Patents

Literature

215 results about "Job shop scheduling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Job shop scheduling or the job-shop problem (JSP) is an optimization problem in computer science and operations research in which jobs are assigned to resources at particular times. The most basic version is as follows: We are given n jobs J₁, J₂, ..., Jₙ of varying processing times, which need to be scheduled on m machines with varying processing power, while trying to minimize the makespan. The makespan is the total length of the schedule (that is, when all the jobs have finished processing).

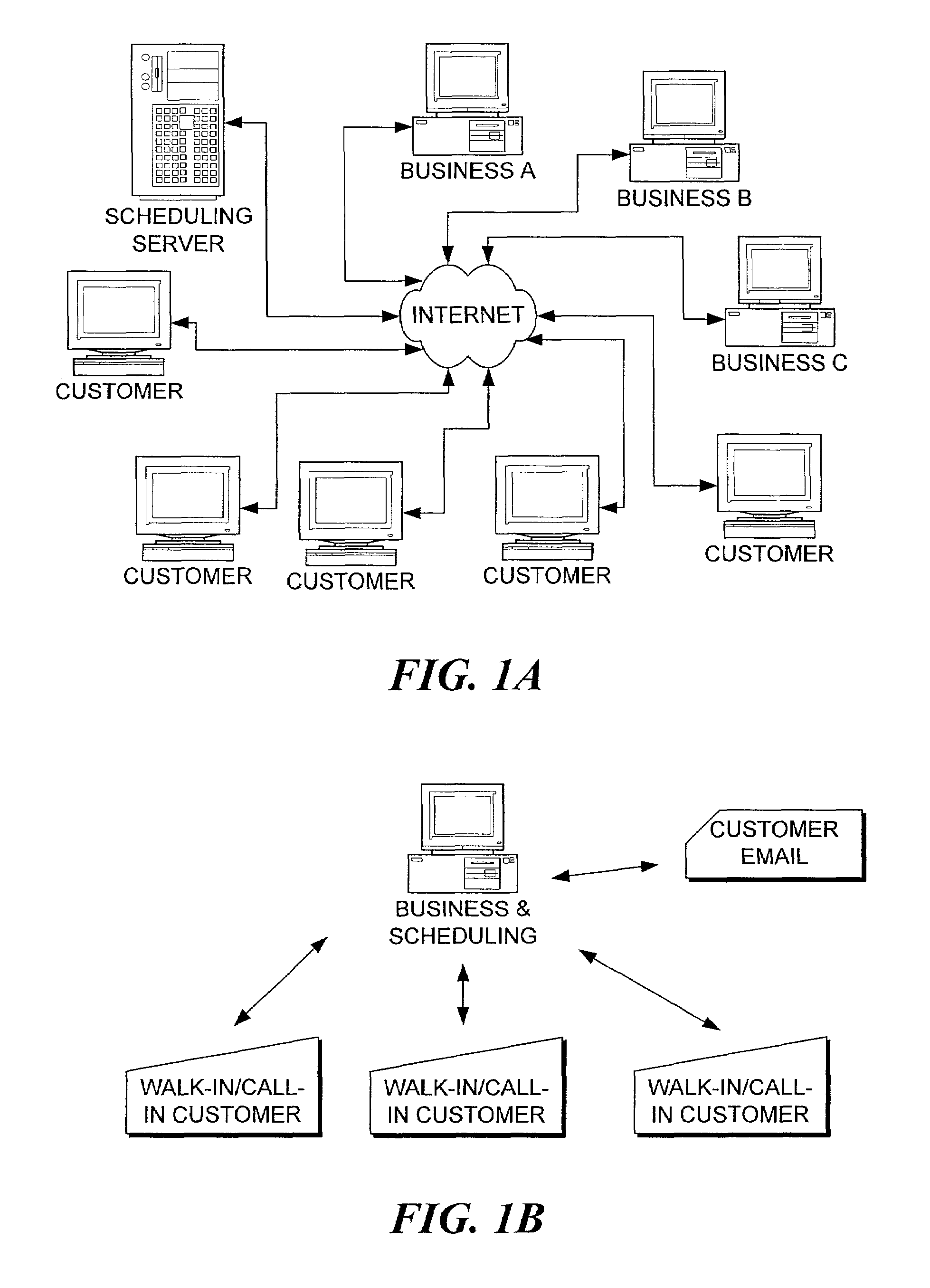

Automated job scheduling based on resource availability

Each job is defined in terms of the tasks / services required to do the jobs, using resources needed to carry out those tasks / services at different times during a scheduling period. Each available resource needed for each task / service is associated with a job ID and different start times for a job, forming proposals. The proposals are preferably created prior to the time that any appointments are made to do the job. If an appointment time requested by a customer to have the job done is available among the proposals created, the appointment is scheduled using the proposal. As each appointment is scheduled, changed, or canceled, the available proposals for the job are automatically modified to reflect the changes in the time that each resource is available to do the tasks / services required for the job.

Owner:MICROSOFT TECH LICENSING LLC

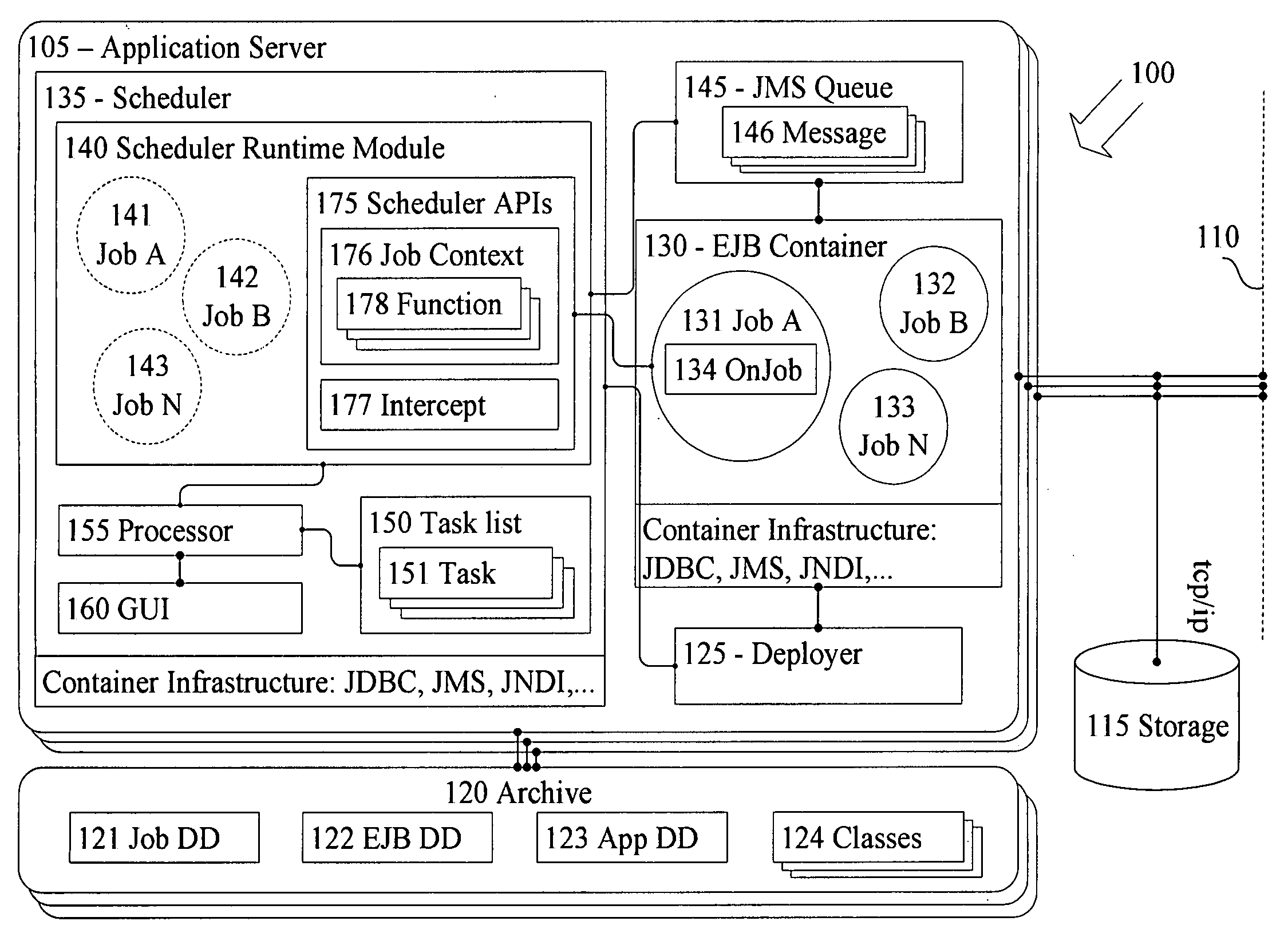

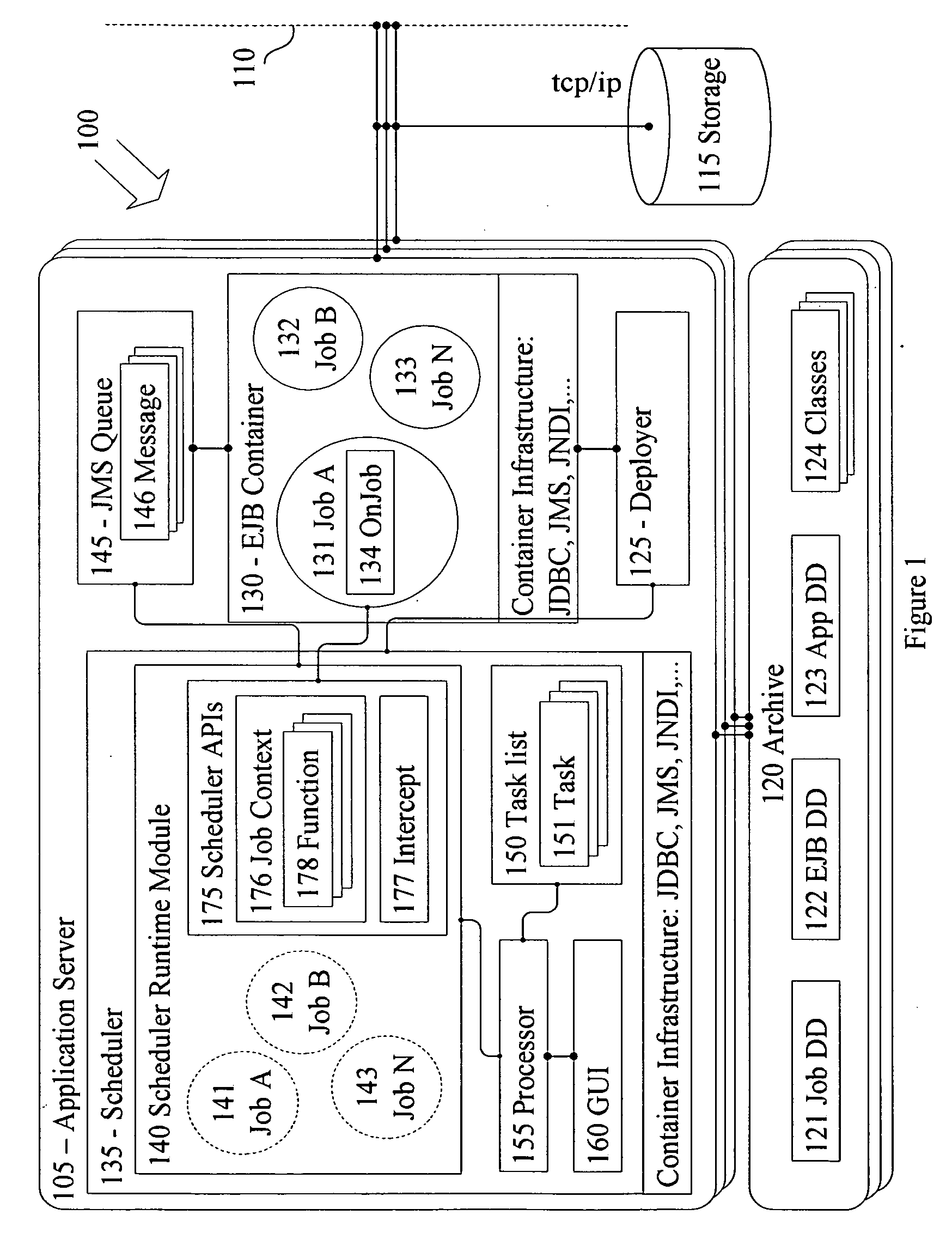

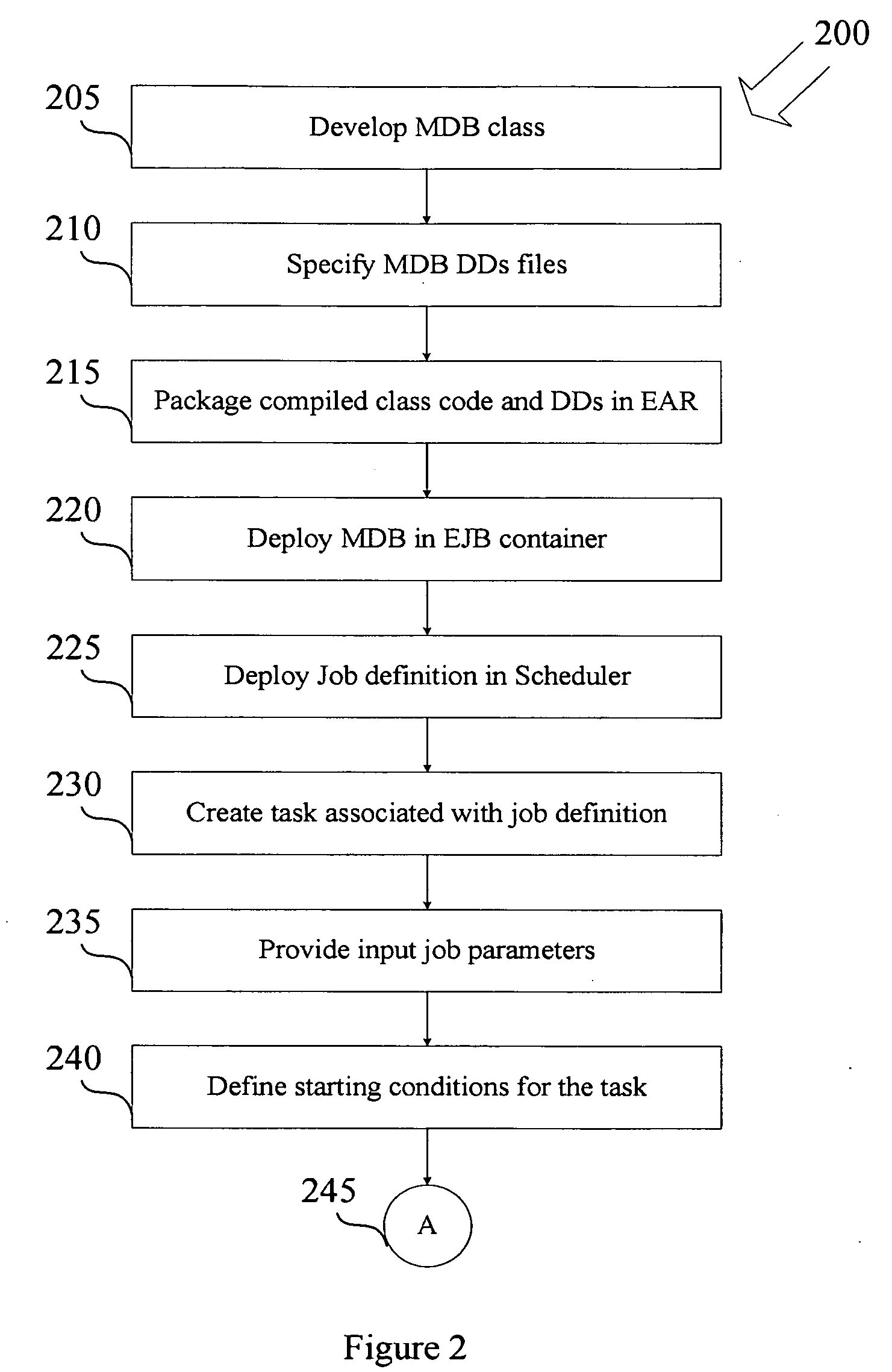

System and method for job scheduling in application servers

ActiveUS20090089785A1Memory systemsDistributed object oriented systemsApplication serverJob shop scheduling

A method and a system for job scheduling in application servers. A common metadata of a job is deployed, the job being a deployable software component. An additional metadata of the job is further deployed. A scheduler task based on the additional metadata of the job is created, wherein the task is associated with a starting condition. The scheduler task is started at an occurrence of the starting condition, and, responsive to this an execution of an instance of the job is invoked asynchronously.

Owner:SAP AG

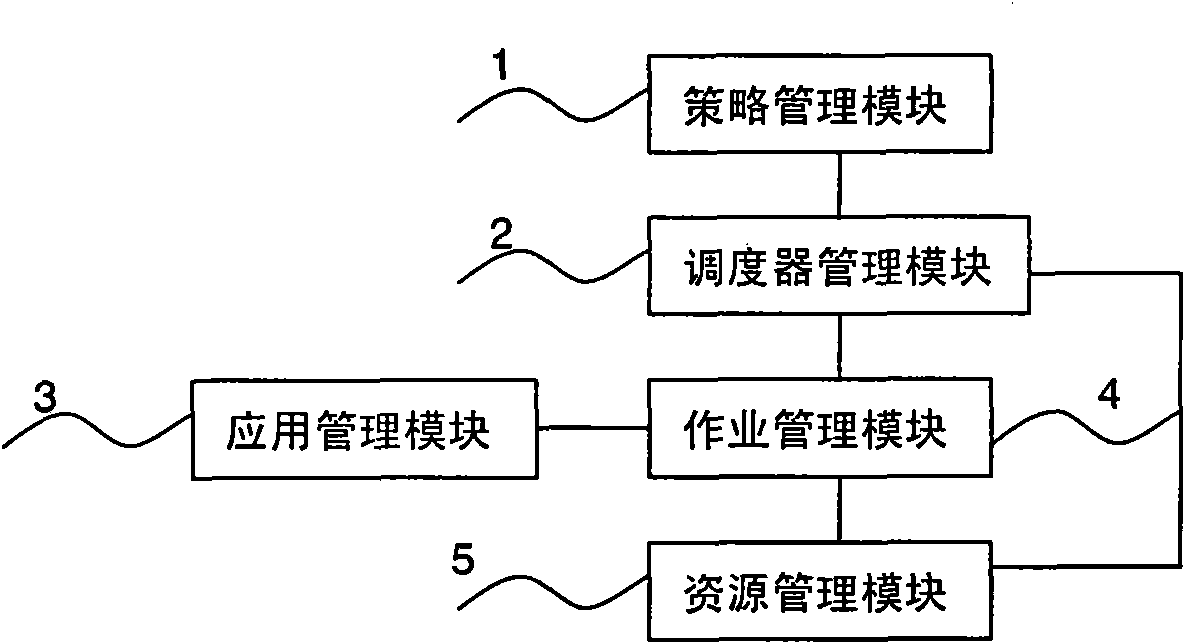

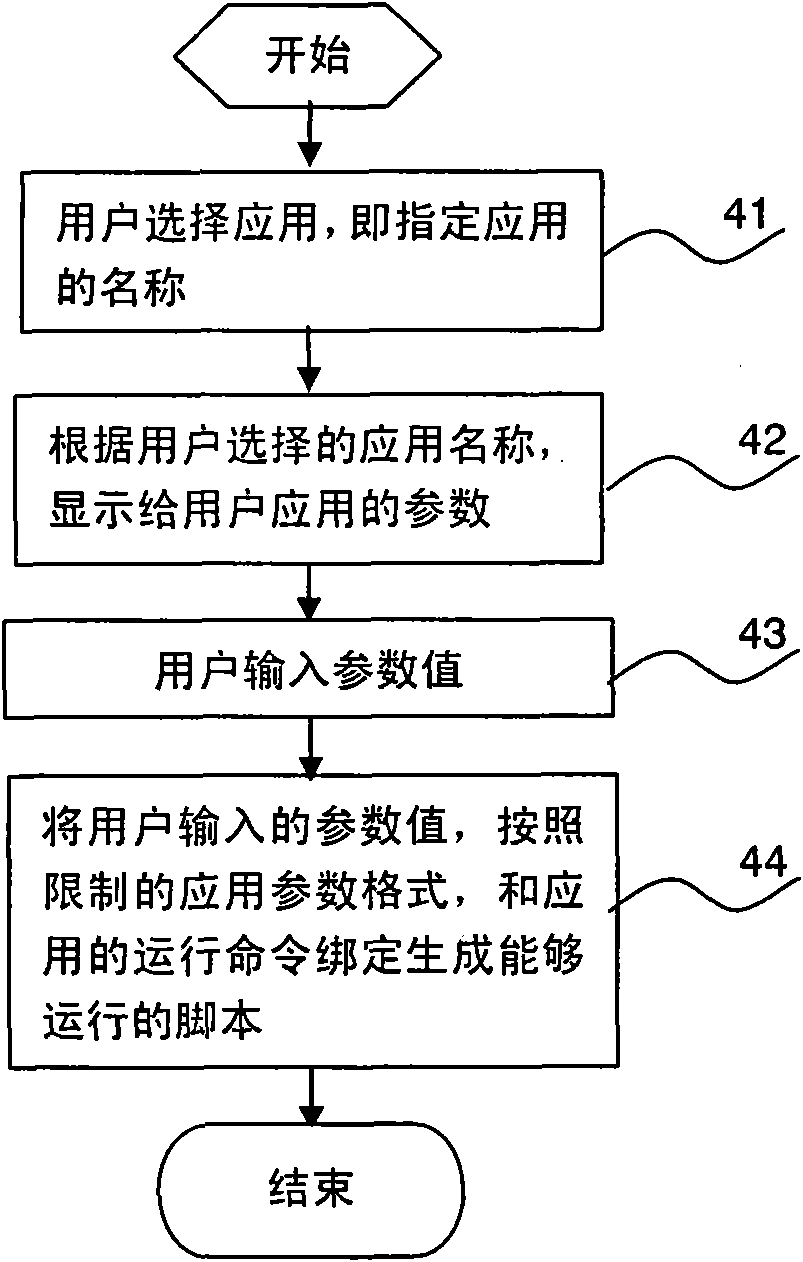

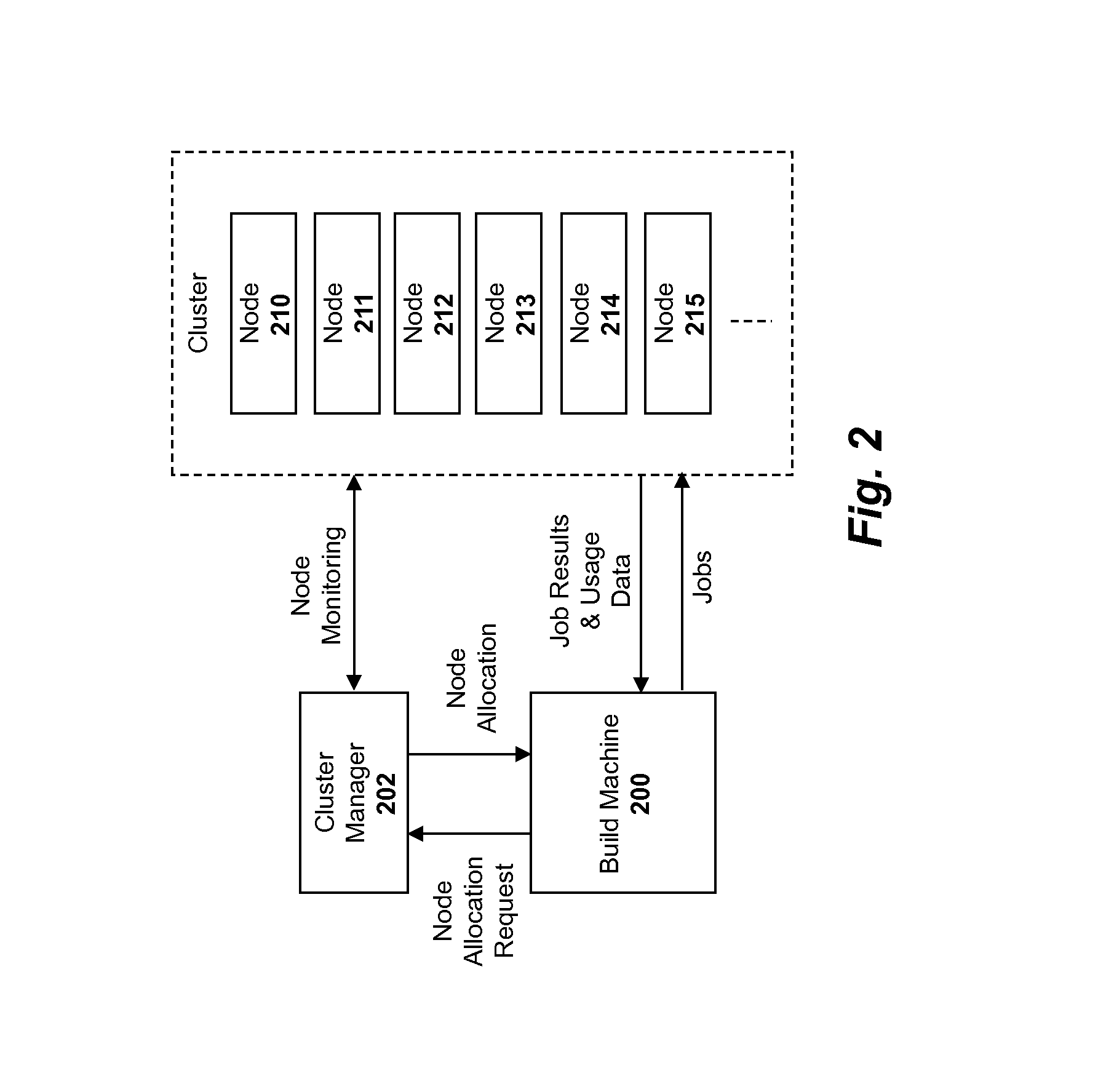

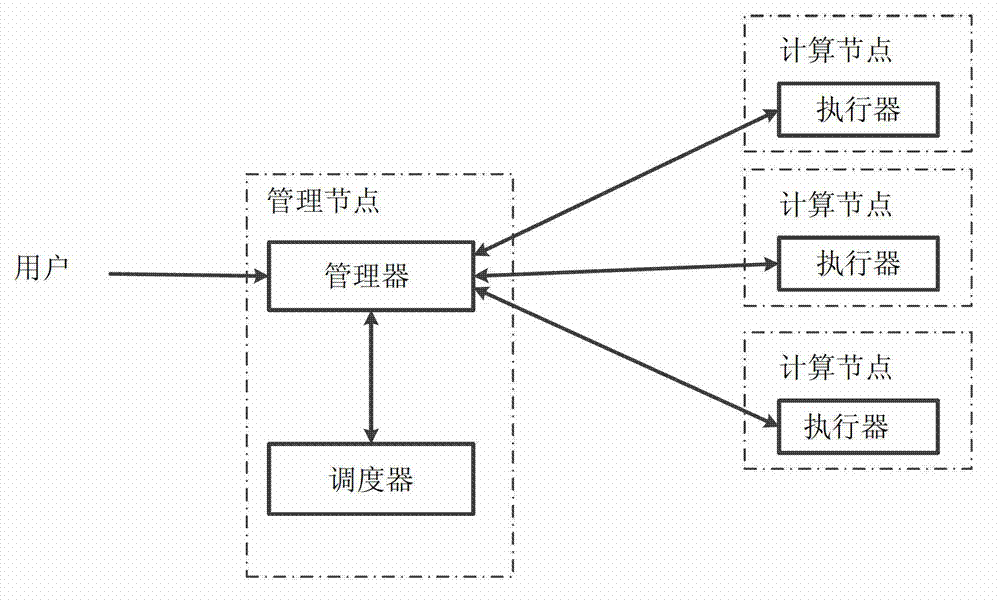

Cluster job scheduling system with elastic framework

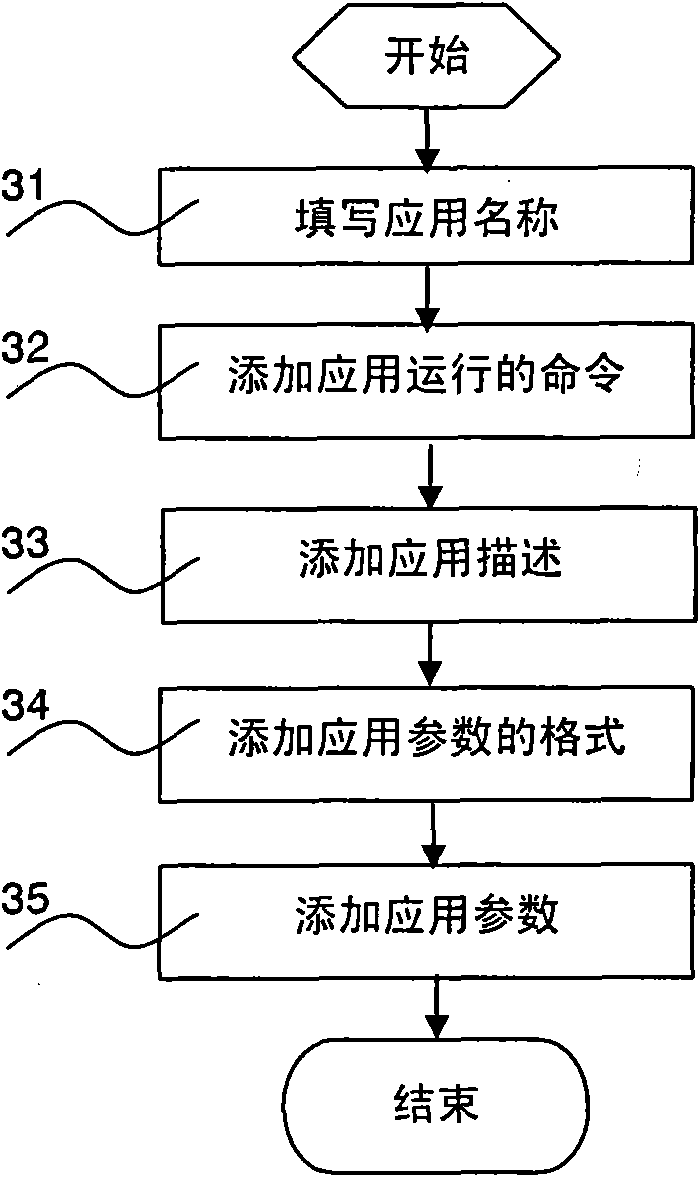

InactiveCN101599026AAlleviate the strain on computing powerEasy to viewMultiprogramming arrangementsData switching networksWeb browserMulti cluster

