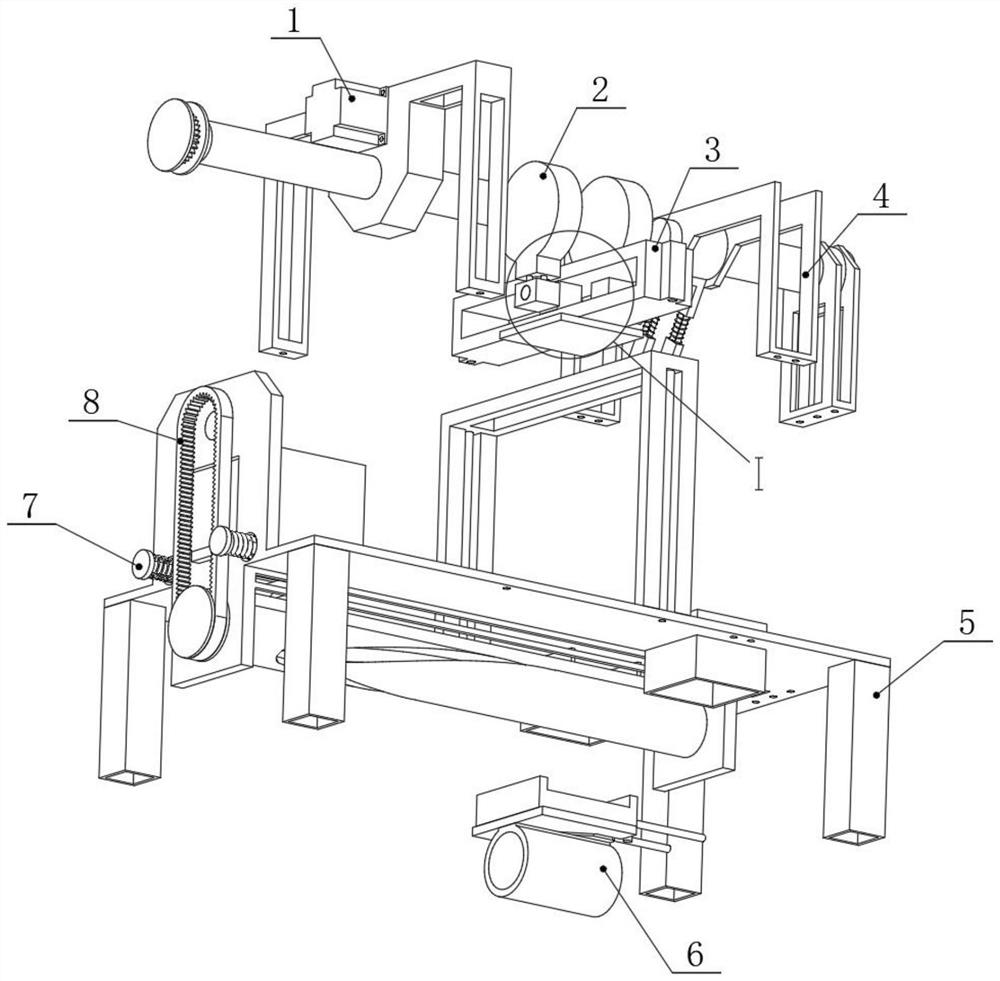

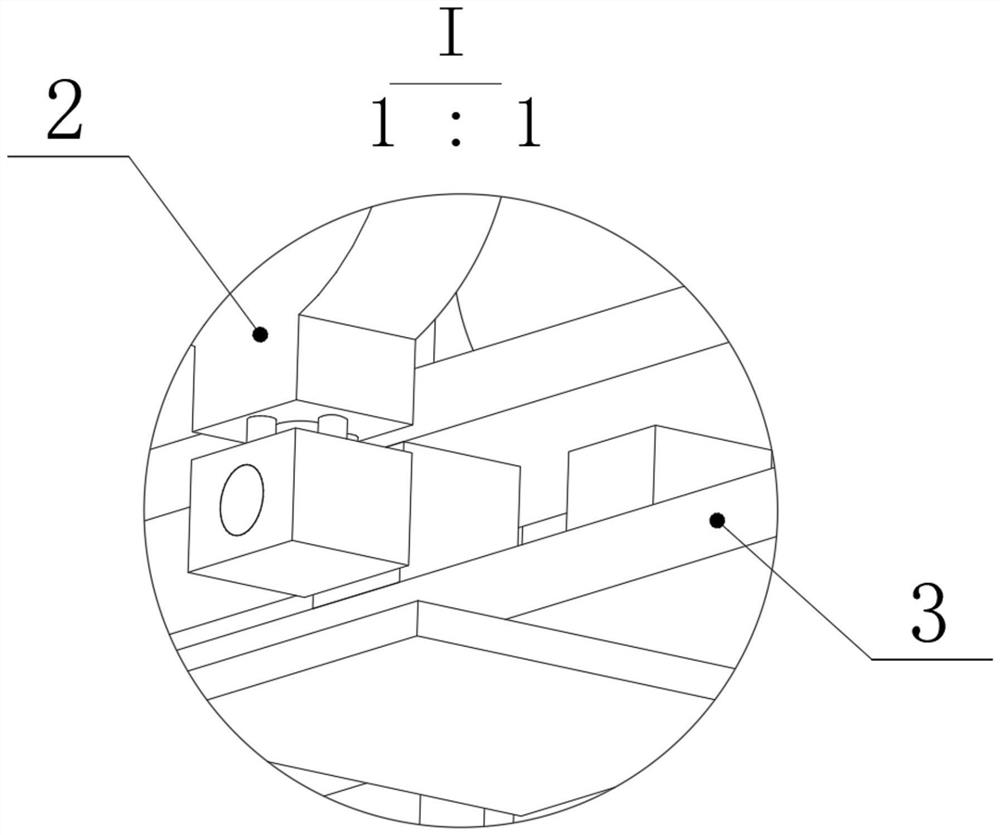

Machining device for metallic shaft tubes

ActiveCN110586752AReasonable structural designSmooth and accurate manufacturingMetal-working feeding devicesPositioning devicesEngineeringMetal

The invention discloses a machining device for metallic shaft tubes, and belongs to the field of mechanical equipment for tube machining. According to the machining device, a driving mechanism and a pipe clamping mechanism are arranged at one side of a machining support in sequence; a machining mechanism is horizontally arranged on the machining support at the upper side of a pipe holding mechanism; a machining rotary plate is vertically arranged at the upper side of a bearing plate support; the machining support at the upper side of the bearing plate support is fixedly provided with a drivingsupport vertically; a pipe holding bearing plate is horizontally arranged at the upper side of an adjusting support seat; a pipe holding slot being of a V-shaped structure is horizontally formed in the pipe holding bearing plate; the output end of a horizontal moving air cylinder is fixedly connected with the middle part of one side of a machining guide plate; and the upper side of the machiningguide plate is vertically and fixedly provided with a punching air cylinder and a slotting air cylinder in sequence in the horizontal direction. The machining device is reasonable in structural designand high in machining automation degree, can efficiently and accurately perform punching and slotting in sequence on the metallic shaft tubes having various sizes, and meets the needs of production and use.

Owner:江苏润森管业有限公司

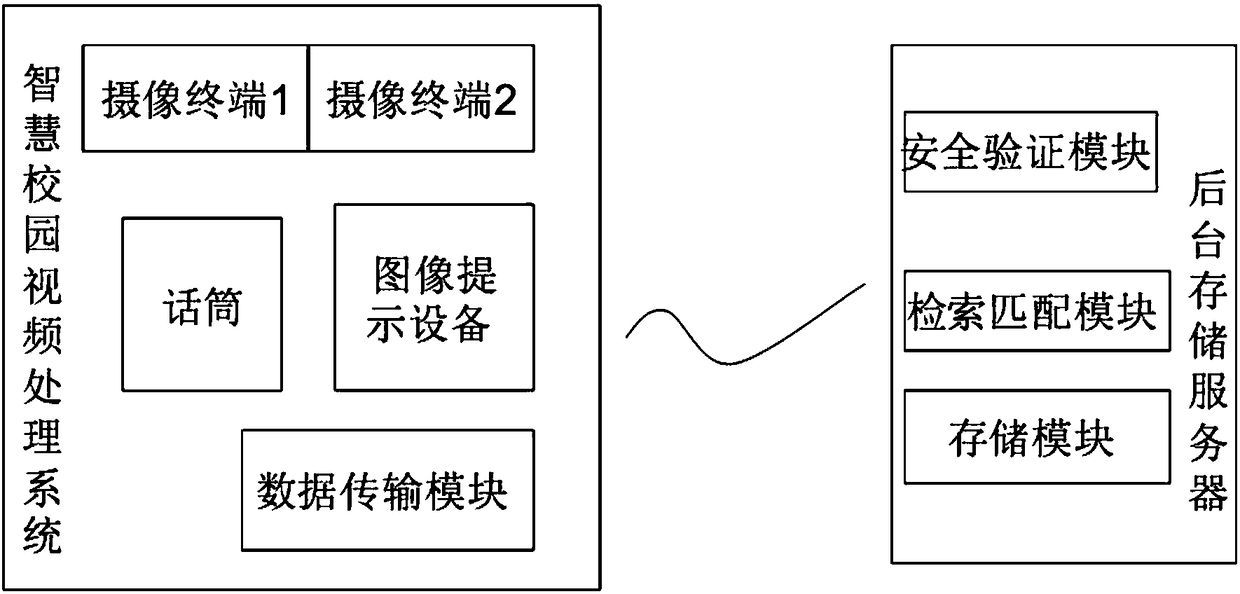

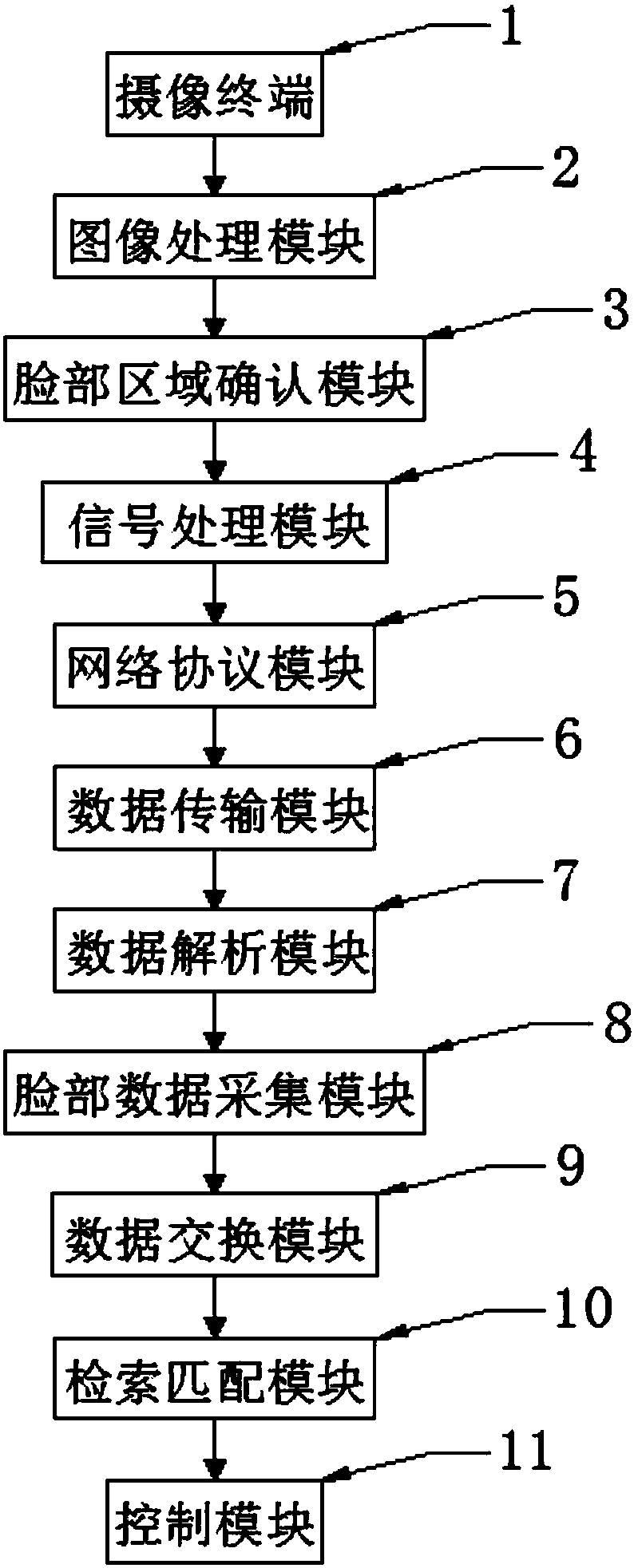

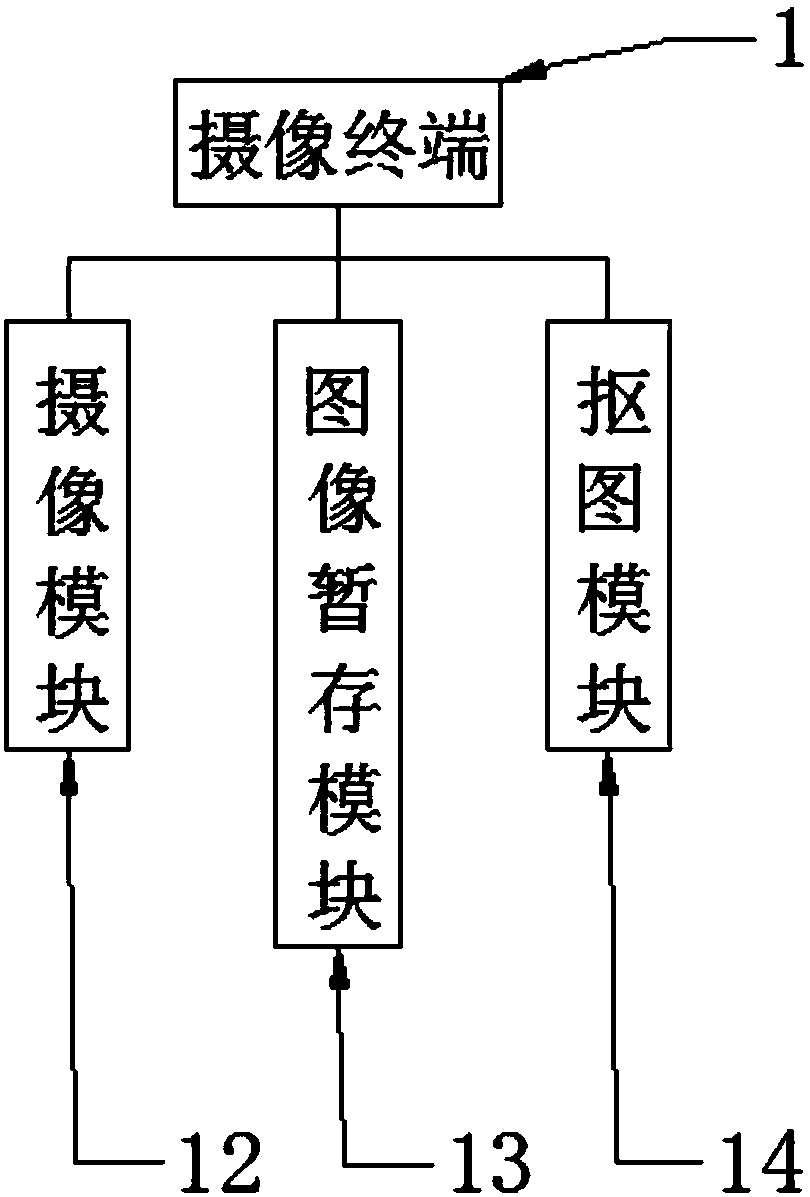

Smart campus video processing system

InactiveCN108600627APrevent malicious misappropriation or theft of informationEnsure safety and stabilityTelevision system detailsCharacter and pattern recognitionData transmissionData analysis

The invention discloses a smart campus video processing system, including an image capturing terminal, wherein the bottom of the image capturing terminal is provided with an image processing module, the bottom of the image processing module is provided with a face region confirming module, the bottom of the face region confirming module is provided with a signal processing module, the bottom of the signal processing module is provided with a network protocol module, the bottom of the network protocol module is provided with a data transmission module, the bottom of the data transmission moduleis provided with a data analysis module, the bottom of the data analysis module is provided with a face data collection module, the bottom of the face data collection module is provided with a data exchange module, the bottom of the data exchange module is provided with a search matching module, and the bottom of the search matching module is provided with a control module. The invention has thebeneficial effects of effectively preventing from malicious theft or information stealing, and ensuring the security and stability of the smart campus.

Owner:DONGGUAN POLYTECHNIC

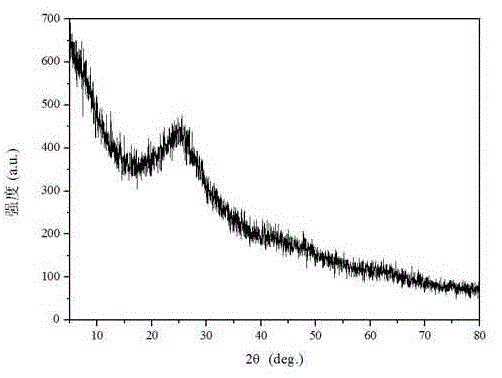

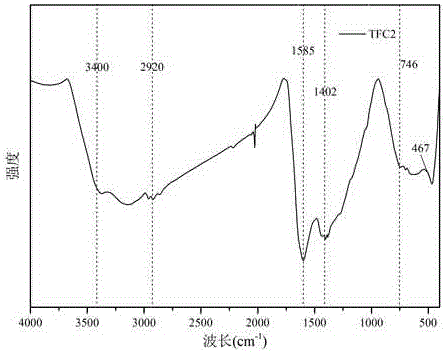

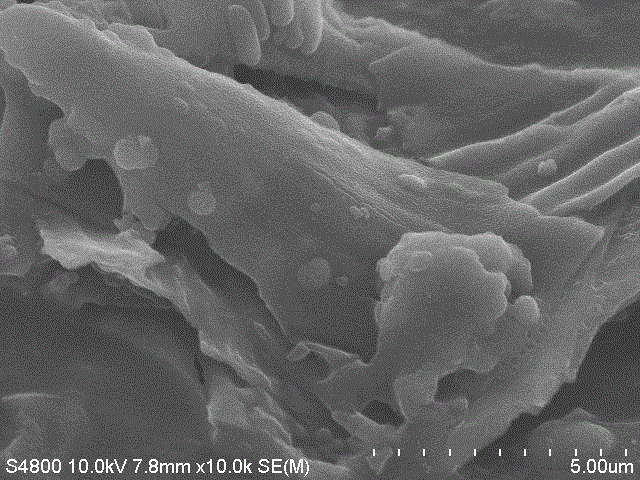

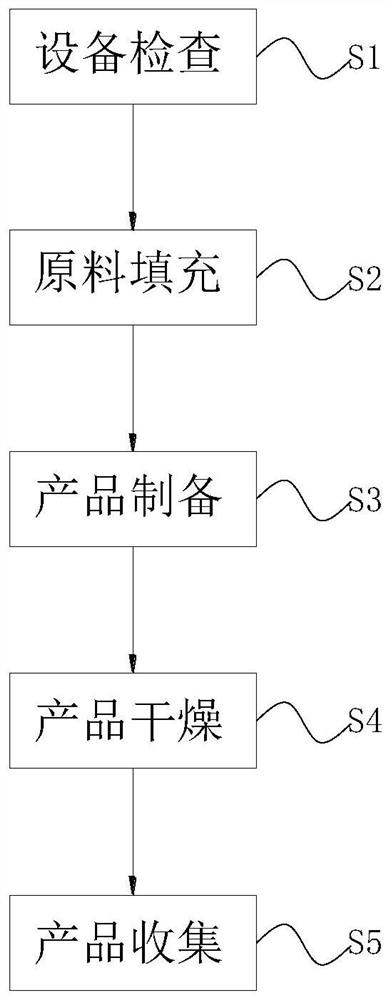

Manufacturing method of biological carbon based on titanium dioxide photocatalytic material

InactiveCN106390971ALower energy bandgapLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationLight ActivityAlcohol

The invention belongs to a practical technology in the field of environmental engineering and provides a manufacturing method of a biological carbon based on titanium dioxide photoactive (multilayered graphene / titanium dioxide) material. The environment-friendly type photocatalytic material with visible light activity is prepared through mainly taking waste animal feather, tetrabutyl titanate, absolute ethyl alcohol, potassium hydroxide and the like as raw materials, utilizing mutual effects of the materials at high temperature and carrying out an integrated heating, cross-linking and carbonization process. A preparation process accords with principles of simplicity, rapidness, greenness and high efficiency; the preparation cost of similar materials is greatly reduced. The prepared novel material has no toxin and harm, is convenient to recycle and has high catalytic efficiency and meets process and engineering requirements of water treatment.

