Patents

Literature

84results about How to "Improve benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-grain nutrition and health hot drink and manufacturing method thereof

InactiveCN104605247AReduce satietyLower fatty acidFood ingredient functionsFood preparationCorn flourFunctional health

The invention relates to multi-grain nutrition and health hot drink. The hot drink comprises a proper amount of soybean meal, black bean meal, black rice flour, red bean flour, corn flour, semen coicis flour, coarse rice powder, small yellow rice (millet) flour, buckwheat, aromatic glutinous rice flour, oat powder, black sesame seed powder, walnut powder, peanut powder, purple sweet potato powder, yam flour, jujube powder, wolfberry powder, longan powder, black fungus powder, oligosaccharides, vegetable fat powder and iodine-free salt. The multi-grain nutrition and health hot drink disclosed by the invention contains twenty natural grains, natural vegetable fat crops and functional health plants which are taken as raw materials, has three effects of comprehensive nutrition, natural fragrance and functional health and is a safe, healthy and functional health food with the advantages of natural fragrance, natural nutrition, comprehensive health and pleasant diet.

Owner:上海塞翁福农业发展有限公司

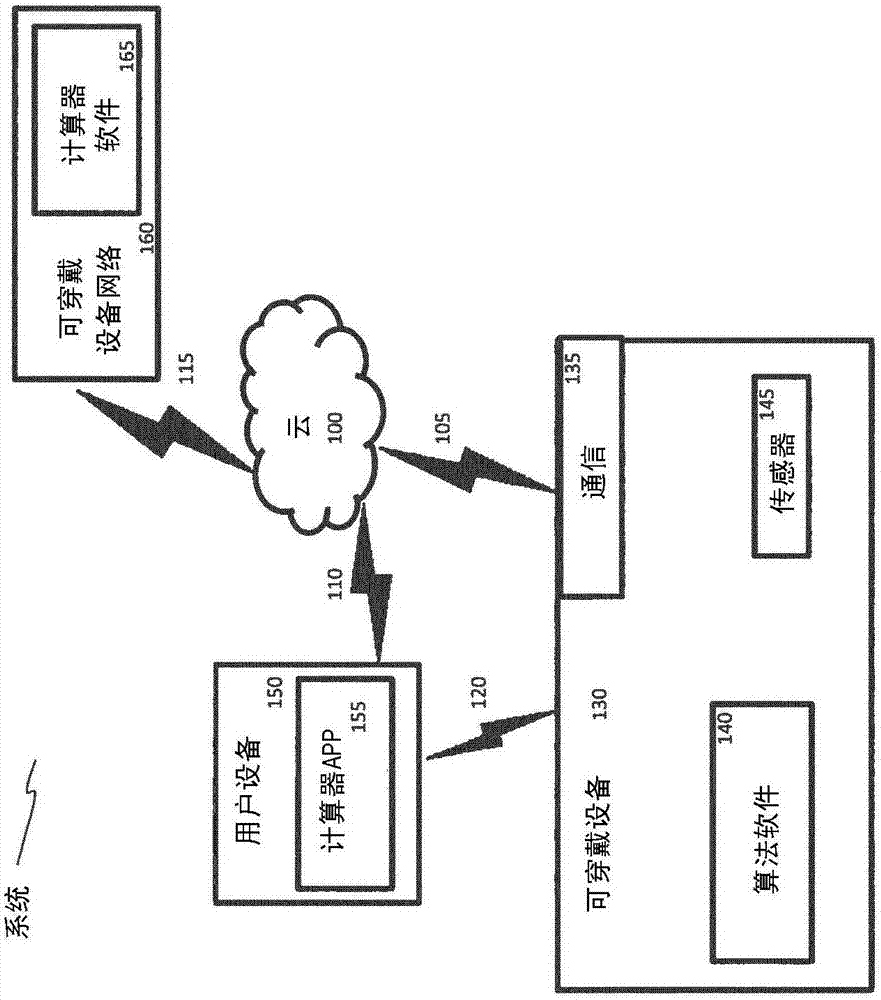

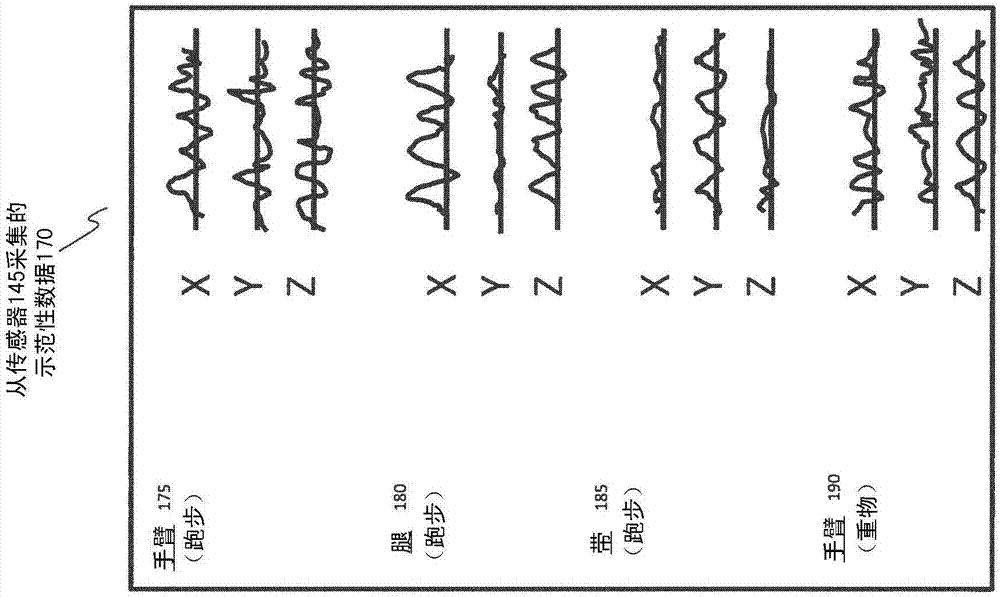

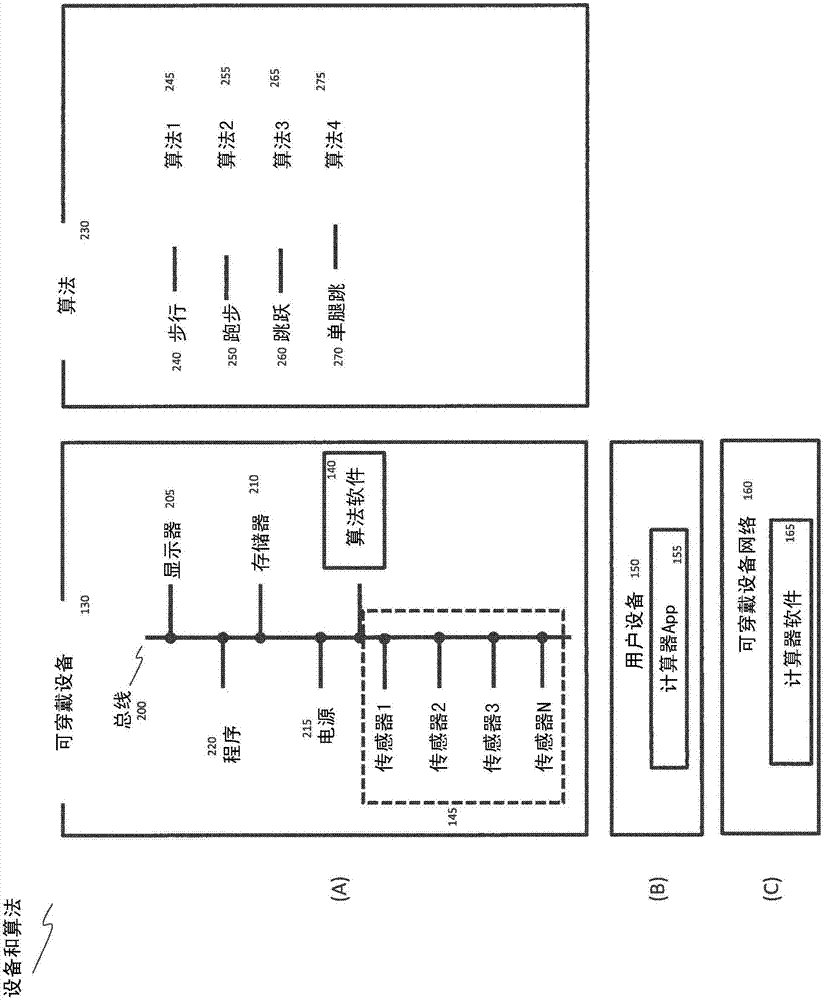

System and method for generating health data using measurements of wearable device

PendingCN106999106AThe Need for Increased AccuracyThe recognition effect is accuratePhysical therapies and activitiesHealth-index calculationData setComputer science

A computer-implemented method or system for generating health data is provided. The method includes receiving a sensor data set measured by one or more sensors of a wearable device over an interval of time, the sensor data set indicating a time series profile of a body parameter of a user of the wearable device over the interval of time. The method also includes determining an activity type of the user matching the time series profile; and calculating a value associated with a health metric, wherein the value is calculated based on the activity type.