The invention provides a cluster job scheduling system with an elastic framework. The job scheduling system adopts a B / S structure, and a client can conveniently submit and manage jobs through a web browser to provide a single system image for multi-cluster job management. The system structure comprises a scheduler management module, a resource management module, a job management module, an application management module and a strategy management module, wherein the scheduler management module can construct different schedulers between clusters and inside the clusters; the schedulers can select and use different scheduling strategies; and the job management module obtains corresponding application configuration and application running commands from the application management module according to the application attributes of jobs. When the job is submitted, a job running script is automatically generated to provide a flexible scheduling mechanism for job scheduling, thereby facilitating users.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

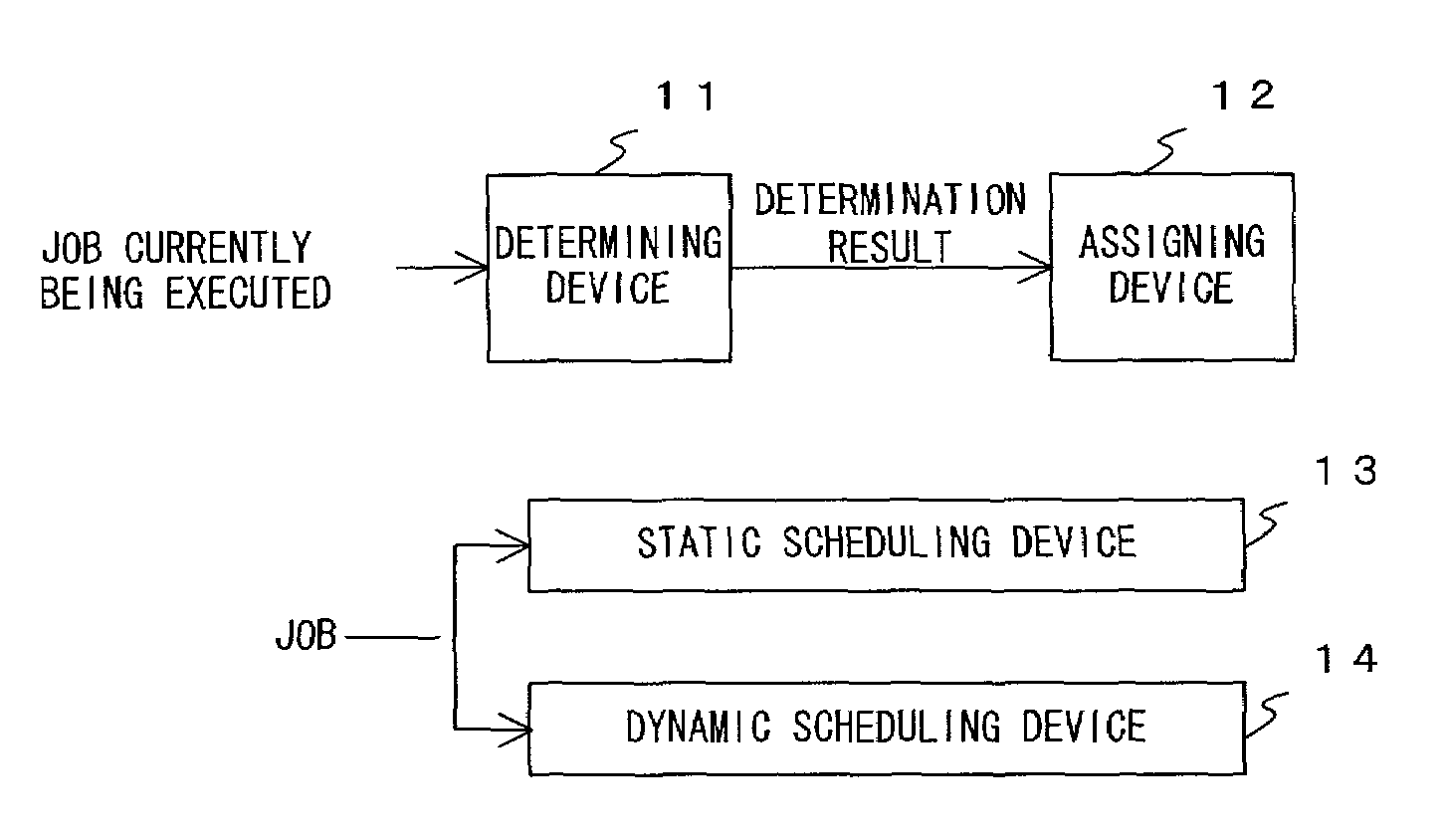

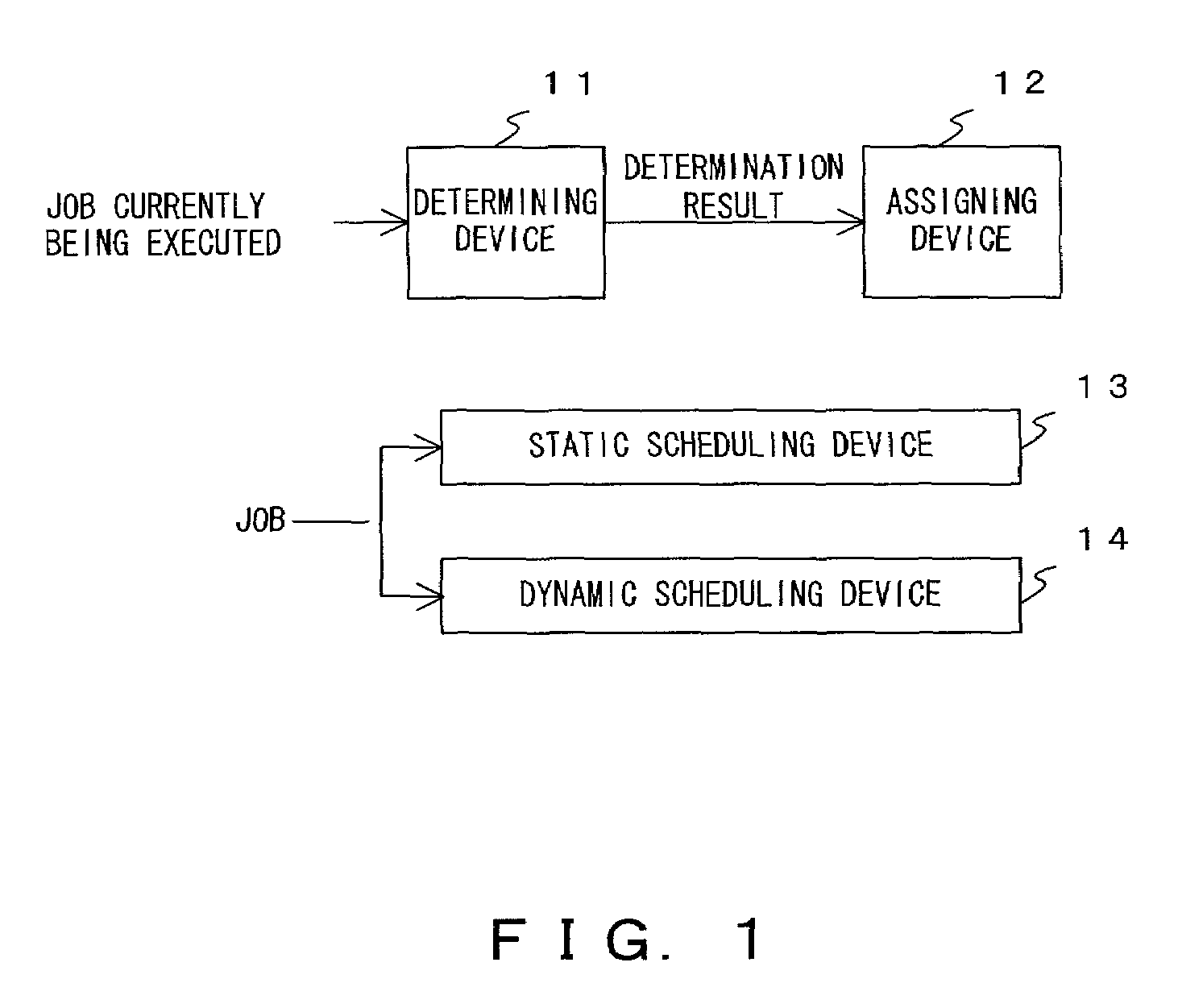

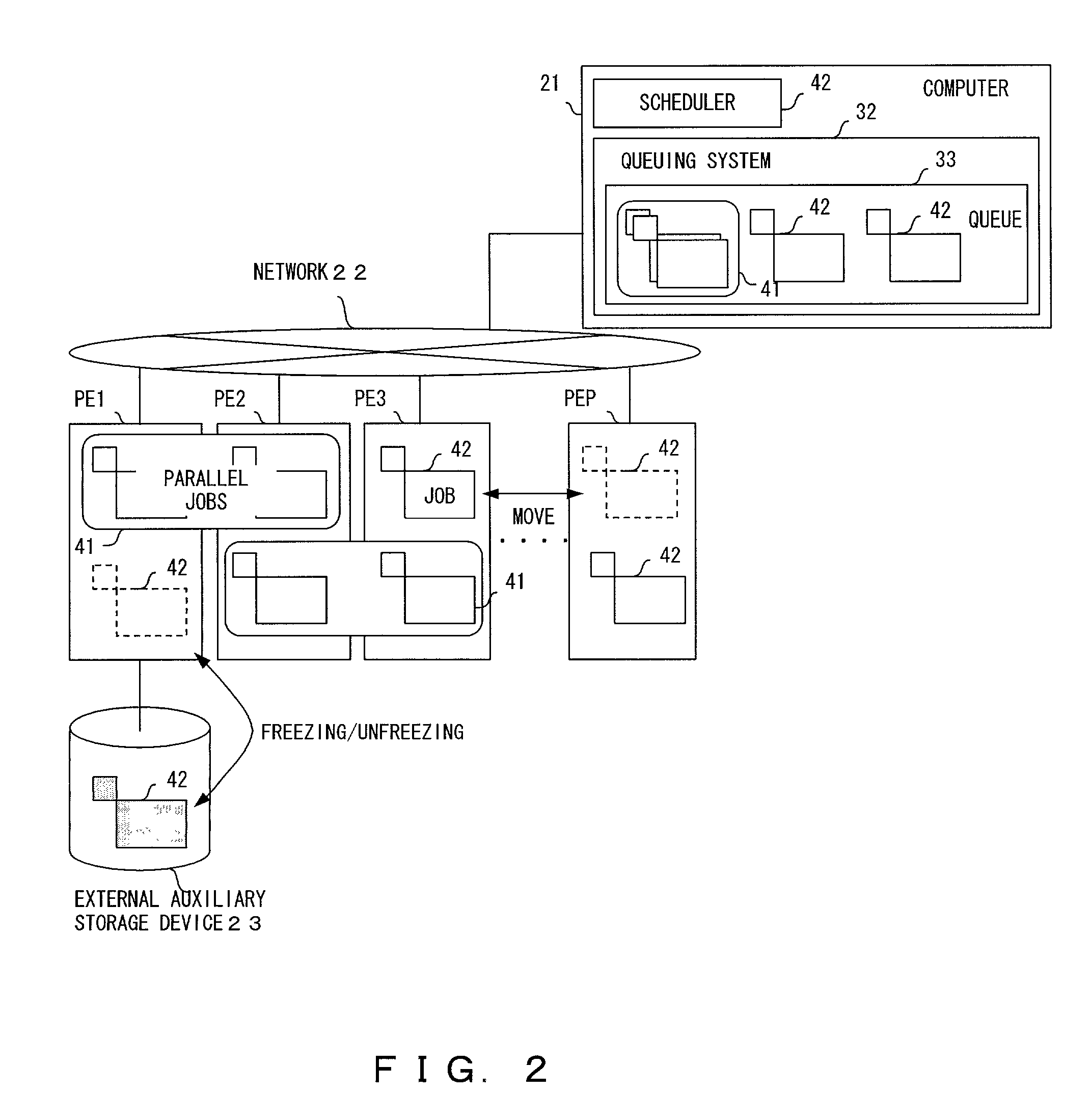

Scheduling apparatus performing job scheduling of a parallel computer system

InactiveUS7024671B2Reduce errorsImprove efficiencyResource allocationDigital computer detailsProcessor elementJob shop scheduling

A job entered into a processor element (PE) of a parallel computer system is moved to a different PE, or written to an external auxiliary storage device by being frozen, with dynamic scheduling. A scheduler estimates the remaining time of execution of each job, compares with a migration / freezing cost, and determines a job to be moved / frozen.

Owner:FUJITSU LTD

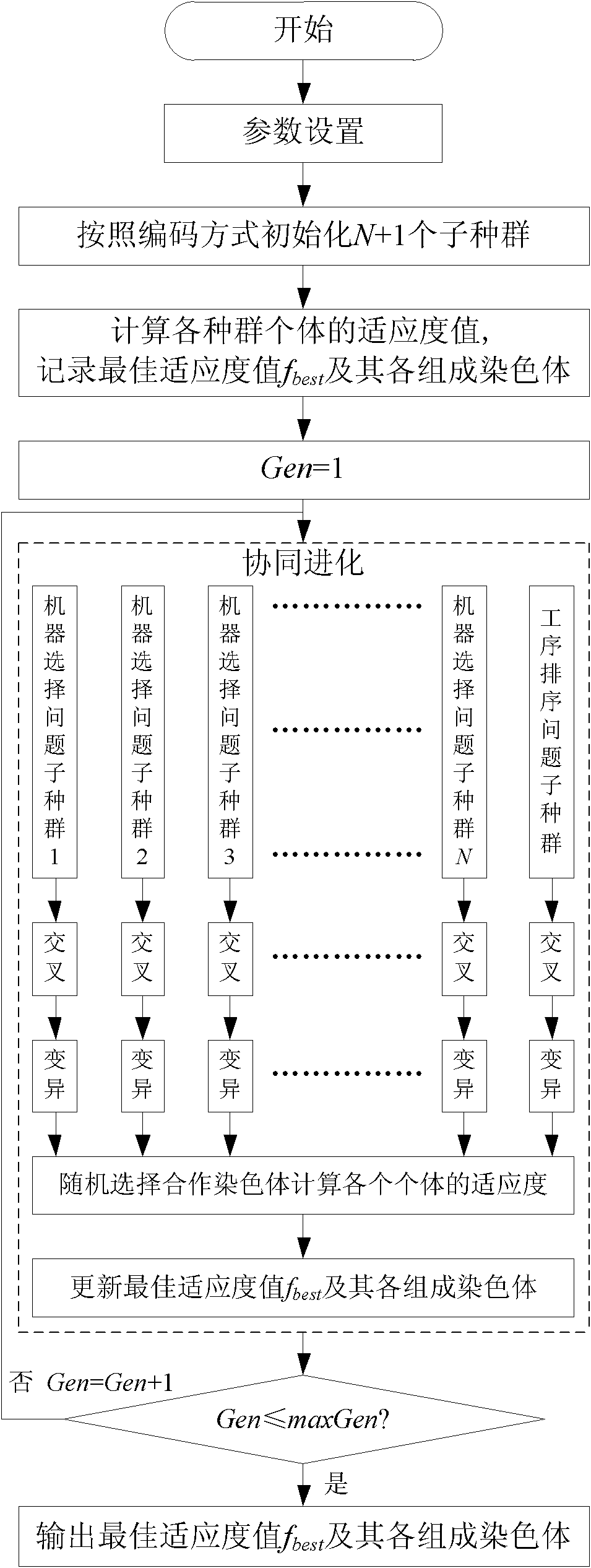

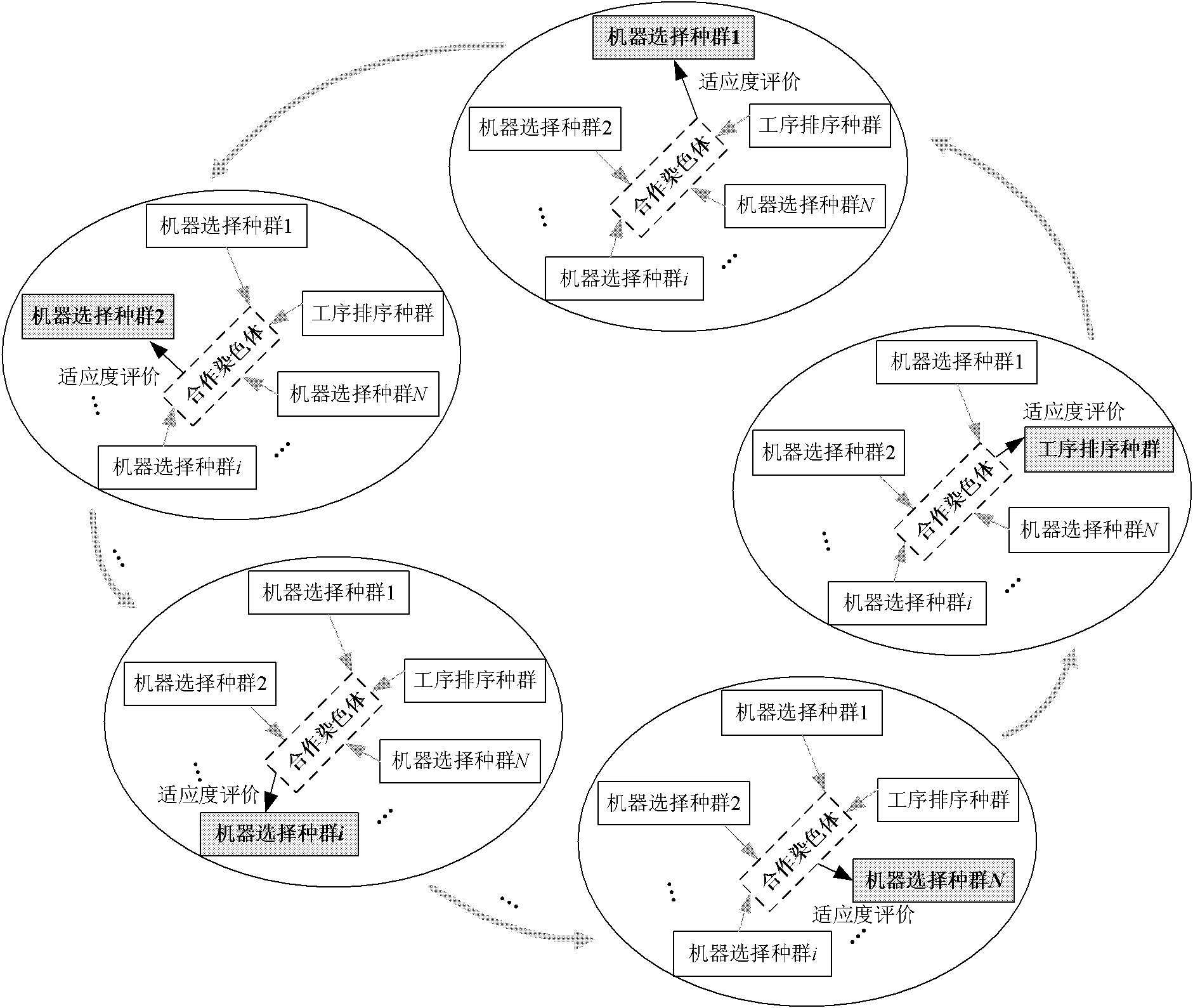

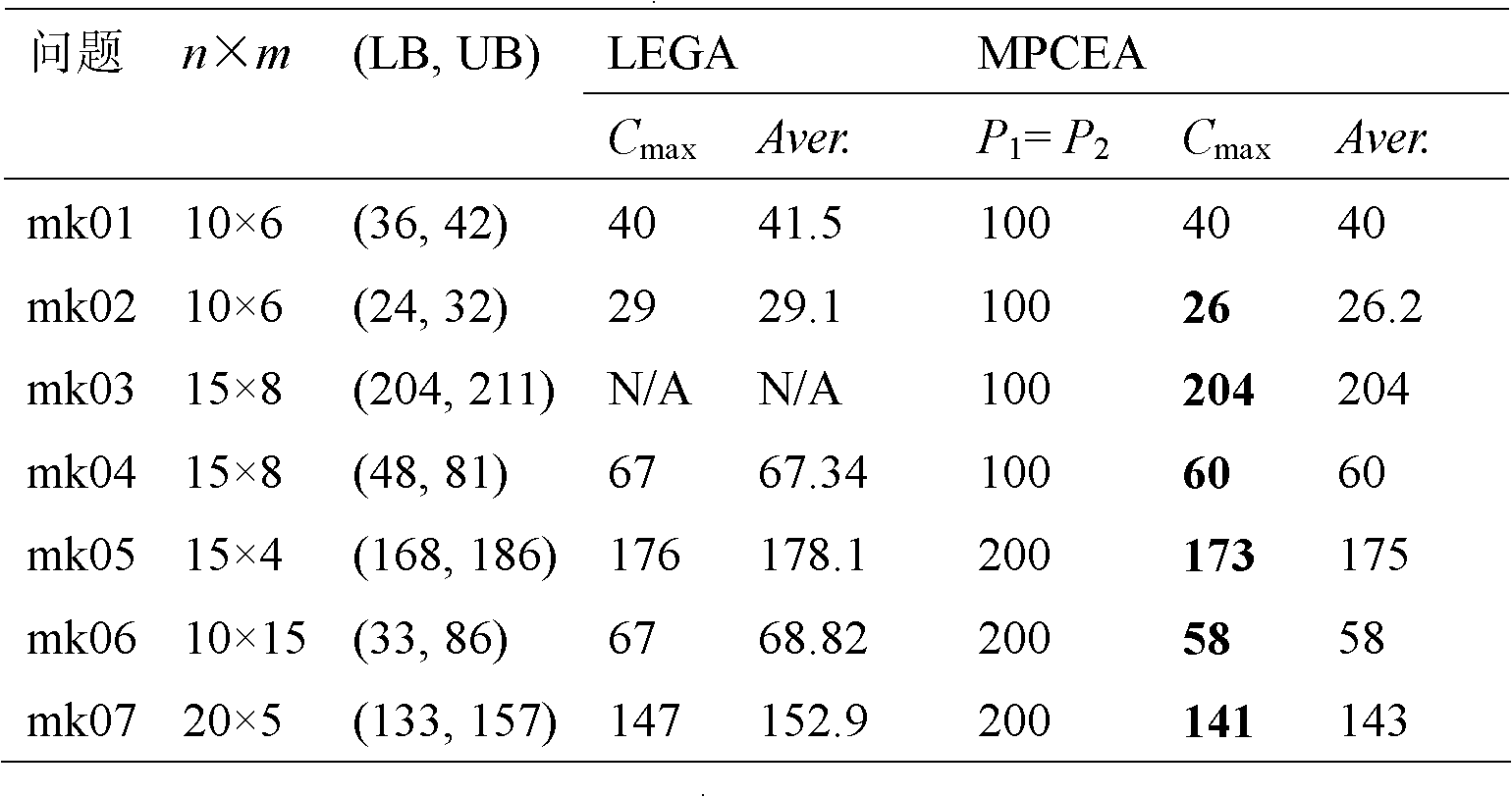

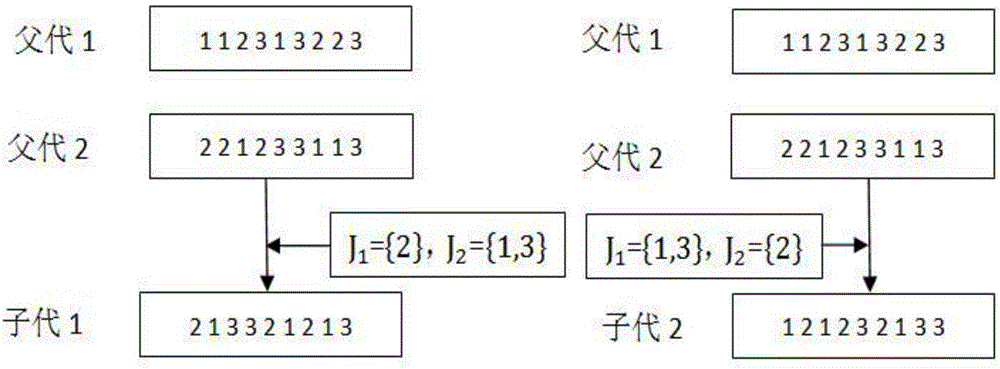

Flexible job shop scheduling method based on multi-species coevolution

InactiveCN101901425AQuality improvementAvoid the disadvantages that the performance cannot be fully utilizedResourcesGuidelineJob shop scheduling

The invention provides a flexible job shop scheduling method based on multi-species coevolution, which belongs to the field of shop scheduling, and mainly overcomes the disadvantage that a flexible job shop scheduling method based on a genetic algorithm can not be exerted fully. The method comprises the main steps of: 1. setting parameters; 2. initializing species according to a set coding method; 3. calculating the fitness value of each chromosome in each species according to a set method, and recording the optimum fitness value and the constitute chromosomes thereof; 4. carrying out multi-species coevolution: carrying out evolution operations, i.e. chiasmata and variation, to chromosomes in each subspecies, and evaluating new chromosomes; and 5. judging whether a method termination criteria is achieved or not: if so, terminating the method and outputting the optimum fitness value and the constitute chromosomes thereof; and otherwise, jumping to the step 4. The invention can be used to obtain a high-quality scheduling scheme suitable for practical production of shops, can shorten production time, and can be used for scheduling management and optimization of the production process of shops.

Owner:HUAZHONG UNIV OF SCI & TECH

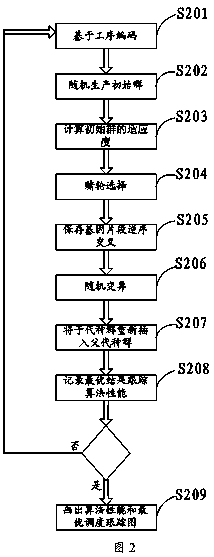

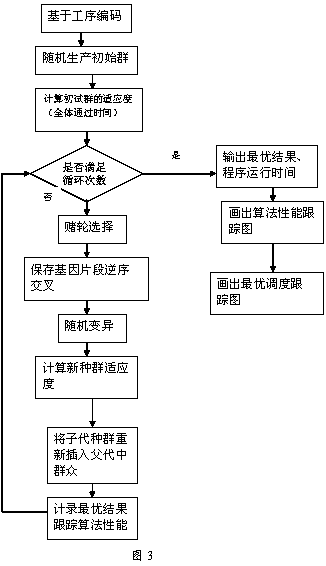

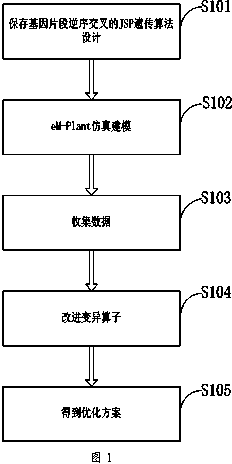

Operation workshop scheduling modeling method based on genetic algorithm

InactiveCN103870647AOptimizing and Harmonizing OperationsImprove Design PerformanceGenetic modelsSpecial data processing applicationsAlgorithms performanceTrace diagram

The invention discloses an operation workshop scheduling modeling method based on a genetic algorithm. The method comprises the steps of JSP genetic algorithm design of reverse cross of a stored gene segment, eM-Plant simulation modeling, data collection, improvement of mutation operator and obtaining of an optimized scheme; the JSP genetic algorithm design of the reverse cross of the stored gene segment comprises the steps of randomly generating an initial group according to a sequence code, calculating the fitness of the initial group, judging whether the cycling times is satisfied, outputting an optimal result and program running time if the cycling times is satisfied, drawing an algorithm performance trace diagram, drawing an optimal scheduling trace diagram, selecting through a roulette wheel if the cycling times cannot be satisfied, reversely crossing the stored gene segment, randomly mutating the gene segment, calculating the fitness of a novel population, re-inserting a filial-generation population to the parental population, and recording the performance of the optimal result trace algorithm. By adopting the method, the running of the production workshop can be optimized and coordinated, the design effect is good, the process is simple, and the production danger and production cost can be reduced.

