Flexible job shop scheduling method based on multi-species coevolution

A workshop scheduling and flexible operation technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as complex solution space, insufficient algorithm performance, and difficulty in finding high-quality scheduling solutions, and achieve simple solution space , the effect of maintaining diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

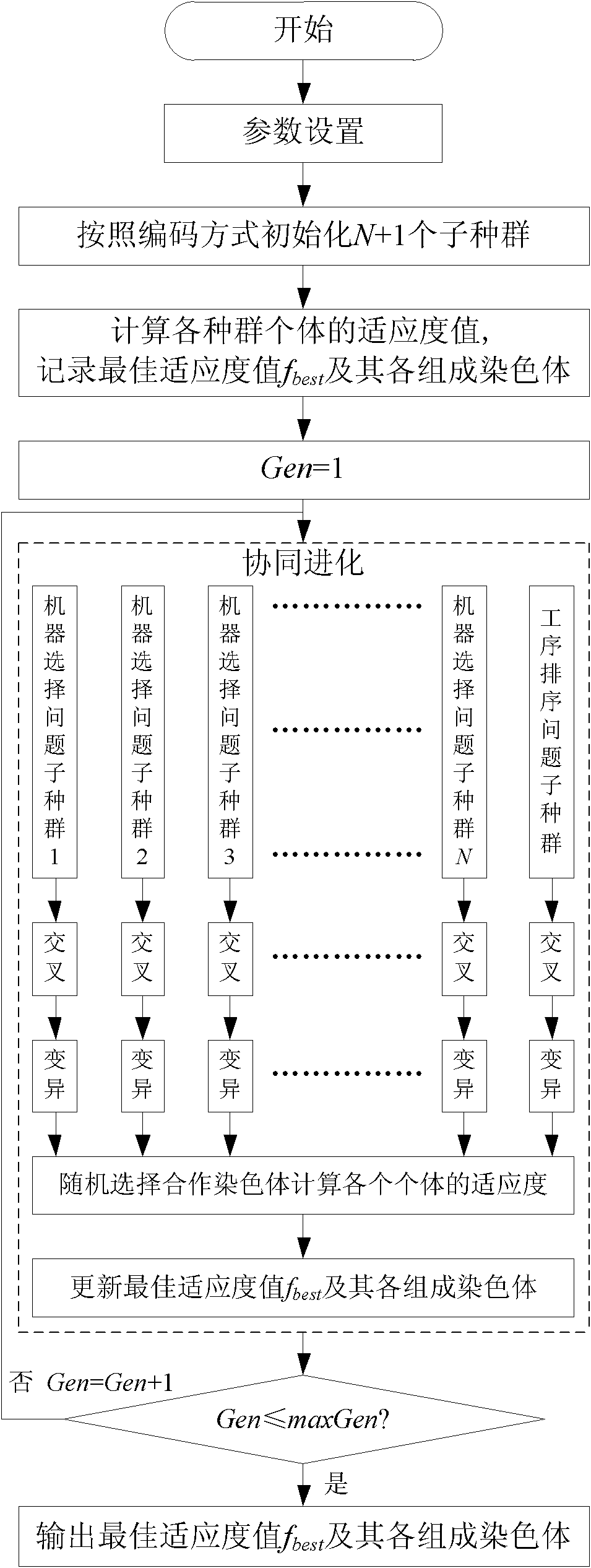

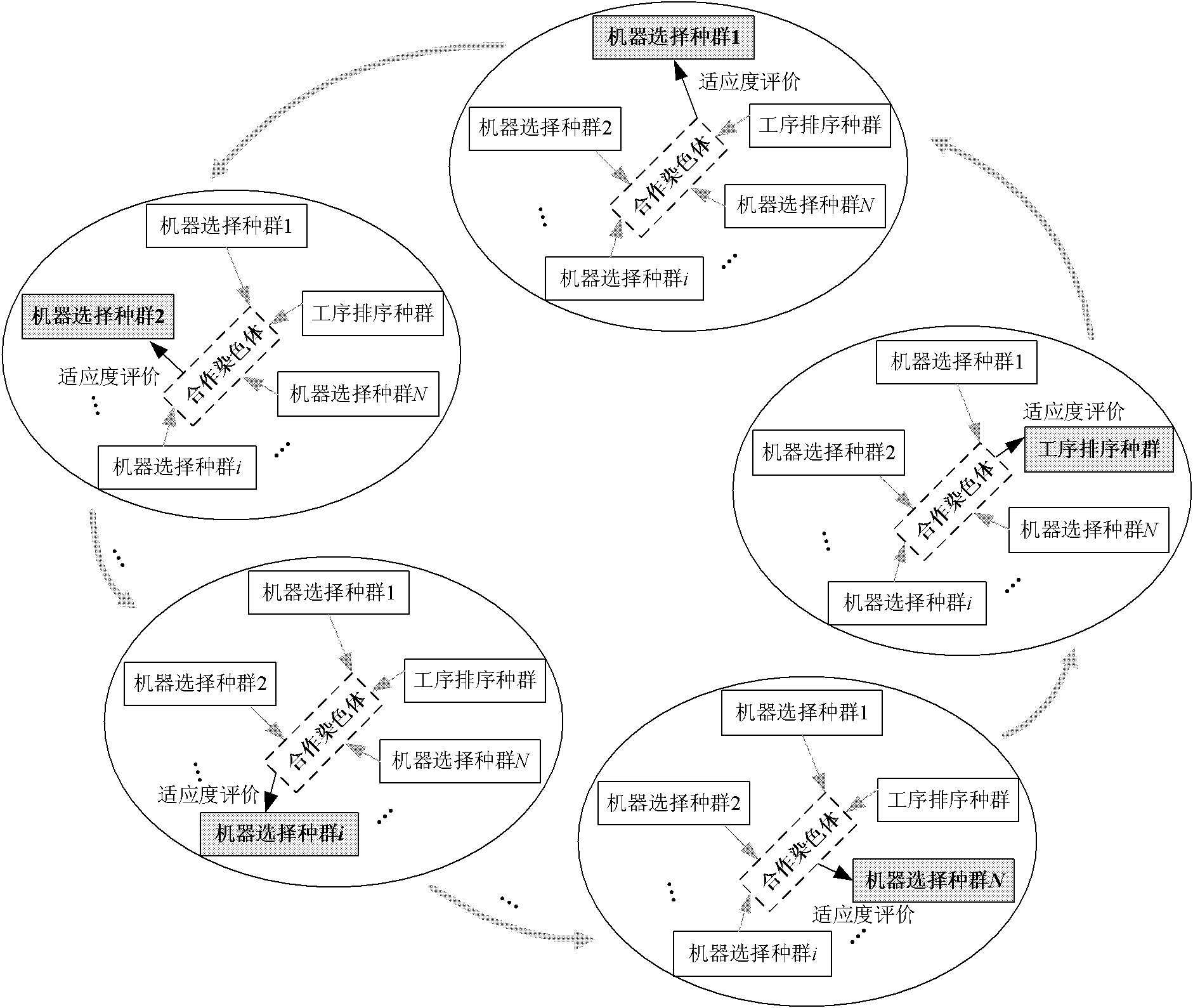

[0033] refer to figure 1 and figure 2 , a flexible job shop scheduling method based on multi-population co-evolution, including the following steps:

[0034] Step 1, parameter setting:

[0035] Assuming that the number of workpieces is N, this method contains N+1 sub-populations, of which N machines select the sub-problem population, and 1 process sorting sub-problem population size. Set the threshold maxGen of the number of algorithm loop iterations, and the population size P of the machine selection sub-problem 1 , the tournament selection factor k 1 , the crossover probability is P c1 , the mutation probability is Pm1 , the tournament selection factor k 2 , the population size of the process ordering subproblem is P 2 , crossover probability P c2 , the mutation probability P m2 .

[0036] Step 2, initialize the population:

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com