Owner:INNER MONGOLIA UNIVERSITY +1

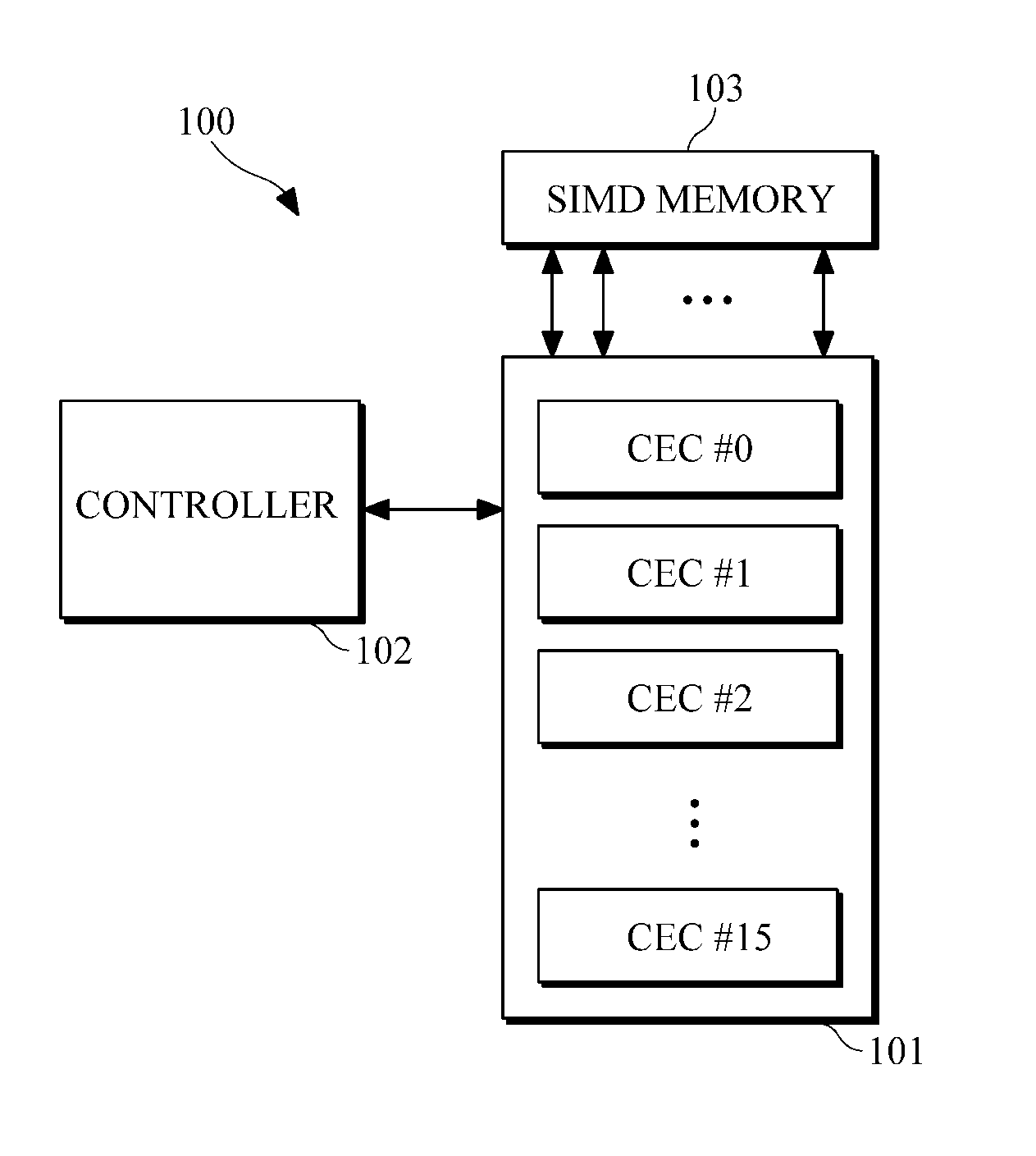

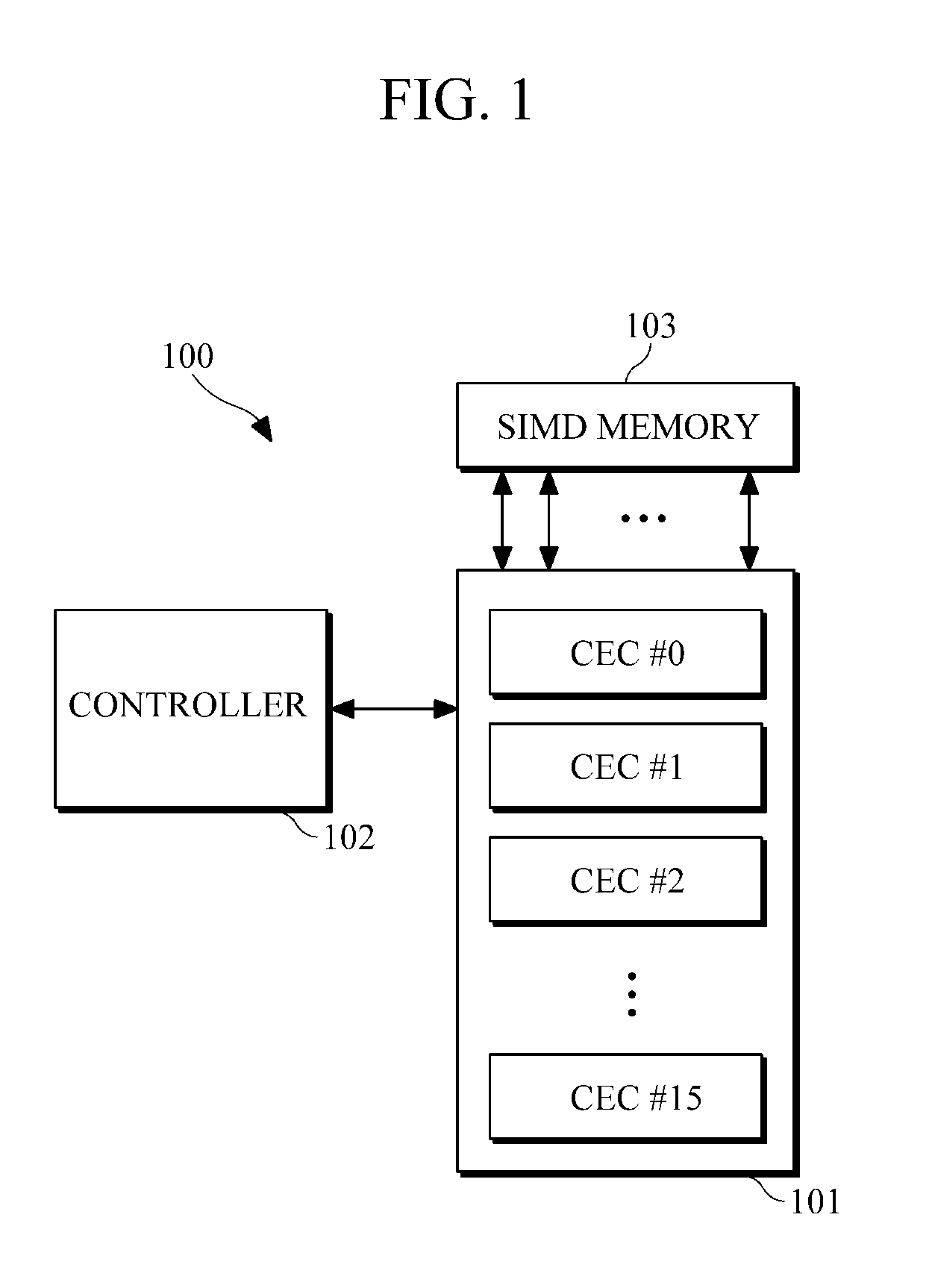

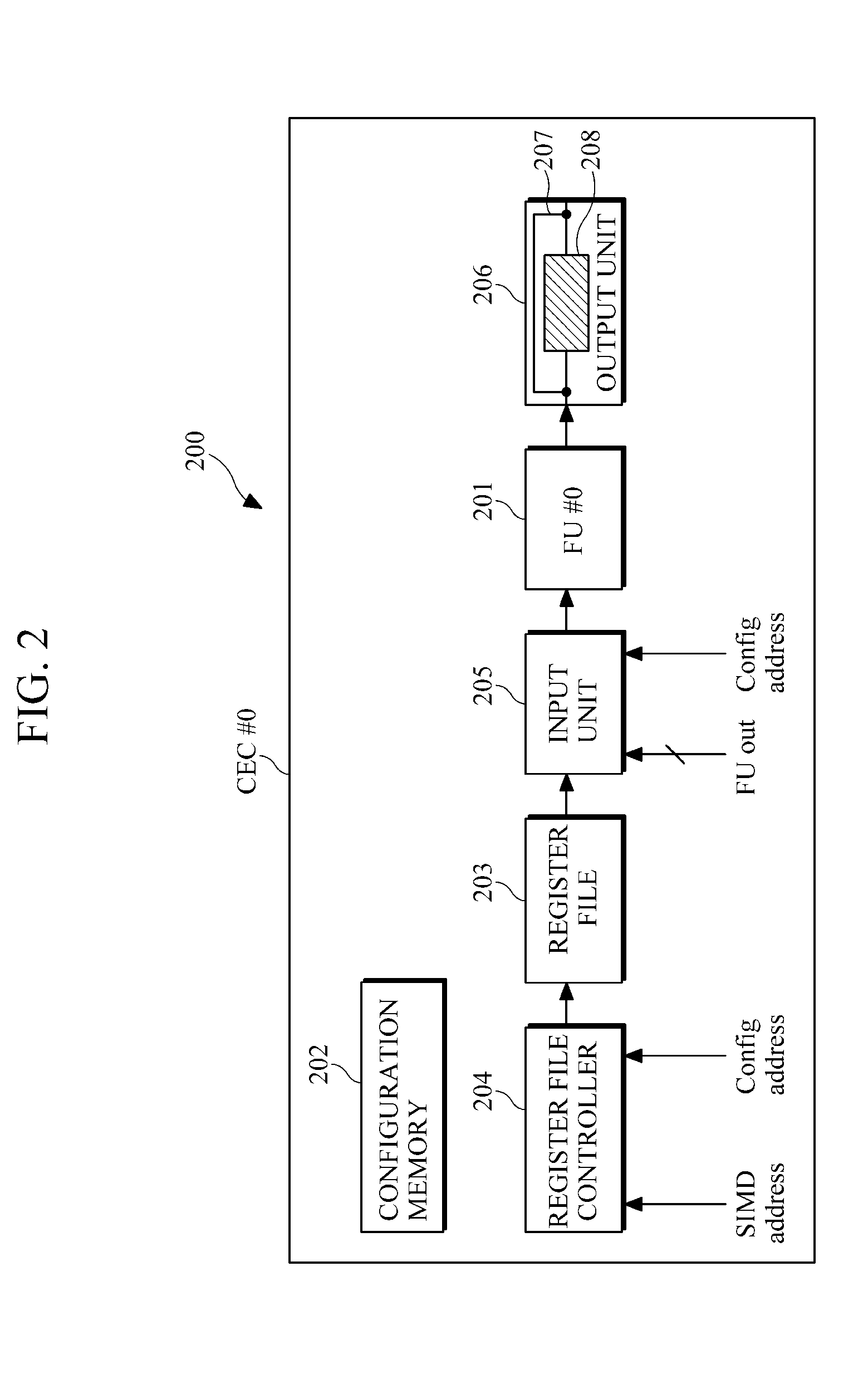

Computing apparatus and method based on a reconfigurable single instruction multiple data (SIMD) architecture

InactiveUS20120166762A1Achieve processing efficiencySingle instruction multiple data multiprocessorsProgram control using wired connectionsSimd architecture

Provided are a computing apparatus and method based on SIMD architecture capable of supporting various SIMD widths without wasting resources. The computing apparatus includes a plurality of configurable execution cores (CECs) that have a plurality of execution modes, and a controller for detecting a loop region from a program, determining a Single Instruction Multiple Data (SIMD) width for the detected loop region, and determining an execution mode of the processor according to the determined SIMD width.

Owner:SAMSUNG ELECTRONICS CO LTD

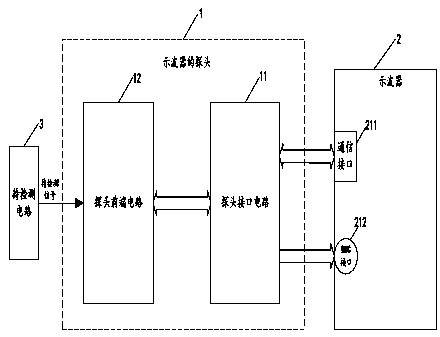

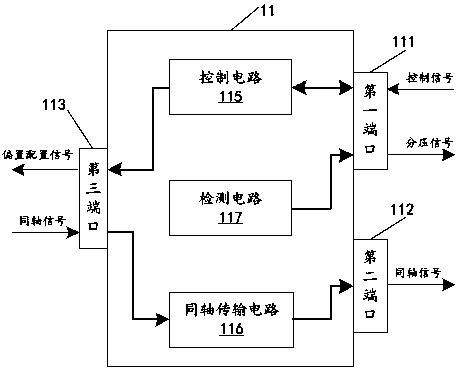

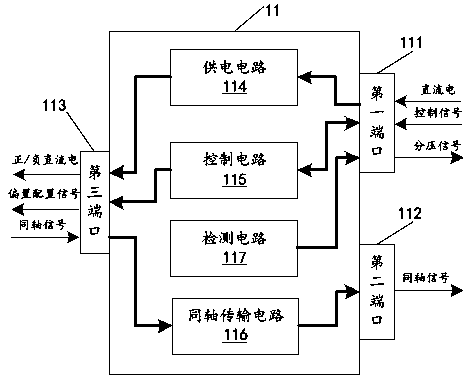

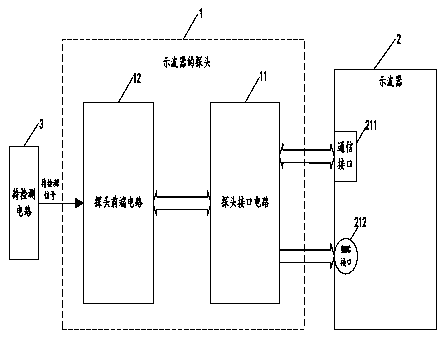

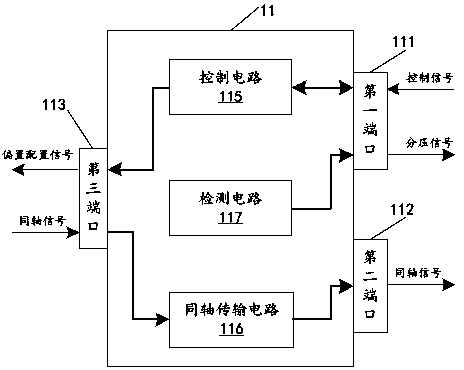

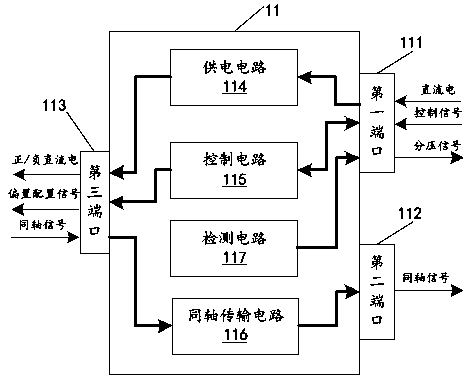

Probe interface circuit and probe adaptation circuit for probe of oscilloscope

ActiveCN111289786AAvoid interferenceMeet electricity demandDigital variable displayCommunication interfaceControl signal

A probe interface circuit and a probe adapter circuit for a probe of an oscilloscope, wherein the probe comprises a probe interface circuit and a probe front end circuit, and the probe interface circuit comprises a control circuit, a detection circuit and a coaxial transmission circuit; the probe interface circuit is used for receiving a control signal generated by the oscilloscope from a communication interface of the oscilloscope, performing DC bias configuration according to the control signal to generate a bias configuration signal, and outputting a bias configuration signal to a probe front-end circuit through the output end of the bias circuit, so that the probe front-end circuit performs direct-current bias superposition on the signal to be detected under the action of the bias configuration signal, and generates a coaxial signal with output impedance matched with a BNC interface of the oscilloscope through attenuation adjustment and impedance adjustment. Because the probe interface circuit can generate the bias configuration signal according to the control signal, the free superposition of the direct current bias of the signal to be detected can be realized, and the functional defects of the existing oscilloscope probe can be overcome.

Owner:SHENZHEN CITY SIGLENT TECH

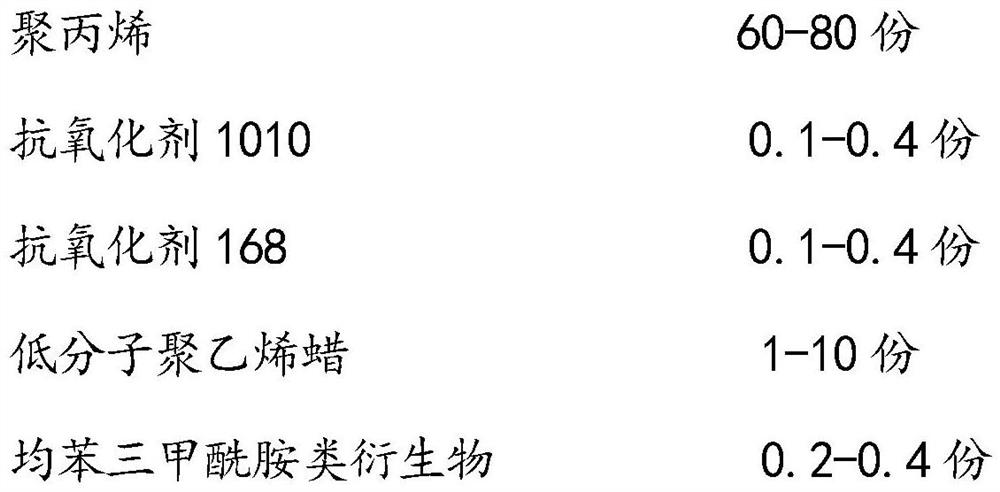

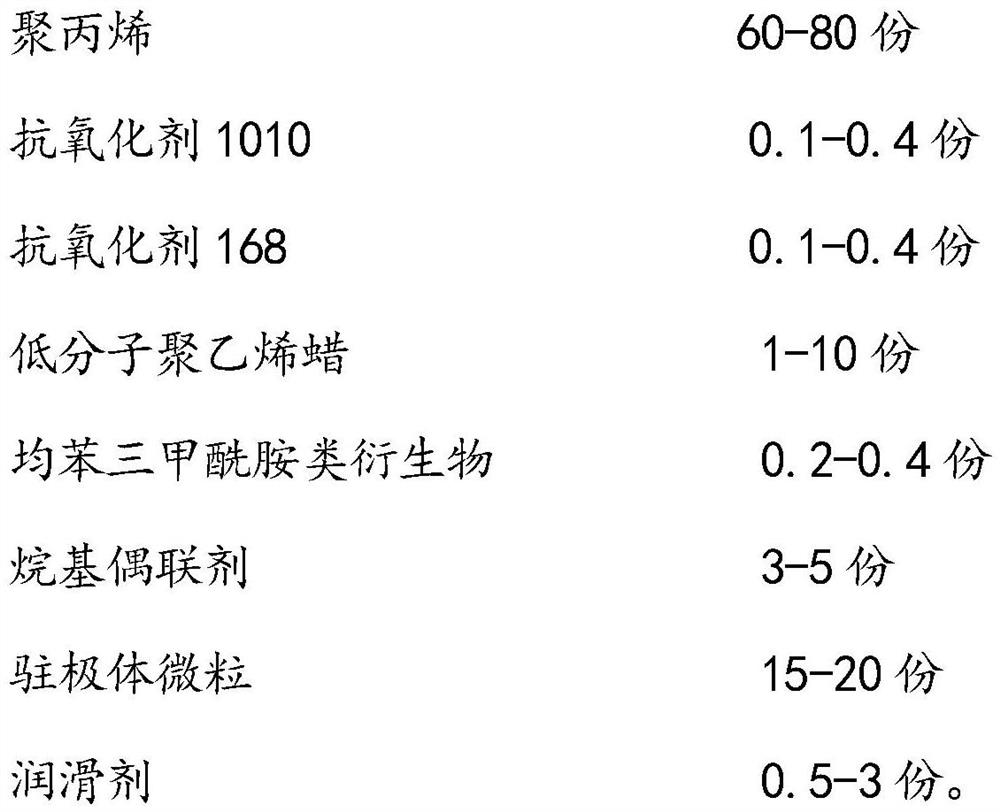

Modified polypropylene master batch, modified melt-blown fabric material and improved melt-blown fabric processing method

PendingCN111892772AHigh crystallinityEasy to captureNon-woven fabricsPerylene derivativesCrystallinity

The invention discloses a modified polypropylene master batch, a modified melt-blown cloth material and an improved melt-blown cloth processing method. The modified polypropylene master batch comprises polypropylene, an antioxidant, low molecular weight polyethylene wax, an alkyl coupling agent, electret particles, a lubricant and modified polypropylene, and the modified polypropylene at least comprises trimesoyl amide derivatives obtained by modifying trimesoyl amide. The invention provides a safer and more effective melt-blown cloth material. By adding the modified nucleating agent, the crystallinity of the polypropylene can be improved, and the capture and charge storage stability of space charges can be obviously improved along with the increase of the crystallinity and the size so that the dosage of the nano electret material can be reduced, the potential risk is reduced, the charge storage amount can be effectively increased, and the charge storage time can be effectively prolonged.