Owner:KONINKLJIJKE PHILIPS NV

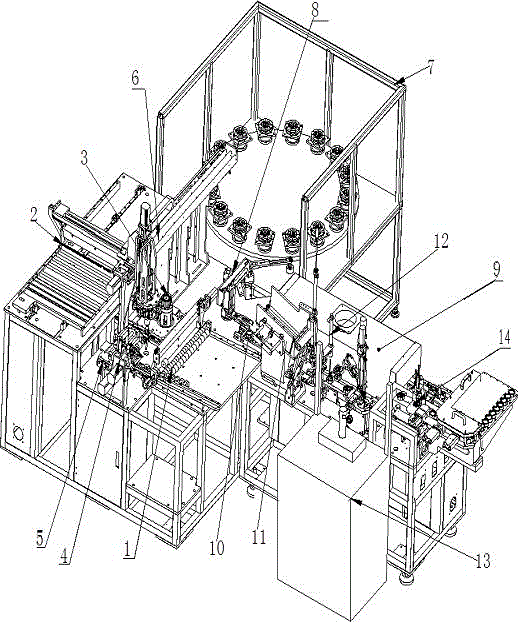

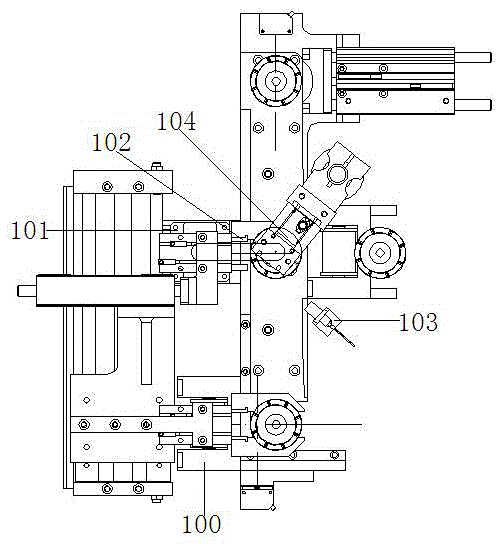

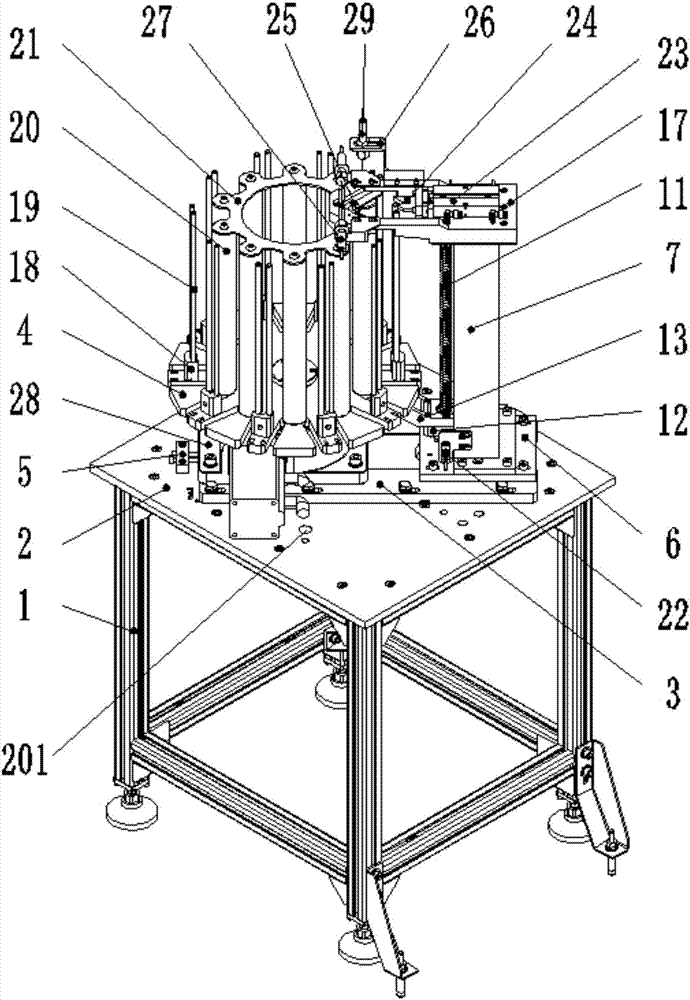

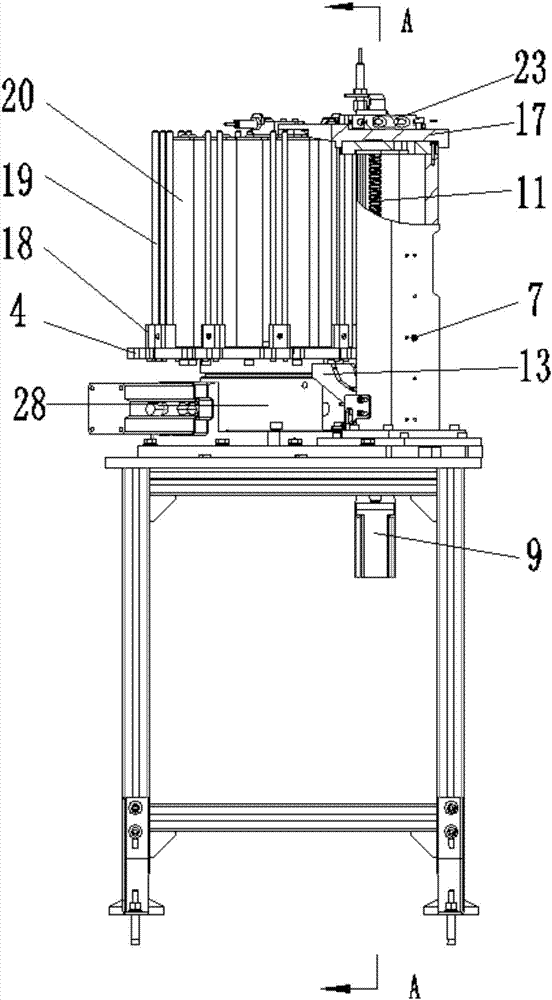

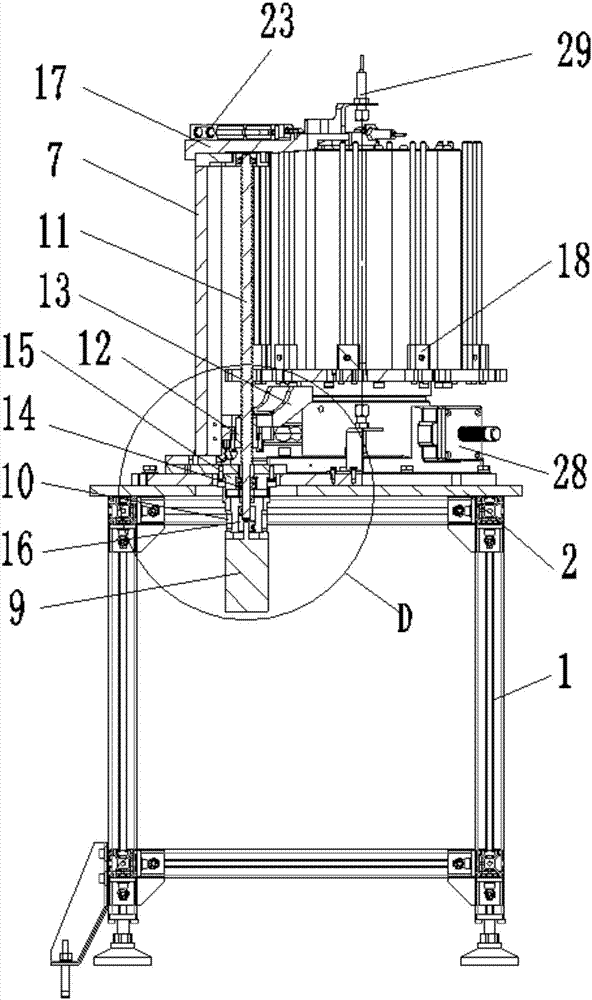

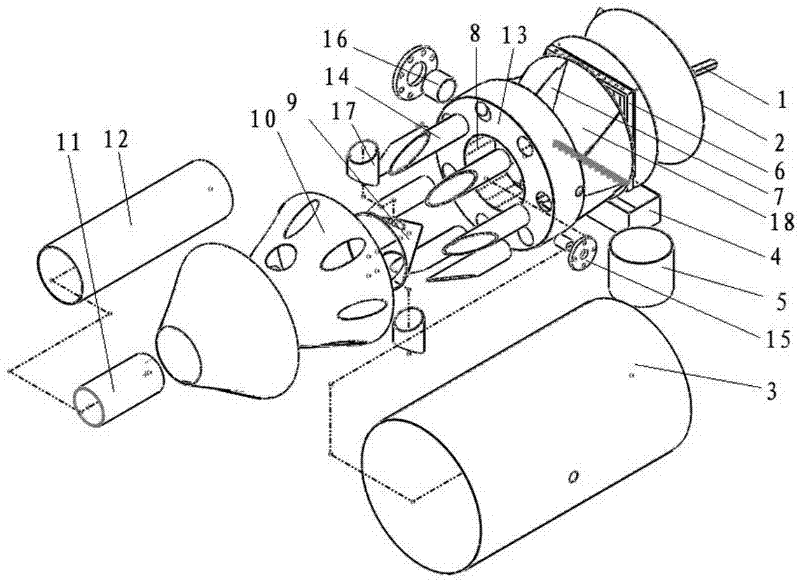

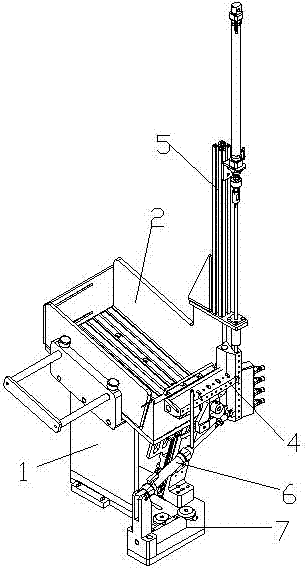

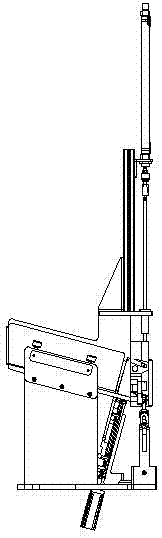

Motor rotor assembly apparatus

InactiveCN105471199AImprove benefitsHigh degree of automationManufacturing stator/rotor bodiesCooking & bakingTransfer mechanism

The present invention discloses a motor rotor assembly apparatus. The apparatus comprises an iron core automatic feeding mechanism 1, a magnetic shoe automatic feeding mechanism, a magnetic shoe uniform arrangement jig mechanism, an iron core gluing mechanism, a glued iron core transferring and overturning mechanism, a magnetic shoe and iron core pre-assembling and transferring mechanism, a magnetic shoe and iron core assembling and curing mechanism, a cured magnetic shoe and iron core transferring mechanism, a conveying and baking mechanism, an rotor outer diameter check mechanism, a rotor axis automatic feeding mechanism, an axis pre-assembling mechanism, an axis and iron core riveting mechanism and an rotor critical dimension check mechanism. Therefore, the motor rotor assembly apparatus is high in automation level, the assembled product quality is easily guaranteed, the manpower costs are reduced, the production efficiency is improved, and the enterprise benefits are increased.

