Platform device for multi-station machining

A technology of mechanical processing and platform devices, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, achieve the effects of improving efficiency, realizing processing efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

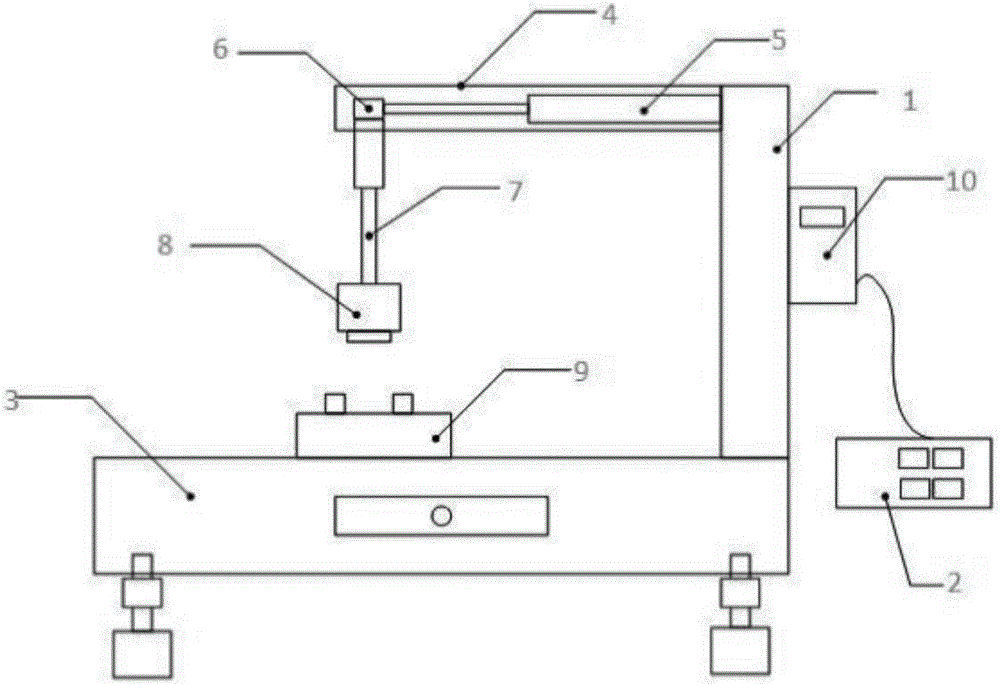

[0023] to combine figure 1 , figure 2 , image 3 This embodiment will be described.

[0024] A platform device for mechanical processing, comprising a column 1, a remote controller 2 and a rectangular support platform 3, a level is installed on the side wall of the support platform 3, the end of the column 1 is welded on the support platform 3, and the mechanical processing The platform 9 is installed on the top of the support platform 3, the remote controller 2 is electrically input and connected to the controller 10, and the top of the column 1 is equipped with a slide rail 4 through the support part 11, and the support part 11 is provided with a horizontal direction. Rotate around the rotation axis in the vertical direction, the controller 10 is electrically input and connected to the support part 11, and the first telescopic rod 5 is installed inside the slide rail 4, and a sliding rod is installed on the top end of the first telescopic rod 5. block 6, a second telesco...

Embodiment 2

[0026] to combine figure 1 , figure 2 , Figure 4 This embodiment will be described.

[0027] Others are the same as in Embodiment 1, except that the column is located in the middle of the long side of the supporting platform 3, and the number of the machining platforms 9 is five.

Embodiment 3

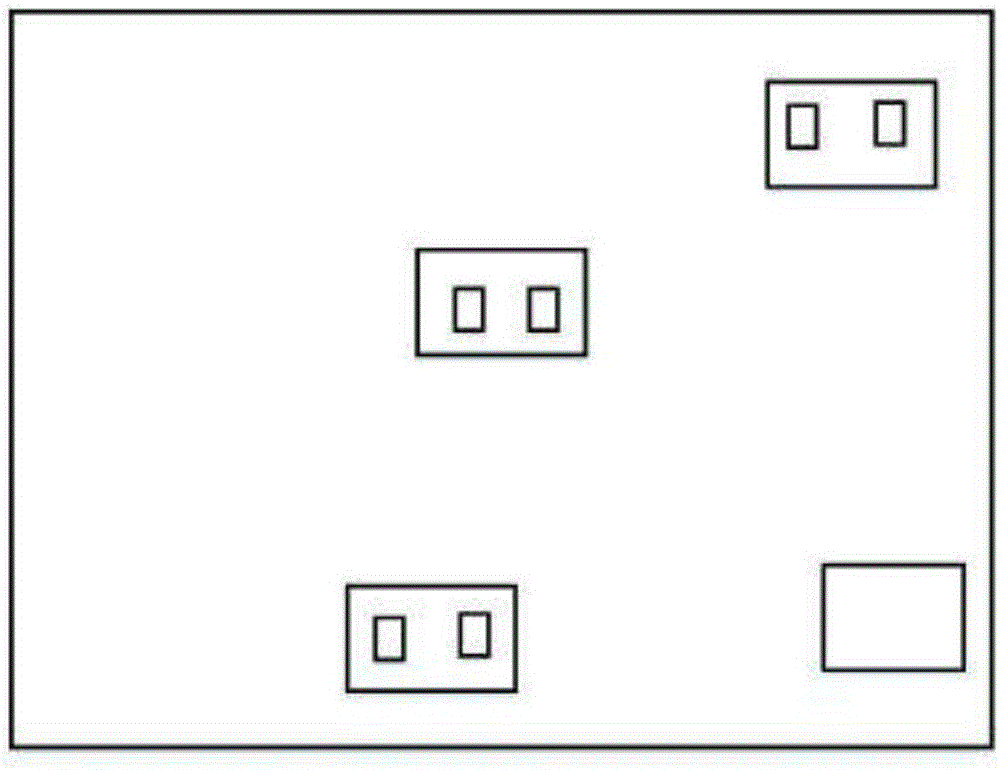

[0029] to combine figure 1 , figure 2 , Figure 5 This embodiment will be described.

[0030] Others are the same as the first and second embodiments, except that the column is located at the center of the supporting platform 3, and the number of the machining platforms 9 is eight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com