Owner:苏州工业园区拓朴环保净化有限公司

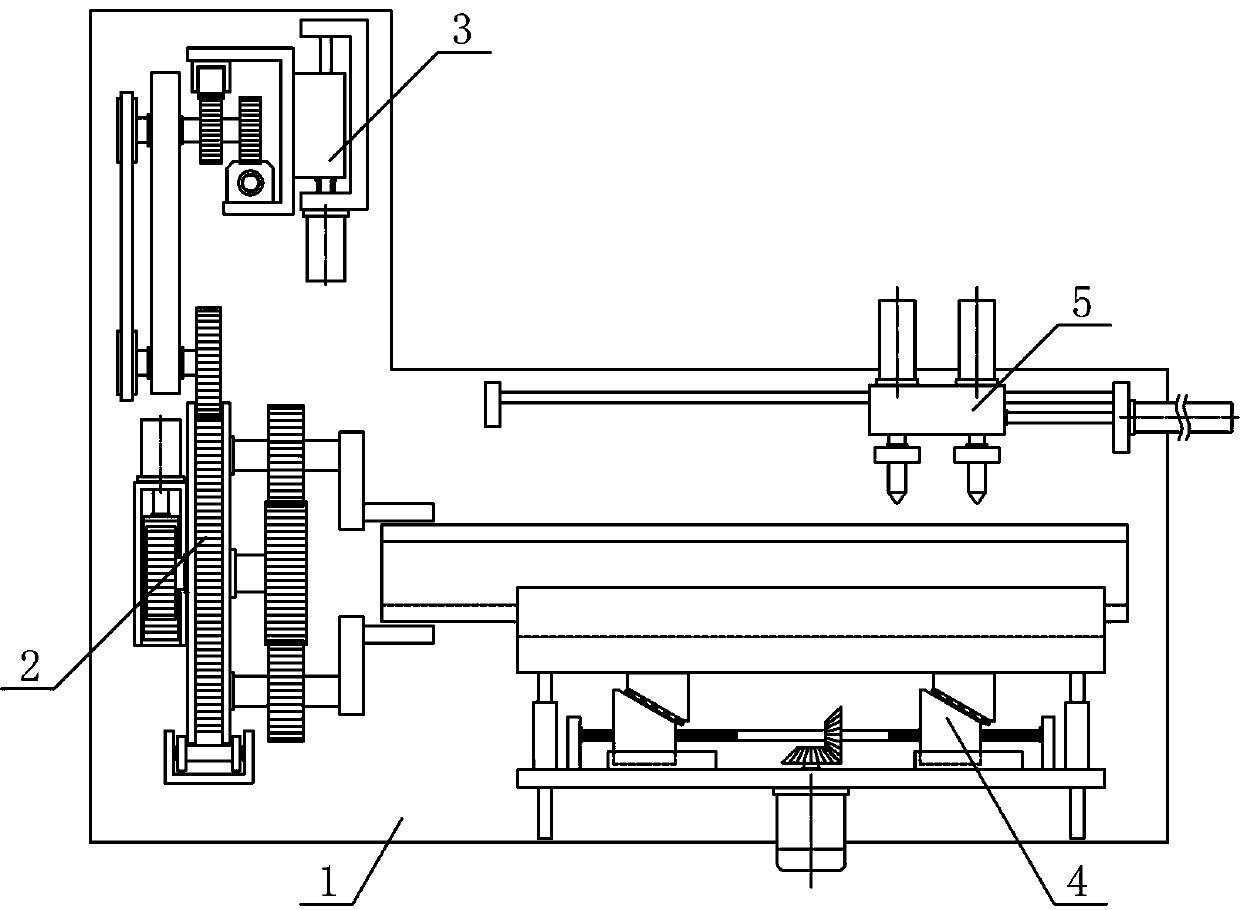

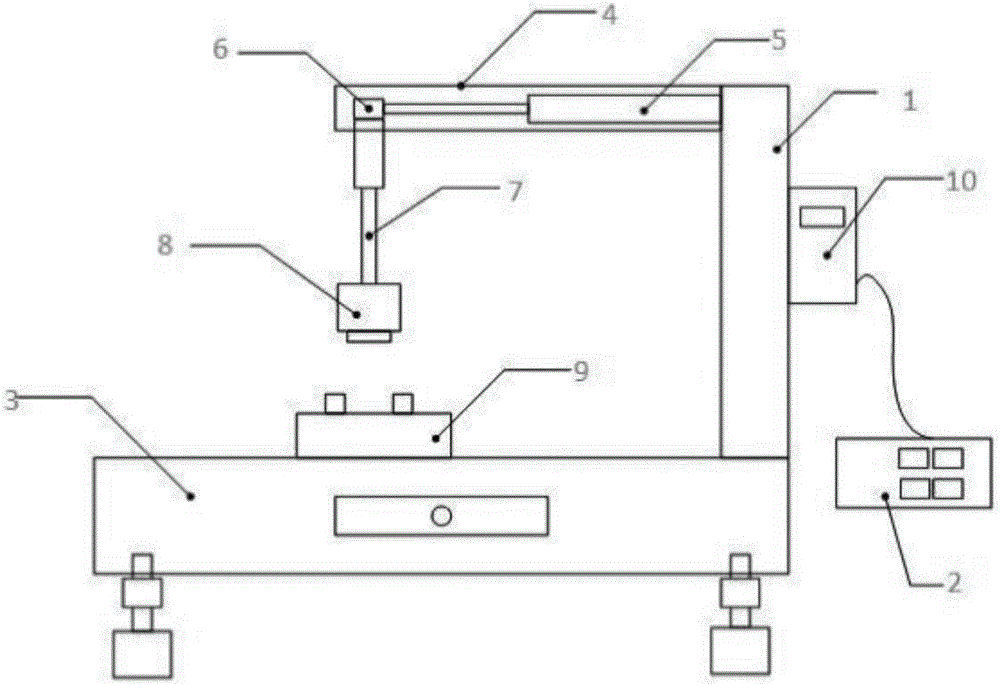

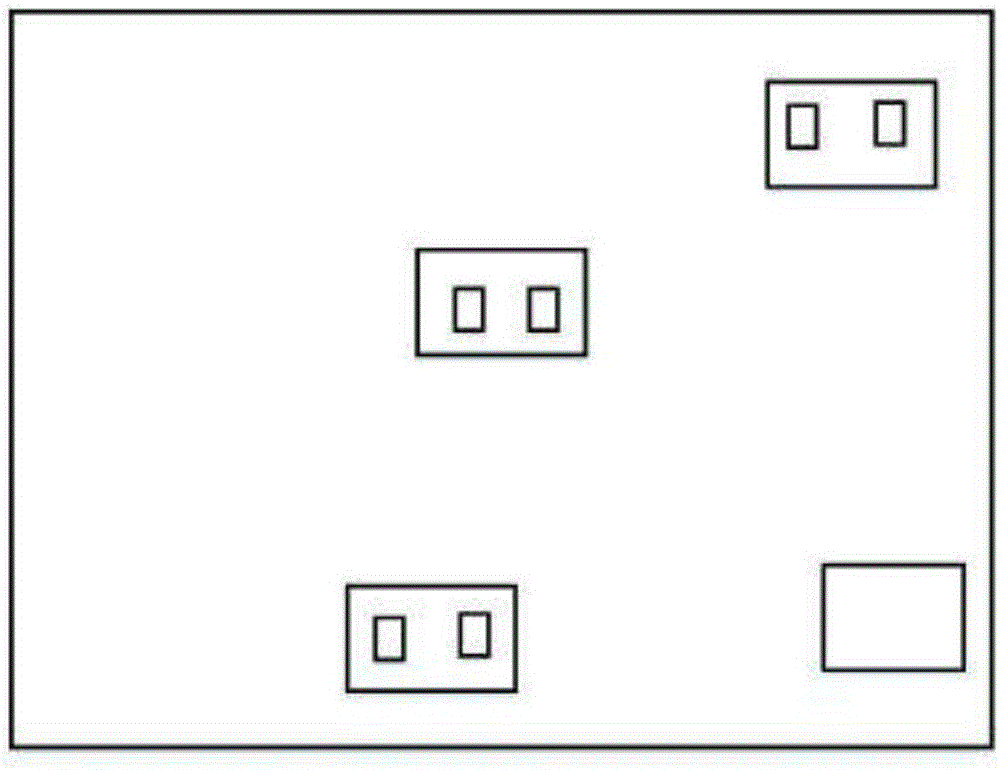

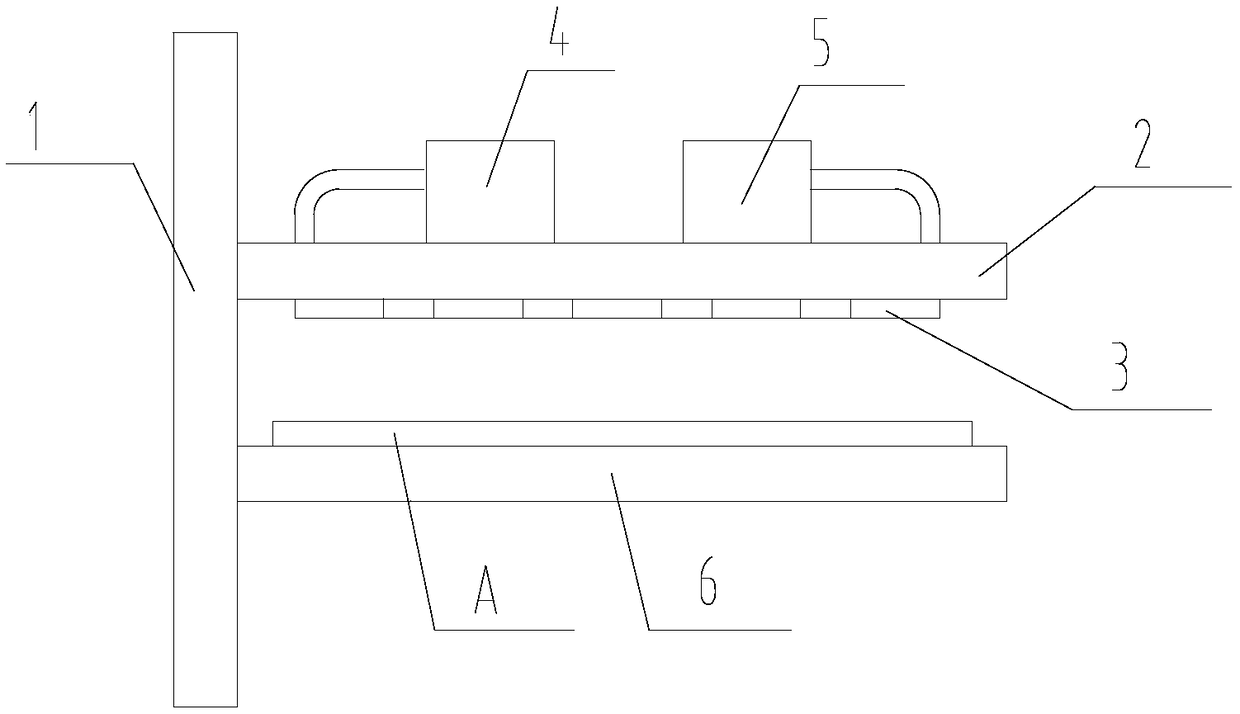

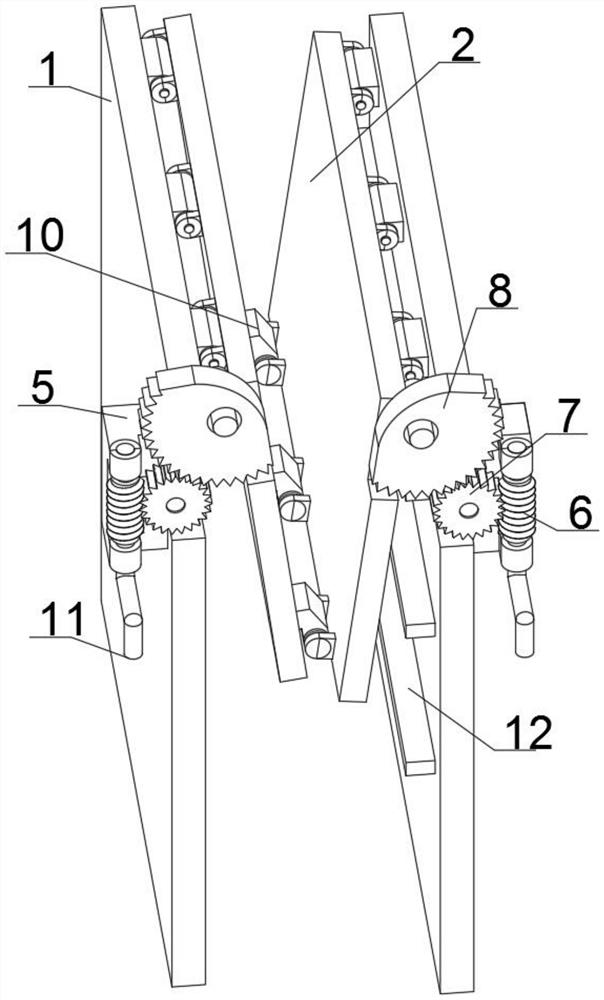

Platform device for multi-station machining

InactiveCN106670827AAchieve processing efficiencyEasy to transformLarge fixed membersRemote controlEngineering

The invention belongs to the field of machining, and particularly relates to a platform device for multi-station machining. The platform device comprises a stand column, a remote-control unit and a rectangular supporting table, the tail end of the stand column is welded to the supporting table, machining tables are arranged at the upper portion of the supporting table, the remote-control unit is in electric input connection with a controller, a sliding rail is arranged at the top end of the stand column through a supporting part, and the supporting part can rotate in the horizontal direction with a rotating shaft in the perpendicular direction as a center; the controller is in electric input connection with the supporting part, a first stretchable rod is installed inside the sliding rail, a sliding block is installed at the top end of the first stretchable rod, a second stretchable rod is installed at the bottom of the sliding block, and a machining device is installed at the lower end of the second stretchable rod; and the controller is in electric input connection with the first stretchable rod and the second stretchable rod. The platform device has the beneficial effects that the machining efficiency can be achieved to the maximum degree; old factory transformation is facilitated, old equipment transformation is facilitated, the efficiency is further improved, and the production cost is reduced.

Owner:张宁峰

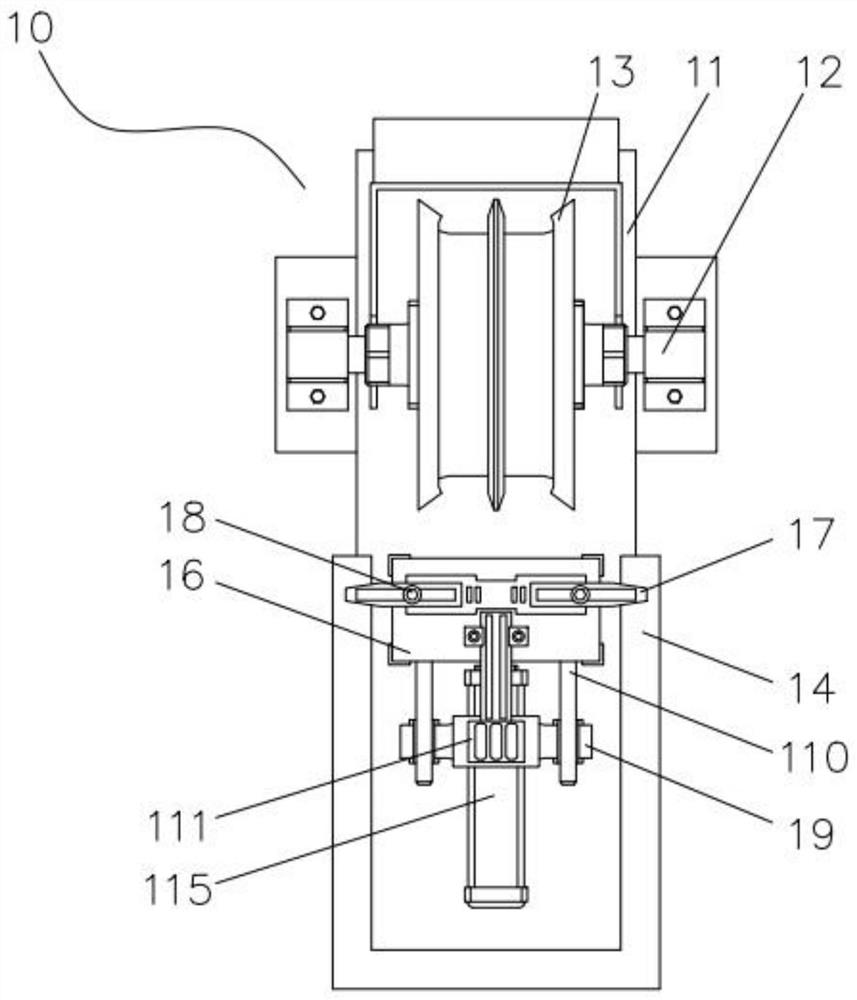

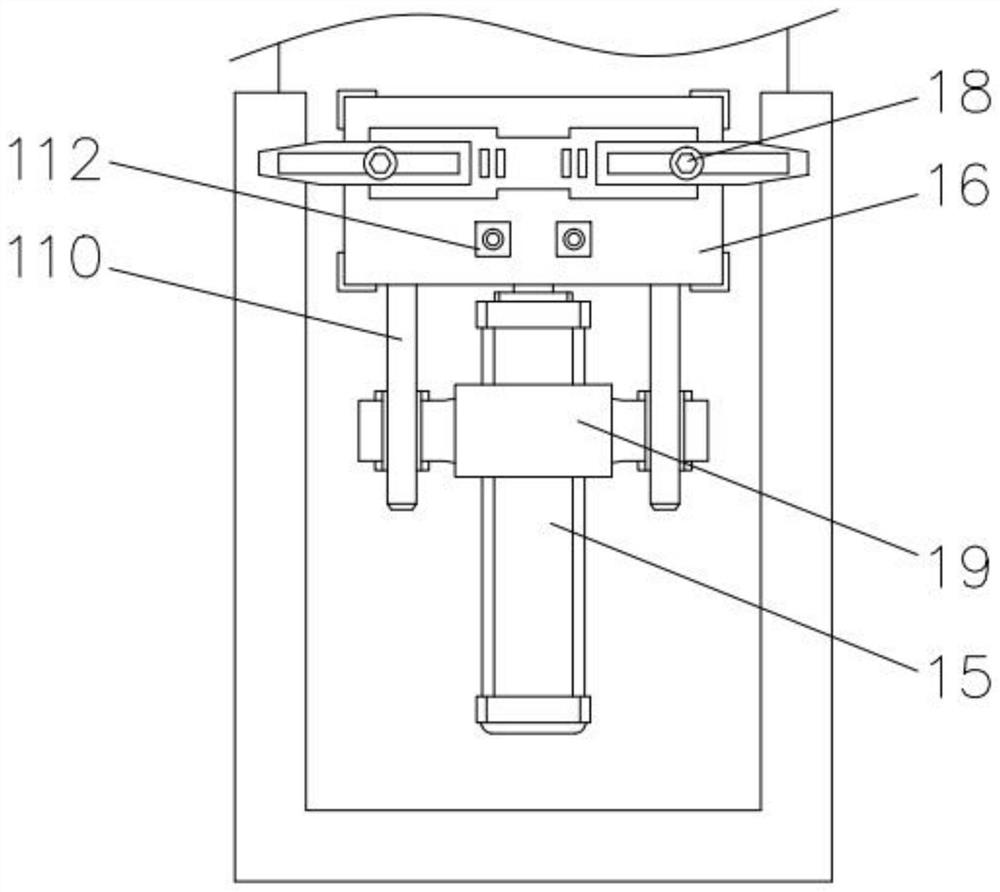

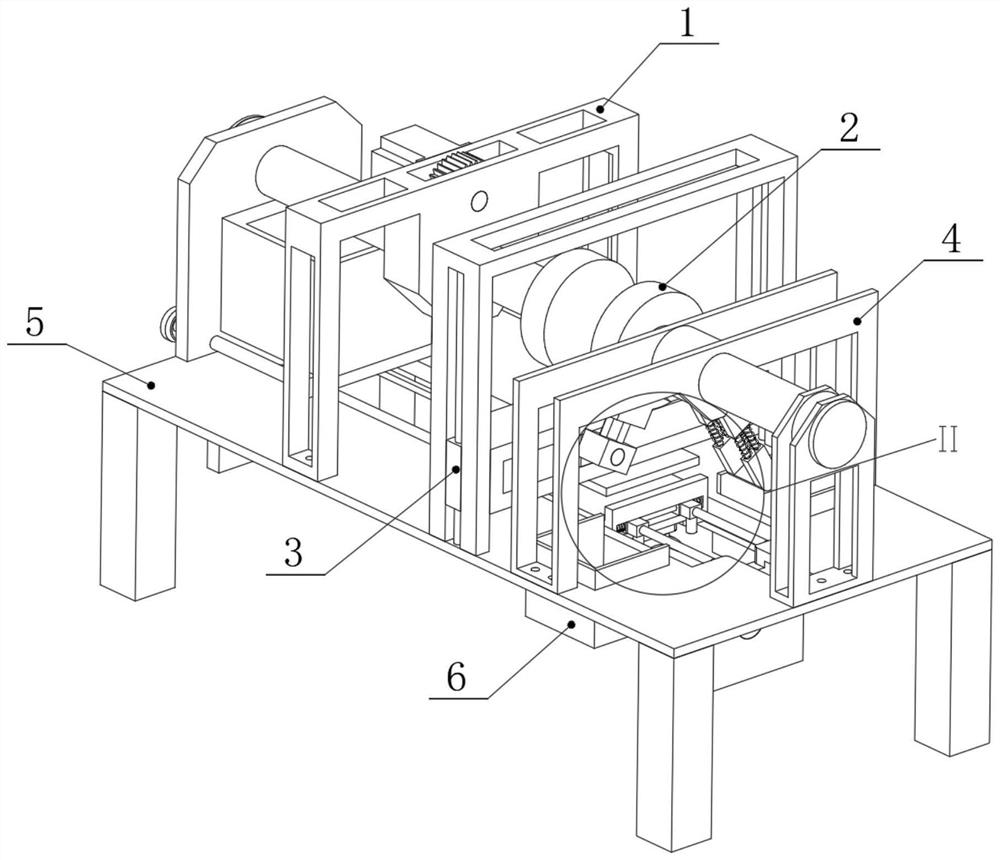

Automatic brake pad production line and brake pad production technology

ActiveCN112901691AAchieve processing efficiencyReduce labor costsLiquid spraying plantsLiquid surface applicatorsSand blastingConveyor belt

The invention provides an automatic brake pad production line. The automatic brake pad production line is used for machining brake pads and sequentially comprises a grinding machining device, a sand blasting device and an electrostatic spraying device; the grinding machining device and the sand blasting device are connected through a conveying belt, and the sand blasting device and the electrostatic spraying device are connected through a conveying belt; the grinding machining device is used for carrying out center cutting and chamfering operation on the working surfaces of the brake pads; the sand blasting device is used for carrying out sand blasting operation on the non-working surfaces of the brake pads; the electrostatic spraying device performs electrostatic spraying operation on the non-working surfaces of the brake pads. The invention further provides a brake pad production technology matched with the automatic production line. The grinding machining device, the sand blasting device and the electrostatic spraying device are connected through the conveying belts, automatic machining can be carried out subsequently only after feeding is carried out on the grinding machining device, the machining efficiency is improved, and the labor cost and the labor intensity are reduced.

