Patents

Literature

66results about How to "Extended processing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

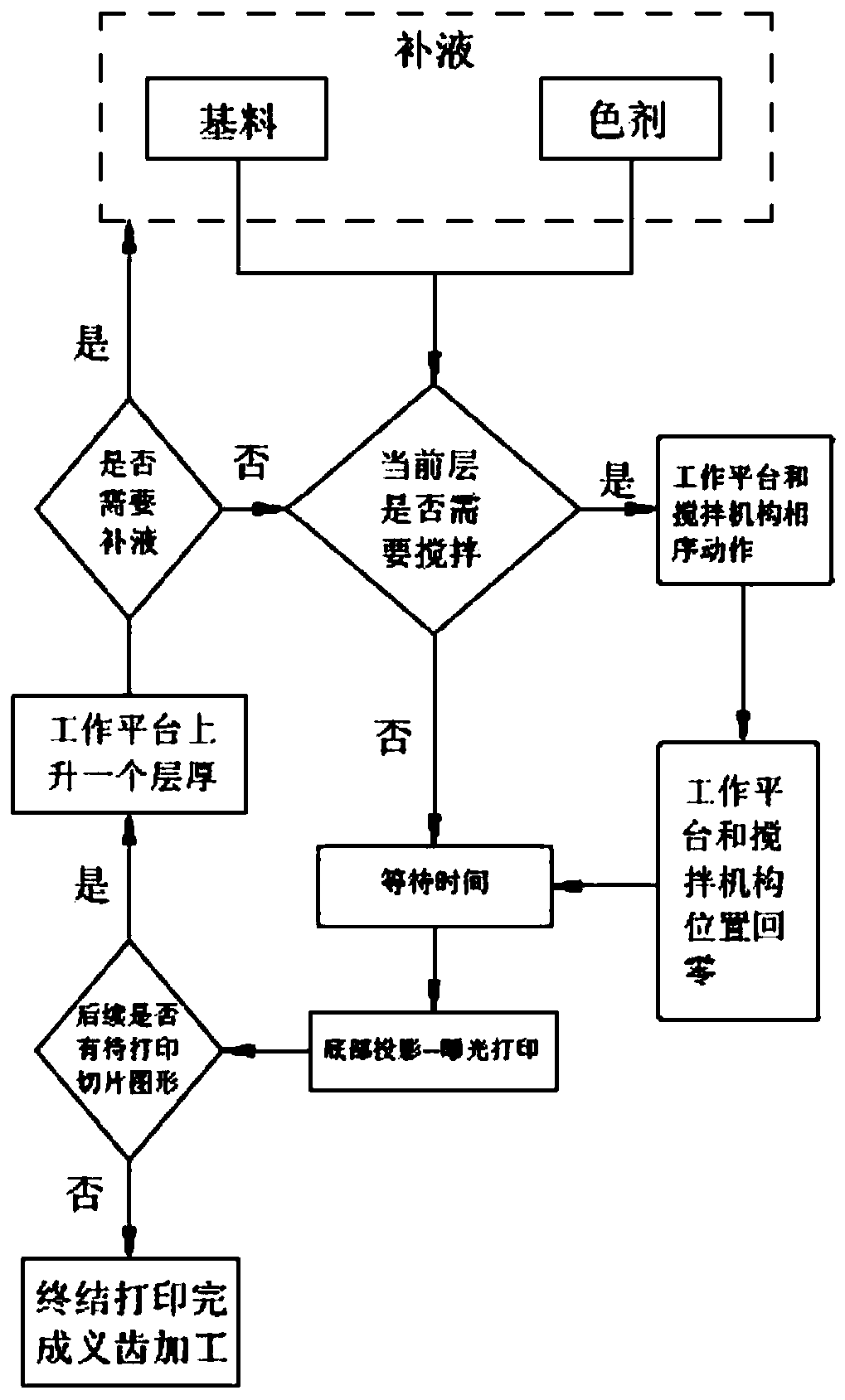

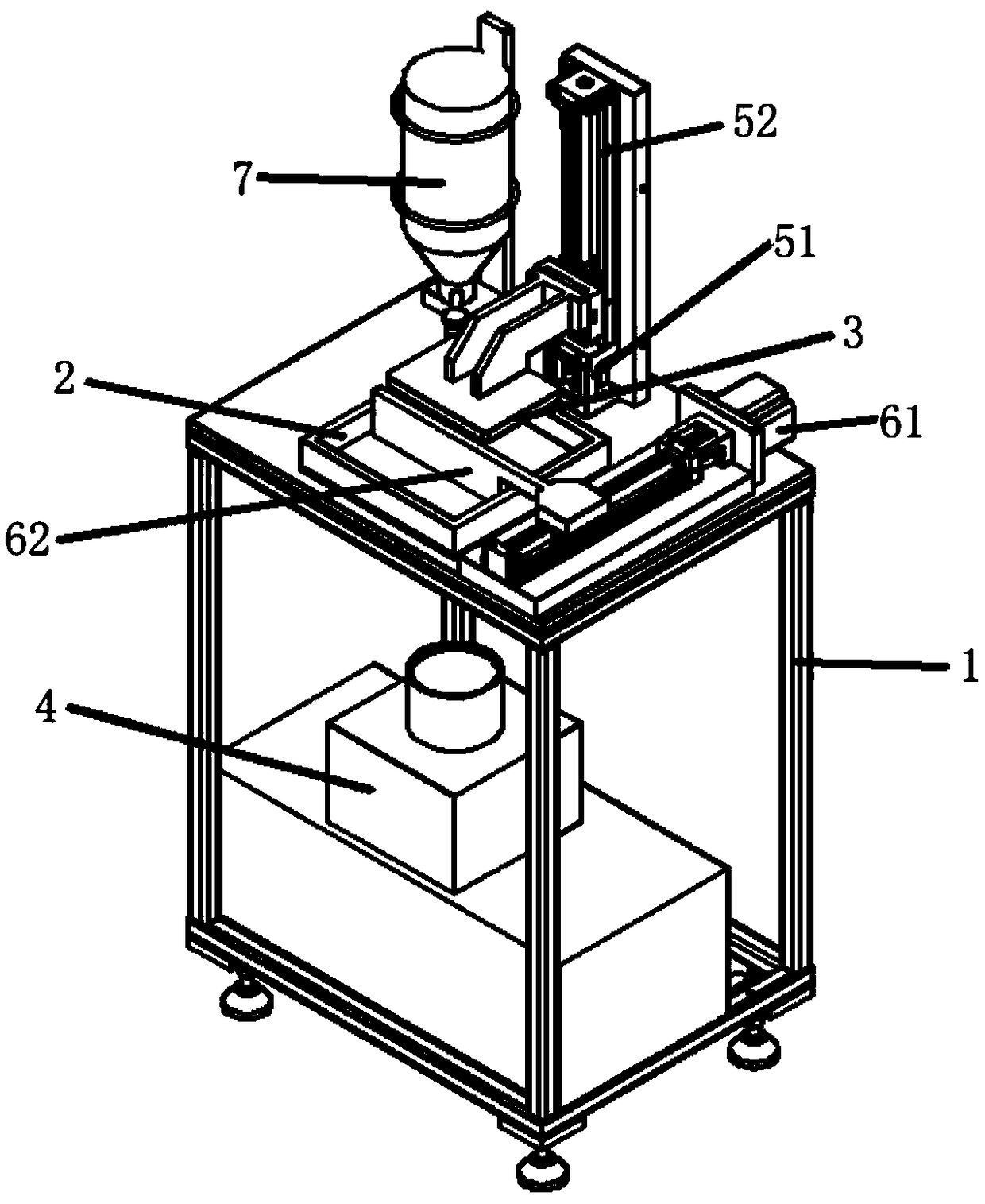

Method and device for ceramic denture 3D printing suitable for light curing molding

ActiveCN106217882AGuaranteed accuracyGuaranteed to mix evenlyAdditive manufacturing apparatusCeramic shaping apparatusData modelLight source

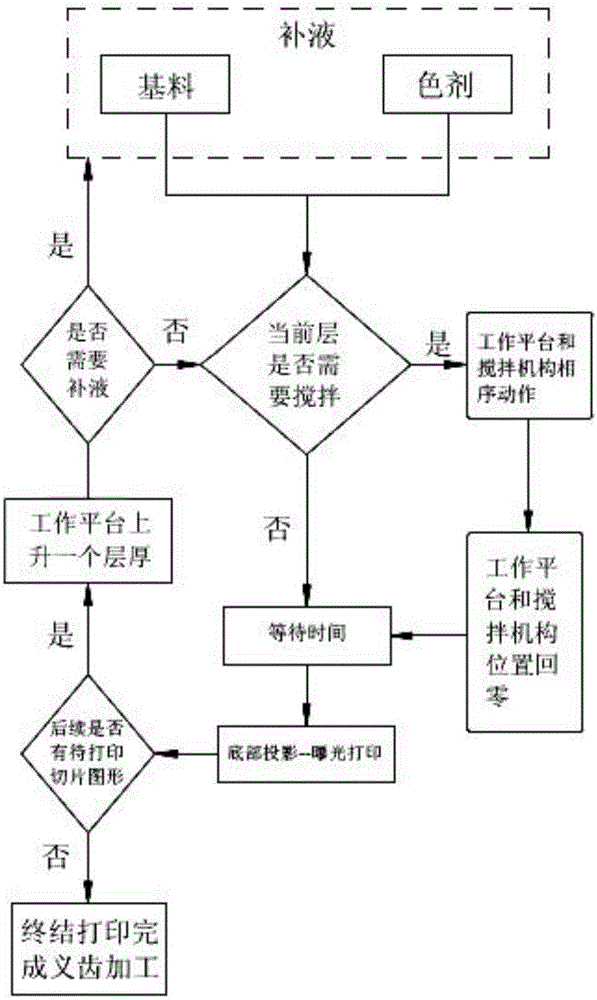

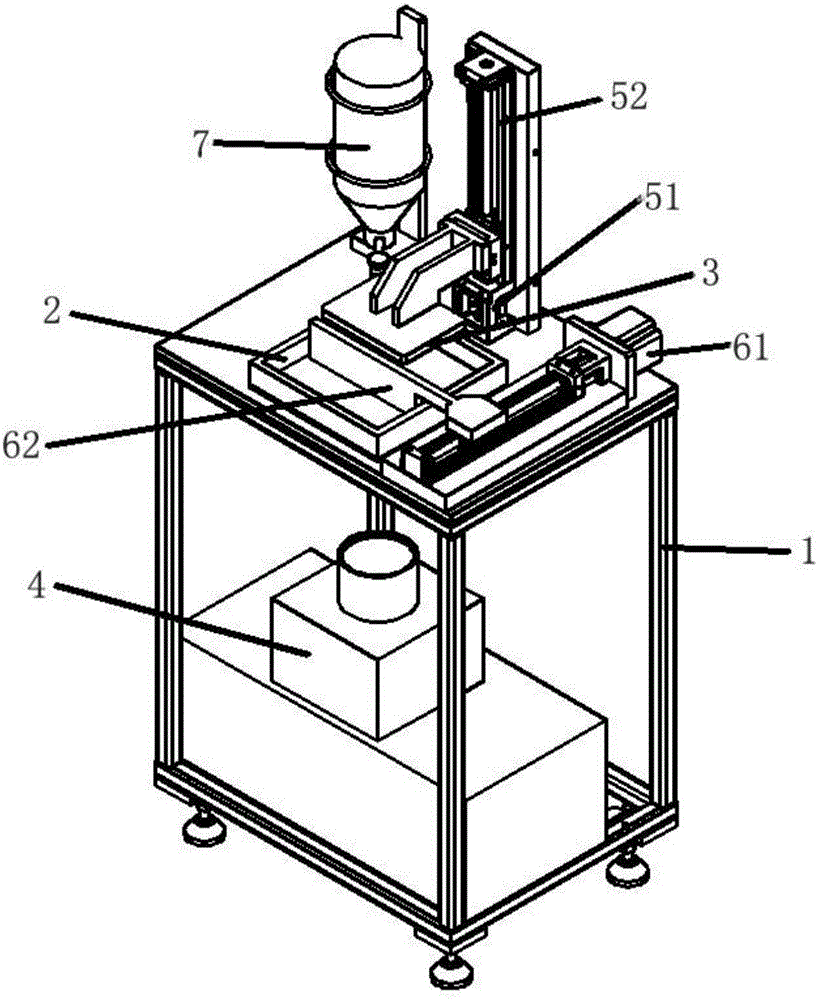

The invention relates to a method and device for ceramic denture 3D printing suitable for light curing molding and belongs to the technical field of tooth making. According to the method, through scanned tooth data and data processing, data of each layer of image after a data model to be printed is sliced are obtained and transmitted to a control system, a liquid supplementing action is controlled through the control system so that the liquid level of a base material can be always kept at the preset height, the base material is configured by photosensitive resin and ceramic powder according to the ratio, and the control system controls completion of stirring of supplemented liquid after liquid supplementing; and a bottom projection manner is adopted for printing, slice images of each layer of image are projected successively, light source exposure is conducted, and curing is completed layer by layer. The method and device have the beneficial effects that the making process is simple, the making efficiency is high, the consumption of materials is low, the making precision is high, and the match is good.

Owner:SHANGHAI UNION TECH

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

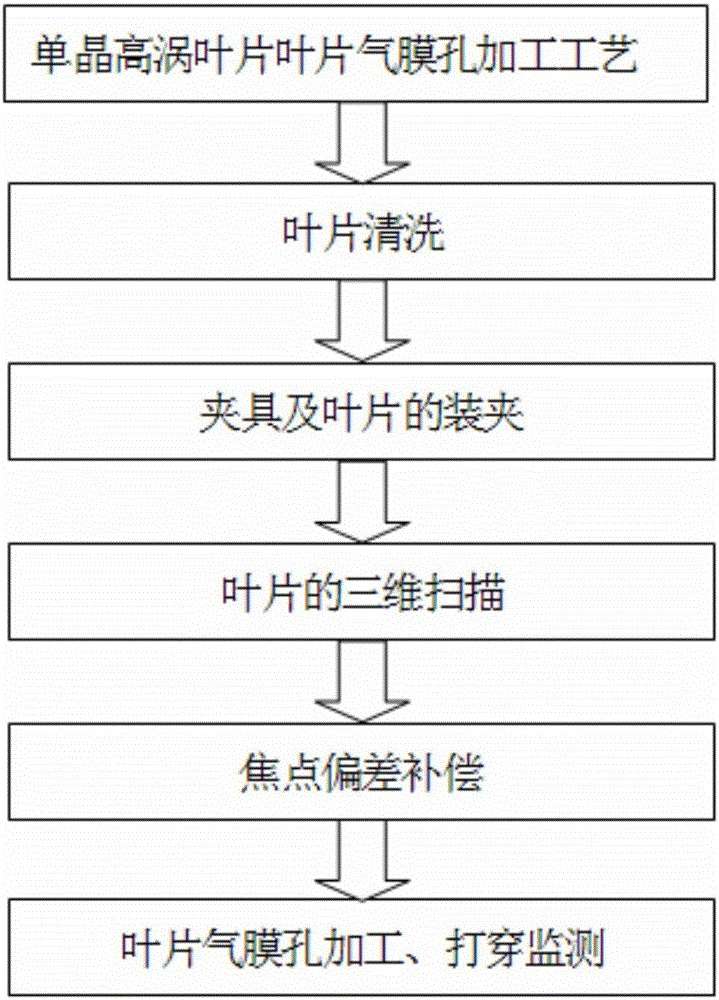

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

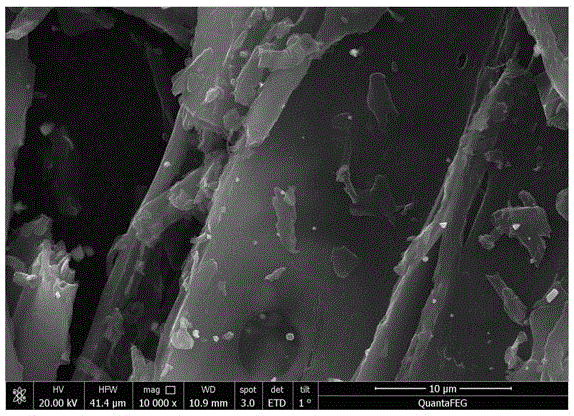

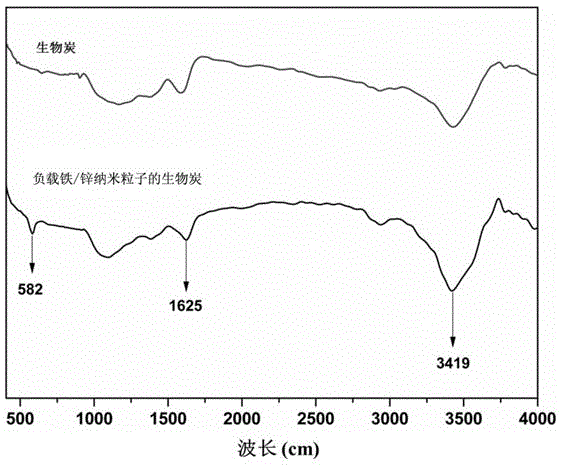

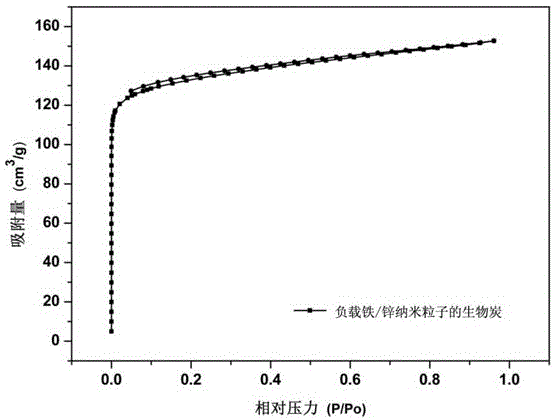

Biological charcoal loaded with iron/zinc nano-particles as well as preparation method and application thereof

ActiveCN106000311AIncrease the areaHigh pore volumeOther chemical processesWater contaminantsNitrophenolEnvironmental engineering

The invention discloses biological charcoal loaded with iron / zinc nano-particles as well as a preparation method and application thereof. The biological charcoal loaded with the iron / zinc nano-particles comprises biological charcoal, iron nano-particles and zinc nano-particles; the iron nano-particles and the zinc nano-particles are loaded in the surface and micro-pores of the biological charcoal. The preparation method takes the biological charcoal as a carrier and the iron nano-particles and the zinc nano-particles are loaded on the biological charcoal through a front immersion method; the prepared biological charcoal loaded with the iron / zinc nano-particles has relatively good magnetism, more functional groups and relatively large specific surface area and pore volume, can be used for rapidly and effectively removing p-nitrophenol in a water body and has the advantages of great adsorption amount, strong adsorption capability, high adsorption efficiency, simplicity in operation and the like.