Owner:苏州爱沛达自动化设备有限公司

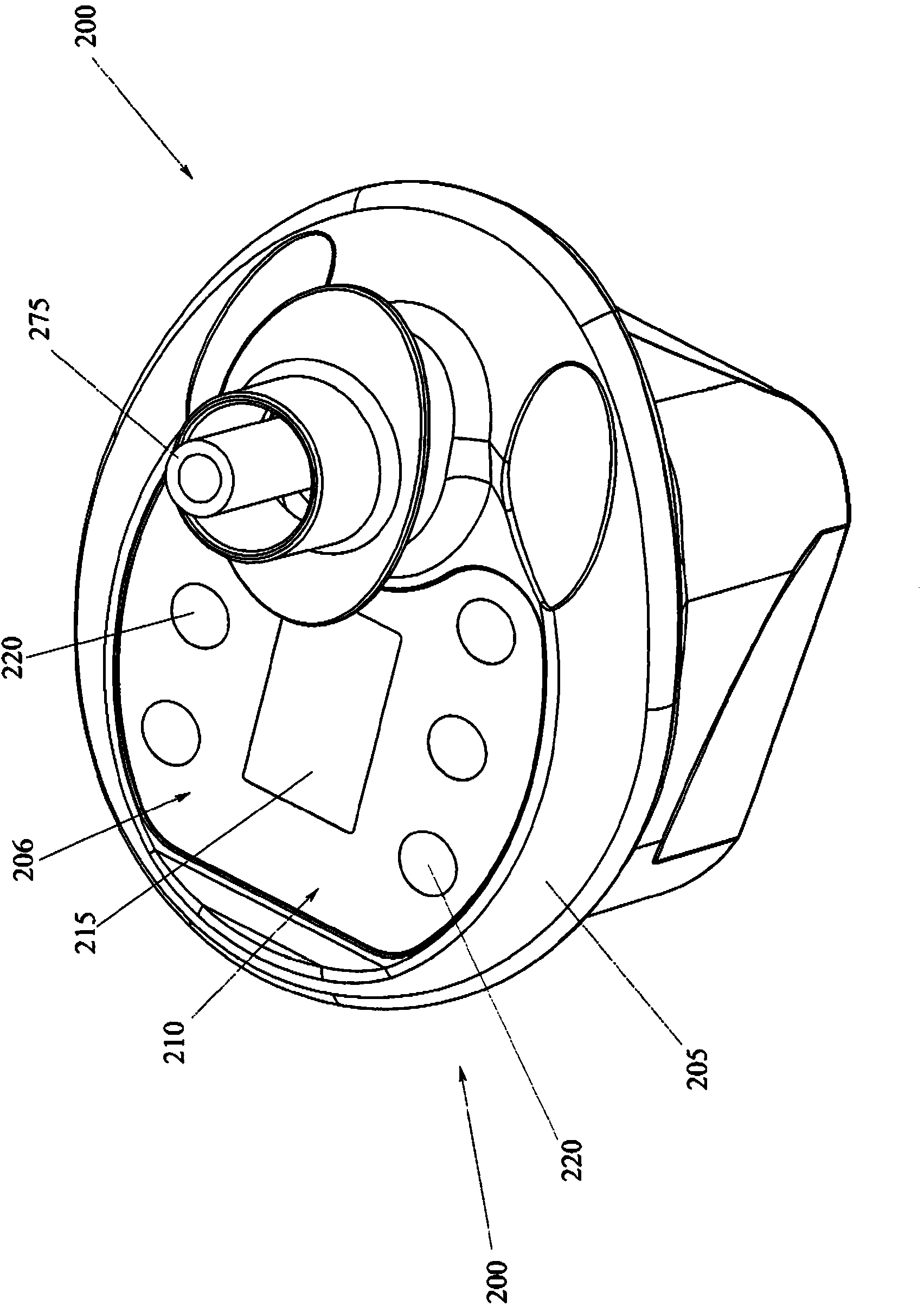

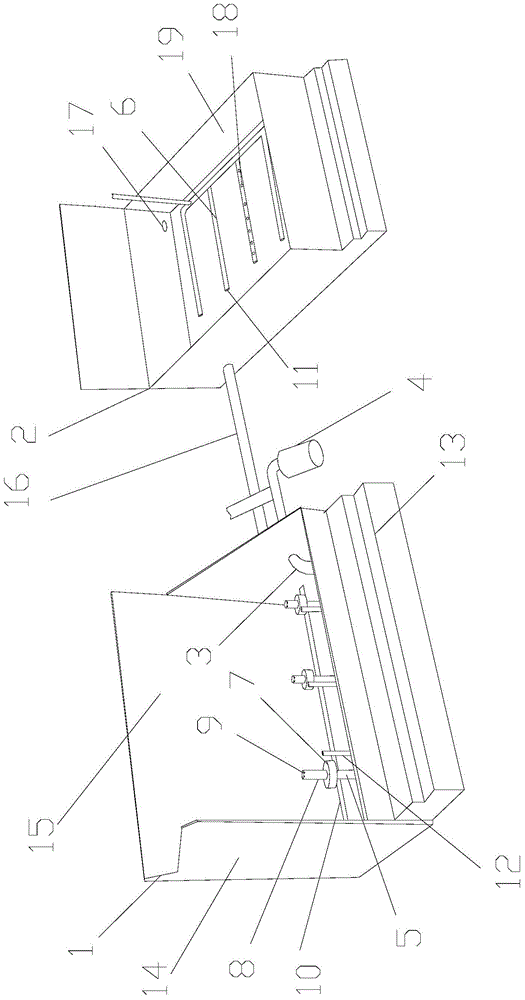

Multi-station rotating and lifting combination feed storage device

InactiveCN107350872ASimple positioning functionBig warehouseDe-stacking articlesMetal working apparatusRobot handStructural engineering

Provided is a multi-station rotating and lifting combination feed storage device. The multi-station rotating and lifting combination feed storage device is provided with a carrying mechanism, a rotating mechanism, a lifting mechanism and a pushing mechanism, wherein the carrying mechanism is installed on a machine body and stacks materials with the help of rotating plates; the rotating mechanism comprises a positioning mechanism restrains materials from being stacked at multiple stations from the inner and outer sides; the positioning mechanism comprises positioning columns on the inner circumference, check blocks on the periphery and positioning uprights, the check blocks are used for adjusting restraining spacing according to material sizes, and the positioning uprights are inserted into the check blocks; and the pushing mechanism is installed at the top end of the lifting mechanism in a matching manner and comprises a pushing air cylinder, an ejector block and a positioning block for positioning fed materials. In the workpiece storage link of machine tool machining, a feed mode of stacked storage, rotating adjustment, linear lifting and positioning pushing is adopted and matched with a truss mechanical arm to finish feeding, the usage space is small, but the storage capacity is large, long-time unsupervised feeding can be realized, and the machining need that a person operates multiple equipment is met. The takt is compact, and production efficiency is greatly improved.

Owner:SHAANXI HALET PRECISION MACHINERY

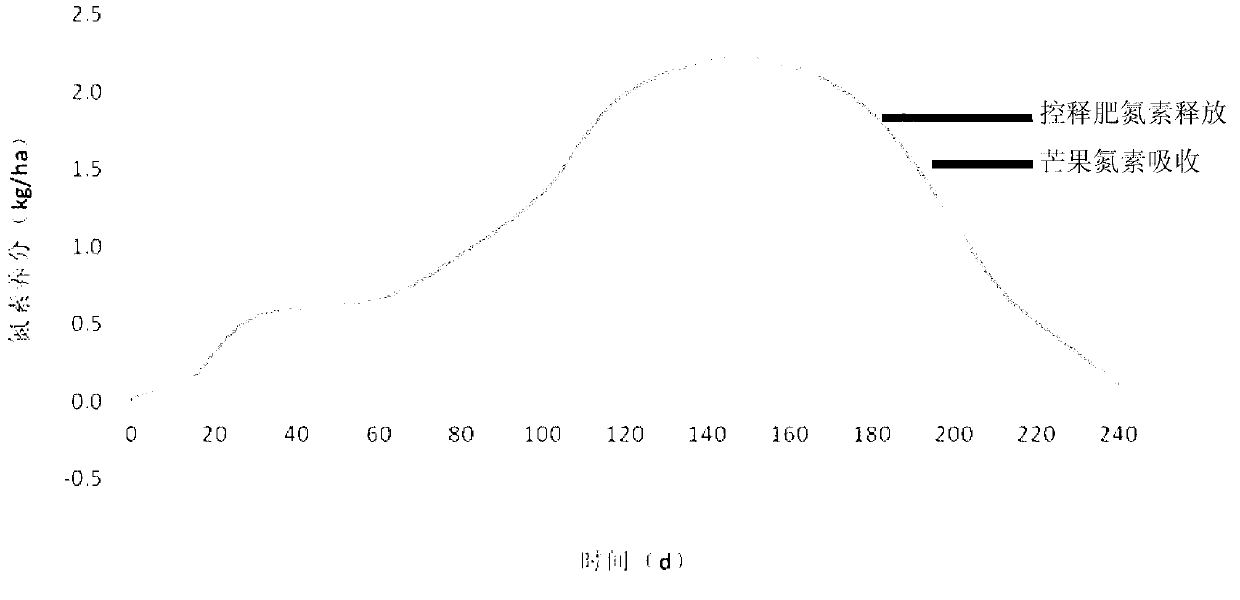

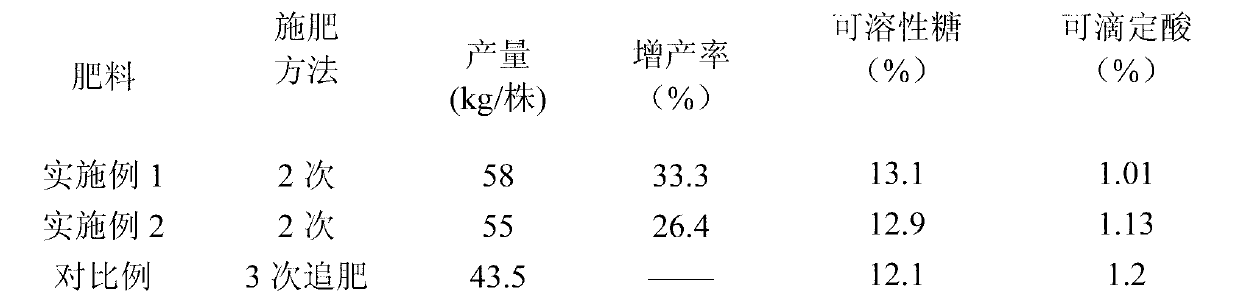

Mango controlled release fertilizer and preparation method thereof

The invention discloses a mango controlled release fertilizer and a preparation method thereof. The controlled release fertilizer is prepared from 3-8% of envelope amount of reaction film-forming polymer coated urea, urea, diammonium phosphate, potassium chloride, borax and the like in a compounding manner. The special nutritional synchronous controlled release fertilizer for mango disclosed by the invention is reasonably proportioned according to the physiological characteristics and nutrient requirement rule of the mango, so as to achieve the targets of reducing fertilizing amount, synchronously supplying nutrients, providing fertilizer efficiency for a long period of time, and increasing production and upgrading. Thus, the production cost is reduced; non-point source pollution is also avoided; the economic benefit is improved; and the controlled release fertilizer has a wide application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +2

