Segmented splicing type granulator hobbing cutter

A segmented splicing and granulator technology, which is applied in the field of granulator equipment, can solve problems such as blade chipping or wear, affect product quality, and increase production costs, so as to facilitate the operation of employees, reduce production costs, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

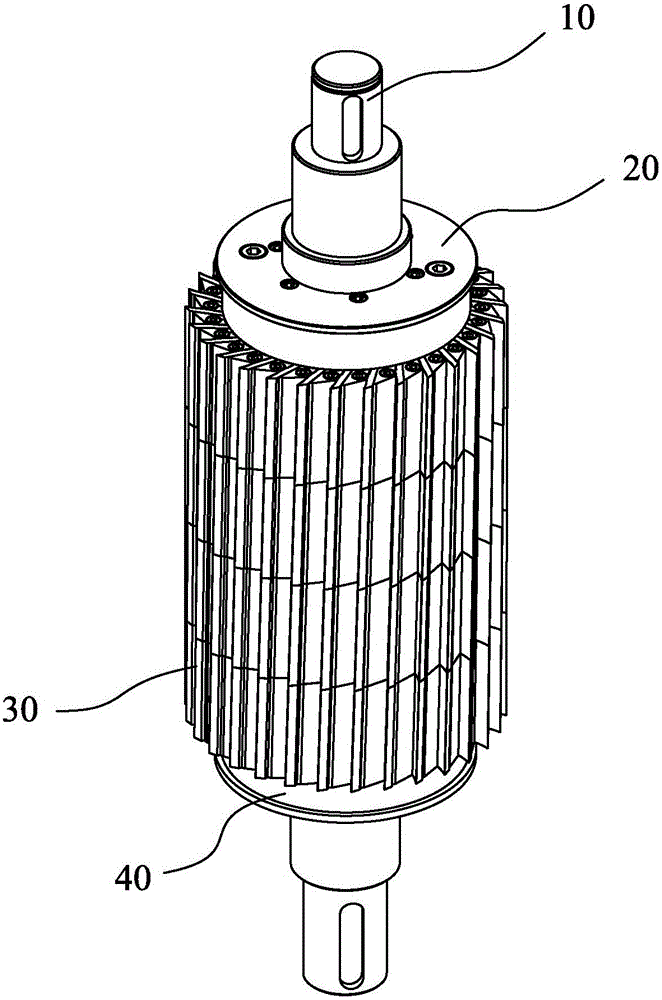

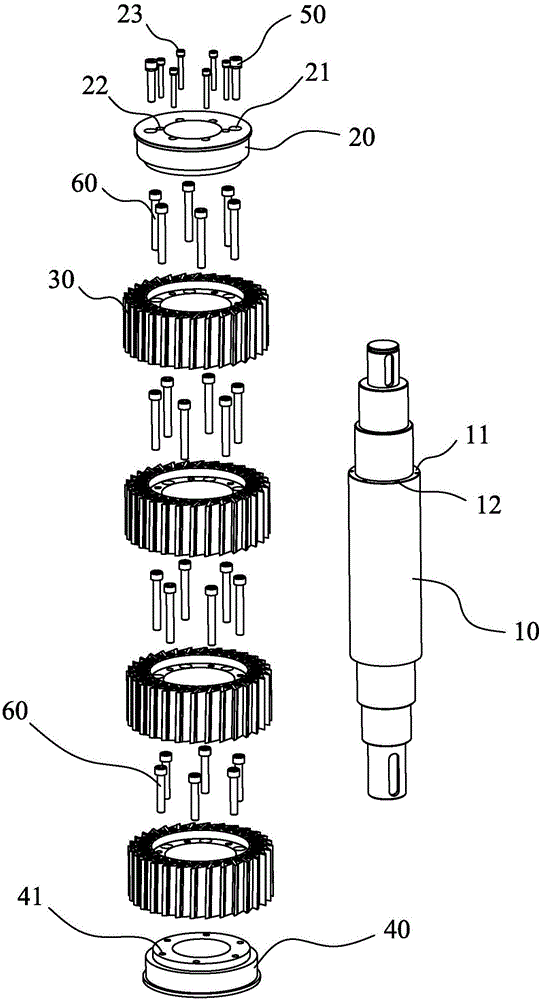

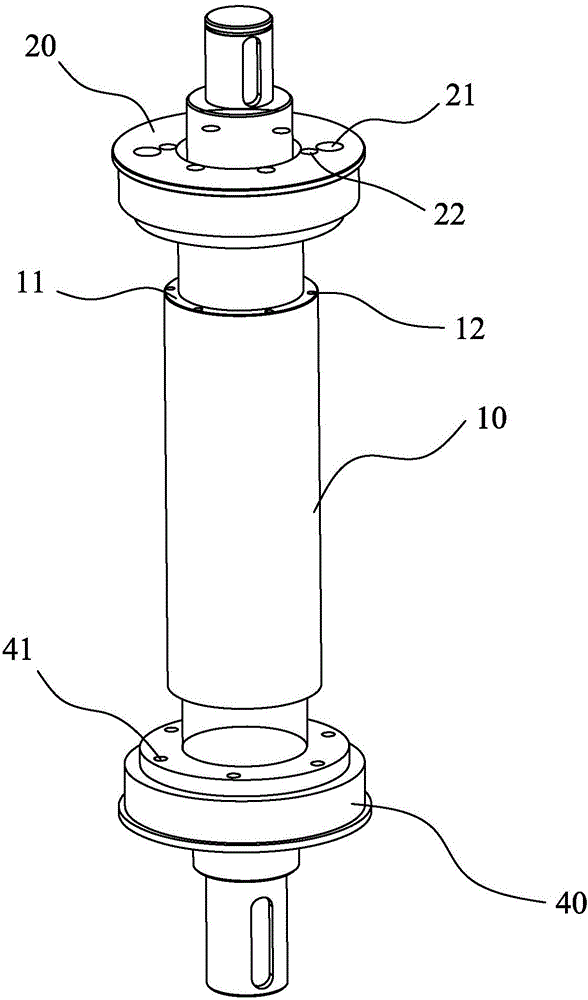

[0027] Such as Figure 1-7 As shown, a segmented splicing pelletizer hob includes a cutter shaft 10, a multi-section hob segment 30 arranged outside the cutter shaft 10, and front end covers 20 and rear end covers respectively arranged at the front and rear ends of the cutter shaft 10. 40, the outer wall of the front end of the cutter shaft 10 is provided with an annular stepped surface 11, the stepped surface is provided with a plurality of evenly distributed threaded holes 12, and the front end cover 20 is provided with the threaded holes 12 Corresponding to the through hole 22 , the front end cover 20 is fixed to the front end of the cutter shaft 10 by screwing the fastening bolt 23 through the through hole 22 and the threaded hole 12 . The hob segment 30 includes a cutter ring 31, a short blade 32 detachably fixed on the outer wall of the cutter ring 31, and a locking piece for fixing the short blade 32. The locking piece is provided with a locking part, and the short blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com