Owner:HUNAN UNIV

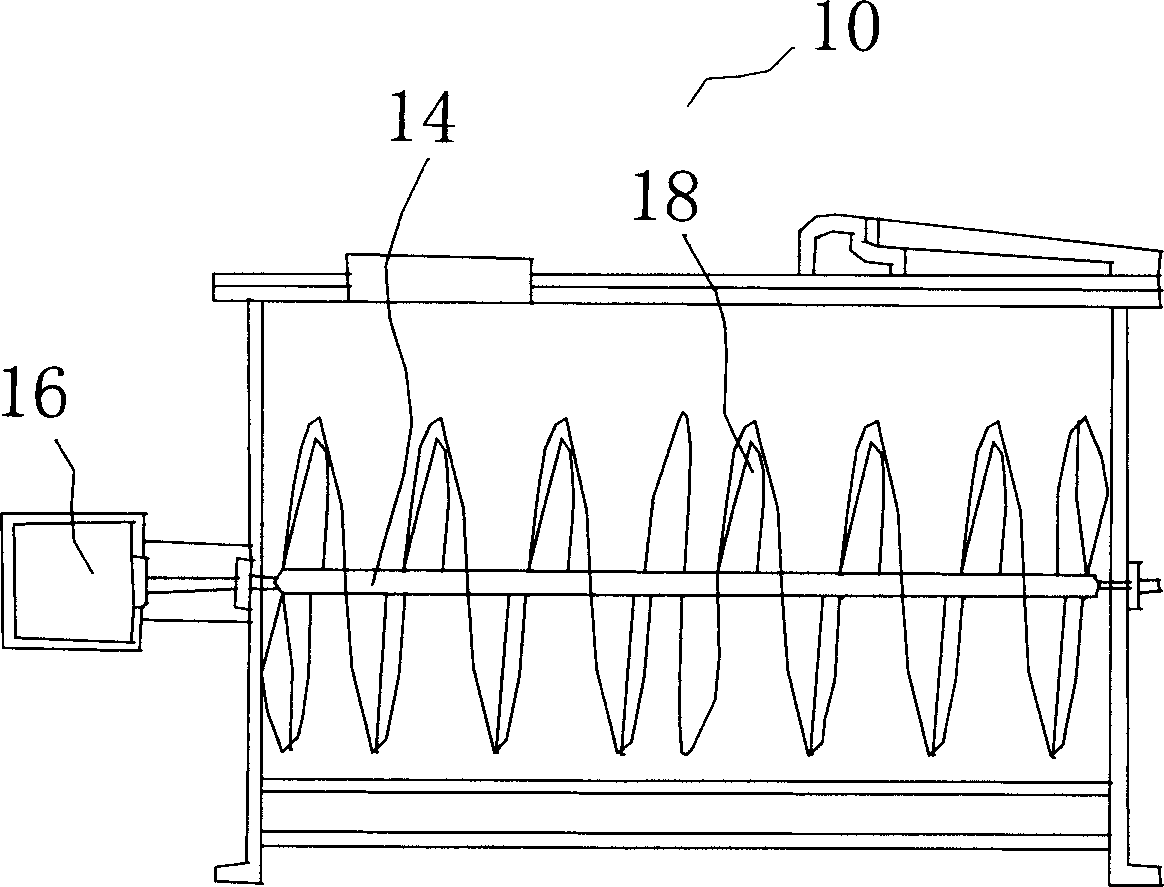

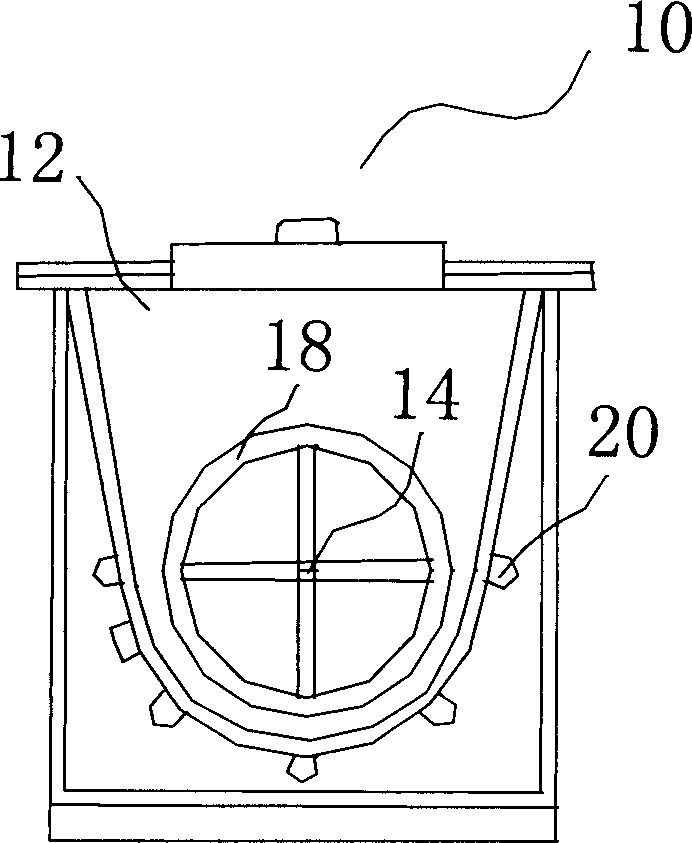

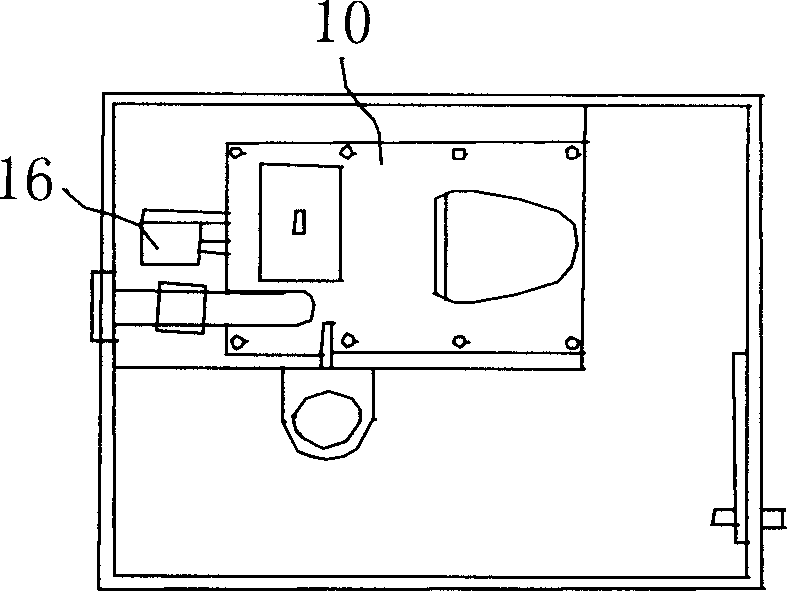

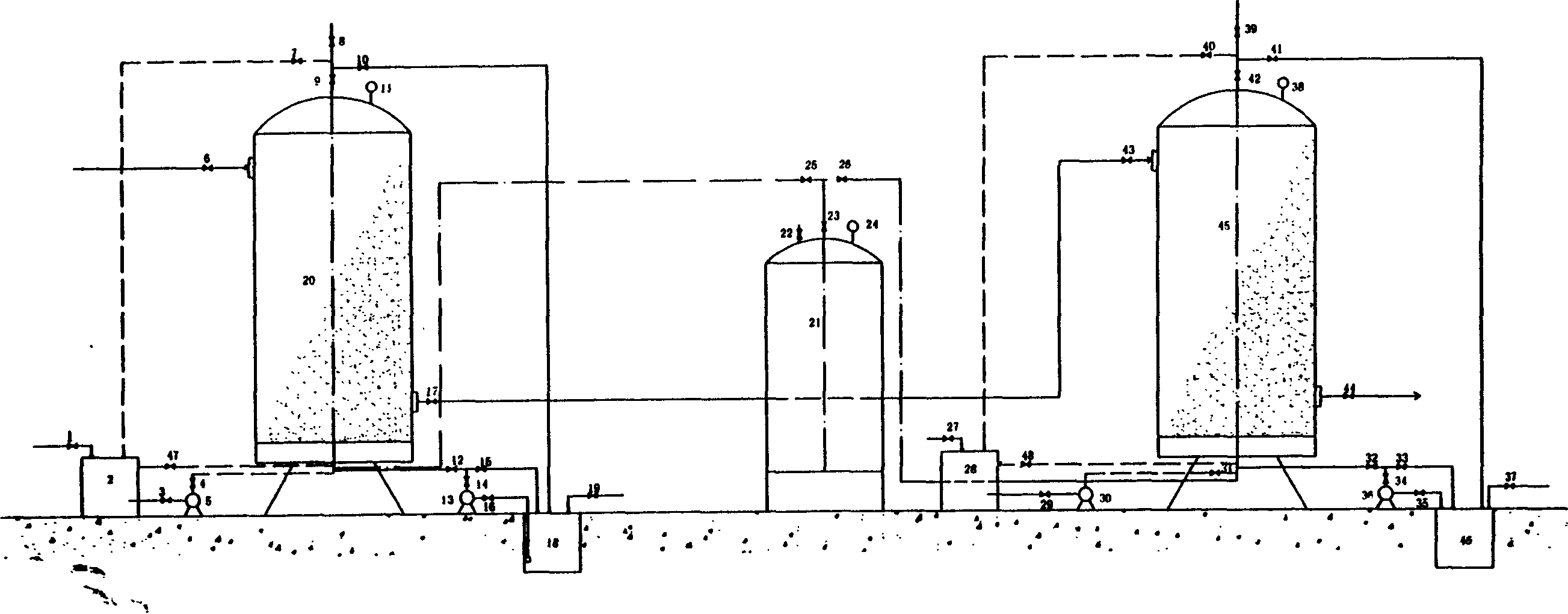

Treatment apparatus for excrement and a bio-toilet using the same and a treatment method for excrement

InactiveCN1735367ABreed fastPromote decompositionSolid waste disposalFlushing devicesTemperature controlSludge

The invention discloses a treatment apparatus for the excrement and a bio- toilet using the treatment apparatus. The treatment apparatus includes a tank, a reactor basin in the tank for containing the raw material and the excrement and having at least two parallel, concave parts having curved profile in the bottom part of the tank, a temperature control means for maintaining the temperature of the basin at a predetermined range; and at least two mixing devices which match with the at least two concave parts, each of them can rotate around a rotation shaft, the helical blade stirrer secured to the rotation shaft by a plurality of spokes. The bio-toilet is waterless, and thus a large quantity of water can be saved and the pollution of the environment due to the drainage of sewage can be avoided. Furthermore, treated by the treatment apparatus of the present invention, the microorganisms and the organic materials are combined and converted into stable loosen soil and the organic components. The load applied to the environment will be decreased and the environmental protection will be most effective by using the bio-toilet of the present invention.

Owner:童铭棻

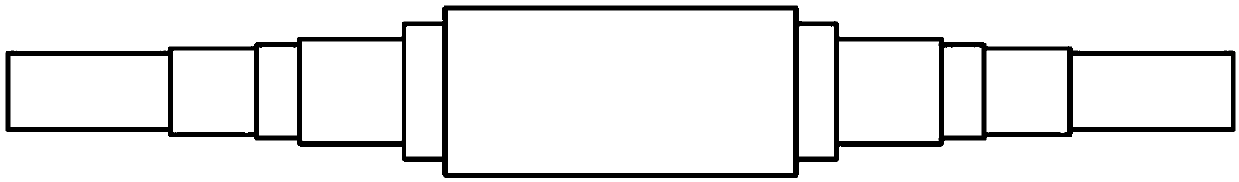

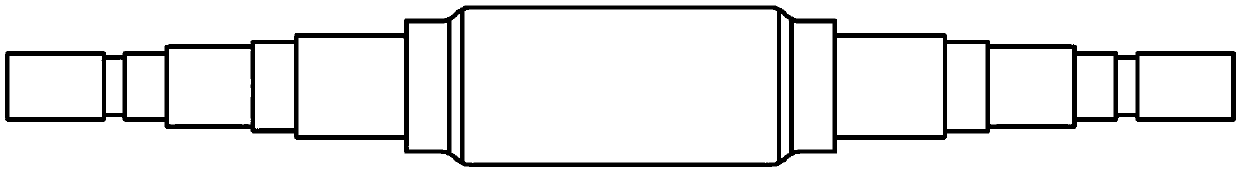

Aluminium (zirconium)-carbon long nozzle, submerged entry nozzle and monolithic stopper refractory products for continuous casting

Aluminium (zirconium)-carbon long nozzle, submerged entry nozzle and monolithic stopper refractory products for continuous casting are prepared by taking corundum, flake graphite, light-burnt alumina, fused mullite-zirconia, fused stabilized zirconia, silicon carbide and silicon powder as the raw refractory materials and phenolic resins as the adhesives through the procedures of material mixing, cold isostatic pressing, fine lathing and anti-oxidization coating spreading. The refractory products dispense with the high-temperature burning process, lower the cost per ton, reduce the labor intensity and speed up the processing cycle.

Owner:王世泰

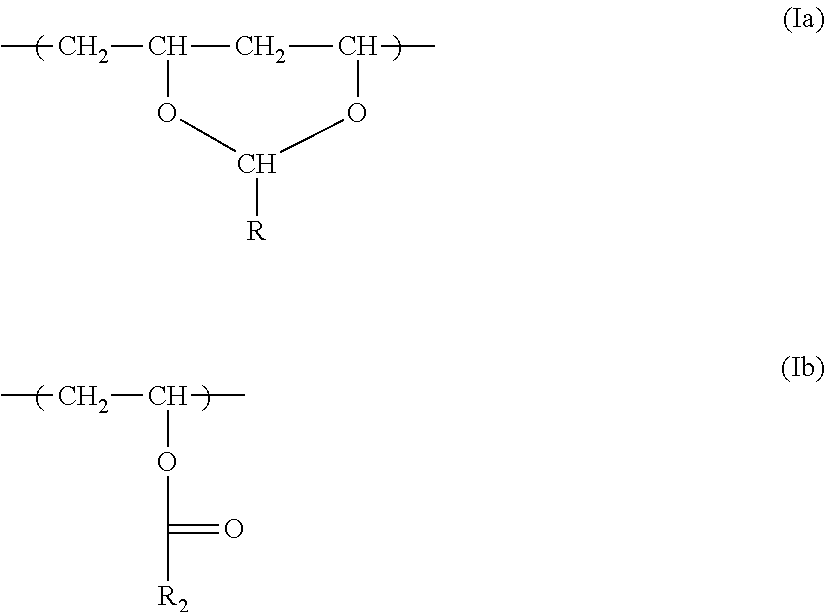

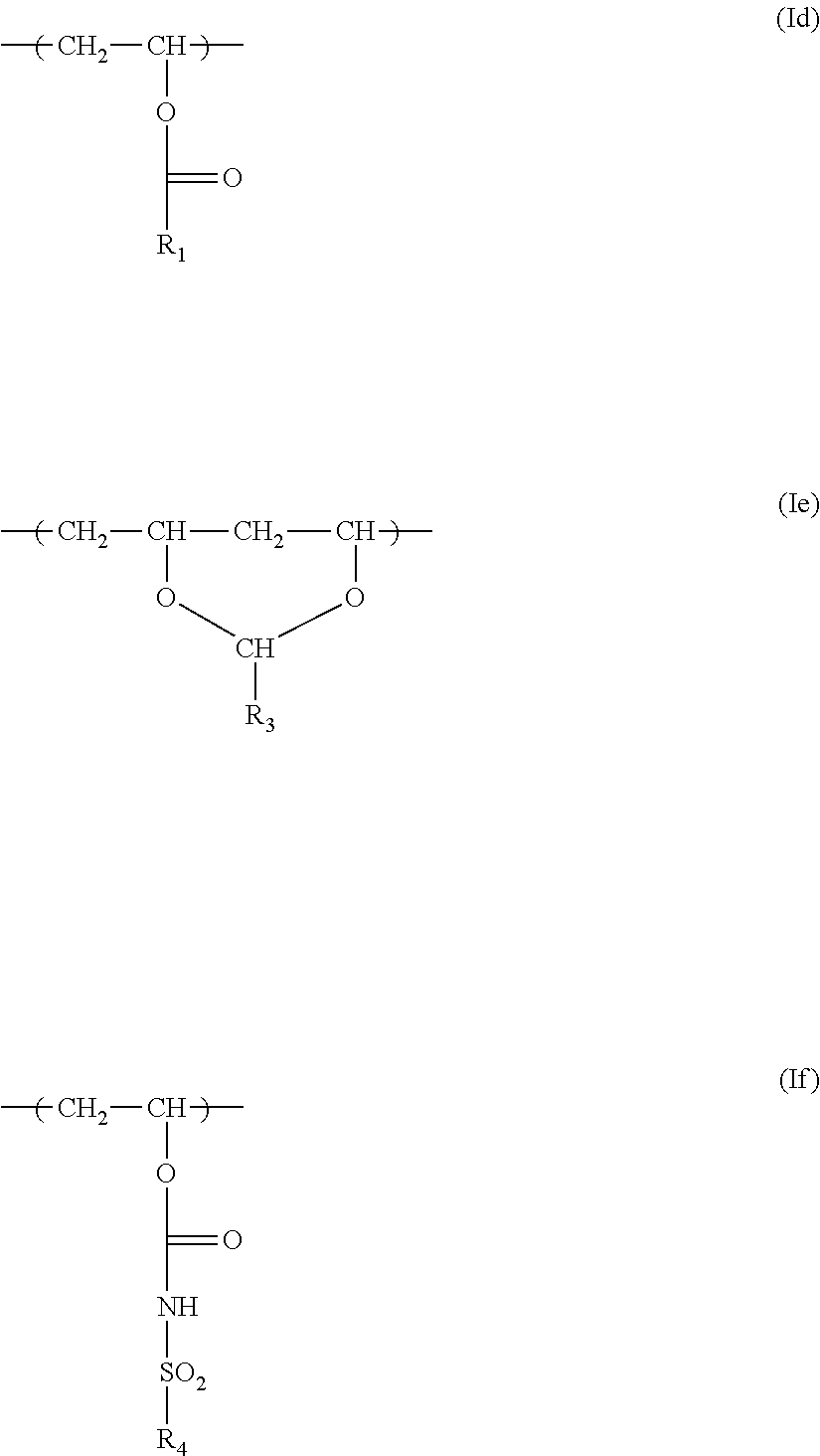

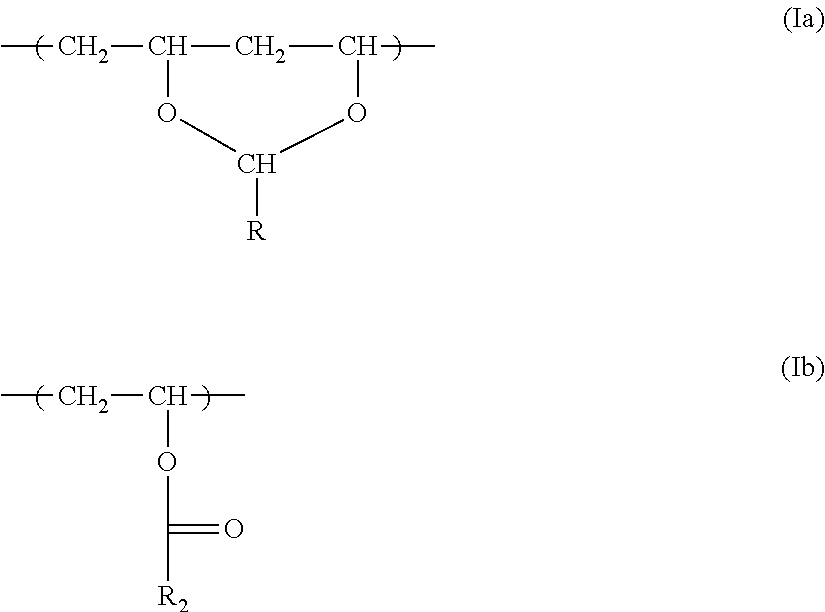

Silicate-free developer compositions

ActiveUS20120129095A1Improve compositionPrevent precipitationPhotosensitive materialsSemiconductor/solid-state device manufacturingZinc cationComplex formation