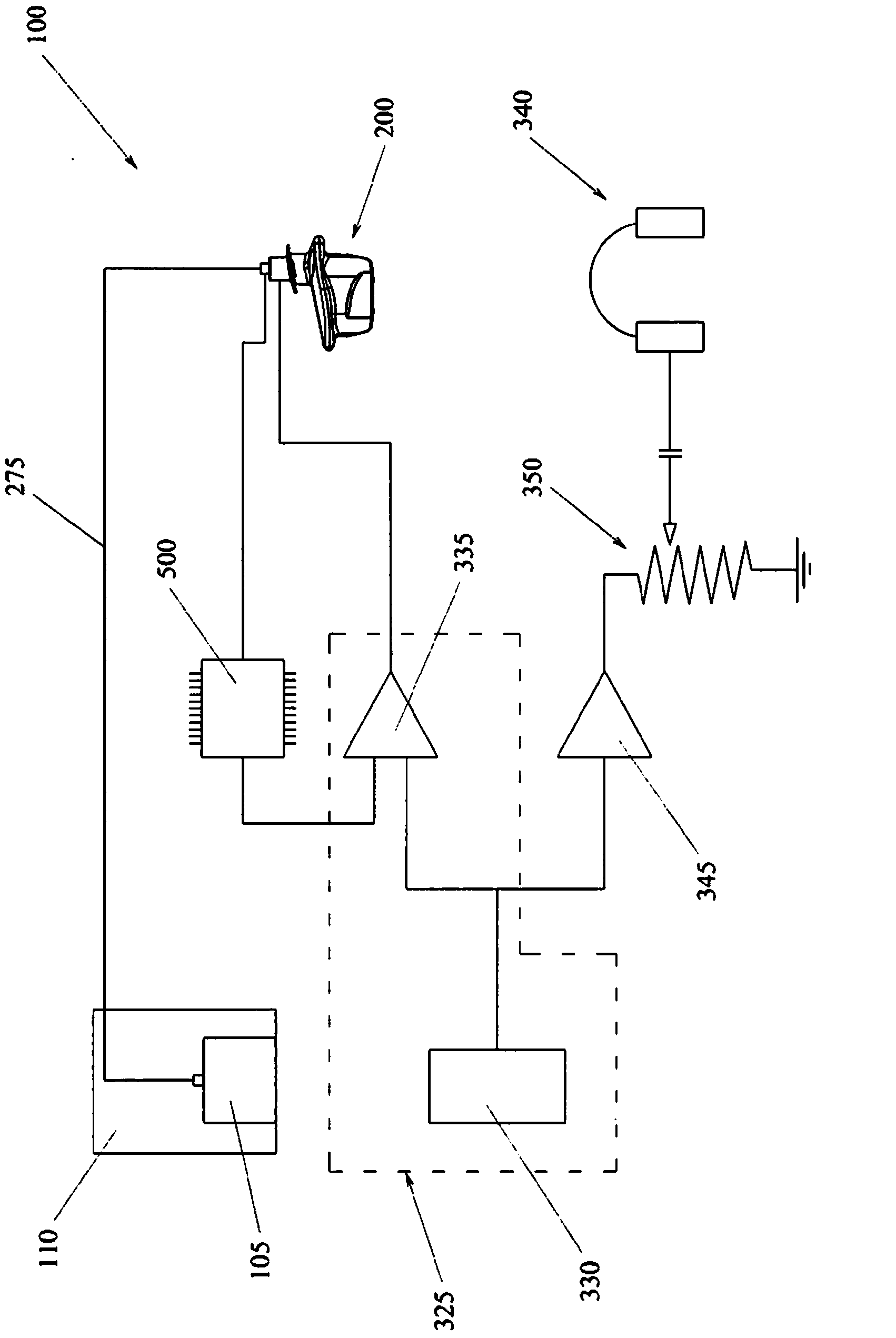

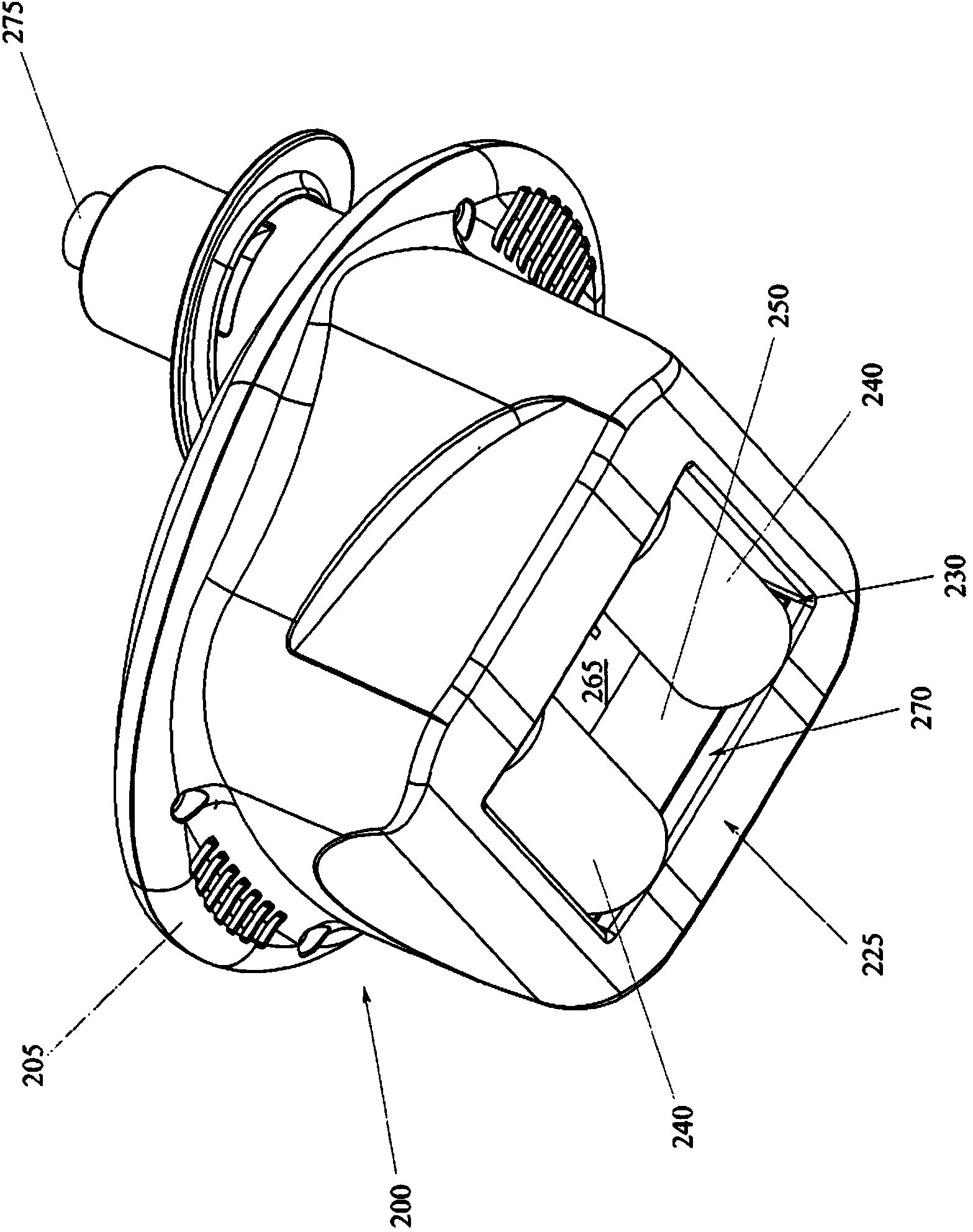

Electromedical device

ActiveCN104144671APromote sportsImprove suction performancePneumatic massageMagnetotherapy using coils/electromagnetsMagnetic transducersMechanical engineering

An electromedical device (100), comprising: a depression chamber (265) provided with an opening (270); aspirating means (105) connected to the depression chamber (265); a pair of rollers (240) suitable for at least partly delimiting the opening (270) of the depression chamber (265); motor means (285) suitable for rotating the rollers (240); a generator (325) of pulsed electric current; and an electromagnetic transducer (320) connected to the generator (325) such as to transform the pulsed electric current into a pulsed magnetic field, the electromagnetic current (320) being configured such that the flow of the pulsed magnetic field crosses the opening (270) of the depression chamber (265).

Owner:MANTIS

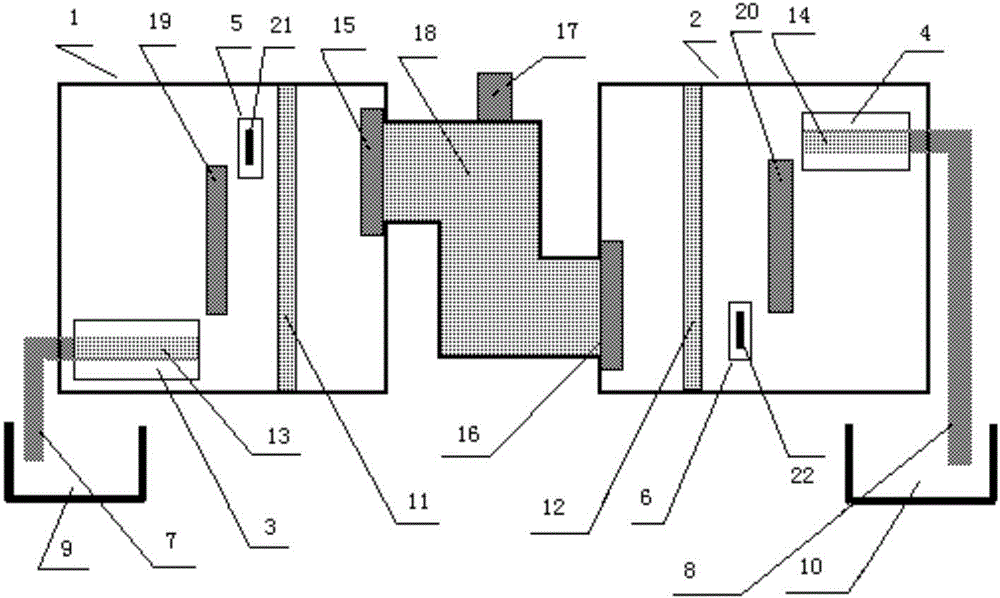

Temperature difference energy chemical battery

InactiveCN105826579ALarge amount of resourcesReduce consumptionDeferred-action cellsElectrolytic agentSalt bridge

The invention relates to a temperature difference energy chemical battery. Two groups of plate electrodes are respectively immersed in pools with salt bridge connection filled with a lioh electrolyte, when the temperature of electrolyte in two pools are different, the temperature difference is generated between two plate electrodes, so that thermoelectric effect is generated, and electric energy is emitted. At the same time, H2 and O2 are generated at two electrodes, and can be used for regenerating of a hydrogen cell. If a salt solution is taken as the electrolyte, NaOH, H2, O2 and CL2 can be obtained, NaOH is a chemical product with wide purpose, and can absorb harmful gas such as CO2, SO2 generated by fire coal power plant for carbon capture, a byproduct Na2CO3 is obtained, and the electrolyte can be used for electrolyzing certain metal salting liquid for extracting the corresponding metal. The chemical battery has wide utilization resource for temperature difference energy, which comprises sea temperature difference energy, thermal power plant waste heat and crops straw burned biomass energy. The chemical battery can replace thermal power plant machine set, and is suitable for large scope, especially coastal and South China sea reef regions.