Owner:XIAN TECH UNIV

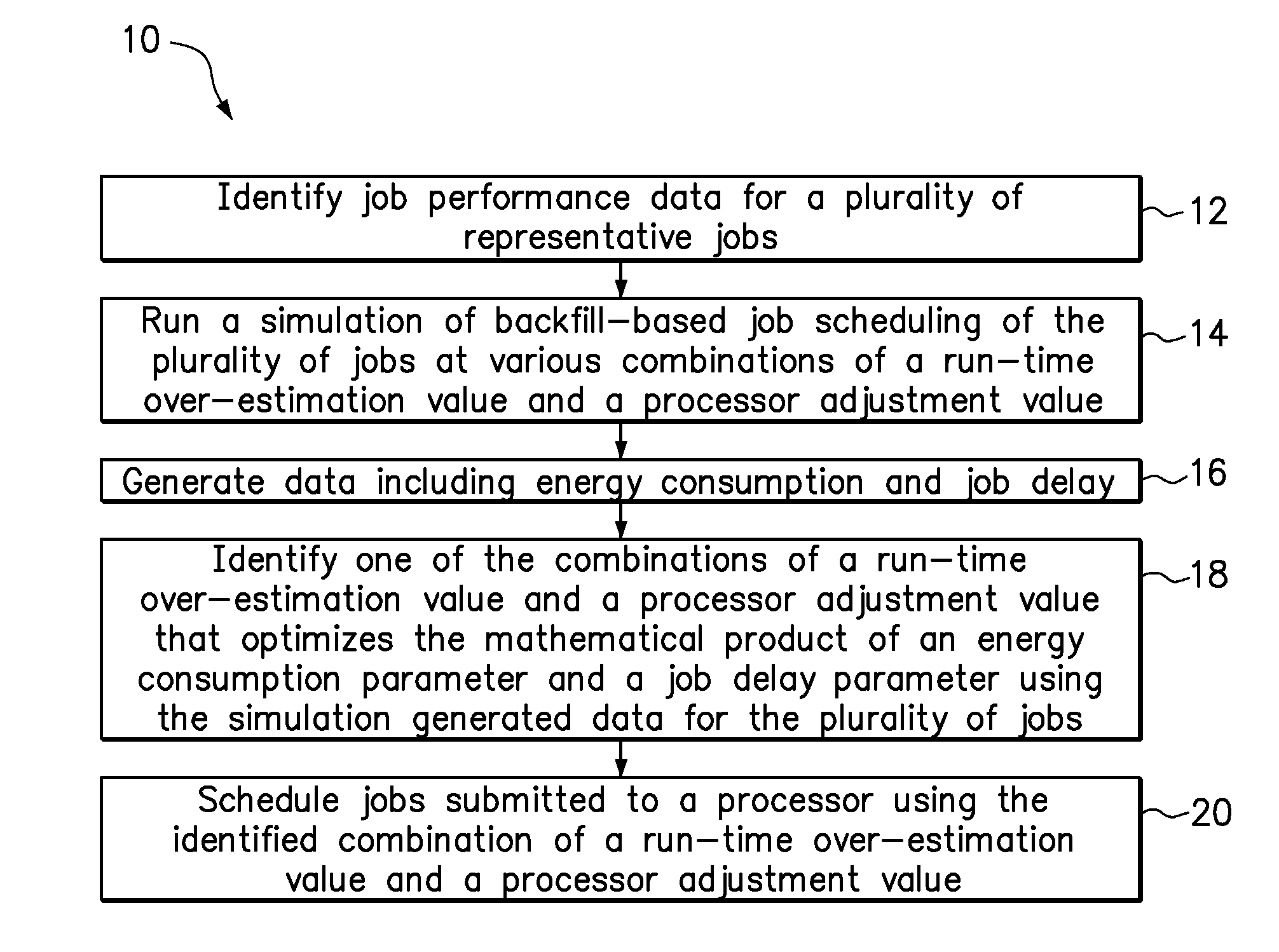

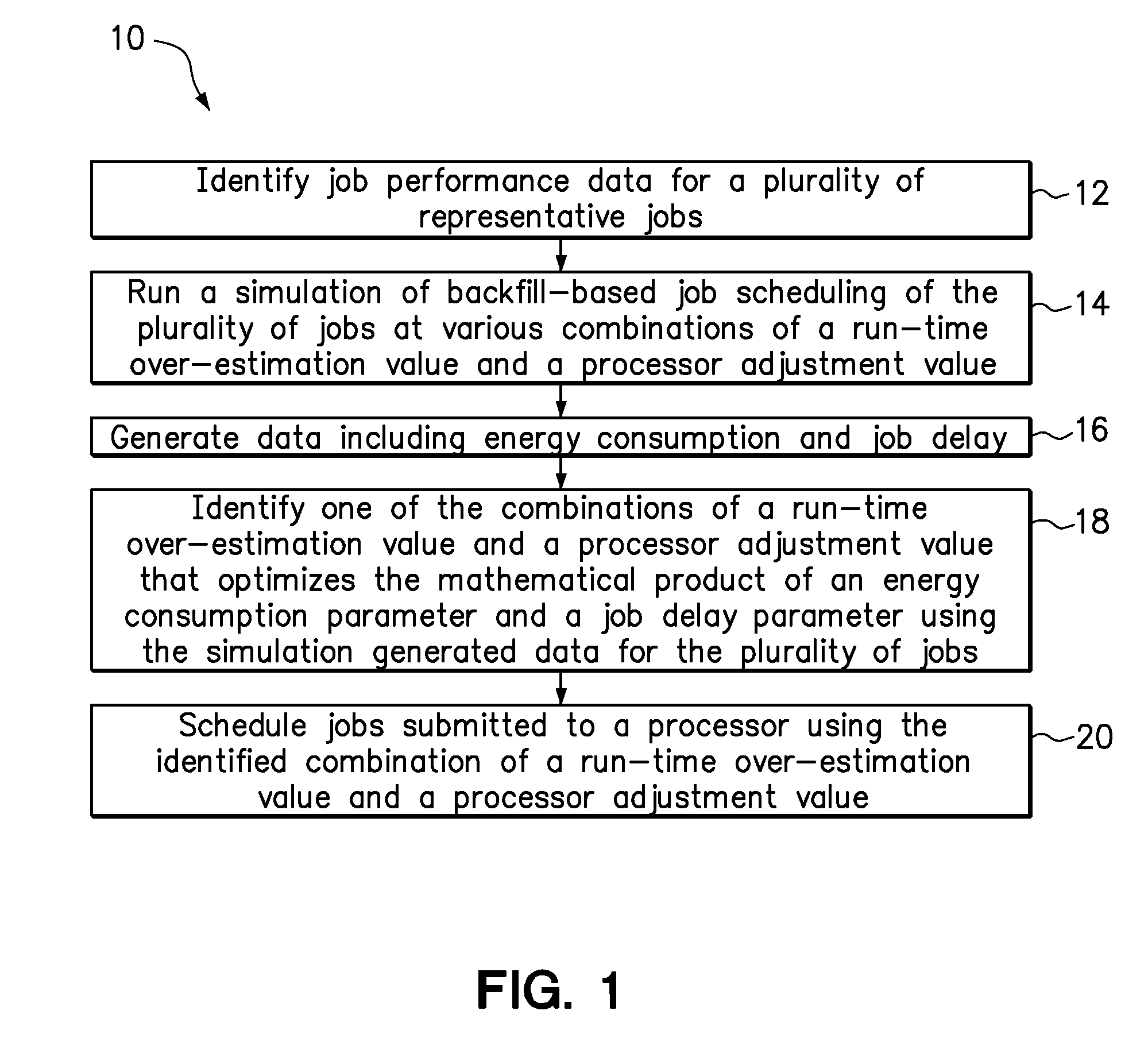

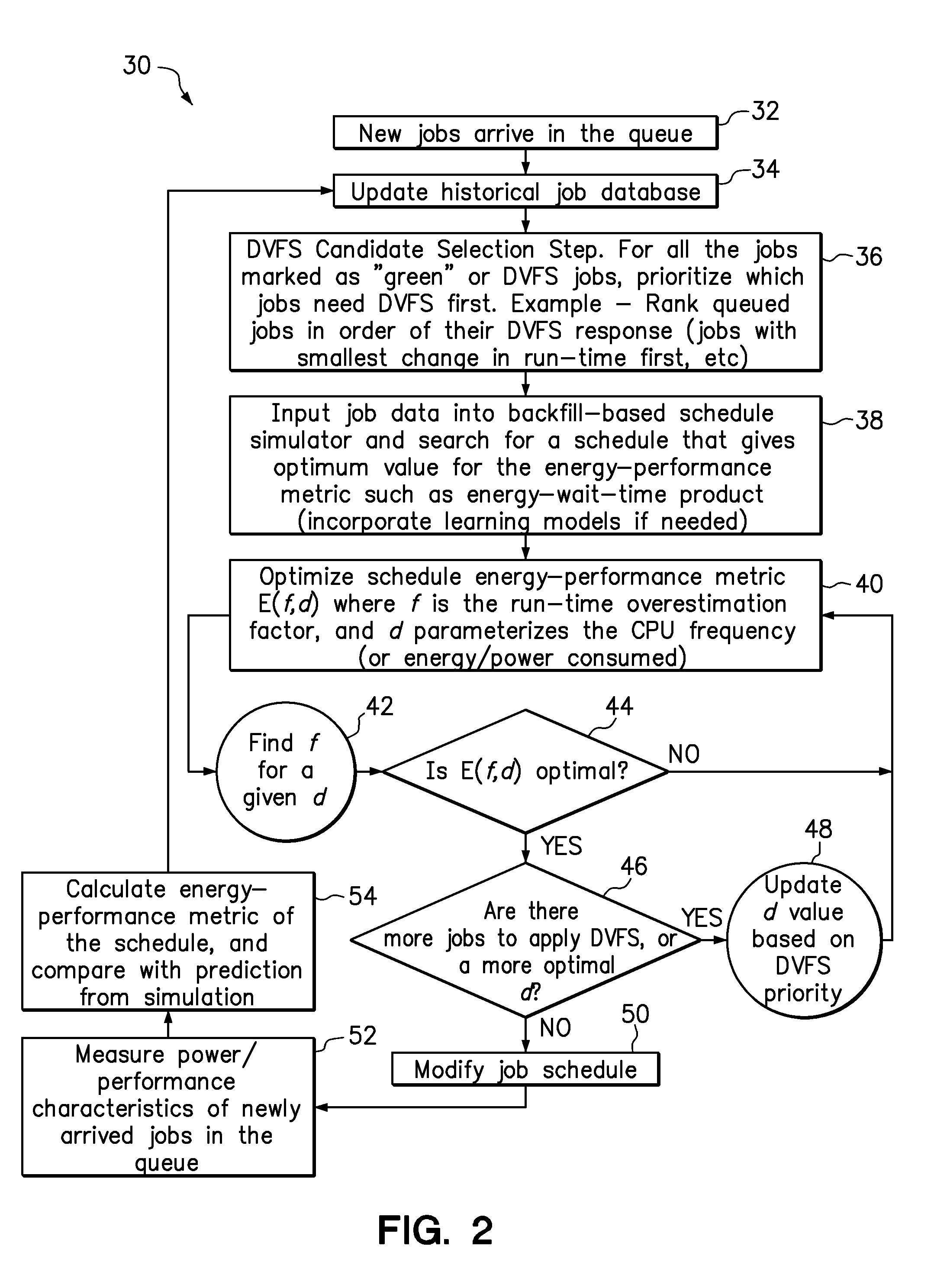

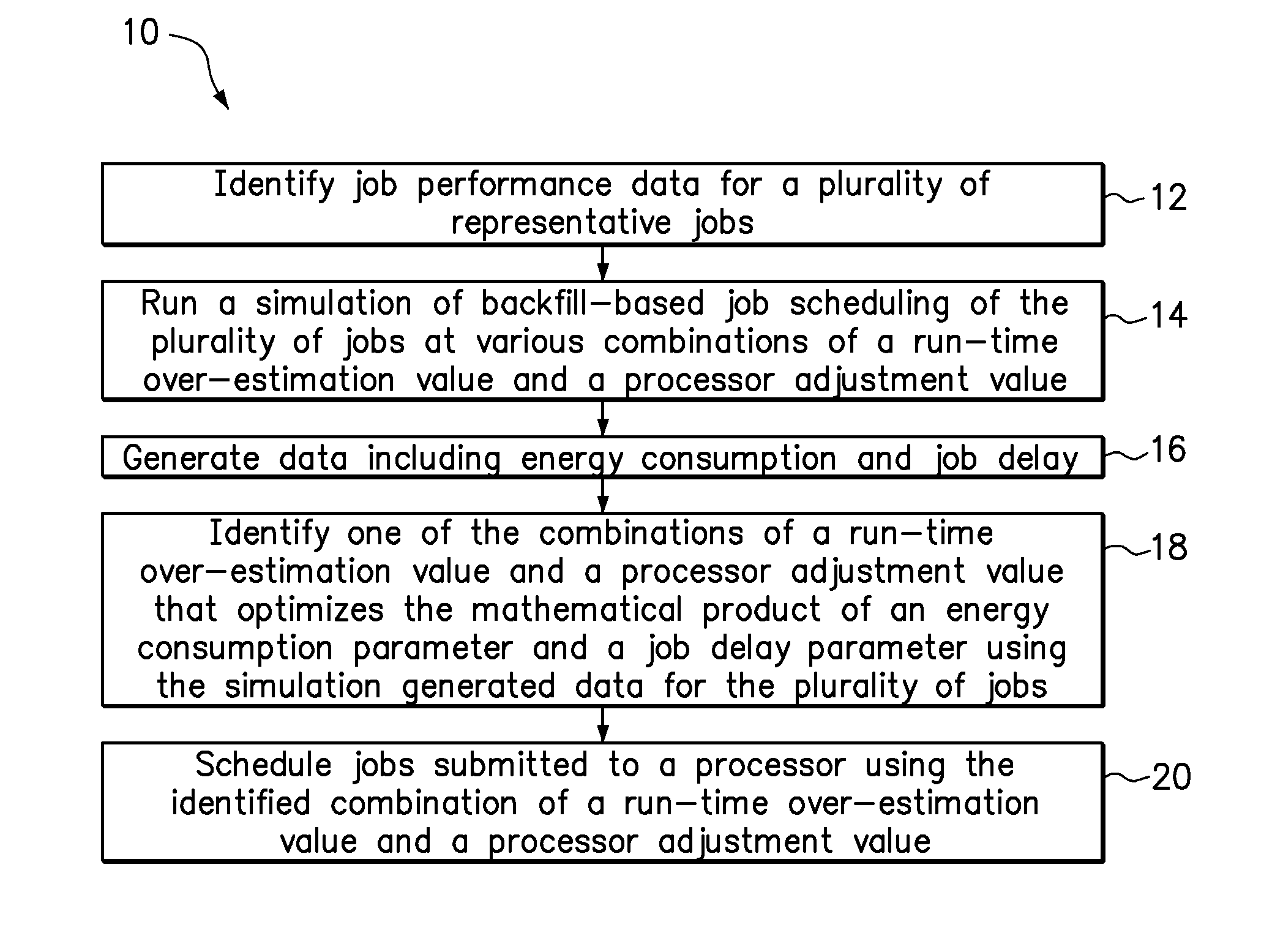

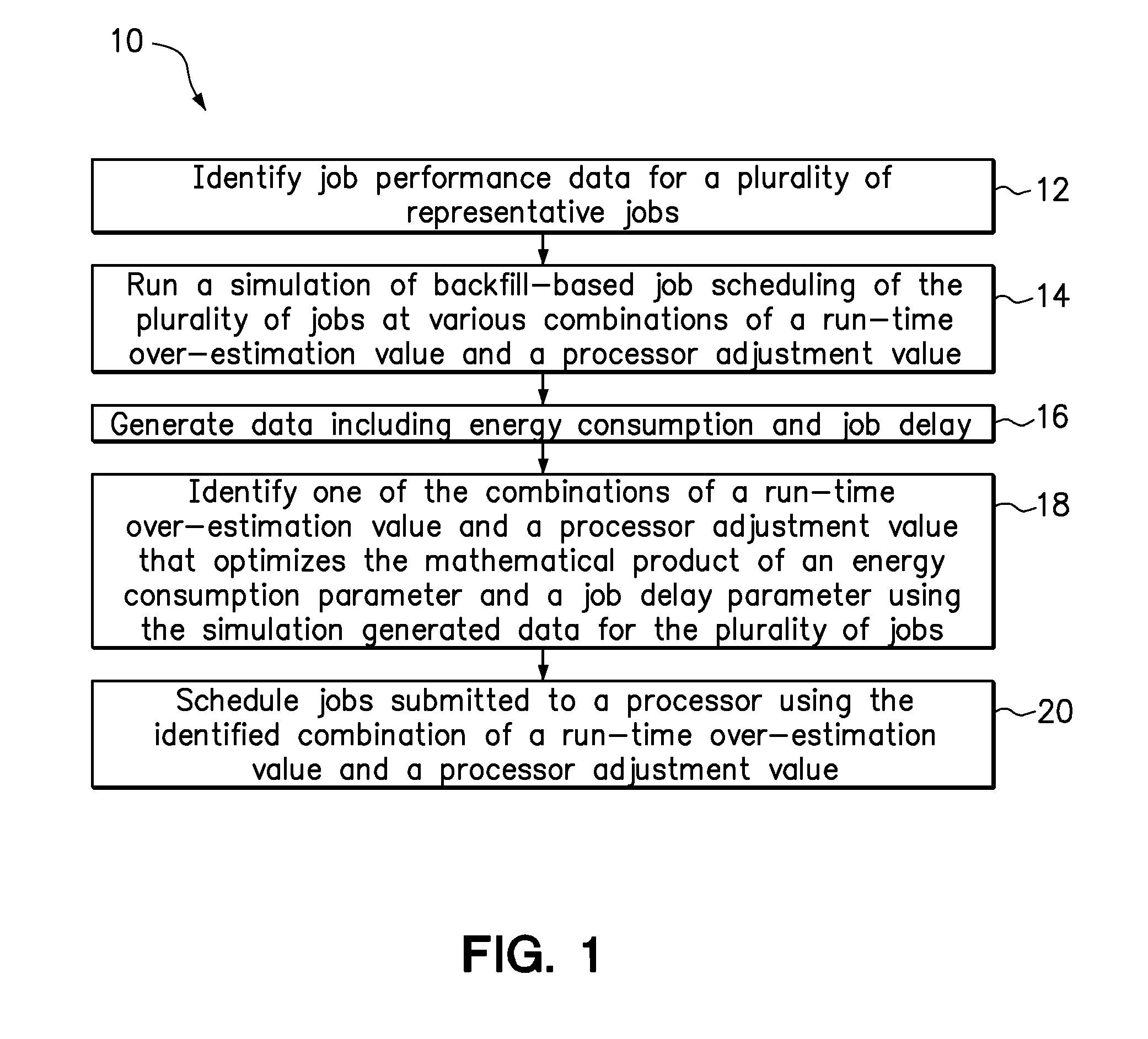

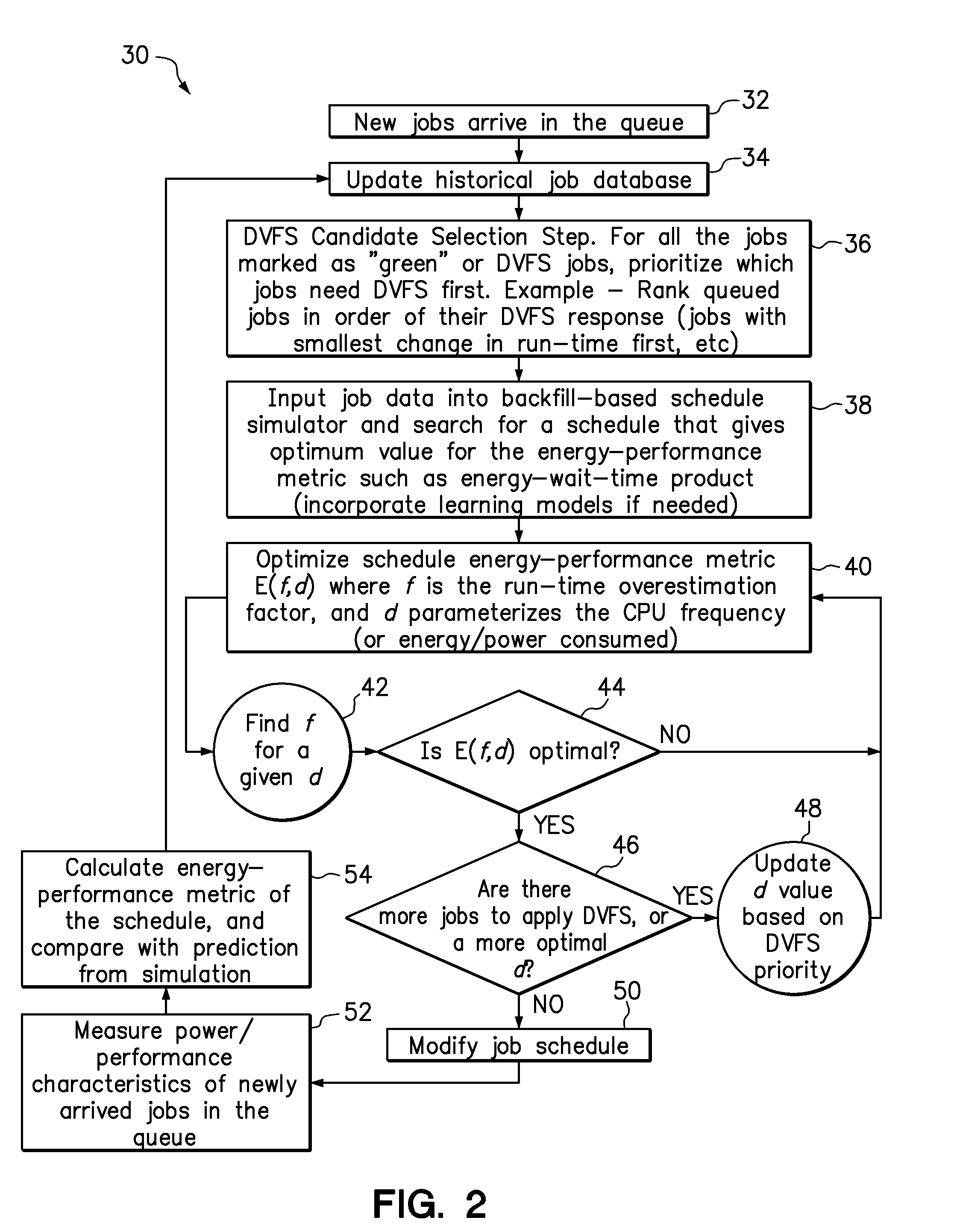

Job scheduling to balance energy consumption and schedule performance

ActiveUS20130139170A1Energy efficient ICTMultiprogramming arrangementsJob shop schedulingParallel computing

An energy-aware backfill scheduling method combines overestimation of job run-times and processor adjustments, such as dynamic voltage and frequency scaling, to balance overall schedule performance and energy consumption. Accordingly, some scheduled jobs are executed in a manner reducing energy consumption. A computer-implemented method comprises identifying job performance data for a plurality of representative jobs and running a simulation of backfill-based job scheduling of the jobs at various combinations of run-time over-estimation values and processor adjustment values. The simulation generates data including energy consumption and job delay. The method further identifies one of the combinations of values that optimizes the mathematical product of an energy consumption parameter and a job delay parameter using the simulation generated data for the plurality of jobs. Jobs submitted to a processor are then scheduled using the identified combination of a run-time over-estimation value and a processor adjustment value.

Owner:LENOVO GLOBAL TECH INT LTD

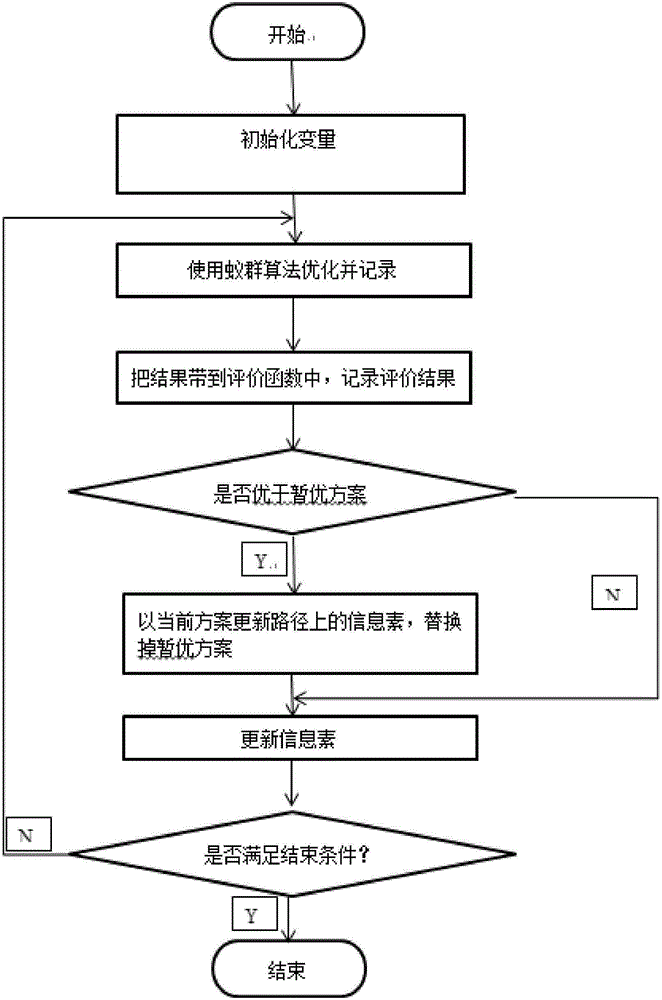

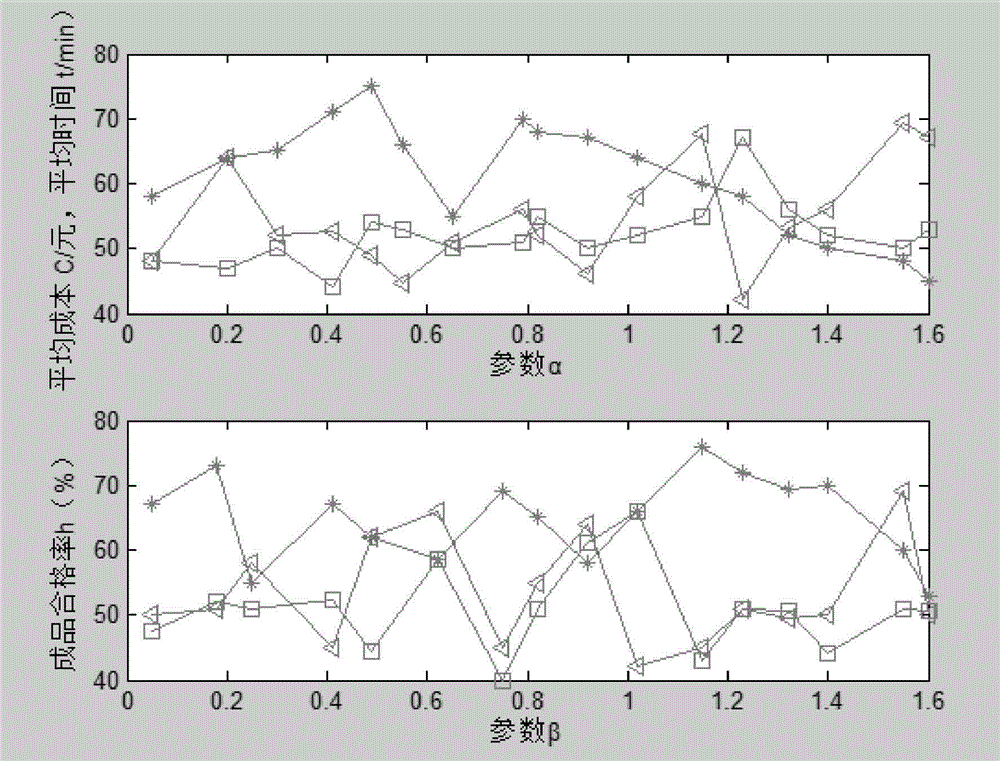

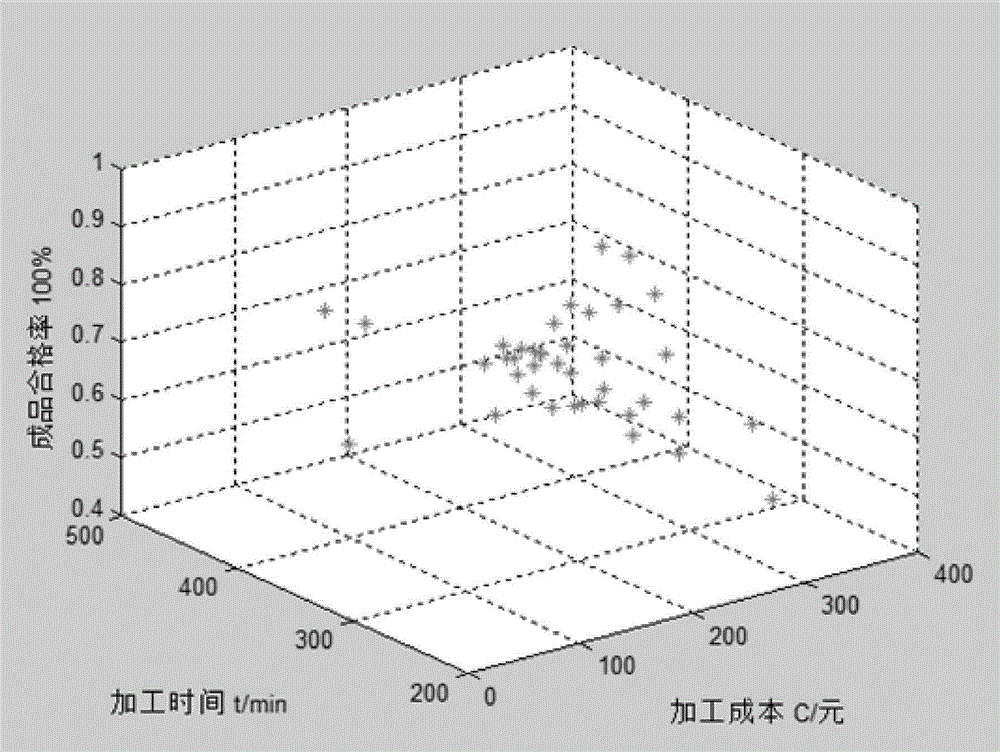

Flexible job-shop scheduling multi-objective method

InactiveCN104914835AReduce manufacturing costGood effectProgramme total factory controlJob shop schedulingJob shop scheduling problem

The invention discloses a flexible job-shop scheduling multi-objective method. The specific implementation procedures of the flexible job-shop scheduling multi-objective method are that: establishing a model for a multi-objective flexible job shop; optimizing the model by using an ant colony algorithm, and evaluating the result to check whether the scheme is the optimal scheme; and improving a pheromone updating rule according to the optimal scheme, and increasing convergence rate of the algorithm to obtain a Pareto optimal solution of a multi-objective flexible job shop scheduling problem. Compared with the prior art, the flexible job-shop scheduling multi-objective method effectively reduces workshop production cost, shortens the processing time, improves qualified rate of products, is high in practicability, and is easy to popularize.