A silicate-free alkaline aqueous developer composition has a pH of at least 12 and comprises a metal cation M2+ selected from barium, calcium, strontium, and zinc cations, and a chelating agent that has a complex formation constant (log K) for the metal cation of at least 3.5 and less than or equal to 4.5, and a log K for aluminum ion that is 7 or less. This developer composition can be used to process positive-working lithographic printing plate precursors to provide lithographic printing plates.

Owner:EASTMAN KODAK CO

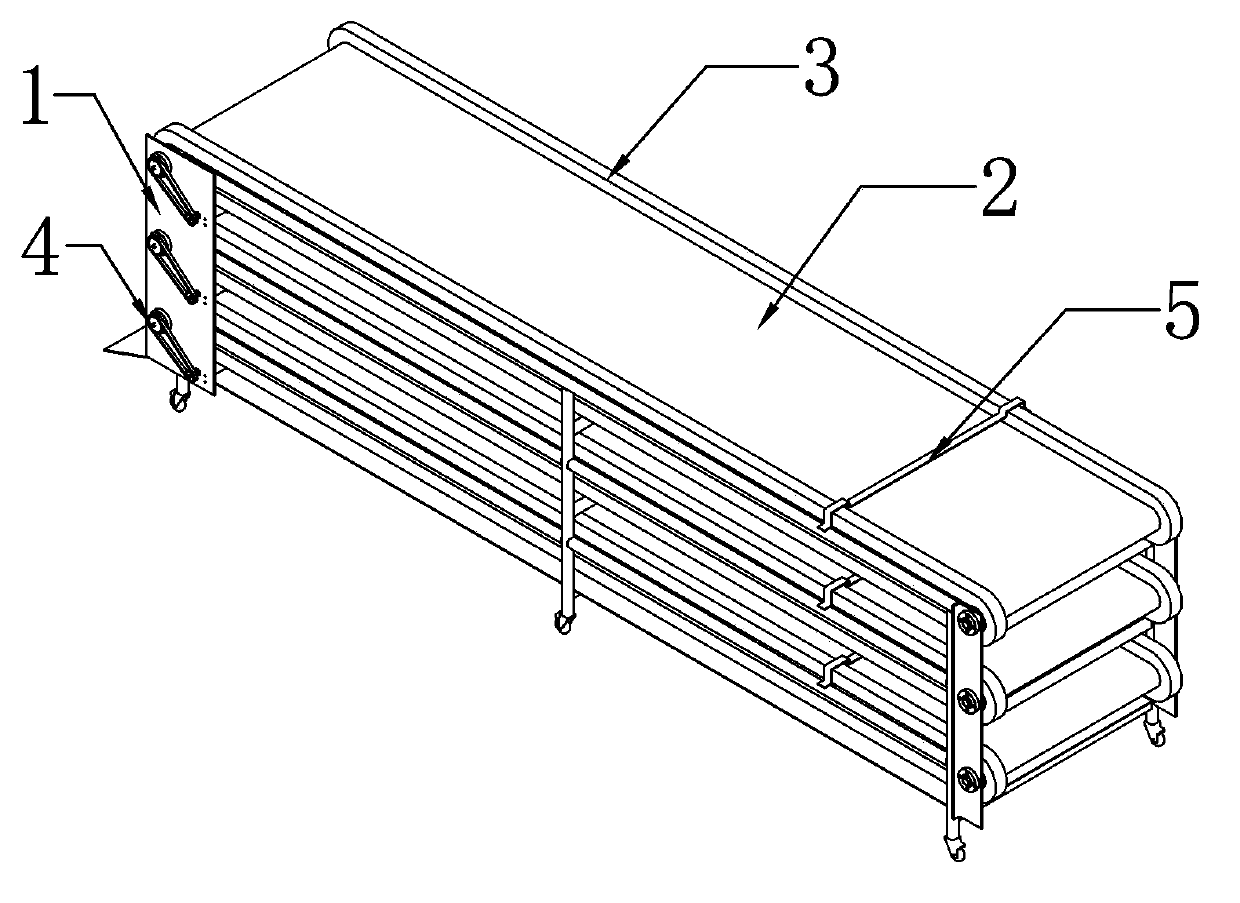

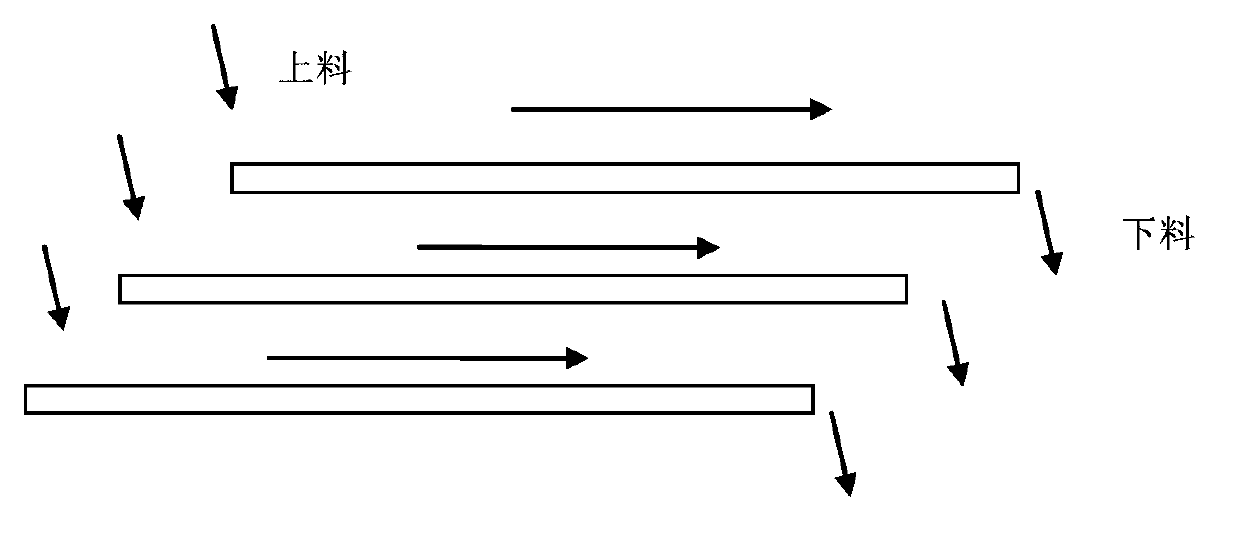

Layered parallel translation type solid organic waste biological treatment bed, and application method thereof

InactiveCN103864475APrevent escapeSmall footprintClimate change adaptationOrganic fertilisersParallel translationEnergy consumption

The invention discloses a layered parallel translation type solid organic waste biological treatment bed. The layered parallel translation type solid organic waste biological treatment bed, and applications thereof comprises a layered frame; each layer of the layered frame is provided with a transmission belt, and a transmission device which is connected with the transmission belt via transmission connection; the two sides of each transmission belt are provided with raised skirt edges. The invention also discloses an application method of the layered parallel translation type solid organic waste biological treatment bed. According to the application method, solid organic waste is delivered into a premixer, and plant material powder and hermetia illucens larvas are delivered into the premixer; an obtained mixture is subjected to transformation for 1 to 2 days on the layers, and then discharging is carried out so as to collect the mixture by a container under the layered frame. The layered parallel translation type solid organic waste biological treatment bed is capable of reducing occupied area, increasing treatment efficiency, shortening treatment cycle, reducing energy consumption, and is convenient for operation and maintenance; treatment is complete; and no secondary pollution is caused.

Owner:深圳市腾浪再生资源发展有限公司

Machining method for utilizing radial forging machine for producing multi-step cold-rolled work roller blank

ActiveCN108672625AReduce manufacturing costReduce blank process weightForging hammersFurnace typesSurface cleaningWater cooling

The invention discloses a machining method for utilizing a radial forging machine for producing a multi-step cold-rolled work roller blank, and belongs to the technical field of metallurgical machinemanufacturing. After electric furnace smelting, LF furnace refining and VD vacuum treatment, fire cutting, annealing, surface shot blasting, coal gas baking and electroslag remelting are conducted tomanufacture an MC6B multi-step cold-rolled work roller blank electroslag ingot; then, annealing and surface cleaning are conducted, and the gas furnace heating heat preservation time is larger than orequal to 24 h; then, arc upsetting plate upsetting, first-time furnace returning heating, upper flattening, lower V-shaped anvil drawing-out, second-time furnace returning heating and radial forgingmachine forging are conducted to manufacture an MC6B multi-step cold-rolled work blank roller blank; and finally, hot saw cutting, normalizing after water cooling, two-segment type spheroidizing annealing and nondestructive inspection checking are conducted, and the radial forging machine is utilized for producing the multi-step cold-rolled work roller blank. According to the machining method, forge piece allowance of a produced roller blank forge piece is small, the machining time is shortened, accordingly, the forge piece technology weight is reduced, and the manufacturing cost is saved.

Owner:建龙北满特殊钢有限责任公司

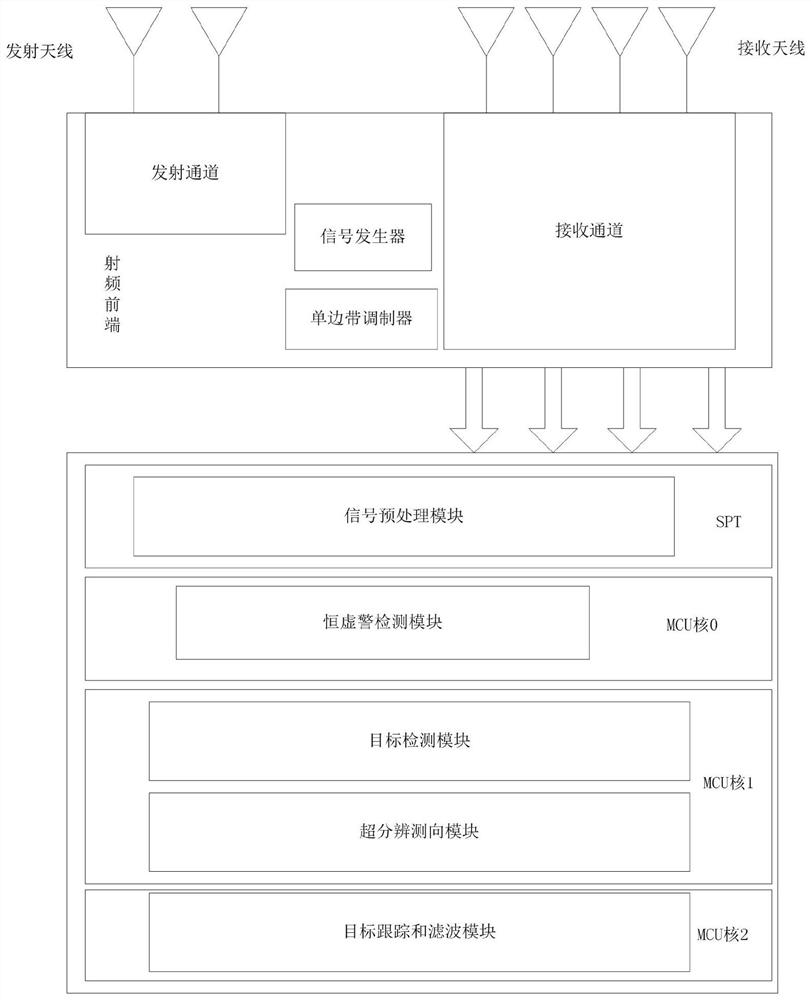

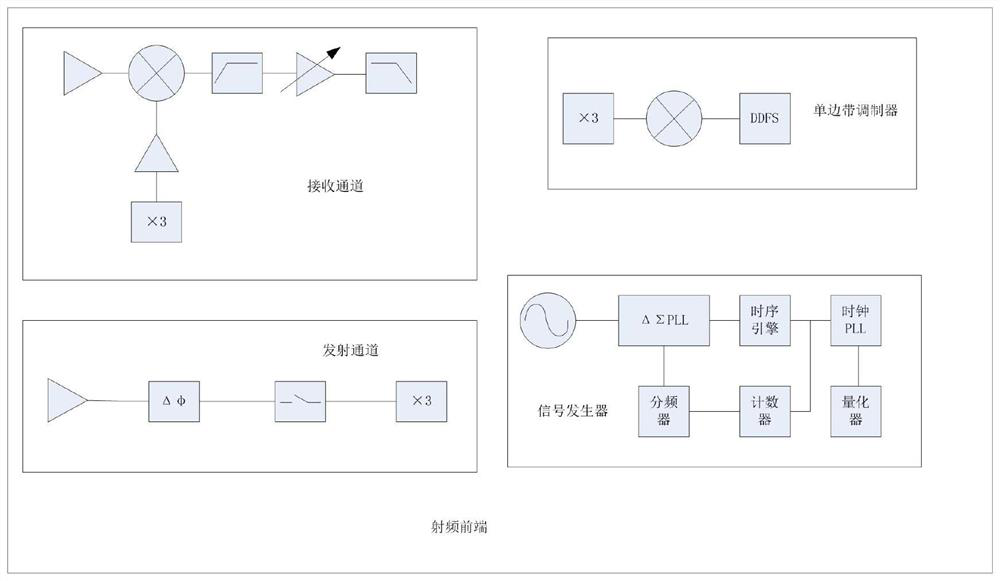

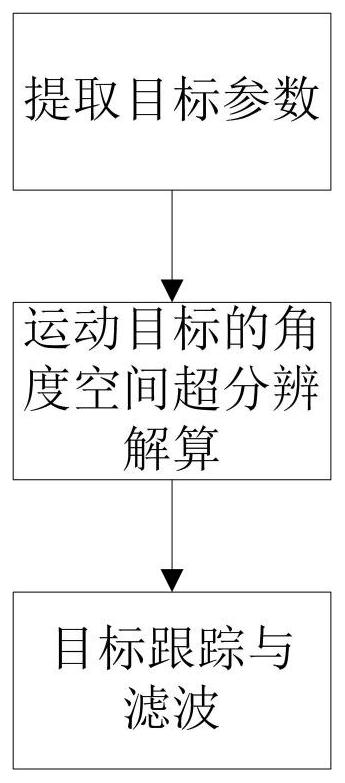

Rapid super-resolution tracking system and method for automobile millimeter-wave radar

PendingCN111896947AMeet real-time requirementsExtended processing cycleRadio wave reradiation/reflectionRadarMillimetre wave

The invention relates to the technical field of radars, in particular to a rapid super-resolution tracking method for an automobile millimeter-wave radar. The system comprises a planar array antenna,a radio frequency front end, a signal preprocessing module, a constant false alarm detection module, a target detection module, a super-resolution direction finding module and a tracking processing module. By means of the angle measurement and target detection tracking method of the system, the MIMO array radar can have the target super-resolution capacity on the basis of rapid direction finding,the requirement of the automobile millimeter wave radar for real-time performance is met, and the processing period is prolonged.

