Biofragmentable straw and method for manufacturing same

A manufacturing method and biological technology, applied in the direction of table utensils, home utensils, table utensils, etc., can solve problems such as easy breakage, and achieve the effects of improving the brittleness of materials, wide utilization value, and improving impact resistance and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

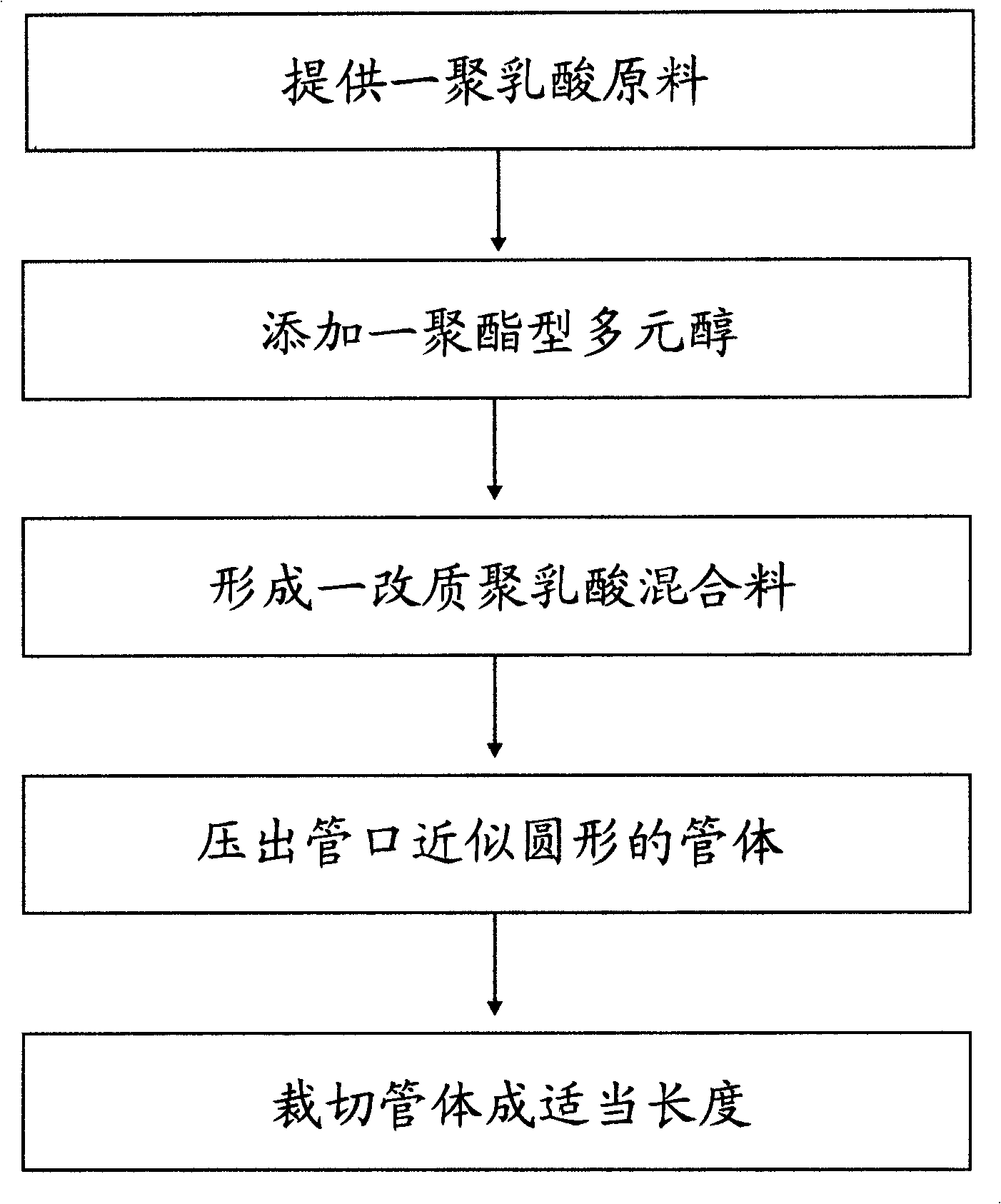

[0029] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the biodegradable straw and its manufacturing method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , manufacturing method, steps, features and effects thereof are described in detail as follows.

[0030] Due to the rigidity of polylactic acid (PLA) material and insufficient flexibility, the material used to make the straw needs to meet the requirement that the incision is not easy to break during manufacture, and can resist bending or external force when inserting the cup film during use. No fragmentation and other requirements. In order to modify the characteristics of PLA materials, it is necessary to add a modifier that increases flexibility. This modifier also needs to meet the conditions of biodegradabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com