Composite coating PCBN cutting tool and preparation method thereof

A cutting tool, composite technology, applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of low service life, poor stability, loss of protection tools, etc., to improve toughness and internal, excellent Abrasion resistance and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

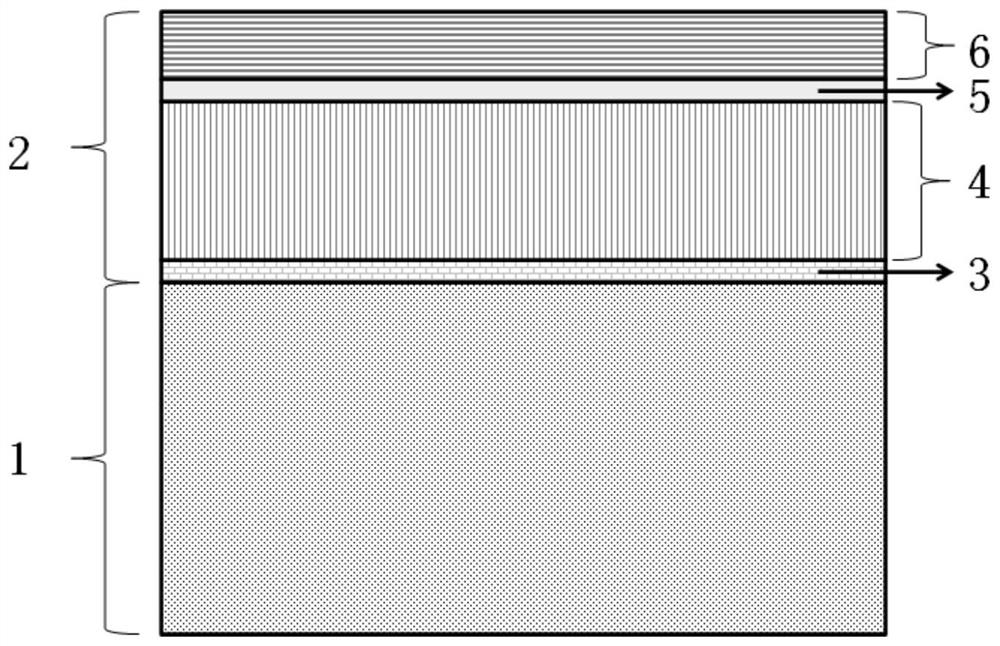

[0036] A kind of composite coating PCBN cutting tool of the present invention, as figure 1 As shown, the tool includes a PCBN tool base 1 and a composite coating 2 coated on the surface of the PCBN tool base 1. The composite coating 2 includes a first transitional hard layer 3 sequentially arranged from the inside to the outside, and a low-pressure CVD method Prepared Al x Ti 1-x C y N 1-y Coating 4, second transition hard layer 5 and Ti prepared by cathodic arc PVD method 1-a-b Al a Me b N coating 6, Al x Ti 1-x C y N 1-y In coating 4, x=0.91, y=0, Ti 1-a-b Al a Me b In N coating 6, a=0.3, b=0.06, Me is the element Si, ie Ti 1-a-b Al a Si b N.

[0037] In this embodiment, the first transitional hard layer 3 is a TiN layer prepared by CVD, and the second transitional hard layer 5 is a TiN layer prepared by cathodic arc PVD.

[0038] In this embodiment, the total thickness of the composite coating is 11.1 μm, the thickness of the first transitional hard layer 3...

Embodiment 2

[0070] A kind of composite coating PCBN cutting tool of the present invention, as figure 1 As shown, the tool includes a PCBN tool base 1 and a composite coating 2 coated on the surface of the PCBN tool base 1. The composite coating 2 sequentially includes a first transitional hard layer 3 and a low-pressure CVD method from the inside to the outside. Al x Ti 1-x C y N 1-y Coating 4, second transition hard layer 5 and Ti prepared by magnetron sputtering PVD method 1-a-b Al a Me b N coating 6, Al x Ti 1-x C y N 1-y In coating 4, x=0.83, y=0.01, Ti 1-a-b Al a Me b In N coating 6, a=0.42, b=0.08, Me is the element Si, namely Ti 1-a-b Al a Si b N.

[0071] In this embodiment, the first transition hard layer 3 is a TiN layer prepared by CVD method, and the second transition hard layer 5 is a TiN layer prepared by magnetron sputtering PVD method.

[0072] In this embodiment, the total thickness of the composite coating is 13.1 μm, the thickness of the first transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com