Flexible job-shop scheduling optimization method

A technology of workshop scheduling and flexible operation, applied in control/regulation systems, instruments, comprehensive factory control, etc., can solve the problems of no substantial improvement, easy to fall into local optimum, low accuracy of firefly algorithm, etc. Stability, the effect of improving the global search ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

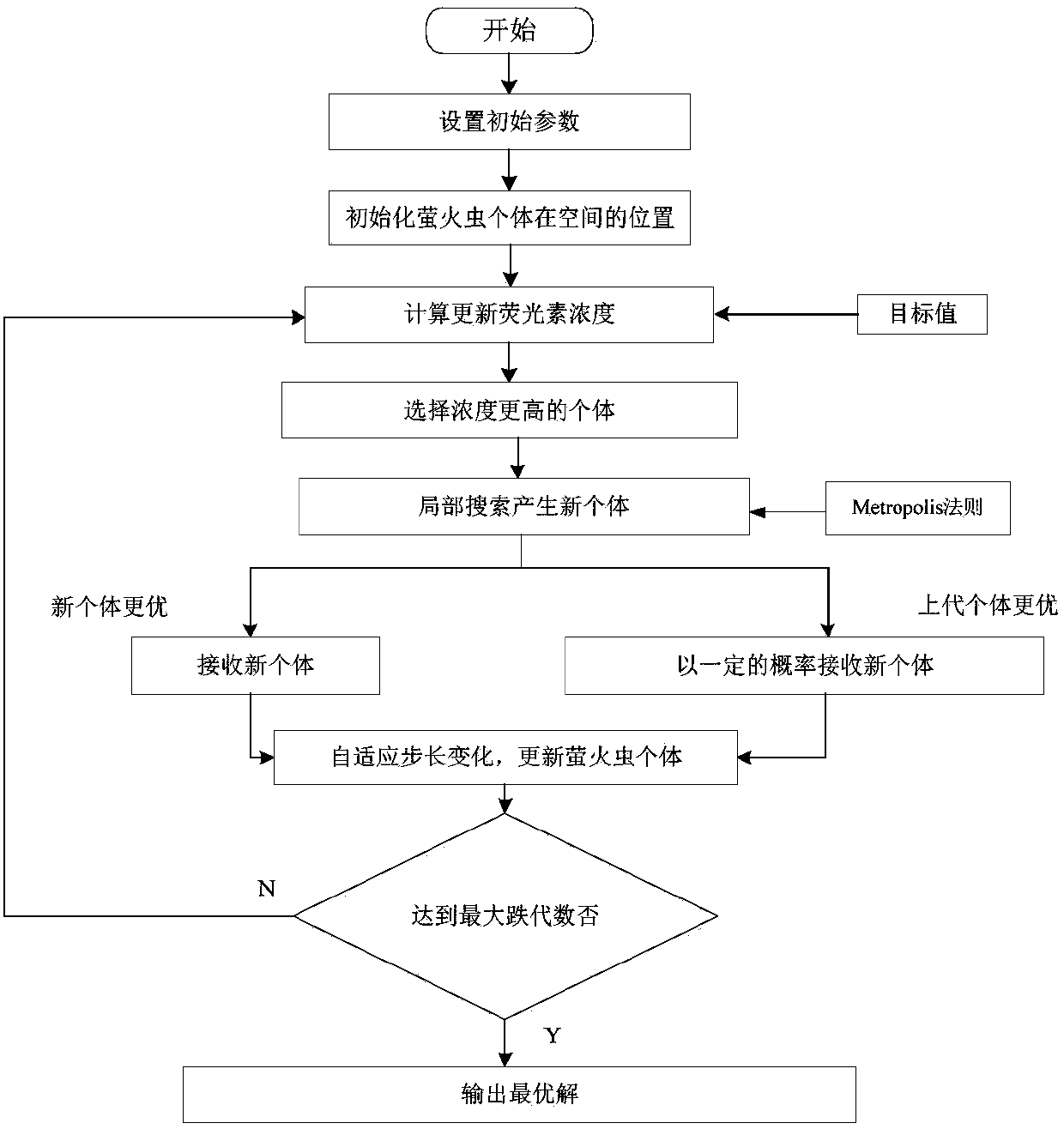

Method used

Image

Examples

Embodiment 1

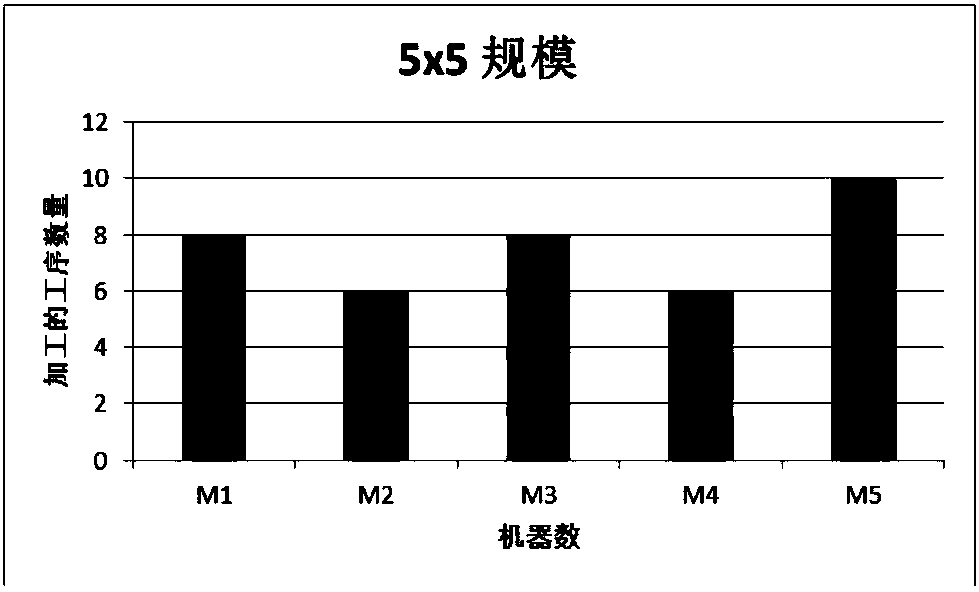

[0069] A JSP problem of 5×5 scale is adopted, that is, 5 workpieces are processed on 5 machines. Each workpiece includes four processes, and the processing sequence is o i1 , o i2 , o i3 , o i4 . where o i1 and o i3 For processing operations, you can only choose to operate on the processing machine; o i2 and o i4 For detection operation, you can only choose to operate on the detection machine. The distribution of machines is that machines 1, 2, and 4 are processing machines, and machines 3 and 5 are testing machines. The constraints of machines and processes are shown in Table 1.

[0070] Table 1 Machine process constraints of 5×5 scale JSP

[0071]

[0072]

[0073] For a more intuitive expression, the number of processes that can be processed on each machine is as follows figure 2 shown.

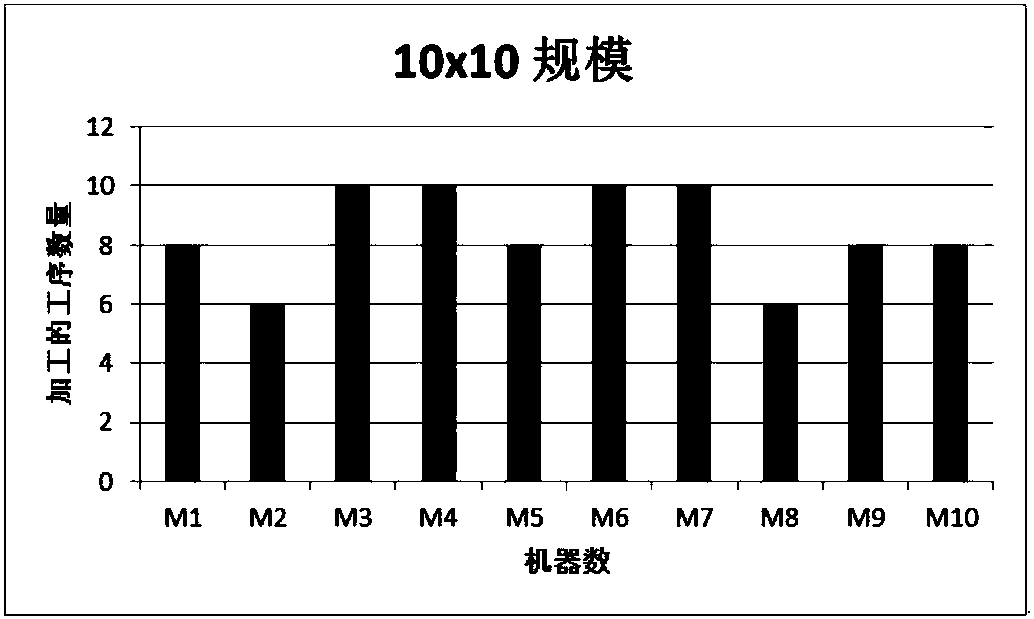

example 2