Owner:QILU UNIV OF TECH

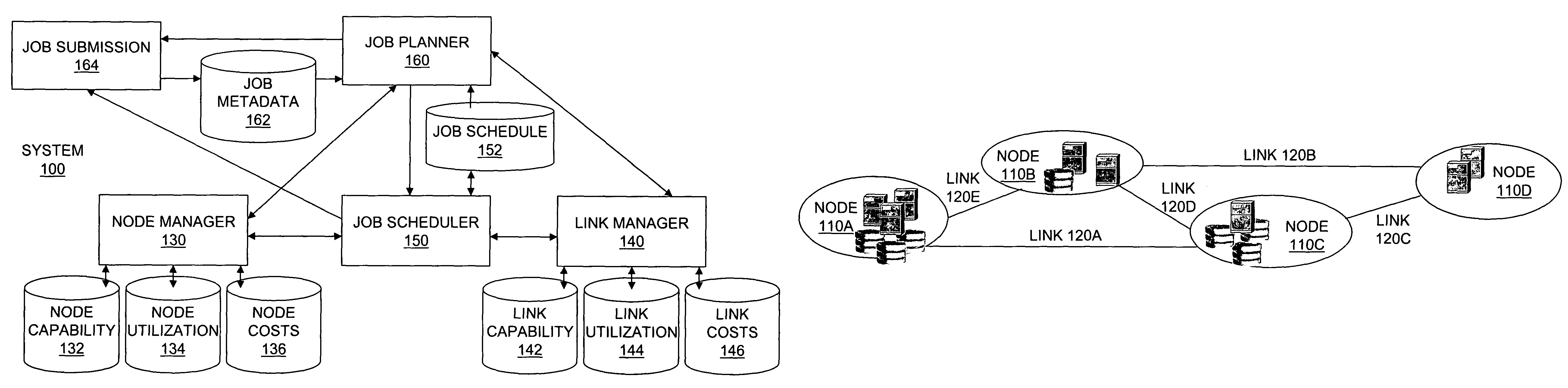

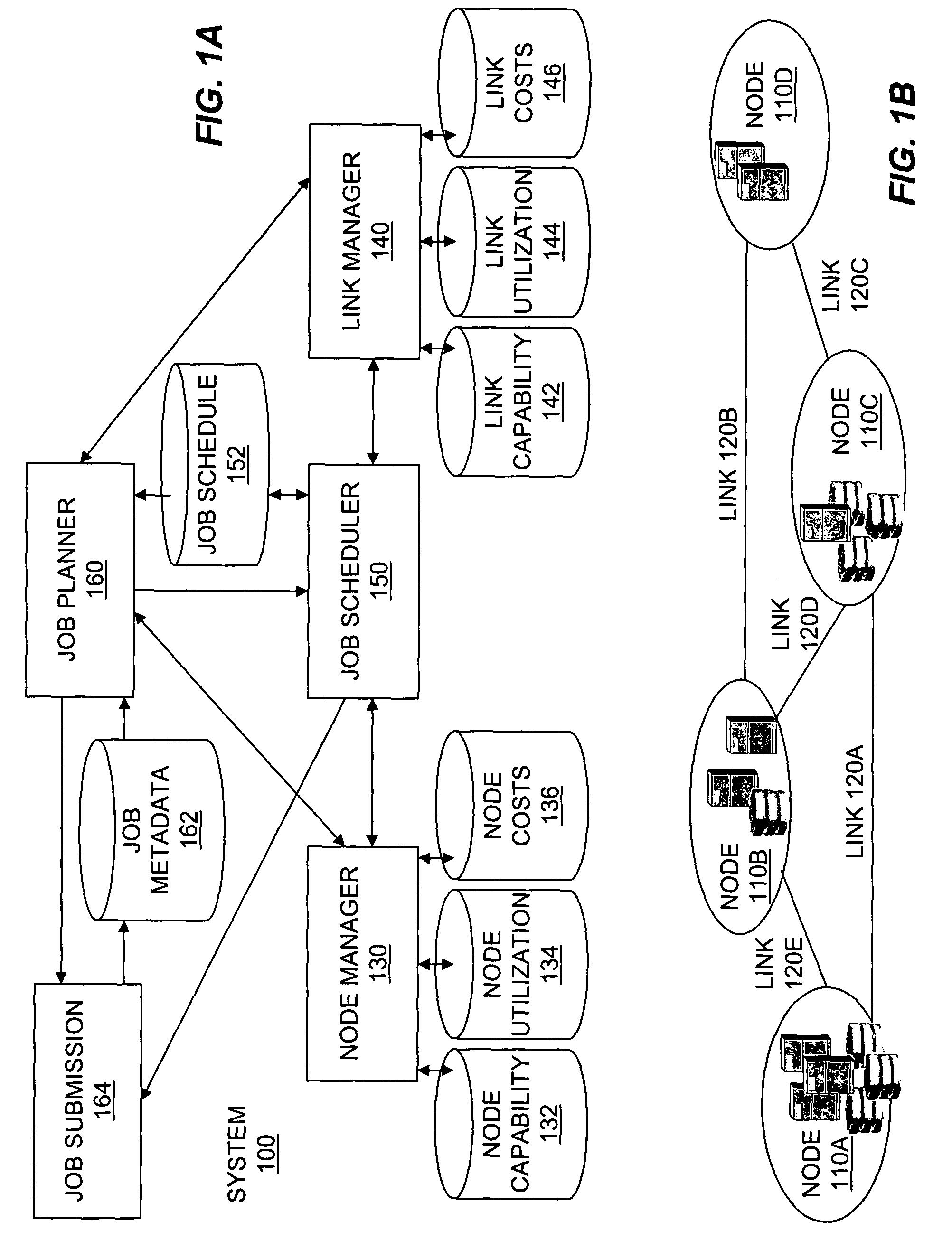

Optimized job scheduling and execution in a distributed computing grid

An arrangement provides optimal job scheduling in a distributed computing grid having a network of nodes. As jobs enter the system, their requirements are matched against the capabilities at each node to determine (step 202) candidate nodes. From this set of candidate nodes, a subset of valid nodes is selected (step 204) that has sufficient bandwidth for the duration of the job on each link that will need to be used by the job if run at that candidate node. For each valid node, a total cost is computed (step 206) to run the job. The cost may include such factors as bandwidth cost, server cost, storage cost, delay costs, and the like. Finally, a lowest cost node is selected (step 207), and the job is scheduled for execution (step 208) and then run (step 209) on that lowest cost node. An arrangement combining job scheduling with bandwidth on demand (BoD) involves a system for scheduling at least one job for execution on a network of nodes joined by links having respective link capacities, each job associated with a transport capacity requirement. The system has a job scheduler (element 150) configured to schedule the at least one job to be executed on at least one selected node, and a link manager (element 140) configured to reserve at least some of the link capacity of at least one of the links connected to the at least one selected node, to match the job transport capacity requirement.

Owner:AT&T INTPROP II L P

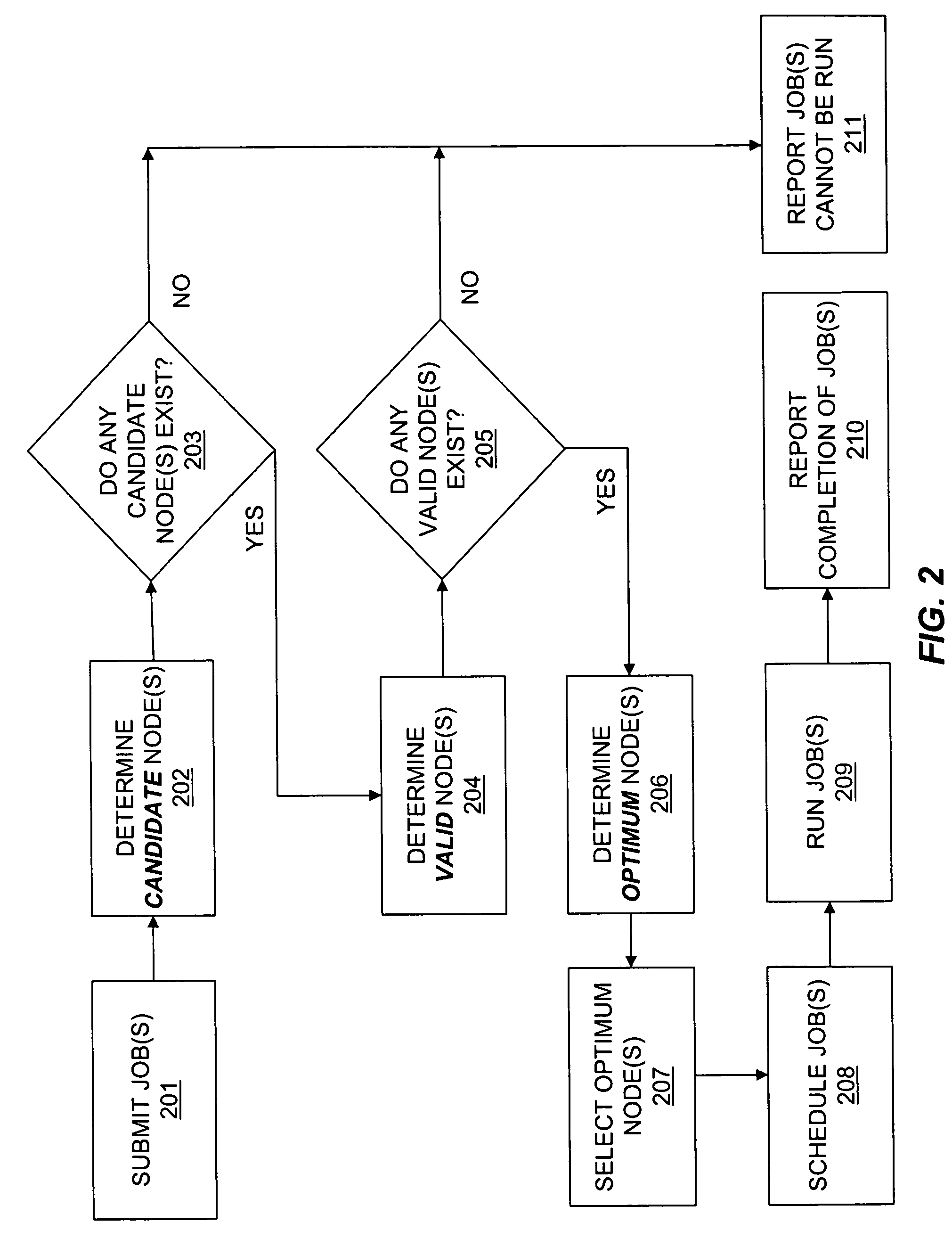

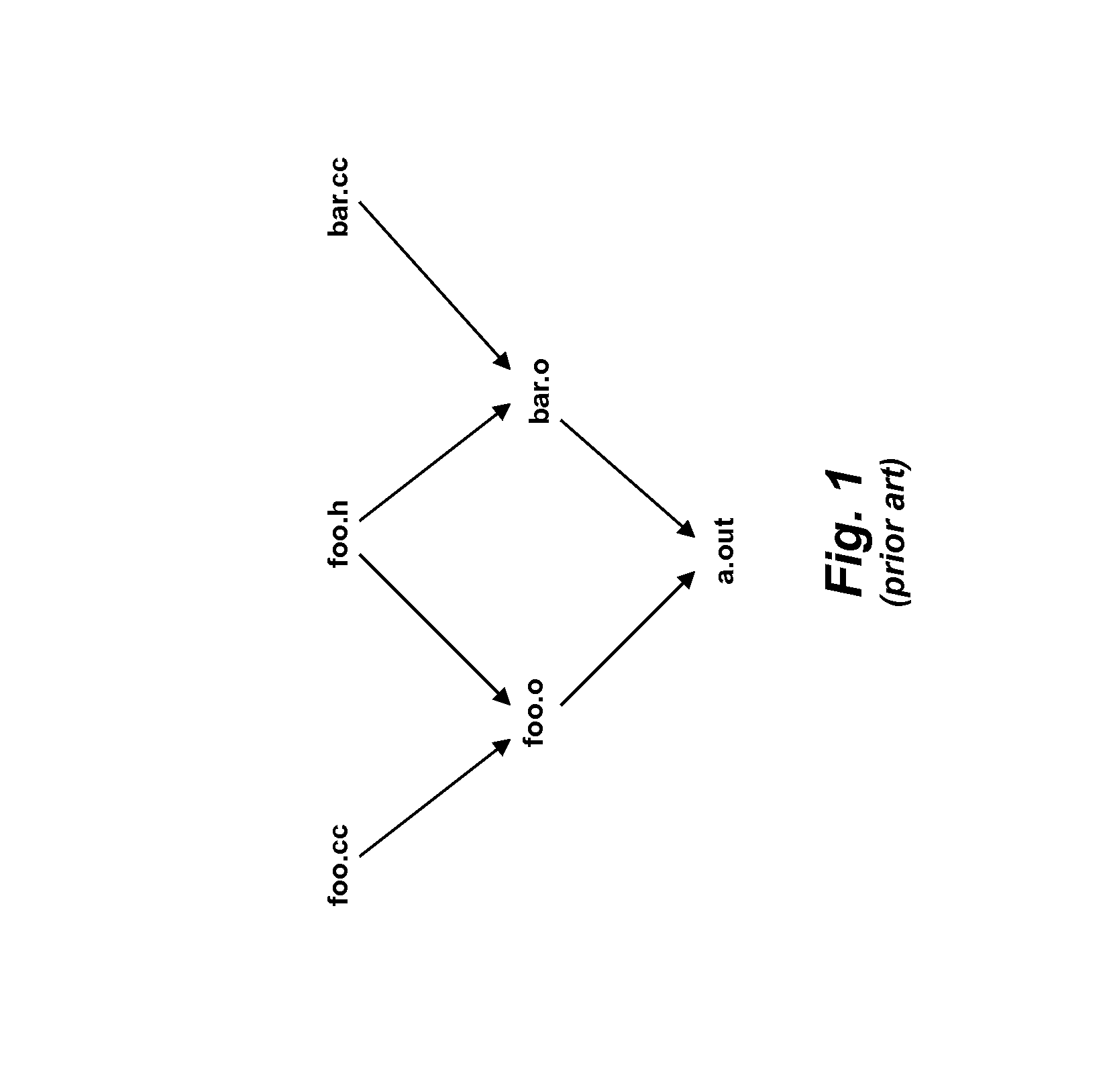

System and method for optimizing job scheduling within program builds

A method for executing program builds comprising: analyzing file dependency information and job duration information associated with jobs of the program build; scheduling jobs for a current program build based on the analysis of the dependency information and the job duration data; executing the jobs according to the schedule; collecting file usage information and new job duration information from each of the jobs; supplementing the file dependency information with the file usage information; and storing the new job duration information to be used for scheduling jobs in subsequent program builds.

Owner:CLOUDEBEES INC +1

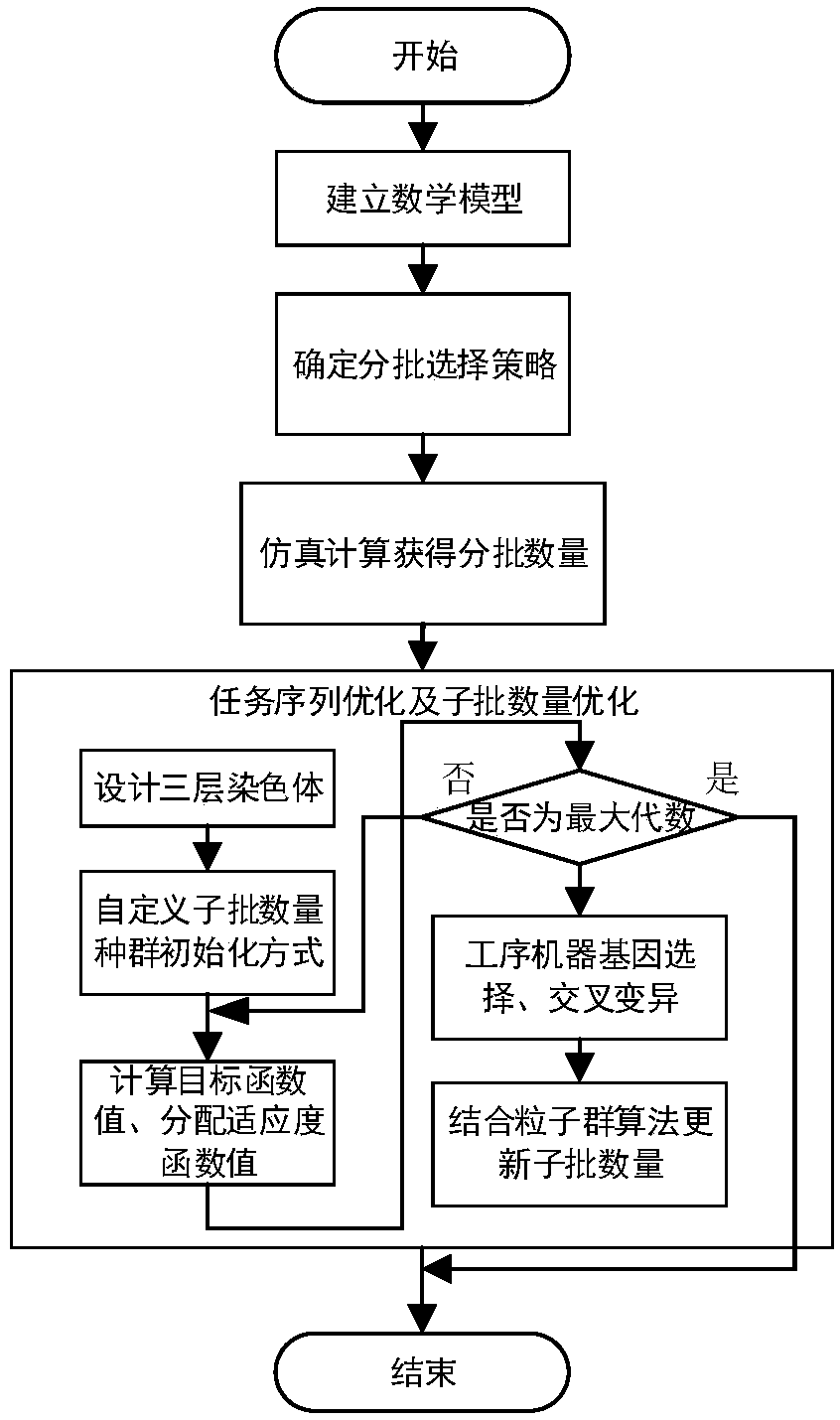

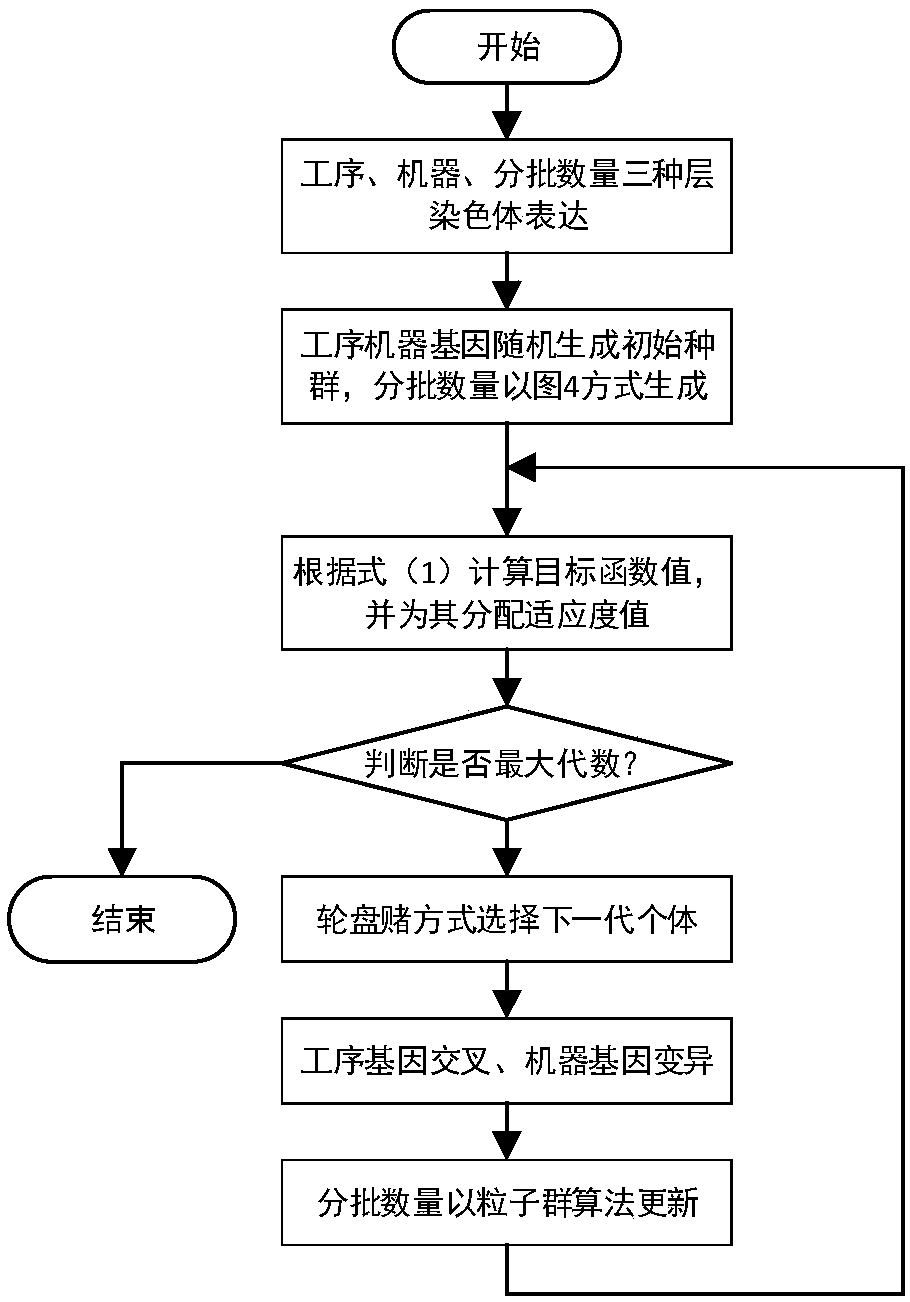

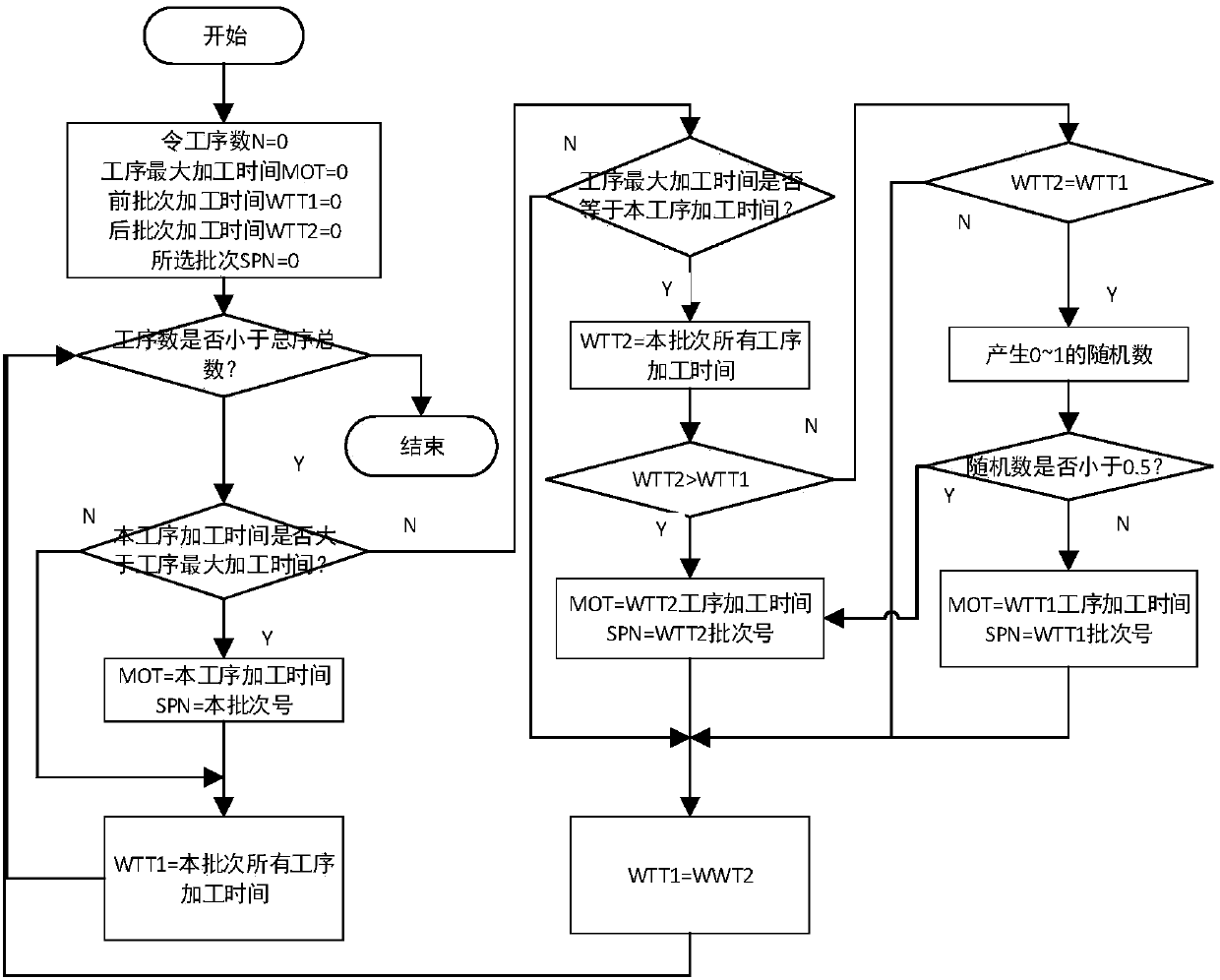

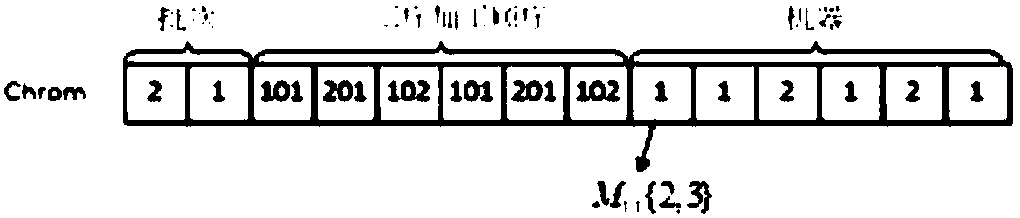

Flexible job shop order insertion dynamic scheduling optimization method

ActiveCN107831745AReduced delay periodImprove the individual population update methodInternal combustion piston enginesProgramme total factory controlMathematical modelParticle swarm algorithm

A flexible job shop order insertion dynamic scheduling optimization method is a solution method aiming at the delay problems caused by the order insertion in the job shop batch dynamic scheduling, andcomprises the steps of on the basis of establishing a mathematical model of the task sequence optimization and the order batch distribution, researching a batch selection strategy, adopting an example simulation mode to obtain the reasonable sub-batch number, at the same time, according to the simulation and calculation of the typical examples, giving a recommending value of the batch number; secondly, based on the three-layer gene chromosomes of the processes, the machines and the order distribution number, taking the minimum maximum time of completion and the delay period as the optimization targets; and finally, adopting a mixed algorithm of a particle swarm optimization algorithm and a genetic algorithm to improve the speed of evolution of the sub-batch number towards an optimal direction, thereby effectively reducing the tardiness quantity. The method is good at reducing the delay period in the job shop dynamic scheduling, and for the conventional genetic algorithm, enables the convergence speed and the stability to be improved substantially, at the same time, fully combines the actual production statuses of the intelligent job shops, greatly promotes the dynamic scheduling solution, and has the great application value in the engineering.

