Active carbon activating treatment for zeolite and its preparation application and regeneration

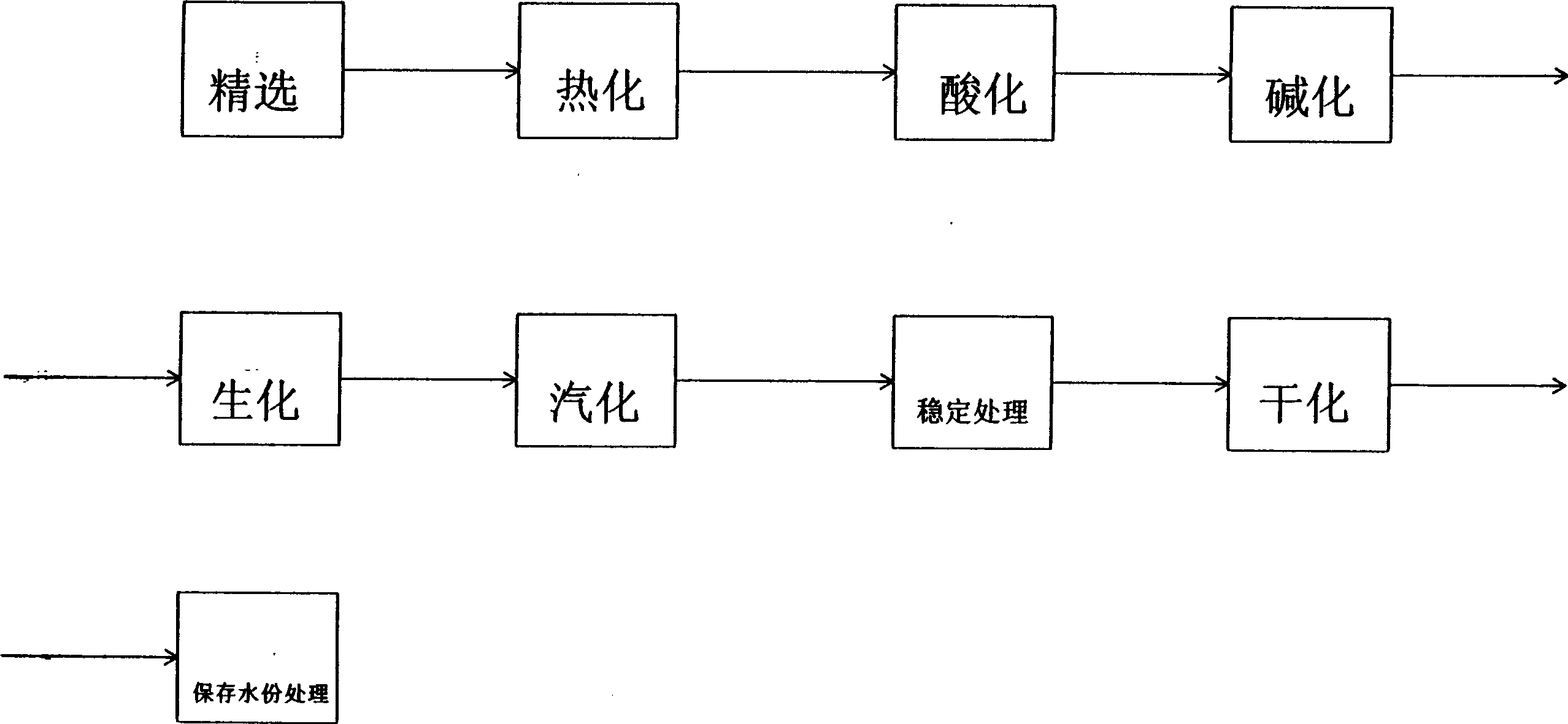

An activation treatment, activated carbon technology, applied in inorganic chemistry, silicon compounds, other chemical processes, etc., can solve the problems of zeolite influence, oxygen-deficient calcination, incomplete regeneration, etc., and achieve the effect of prolonging the service period and enhancing the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

