All-ceramic wavelength division multiplexer and production method thereof

A wavelength division multiplexer and ceramic technology, which is applied in the field of all ceramic wavelength division multiplexers and its preparation, can solve the problems of fiber insertion loss, increased return loss, precise positioning of optical fibers, and the inability to produce high-precision full ceramic wavelength division Multiplexer and other issues, to achieve the effect of high concentration, regular shape, ultra-fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

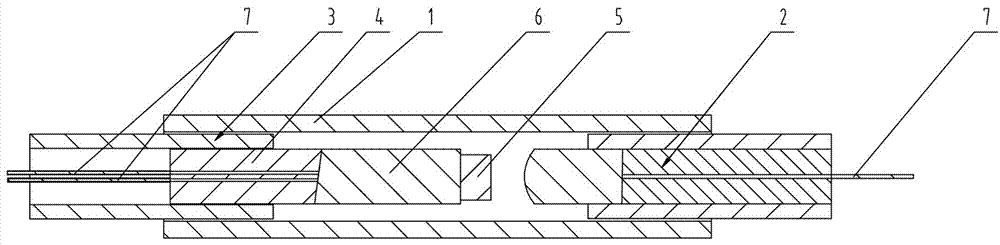

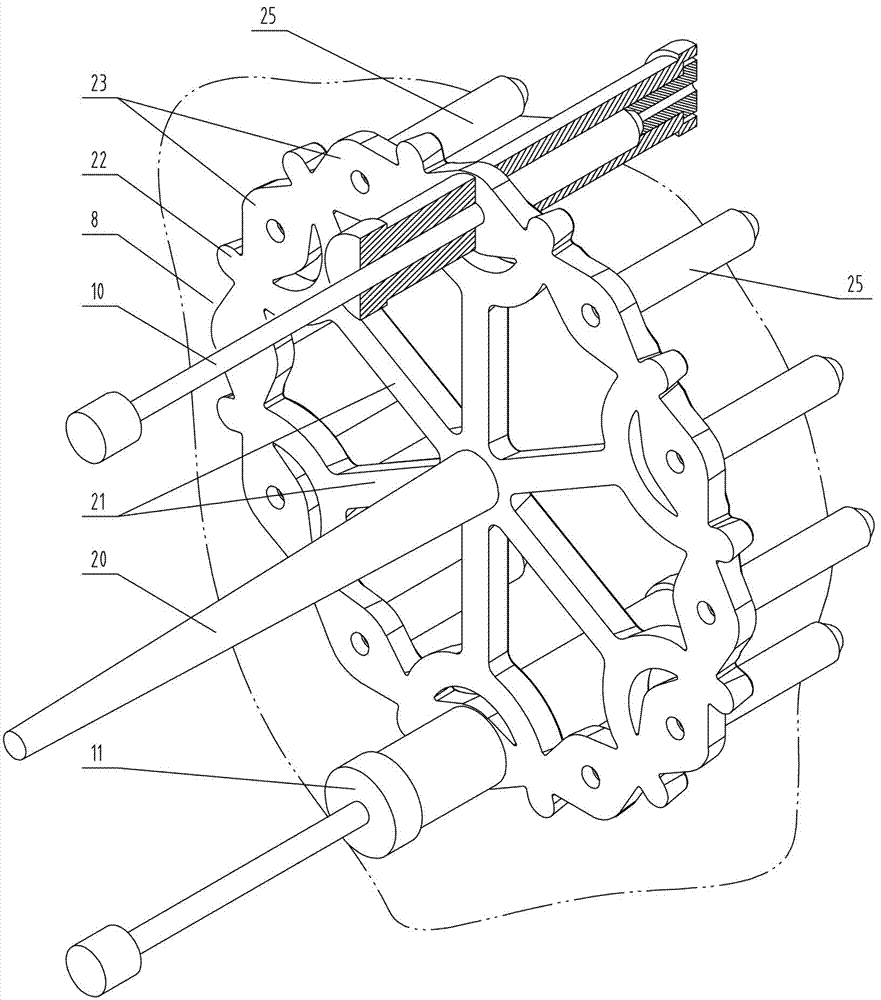

[0045] see figure 1 , Figure 8 , Figure 9 , an all-ceramic wavelength division multiplexer of the present embodiment has a sleeve 1, and a single-core optical fiber collimator 2 and a double-core optical fiber reflector 3 are housed in the sleeve 1. The wavelength division multiplexer, single-core optical fiber The sleeves used in the fiber collimator 2 and the dual-core fiber reflector 3 are made of ceramic materials, and the single-core ferrule used in the single-core fiber collimator 2 is a circular microporous ceramic ferrule , the dual-core ferrule used in the dual-core optical fiber reflector 3 is a special-shaped microporous ceramic ferrule 4 .

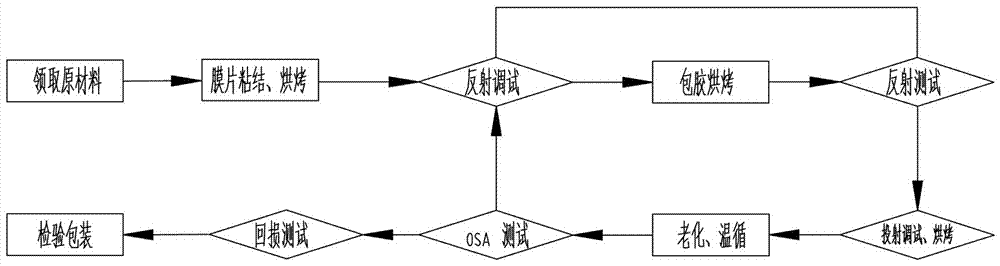

[0046] see figure 1 , figure 2 , Figure 8 , Figure 9 , a method for preparing an all-ceramic wavelength division multiplexer of the present embodiment consists of the following steps in turn:

[0047] (1) Diaphragm bonding: place the filter 5 on the plane of the G lens 6, apply a circle of UV glue at the junction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com