Owner:厦门永煌兴刹车蹄片制造有限公司

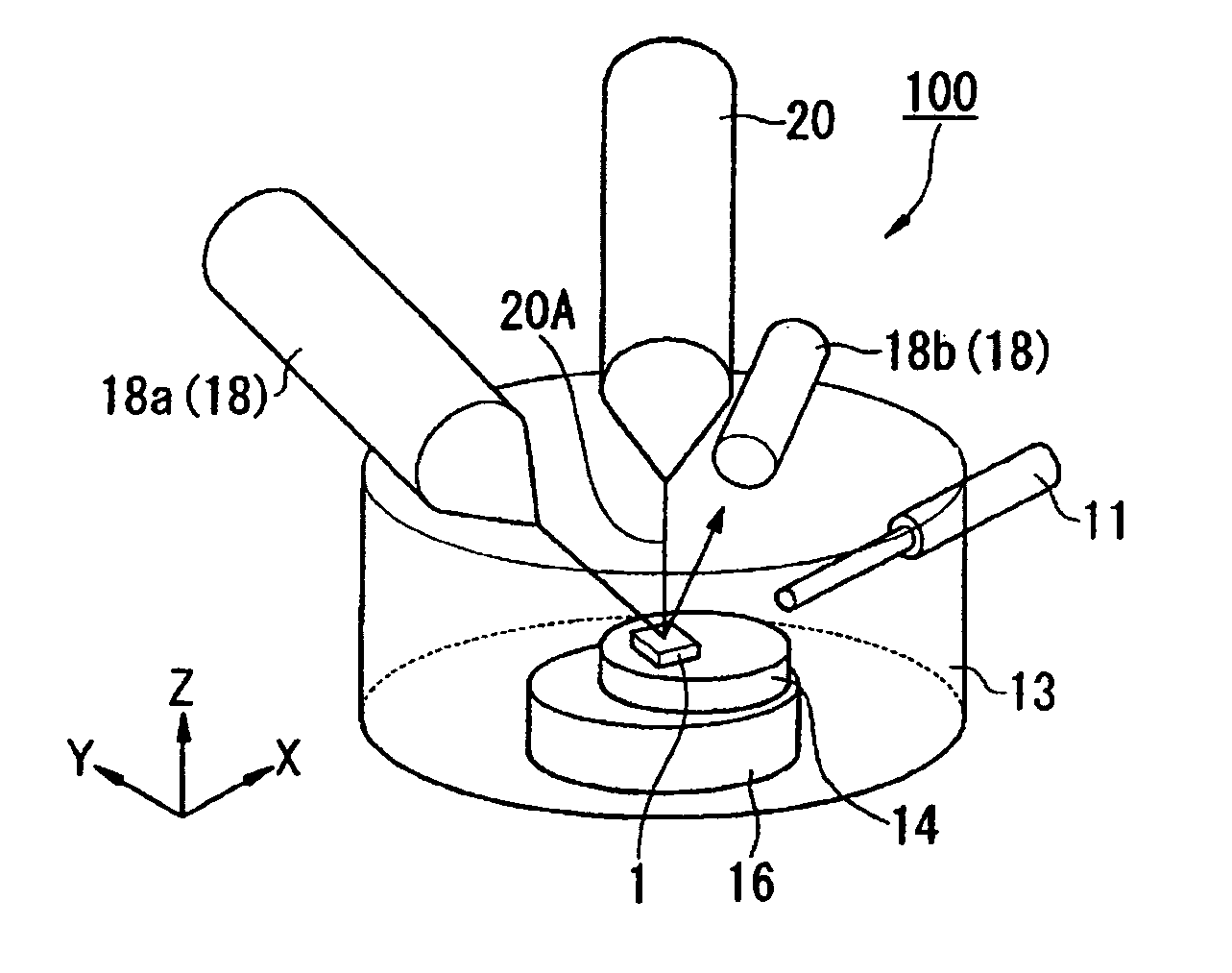

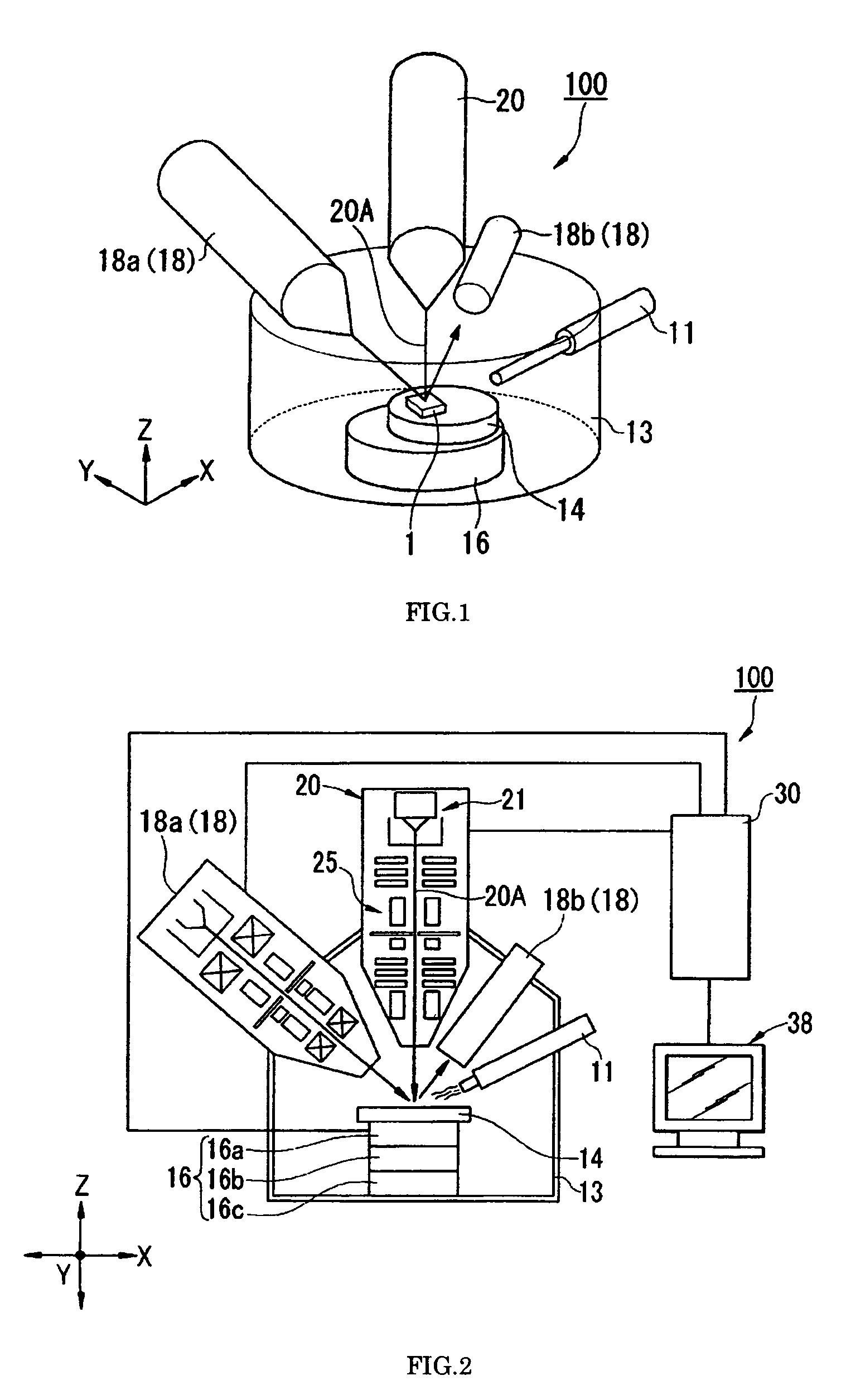

Section processing method and its apparatus

ActiveUS8306264B2Achieve processing efficiencySemiconductor/solid-state device testing/measurementElectric discharge tubesLight beamIon beam

A section processing apparatus has a mark forming control portion that transmits control information for forming marks on a surface of a sample. Each of the marks has at least two portions intersecting at a converging portion located at a previously determined position of an observation target section of the sample or in the vicinity of the previously determined position. A first focused ion beam apparatus emits a first focused beam for forming each of the marks on the surface of the sample based on the control information transmitted by the mark forming control portion and for processing a section of the sample. The section of the sample is processed by scanning the first focused beam in parallel with the at least two portions of the marks in the direction of the converging portion, while the section of the sample and positions of the marks are observed by a second focused ion beam apparatus, and to finish processing of the section of the sample when the first focused beam reaches the converging portion or a vicinity thereof.

Owner:HITACHI HIGH TECH SCI CORP

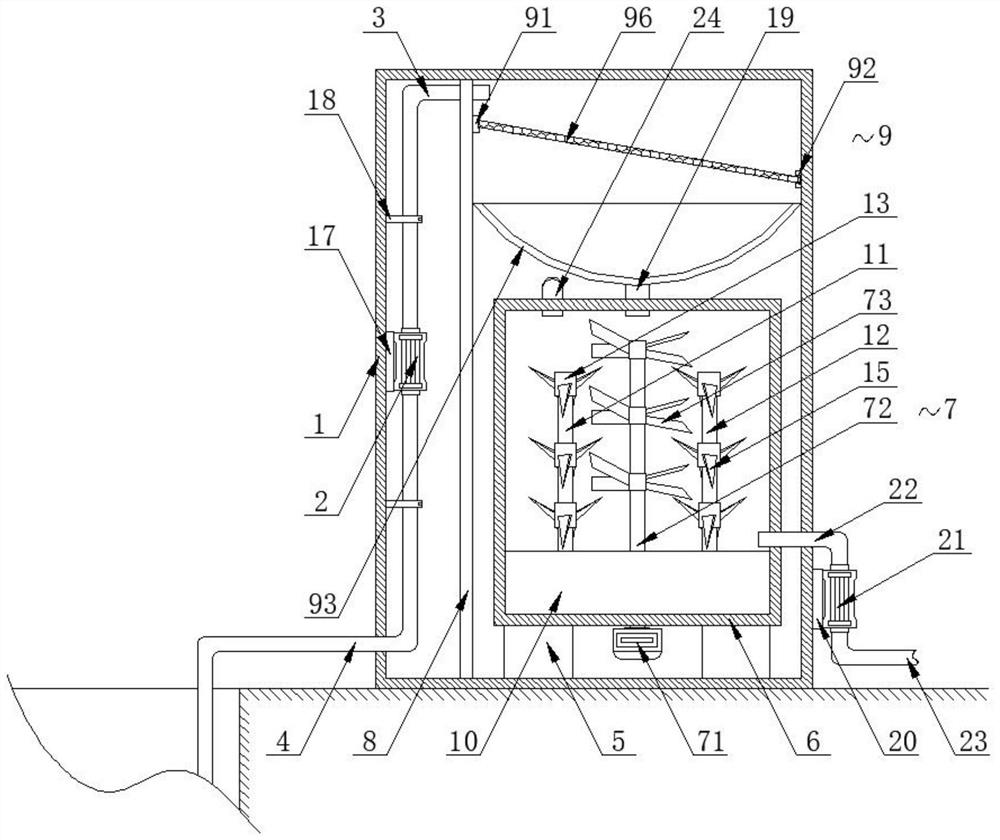

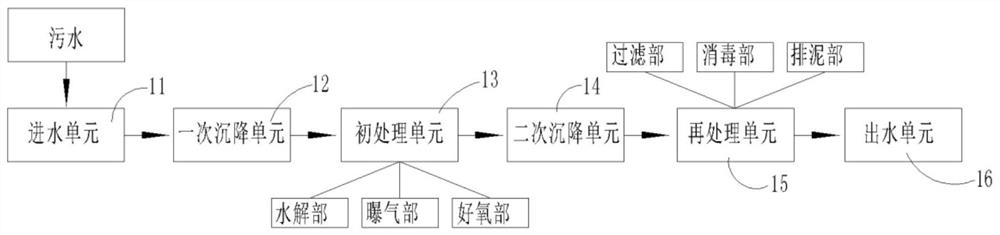

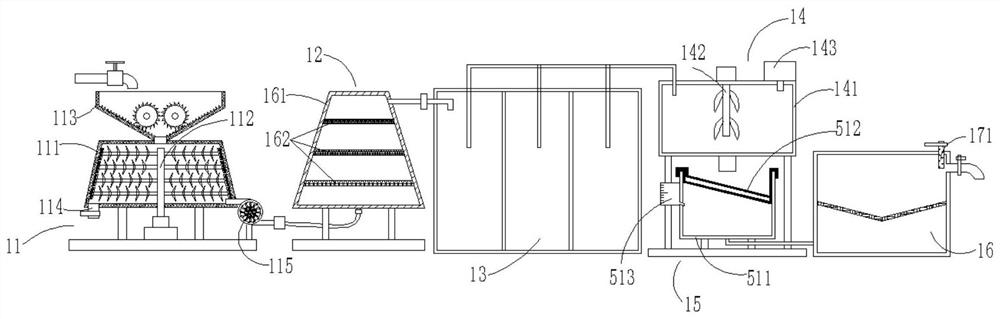

Environment-friendly sewage treatment equipment

InactiveCN111573903AEasy to reuseEasy to handleSpecific water treatment objectivesTreatment involving filtrationSewageSewage treatment

Provided in the invention is environment-friendly sewage treatment equipment comprising a shell, an energy utilization assembly, a first filter plate, a slag removal assembly, a waste slag recovery assembly and a stirring assembly. The upper end of the shell is provided with a water inlet pipe and a water outlet pipe is arranged at the lower end of the shell; the energy utilization assembly is arranged in the shell. The slag removal assembly, the first filter plate and the stirring assembly are sequentially arranged below the energy utilization assembly; and the waste slag recovery assembly matching the first filter plate is arranged outside the shell. The energy utilization assembly is arranged to provide energy for the slag removal assembly and the waste slag recovery assembly, the production cost is lowered, and the energy consumption is reduced; the first filter plate, the slag removal assembly and the waste slag recovery assembly are matched to recover industrial filter residues,so that on the one hand, resources are conveniently reutilized, on the other hand, the sewage treatment effect is enhanced, and the environment is protected; the stirring assembly is arranged, simultaneous turbulence in a vertical direction and a horizontal direction is achieved, the action effect of purification and disinfection agents is improved, and the sewage treatment efficiency and treatment effect are achieved.

