Manufacturing method of sugarcane press roll

A manufacturing method and press roll technology, applied in the field of roll shaft manufacturing, can solve the problems of low processing cost, short processing cycle, short service life, etc., and achieve the effects of convenient maintenance, increased product service life, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

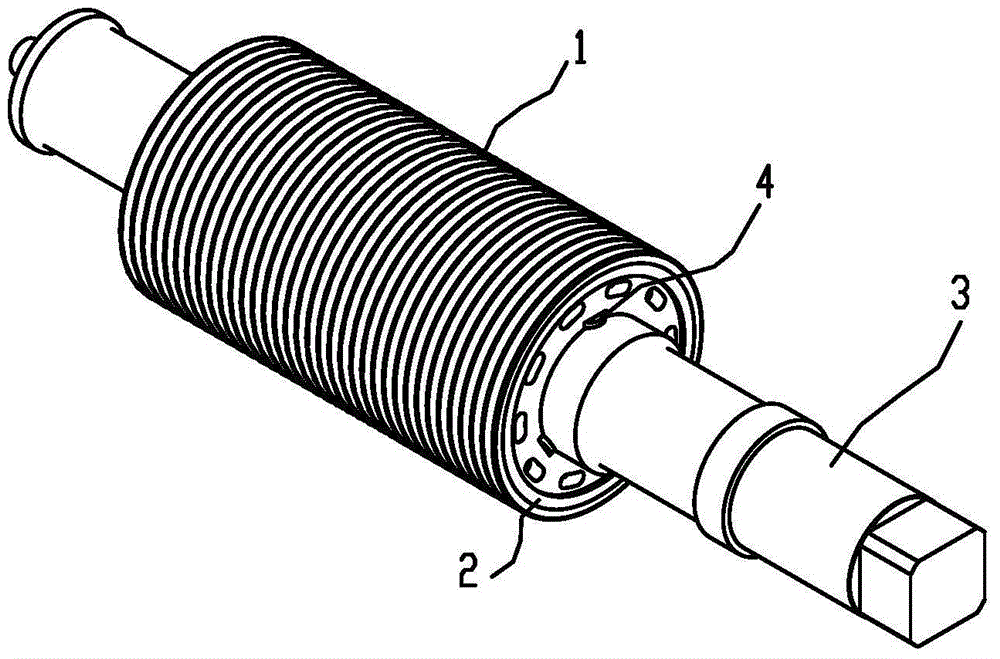

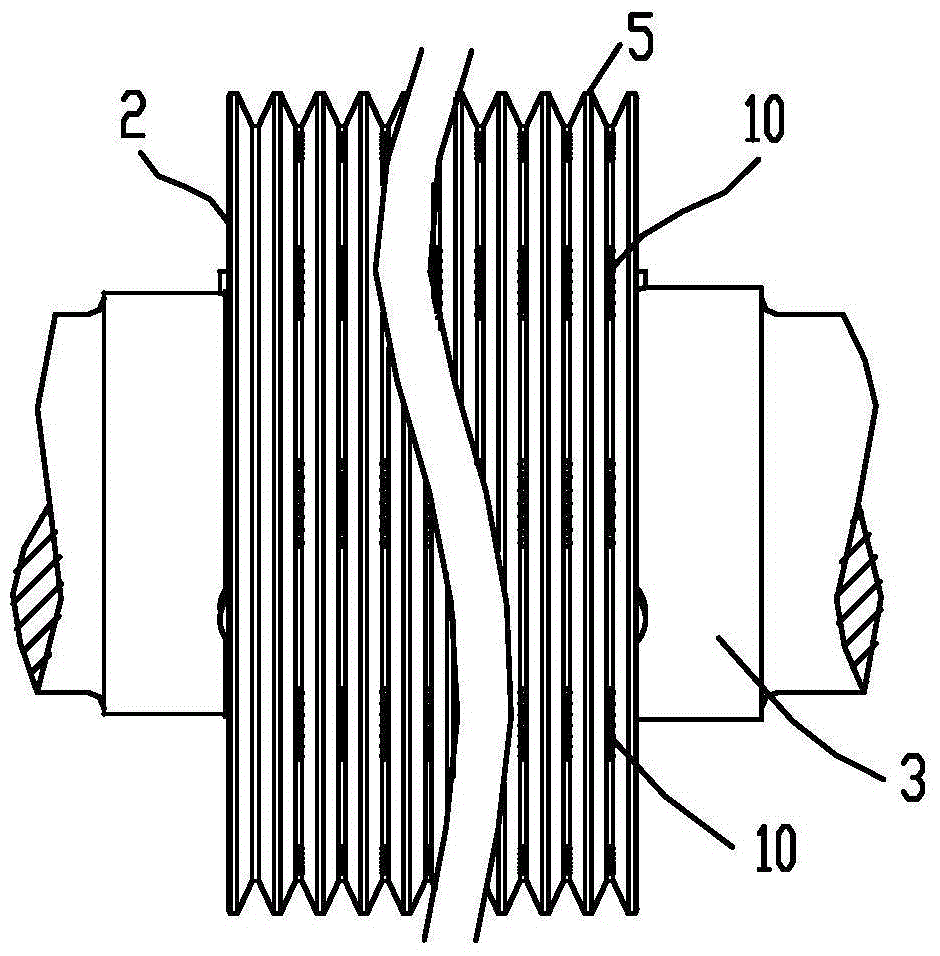

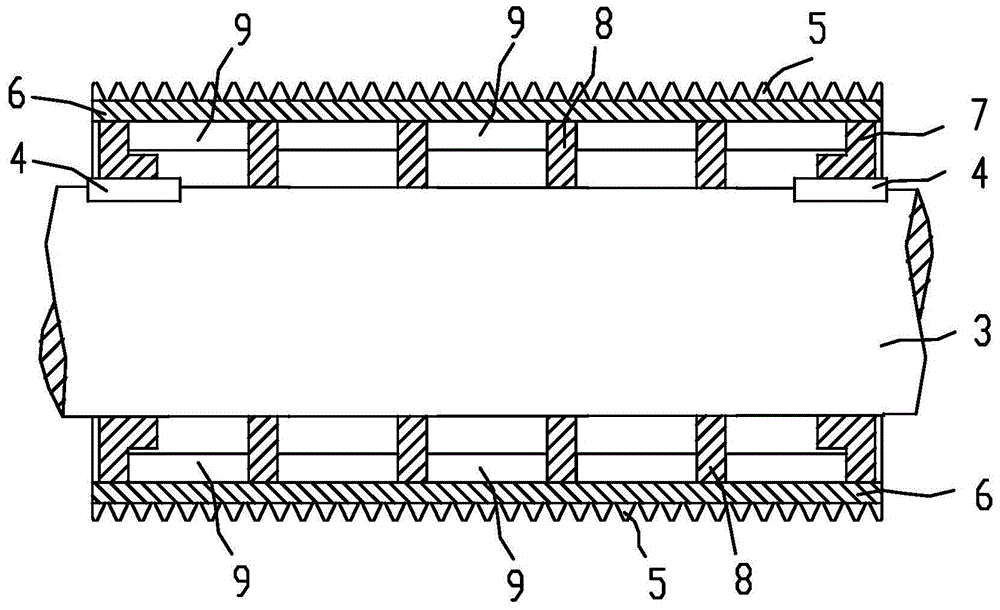

[0022] The invention discloses a manufacturing method of a sugarcane pressing roll, which comprises a roll shell 2 and a roll shaft 3, and the roll shell 2 is fastened on the roll shaft 3 through a shrink-fit interference fit; the roll shell 2 includes roll teeth 5 , shell 6 and support frame 7, form the shell 6 of the roll shell 2 by forming the steel plate roll, and weld the annular support frame 7 in the inner cavity of the shell 6 and form the inner hole of the roll shell 2, in the shell 6 Weld the roller teeth 5 on the outer surface, then machine the roller teeth 5 and the inner hole of the roller shell 2, and finally fit the roller shell 2 onto the roller shaft 3 through the inner hole of the roller shell 2.

[0023] The key points of the present invention include: the roller shell 2 is manufactured by welding process, which is different from the casting method used in the traditional process. Compared with the traditional process, the present invention shortens the overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com