Owner:SOUTHWEST JIAOTONG UNIV

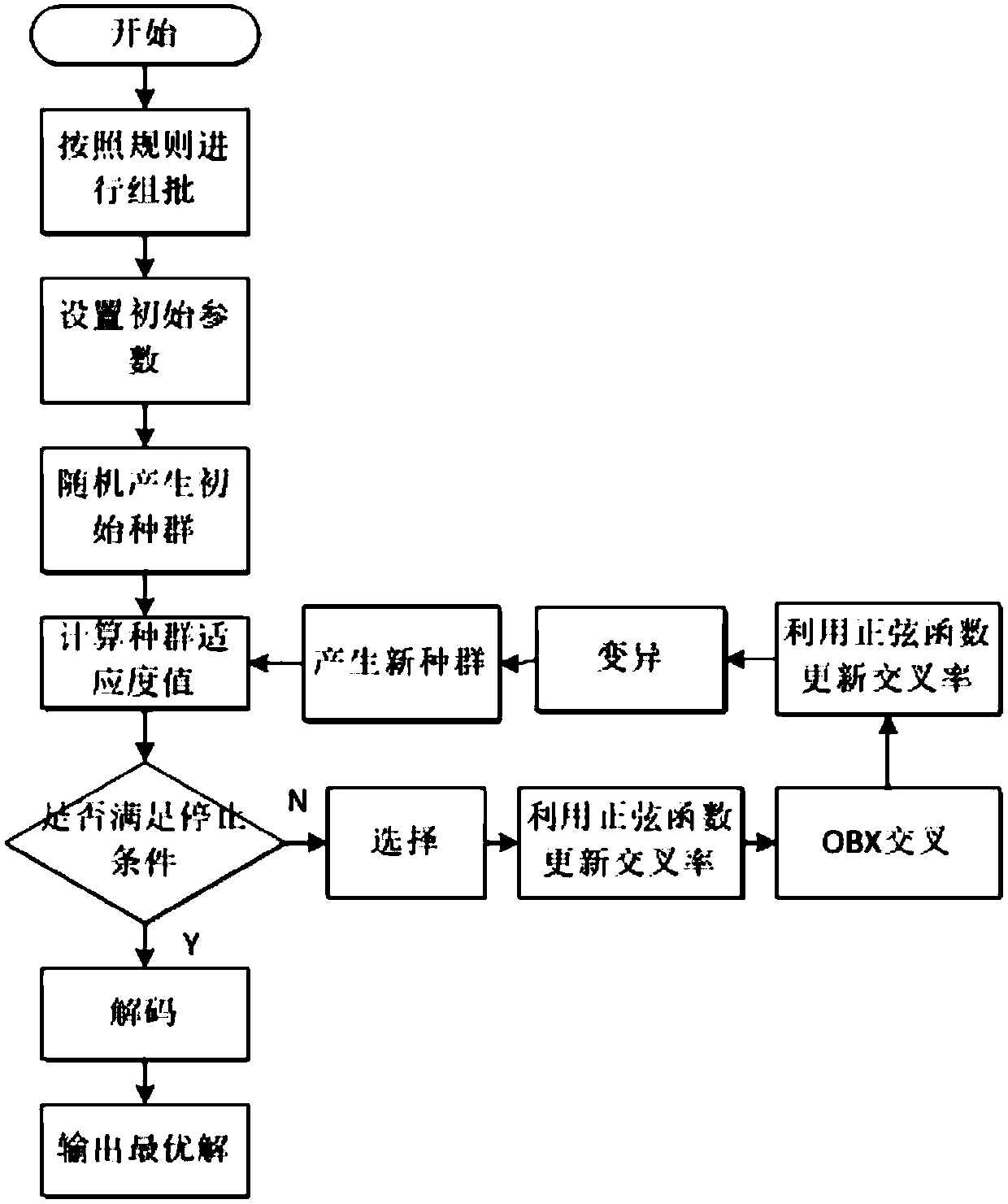

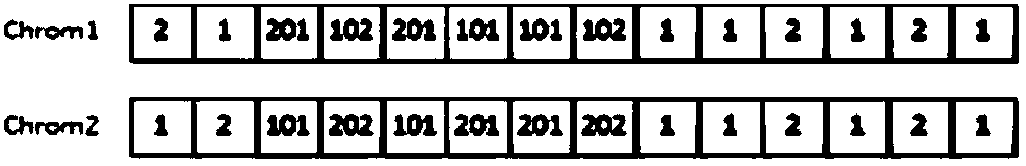

Large-scale flexible work workshop scheduling optimization method

The invention provides a large-scale flexible work workshop scheduling optimization method. A large-scale production task is reorganized to be downscaled and then solving and optimization are performed by using the adaptive improved genetic algorithm. The method comprises the following concrete steps that (1) the workpieces of which the processing technology is similar, the workpiece dimension iswithin the same range and the blank material is the same are clustered and grouped for batching so as to reduce the problem solving scale; and (2) the initial parameter of the algorithm is set, the three-layer gene coding technology, the OBX crossover mode and the certain variation strategy are adopted, the crossover length is selected through combination of the simulation experiment and optimization and solving are performed by using the adaptive improved genetic algorithm. According to the method, the problem solving scale can be reduced and the solving speed can be improved; and the workpiece completion time and delay time can be reduced.

Owner:SOUTHWEST JIAOTONG UNIV

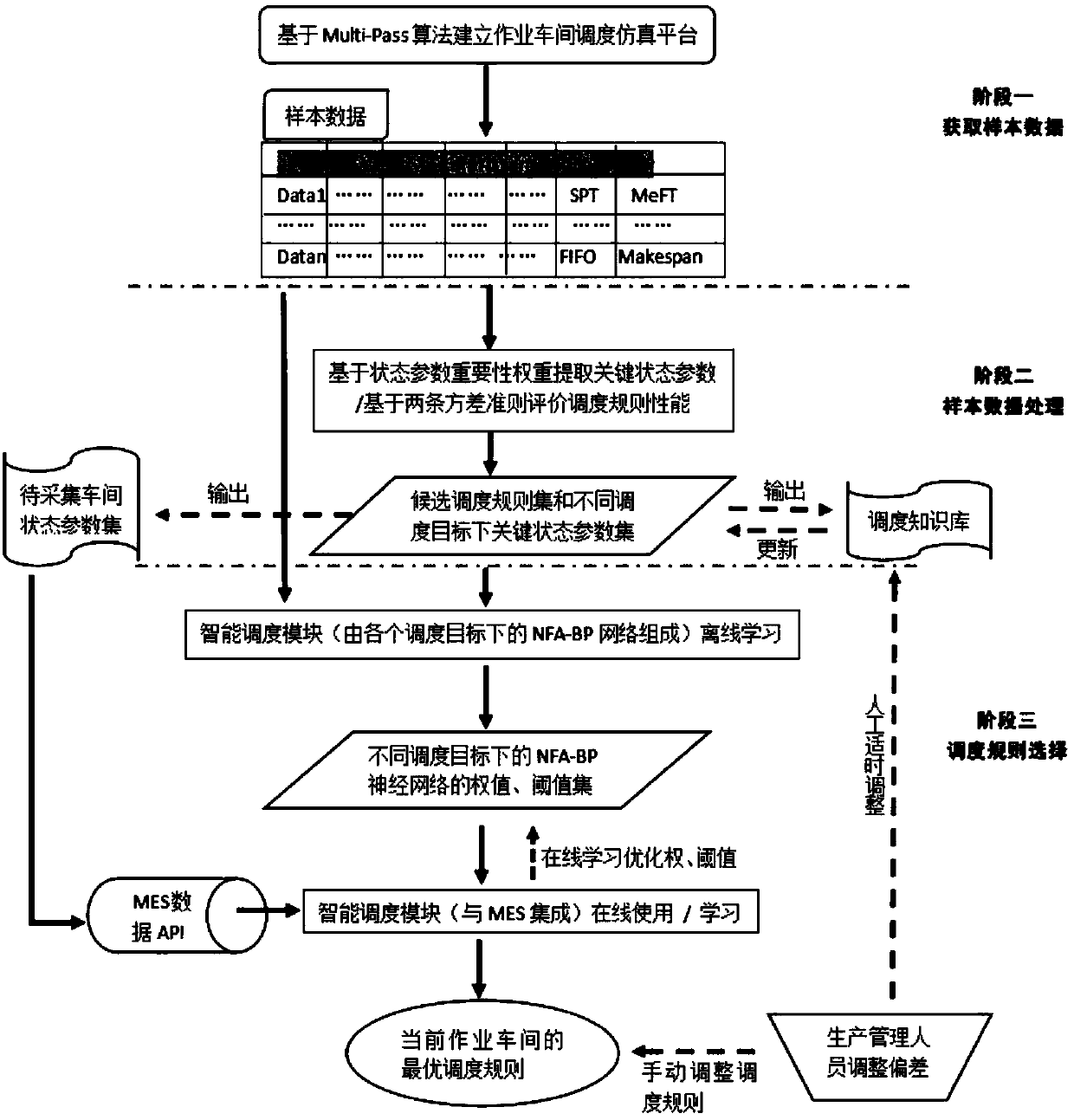

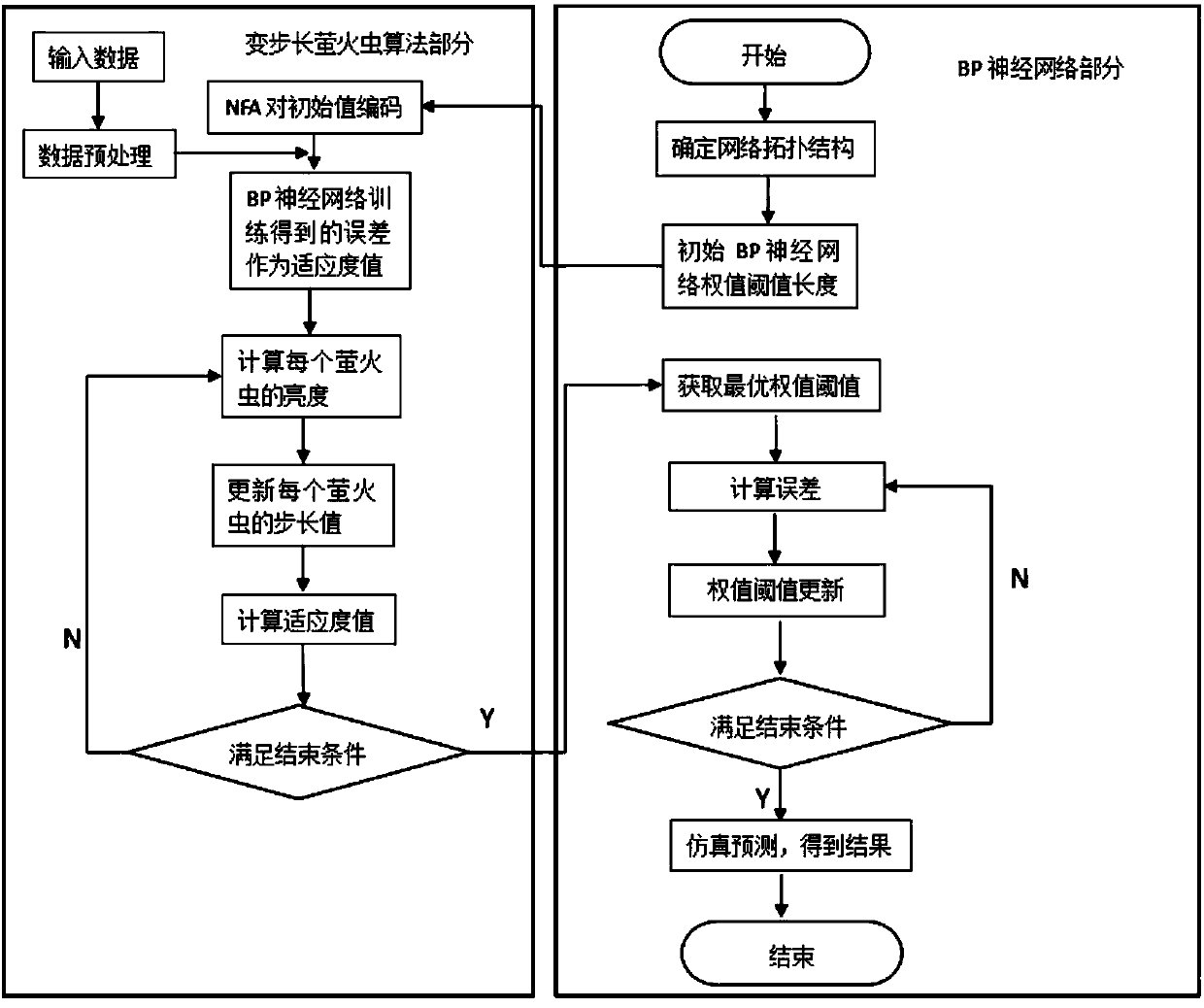

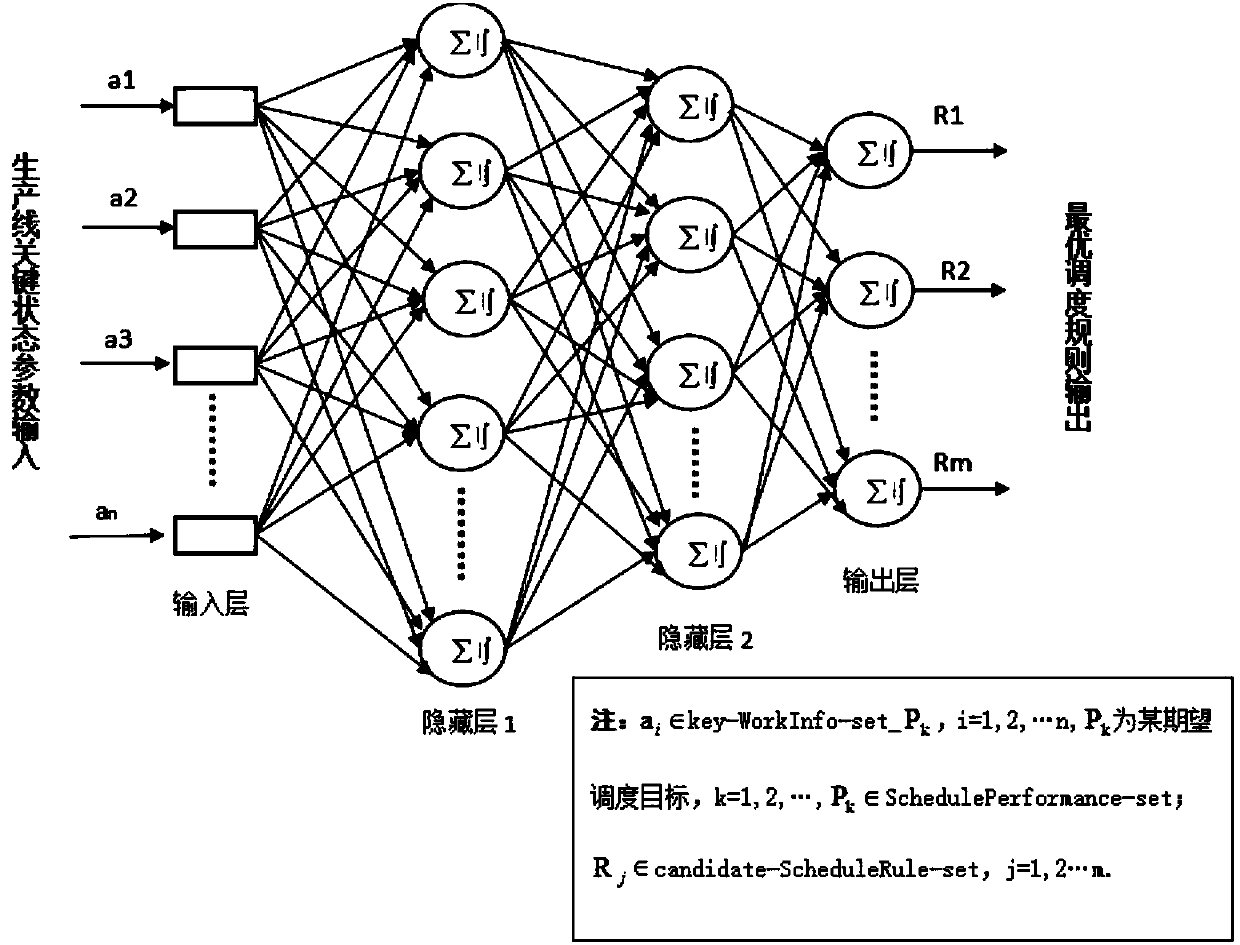

Production-data-driven dynamic job-shop scheduling rule intelligent selection method

ActiveCN107767022ATimely and accurate dynamic responseScheduling results are excellentGenetic modelsForecastingOptimal schedulingJob shop scheduling

The invention provides a production-data-driven dynamic job-shop scheduling rule intelligent selection method and belongs to the manufacturing enterprise job shop production planning and scheduling application field. The method mainly comprises the following steps: introducing a Multi-Pass algorithm simulation mechanism, establishing a job-shop production scheduling simulation platform, and generating production planning and scheduling sample data; screening the obtained sample data and generating a scheduling parameter set; designing BP neural network models for scheduling knowledge learningunder different scheduling targets; optimizing training of the BP neural networks through a new firefly algorithm to obtain NFA-BP models; integrating the NFA-BP models under various scheduling targets into an intelligent scheduling module, which is integrated with a job shop MES system to guide on-line scheduling; manually adjusting online production planning and scheduling deviation and updatingthe scheduling parameter set, and the intelligent scheduling module carrying out online optimization learning; and the intelligent scheduling module adapted to real workshop production status outputting optimal scheduling rules according to current job conflict decision points.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

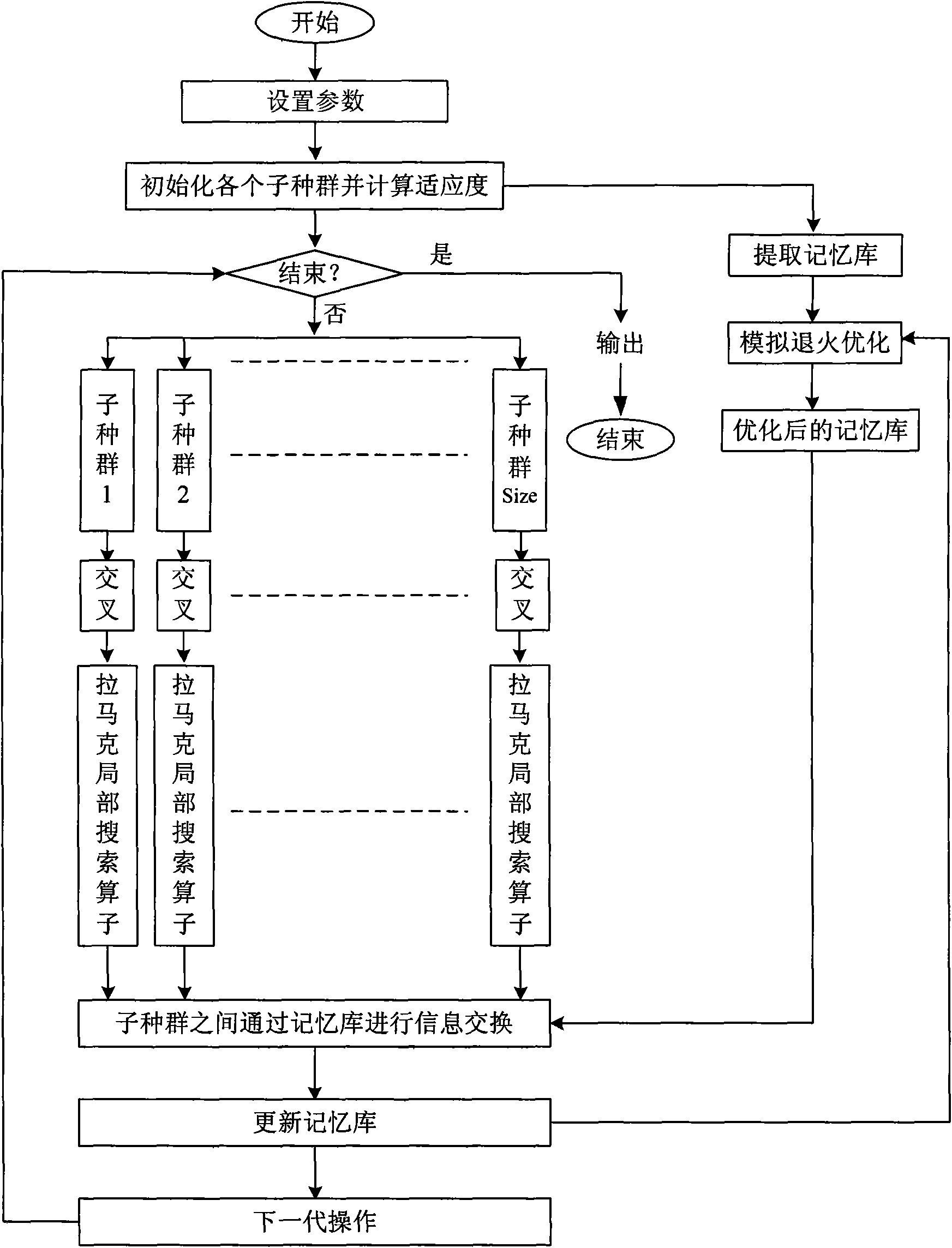

Job-shop scheduling method based on multi-population evolution mechanism

InactiveCN101630380AAvoid excessive competitionDiversity guaranteedGenetic modelsResourcesLocal optimumSub populations

The invention discloses a job-shop scheduling method based on multi-population evolution mechanism, which pertains to the computer field and mainly solves the problem that the present job-shop scheduling method of multi-population genetic algorithm is easy to be trapped into local optimization and poor local search ability. The method comprises the steps of (1) setting parameters and initializing the population; (2) evaluating the chromosomes and the initial memory bank of the population, optimizing the initial memory bank by means of the simulated annealing algorithm; (3) judging whether the termination condition is satisfied, if so, outputting the currently obtained optimal scheduling plan; otherwise, continuing step 4; (4) carrying out the crossover and mutation operation on the chromosomes in each sub-population; (5) communicating the sub-population with the memory bank; and (6) updating the memory bank and optimizing the memory bank by means of the simulated annealing algorithm, and then returning to step (3). The job-shop scheduling method of the invention can obtain the job-shop scheduling plan with high quality, shorten the production time and can be used for selecting the job-shop scheduling plan.