Owner:JINAN ANJIER IND CO LTD

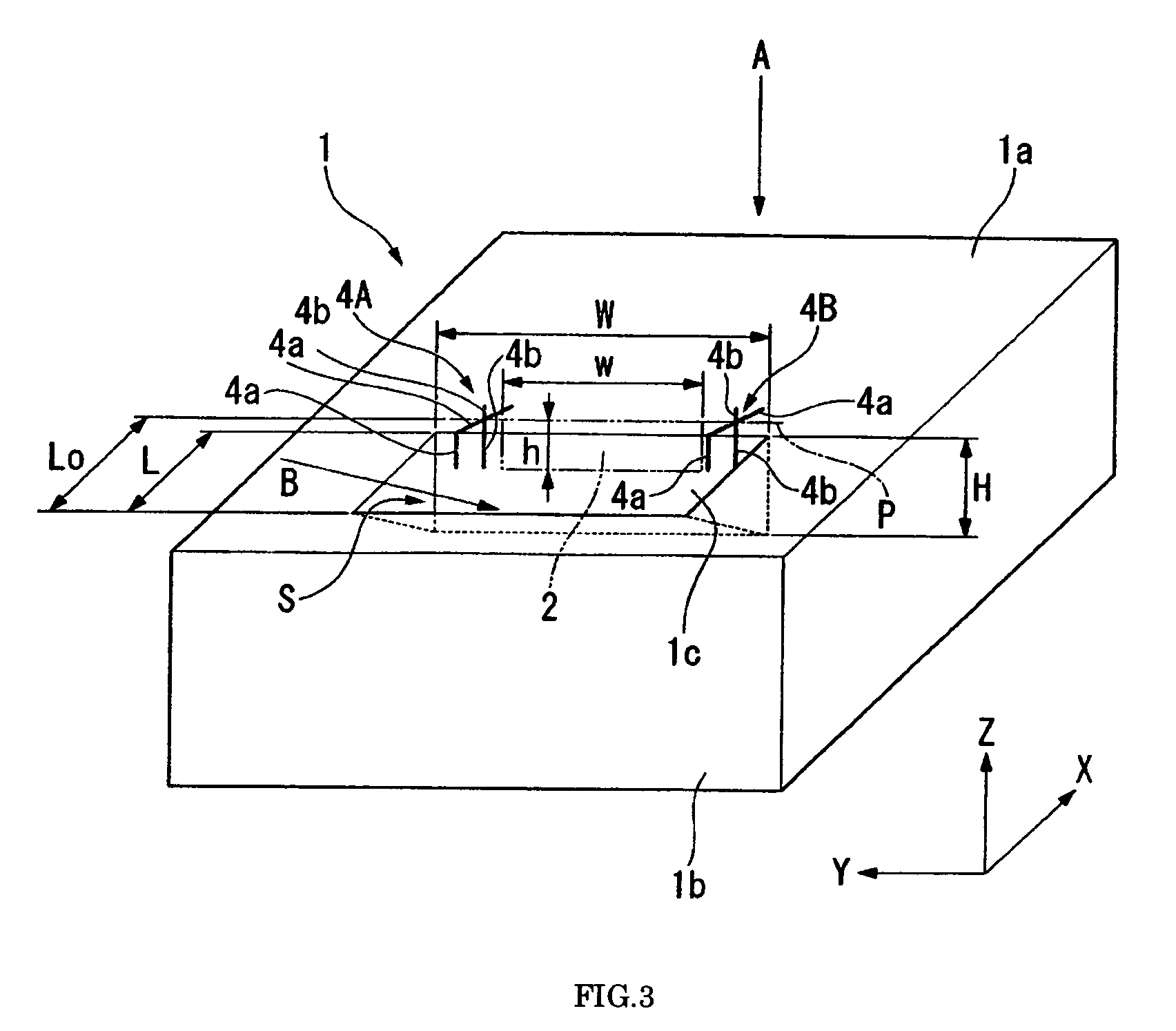

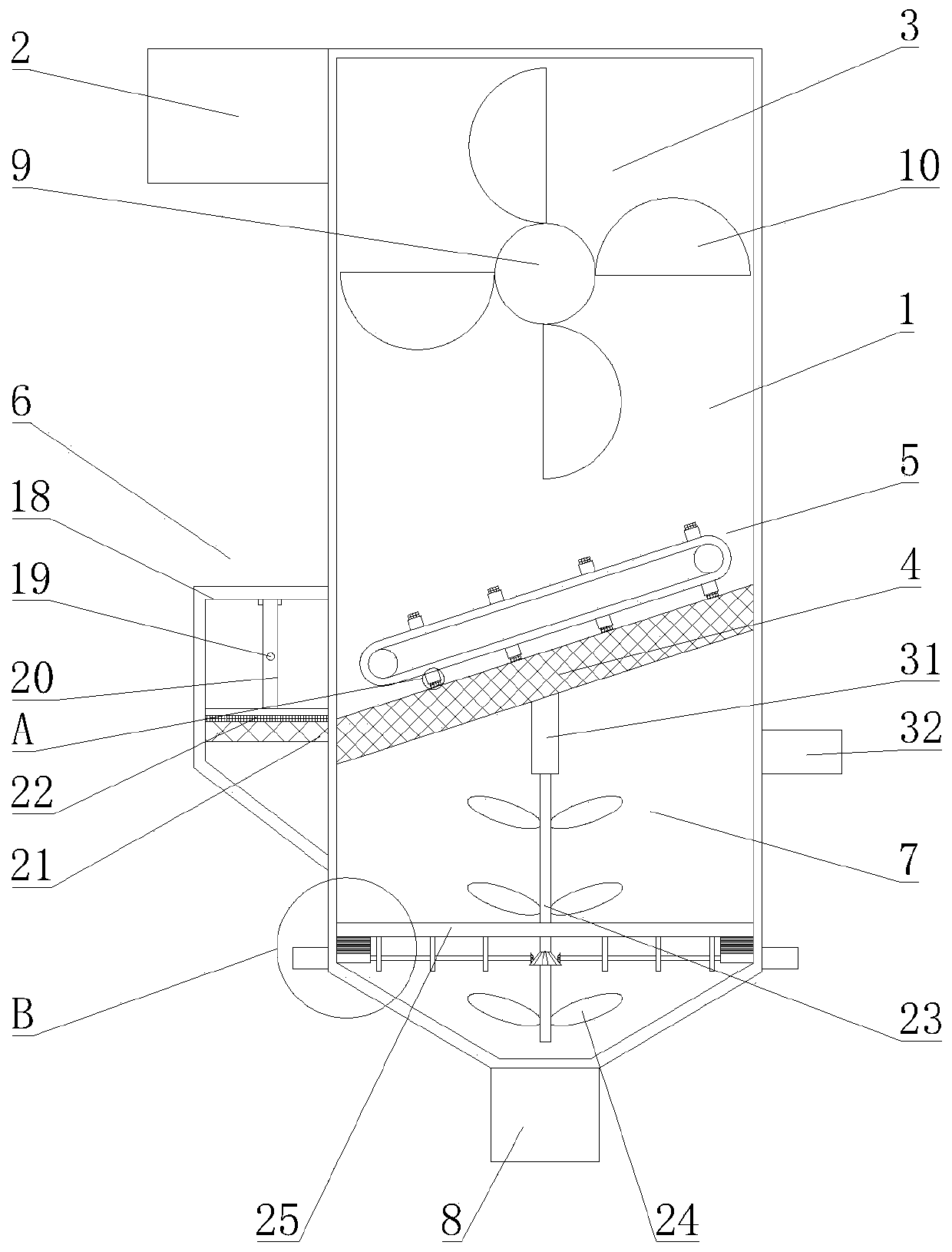

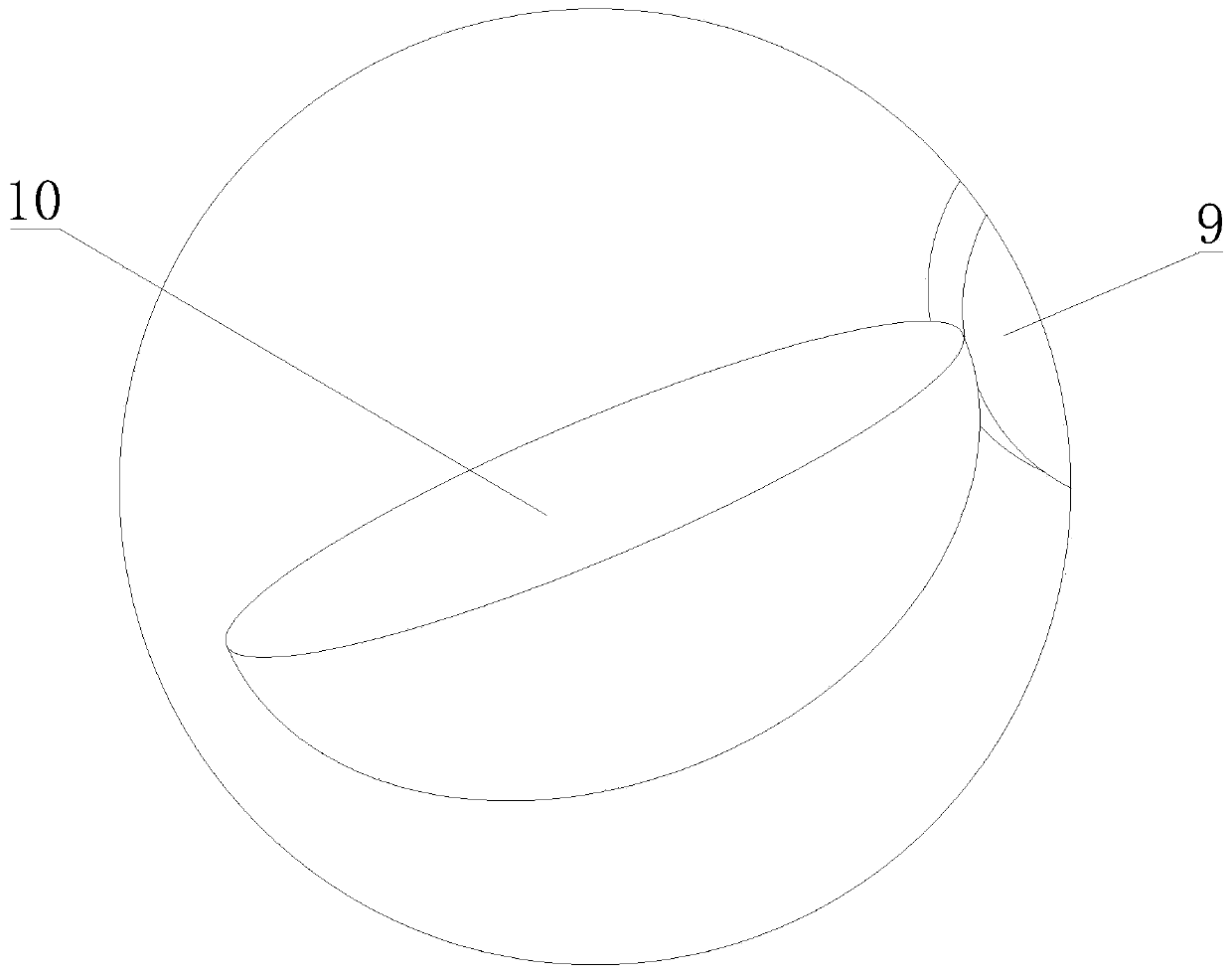

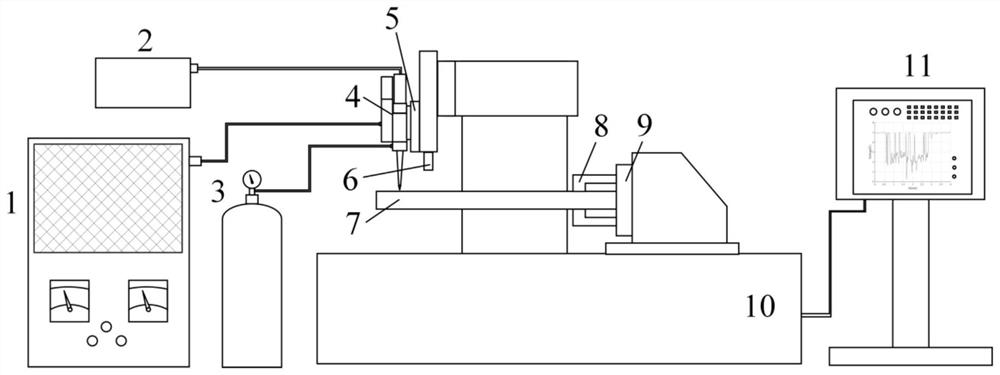

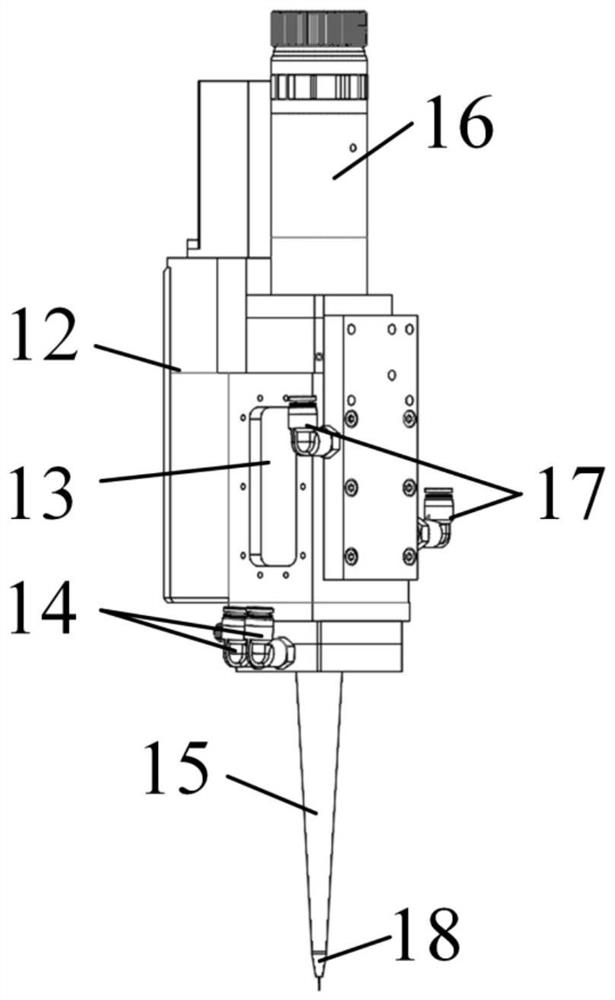

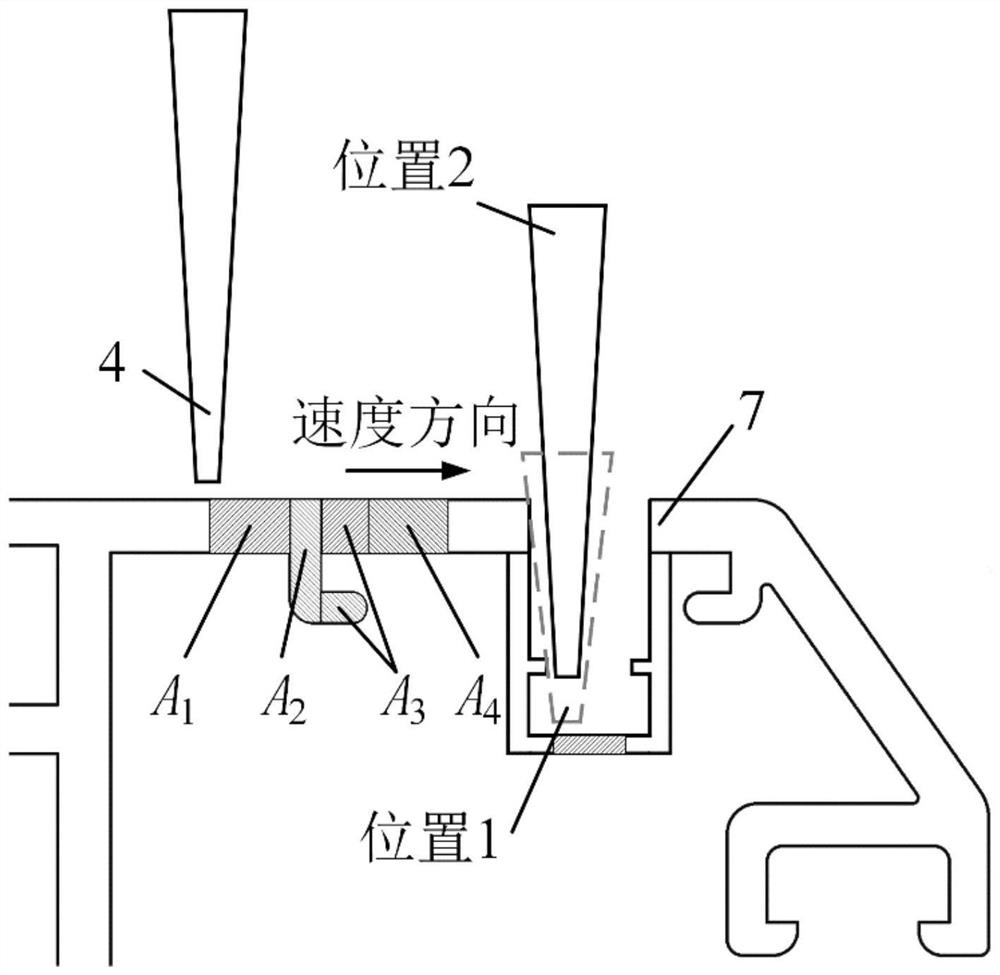

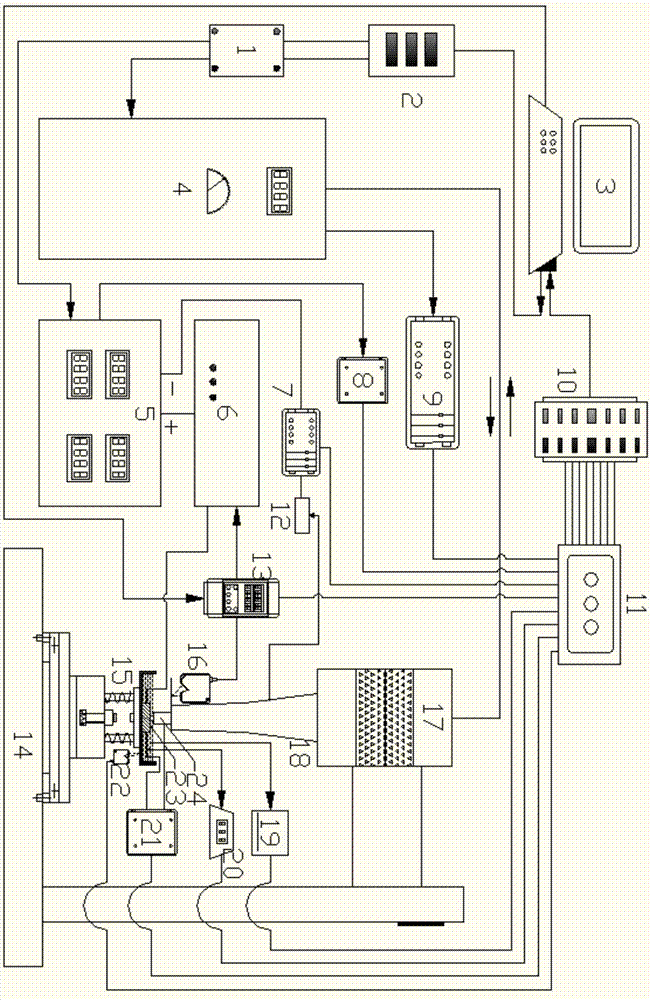

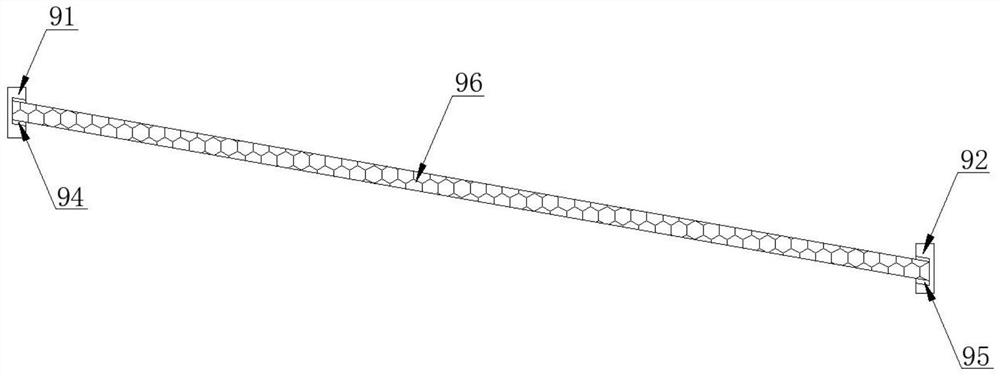

Laser cutting device and cutting method for profiled bar

ActiveCN113084365AAchieve processing efficiencyAvoid drossLaser beam welding apparatusErbium lasersLaser cutting

The invention discloses a laser cutting device for a profiled bar. The laser cutting device for the profiled bar comprises a cooling-water machine (1), a laser (2), an air source (3), a laser cutting head (4), a laser cutting head fast forward shaft (5), a scanning lens (6), a profiled bar clamp (8), an ultrasonic auxiliary generating device (9), a machine tool body (10) and a control panel (11). The invention further discloses a laser cutting method for the profiled bar. The laser cutting method for the profiled bar aims at the characteristics of complex change of the section shape and the wall thickness of the profiled bar and the machining requirement for a large number of deep groove type holes, the laser cutting speed is matched on the basis of full-power laser energy output according to the change of the thickness and the shape of the section contour, and therefore the machining efficiency is maximized. Meanwhile, an optical module in the laser cutting head of the device adopts a long-focus focus lens, and is matched with a long taper sleeve, so that active anti-interference machining of the deep groove type holes is realized.

Owner:HUNAN UNIV

A real-time optimization control system and control method of ultrasonic composite electrical machining technology

InactiveCN104722866BHigh productivity requirementsStable processing parametersMechanical vibrations separationElectric circuitsControl signalState parameter

Owner:YANGZHOU UNIV

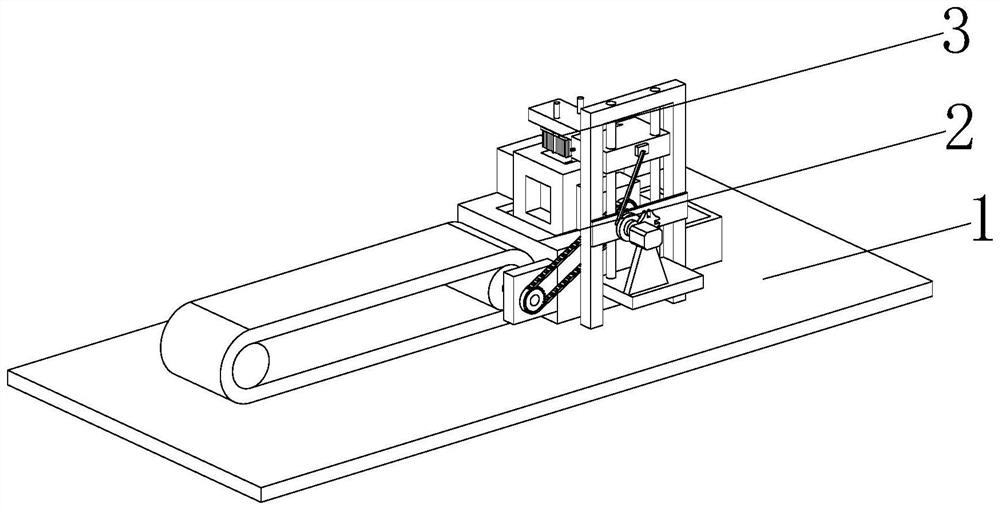

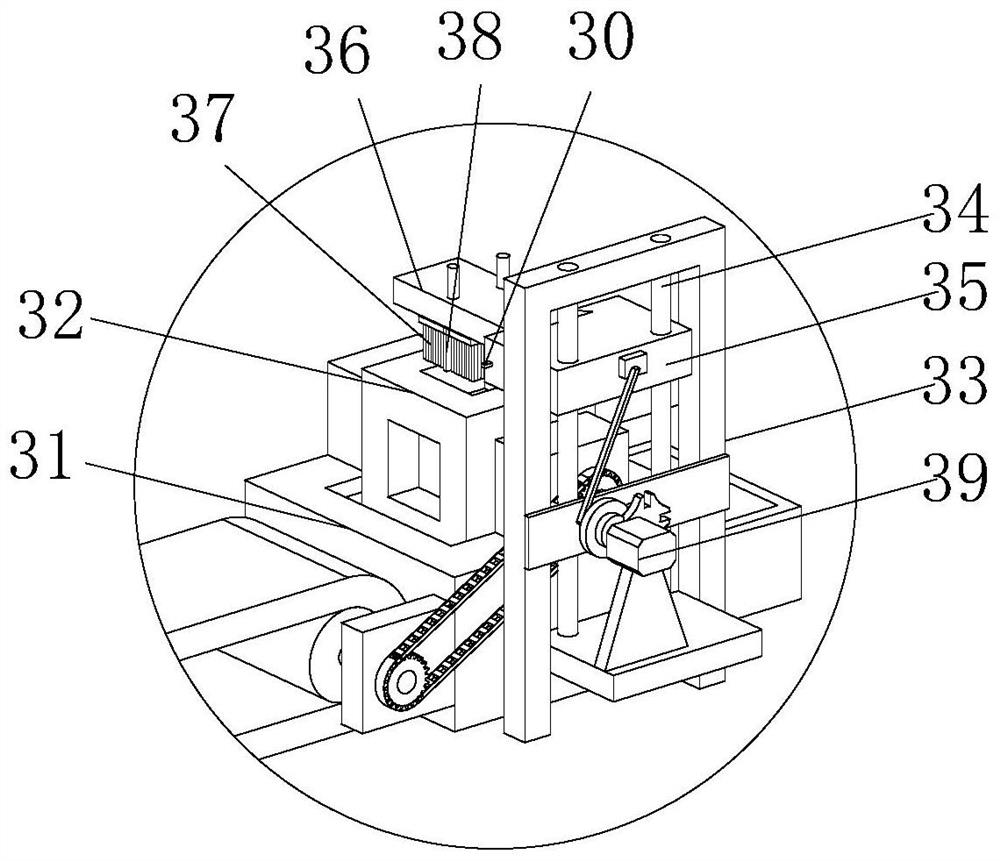

Preparation process of porous catalyst

InactiveCN112916052AAchieve processing efficiencyPrevent take outCatalyst activation/preparationPorous catalystPtru catalyst

The invention provides a porous catalyst preparation process, and relates to the field of porous catalysts. The porous catalyst preparation process comprises a bottom plate, a filling device and a material ramming device.The filling device is fixedly installed on the bottom plate, and the material ramming device is arranged at the upper end of the filling device.According to the porous catalyst preparation process, automatic batch production of porous catalysts can be achieved, and the production efficiency can be improved. The cost consumption is reduced. Meanwhile, the situation that products are damaged in the product adding process can be prevented. And secondly, products are cut in the production process, secondary treatment does not need to be independently carried out, and the production speed is further increased.

Owner:杭州凌瑞新材料科技有限公司

Scene processing method, device and equipment, storage medium and product

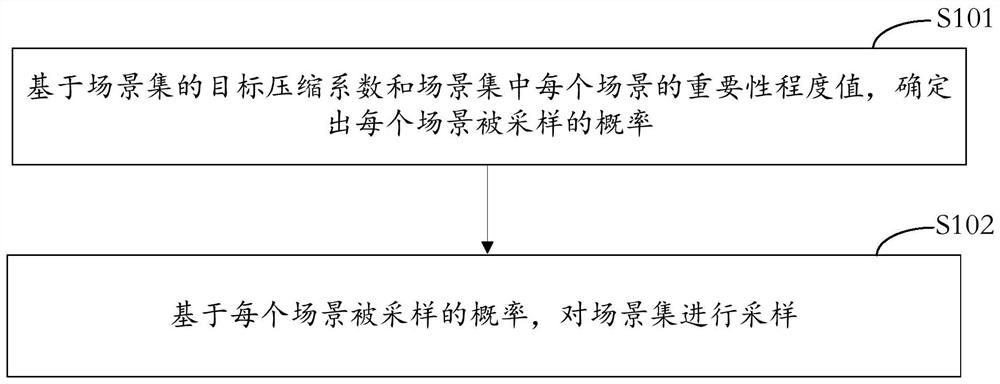

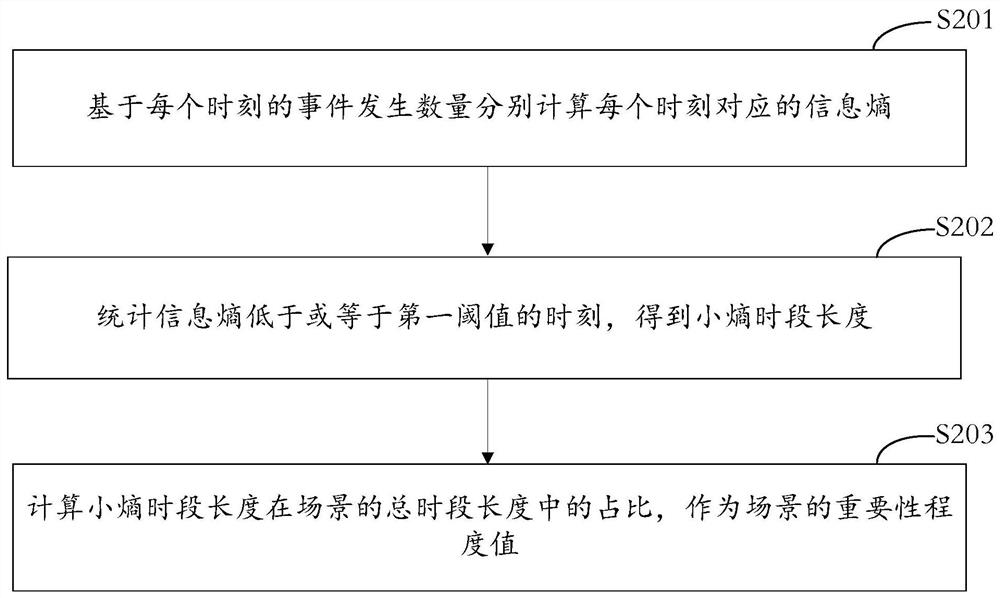

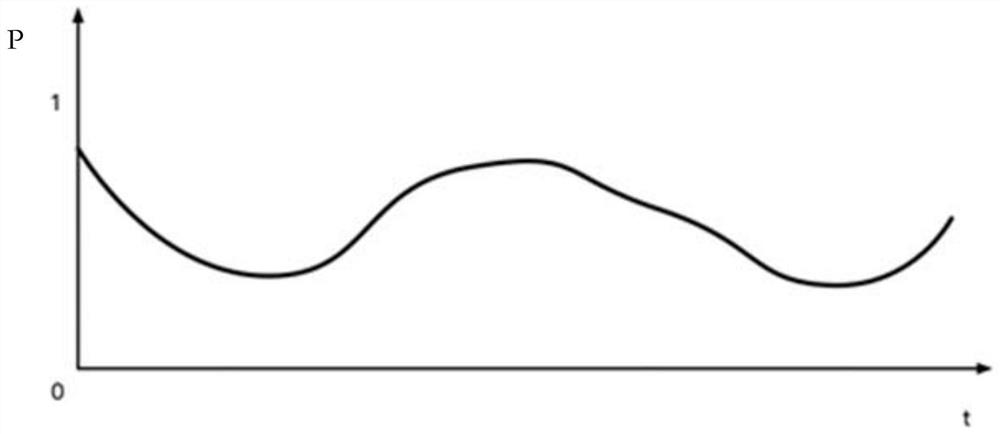

PendingCN112583414AIncrease sampling diversityAchieve processing efficiencyCode conversionComputer visionEngineering

The invention discloses a scene processing method, device and equipment, a storage medium and a product, and relates to the fields of automatic driving, intelligent transportation and the like. According to the specific implementation scheme, the method comprises the steps of determining a probability that each scene is sampled based on a target compression coefficient of a scene set and an importance degree value of each scene in the scene set; and based on the probability that each scene is sampled, sampling the scene set to realize compression of the scene set. By means of the method, the sampling diversity is improved, and the balance among the processing efficiency, the sampling diversity and the comprehensiveness is realized.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

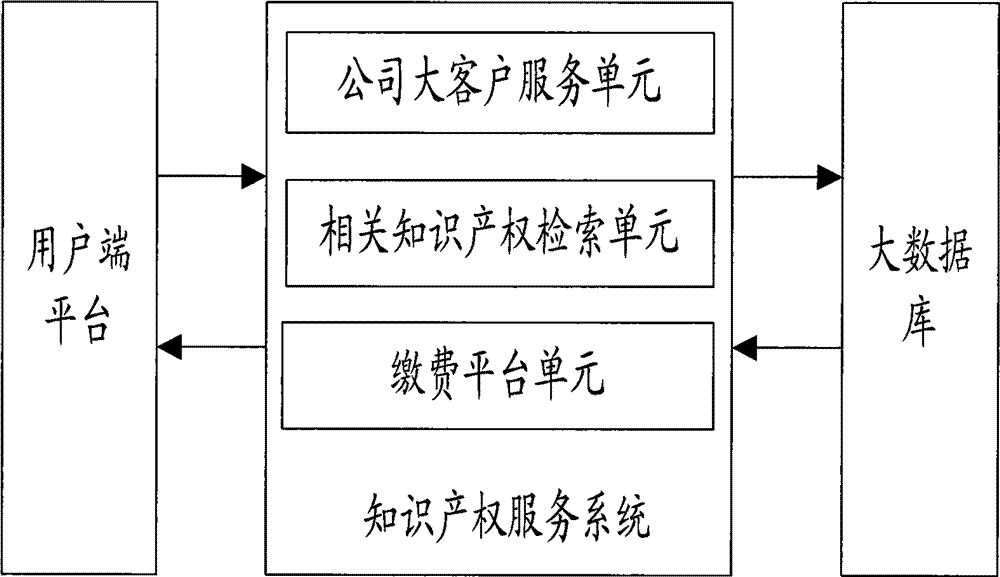

Intellectual property service platform system

InactiveCN104517256AAchieve processing efficiencyImprove intellectual property servicesData processing applicationsSpecial data processing applicationsIntellectual propertyService provision

The invention discloses an intellectual property service platform system, and belongs to the technical field of intellectual properties. The intellectual property service platform system comprises a big database, an intellectual property service system and a client platform, wherein the big database is used for storing big data of the intellectual property; the intellectual property service system is connected with the big database and used for analyzing and processing the data required to be queried by a client; the client platform is connected with the intellectual property service system and used for providing a window to enable a user to input a service required to be queried conveniently. The intellectual property service platform system has the benefits that high data processing efficiency is realized, and an intellectual property service required to be queried by the client is improved.