Owner:李效雨

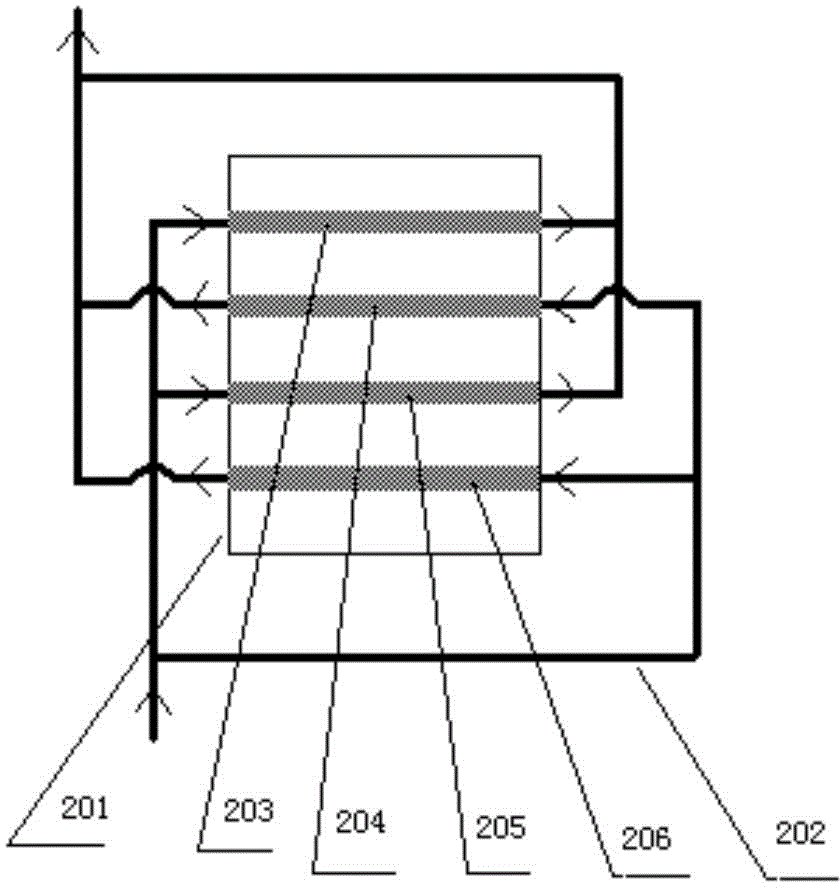

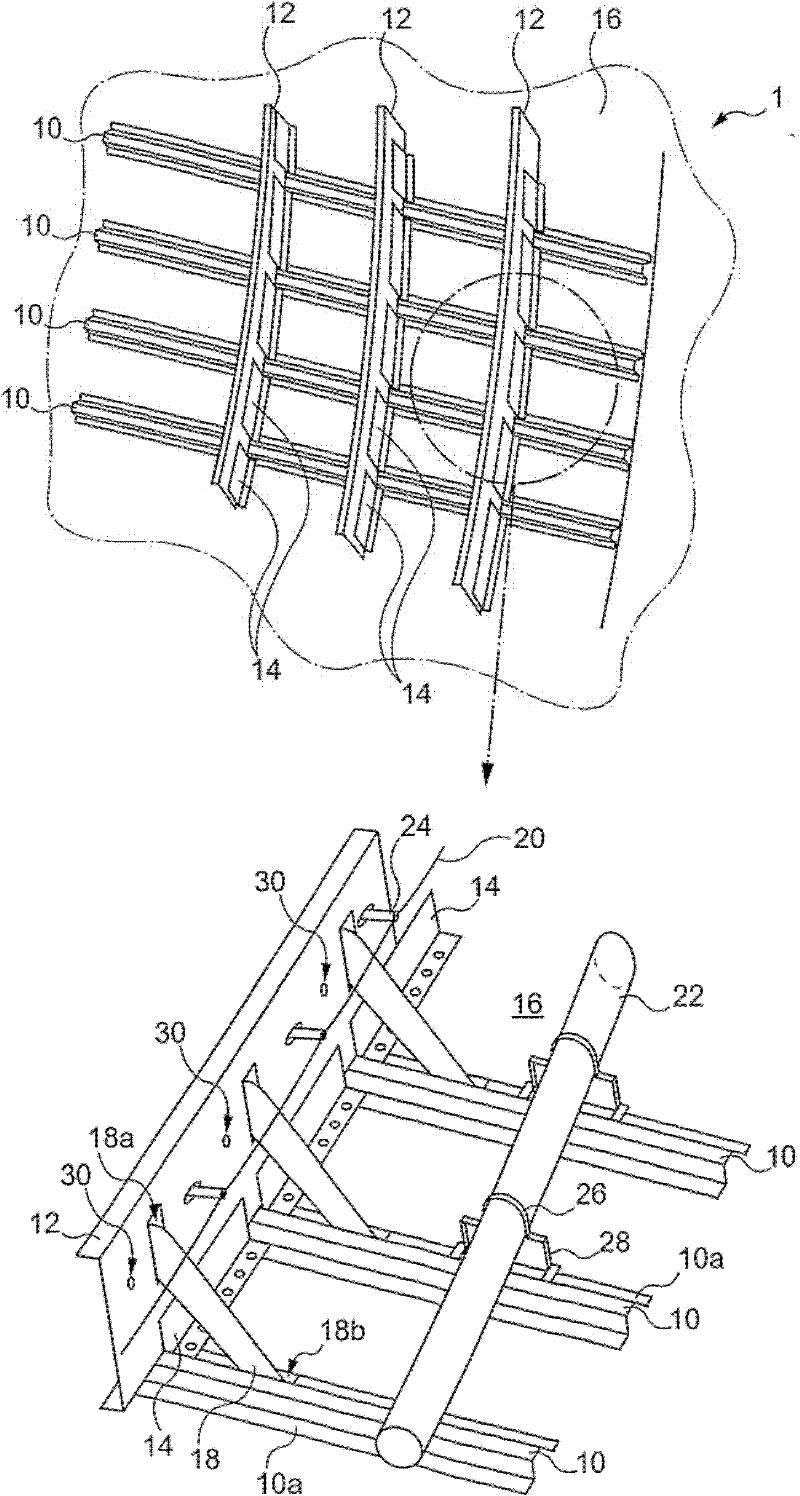

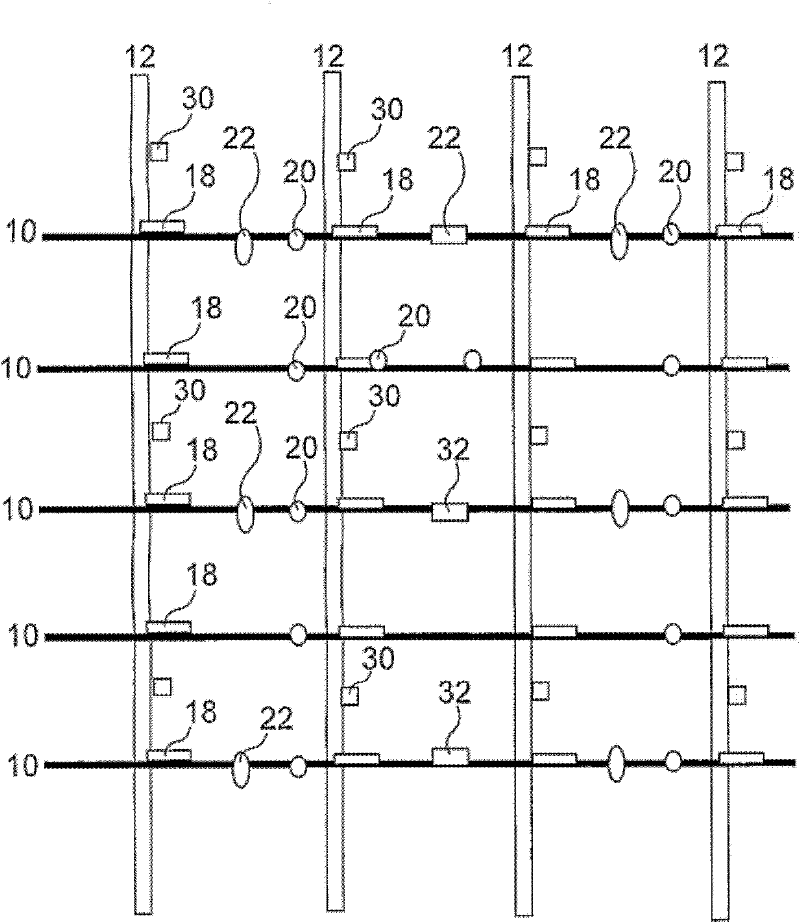

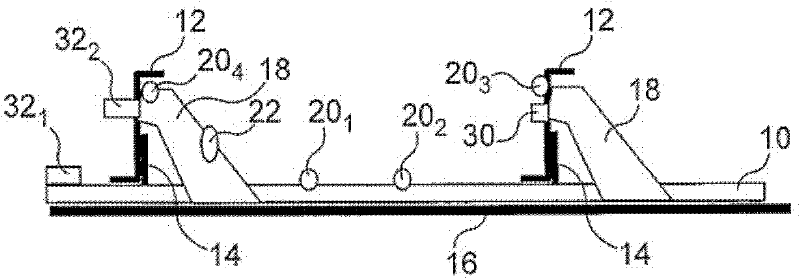

Fuselage structure for the combined fastening of an insulation mattress and devices, and aircraft including such a structure

ActiveCN102196963AEliminate weakeningReduce decreaseFuselage bulkheadsFuselage insulationConsecutive frameOxygen

The present invention relates to the installation of systems in aircraft fuselages such as thermophonic insulation mattresses (300) and devices (102, 122) such as onboard systems, and bundles of electric wires or fluid ducts (air, water, oxygen, hydraulic fluid). The invention more particularly relates to a structure (100) for fastening onto an aircraft fuselage including at least frames (112) and stringers (110), said structure including: fuselage stabilisers (118, 118') connecting the frames and stringers, wherein two stabilisers (118, 118') of two consecutive frames (112, 112') face each other between the two consecutive frames; and a strip board (200) connecting said two stabilisers and including fastening means (206, 212, 212', 212'') arranged so as to receive corresponding fastening means of said insulation mattresses (300) and said devices (120, 122).

Owner:AIRBUS OPERATIONS GMBH

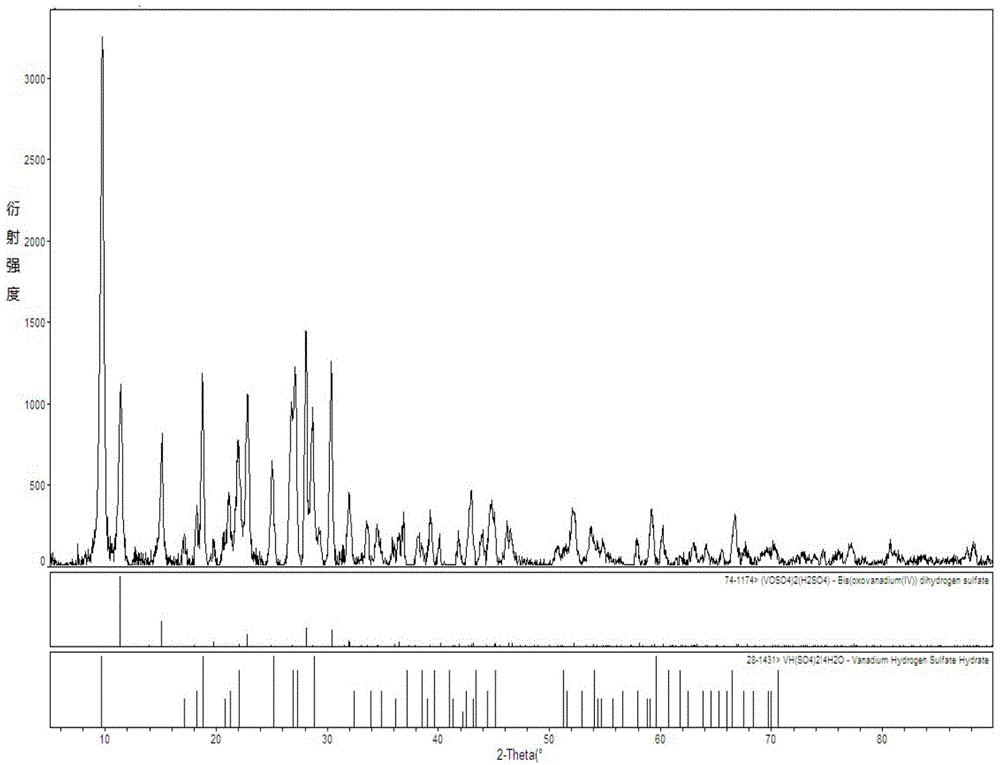

Production method and application of vanadium cell electrolyte crystal

ActiveCN104934623AReduce shipping costsLow costFinal product manufactureRegenerative fuel cellsSulfate radicalsSulfate

The invention discloses a production method and application of a vanadium cell electrolyte crystal. The production method comprises the following steps: a, adding vanadium sulfate in concentrated sulfuric acid, and stirring the mixture uniformly, wherein the mass ratio of the vanadium sulfate to the concentrated sulfuric acid is 0.5 to 4; b, stirring materials obtained in the step a for 1-24 h at the temperature of 20-150 DEG C; and c, cooling materials obtained in the step b to room temperature. Different from traditional vanadyl sulfate and vanadium sulfate crystals, the crystal obtained by the method contains additional sulfate radicals, wherein the proportion of total sulfate radicals to vanadium accords with the specification requirement of an electrolyte; as long as the crystal is dissolved in water, a vanadium electrolyte can be obtained once, and the preparation operation of the concentrated sulfuric acid on project site is not needed; and the scheme obviously reduces the transportation cost of a traditional liquid transportation method, and the flexibility of transportation is improved.