Owner:镇江盛益系统科技有限公司

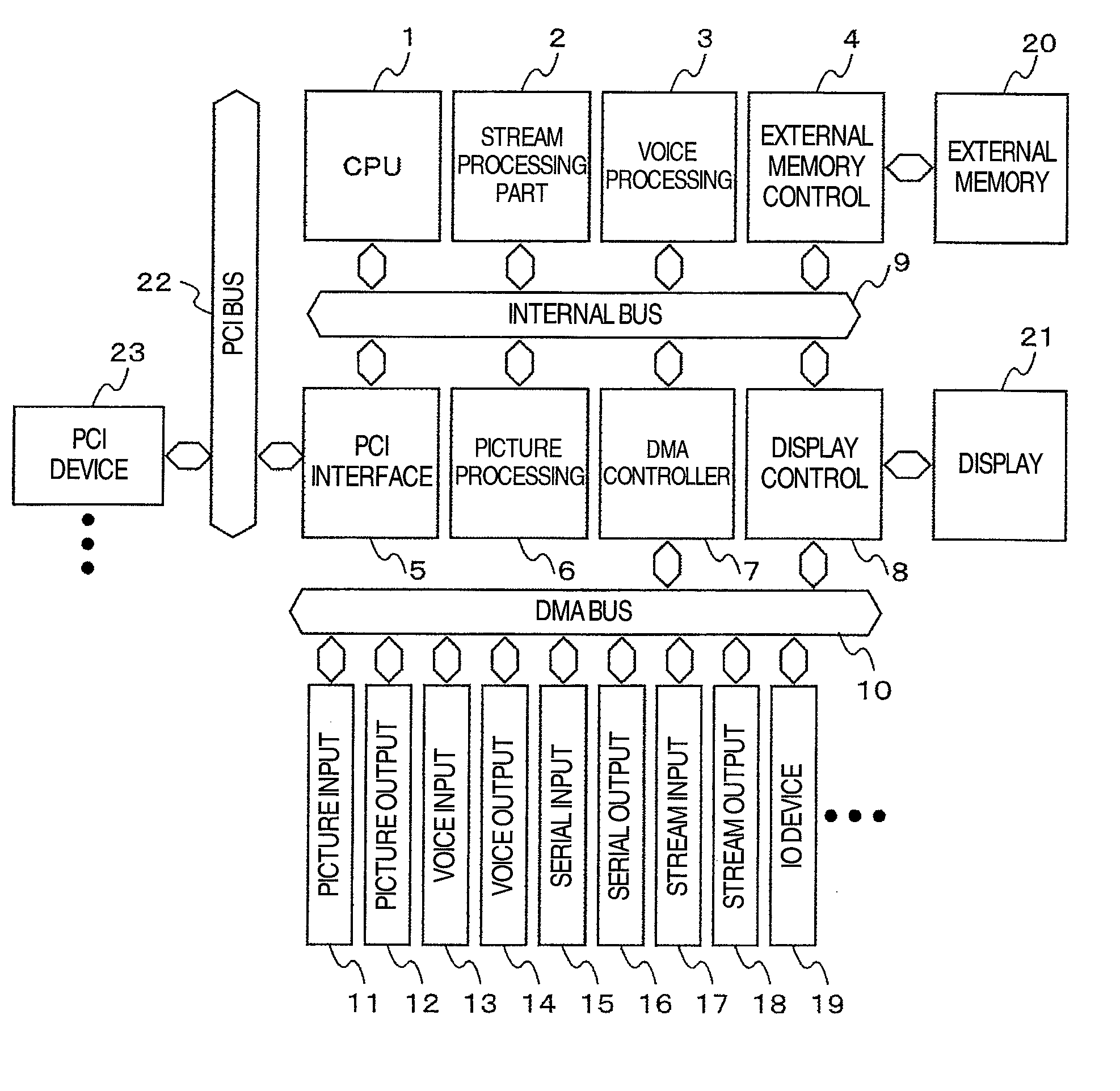

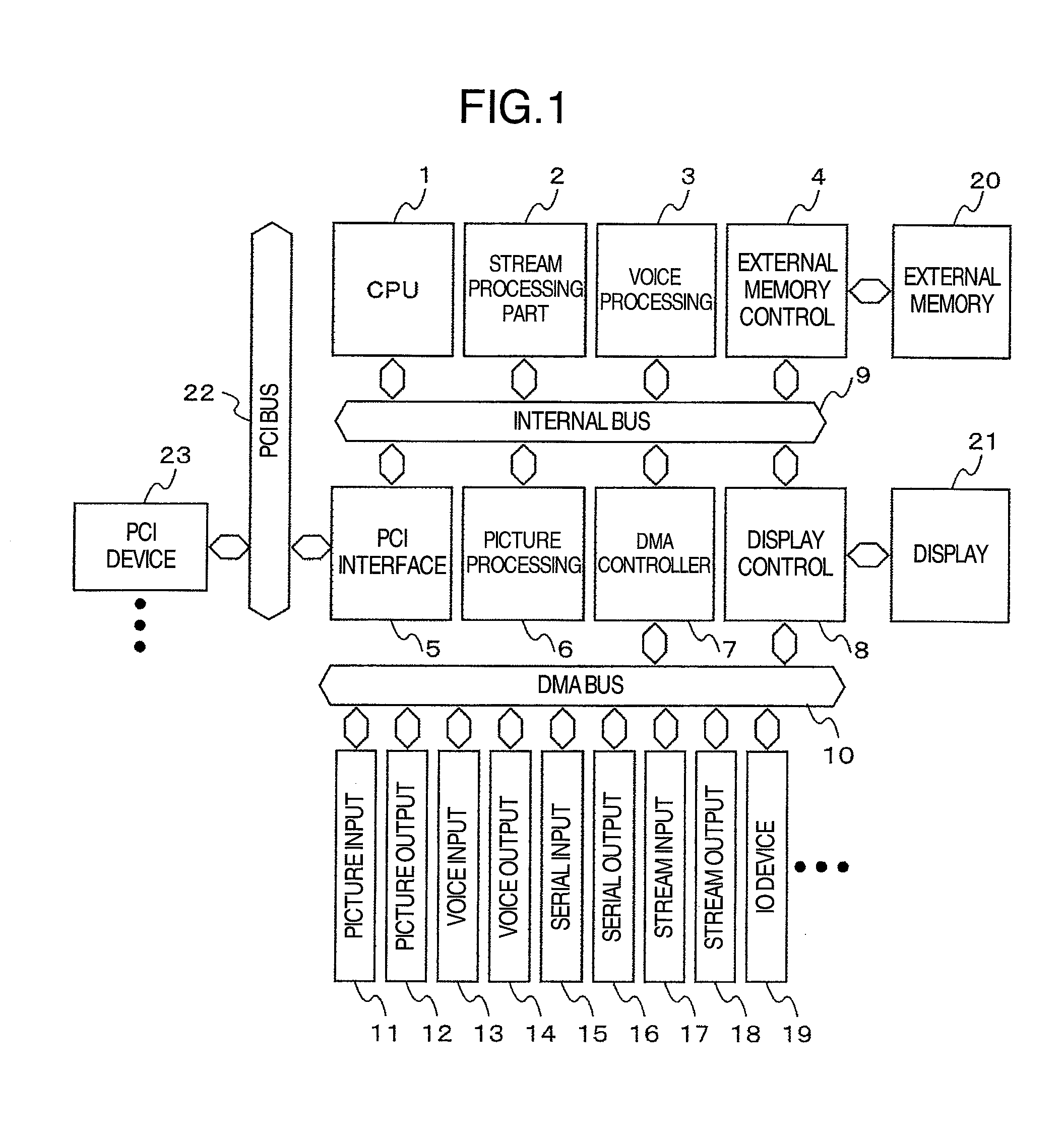

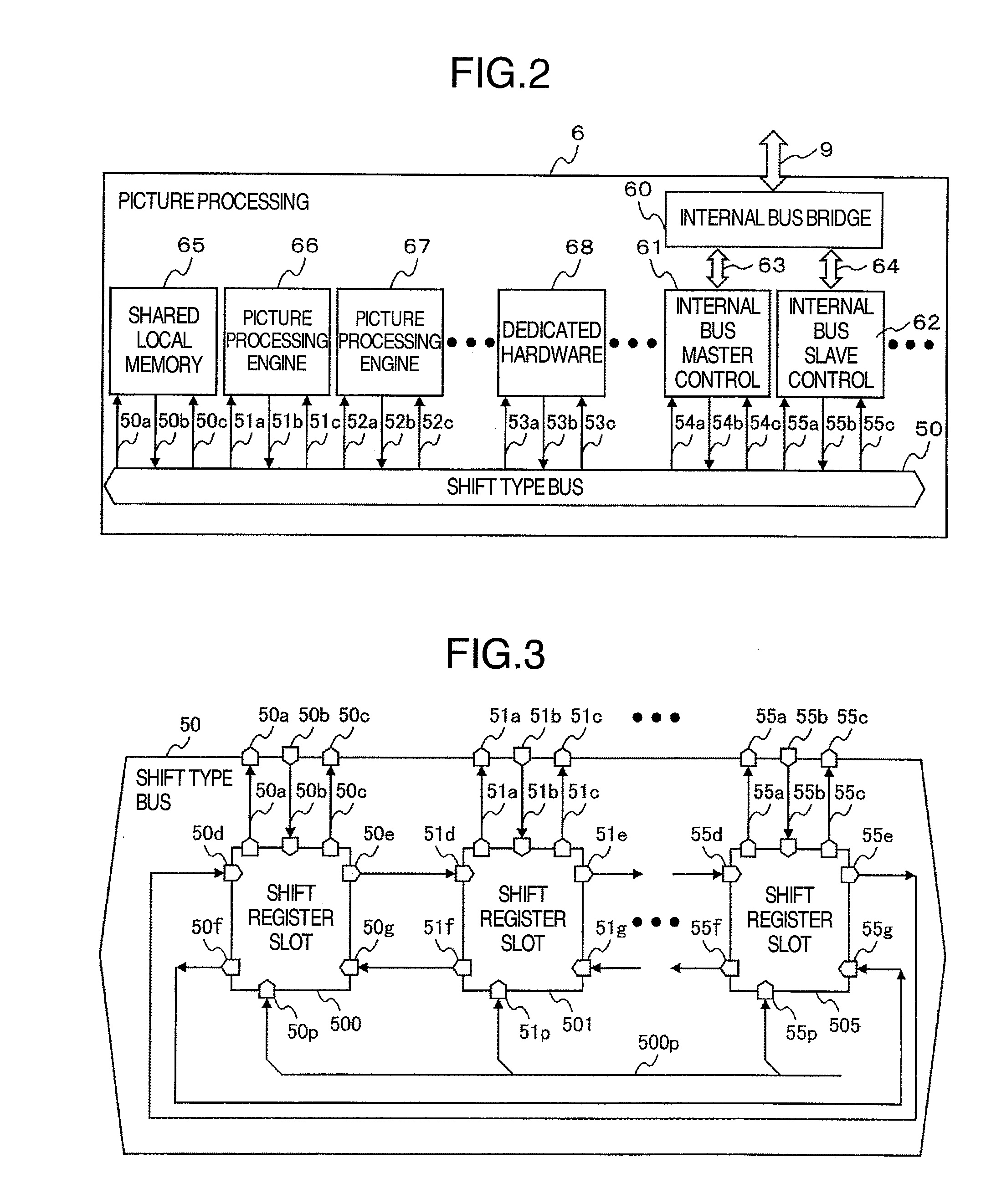

Picture Processing Engine and Picture Processing System

InactiveUS20070294514A1Reduce power consumptionReduce in quantityGeneral purpose stored program computerMultiple digital computer combinationsInstruction memoryImaging processing

To provide a technique to reduce power consumption when carrying out image processing by processors. For the purpose of this, for example, a means for specifying a two-dimensional source register and destination register is provided in an operand of an instruction, and the processor includes a means which executes calculation using a plurality of source registers in a plurality of cycles and obtains a plurality of destinations. Moreover, in an instruction to obtain a destination using a plurality of source registers and consuming a plurality of cycles, a data rounding processing part is connected to a final stage of a pipeline. With such configurations, the power consumed when reading an instruction memory is reduced by reducing the access frequency to the instruction memory, for example.

Owner:RENESAS ELECTRONICS CORP

Silicate-free developer compositions

ActiveUS8530143B2Extended processing cycleSimple compositionPhotosensitive materialsSemiconductor/solid-state device manufacturingAluminum IonAlkaline water

A silicate-free alkaline aqueous developer composition has a pH of at least 12 and comprises a metal cation M2+ selected from barium, calcium, strontium, and zinc cations, and a chelating agent that has a complex formation constant (log K) for the metal cation of at least 3.5 and less than or equal to 4.5, and a log K for aluminum ion that is 7 or less. This developer composition can be used to process positive-working lithographic printing plate precursors to provide lithographic printing plates.