Owner:XIDIAN UNIV

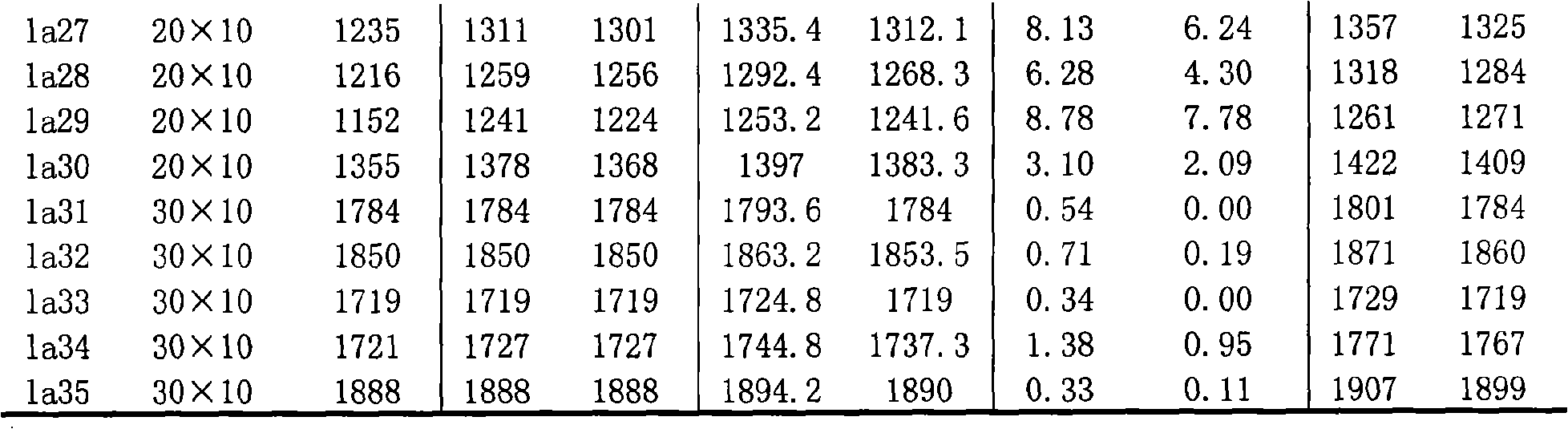

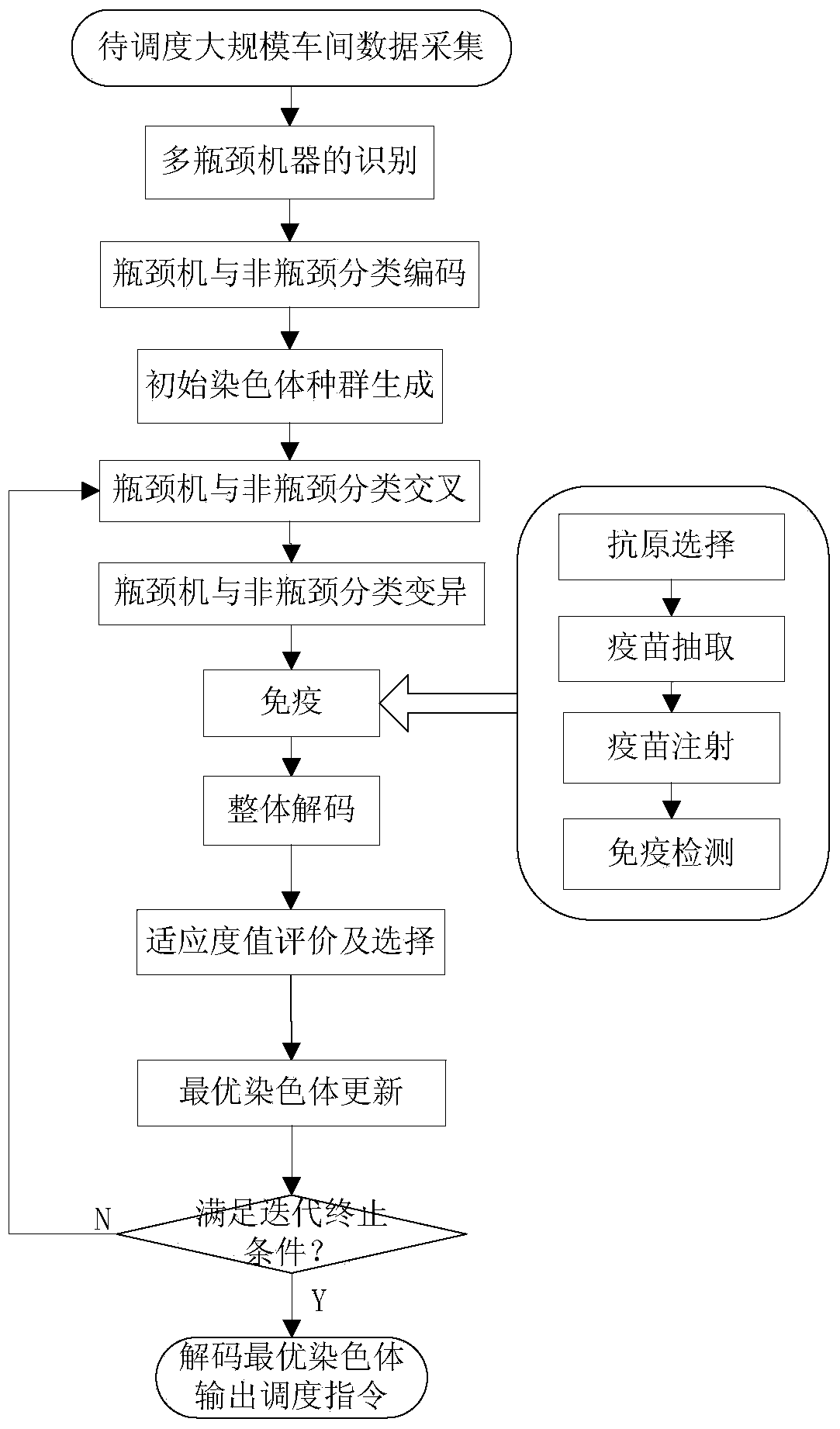

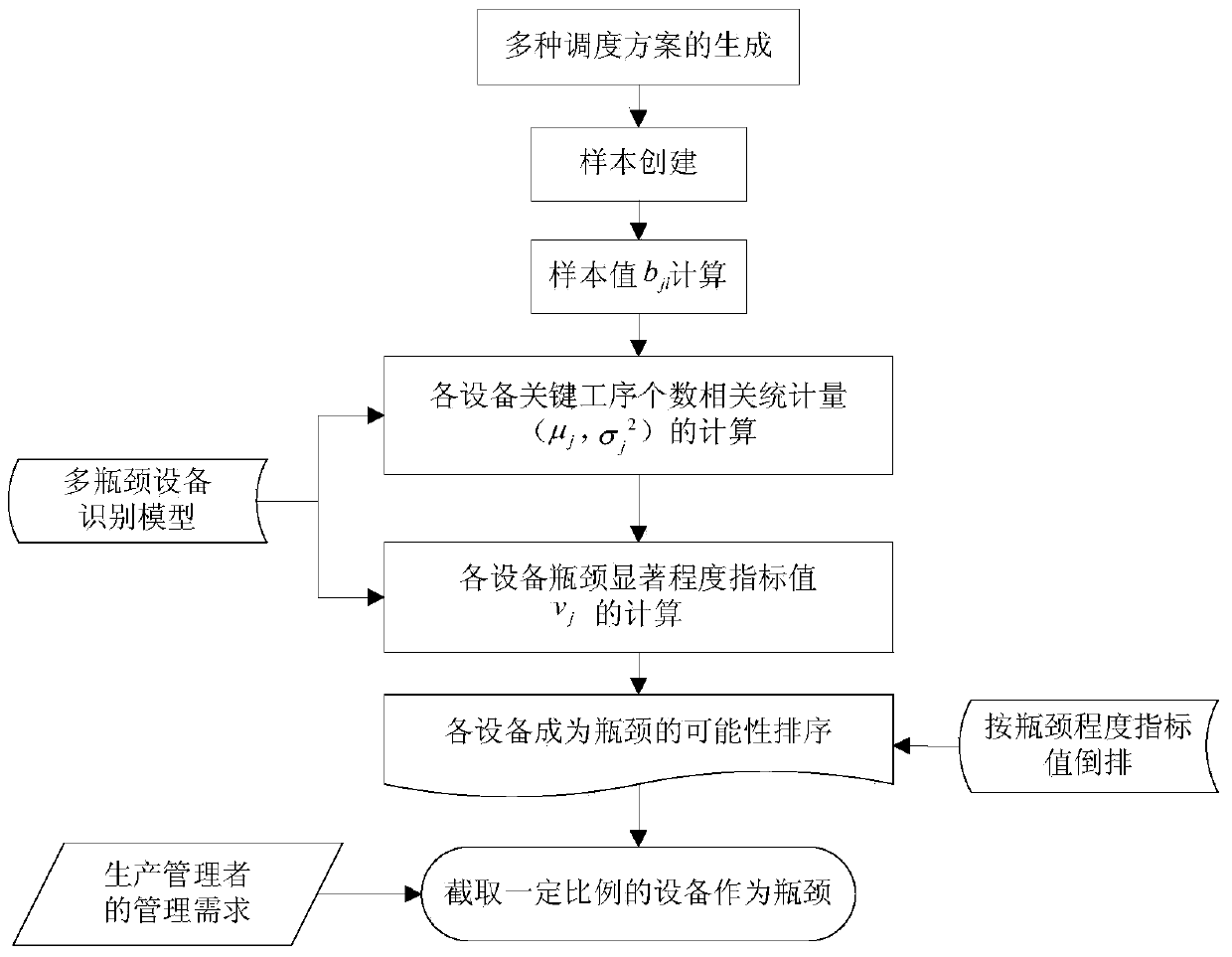

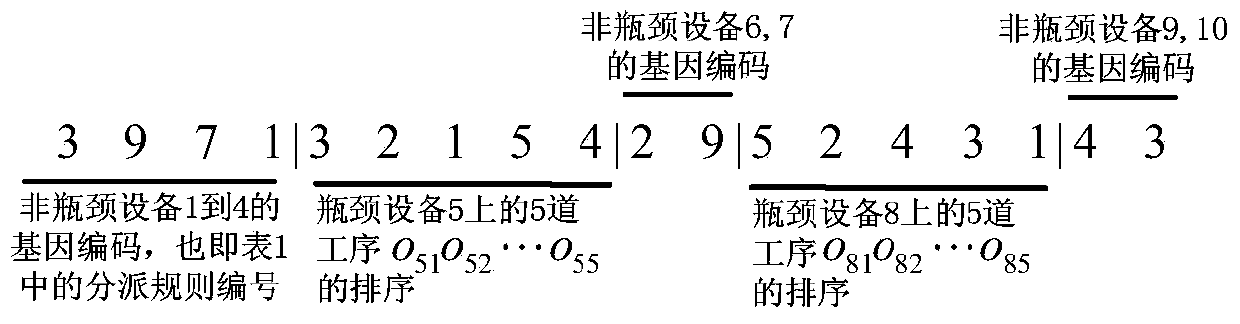

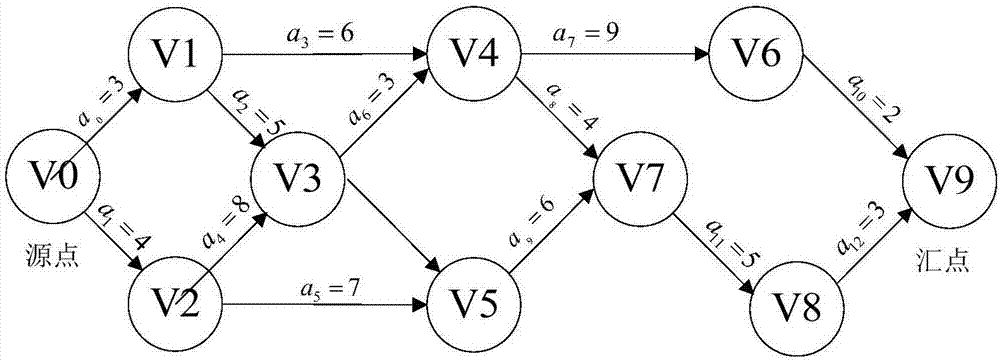

Large-scale operation workshop scheduling method based on bottleneck equipment decomposition

InactiveCN103530702AShortened gene lengthImprove the speed of genetic immune operationGenetic modelsForecastingDecompositionData acquisition

The invention discloses a large-scale operation workshop scheduling method based on bottleneck equipment decomposition. The large-scale operation workshop scheduling method based on the bottleneck equipment decomposition comprises the following steps of (1) acquiring data and modeling; (2) carrying out recognition on bottleneck equipment based on a key path method; (3) sorting and encoding the bottleneck equipment and non-bottleneck equipment; (4) generating an initial chromosome population; (5) carrying out cross and mutation operations on the chromosome population; (6) inoculating an immune operator to the chromosome population; (7) carrying out decoding and fitness value calculation operations on chromosomes; (8) updating an optimal chromosome and an optimal fitness value of an algorithm; (9) judging whether a method ending rule is achieved or not, starting a step (10) if the method ending rule is achieved, and otherwise, jumping to the step (5) to carry out the next iteration; (10) finding out the optimal chromosome from the step (9) to decode, and obtaining a scheduling command to schedule. According to the large-scale operation workshop scheduling method based on the bottleneck equipment decomposition, which is disclosed by the invention, a satisfactory scheduling scheme can be obtained in a shorter time, the production efficiency of an operation workshop can be improved, and the large-scale operation workshop scheduling method based on the bottleneck equipment decomposition can be applied to scheduling management and optimization of the production process of the workshop.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

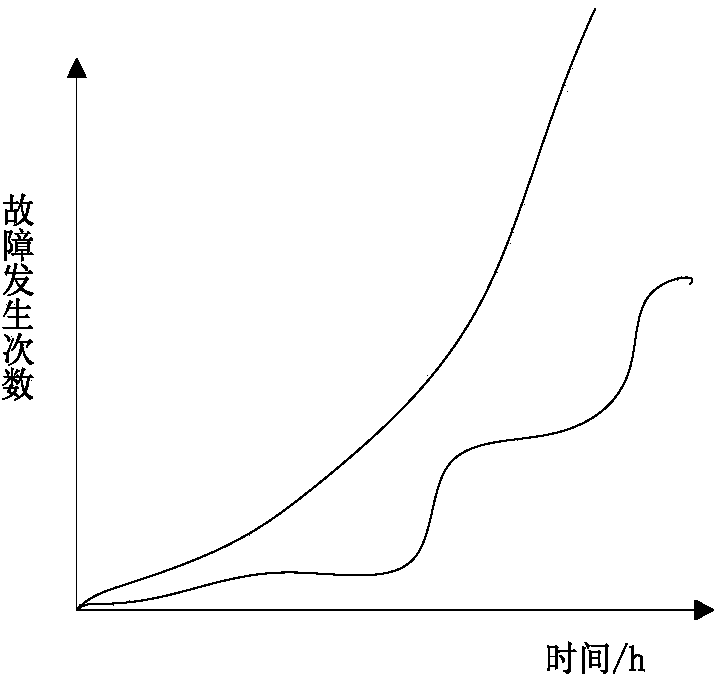

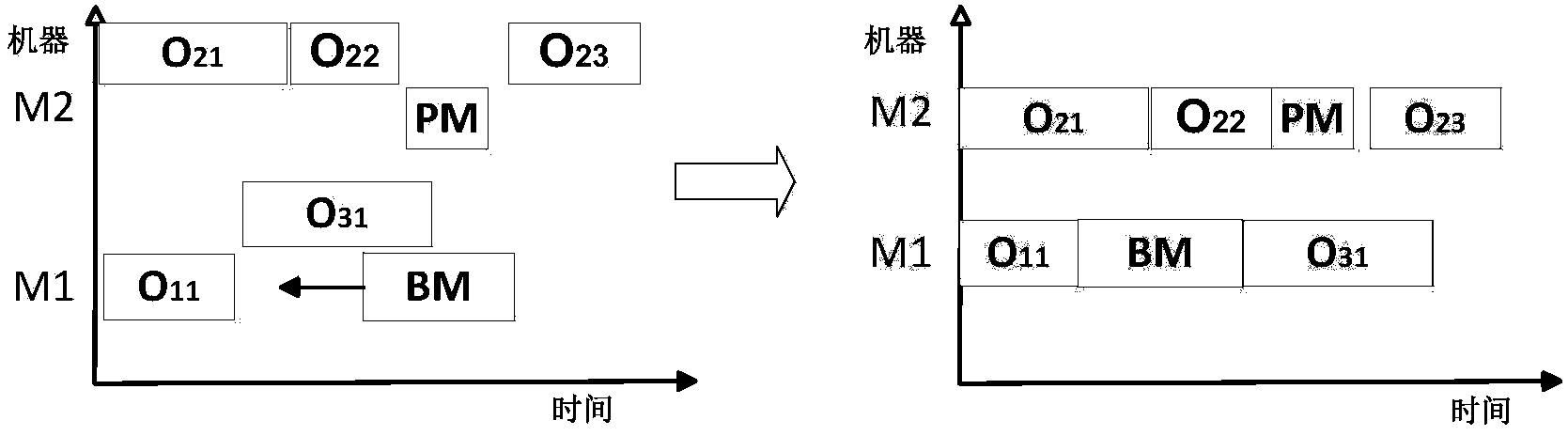

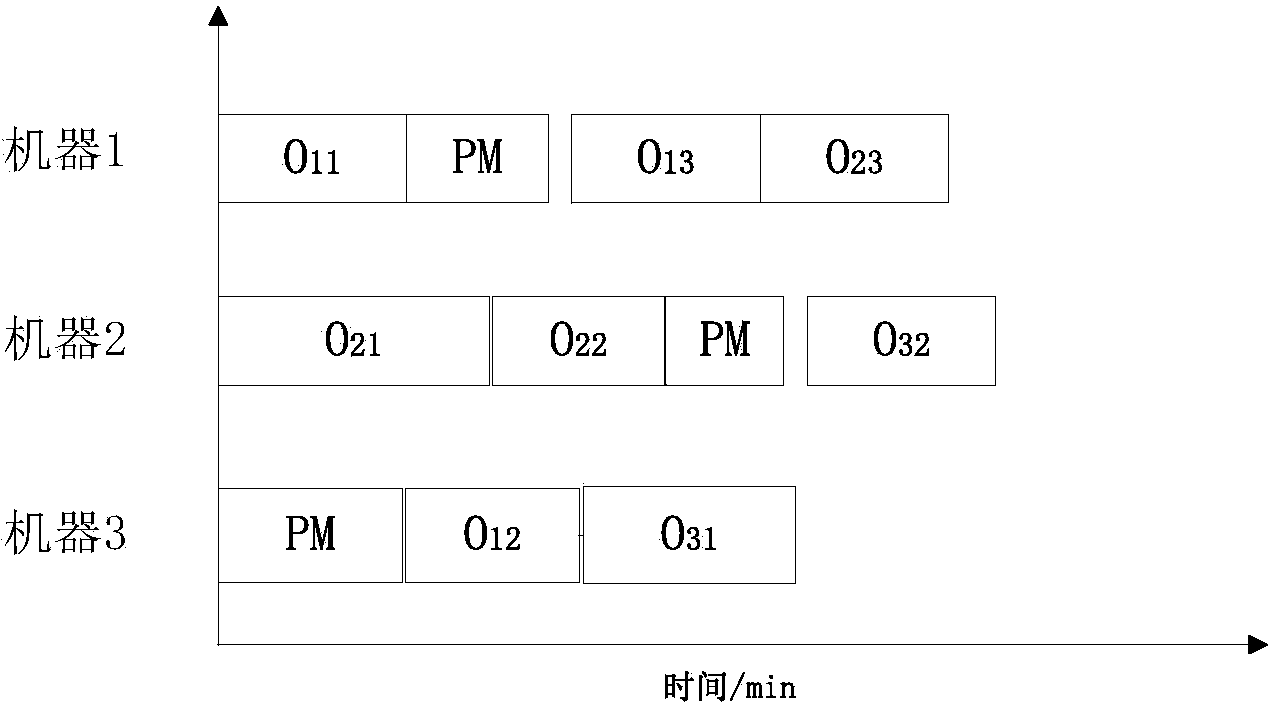

Equipment preventive maintenance and flexible job shop scheduling integrated optimization method

InactiveCN104111642AAbundant means of dynamic exchangeExpand your searchTechnology managementProgramme total factory controlCompletion timeChemical reaction

The invention discloses an equipment preventive maintenance and flexible job shop scheduling integrated optimization method. The method is characterized by specifically comprising: first of all, according to an operation sequence, an equipment maintenance period, and a constraint condition of uninterrupted production process of each operation and non-conflict production process and equipment maintenance process of a flexible job shop scheduling problem, establishing an integrated optimization model of a flexible job shop scheduling and equipment maintenance plan, which takes cost and efficiency into consideration; secondary, optimizing multiple targets by use of a hybrid multi-objective chemical-reaction optimization method, the multiple targets comprising maximum completion time, total production cost and total equipment preventive maintenance cost; and finally, obtaining an optimization solving result, such that a flexible job shop scheduling plan can be obtained. The method can realize the goals of reducing the maximum completion time, the production cost and the equipment maintenance cost and can obtain an optimal flexible job shop scheduling scheme.

Owner:HUAZHONG UNIV OF SCI & TECH

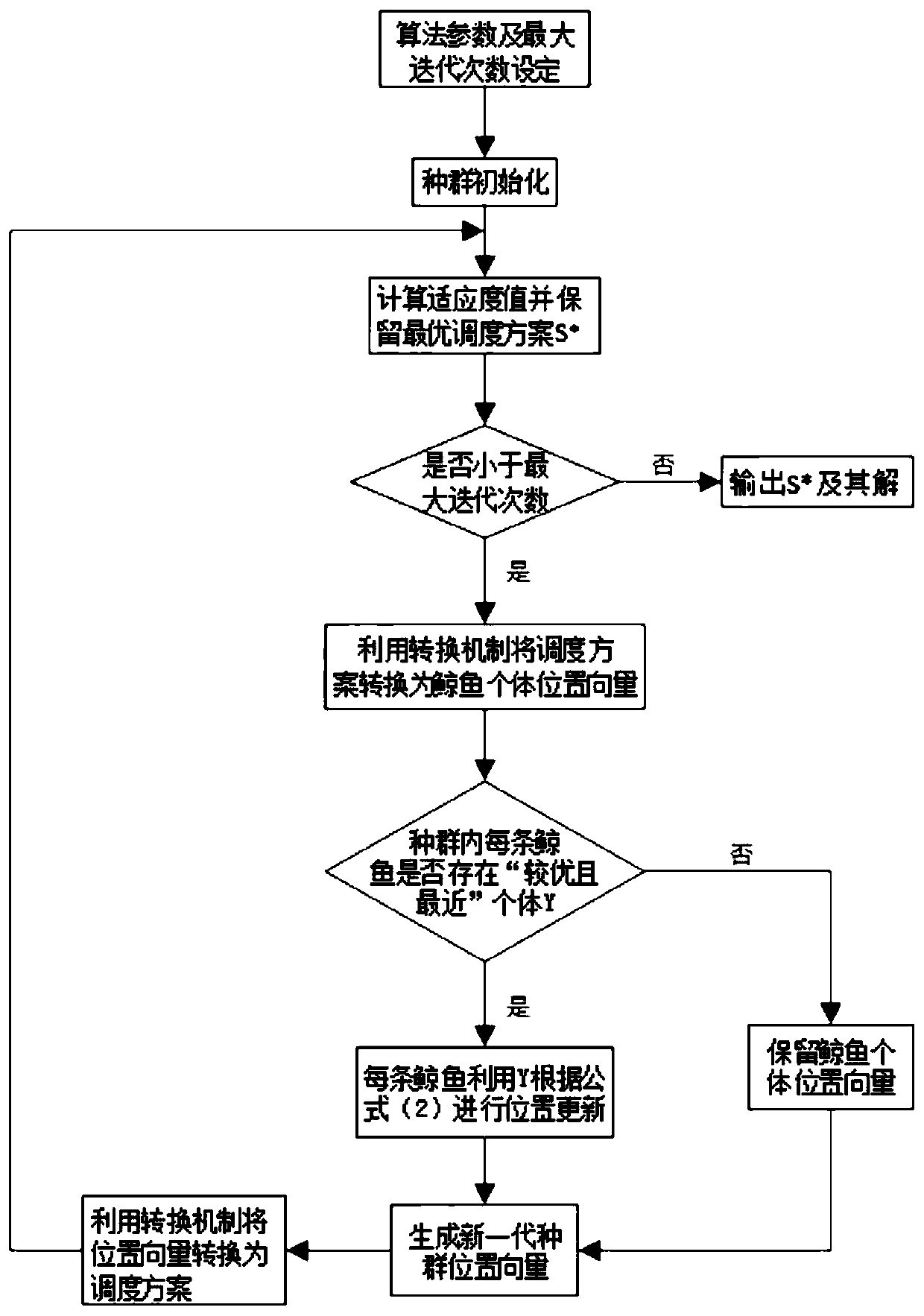

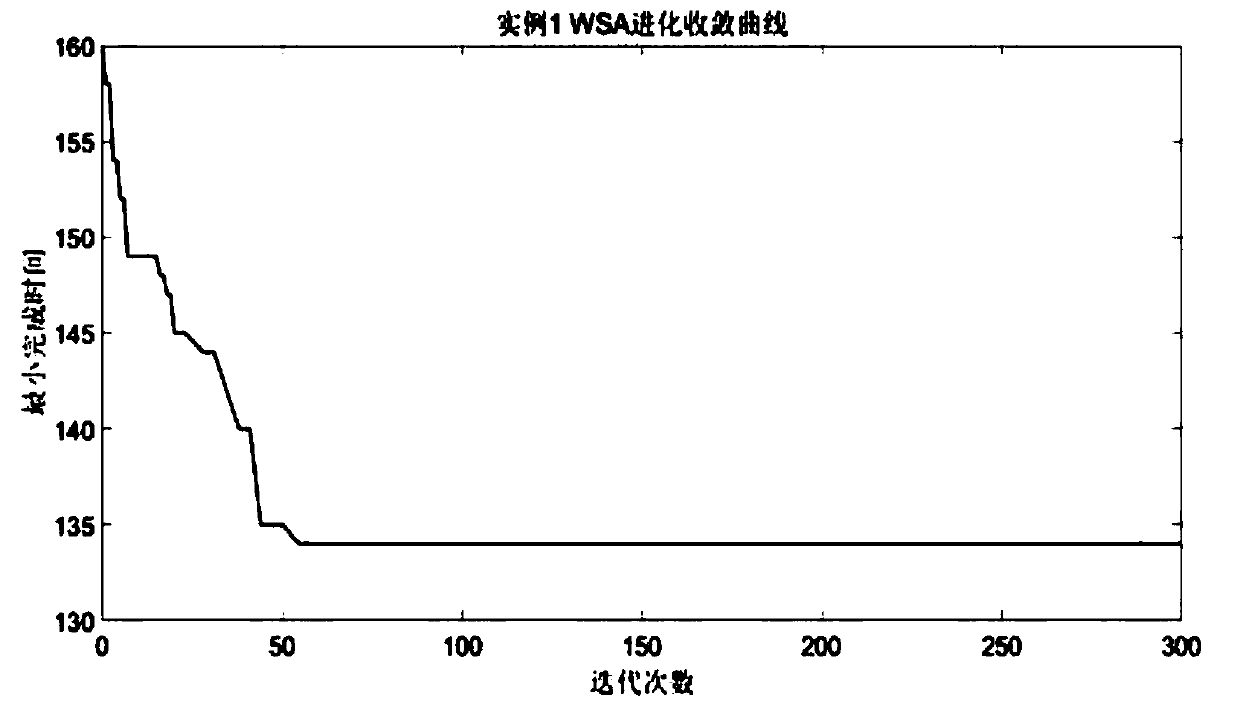

A method for solving flexible job shop scheduling based on an improved whale algorithm

PendingCN109886588AImprove local search capabilitiesVerify validityBiological modelsChaos modelsMathematical modelOptimal scheduling

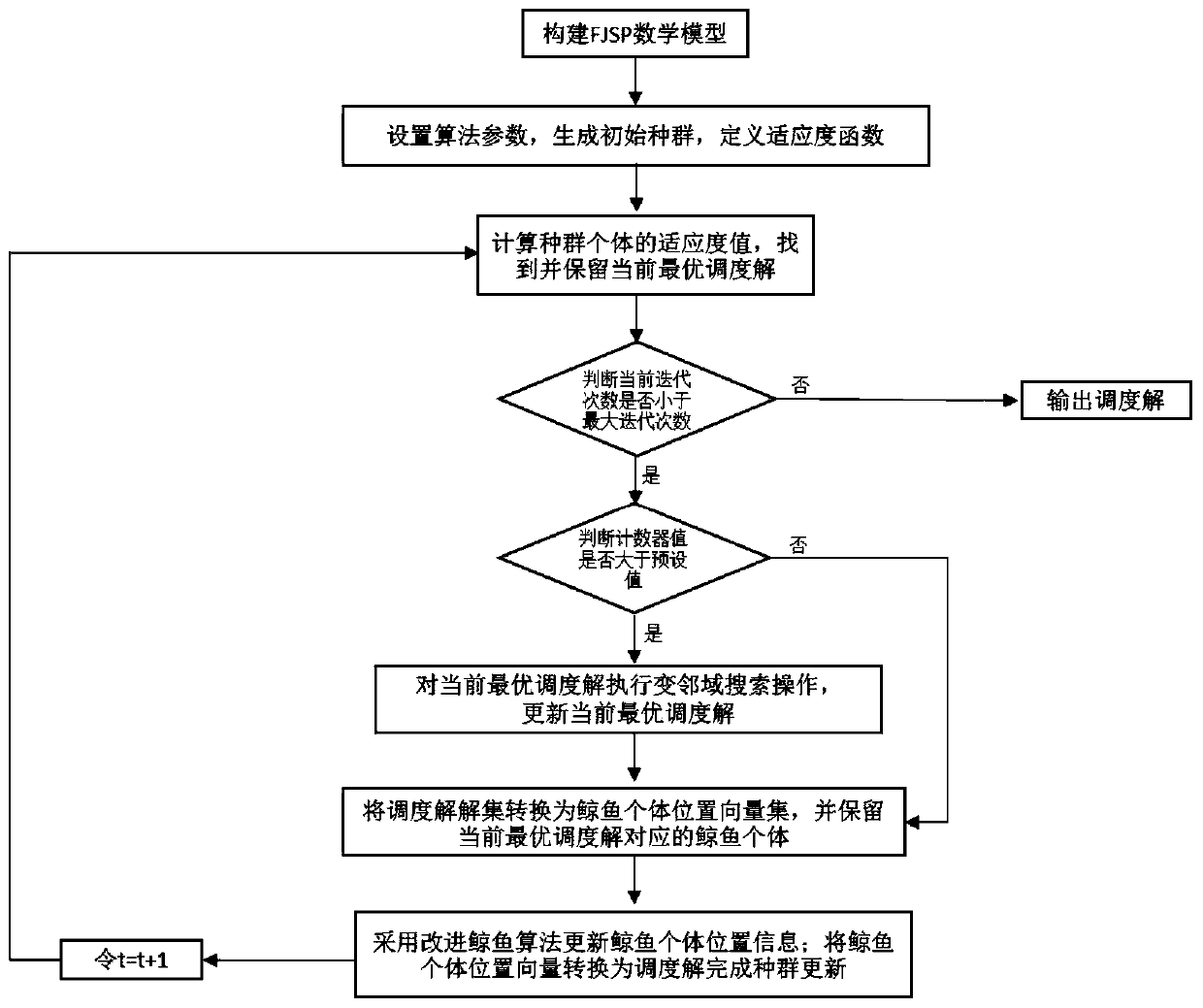

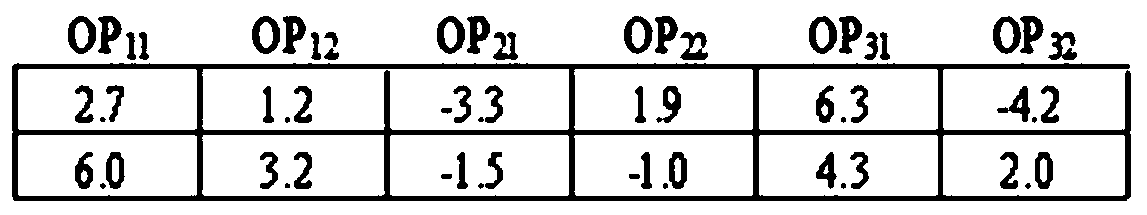

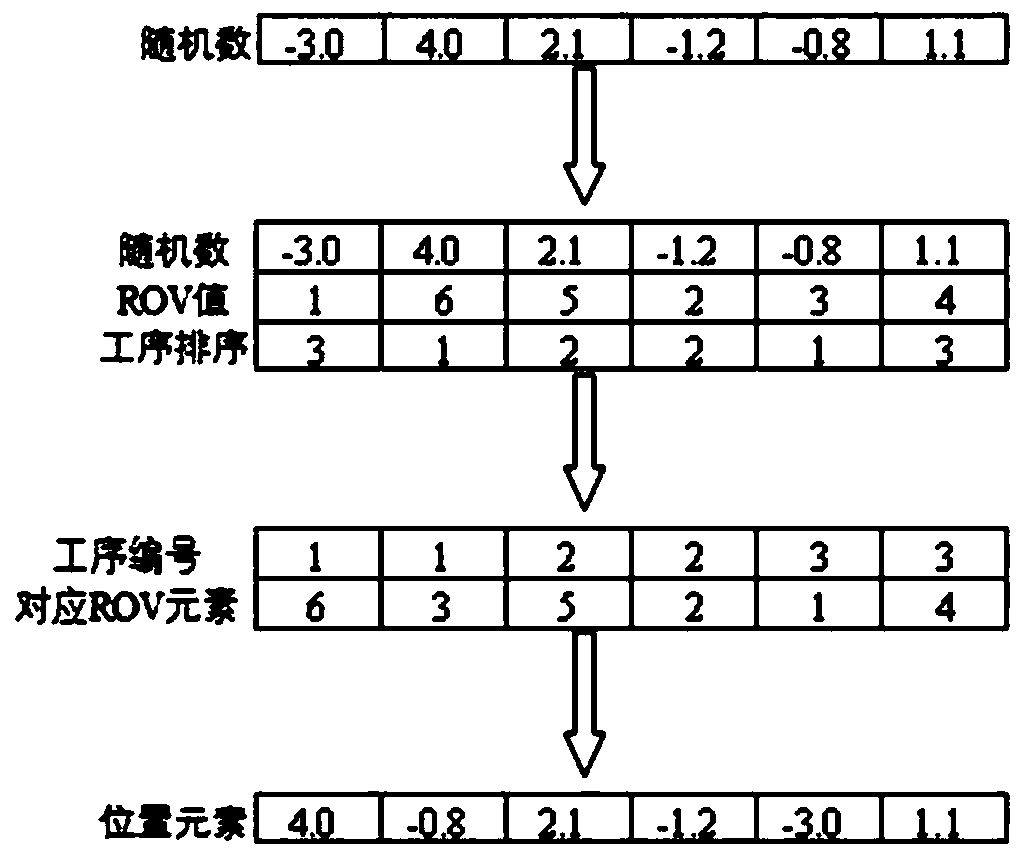

The invention discloses a method for solving flexible job shop scheduling based on an improved whale algorithm. The method comprises the following steps: 1) establishing a mathematical model of a flexible job shop scheduling problem; 2) setting algorithm parameters and generating an initial population; 3) obtaining a current optimal scheduling solution; 4) judging whether the current number of iterations is greater than the maximum number of iterations; if yes, outputting a scheduling solution; if not, judging whether the counter value of the current optimal individual is not smaller than a preset value or not; if yes, carrying out variable neighborhood search operation, and updating a scheduling solution; if not, converting the scheduling solution into a whale individual position vector,and retaining the whale individual corresponding to the scheduling solution; and 5) updating whale individual position information by adopting an improved whale algorithm, converting the whale individual position vector into a scheduling solution to complete population updating, adding 1 to the number of iterations, and returning to the step 3). According to the method disclosed by the invention,all optimal solutions of flexible job shop scheduling can be well solved, and the solving speed and precision are improved.