Owner:WUHU LERUISI INFORMATION CONSULTING

Machine part machining device and machining method in mechanical field

ActiveCN114749572AImprove processing efficiencyEasy to processMetal-working feeding devicesStripping-off devicesMachine partsEngineering

The machine part machining device comprises a guiding device, a transmission device is fixedly installed at the position, close to the front portion, of the upper end face of the guiding device, and the transmission device and the guiding device are connected in a meshed mode through a tooth-shaped belt; a limiting die holder is slidably clamped to the center of the upper end face of the guide device, a feeding device is slidably clamped to the position, close to the bottom, of the inner end face of the guide device, and a discharging device is fixedly arranged at the position, close to the rear portion, of the upper end face of the guide device. By arranging the guiding device and the feeding device, when the mechanical parts are machined, through cooperation of the guiding device and the feeding device, the mechanical parts can be automatically and accurately discharged one by one, meanwhile, feeding, machining and discharging can be automatically integrated, and the follow-up machining efficiency of the mechanical parts is improved to the maximum extent.

Owner:PINGJIANG VOCATIONAL TECHNICAL SCHOOL

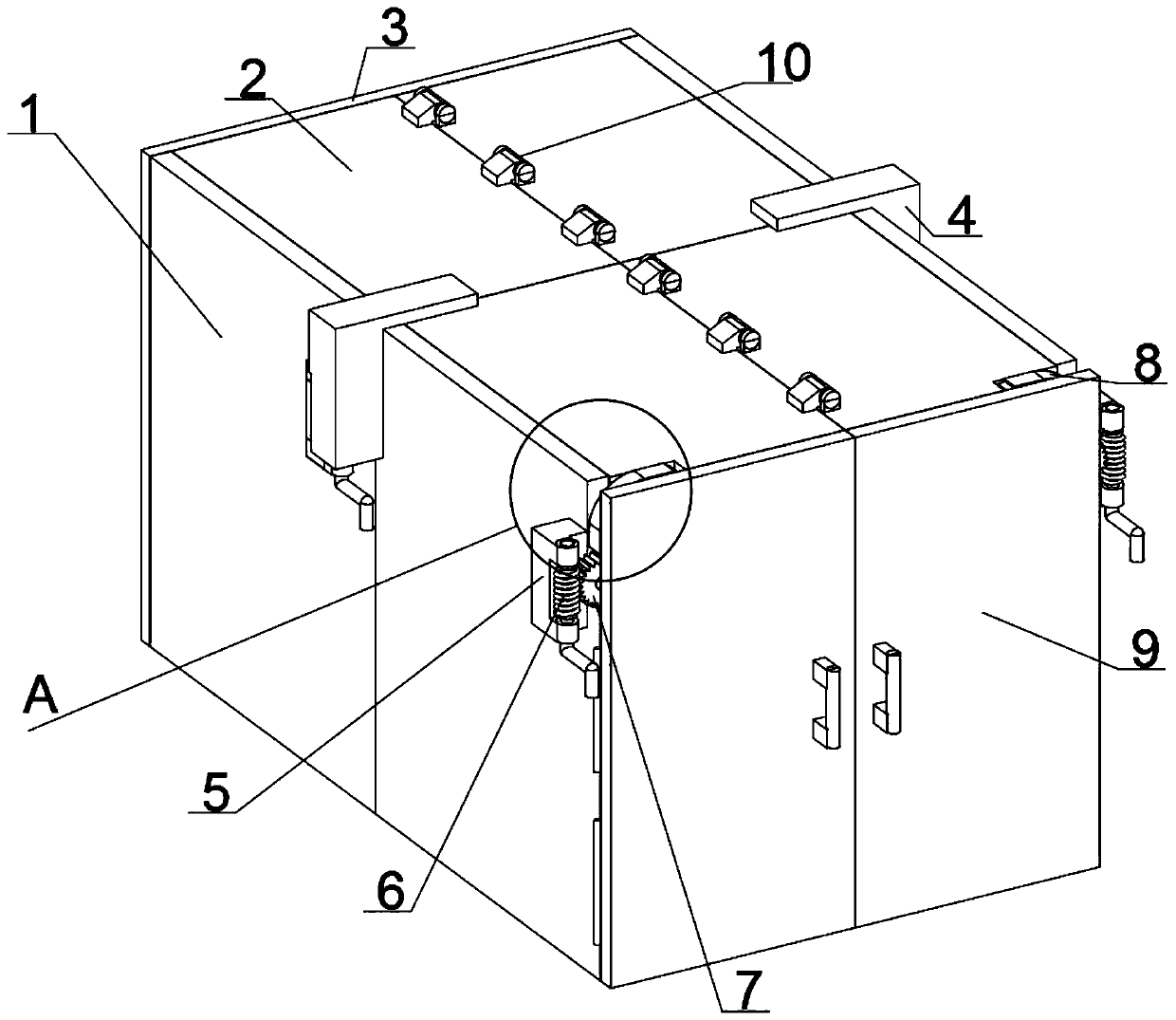

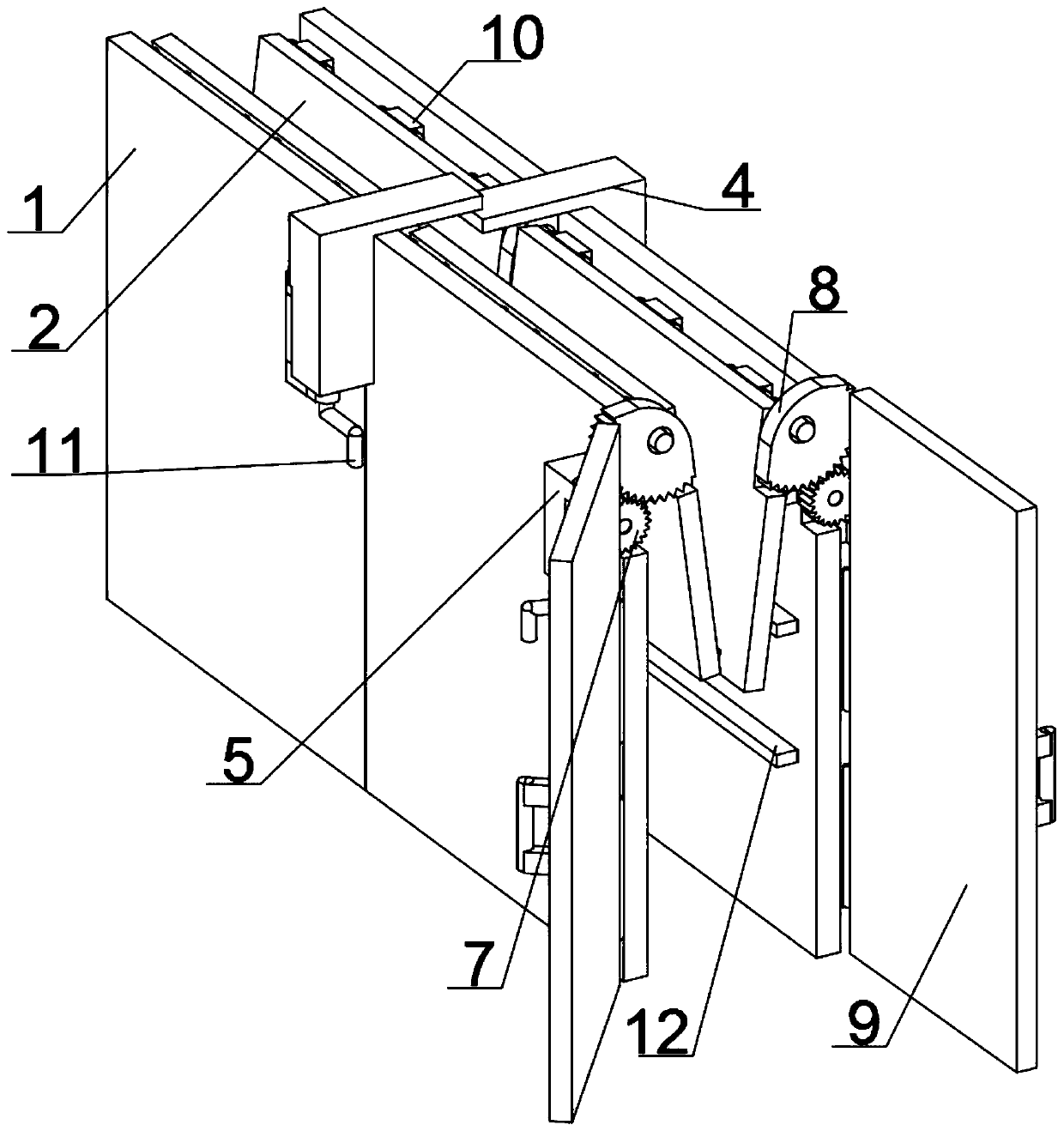

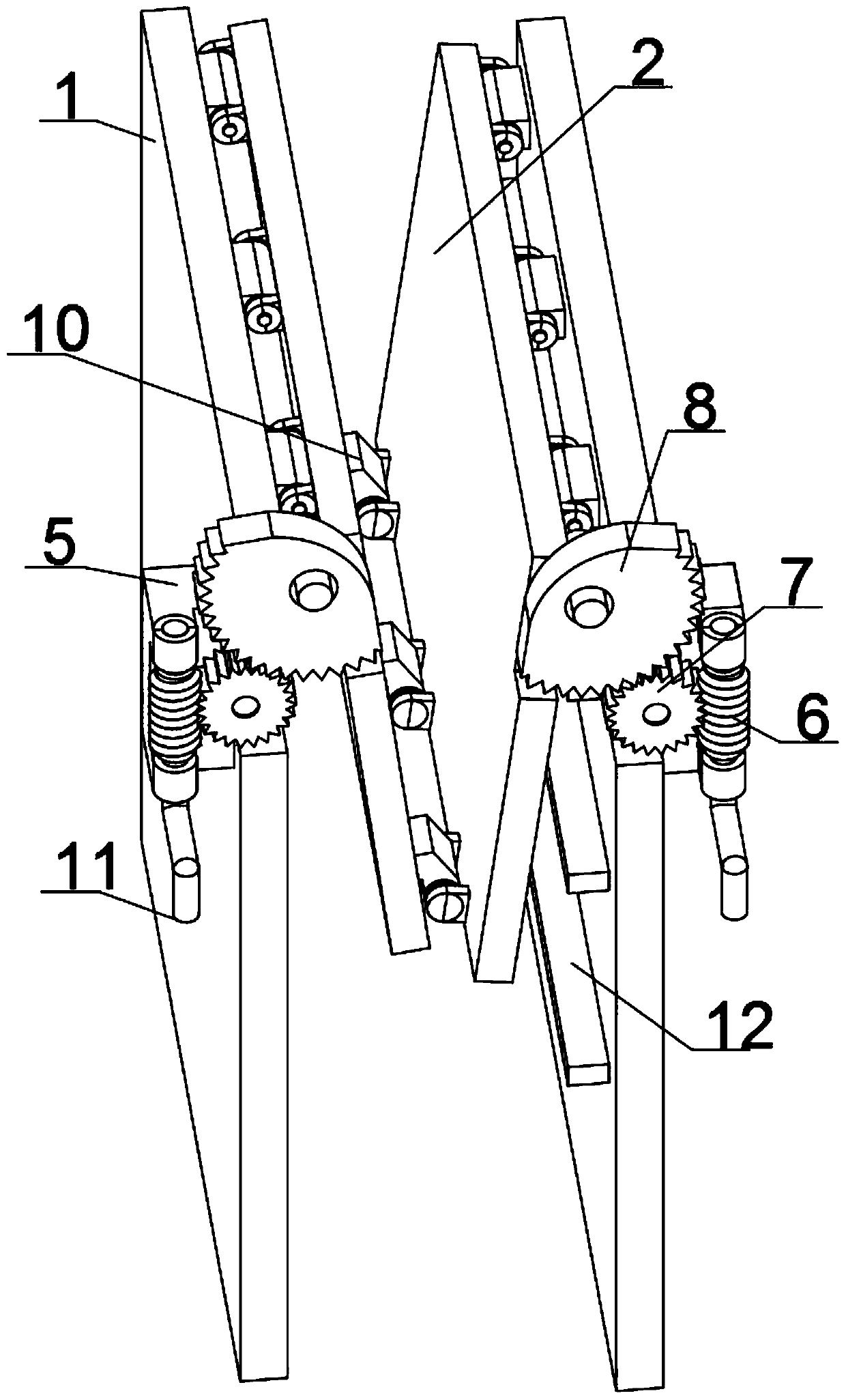

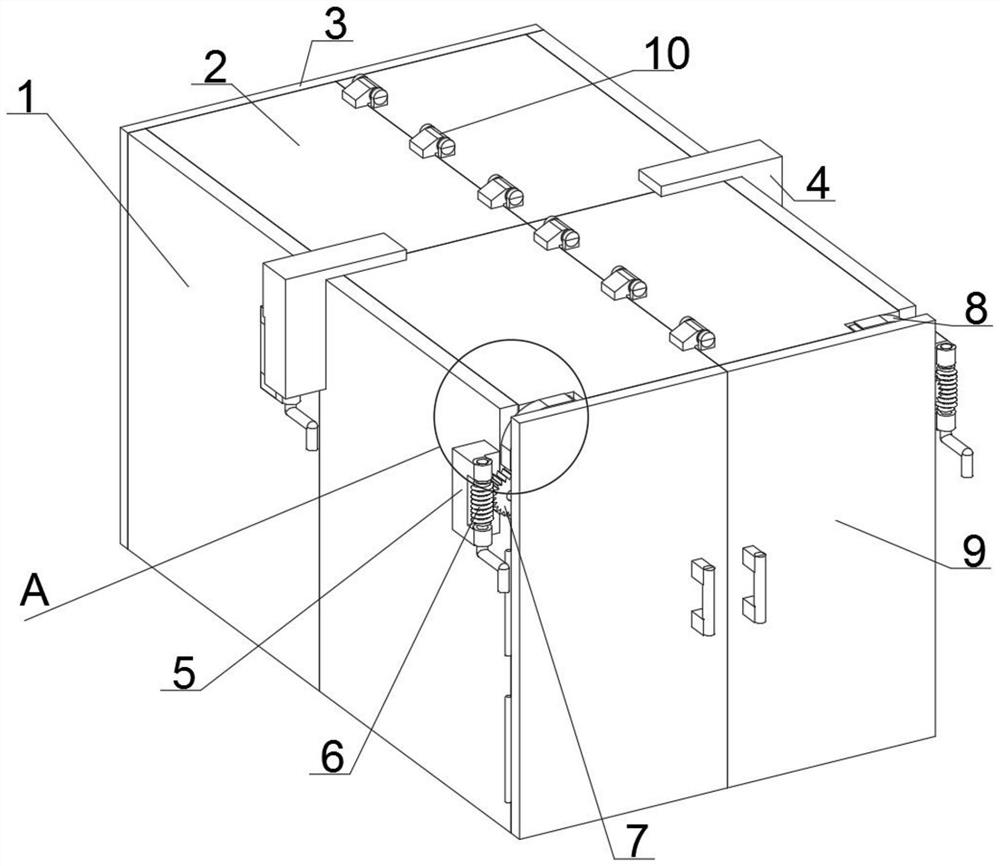

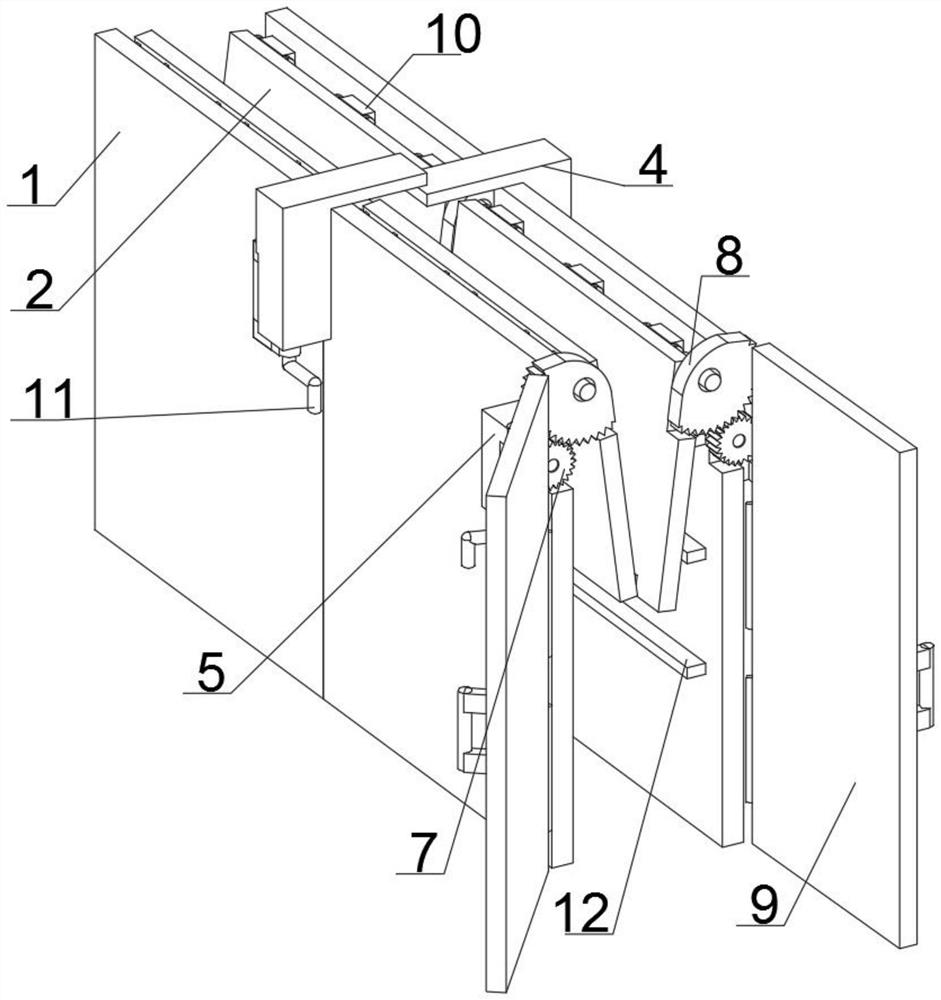

Retractable type tobacco baking room

The invention provides a retractable type tobacco baking room. The baking room includes side plates, top plates, a back plate, baffles, worm frames, worms, worm wheels, rotating wheels, doors, liftingears, handles and a beam; side faces of the doors are hinged to the front ends of the side plates, the back ends of the side plates are connected to the back plate through bolts; the worm frames areprovided with the worms; shafts of the worm wheels are connected to the inner surfaces of the side plates in a welding mode, and the worm wheels are meshed with the worms; two edges of the top platesare arranged on the upper ends of the side plates through the lifting ears; and the beam is connected to the inner sides of the side plates in a welding mode, and the handles are connected to the lower ends of the worms in the welding mode. To sum up, compared with an existing baking room, the retractable type tobacco baking room can be folded, saves spaces and facilitates transportation by installed on a planting site after moved, so that tobacco leaves can be directly processed after picked, and the burden of transportation is reduced, and in addition, a plurality of groups of side plates and top plates can be spliced together to increase the capacity of the baking room to meet processing needs.

Owner:GUIZHOU UNIV

Intelligent management system for intellectual property

InactiveCN107480952AAchieve processing efficiencyIntellectual Property Services for Improving InquiriesOffice automationTrademarkIntellectual property

The invention discloses an intelligent management system for intellectual property, and the system comprises an information retrieval and statistical module, an expense management module, a trademark management module, an agency management module and an authority management module, wherein the information retrieval and statistical module, the expense management module, the trademark management module, the agency management module and the authority management module are connected with each other and communicate with each other. The system provided by the invention achieves the improvement of the retrieval efficiency and processing efficiency of data, and improves the intellectual property services that a user terminal needs to search.