Owner:大连融科储能集团股份有限公司

A t single crystal solar cell sheet texturing process

InactiveCN109103297ASimple equipmentImprove benefitsFinal product manufacturePhotovoltaic energy generationPolyethylene glycolSingle crystal

A single crystal solar cell sheet pile making process includes such step as preparing raw material of texturing liquid, including deionized wat, alkaline dispersant, polyethylene glycol, aldehyde, nickel powder and activating agent, and preparing texturing liquid; preparing battery sheet cleaning liquid to clean the battery sheet; texturing the battery sheet pre-treated with the texturing liquid.The raw material of the texturing liquid and the cleaning liquid of the battery sheet provided by the invention are easy to prepare and the cost is applicable. The method of pre-treatment and cleaningin advance is adopted for cashmere making, the cashmere making effect is uniform and stable, and the subsequent washing after cashmere making is more convenient and effective, which greatly reduces the follow-up washing cost and improves the benefit of the enterprise.

Owner:安徽英发三友新能源科技有限公司

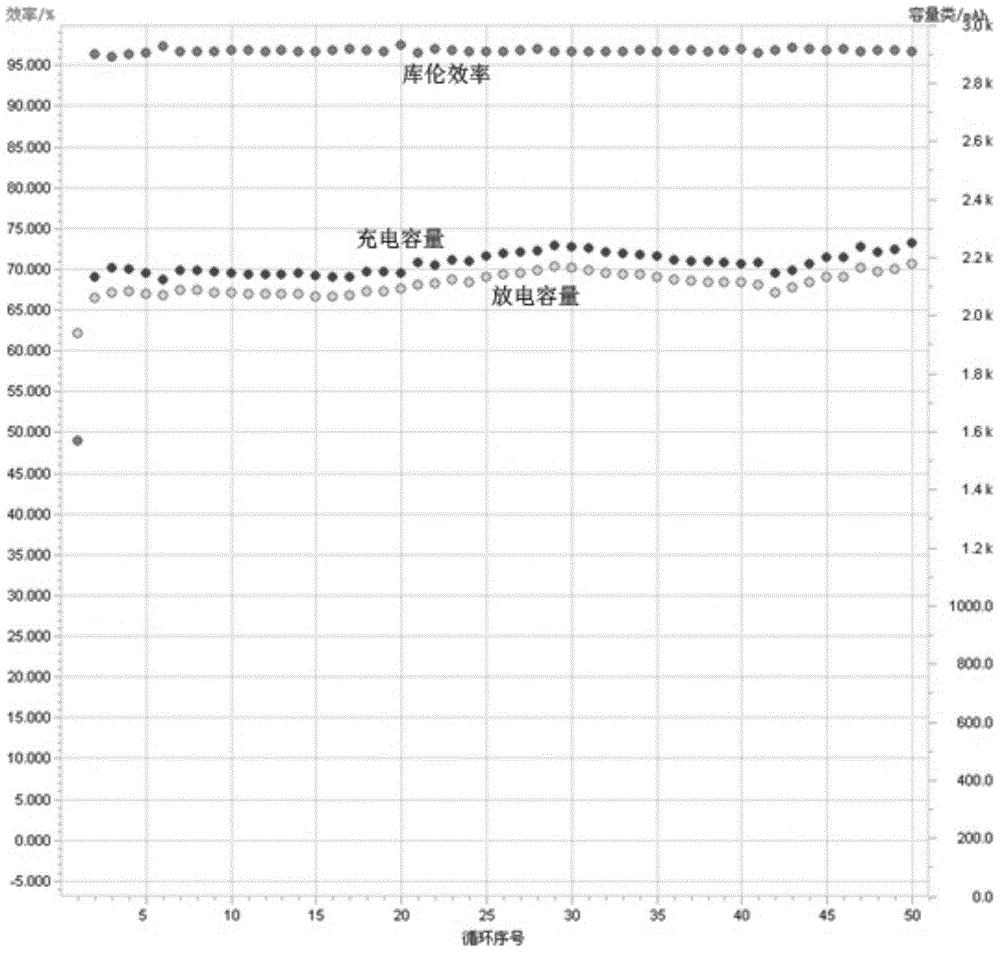

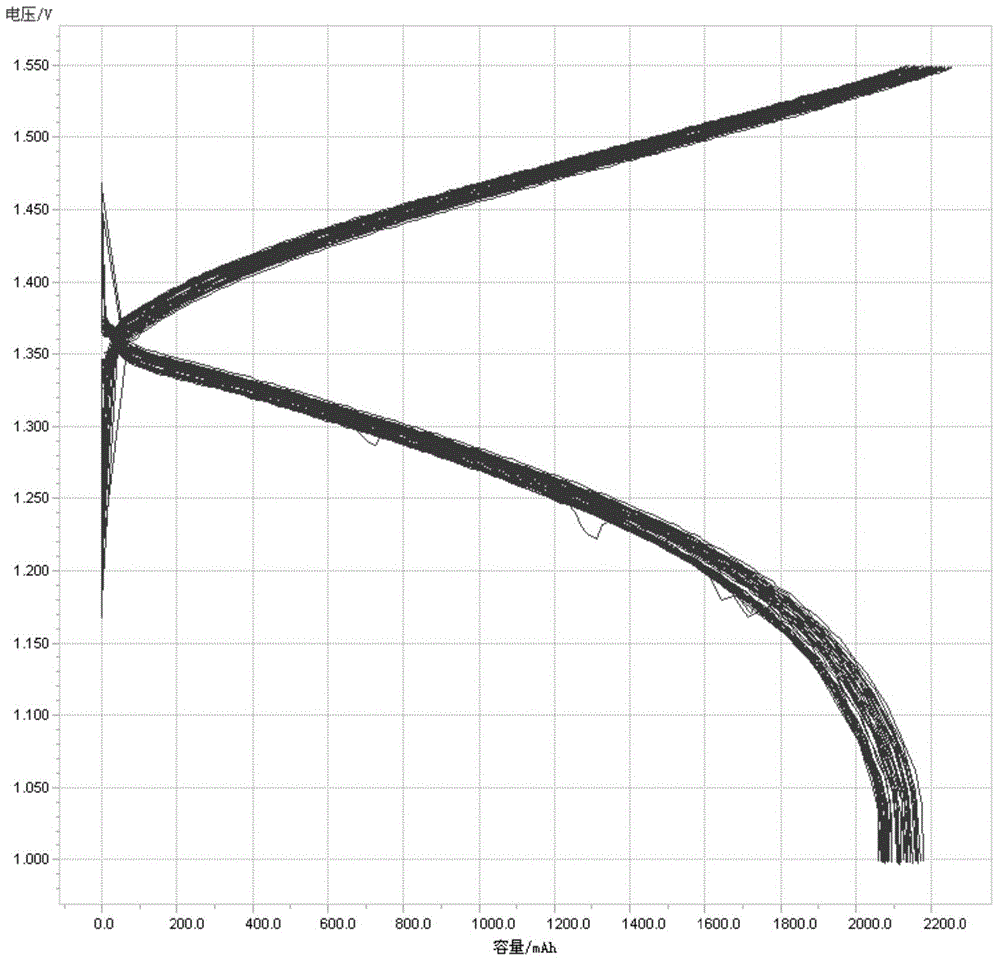

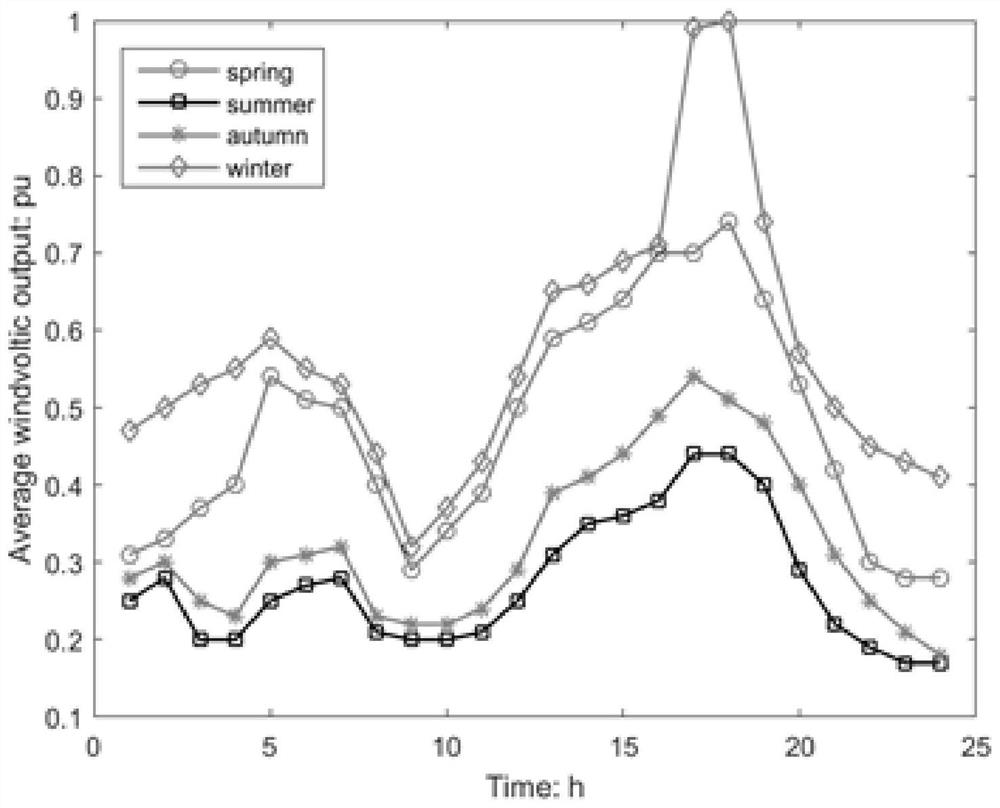

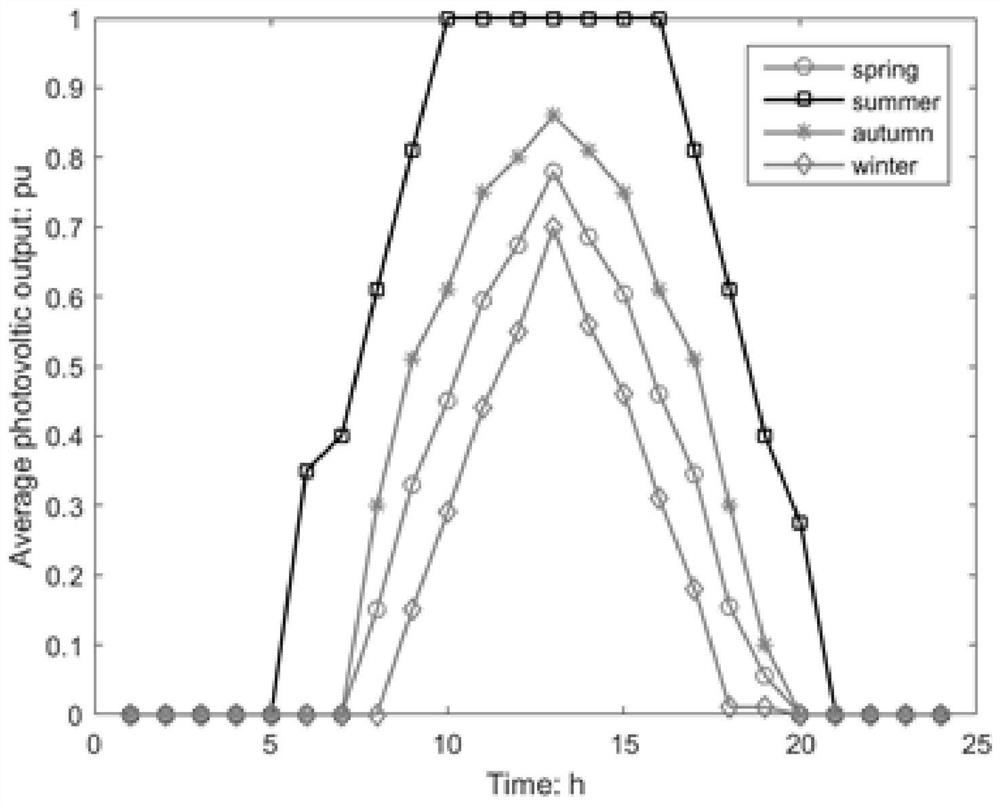

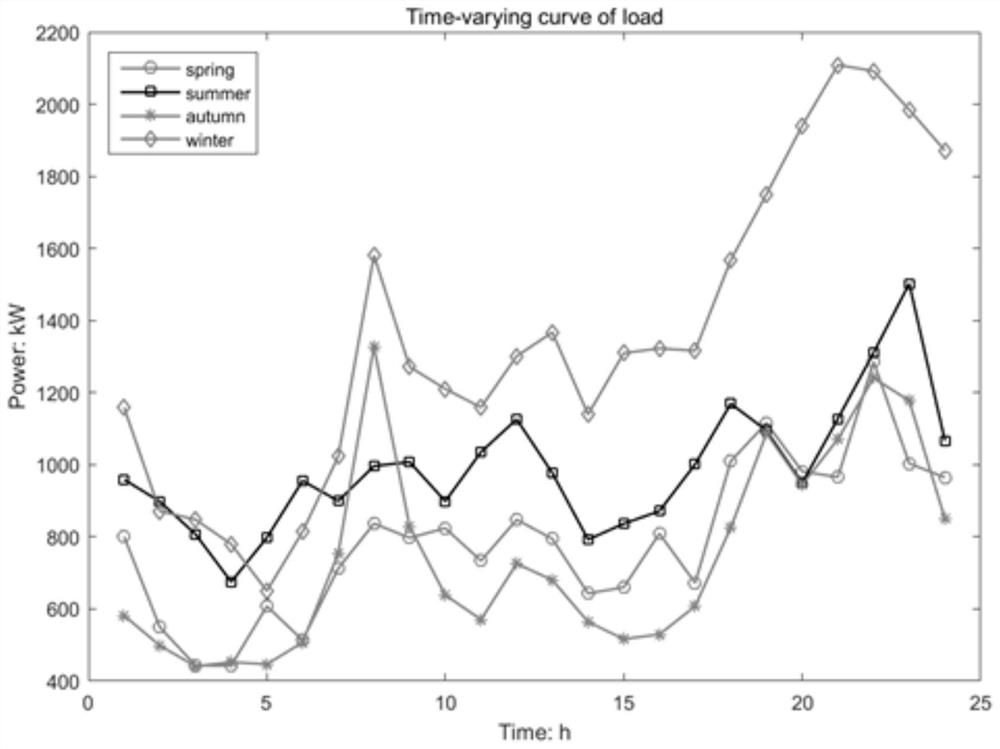

Distributed power supply planning method based on capacity limitation of power supply equipment

PendingCN113128844AImprove rationalityImprove business benefitsMarket predictionsResourcesPower transmissionSystems engineering

The invention discloses a distributed power supply planning method based on capacity limitation of power supply equipment. The method comprises the following steps: establishing a user side load response model based on time-of-use electricity price; according to a user load demand, in combination with a micro-grid operation strategy, establishing a target function taking the maximum total income of micro-grid planning as a target; and in combination with the constraint condition, optimizing the target function, and performing distributed power supply planning according to an optimization result. On the premise that a power transmission network is not comprehensively transformed, the electricity demand of a user is met and the capital construction cost of a power supply enterprise is reduced by adding a photovoltaic / wind power / energy storage system; photovoltaic, wind power and energy storage micro-grids are planned and configured by considering the influence of different weathers on photovoltaic power generation, so that the rationality of distributed energy distribution is improved; the maximum influence of the time-of-use electricity price on the microgrid income is considered, the benefits of enterprises are improved, and the electric power cost is reduced.

Owner:国网江西省电力有限公司赣州供电分公司 +1

Prednisolone refining technology

The invention discloses a prednisolone refining technology, and belongs to the field of chemical pharmacy. The refining technology adopting finished prednisolone as a raw material and a dichloromethane, methanol and water mixed solution as a refining solvent system comprises the following steps: adding a Girard's reagent T and glacial acetic acid to the refining solvent system, adding the raw material prednisolone, carrying out stirring heating to realize refluxing dissolving, then refluxing for a period of time, cooling the obtained solution, and adding water to the above obtained system in a dropwise manner at a proper temperature under a controlled speed to slowly precipitate prednisolone in dropwise addition process in order to obtain refined prednisolone. The technology is in favor of improving the product quality and increasing the enterprise benefit.

Owner:HENAN LIHUA PHARMA

Making technology of bamboo leaf tea

