Touch screen monitoring system

A monitoring system and touch screen technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as difficulty in ensuring accurate test results and inconsistent testing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

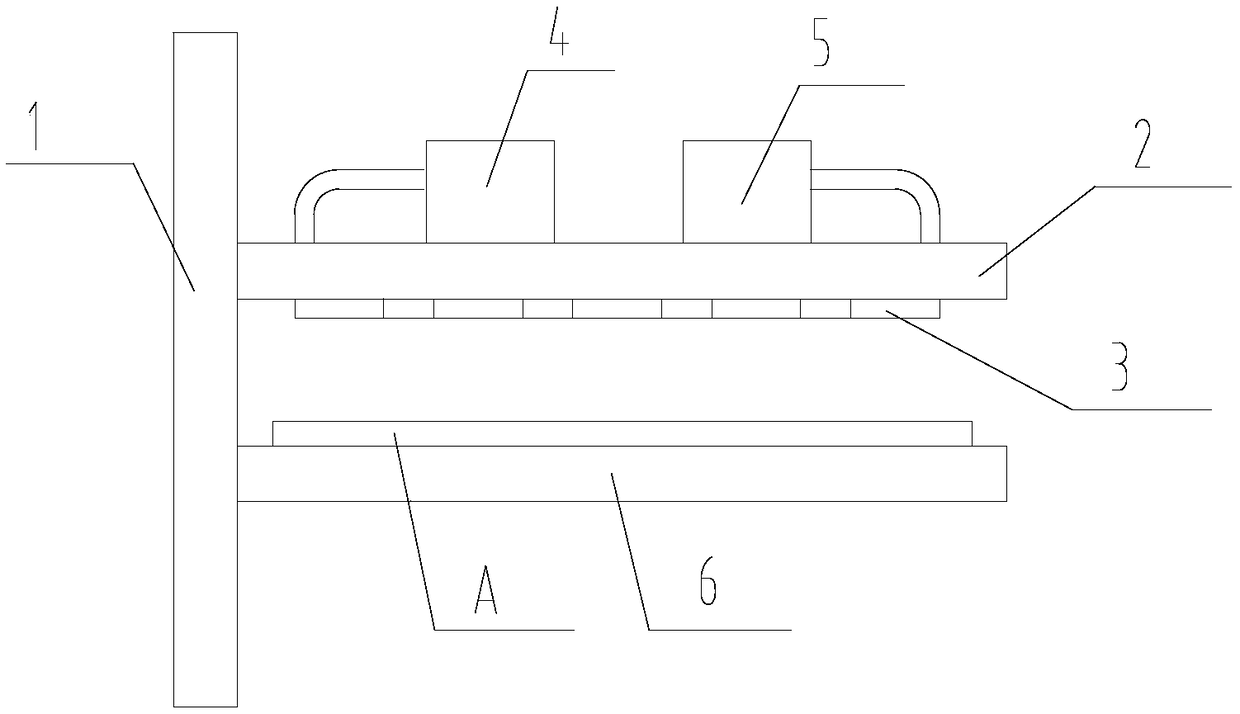

[0020] Reference figure 1 , A touch screen monitoring system proposed by the present invention includes: a support frame 1, a pressure plate 2, a camera, and a control module. The pressing plate 2 is a transparent hard plate.

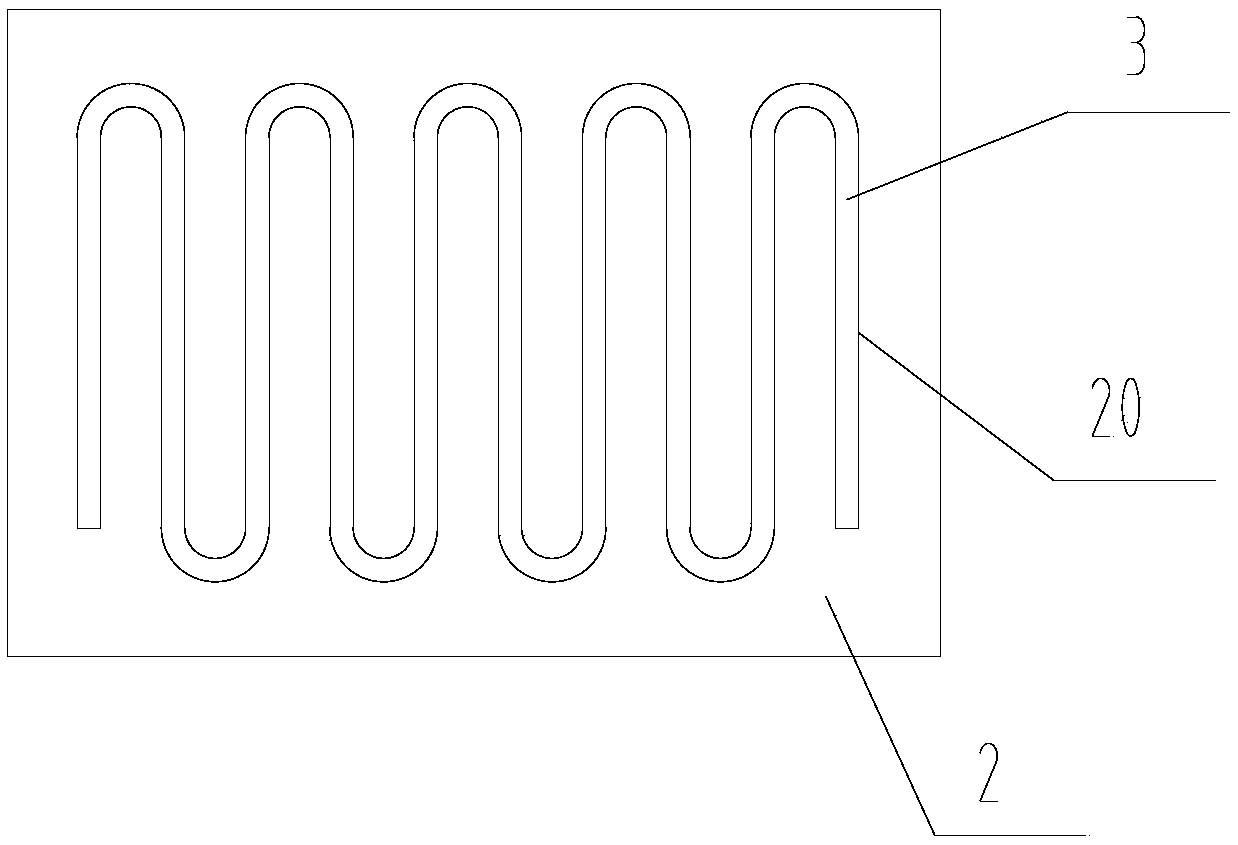

[0021] The pressing plate 2 is horizontally installed on the support frame 1, and the lower surface of the pressing plate 2 is provided with a groove 20, and the groove 20 forms a continuous curve shape on the lower surface of the pressing plate 2 as a detection curve. An expansion tube 3 is installed in the groove 20, and one end of the expansion tube 3 is connected with an air supply device 4, and the other end is connected with a vacuum pump 5. The expansion tube 3 is a transparent hose.

[0022] A splint 6 is also installed on the supporting frame 1, the splint 6 is located below the pressing plate 2, and the upper surface of the splint 6 is provided with a detection groove for placing the touch screen A. When the touch screen A is placed in the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com