Owner:CHANGAN UNIV

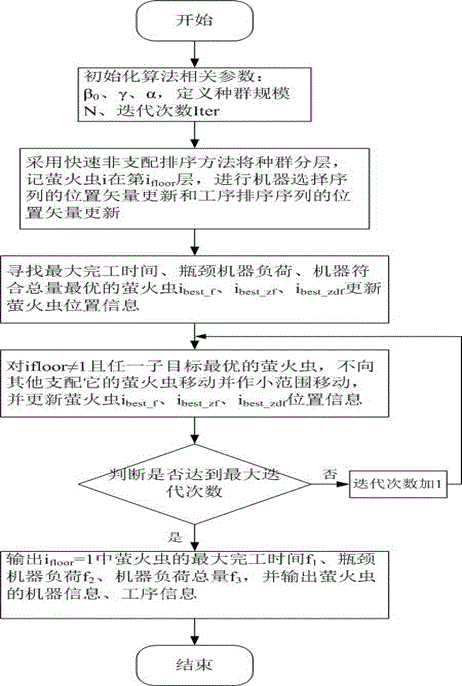

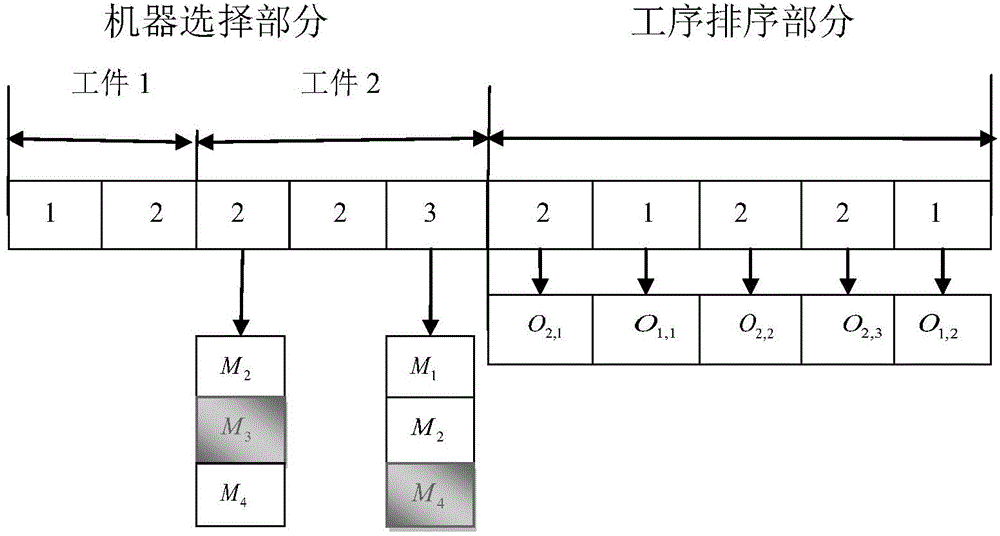

Multi-objective flexible job shop scheduling method based on discrete firefly algorithm

The invention provides a multi-objective flexible job shop scheduling method based on a discrete firefly algorithm. The method comprises the steps that a mathematical model is established for a multi-objective flexible job shop scheduling problem; a segment coding method is used to code a firefly, and a machine selection part and a process sorting part are divided; the discrete firefly algorithm is used to optimize the model to acquire a Pareto optimal solution set; and a solution corresponding to the actual need is selected from the Pareto optimal solution set, and decoding is carried out to output machine selection position information and process sorting position information. Compared with the existing method, the multi-objective flexible job shop scheduling problem optimizing method has the advantages that the global optimization ability of the algorithm is improved; the overall processing time is shortened; the job shop production cost is reduced; and the method meets actual production needs.

Owner:XIANGTAN UNIV

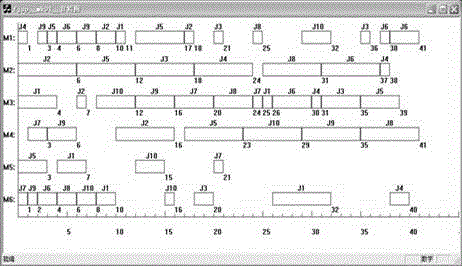

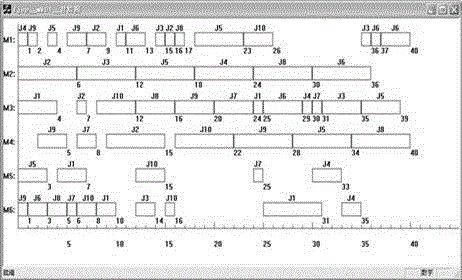

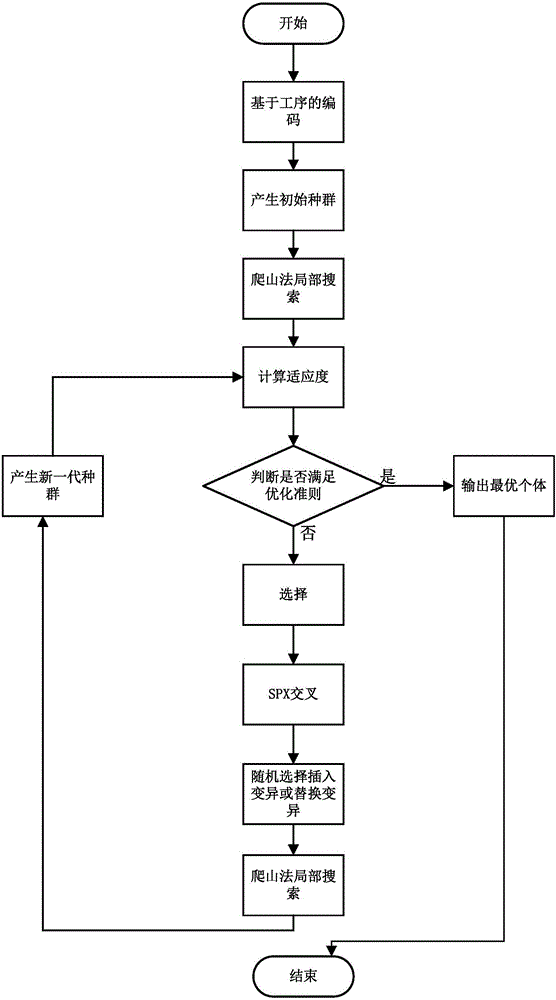

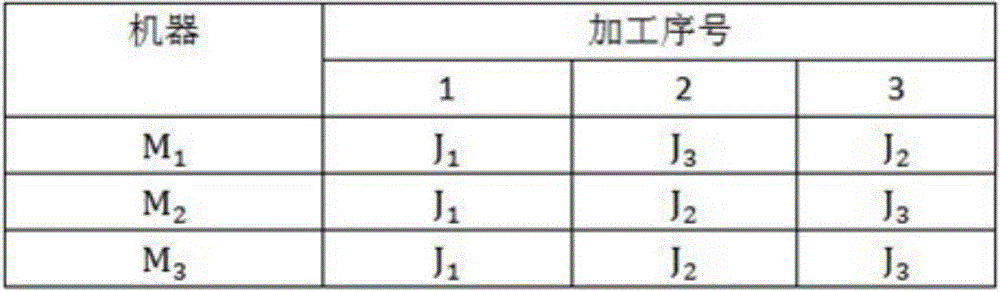

Improved culture gene algorithm for solving multi-objective flexible job shop scheduling problem

InactiveCN106611379AFast solutionStrong global search capabilityData processing applicationsArtificial lifeLocal optimumGuideline

The invention relates to the technical field of job shop scheduling, in particular to an improved culture gene algorithm for solving a multi-objective flexible job shop scheduling problem. The algorithm comprises the following steps of performing process-based encoding; generating an initialized population; performing local search by a hill-climbing method; calculating fitness; judging whether an optimization criterion is met or not (if yes, generating an optimal individual and ending the algorithm, otherwise, executing the next step); performing selection; performing SPX crossover; performing mutation; performing local search by the hill-climbing method; generating a new-generation population; calculating fitness; and circulating the process. The algorithm is improved as follows: the local search is performed by utilizing the hill-climbing method, so that local optimum can be escaped for obtaining a better solution, and the calculation time can be shortened; and in addition, the crossover and mutation modes of the algorithm are improved, the SPX crossover method is adopted, and one of two methods of insertion mutation and replacement mutation is randomly selected for mutating individuals in the population by an equal probability Pm during mutation.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

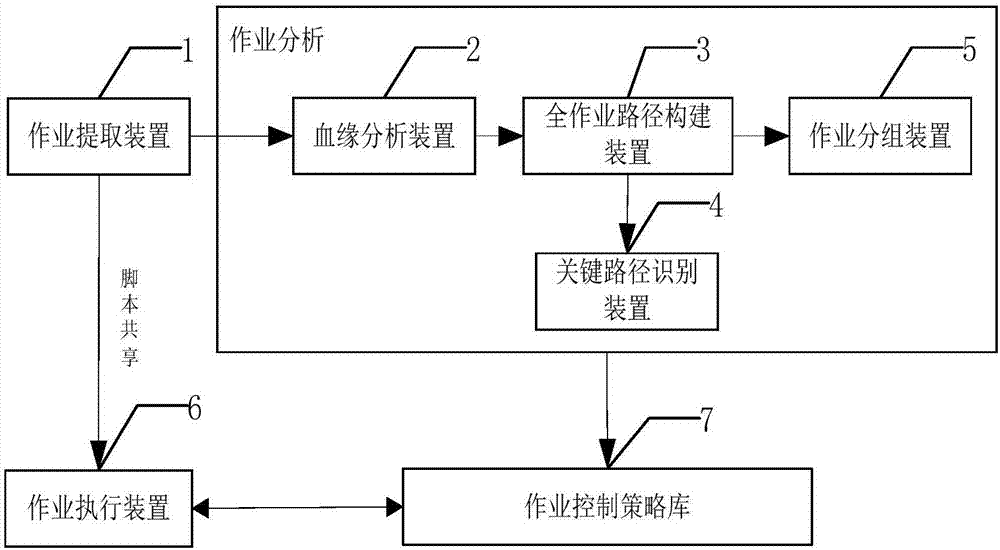

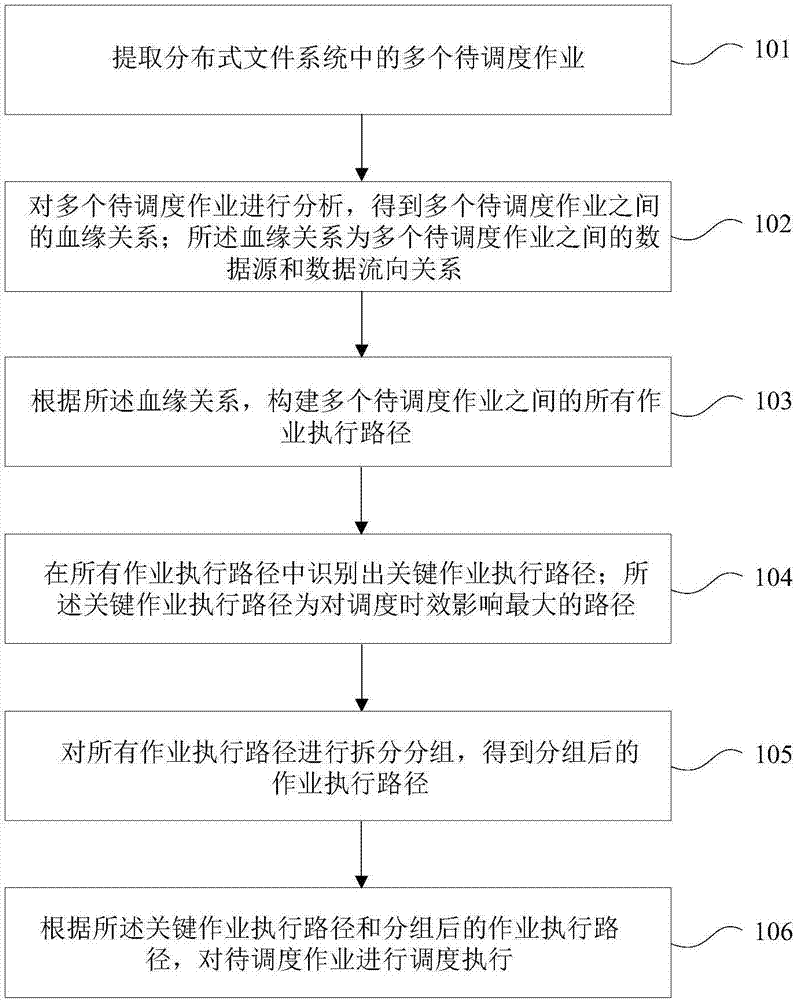

Distributed system job scheduling system and method

ActiveCN107239335AImplement automatic configurationImprove timelinessProgram initiation/switchingResource allocationDistributed File SystemJob shop scheduling

The invention provides a distributed system job scheduling system and method. The system comprises a job extracting device for extracting multiple jobs to be scheduled in a distributed file system, a consanguinity analysis device for analyzing the multiple jobs to be scheduled to obtain the consanguinity among the multiple jobs to be scheduled, a complete job path construction device for constructing all job execution paths among the jobs to be scheduled according to the consanguinity, a critical path recognition device for recognizing a key job execution path from all job execution paths, a job grouping device for splitting and grouping all the job execution paths to obtain grouped job execution paths, and a job execution device for executing the jobs to be scheduled according to the key job execution path and the grouped job execution paths. According to the technical scheme, massive job scheduling sequences are automatically configured, resources are reasonably assigned, data is traceable, and the job scheduling efficiency is improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

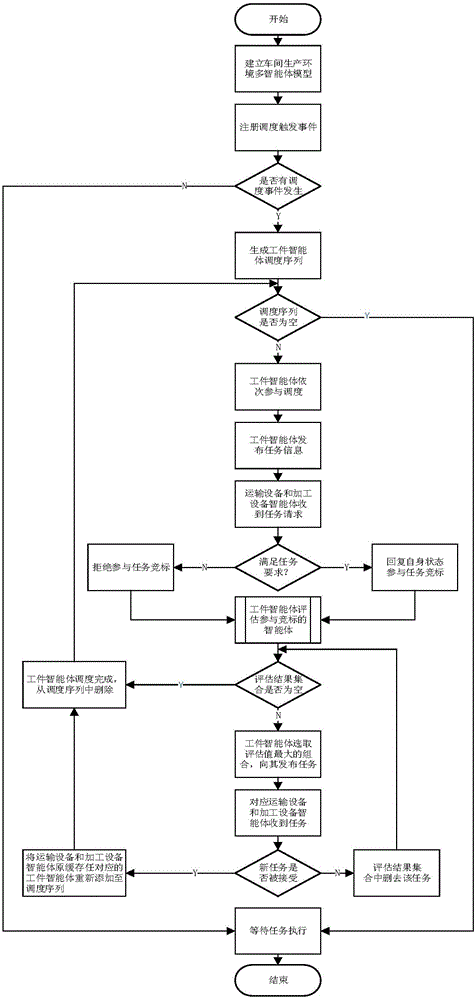

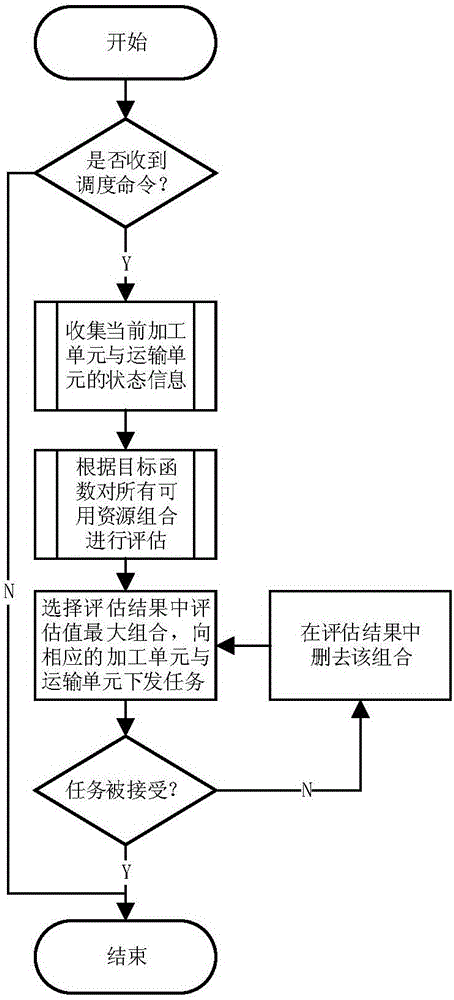

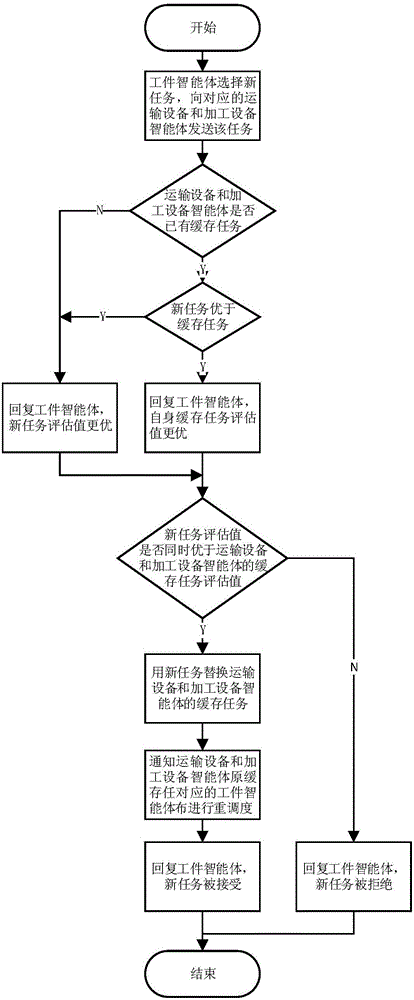

Real-time job shop scheduling control method in complicated production environment

ActiveCN106094759AReduce invalid scheduling calculationsReduce error accumulationProgramme total factory controlEvent triggerJob shop scheduling

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

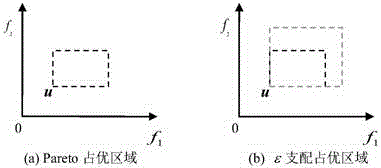

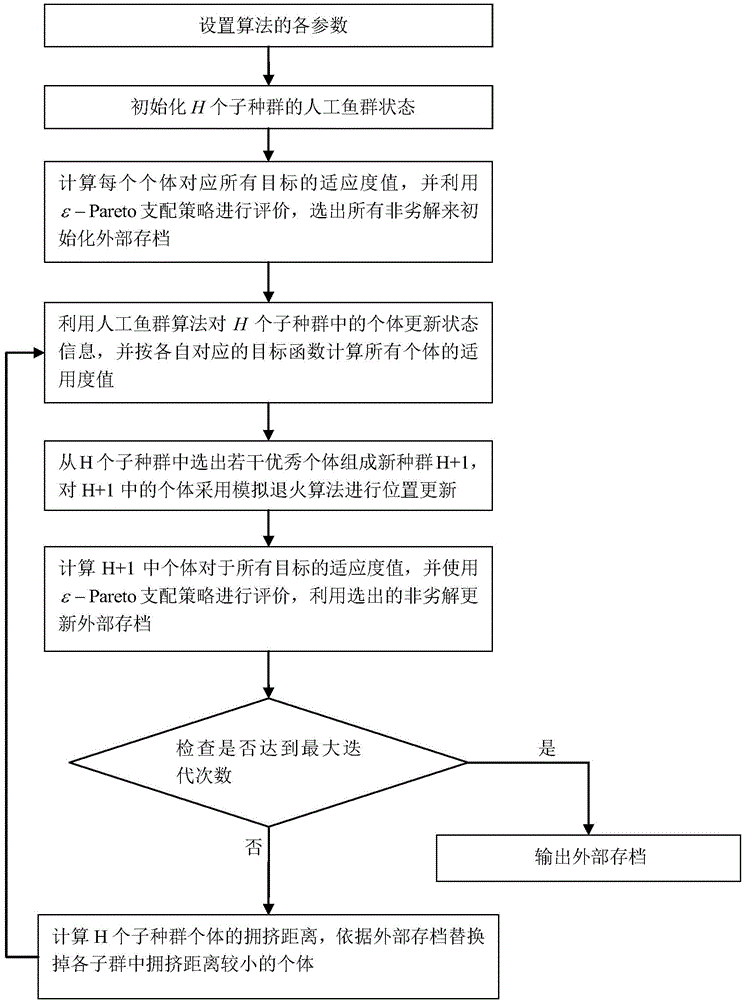

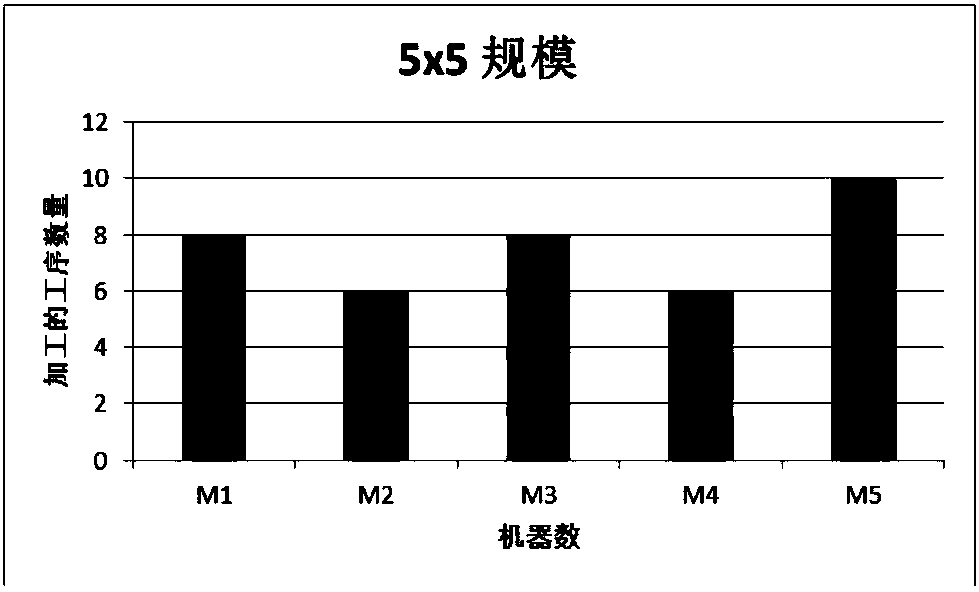

Multi-target flexible job shop scheduling method based on cooperative hybrid artificial fish swarm model

The invention belongs to the crossing field of a computer application technology and production manufacturing. A natural computing technology is used to optimize a multi-target flexible job shop scheduling problem. A problem that a cooperative hybrid artificial fish swarm algorithm is used to solve multi-target flexible job shop scheduling is provided. The method is characterized in that a foraging behavior with a distribution estimation attribute and an artificial fish attraction behavior are designed to improve an artificial fish swarm model; a cooperation idea is introduced into the model; through multiple population cooperation of the fish swarm, global searching is performed and is cooperated with a simulation annealing algorithm so as to enhance an algorithm local searching capability; aiming at a multi-target problem, an improved epsilon-Pareto dominant strategy is designed to evaluate an individual applicable degree value. The method in the invention has the following advantages that problems of slow later-period convergence, a poor local optimizing ability and the like, which exist in the artificial fish swarm algorithm during a searching process, can be overcome; through cooperative optimization, a pareto solution set with good quality and dispersibility is obtained.

Owner:DALIAN UNIV OF TECH

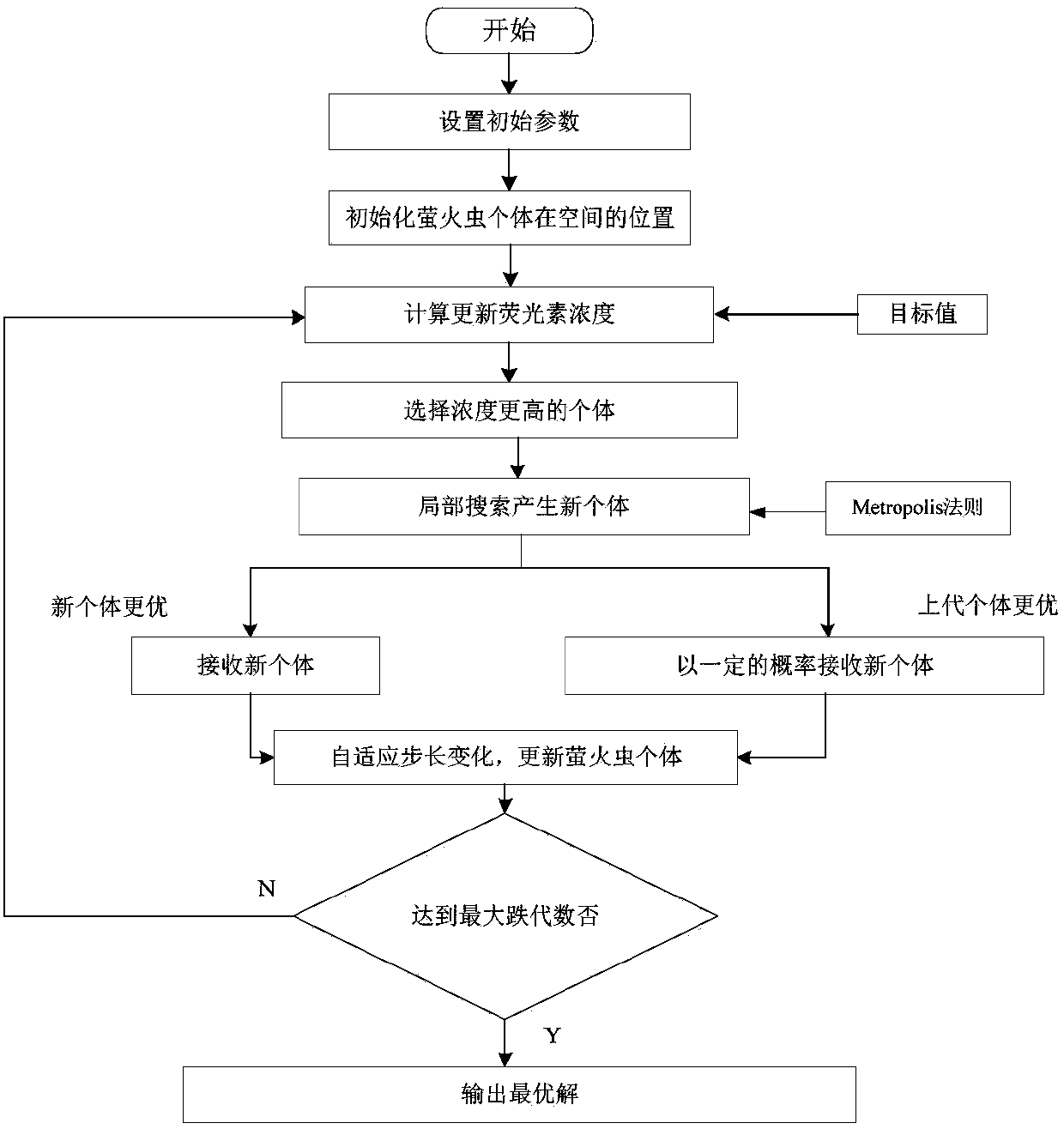

Flexible job-shop scheduling optimization method

ActiveCN107817772AImprove global search performanceImprove calculation stabilityProgramme total factory controlJob shop schedulingJob shop scheduling problem

The invention relates to a flexible job-shop scheduling optimization method, which applies the Metropolis criterion and the sinusoidal adaptive step length to a firefly algorithm so as to optimize andsolve a discrete problem. On the basis of building a mathematical model, an initial solution population of a discrete combination problem is randomly generated, then local search in an individual domain is performed according to the Metropolis criterion in simulated annealing to generate a new individual, the internal energy difference between the new individual and the original individual is calculated, the new individual is accepted according to a certain probability, and global search is performed on each generation by using the discrete firefly algorithm with the sinusoidal adaptive steplength until an optimal solution is searched. The method can better search an optimal solution of the FJSP (Flexible Job-Shop Scheduling Problem) in the global space and has better search precision, search efficiency and stability, thereby having important significance and significant engineering practical application values for solving discrete problems such as job-shop scheduling.