A making technology of bamboo leaf tea comprises the following steps: selecting current year new bamboo leaves, arranging the leaves, cutting the leaves to form leaf pieces with the length of 1cm, crushing the leaf pieces, Concretio Silicea Bambusae and bamboo shavings to form coarse powder, mixing the coarse powder with honey, putting the obtained mixture in a universal device steamer, adding purified water, steaming through a universal device steam method for 40min until the mixture is completely cooked, putting the cooked mixture in a fermentation tank, and brewing for 72h to obtain a comprehensive fermentation liquid for later use; selecting fresh bamboo leaf pieces, steaming through a steam method for 5min, adding the steamed bamboo leaves into a stir-frying pot, stir-frying until the leaf pieces are naturally cured and delicate fragrance overflows, and taking the stir-fried leaf pieces out of the pot; and fully mixing the comprehensive fertilization liquid with the stir-fried bamboo leaf tea, drying, taking out the obtained leaf tea, cooling, and arranging to obtain the bamboo leaf tea.

Owner:王跃进

Chinese hawthorn leaf total flavone extracting process

The invention belongs to the technical field of plant extraction and discloses a Chinese hawthorn leaf total flavone extracting process. The Chinese hawthorn leaf total flavone extracting process comprises the steps of cane sugar soaking, ultraviolet irradiation, flocculation and impurity removing, alcohol extraction, extraction, drying and the like. The process is simple, feasible, low in cost and high in product purity.

Owner:FUYANG HUAIBANG MACHINERY

Interplanting method for phyllostachys pubescens and rhizoma curculiginis

InactiveCN109042016AIncrease profitIncrease farmers' benefitFertilising methodsPlant cultivationFertilizerWeed

The invention discloses an interplanting method for phyllostachys pubescens and rhizoma curculiginis. By reasonably interplanting the phyllostachys pubescens and rhizoma curculiginis, the available land of phyllostachys pubescens is sufficiently utilized, rhizoma curculiginis does not compete for fertilizer, light and water with phyllostachys pubescens, phyllostachys pubescens overshadows rhizomacurculiginis, and growth of rhizoma curculiginis is easy; the advantages of growth competition between rhizoma curculiginis and weeds and competition between phyllostachys pubescens and the weeds areused for reducing the weeding frequency in intertillage and lowering labor intensity, and meanwhile comprehensive production benefits are increased. The interplanting method is easy to operate, remarkable in benefit and quite easy to popularize.

Owner:紫云自治县紫香源农林科技有限责任公司

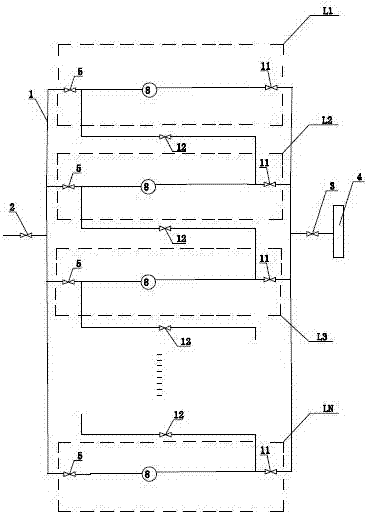

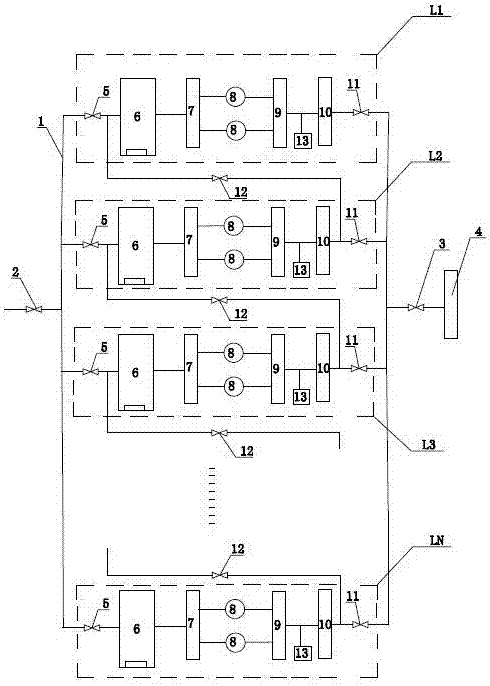

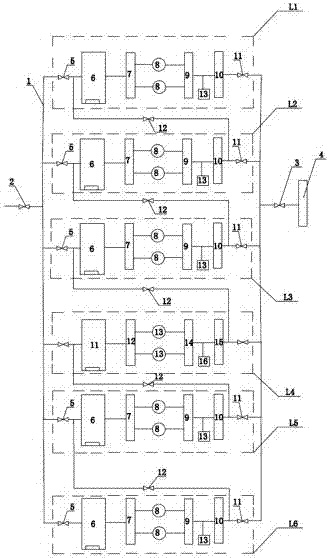

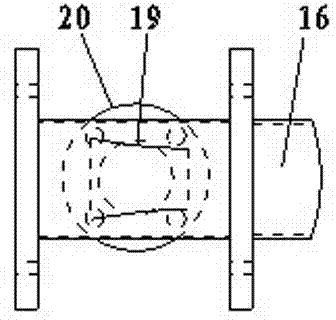

Compression level switchable compressor and use method thereof

InactiveCN106930927AExpand the scope of applicable working conditionsReduce equipment input costsPositive displacement pump componentsPipeline systemsParallel compressionComputer engineering

The invention discloses a compressor with switchable compression stages and a method for using the same, comprising a pipeline, an inlet valve and an outlet valve are arranged on the pipeline, and N parallel compressors are arranged on the pipeline between the inlet valve and the outlet valve. Pipelines, N≥2, each compression pipeline is provided with a front valve, a compression cylinder, and a rear valve in sequence; there is also a series-parallel regulating valve between any two adjacent compression pipelines, and the series-parallel regulating valve is located in the pipeline. One end is connected to the pipe between the compression cylinder and the rear valve of one of the compression lines, and the other end is connected to the pipe between the compression cylinder and the front valve of the other compression line. The compressor of the present invention can realize compression level switching.

