Job shop scheduling method based on improved fruit fly optimization algorithm

A job shop and scheduling method technology, applied in the direction of calculation, control/regulation system, prediction, etc., can solve the problems of high computational complexity, can not effectively solve the problem of workshop scheduling, many parameter settings, etc., to achieve simple algorithm implementation and solution. Job shop scheduling problem, effect of few parameter settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific implementation

[0051] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

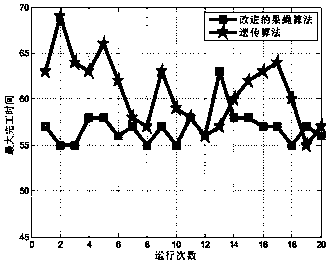

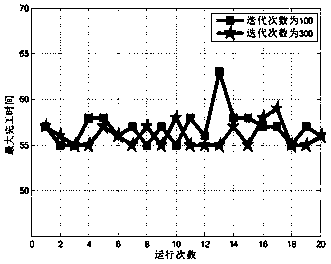

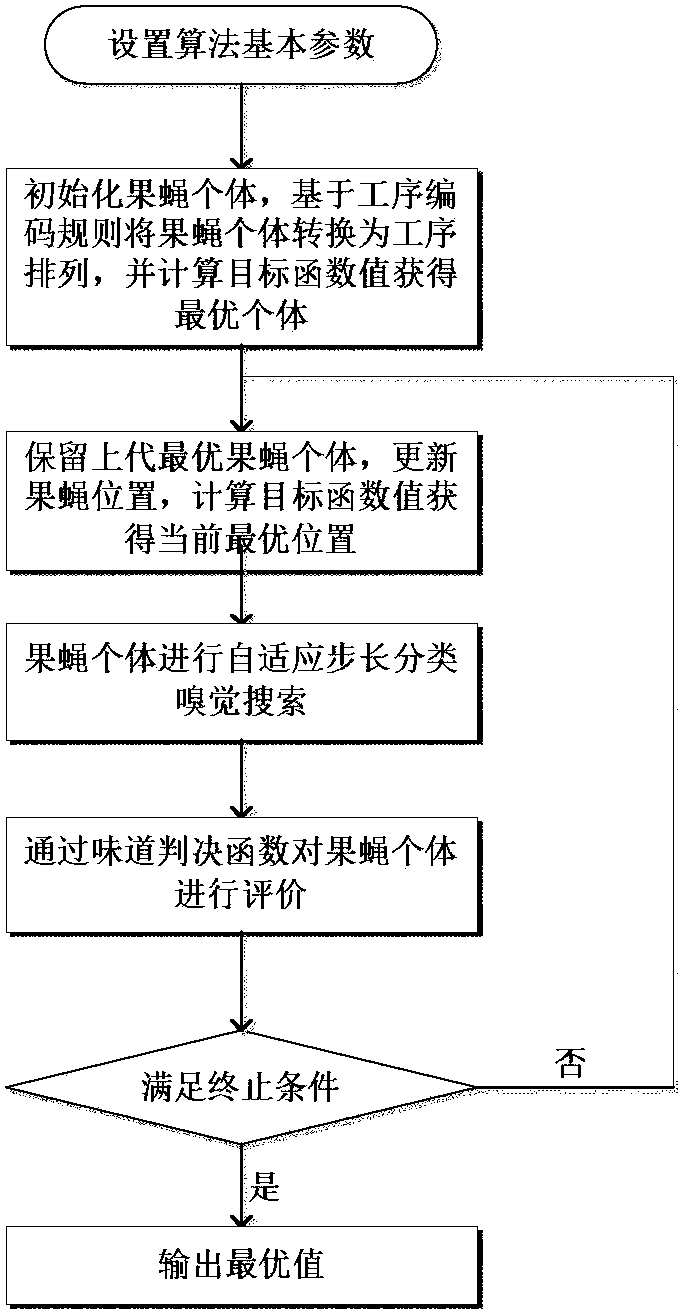

[0052] figure 1 It is a flowchart of the operation of the present invention. First, determine the initial population size and the maximum number of iterations of the improved Drosophila algorithm. Then use the known number of workpieces and machines to generate fruit fly individuals, use the known completion time of the workpiece process to calculate the maximum completion time of fruit fly individuals, and keep the fruit fly individuals with the smallest time. Then, a classification olfactory search with adaptive step size is carried out within the fruit fly population to generate a new fruit fly population. Calculate the maximum completion time of each fruit fly individual in the new fruit fly population, and select the optimal individual, compare this optimal individual with the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com