Owner:苏州市智水环境科研技术有限公司

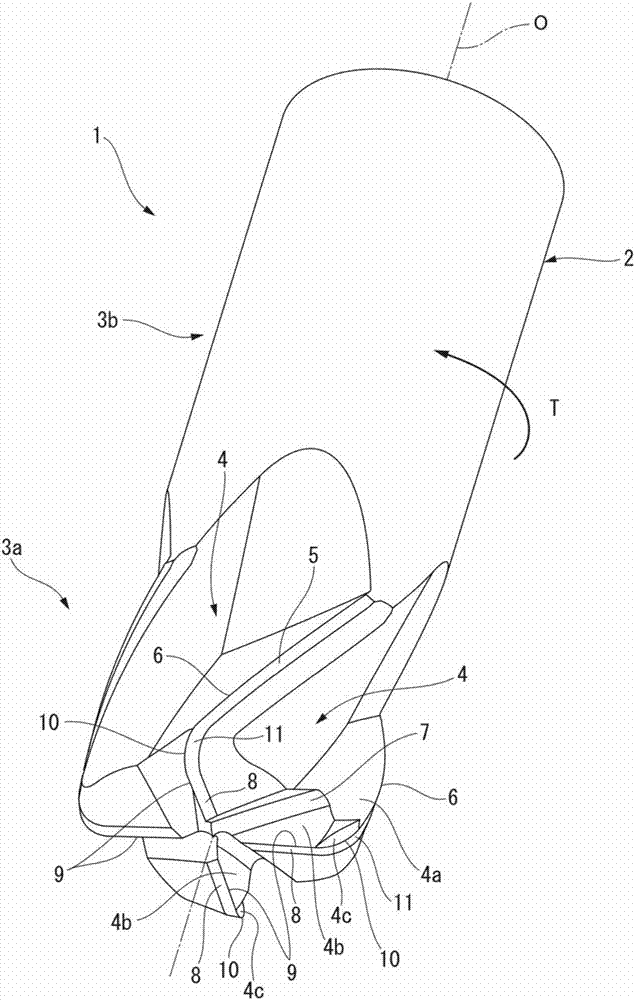

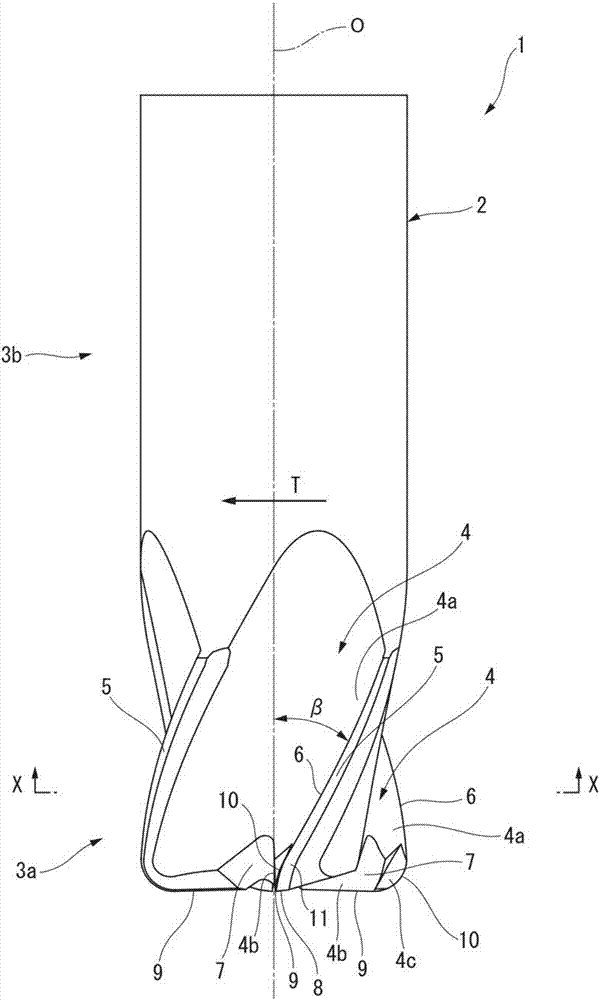

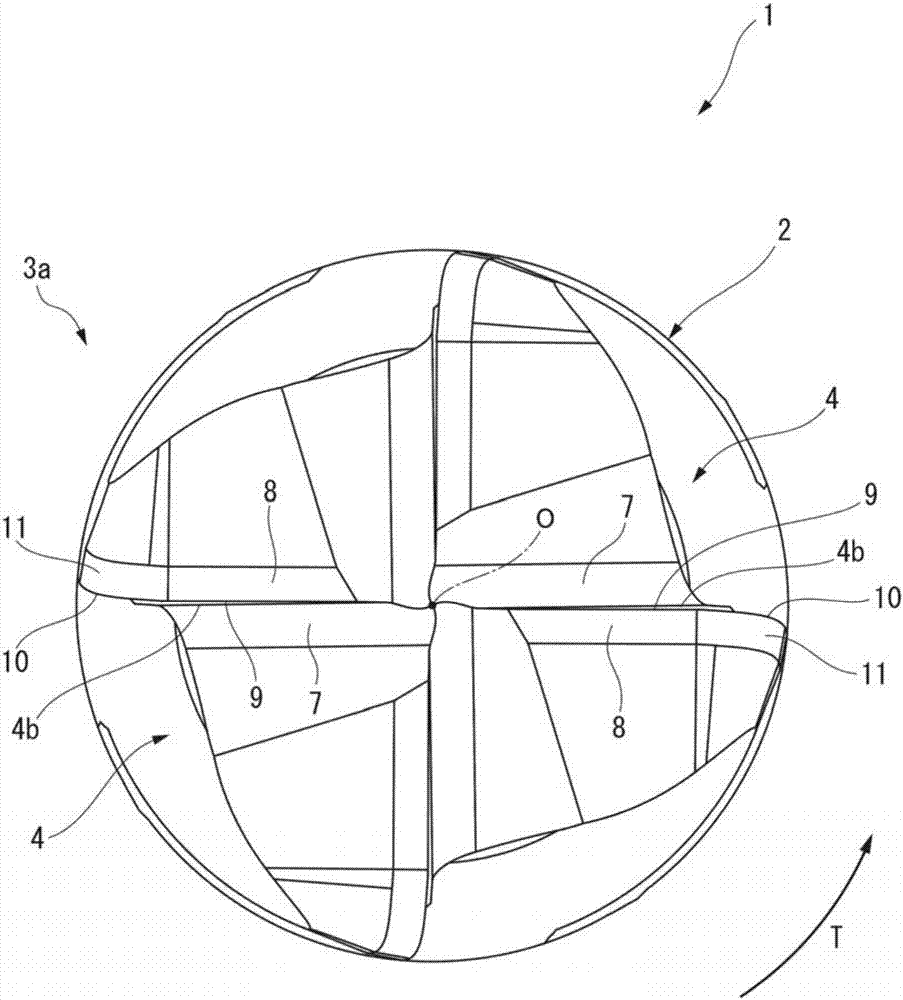

Radius end mill, ball end mill, and end mill

InactiveCN107000080AAchieve processing efficiencyHigh strengthMilling cuttersWorkpiecesMilling cutterEngineering

The present invention is provided with: a ceramic end mill main body (2); chip discharge grooves (4) formed in an outer periphery of the end mill main body (2); outer peripheral cutting edges (6) formed at intersecting ridge lines between wall surfaces which face in a tool rotation direction (T), in the chip discharge grooves (4), and an outer peripheral surface of the end mill main body (2); base cutting edges formed at intersecting ridge lines between the wall surfaces in the chip discharge grooves (4) and a tip end surface of the end mill main body (2); and corner cutting edges which are located in tip end outer peripheral portions of the end mill main body (2), connect the outer ends of the base cutting edges with the tip ends of the outer peripheral cutting edges (6), and are formed in the shape of convex curved lines which have a convexity facing toward the tip end outer peripheral side of the end mill main body (2). From among the outer peripheral cutting edges (6), the base cutting edges and the corner cutting edges, a radial rake angle (angle alpha) of at least the outer peripheral cutting edges (6) is set to a negative angle. The radial rake angle (angle alpha) of the outer peripheral cutting edges (6) is between -20 deg and -10 deg.

Owner:MITSUBISHI MATERIALS CORP

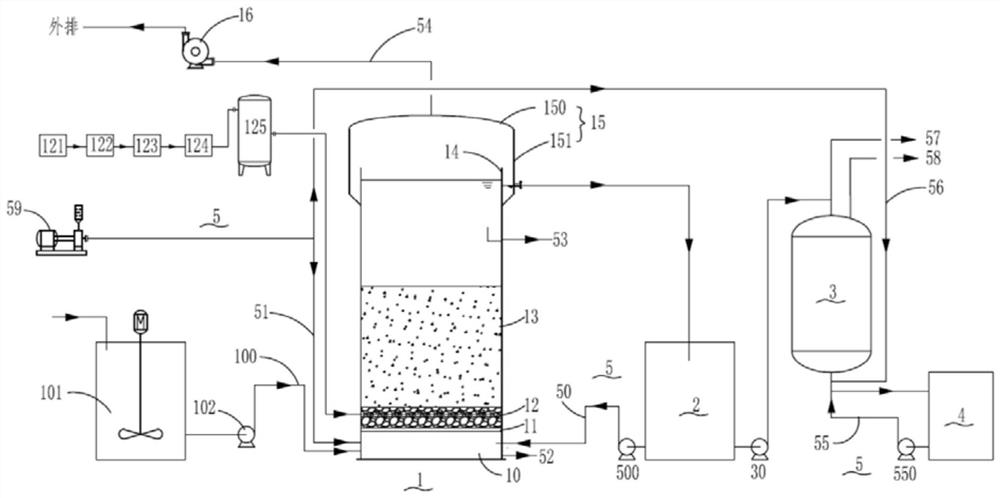

Advanced treatment device and process for high-salt degradation-resistant sewage

PendingCN114394716AAchieve processing efficiencyAchieving degradation efficiencySpecific water treatment objectivesTreatment involving filtrationBiological activated carbonSewage

The invention discloses an advanced treatment device for high-salt degradation-resistant sewage, which comprises a biological activated carbon reactor, a filter plate, a supporting layer and a biological activated carbon layer are sequentially arranged in the biological activated carbon reactor from bottom to top, filter caps are distributed on the filter plate, an aeration unit is arranged in the supporting layer, activated carbon and biological flora are arranged in the biological activated carbon layer, and the biological flora is arranged in the biological activated carbon reactor. A water outlet unit is also arranged on the upper side of the biological activated carbon layer; a water inlet pipe for feeding sewage is also connected to a bottom accommodating cavity positioned on the lower side of the filter plate in the biological activated carbon reactor; an inlet of the sand filter reactor is communicated with the water outlet unit, and the sand filter reactor is further provided with a purified water outlet; the backwashing unit is communicated with the bottom accommodating cavity of the biological activated carbon reactor and is also communicated with the sand filter reactor. The invention also provides a corresponding deep treatment process. The advanced treatment device and process for the high-salt degradation-resistant sewage are excellent in sewage treatment effect, low in energy consumption and low in operation cost.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