Owner:EASTMAN KODAK CO

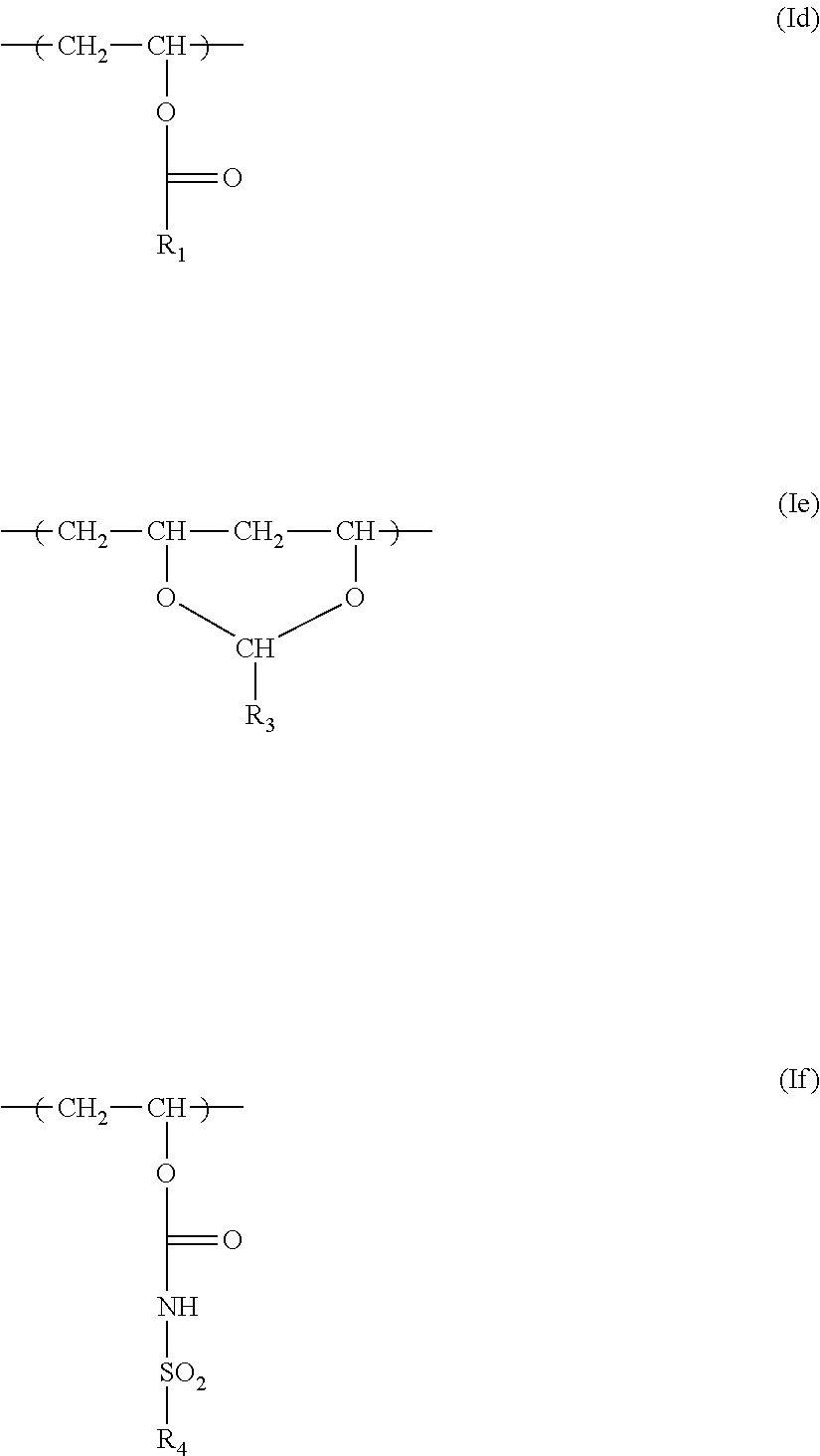

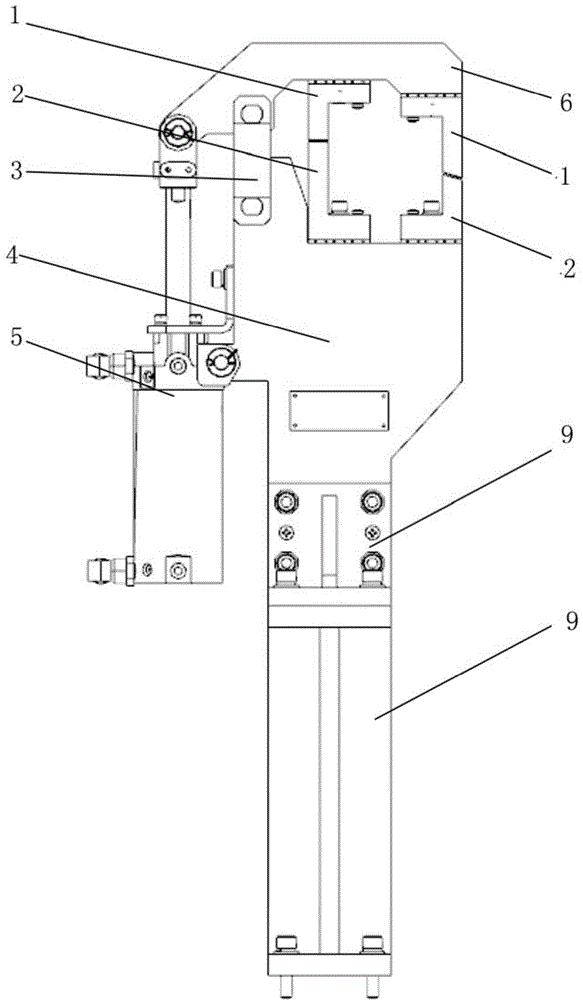

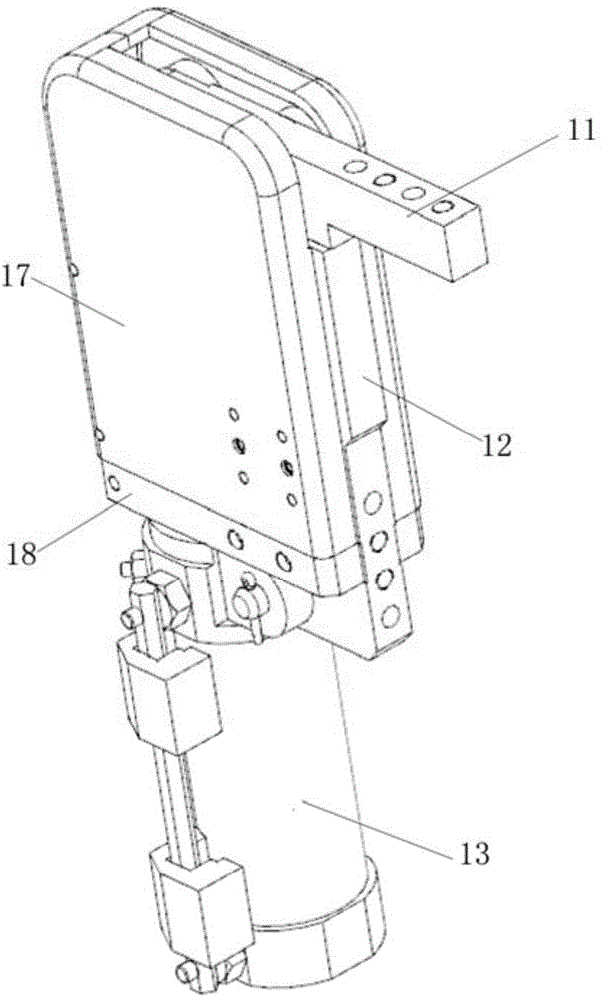

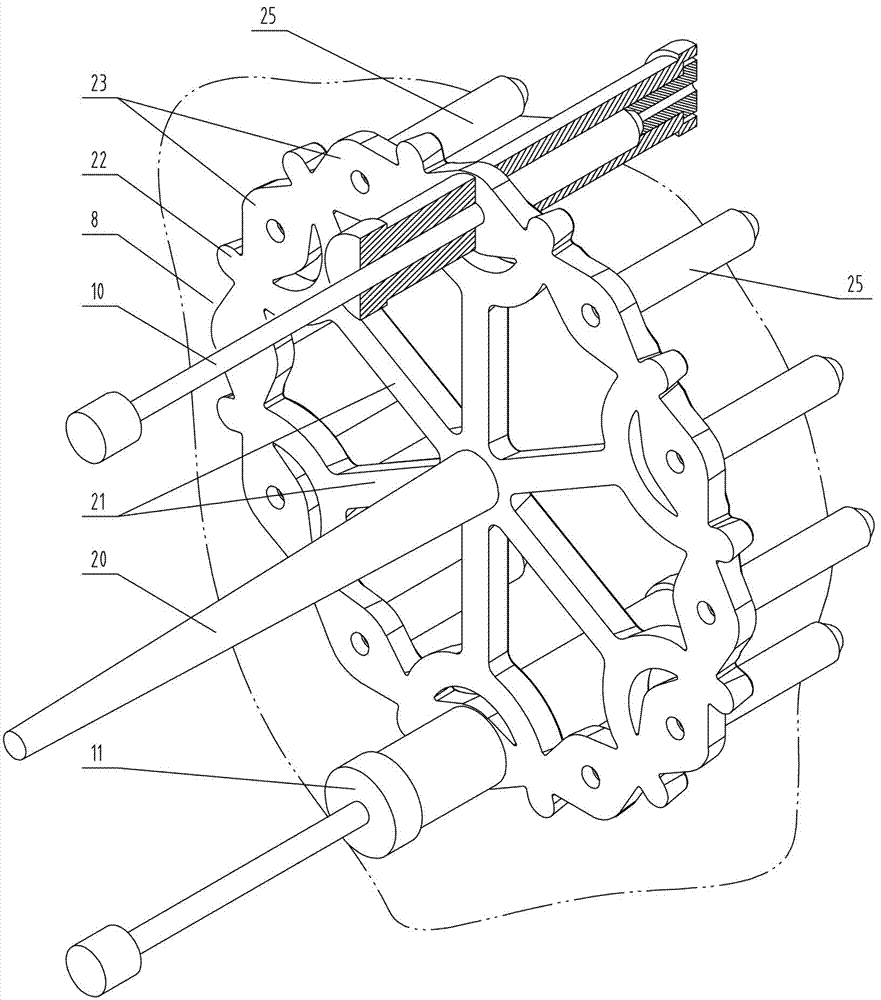

Modularization positioning fixture and positioning fixture assembly

ActiveCN105773024AExtended service lifeEasy to installWelding/cutting auxillary devicesAuxillary welding devicesModular fixtureModularity

The invention discloses a modularization positioning fixture and a positioning fixture assembly. The modularization positioning fixture comprises a pressure head, a first connecting plate, a first clamping air cylinder and a dustproof cover; one end of the pressure head is hinged to the front end of an extending rod of the first clamping air cylinder, and the middle portion of the pressure head is hinged to the first connecting plate; and the periphery of the extending rod of the first clamping air cylinder is surrounded by the dustproof cover. The modularization positioning fixture is simple in structure and small in size; moving parts are effectively protected, and the service life of the fixture is prolonged; the modularization positioning fixture is convenient to install, safe in use and high in efficiency; and standard modules are directly called, the machining period is short, the cost is low, and the opening angle of the fixture is large.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

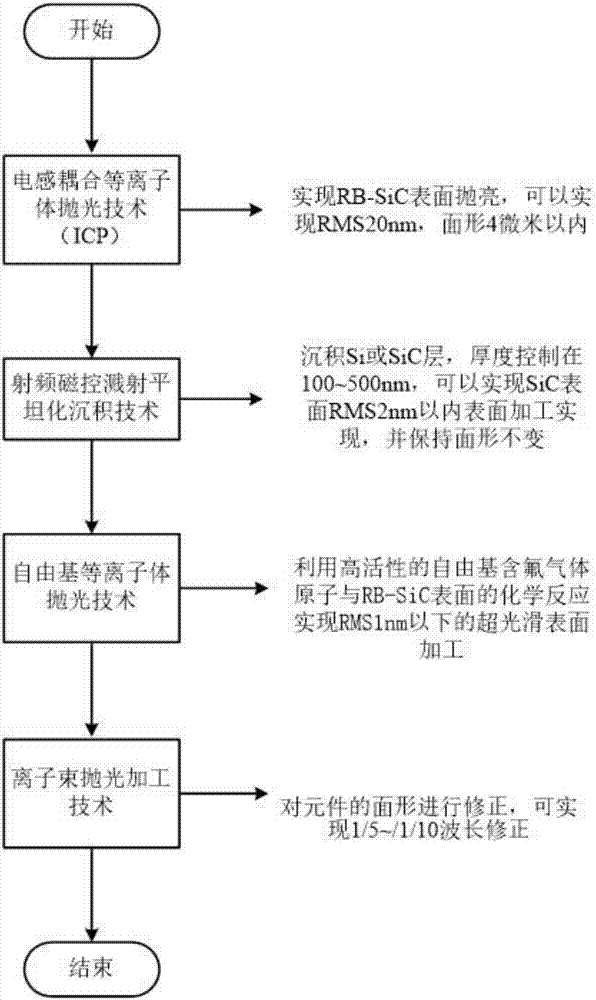

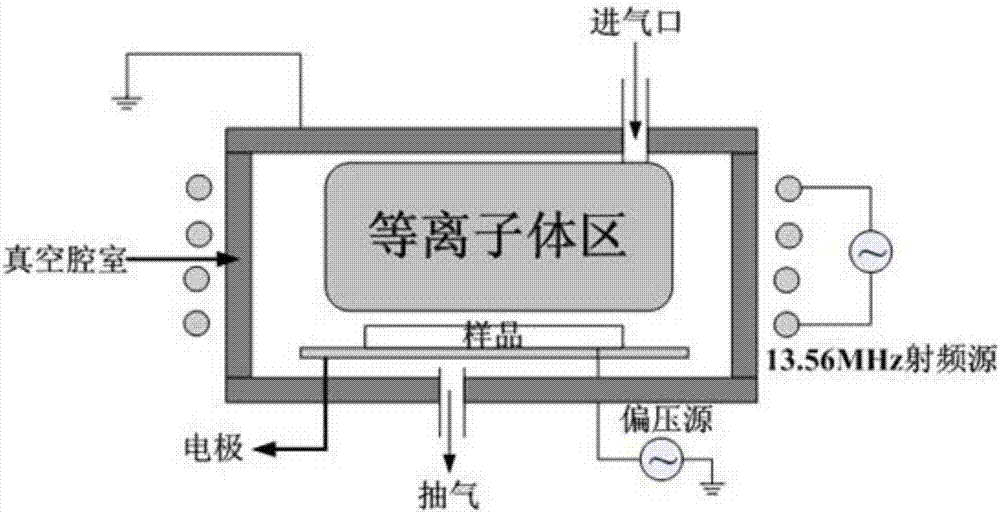

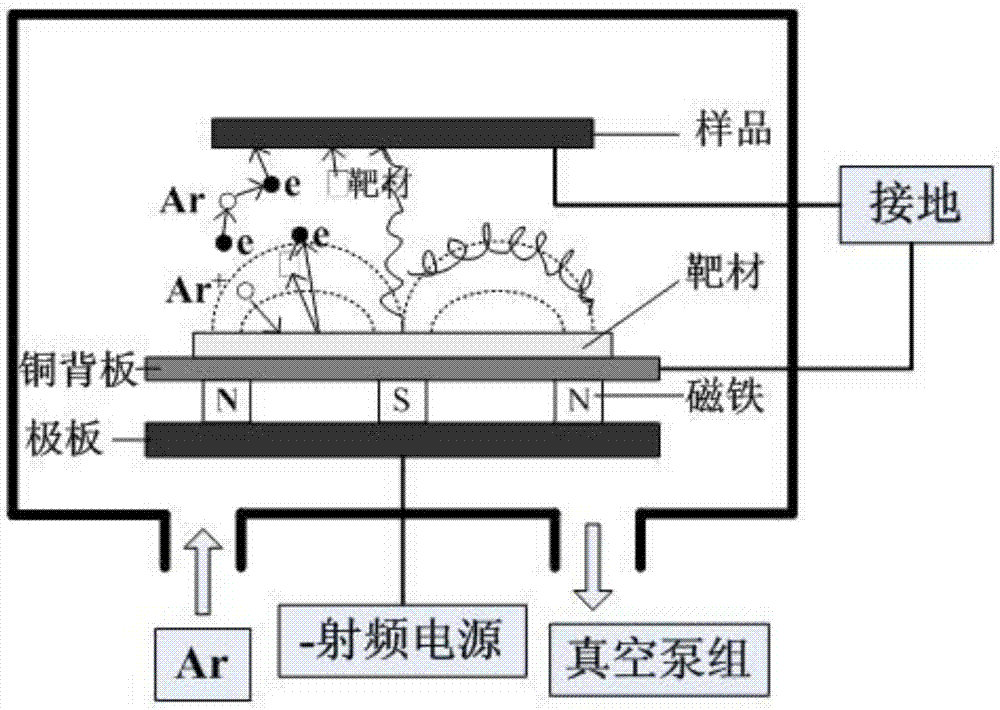

Machining method for polishing process of RB-SiC optical element

ActiveCN107052913AProcessing method shortenedShorten the processing cycleOptical surface grinding machinesMicrowaveRadio frequency magnetron sputtering

The invention discloses a machining method for the polishing process of an RB-SiC optical element. The machining method for the polishing process of the RB-SiC optical element comprises the steps that fine-grinding polishing of the RB-SiC optical element is achieved through the inductive coupling plasma polishing technique firstly, then a planarized nano-layer is deposited on the optical surface through the radio frequency magnetron sputtering surface planarization technique, and finally ultra-smooth surface machining of the optical element is achieved through the ion beam polishing shape-correction technique with the assistance of the free-radical microwave plasma polishing technique. Compared with the prior art, the plasma polishing technique is adopted by the novel machining method for polishing the RB-SiC optical element to replace a traditional optical machining method, the preparation technique of the planarized nano-layer and the ion beam shape-correction polishing technique are combined, the machining cycle of the large-diameter RB-SiC optical element is greatly shortened, and machining method for the polishing process of the RB-SiC optical element has the characteristics of high efficiency, high precision and low loss.

Owner:XIAN TECHNOLOGICAL UNIV

Two-step deposition tchnique for dielectric layer between metalic wires

InactiveCN1540727AExtended processing cycleReduce processing timeSemiconductor/solid-state device manufacturingMetal interconnectHigh density

In order to raise yield of Chemical Vapor Deposition (CVD) of high-density plasma (HDP), HDPCVD technique is optimized. HDPCVD technique is utilized for space filling mainly. The invention is pointed to space filling in A / R ratio between depth and width of groove as less than or equal to 2.3. the invention shortens deposition time 20-30% so as to raise yield of HDPCVD device.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

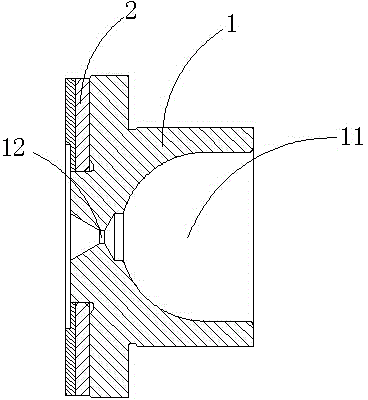

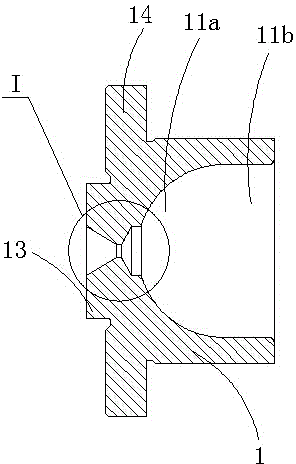

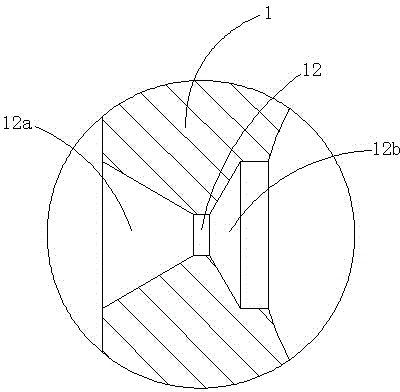

Plunger piston shoe structure used for swash plate type axial plunger pump or motor

PendingCN104481865AEasy to processReduce processing costsPositive displacement pump componentsLiquid fuel engine componentsEngineeringCopper

The invention discloses a plunger piston shoe structure used for swash plate type axial plunger pump or motor; the plunger piston shoe structure used for swash plate type axial plunger pump or motor comprises a piston shoe body; the piston shoe body is provided with a sphere containing chamber which is matched with a plunger head; an oil injection hole is opened in the piston shoe body; the oil injection hole is communicated with the sphere containing chamber, wherein the end of the piston shoe body far away from the sphere containing chamber is fixed with a lining plate; the lining plate is made by the composition of a copper base layer and a steel base layer, the steel base layer is firmly adhered to the end face of the piston shoe body; the lining plate is detachably matched with the piston shoe body. The plunger piston shoe structure used for swash plate type axial plunger pump or motor has the advantages that a split type structure is used, the structure is simple, the machining of the piston shoe is convenient, the machining cost is reduced; only the lining plate is to be changed if the most easily damaged copper surface of the piston shoe is damaged, and the piston shoe body can still be used, thus providing convenience for maintaining the piston shoe, greatly reducing the cost of usage and maintenance, and increasing the duty cycle of the piston shoe.

Owner:SAIKESI HYDRAULIC TECH CO LTD

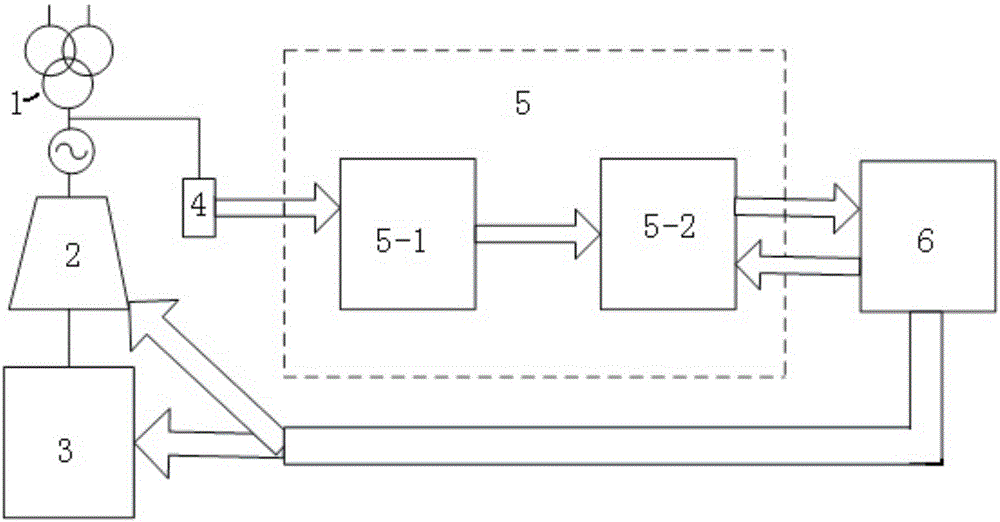

Primary frequency regulation device of thermal power generating unit

ActiveCN106432997AHigh strengthImprove electrical performanceInductances/transformers/magnets manufactureCoatingsPower gridInductor

The invention provides a primary frequency regulation device of a thermal power generating unit. The device is characterized by comprising a generator set (1), a steam turbine (2), a coal-fired boiler (3), a primary frequency regulation control device (5) and a decentralized control device (6). One end of the generator set (1) is connected with the steam turbine (2), the steam turbine (2) is connected with the coal-fired boiler (3), the other end of the generator set (1) is connected with the primary frequency regulation control device (5) through a voltage mutual inductor (4), the primary frequency regulation control device (5) is connected with one end of the decentralized control device (6), and the other end of the decentralized control device (6) is connected with the steam turbine (2) and the coal-fired boiler (3) respectively. The device is simple in connection and convenient to use, and high-speed high-precision acquisition of power grid frequency signals can be achieved.