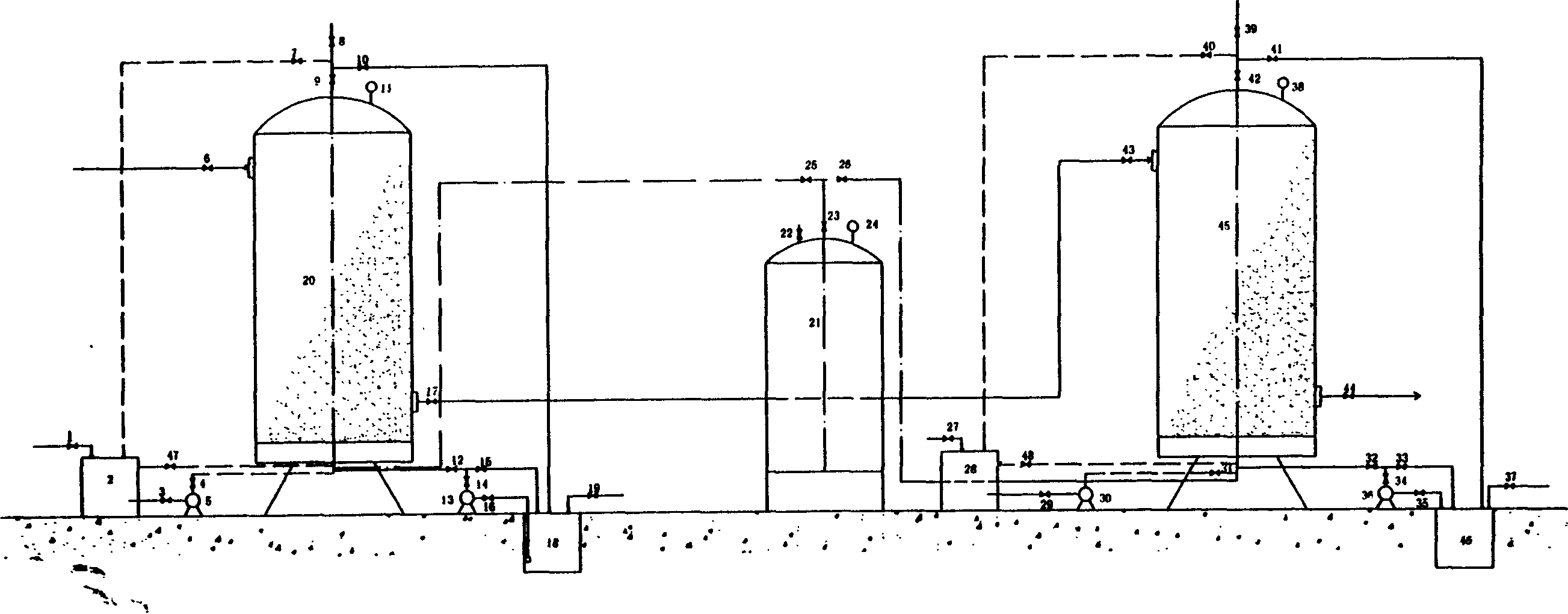

[0019] The implementation process of the two processes of alkalization and biochemistry is used to illustrate the realization procedures of the entire nine processes. Two process implementation procedures of alkalization and biochemistry. First, open the zeolite delivery valve 6 processed by the upper process, and fill the alkalization tank with zeolite, which is completed by pressurizing with water. Open the alkali solution pump 5, water suction valve 3, and water lift valve 4 to pump the alkali solution into the tank, close valves 9, 6, 17, 12, 4, open the steam delivery valve 25, and send 0.35m vapor pressure to the alkalization tank , The temperature is 200 ℃ steam for a certain hour, stop the steam, open the alkali solution replay valve 47, put the alkali solution back into the pool, close the alkali solution replay valve 47, alkali solution pump water valve 4, return valve 15, open for cleaning Return water valve 10, circulating valve 12, circulating pump water raising valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com