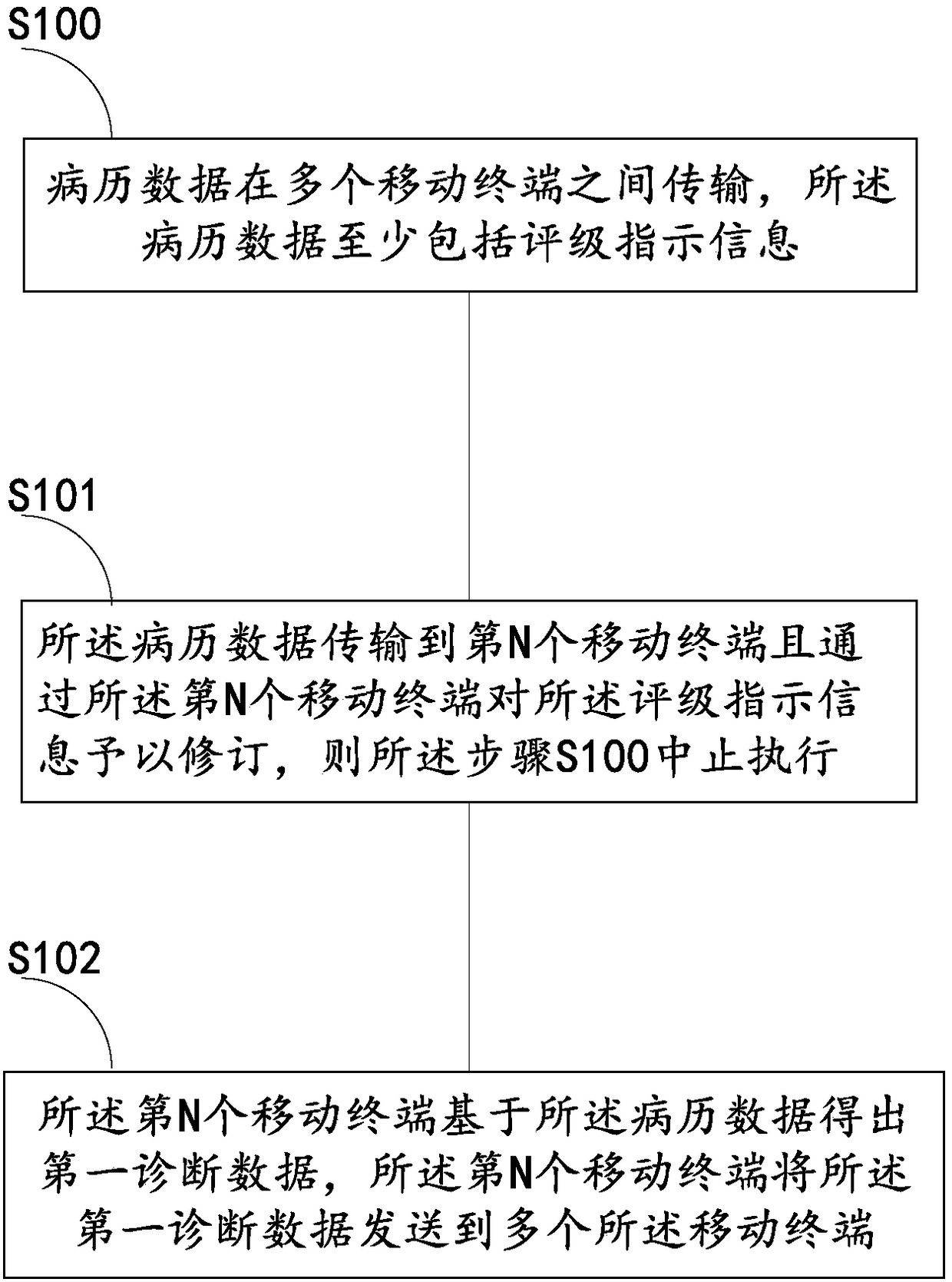

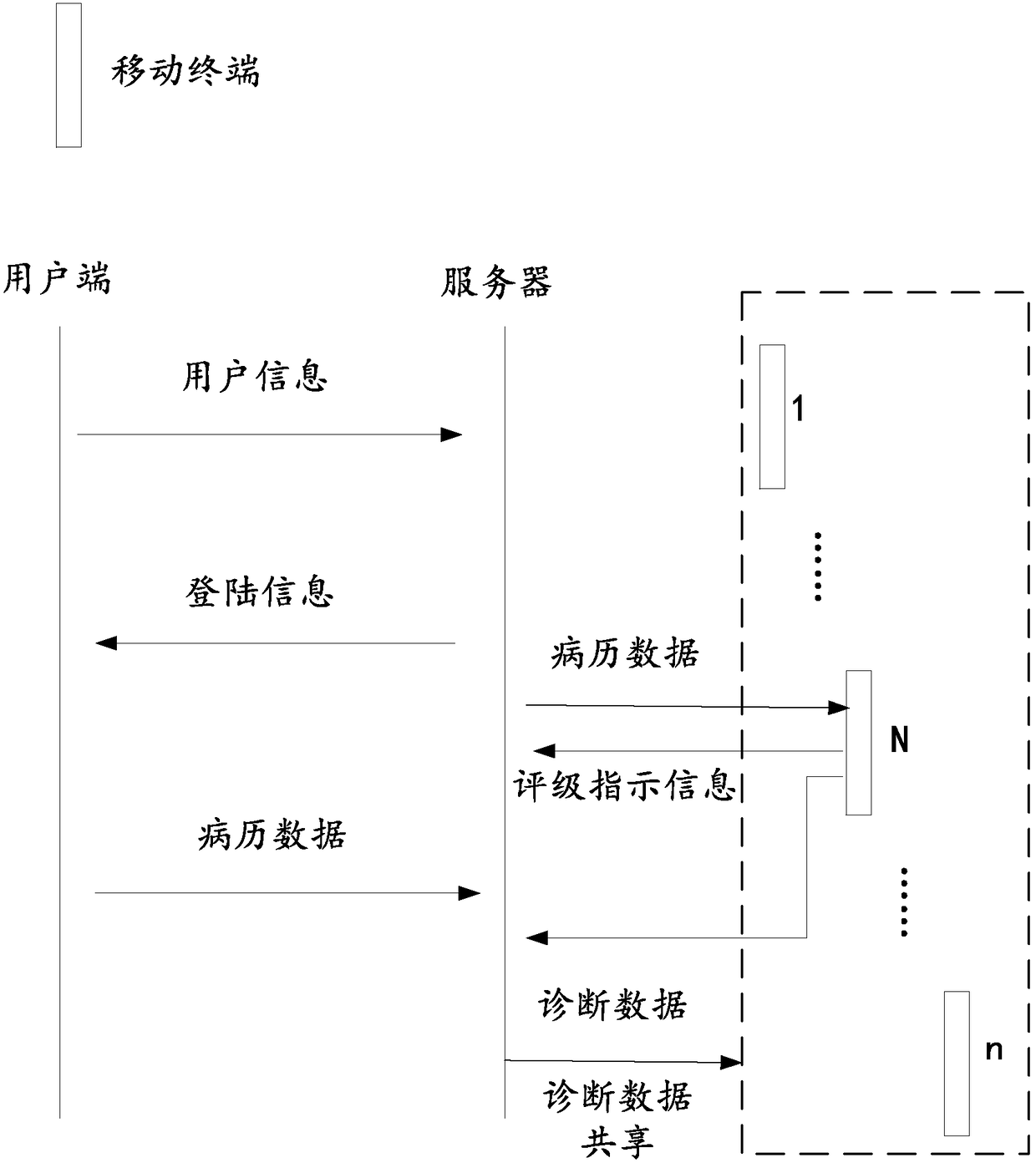

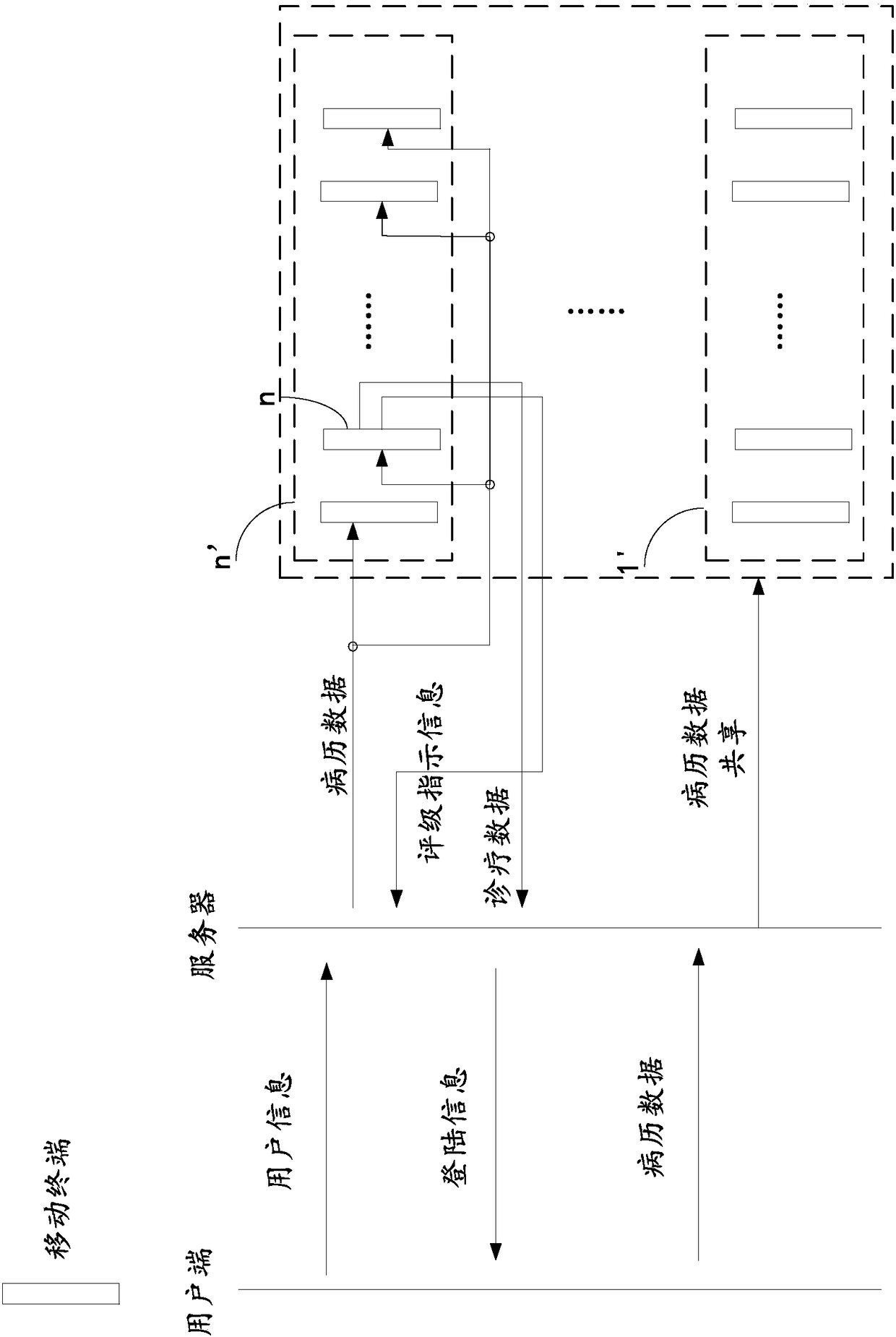

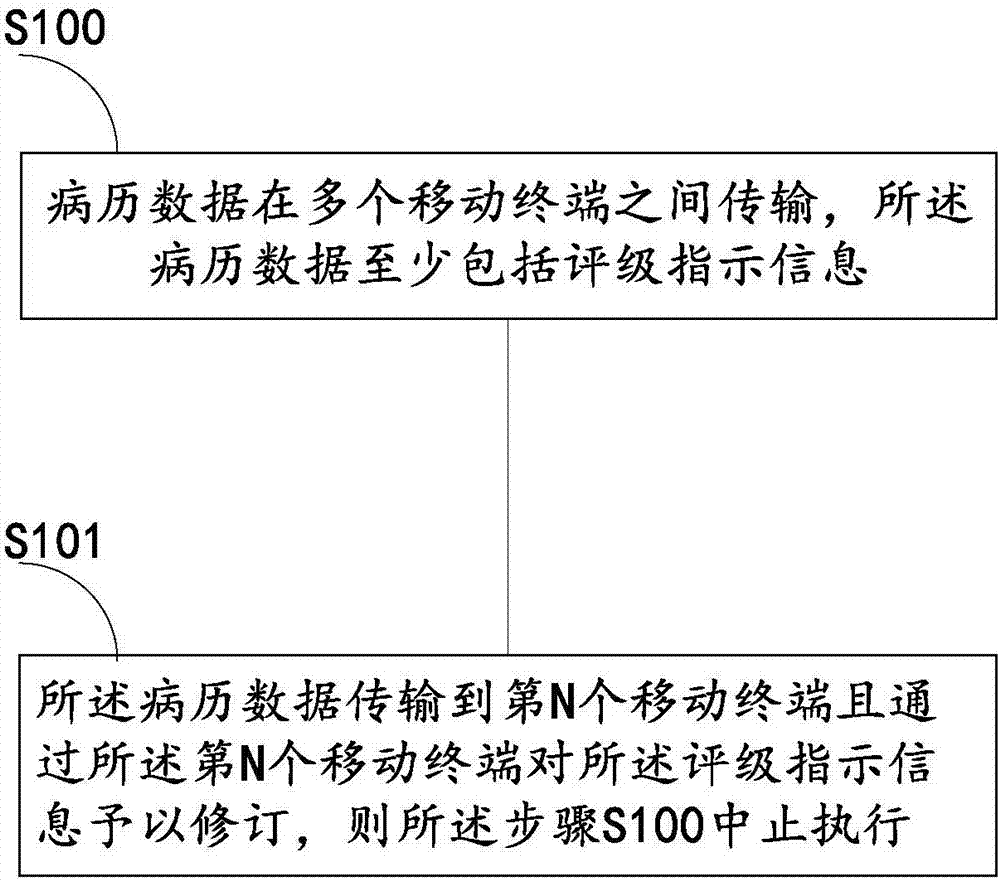

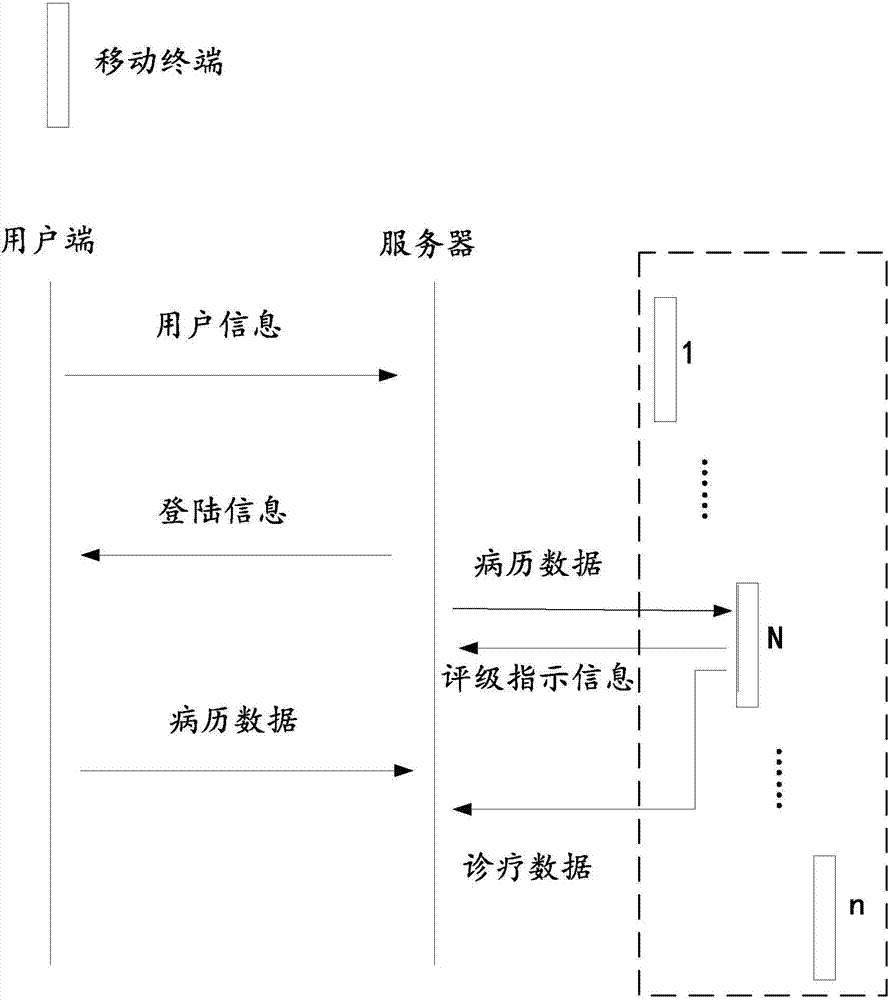

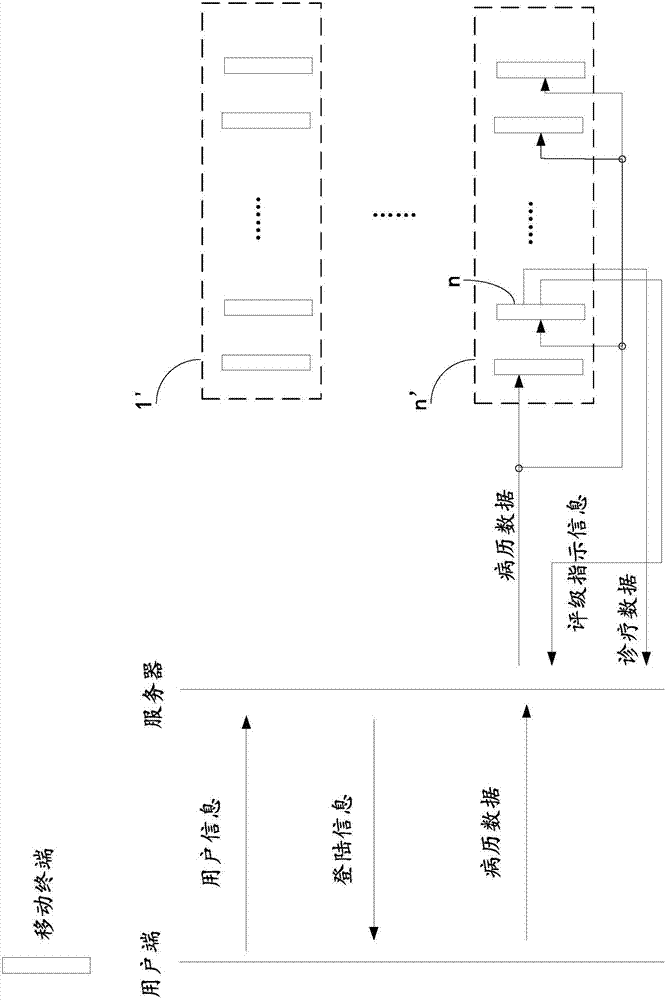

A medical education method based on mobile terminal

ActiveCN107347088BImprove effectivenessImprove processing efficiencyData processing applicationsTransmissionInformation processingDiagnostic data

The present invention provides a medical education method based on a mobile terminal, which includes the following steps: a. medical record data is transmitted between multiple mobile terminals, and the medical record data includes at least rating indication information; b. the medical record data is transmitted to the Nth mobile terminal and the rating indication information is revised by the Nth mobile terminal, then the execution of the step a is terminated; c. The Nth mobile terminal obtains the first diagnosis data based on the medical record data, The Nth mobile terminal sends the first diagnosis data to a plurality of the mobile terminals. The present invention can realize the information configuration of the information corresponding processing terminal by setting the instruction information of the medical record data, and based on this control the circulation path of the medical record data among the mobile terminals, enhance the effectiveness of information dissemination, and improve the efficiency of information processing.

Owner:SHANGHAI MINGPIN MEDICAL DATA TECH CO LTD

Extraction well device for treating polluted underground water

InactiveCN112408627AFully processedEffective filteringTreatment involving filtrationMultistage water/sewage treatmentFiltrationStructural engineering

The invention relates to an extraction well device for treating polluted underground water, a filtering mechanism comprises a first mounting block, a second mounting block and a concave plate, a firstclamping groove is formed in the side, close to the second mounting block, of the first mounting block, a second clamping groove is formed in the side, close to the first mounting block, of the second mounting block, and a filter plate is clamped between the interior of the first clamping groove and the interior of the second clamping groove. According to the extraction well device for treating polluted underground water, through cooperative use of the first mounting block, the second mounting block, the concave plate, the first clamping groove, the second clamping groove and the filter plate, the filter plate is used for performing sewage filtration on underground water of a stratum, soil particles and suspended solids are effectively filtered, and after an underground water extraction well is used, the underground water extraction well is generally left in a site, a filter layer material is difficult to take out, so that the problems that the construction efficiency of an existing extraction well is relatively low and the filter layer material is difficult to take out are solved.

Owner:天明环境修复有限公司

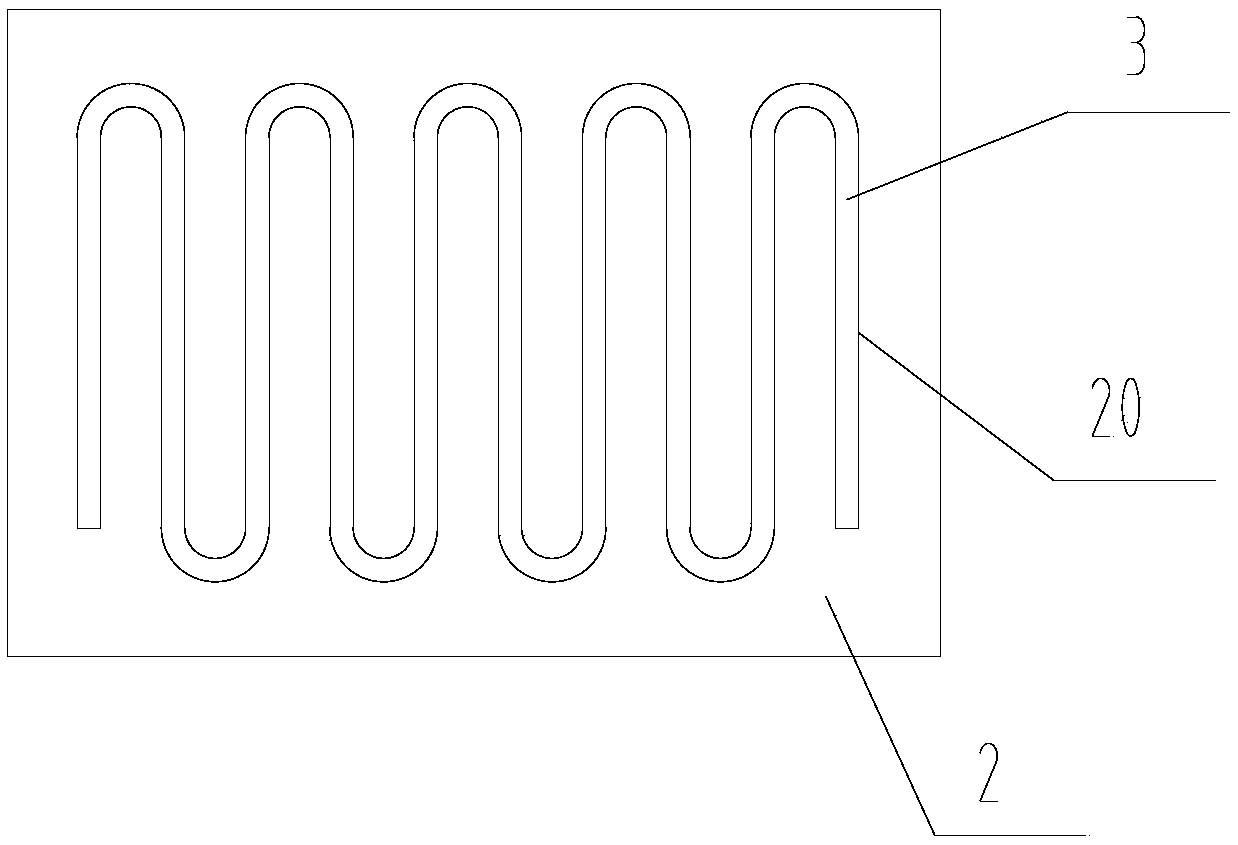

Touch screen monitoring system

ActiveCN109116151AAchieve processing efficiencyAchieve transfer efficiencyElectrical testingOptical apparatus testingCurve shapeMonitoring system

Provided in the invention is a touch screen monitoring system comprising a support frame, a pressing plate, a camera and a control module. The pressing plate is made of a transparent hard board and isinstalled on the support frame; a groove is formed in the lower surface of the pressing plate; and the groove forms a continuous curve shape in the lower surface of the pressing plate. An expansion tube is installed in the groove; one end of the expansion tube is connected with a gas supply device and the other end is connected with a vacuum pump; and the expansion tube is a transparent hose. Thecontrol module connected with the camera is used for acquiring a drawing track of the expansion tube on the touch screen during the inflation process during the detection process by the camera, comparing the drawing track with a detection curve, and determining whether the touch screen is qualified based on the comparison result. Therefore, on the one hand, the concrete implementation effect of sensitivity detection of the touch screen is realized and thus the detection accuracy is ensured; and on the other hand, the internal electric signal processing and transmission efficiency detection ofthe touch screen are realized.

Owner:安徽格林开思茂光电科技股份有限公司

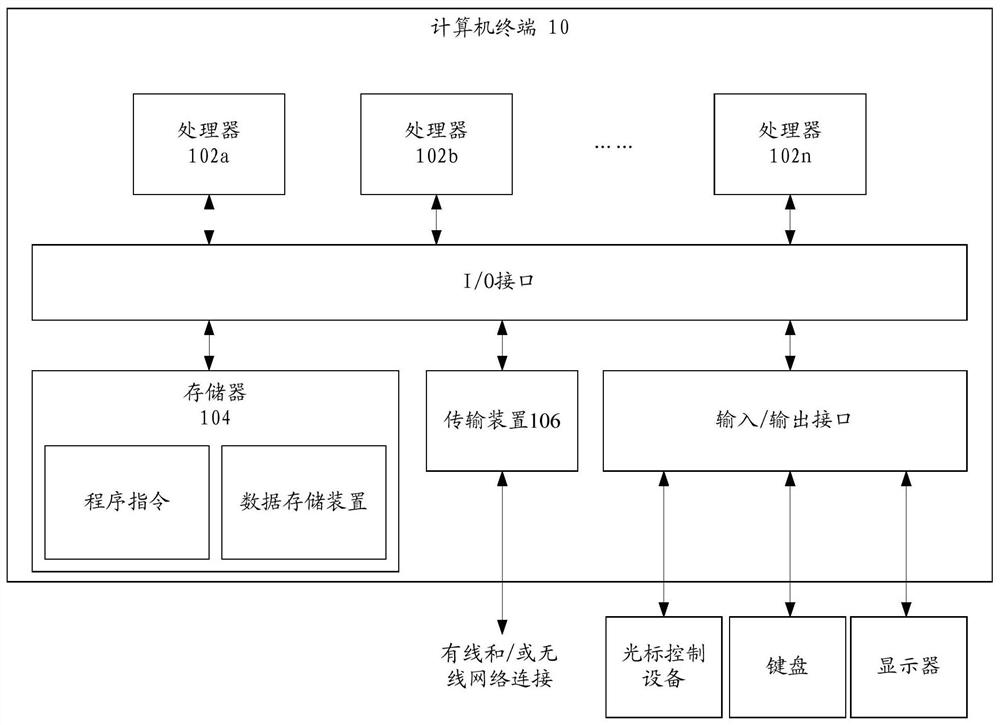

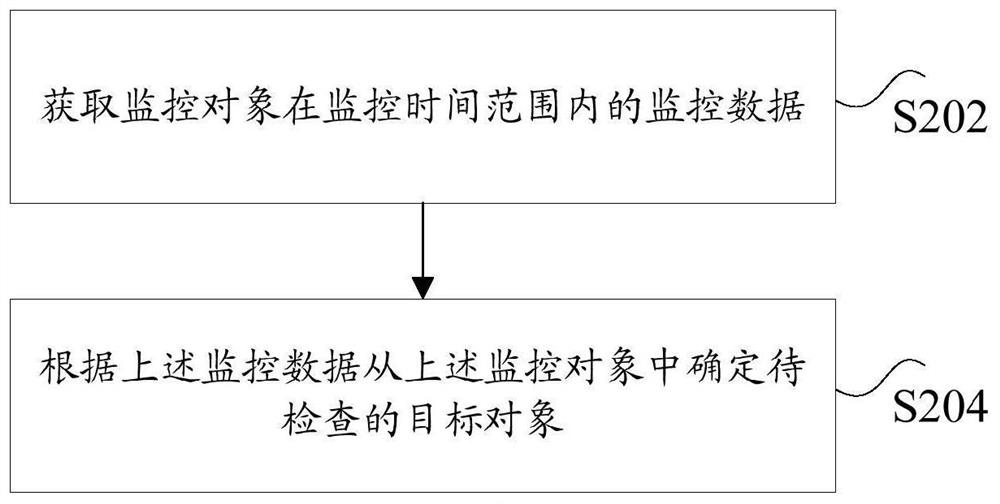

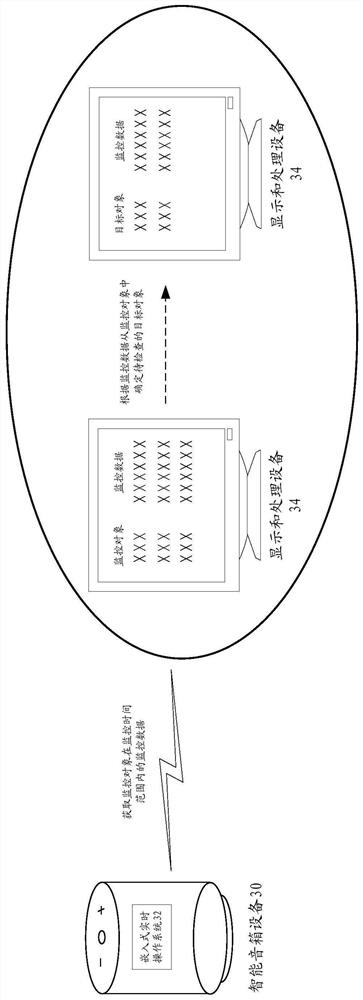

Monitoring data processing method and device and monitoring method of embedded system

PendingCN114064375AImprove monitoring accuracyAchieve accuracyHardware monitoringTime rangeEmbedded system

The invention discloses a monitoring data processing method and device and a monitoring method of an embedded system. The method comprises the steps of obtaining monitoring data of a monitoring object in a monitoring time range, where the monitoring object comprises at least one of a to-be-monitored system task and a to-be-monitored peripheral interruption, and the monitoring data is used for recording duration information and frequency information of the monitoring object in the monitoring time range; and determining a to-be-checked target object from the monitoring objects according to the monitoring data. The technical problems that in the prior art, an embedded system monitoring method is limited in application scene and low in monitoring accuracy are solved.

Owner:ALIBABA GRP HLDG LTD

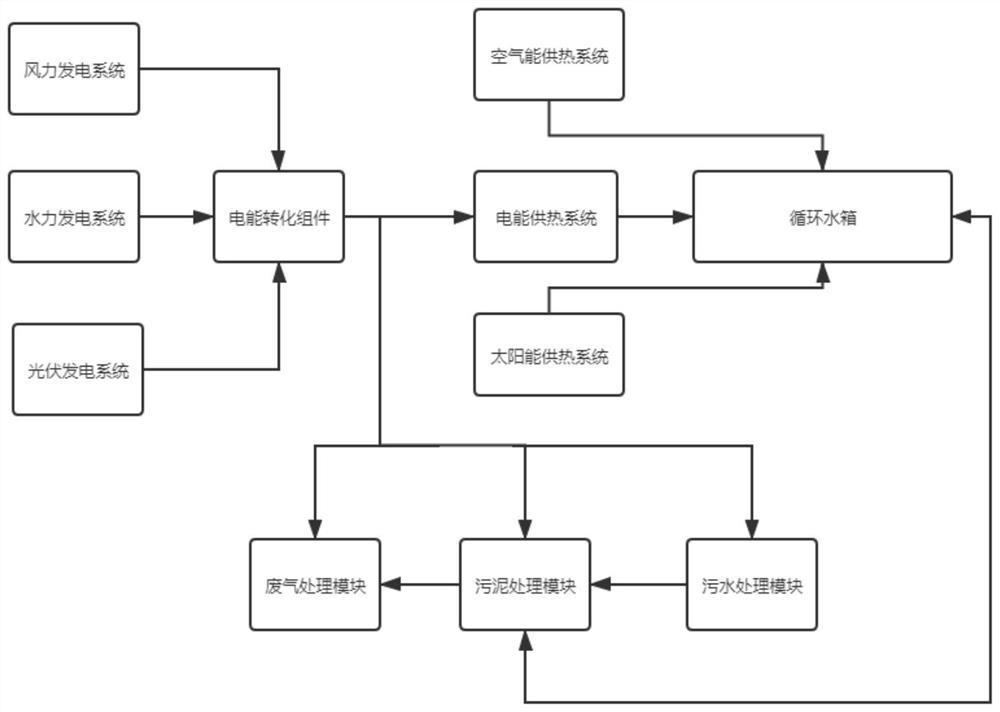

Sewage treatment system based on solar combined energy supply

PendingCN113772888ANo emission pollutionRealize energy saving and environmental protectionSolar heating energyTreatment using aerobic processesSludgePv generation

The invention discloses a sewage treatment system based on solar combined energy supply. The system comprises an energy supply module, a sewage treatment module, a sludge treatment module and a waste gas treatment module, wherein the sewage treatment module, the sludge treatment module and the waste gas treatment module are all connected with the energy supply module, the energy supply module comprises a power supply assembly, a heat supply assembly, a control assembly, an electric energy conversion assembly and a circulating water tank, the power supply assembly is connected with the electric energy conversion assembly, the heat supply assembly is connected with the circulating water tank, the power supply assembly comprises a photovoltaic power generation system, a wind power generation system and a hydroelectric generation system, the heat supply assembly comprises a solar heat supply system, an air energy heat supply system and an electric energy heat supply system, and the electric energy conversion assembly is connected with the electric energy heat supply system. According to the invention, solar energy is used as a main energy source, and a plurality of energy sources are combined, so that all-weather non-stop pollution-free sewage treatment is realized, the energy sources are reasonably utilized, zero emission is realized, and energy conservation and environmental protection in a real sense are realized.

Owner:湖南绍勋新能源科技有限公司

A probe interface circuit and a probe adaptation circuit for a probe of an oscilloscope

ActiveCN111289786BAvoid interferenceMeet electricity demandDigital variable displayCommunication interfaceControl signal

A probe interface circuit and a probe adaptation circuit for a probe of an oscilloscope, wherein the probe includes a probe interface circuit and a probe front-end circuit, the probe interface circuit includes a control circuit, a detection circuit and a coaxial transmission circuit; The communication interface of the oscilloscope receives the control signal generated by the oscilloscope, and configures the DC offset according to the control signal to generate the offset configuration signal, and outputs the offset configuration signal to the probe front-end circuit through its output terminal, so that the probe front-end circuit is in the Under the action of the bias configuration signal, the DC bias is superimposed on the signal to be detected, and the coaxial signal with the output impedance matching the BNC interface of the oscilloscope is generated through attenuation adjustment and impedance adjustment. Since the probe interface circuit can generate the offset configuration signal according to the control signal, it is beneficial to realize the free superposition of the DC offset of the signal to be detected, and overcome the functional deficiencies of the existing oscilloscope probe.

Owner:SHENZHEN CITY SIGLENT TECH

Hierarchical diagnosis and treatment method based on mobile terminal

ActiveCN107547575AImprove effectivenessImprove processing efficiencyTransmissionSpecial data processing applicationsMedical recordInformation processing

The invention provides a hierarchical diagnosis and treatment method based on a mobile terminal. The method comprises the following steps: a, transmitting medical record data among multiple mobile terminals, wherein the medical record data at least comprises rating indication information; b, transmitting the medical record data to the N-th mobile terminal and revising the rating indication information through the N-th mobile terminal, and suspending the execution in the step a. By using the method provided by the invention, the information configuration of the information corresponding processing terminal can be realized by setting the indication information of the medical record data, a circulating path of the medical record data between the mobile terminals is controlled based on the information configuration, the effectiveness of the information propagation is enhanced, and the information processing efficiency is improved.

Owner:SHANGHAI MINGPIN MEDICAL DATA TECH CO LTD

A kind of telescopic flue-cured room

ActiveCN110140990BIncrease the lengthLarge capacityTobacco preparationBolt connectionCuring of tobacco

The invention provides a retractable tobacco flue-curing room, which comprises a side plate, a top plate, a back plate, a baffle plate, a worm frame, a worm, a worm wheel, a rotating wheel, a door, lifting lugs, a handle and a beam; the side of the door passes through The front end of the side plate is hingedly connected, and the rear end of the side plate is connected with the back plate by bolts; the worm is installed on the worm frame; the shaft of the worm wheel is connected to the inner surface of the side plate by welding, and the worm wheel and The worm is engaged; the two sides of the top plate are installed on the upper end of the side plate through lifting lugs; the beam is connected to the inner side of the side plate by welding, and the handle is connected to the lower end of the worm by welding; in summary, it can be seen that, Compared with the existing flue-cured room, it can be folded, saves space, and is also convenient for transportation. After moving the position, install the flue-cured room on the planting site, and directly process it after picking, which reduces the burden of transportation. Multiple sets of side panels and top panels can be spliced. Increase the capacity of the flue-cured tobacco room to meet processing needs.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com