Owner:山东纳鑫电力科技有限公司

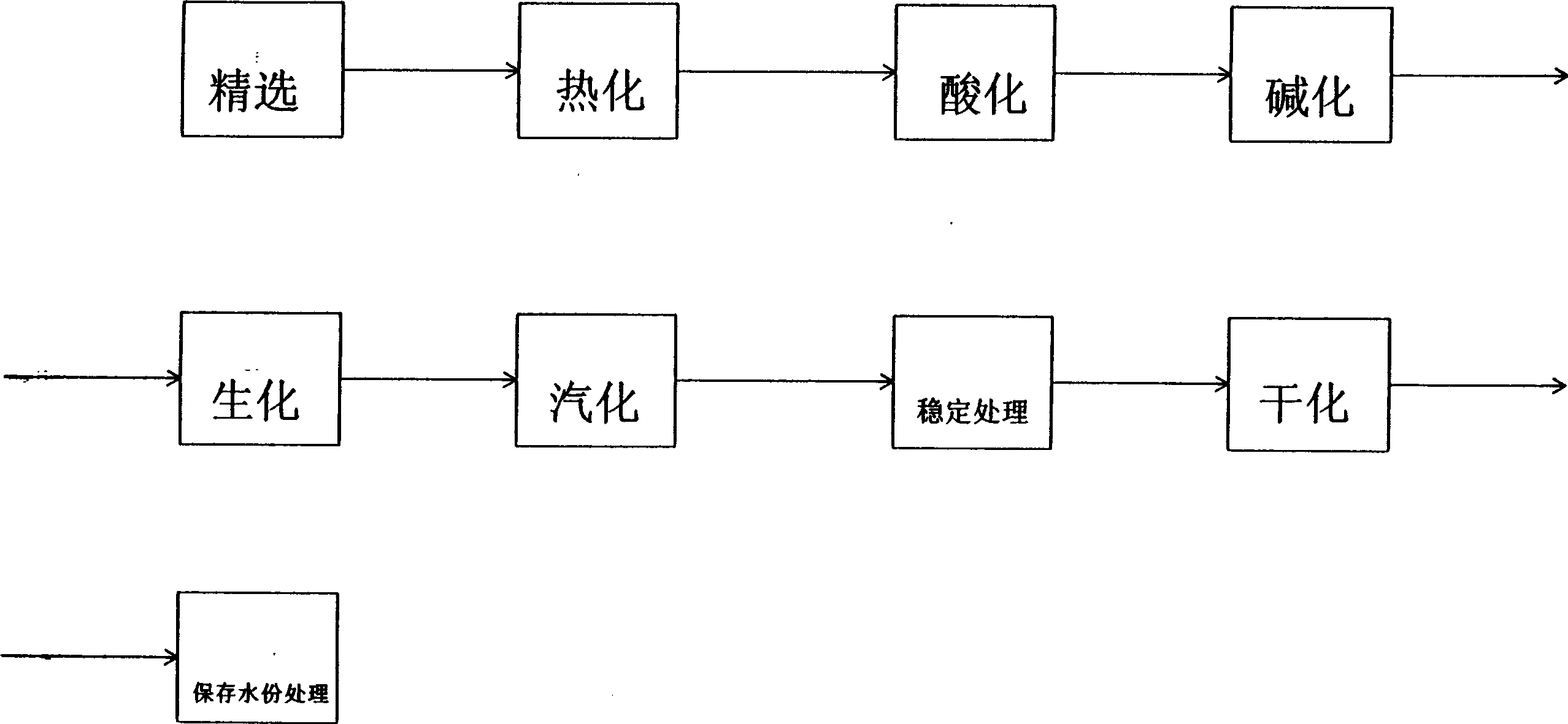

Active carbon activating treatment for zeolite and its preparation application and regeneration

InactiveCN1623652AExtended processing timeExtended processing cycleOther chemical processesAluminium silicatesManganeseWater quality

A process for activating and regenerating zeolite includes such steps as choosing the grayish-green clinoptilolite particles, calcining in the oxygen filled non-metal furnace, air-floating in the low-concentration acid solution, high-temp steaming by alkali solution, washing, immersing in the solution aluminium salt and alum, cyclic boiling for regenerating, high-temp steam washing, immersing in the solution of stabilizer for raising pH value, fast drying and sealing in plastic bags.

Owner:戴福才 +2

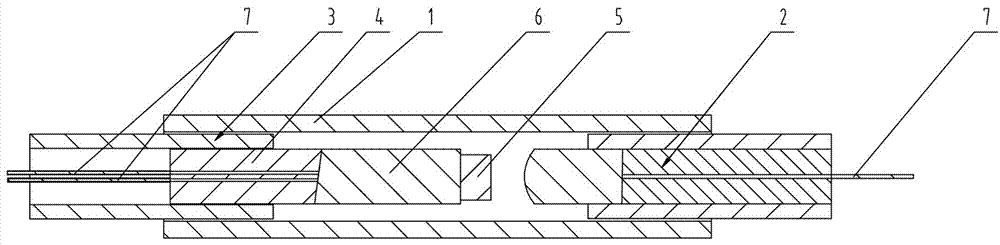

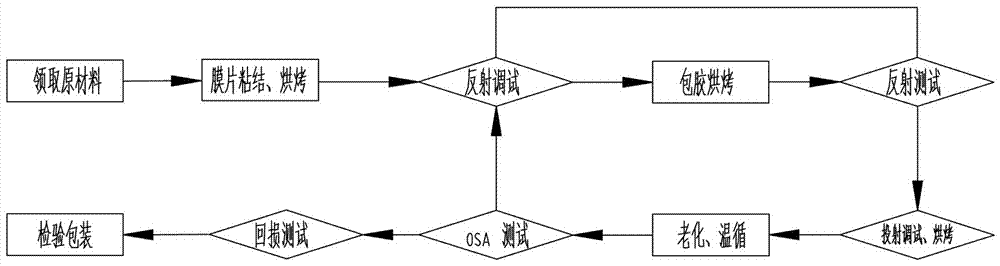

All-ceramic wavelength division multiplexer and production method thereof

ActiveCN107162589ASimple production processHigh energy consumptionOptical light guidesFiberMultiplexer

The invention provides an all-ceramic wavelength division multiplexer and a production method thereof; the all-ceramic wavelength division multiplexer has a sleeve, a single-core fiber collimator and a double-core fiber reflector are mounted in the sleeve, all the sleeve of the wavelength division multiplexer, a sleeve of the single-core fiber collimator and a sleeve of the double-core fiber reflector are of ceramic, a single insert core of the single-core fiber reflector is a circular microporous ceramic insert core, and a double insert core of the double-core fiber reflector is a special-deformed microporous ceramic insert core; the defect that a traditional glass wavelength division multiplexer is fragile and difficult to process is overcome; the process of the all-ceramic wavelength division multiplexer of the invention is simple, high in production efficiency and low in manufacture cost, and the all-ceramic wavelength division multiplexer has the advantages of low insertion loss, high echo loss, good reliability and the like and is easier to process, lower in cost, better in uniformity, less prone to ambient influence and higher in reliability as compared with traditional glass wavelength multiplexers; the wavelength multiplexer produced by using the method has transmission insertion loss of 0.35 dB and below.

Owner:黄石晨信光电股份有限公司

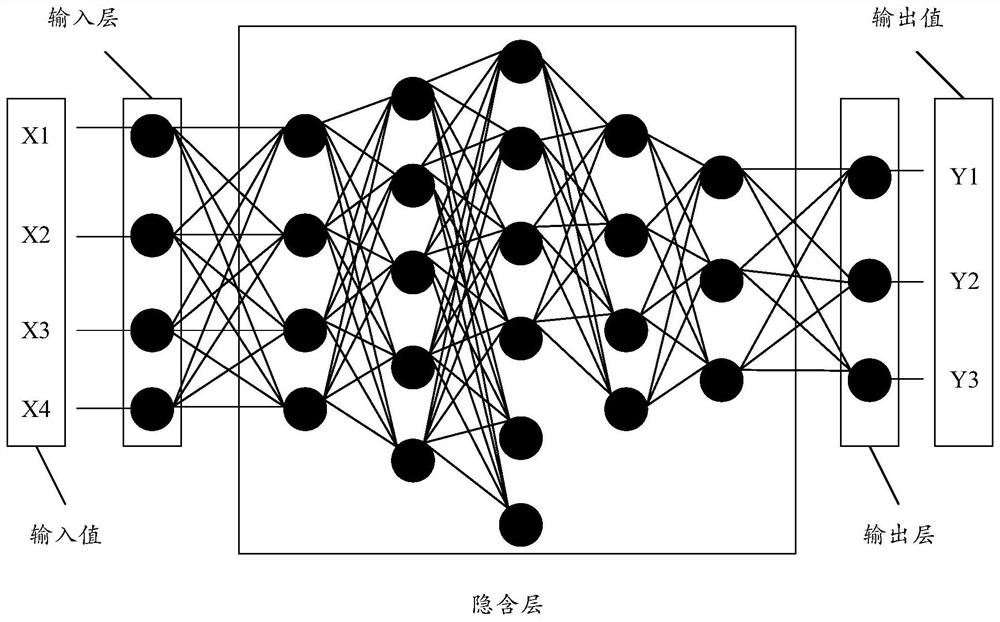

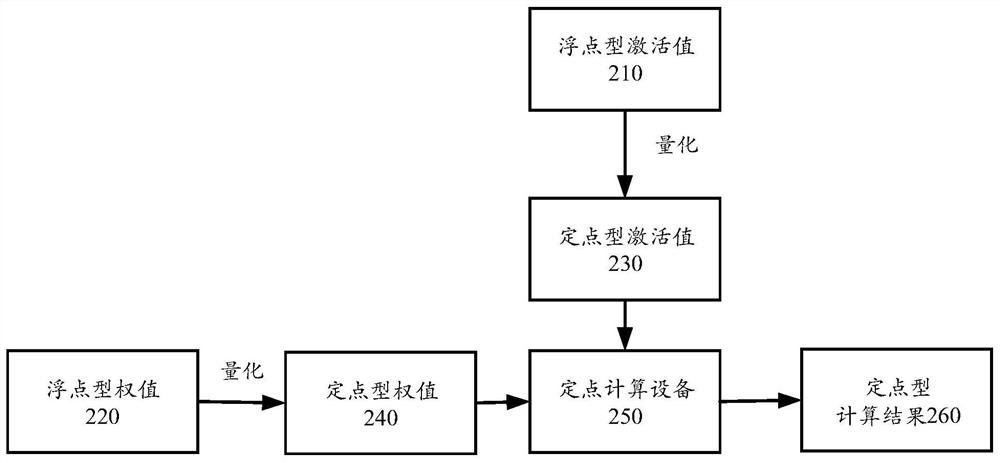

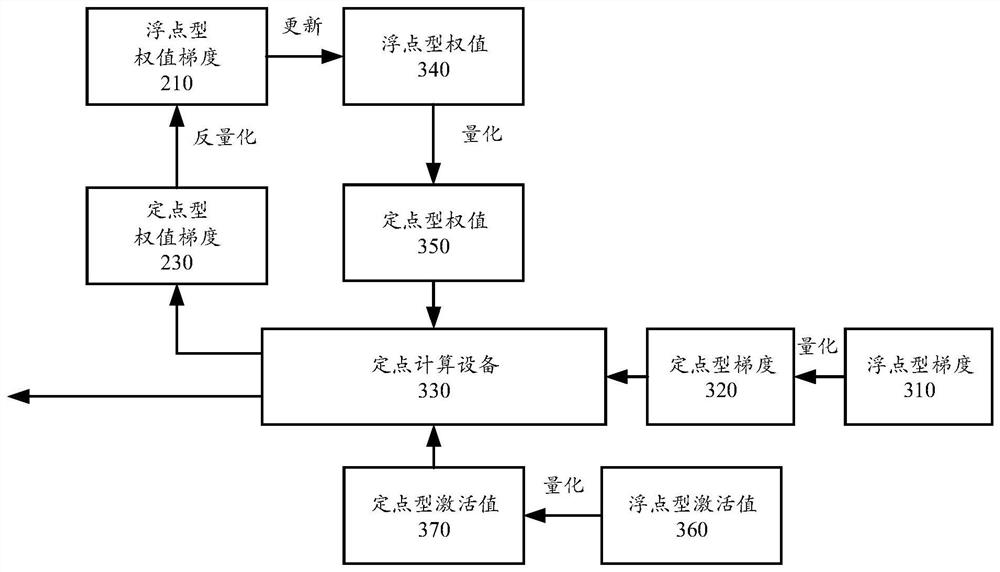

Quantitative calibration method, computing device and computer readable storage medium

PendingCN113947177AEasy to optimizeReduce computationNeural architecturesPhysical realisationInterface (computing)Computer engineering

The invention discloses a quantitative calibration method, a computing device and a computer readable storage medium. The computing device may be included in a combined processing device, and the combined processing device may also include an interface device and other processing devices. The computing device interacts with other processing devices to jointly complete computing operation specified by a user. The combined processing device can further comprise a storage device, and the storage device is connected with the computing device and the other processing devices and used for storing data of the computing device and the other processing devices. According to the scheme, new quantization difference measurement is used for optimizing quantization parameters, so that certain quantization reasoning precision is kept while various advantages are achieved through quantization.

Owner:ANHUI CAMBRICON INFORMATION TECH CO LTD

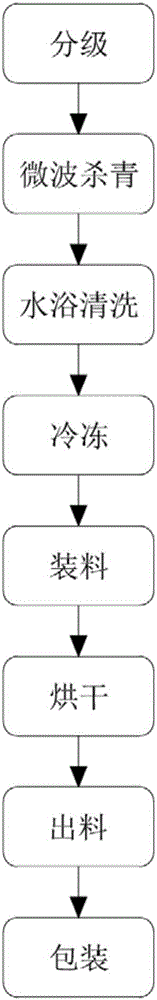

Green prickleyash drying method

InactiveCN106387829AColor is well preservedEasy to openFood processingFood preservationWater bathsMicrowave

The invention discloses a green prickleyash drying method in the technical field of processing of green prickleyash. The green prickleyash drying method comprises the working procedures of performing classification, performing microwave fixation, performing water-bath cleaning, performing refrigerating, performing loading, performing drying, performing discharging and performing packaging. The green prickleyash drying method comprises the specific steps of S1, performing classification; S2, performing microwave fixation; S3, performing water-bath cleaning; S4, performing refrigerating; S5, performing loading; S6, performing drying; S7, performing discharging; and S8, performing packaging. The scientific green prickleyash drying method is adopted, and drying is performed twice, so that the water content in green prickleyash can be accurately controlled; the processing period is short, a heating manner of a heat pump drying machine is utilized, the heating time is short, the quality is good, the product color is good, the internal quality is good, the energy consumption rate is low, industrialized drying and processing requirements of green prickleyash can be met, besides, the processing period of the green prickleyash can be prolonged, and the use efficiency of equipment is improved.

Owner:HONGYA HEXIN AGRI TECH DEV

Method and device for 3D printing ceramic dentures suitable for photocuring

ActiveCN106217882BGuaranteed levelHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusGraphicsControl system

The invention relates to a method and device for 3D printing ceramic dentures suitable for light-curing molding, which belong to the technical field of tooth production. In the method, tooth data obtained by scanning are processed to obtain images of each layer after slicing the data model to be printed. The data is sent to the control system, and the control system controls the liquid level to maintain the liquid level of the base material at the preset height. The base material is configured in proportion to the photosensitive resin and ceramic powder. After the liquid replenishment, the control system controls the filling liquid. After the mixing is completed, the bottom projection method is used for printing, and the sliced graphics of each layer of the image are projected one by one, and the light source is exposed to complete the curing layer by layer. The invention has the advantages of simple production process, high production efficiency, less consumables, high production precision and good matching.

