Machine part machining device and machining method in mechanical field

A technology of mechanical parts and processing devices, which is applied in the field of mechanical parts processing devices, can solve the problems of wasting time and energy, insufficient automation, and reducing the efficiency of mechanical parts, so as to reduce processing costs, improve adaptability, and improve tightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

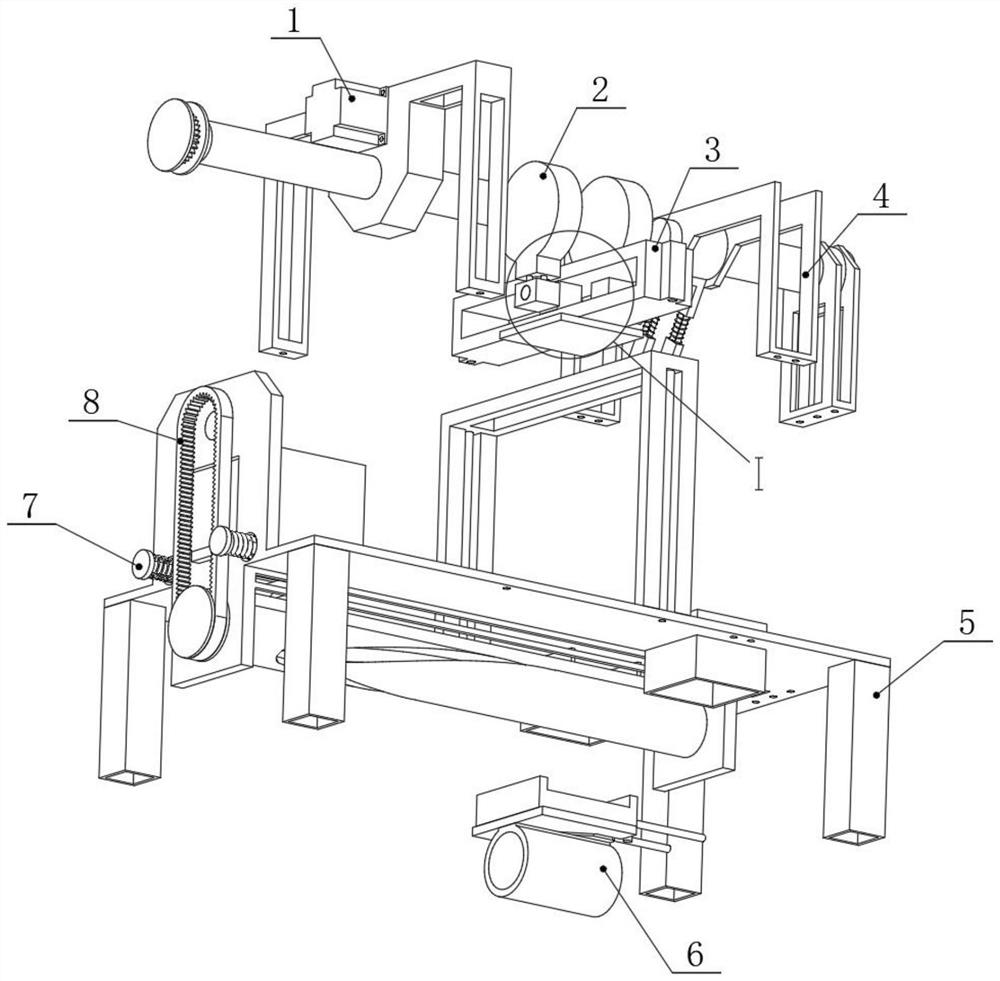

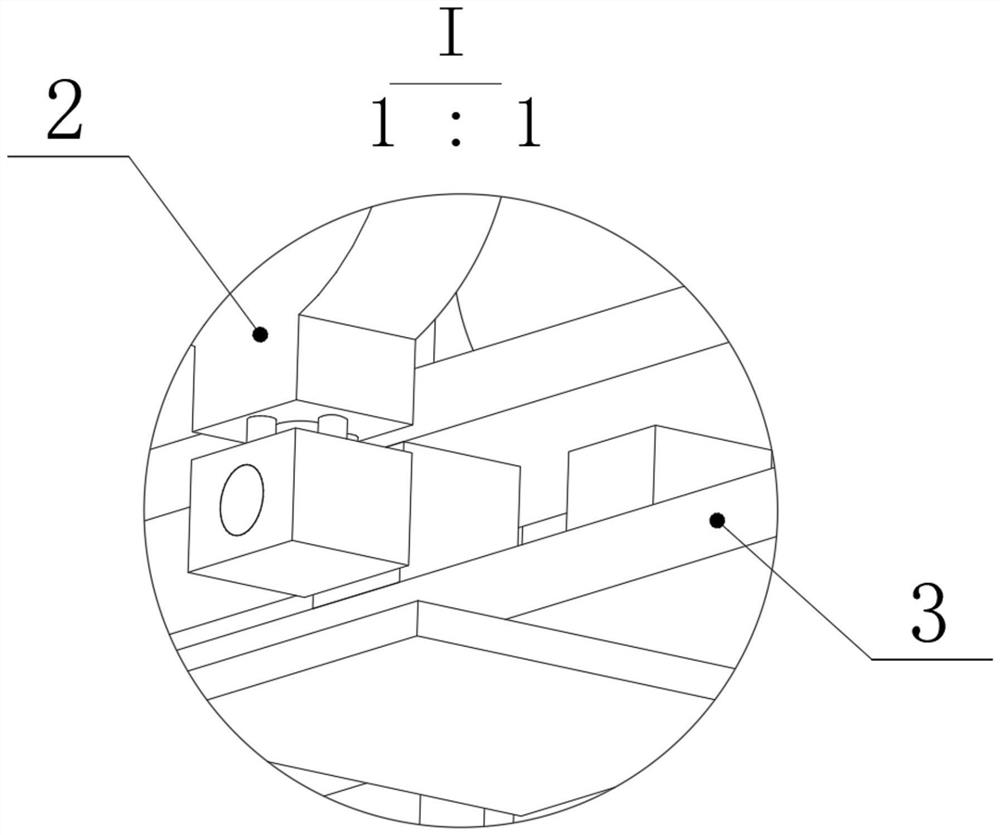

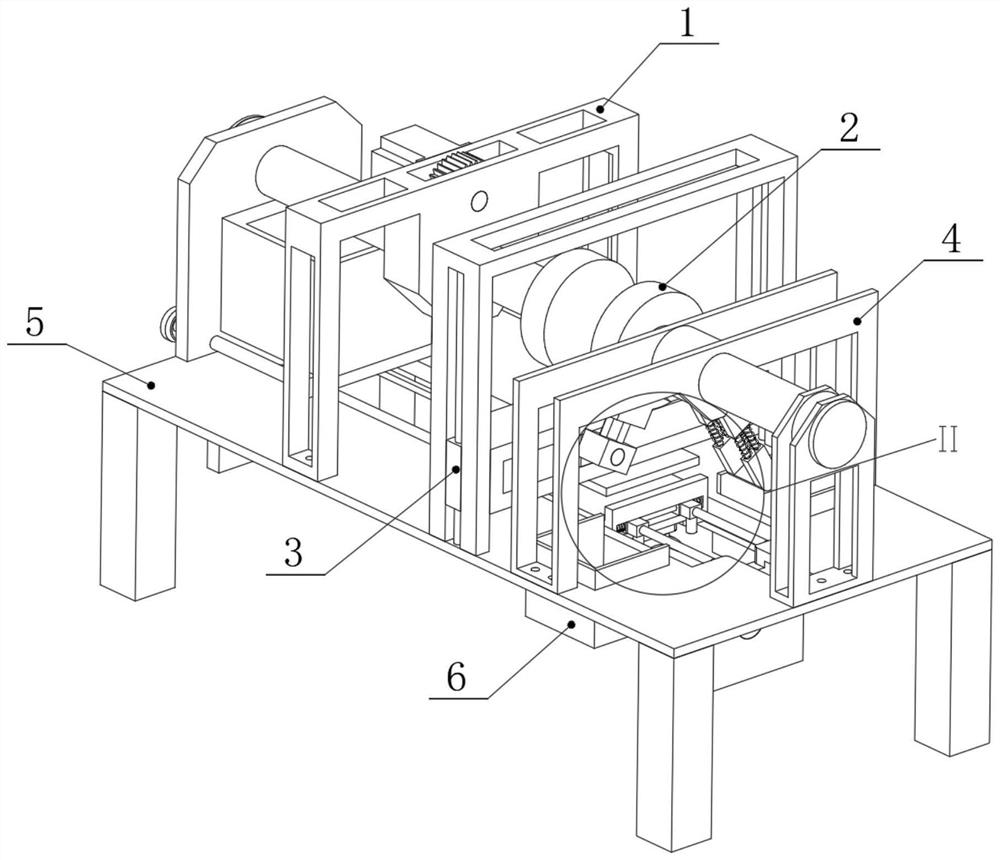

[0045] see Figure 1-15 , the present invention provides a technical solution: a mechanical parts processing device in the mechanical field, comprising a guide device 5, the upper end surface of the guide device 5 is fixedly installed with a transmission device 1 near the front, and the transmission device 1 and the guide device 5 are fixedly installed. The toothed belt 8 is engaged in meshing connection between the two, the upper end surface of the guide device 5 is slidably clamped to the limit die base 3, and the inner end surface of the guide device 5 is slidably clamped near the bottom. A feeding device 4 is fixed on the upper end surface near the rear. Both the transmission device 1 and the feeding device 4 are slidably connected with the limit die base 3 through the adjusting device 2, and the front end surface of the guiding device 5 is elastically slidably connected in the middle. Limiting device 7;

[0046] like Figure 15 , the limiting device 7 includes a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com