Ultrasonic combined electric machining technology real-time optimizing control system and control method thereof

A control system and electric machining technology, applied in electric machining equipment, metal machining equipment, circuits, etc., can solve the problems of difficulty in maintaining the stability of the machining process, machining efficiency, and precision degradation, and achieve efficiency optimization and high precision. Processing and maintaining stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

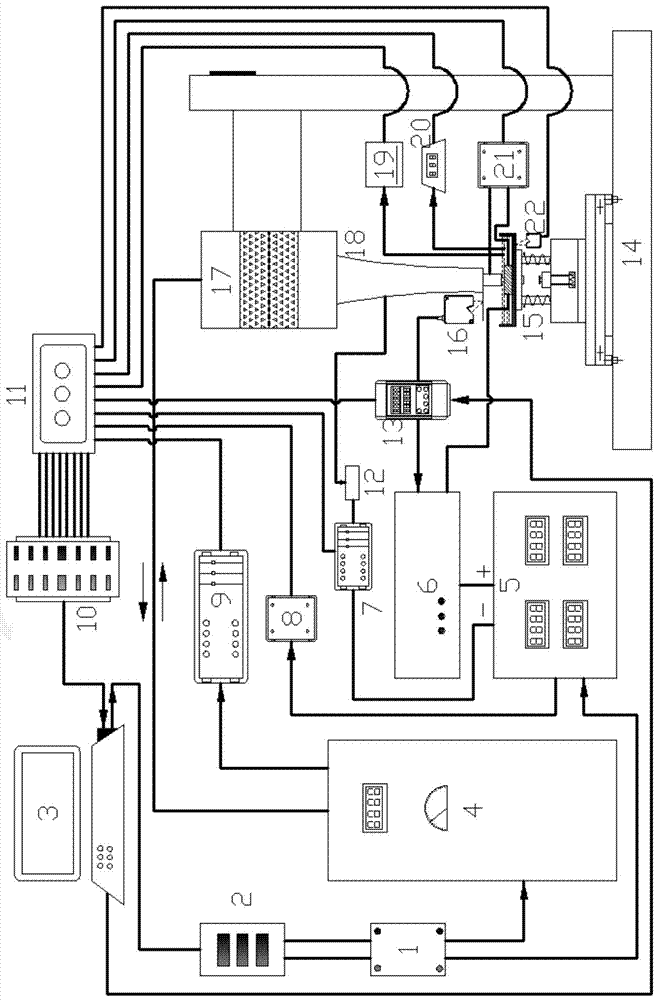

[0024] The control system of the present invention is as figure 1As shown, it includes the power amplifier circuit 1, the power amplifier circuit 1 is respectively connected to the output interface D\A2, the ultrasonic power supply 4, and the pulse power supply 5, the output interface D\A2 is connected to the control computer 3, and the control computer 3 is connected to the laser via a USB interface cable. The micro-displacement sensor controller 13 is connected, the ultrasonic power supply 4 is connected to the current sensor 9 and the transducer 17 respectively, the control computer 3 is connected to the synchronous data acquisition card 10, the synchronous data acquisition card 10 is connected to the signal conditioning circuit 11, and the signal conditioning circuit 11 is connected to the current Sensor 9, pulse power supply voltage sensor 8, cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com