[0075] Example 2 adopts a JSP problem with a scale of 10×10, that is, 10 workpieces are processed on 10 machines. The process constraints of each workpiece are the same as those in Example 1, and in Example 2. The first 6 machines are processing machines, and the last 4 machines are testing machines. The number of processes that can be processed on each machine is as follows: image 3 shown.

Embodiment 3

[0077] Example 2 adopts a JSP problem with a scale of 20×16, that is, 20 workpieces are processed on 16 machines. The process constraints of each workpiece are the same as those in Example 1, and in Example 3. The first 10 machines are processing machines, and the last 6 machines are testing machines. The number of processes that can be processed on each machine is as follows: Figure 4 shown.

[0078] specific operation

[0079] Establish the optimized mathematical model of example 1 according to formula (1)-(4):

[0080] Objective function:

[0081]

[0082] Constraint equation:

[0083] S k ≥0,P k ≥0 k=O 1 ,O 2 ,O 3 ,O 4 ;

[0084] S k -S k-1 ≥P k-1 k=O 1 ,O 2 ,O 3 ,O 4 ;

[0085] S k -S j ≥P k or S j -S k ≥P j (k,j)∈E h ,h∈(1,2,...,5)

[0086] The operation methods of the other two examples are the same. After obtaining the mathematical model, according to the principle and basis of initial parameter selection, the firefly population size N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com