Retractable type tobacco baking room

A flue-cured room, telescopic technology, applied in the structural field of the flue-cured room, can solve the problems of wasting time, unfixed planting site, etc., and achieve the effect of increasing capacity, saving space, and convenient folding and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

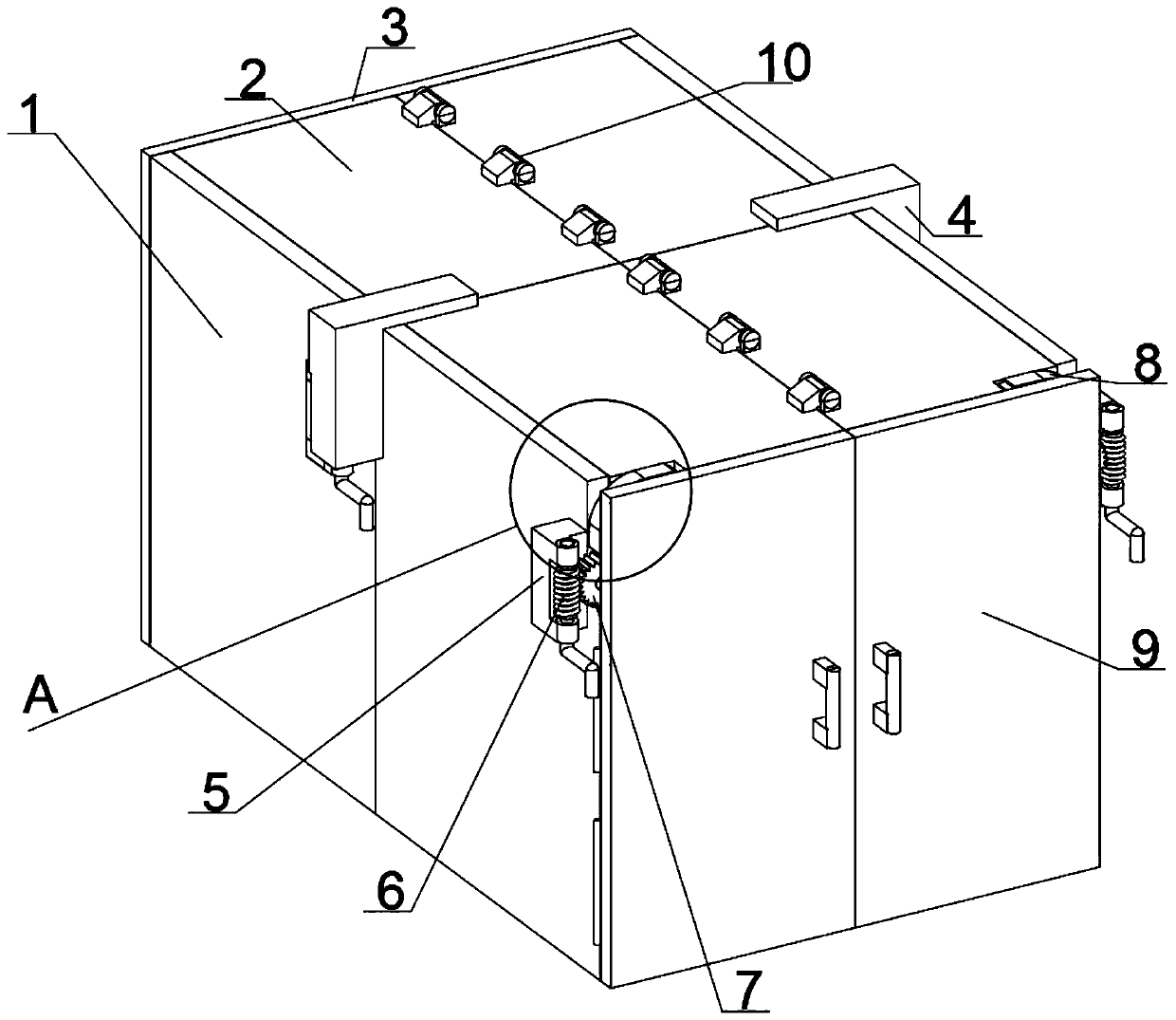

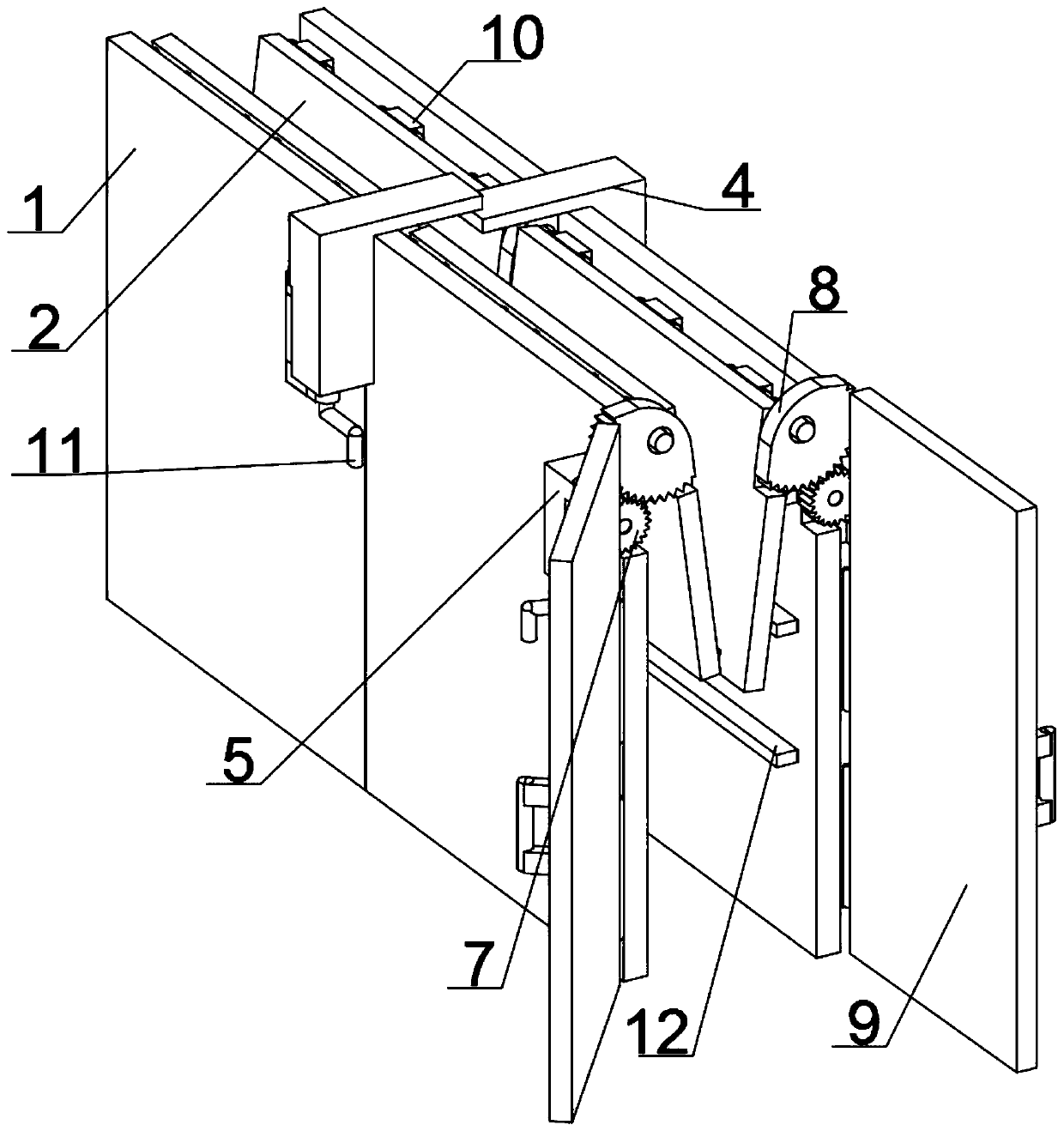

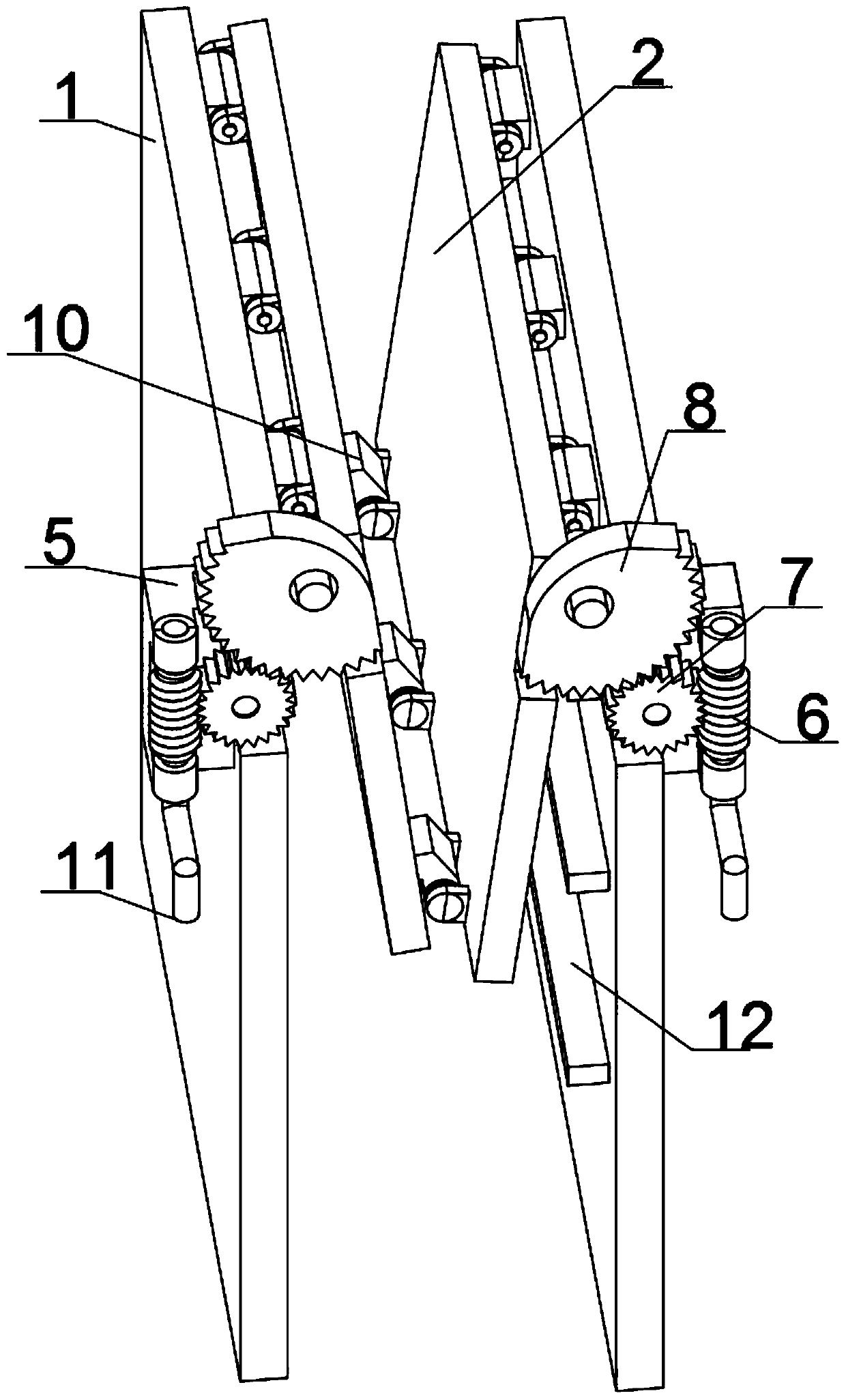

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The present invention provides a retractable tobacco flue-curing room, which includes a side panel 1, a top panel 2, a rear panel 3, a baffle panel 4, a worm frame 5, a worm screw 6, a worm wheel 7, a rotating wheel 8, a door 9, a lifting lug 10, and a handle 11 and a crossbeam 12; the side of the door 9 is hingedly connected to the front end of the side plate 1, and the rear end of the side plate 1 is connected with the back plate 3 by bolts; the worm 6 is installed on the worm frame 5; The shaft of the worm wheel 7 is connected to the inner surface of the side plate 1 by welding, and the worm wheel 7 is engaged with the worm 6; the two sides of the top plate 2 are installed on the upper end of the side plate 1 through the lifting lug 10; the crossbeam 12 is welded Connected to the inner side of the side plate 1, and the handle 11 is connected to the lower end of the worm 6 by welding; the baffle 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com