Owner:SHANGHAI UNION TECH

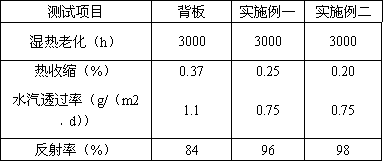

Preparation method of high reflection solar cell back plate film

ActiveCN107611223AImprove reflectivityGood adhesionFilm/foil adhesivesLaminationCelsius DegreeRoom temperature

The invention discloses a preparation method of a high reflection solar cell back plate film. The method comprises: a twin-screw extruder is used to respectively prepare an adhesive layer master batch, a barrier layer master batch and a high reflection master batch; four single-screw extruders are used to extrude lip films of the three master batches melted under the 250 degrees Celsius from the casting heads; a non-woven fabric layer is added to two barrier layers to be used as a base layer, so that the lip films is extruded and casted onto the surface of the non-woven fabric layer to form one piece, and after the lip film is cooled down to room temperature by cooling rolls, the high reflection solar cell back plate film is achieved.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

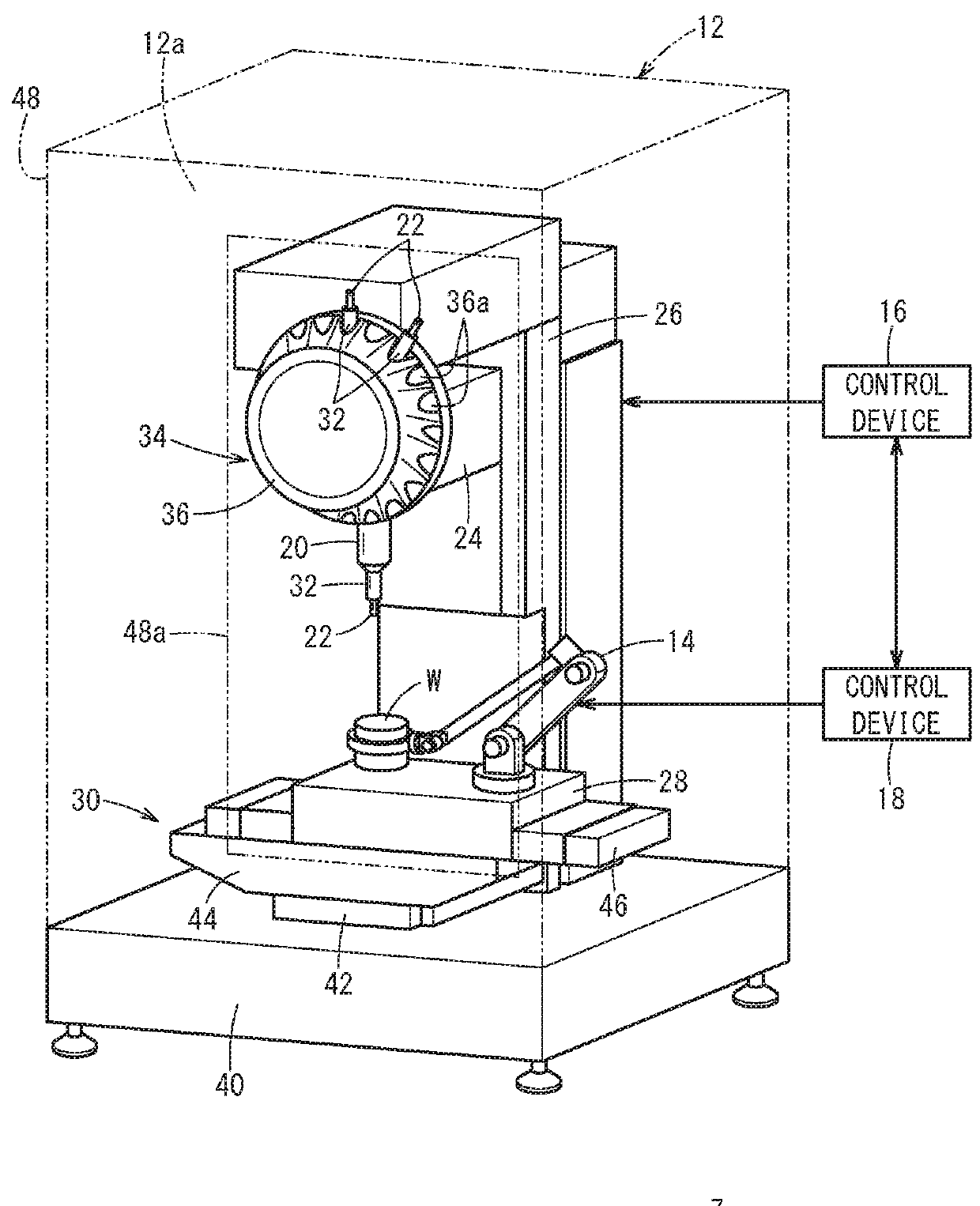

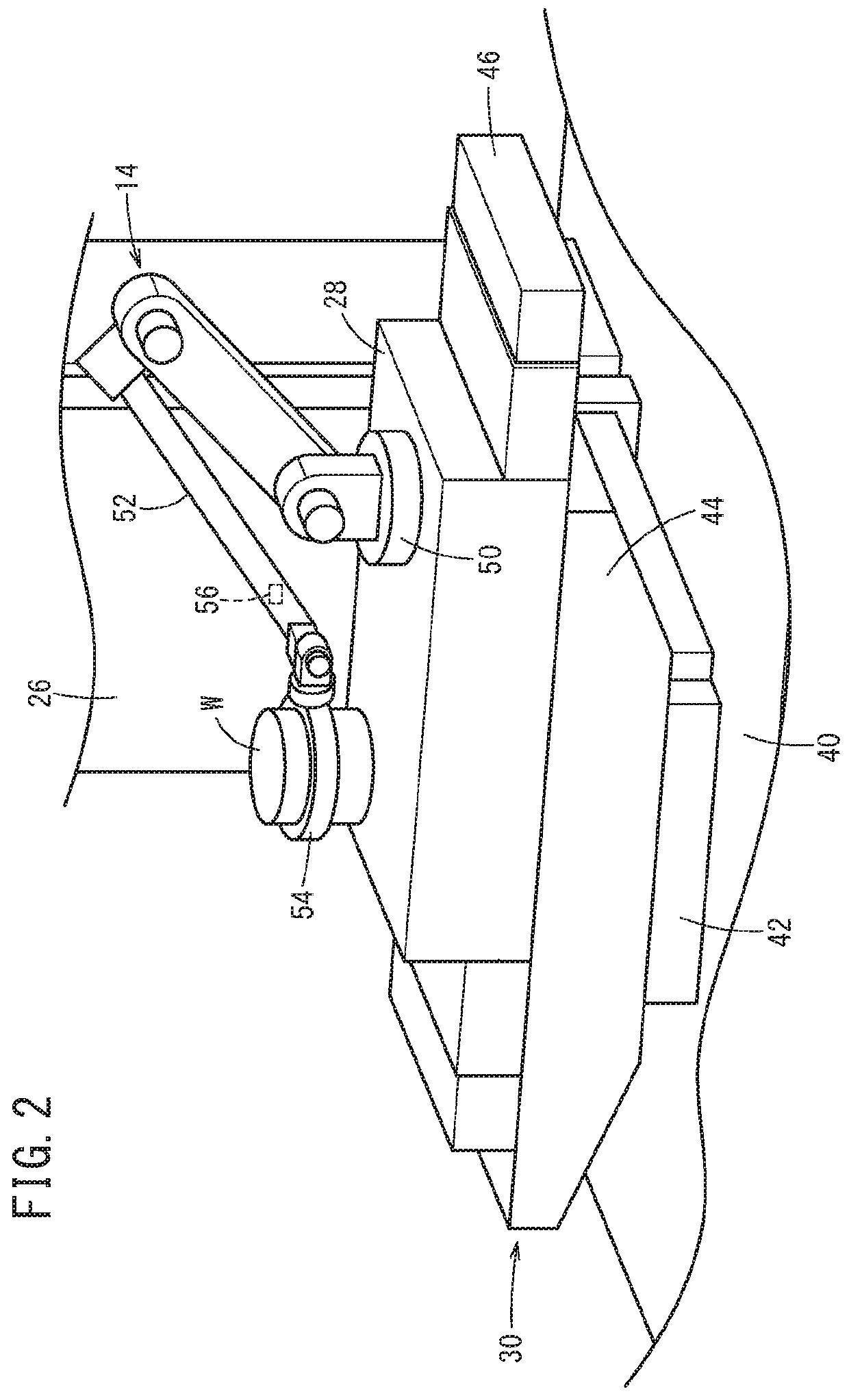

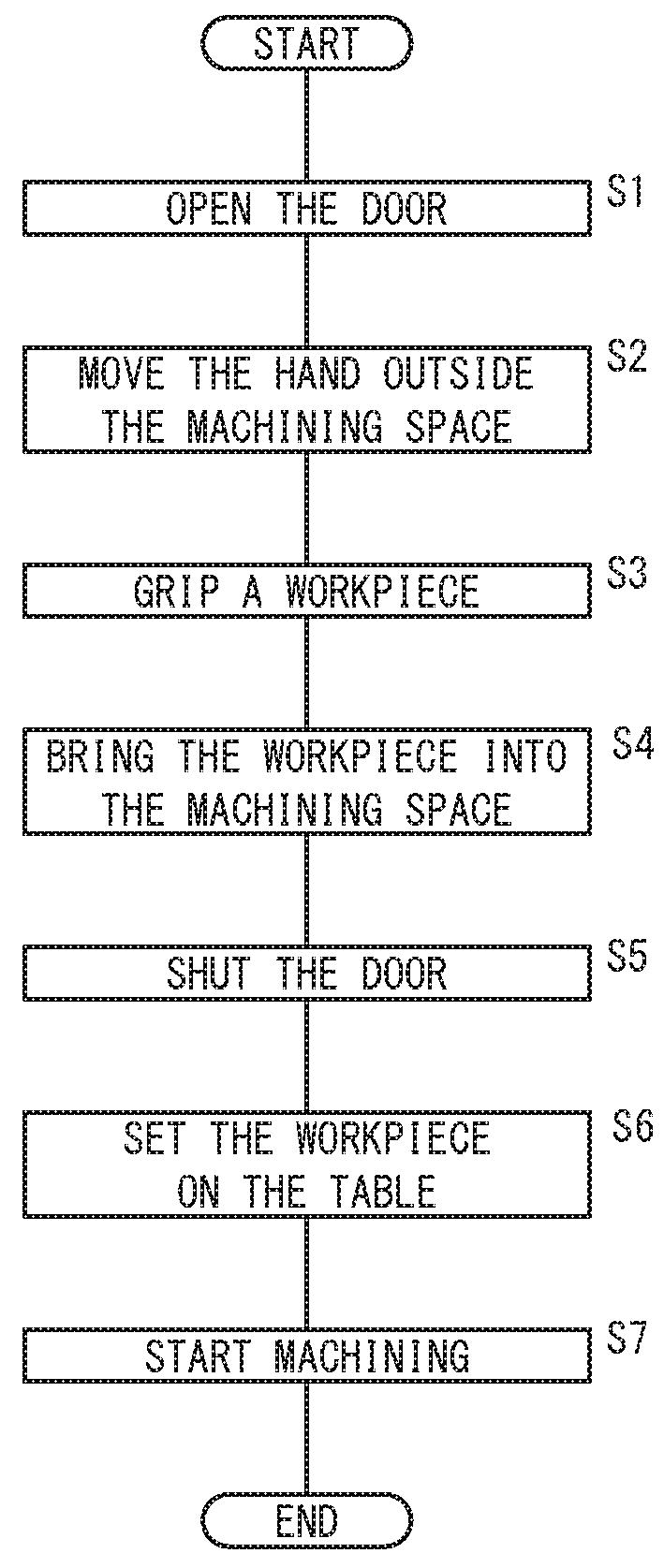

Machine tool system and clamping method

ActiveUS20180272487A1Extended machine cycle timeExtension of timeProgramme controlProgramme-controlled manipulatorMachine toolIndustrial engineering

A machine tool system includes: a machine tool for machining a workpiece set on a table using a tool attached to a spindle; and a robot for gripping the workpiece. The robot is installed on the table and performs a setting operation for setting the workpiece on the table and a clamping operation for clamping the workpiece.

Owner:FANUC LTD

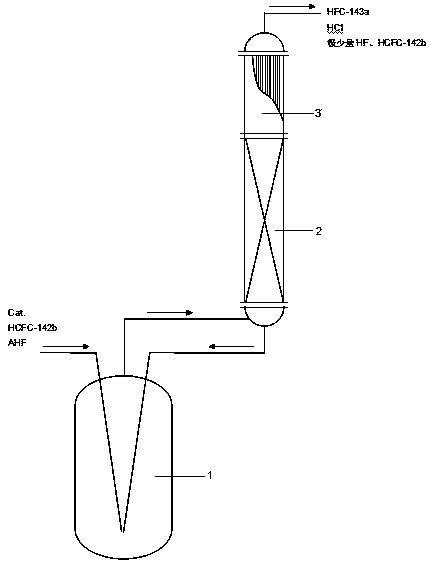

Synthesis method of 1, 1, 1-trichloroethane

InactiveCN108046981AImprove catalytic performanceOperational securityPreparation by halogen replacementChemical synthesisHydrogen fluoride

The invention discloses a synthesis method of 1, 1, 1-trichloroethane and belongs to the technical field of chemical synthesis. The synthesis method includes following steps: using 1-chloro-1, 1-difluoroethane and hydrogen fluoride as raw materials for liquid-phase fluoridation, wherein a liquid-phase fluoridation catalyst is one of or a mixture of tetravalent tin compound and halogenosulfonic acid. Before feeding, a mixture of a liquid-phase catalyst and hydrogen fluoride is heated to obtain an active catalyst; a fluoridation separation process is adopted, so that side reaction can be controlled effectively, reaction conditions are mild, conversion rate and selectivity are high, the conversion rate reaches higher than 99.6%, and the selectivity reaches 99.9%. A liquid-phase fluoridation catalyst system is adopted, so that corrosion speed of a reactor material can be controlled effectively, service life is long, and operation is safe and reliable.

Owner:东阳市巍华制冷材料有限公司

Continuous-casting and continuous-drawing processing technique of N6 nickel alloy wire

The invention relates to a continuous-casting and continuous-drawing processing technique of an N6 nickel alloy wire. The continuous-casting and continuous-drawing processing technique is characterized by comprising the following steps: during smelting and drawing, charging nitrogen into an upper space of melted metal; putting an electrolytic nickel plate and N6 alloy leftovers together into an intermediate-frequency smelting furnace; simultaneously adding graphite carbon of which the weight is 0.1 percent of the weight of the electrolytic nickel plate; controlling the temperature to be 1470+ / -20 DEG C to melt the metal; adding NiMg alloy according to a proportion of 0.4Kg / 100Kg for degassing; keeping the temperature; starting continuous-casting of a lead wire; regulating the ratio of pulse rotation length to stagnation distance to be 7:3 and regulating the drawing speed to be 2m / min to 5m / min; synchronously adding cooling water of which the pressure is 0.08Mpa to 0.12MPa. The continuous-casting and continuous-drawing processing technique of the N6 nickel alloy wire has the beneficial effects of reducing a plurality of processing steps such as peeling of a blank material, hot-rolling blooming and primary draw-molding of a wire ingot, prolonging the processing period of the wire and improving the comprehensive rate of finished products, and also lowering the processing cost of the wire.