Owner:SOUTHWEST JIAOTONG UNIV

A method for solving flexible job shop scheduling based on a hybrid whale swarm algorithm

The invention discloses a method for solving flexible job shop scheduling based on a hybrid whale swarm algorithm, and the method comprises the steps: firstly defining the coding mode of flexible jobshop scheduling as two-stage random key coding, and then carrying out the mapping conversion through employing a conversion mechanism; Defining the shortest total processing time for solving the fitness function as an optimization target; Secondly, initializing parameters and whale population in the flexible job shop scheduling problem by adopting a whale group algorithm, wherein initialization isdivided into a sorting scheme of a random generation process and a genetic variation mode of an improved genetic algorithm to generate a better machine distribution scheme corresponding to the sorting scheme of the process, and then a better initial population is generated; Calculating the fitness value of each scheduling scheme, and finding and reserving the best scheduling solution; And finally, outputting the optimal scheduling solution and the corresponding fitness function value to obtain a solved optimal scheduling scheme, and solving the problems of low solution precision and low convergence rate in the existing flexible job shop scheduling problem.

Owner:CHANGAN UNIV

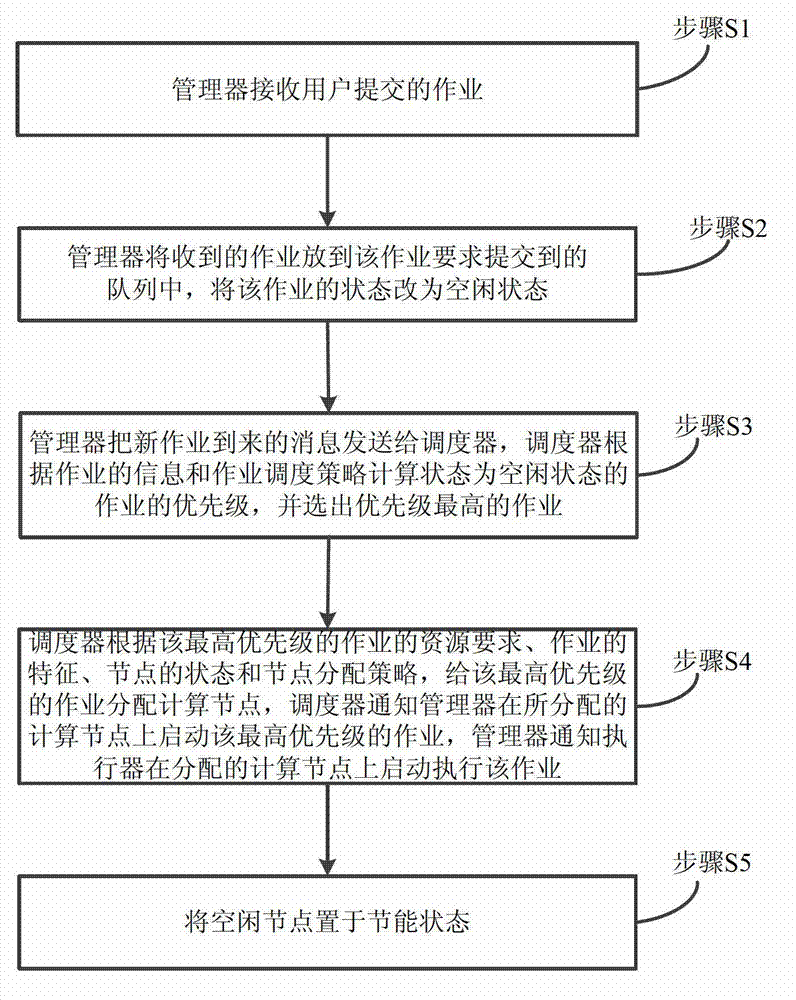

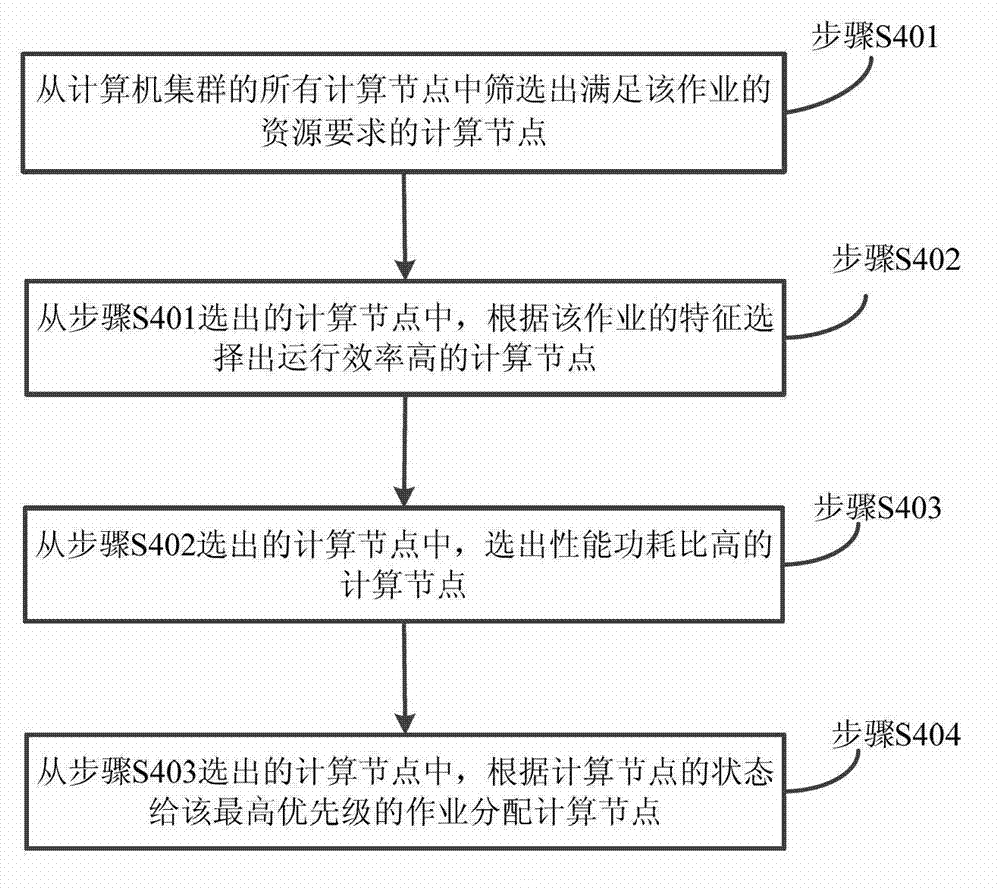

Energy-saving job scheduling system

ActiveCN102929720AReasonable control of wake-up timeAvoid consumptionEnergy efficient ICTResource allocationComputer clusterJob shop scheduling

The invention provides an energy-saving job scheduling system applied to a computer cluster. The scheduling process comprises the following steps that: step S1, a job submitted by a user is received by a manager; step S2, the job received by the manager is put in a queue, in which the job is required to be submitted, by the manager, the state of the job is changed into an idle state; step S3, a message that a new job comes is sent to a scheduler by the manager, priorities of jobs in the idle states are counted according to information of the jobs and scheduling policies of the jobs, and the job with the highest priority is selected; step S4, a counting node is allocated to the job with the highest priority by the scheduler according to resource requirements of the job with the highest priority, job features, a node state and a node scheduling policy, the manager is informed by the scheduler to start the job with the highest priority on the distributed counting node, and an actuator is informed by the manger to start and execute the job on the distributed counting node; and step S5, idle nodes are located in energy-saving states. According to the energy-saving job scheduling system, the time for awakening each node and enabling each node to enter the energy-saving state is reasonably controlled.

Owner:中科曙光国际信息产业有限公司 +1

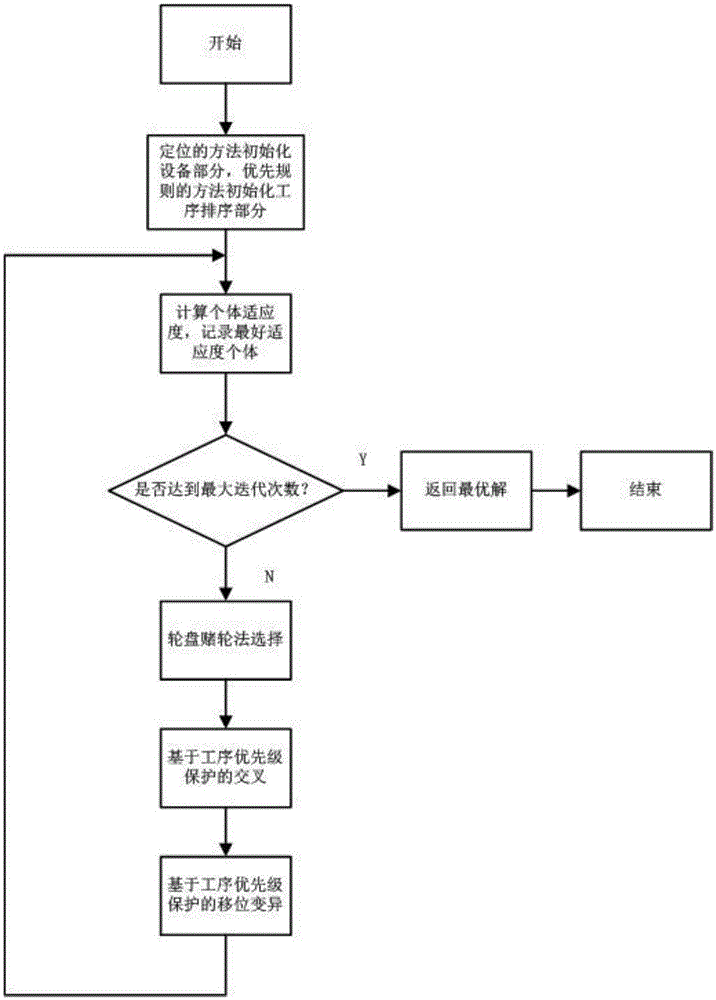

Improved genetic algorithm for flexible workshop scheduling

InactiveCN106610654AIncrease diversityImprove performanceTotal factory controlProgramme total factory controlAlgorithmGenetic algorithm

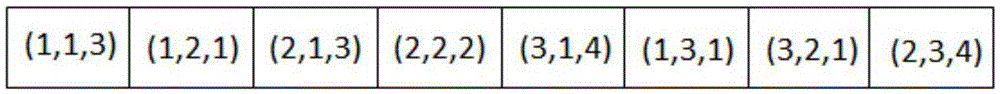

The invention proposes an improved genetic algorithm for flexible workshop scheduling, and the algorithm relates to the technical field of workshop scheduling, and specifically relates to the technical field of flexible workshop scheduling. The invention aims at the problems that a conventional genetic algorithm is complex in coding mode, is difficult for decoding, is weaker in search and development capability and is liable to be mature early and a non-feasible solution is liable to appear in the operation of a genetic operator. Compared with a conventional algorithm, the algorithm has the following improvements that 1, the coding is just performed on one chromosome, a coding chromosome gene consists of a ternary array (i, j, k), the coding mode is simple and convenient, and there is no need of decoding; 2, a positioning method is employed for selecting equipment for the process according to two different rules, and three known effective scheduling rule is employed for process arrangement; 3, crossing and mutation operations employ a genetic operator based on process priority protection; 4, before mutation, the probability of individual and genetic mutation is calculated through a formula, thereby achieving more accordance with the natural law. The algorithm is high in practicality.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

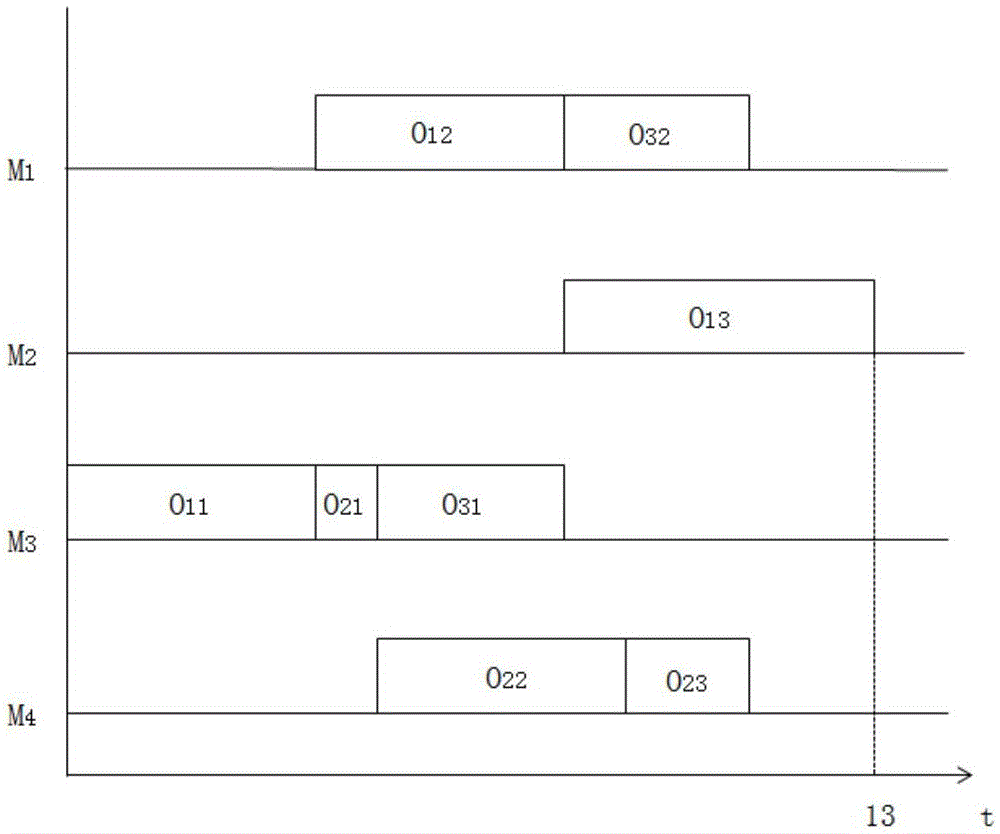

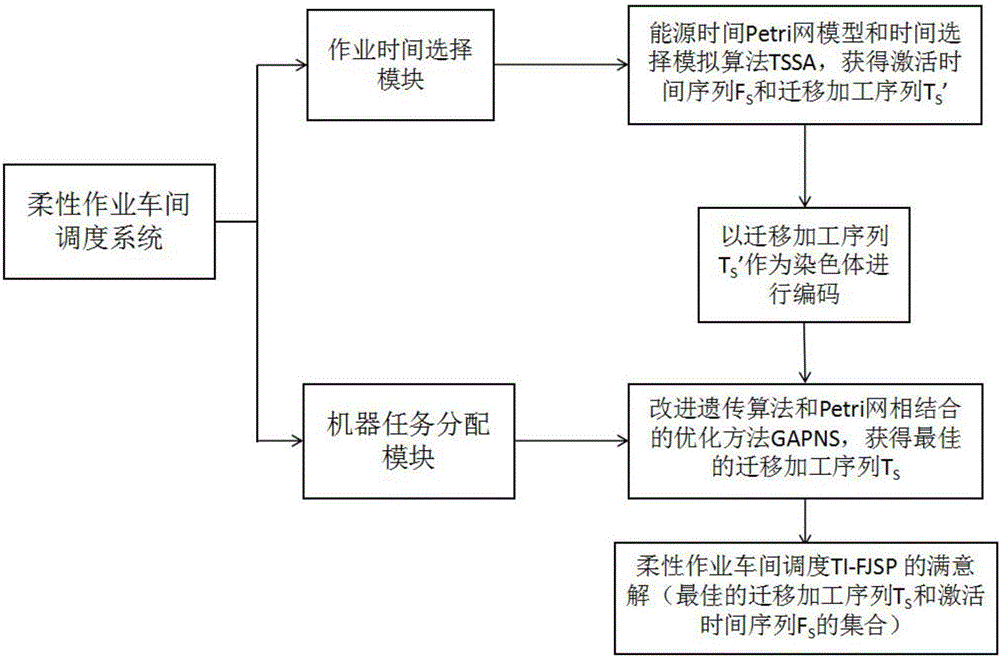

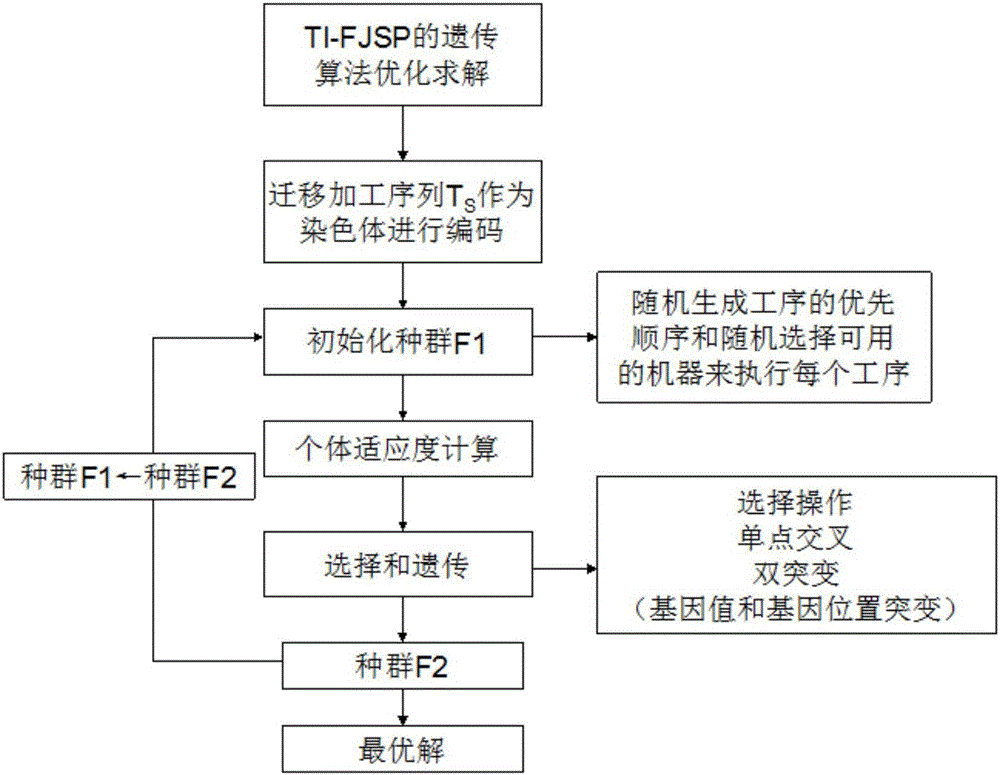

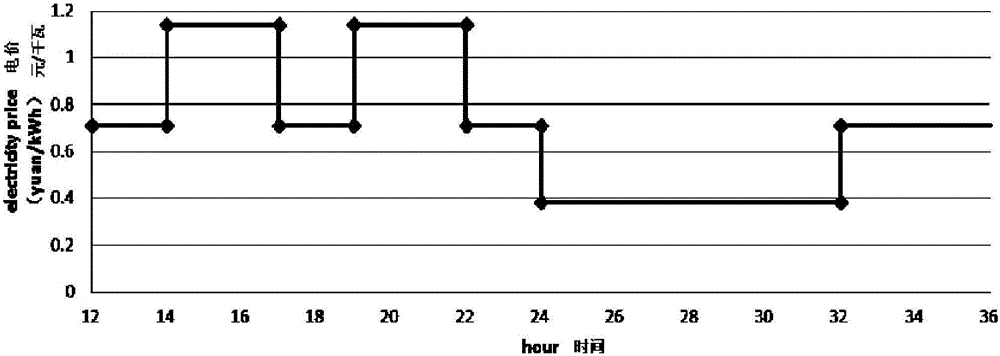

Flexible job shop scheduling system based on Petri network and improved genetic algorithm

The invention discloses a flexible job shop scheduling system based on a Petri network and an improved genetic algorithm. The flexible job shop scheduling system is a system for minimizing completion time and power consumption according to peak-valley electricity price and indirect energy consumption, and comprises a job time selection module and a machine task assigning module, wherein the job time selection module is used for obtaining a migration activation time sequence FS and a migration processing sequence TS' by establishing an energy time Petri network model and a time selection simulation algorithm TSSA; the machine task assigning module is used for simulating by combination of improved genetic algorithm and the Petri network, finding out an optimal migration processing sequence TS, and obtaining a satisfactory solution of flexible job shop scheduling TI-FJSP. By adopting the flexible job shop scheduling system disclosed by the invention, making and implementation of a production plan can be effectively optimized, and a production mode with the lowest cost is provided for a company according to the peak-valley electricity price, so that the production cost of the company can be lowered, the utilization rate of energy can be increased, energy allocation can be optimized, resources can be saved, the environment can be protected, the economic benefits of the company can be optimized, and the industrial competitiveness of the company can be improved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Job scheduling to balance energy consumption and schedule performance

A computer program product including computer usable program code embodied on a computer usable medium, the computer program product comprising: computer usable program code for identifying job performance data for a plurality of representative jobs; computer usable program code for running a simulation of backfill-based job scheduling of the plurality of jobs at various combinations of a run-time over-estimation value and a processor adjustment value, wherein the simulation generates data including energy consumption and job delay; computer usable program code for identifying one of the combinations of a run-time over-estimation value and a processor adjustment value that optimize the mathematical product of an energy consumption parameter and a job delay parameter using the simulation generated data for the plurality of jobs; and computer usable program code for scheduling jobs submitted to a processor using the identified combination of a run-time over-estimation value and a processor adjustment value.

Owner:LENOVO GLOBAL TECH INT LTD

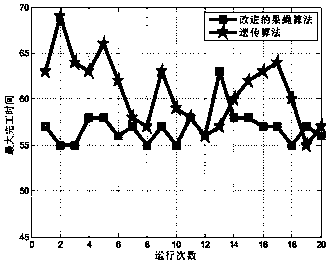

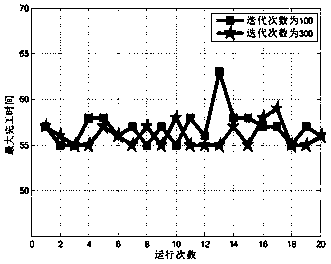

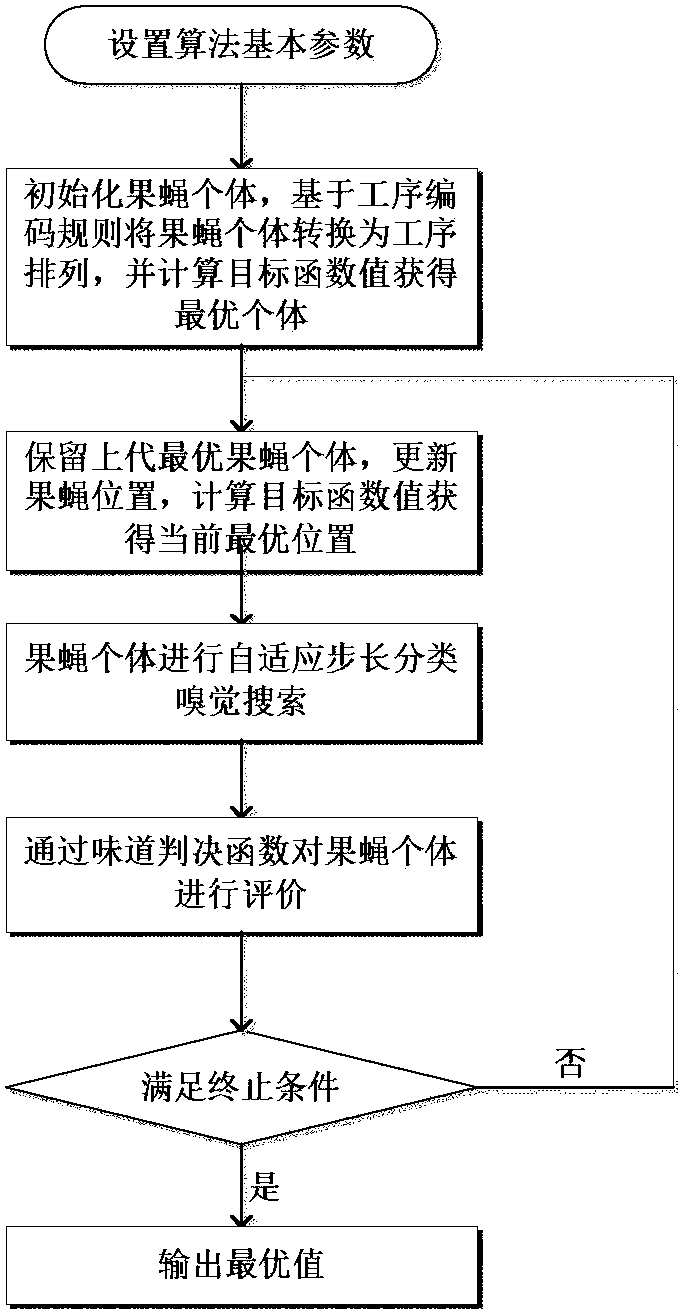

Job shop scheduling method based on improved fruit fly optimization algorithm

InactiveCN108108829AReduce settingsStrong global optimization abilityForecastingResourcesCompletion timeMathematical model

The invention presents a job shop scheduling method based on an improved fruit fly optimization algorithm. The method comprises the following steps: establishing a mathematical model of a job shop according to the characteristics of the job shop, and constructing the constraint conditions for the processing order of different working procedures of each work piece and the constraint conditions forthe processing order of the working procedures of different work pieces on each machine; and establishing a job shop scheduling objective function based on minimum maximum completion time, forming individual fruit flies through a coding method based on working procedures, enabling the fruit fly colony to quickly find the minimum value of a taste concentration determination function through a classification olfactory random search method based on adaptive step size, and obtaining an optimal solution of job shop scheduling, namely, an optimal scheme of job shop scheduling. The algorithm is simple to implement, and requires only two parameters. Moreover, the algorithm has strong global optimization ability, and can be used to solve the job shop scheduling problem.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD +1

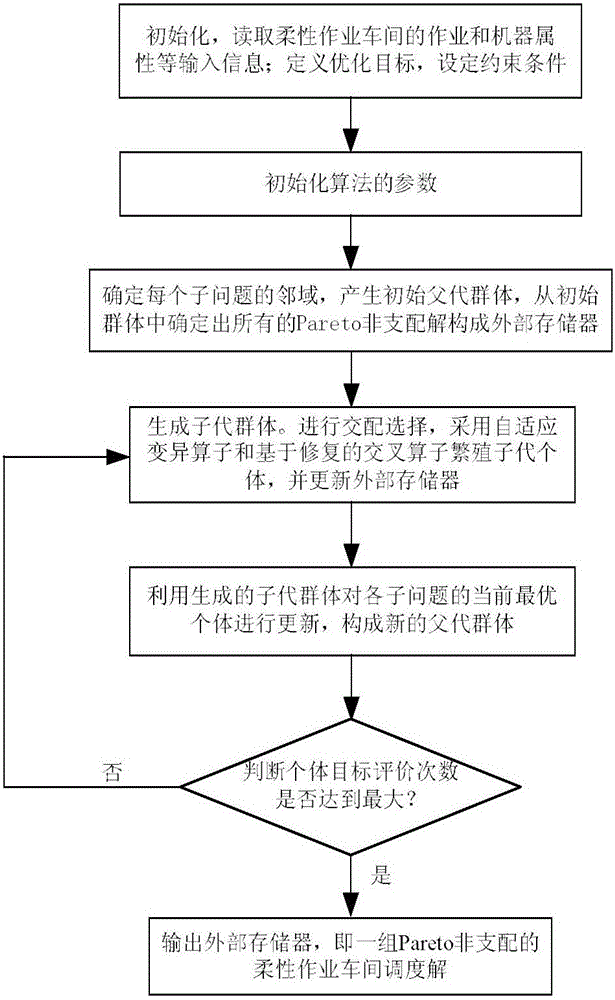

Flexible workshop robustness scheduling method based on decomposition multi-target evolution algorithm

The invention discloses a flexible workshop robustness scheduling method based on a decomposition multi-target evolution algorithm. The method comprises the following steps: 1, reading such input information as operation, machine attributes and the like of a flexible operation workshop, defining an optimization object, and setting constraint conditions; 2, initializing parameters of the algorithm; 3, determining an adjacent domain of each subproblem, generating an initial parent group, and determining all Pereto non-dominant solutions from the initial group so as to form an external memory; 4, generating a child group, carrying out mating selection, breeding child individuals by use of an adaptive variation operator and a restoration-based intersection operator, and updating the external memory; 5, by use of the generated child group, updating a current optimal individual of each subproblem, and forming a new parent group; and 6, when it is determined that the individual object evaluation frequency reaches the maximum, outputting the external memory, i.e., a group of Pareto non-dominant flexible operation workshop scheduling solutions, and if the frequency does not reach the maximum, skipping to the fourth step. According to the invention, scheduling tasks in a flexible operation workshop can be rapidly and efficiency realized.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com