Owner:中色创新研究院(天津)有限公司

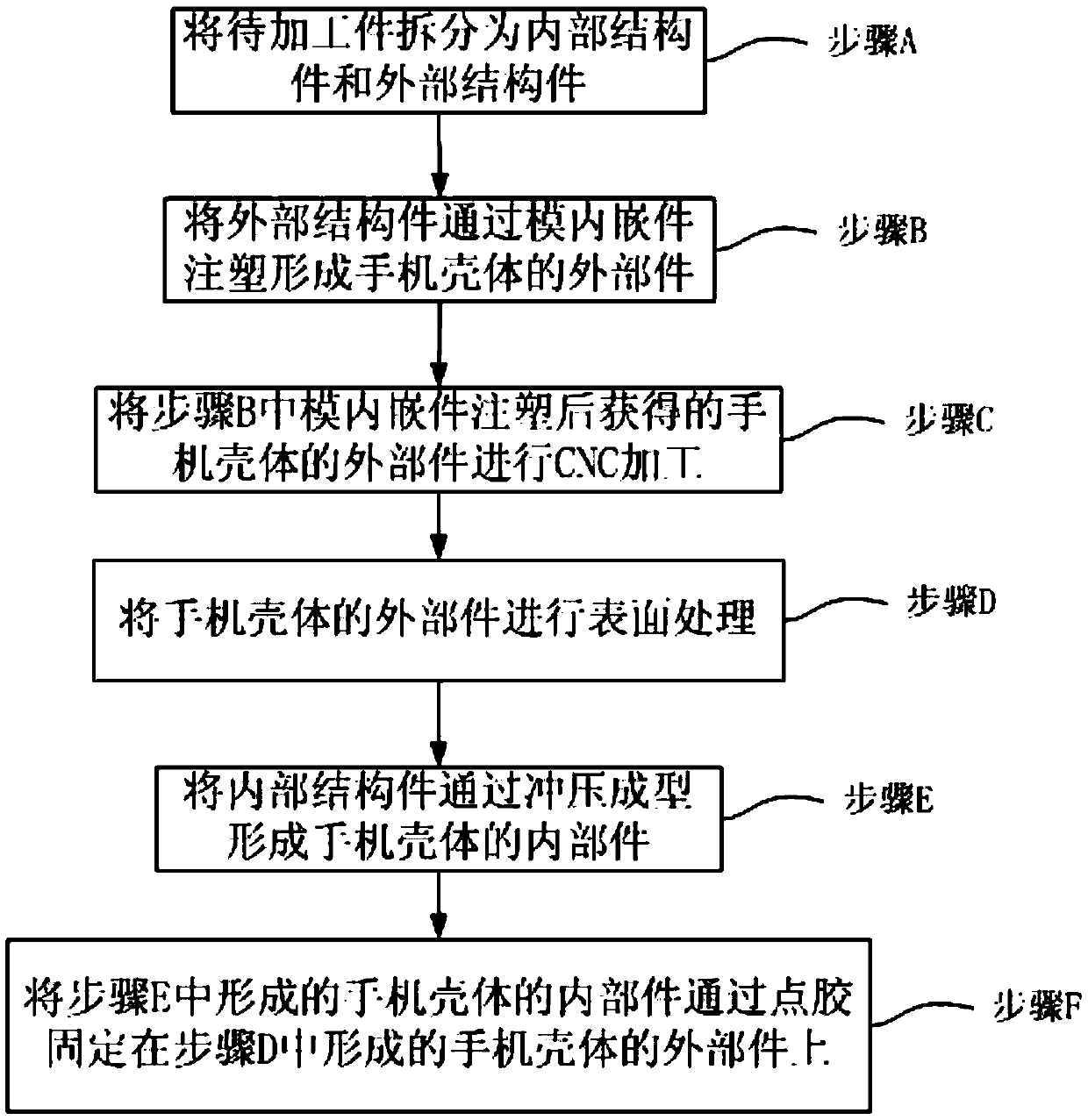

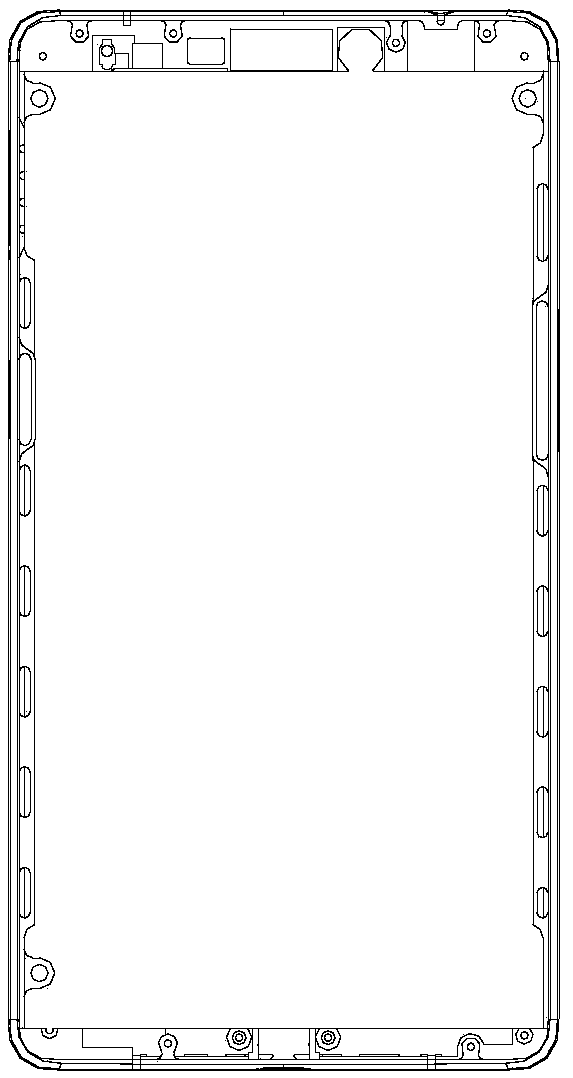

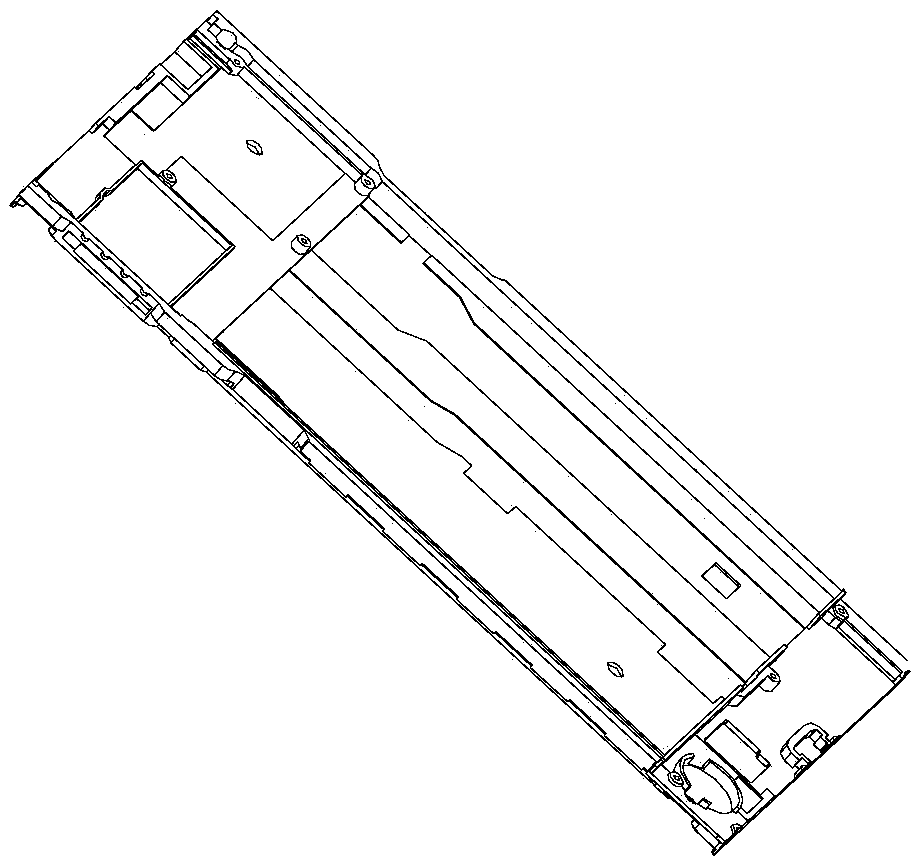

Processing technique of mobile phone shell, mobile phone shell, and mobile phone

InactiveCN105516401AResolution cycleSolve efficiency problemsTelephone set constructionsComputer scienceMobile phone

The invention, which belongs to the field of mobile phone parts and a processing method thereof, discloses a processing technique of a mobile phone shell, a mobile phone shell, and a mobile phone, thereby solving a problem of high production cost of the existing mobile phone metal shell. The processing technique is implemented by the following steps that: a to-be-processed component is split into an internal structural component and an external structural component; the external structural component is processed by in-mould insert injection molding to form an external component of a mobile phone shell; the moulded internal structural component and the external component of the mobile phone shell are fixed to form a mobile phone shell. The provided mobile phone shell is manufactured by using the processing technique. Besides, the provided mobile phone includes the mobile phone shell. Therefore, with the processing technique, the processing efficiency of the mobile phone shell can be improved; the processing period can be shortened; and the processing cost can be lowered. The mobile phone shell and the mobile phone having the same have advantages of low mobile phone manufacturing cost, high production efficiency, and beautiful and elegant appearance and are suitable for large-scale popularization and application.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

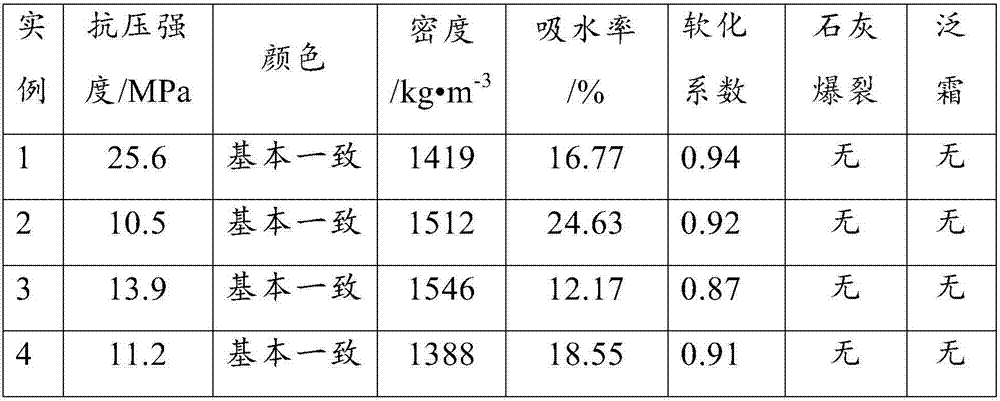

Method for preparing river mud sintered brick

InactiveCN106938913AWide firing temperature rangeHighly adjustableCeramic materials productionClaywaresBrickRoom temperature

The invention belongs to the technical field of building materials, and discloses a method for preparing a river mud sintered brick, and the method is as follows: adding a modifier into screened and purified river mud, and dewatering the river mud to obtain a first mud material; stirring the first mud material, pressing and molding to obtain a brick blank; drying the brick blank in turn at room temperature and in a drying chamber to obtain a to-be-burnt brick blank; pre sintering the to-be-burnt brick blank at 400 to 600 DEG C, and heating to 850 to 1000 DEG C for secondary-section firing. The invention provides the method for preparing an energy saving and consumption reducing river mud sintered brick.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

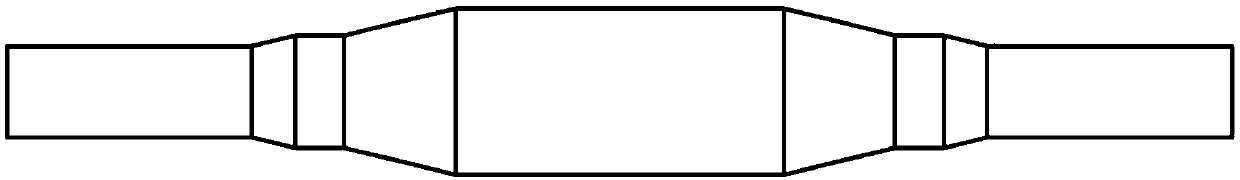

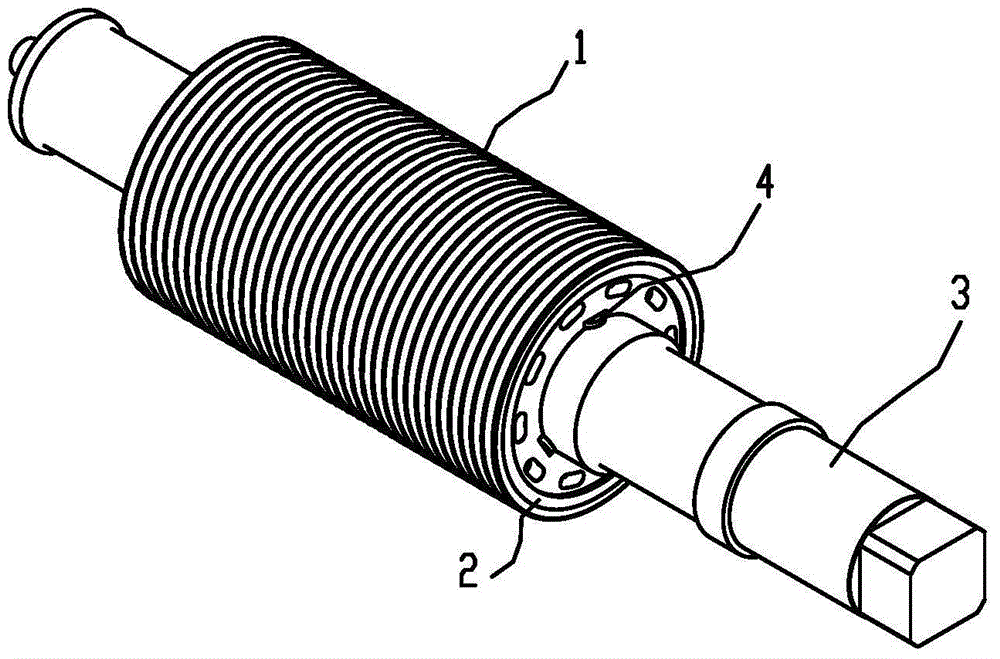

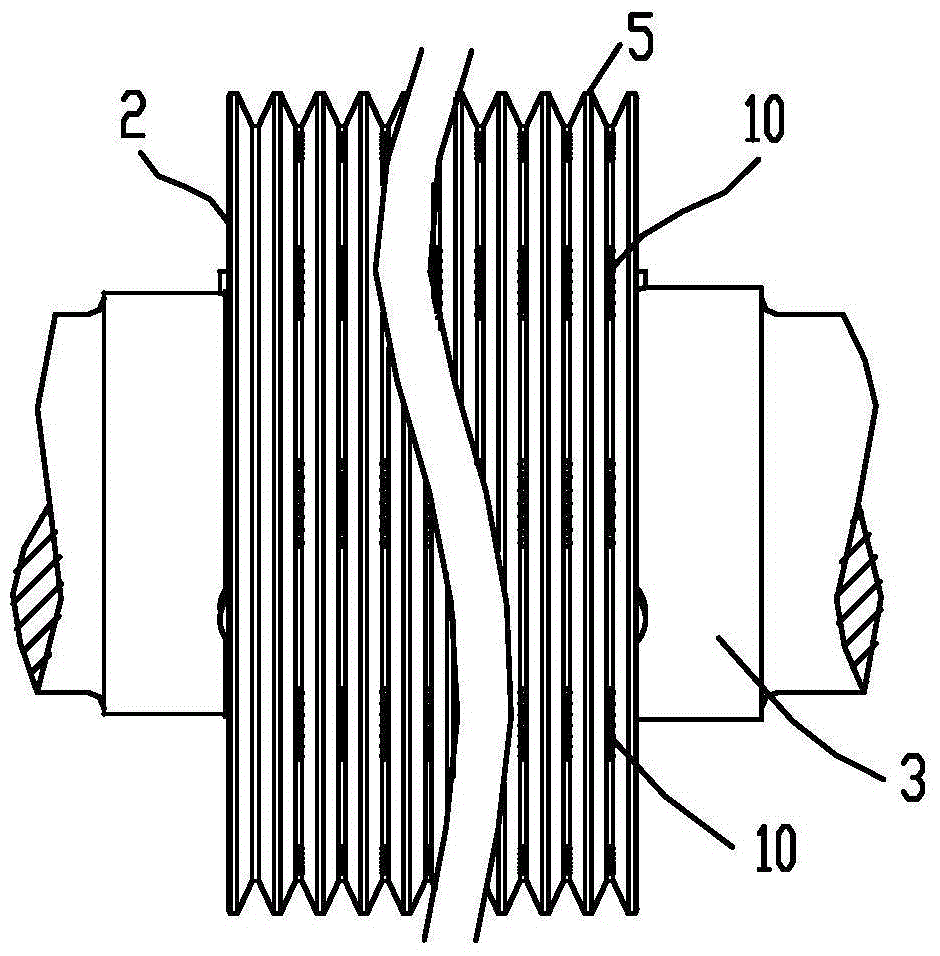

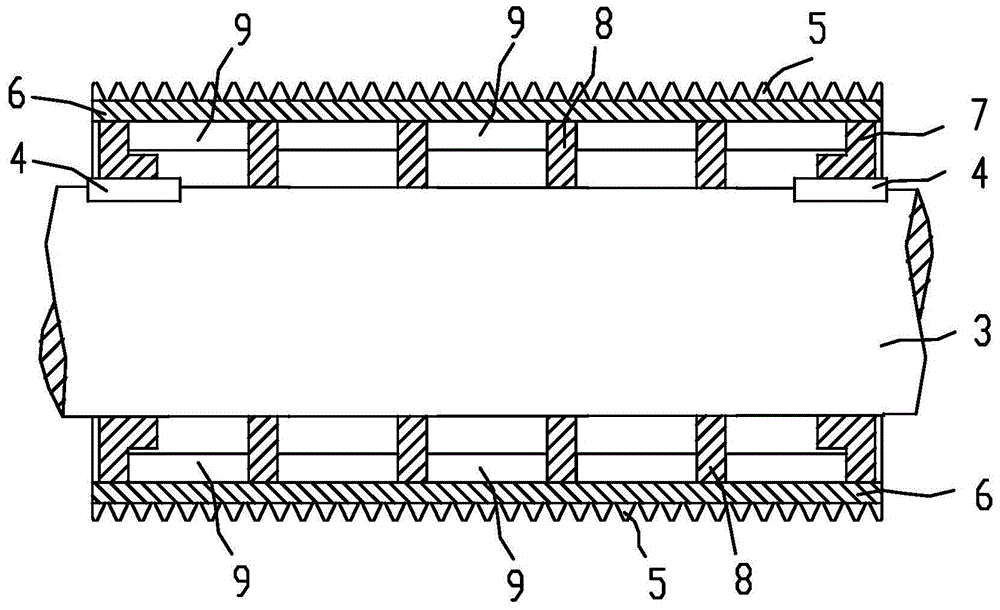

Manufacturing method of sugarcane press roll

InactiveCN105033577AReduce processing costsExtended service lifePressesJuice extraction from sugarcaneManufacturing technologyRoll forming

The invention belongs to the technical field of roll shaft manufacture, and provides a manufacturing method of a sugarcane press roll. The sugarcane press roll comprises a roll shell and a roll shaft, the roll shell is tightly fixed on the roll shaft through shrink fit and clearance fit, the roll shell comprises roll teeth, a shell body and a support frame, the shell body of the roll shell is formed by conducting roll forming on a steel plate, the annular support frame is welded to the interior of an inner cavity of the shell body to form a roll shell inner hole, the roll teeth are welded to the outer side face of the shell body, machining is conducted on the roll teeth and the roll shell inner hole, and the roll shaft is sleeved with the roll shell in a shrink fit mode through the roll shell inner hole. According to the manufacturing method of the sugarcane press roll, the prominent problems that for traditional roll shell manufacture, a large number of raw materials are needed, the manufacturing time is long, the processing cost is high, the service life is short, the maintenance is difficult, and the maintenance cost is high are solved; the sugarcane press roll which is short in processing period and low in processing cost is provided for sugar enterprises.

Owner:南宁钛银科技有限公司

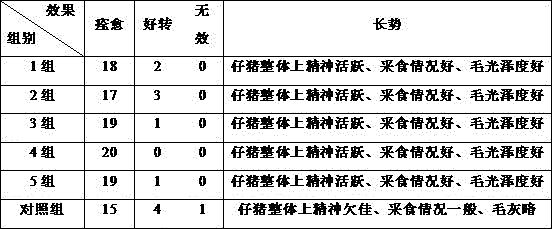

Traditional Chinese medicine preparation for treating piglet dyspepsia and preparation method thereof

InactiveCN106729126AGood for indigestionHarmless to healthDigestive systemPlant ingredientsPericarpium citri reticulataeChinese drug

The invention belongs to the technical field of traditional Chinese medicine processing methods, and provides a traditional Chinese medicine preparation for treating piglet dyspepsia and a preparation method thereof. The traditional Chinese medicine preparation for treating piglet dyspepsia comprises the following raw materials: 18-25 parts of scutellaria baicalensis, 10-15 parts of pericarpium citri reticulatae, 10-15 parts of pericarpium citri reticulatae viride, 11-17 parts of rheum officinale, 9-17 parts of rhizoma anemarrhenae, 4-17 parts of medicated leaven, 10-22 parts of rhizoma acori graminei, 8-13 parts of caulis bambusae in taeniam, 10-13 parts of cortex moutan, 2-13 parts of polygala tenuifolia and 5-14 parts of tabasheer. Traditional Chinese medicinal materials are rationally selected for combination according to the compatibility principle, and the whole formula is non-toxic and free of residual, has a good effect of treating the piglet dyspepsia, is harmless to the health of the piglet, and meanwhile is conducive to improving the immunity of the piglet and promoting the growth of the piglet.

Owner:安徽天安生物科技股份有限公司

Continuous Casting and Drawing Process of n6 Nickel Alloy Wire Rod

ActiveCN104475468BExtended processing cycleReduce processing costsIntermediate frequencyNitrogen gas

The invention relates to a continuous-casting and continuous-drawing processing technique of an N6 nickel alloy wire. The continuous-casting and continuous-drawing processing technique is characterized by comprising the following steps: during smelting and drawing, charging nitrogen into an upper space of melted metal; putting an electrolytic nickel plate and N6 alloy leftovers together into an intermediate-frequency smelting furnace; simultaneously adding graphite carbon of which the weight is 0.1 percent of the weight of the electrolytic nickel plate; controlling the temperature to be 1470+ / -20 DEG C to melt the metal; adding NiMg alloy according to a proportion of 0.4Kg / 100Kg for degassing; keeping the temperature; starting continuous-casting of a lead wire; regulating the ratio of pulse rotation length to stagnation distance to be 7:3 and regulating the drawing speed to be 2m / min to 5m / min; synchronously adding cooling water of which the pressure is 0.08Mpa to 0.12MPa. The continuous-casting and continuous-drawing processing technique of the N6 nickel alloy wire has the beneficial effects of reducing a plurality of processing steps such as peeling of a blank material, hot-rolling blooming and primary draw-molding of a wire ingot, prolonging the processing period of the wire and improving the comprehensive rate of finished products, and also lowering the processing cost of the wire.

Owner:中色创新研究院(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com