Owner:SHANDONG KERUI COMPRESSOR

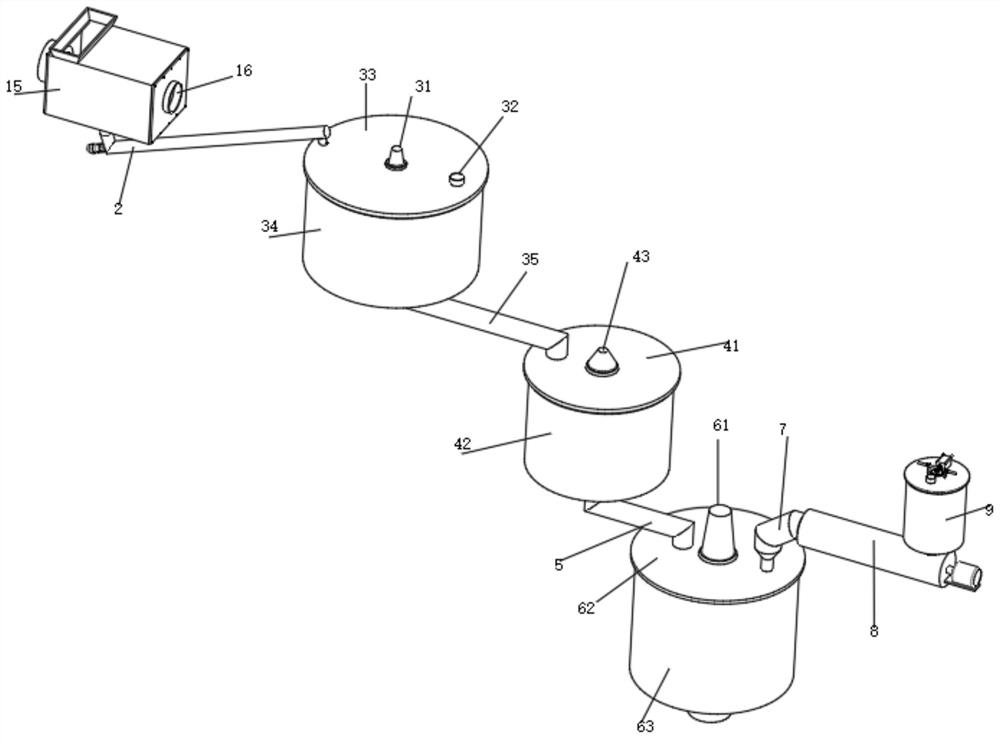

Vaseline recycling system

InactiveCN104386770AIncrease the heating areaEasy to separateFatty/oily/floating substances removal devicesHollow article cleaningPulp and paper industryEngineering

The invention relates to the technical field of vaseline production and particularly relates to a vaseline recycling system. The vaseline recycling system is characterized by comprising a cleaning tank, a recycling tank, a steam pipeline and a high-pressure pump, wherein steam branch pipes are arranged inside the cleaning tank vertically, coil pipes are arranged in the recycling tank, the steam branch pipes and the coil pipes are respectively communicated with the steam pipeline, wherein the steam pipeline is connected with a steam boiler, the high-pressure pump is communicated with one side of the steam pipeline, each steam branch pipe is connected with a steam sprayer through a flange, air outlets are formed around each steam sprayer, support beams for supporting a recycling barrel are arranged on two sides of the steam pipeline; at least two coil pipes are arranged and are positioned in parallel at the bottom of the recycling tank; and an air outlet is arranged at the front part of each coil pipe. The vaseline recycling system is simple in structure, can be used for rapidly cleaning the recycling barrel and is high in cleaning speed; due to use of steam for cleaning, the recycling barrel can be cleaned completely from all angles without any dead angle left.

Owner:TIANJIN HONGFA SHUANGSHENG VASELINE

New technology for producing high-purity active magnesium oxide by using waste residue of magnesium metal smelting

InactiveCN106379923AIncrease useWide range of usesMagnesiaPreparation from chloridesFiltrationAcid dissolution

New technology for producing high-purity active magnesium oxide by using waste residue of magnesium metal smelting adopts waste residue of magnesium smelting as a raw material. The technology comprises: raw material crushing, acid dissolution, filtration, impurity removal, refining, dehydration, dynamic thermal crushing and washing, drying and dynamic calcination. The magnesium oxide product is high in purity and activity, low in calcium and boron, high and stable in quality, and extremely low in cost. The technology allows resources to be saved and efficiently cycled, is free of pollution and simple in production process, allows continuous circulating production to be achieved, and is significant in production benefit.

Owner:李卿

Energy coordination transaction method based on block chain

InactiveCN111815406ATransaction is simpleTransaction transparencyDigital data protectionBuying/selling/leasing transactionsFinancial transactionEnergy market

The invention relates to an energy coordination transaction method based on a block chain, which is applied to an energy coordination transaction system, and the energy coordination transaction systemcomprises an approval transaction terminal and an intelligent transaction platform; the approval transaction terminal comprises an authentication module and a service module; the business module is divided into a real-time transaction unit and a transaction tracking unit; the intelligent transaction platform comprises an intelligent matching module and a transaction module. According to the invention, the blockchain technology and the energy transaction are combined, the transaction is simple, the user can be stimulated to participate in the energy market, the energy transaction is more transparent, and the energy transaction market is more standardized; meanwhile, the trust degree of two parties in the energy transaction process is improved by utilizing the tamper-proof characteristic ofthe block chain; meanwhile, an intelligent coordination system is used for better promoting energy supply and demand side matching and promoting benefits of all parties.

Owner:潘小胜

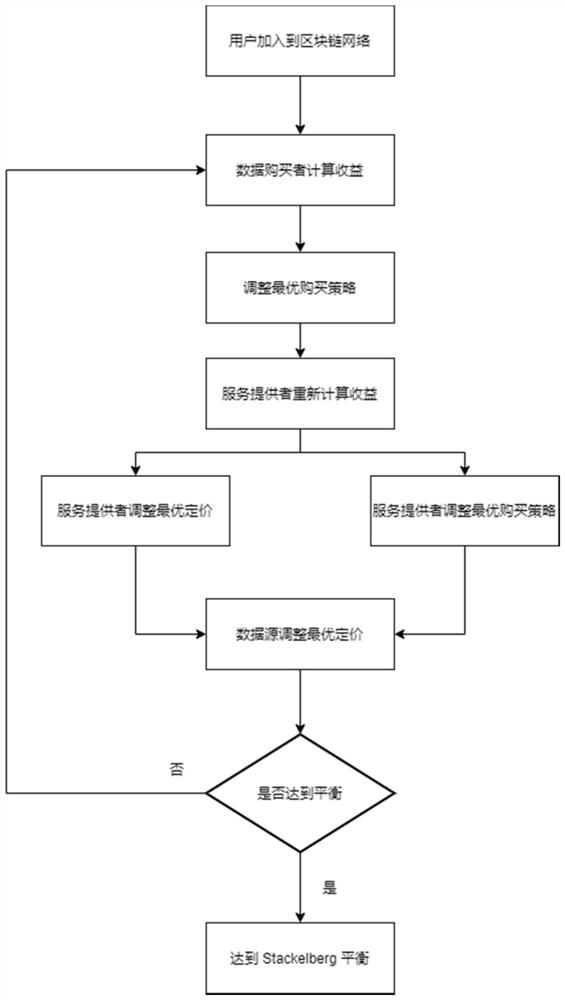

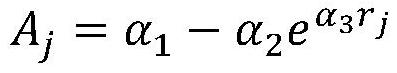

Data pricing method of shared automobile data market based on block chain

PendingCN112767021AGuaranteed personal rationalityMechanism is realFinanceProduct appraisalOriginal dataMarket place

The invention discloses a data pricing method of a shared automobile data market based on a block chain, and the method comprises the steps: firstly a shared automobile data transaction market is created based on an alliance chain, and the data transaction market comprises a data source, a data service provider and a data buyer; the data source performs original data pricing, the data service provider purchases source data, performs data processing and performs data pricing, and the data buyer purchases data from the service provider; secondly, the value of the data is determined according to three factors including the privacy quality of the data, the quantity quality of the data and the accuracy quality of the data; and finally, the data source, the data service provider and the data buyer perform data pricing interaction through a three-layer Stackelberg game. The individual rationality of the buyer is ensured, the whole mechanism is very real, any participant can adopt an optimal strategy to improve the benefit of the participant, a Nash equilibrium state is achieved, and the game is kept balanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

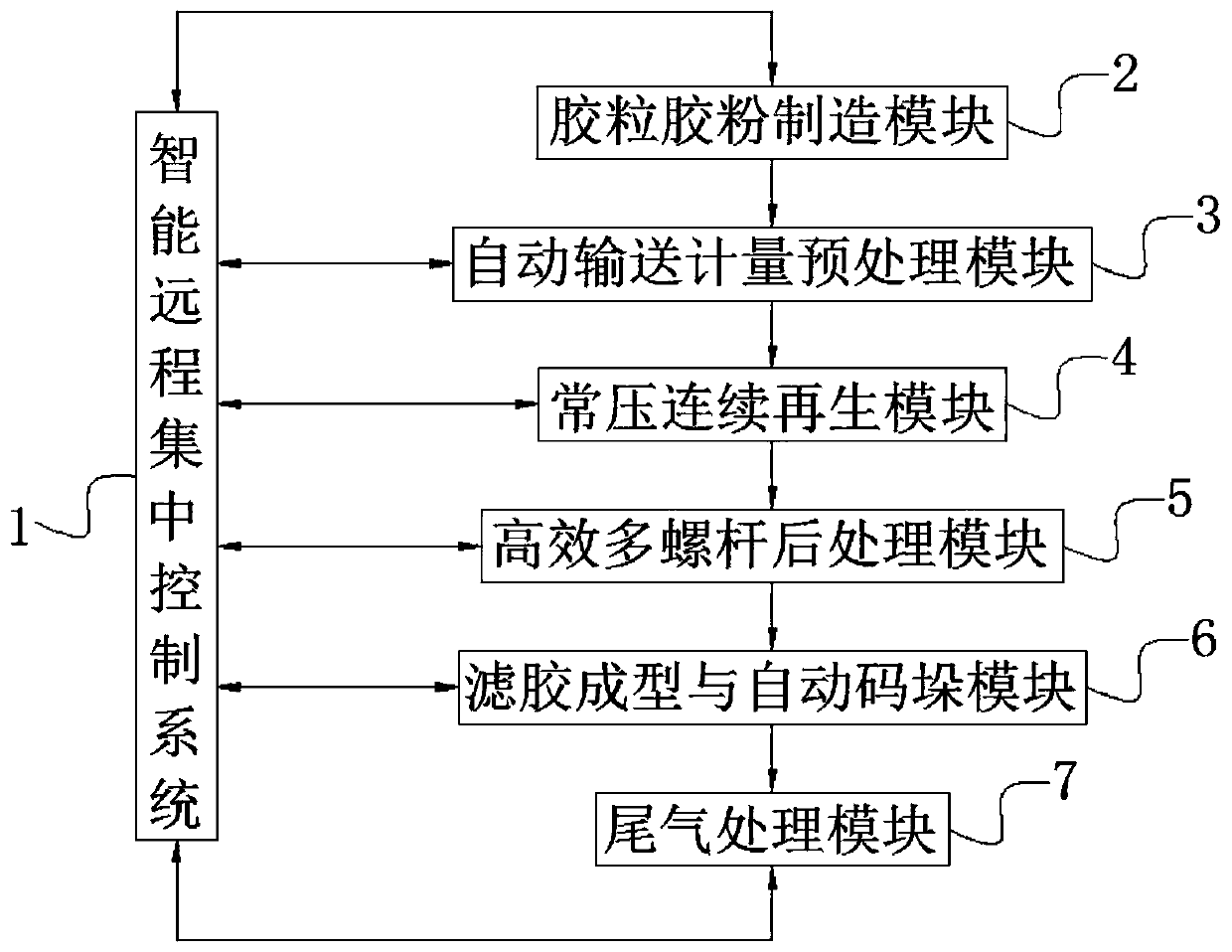

Recycling system and recycling method of renewable resources

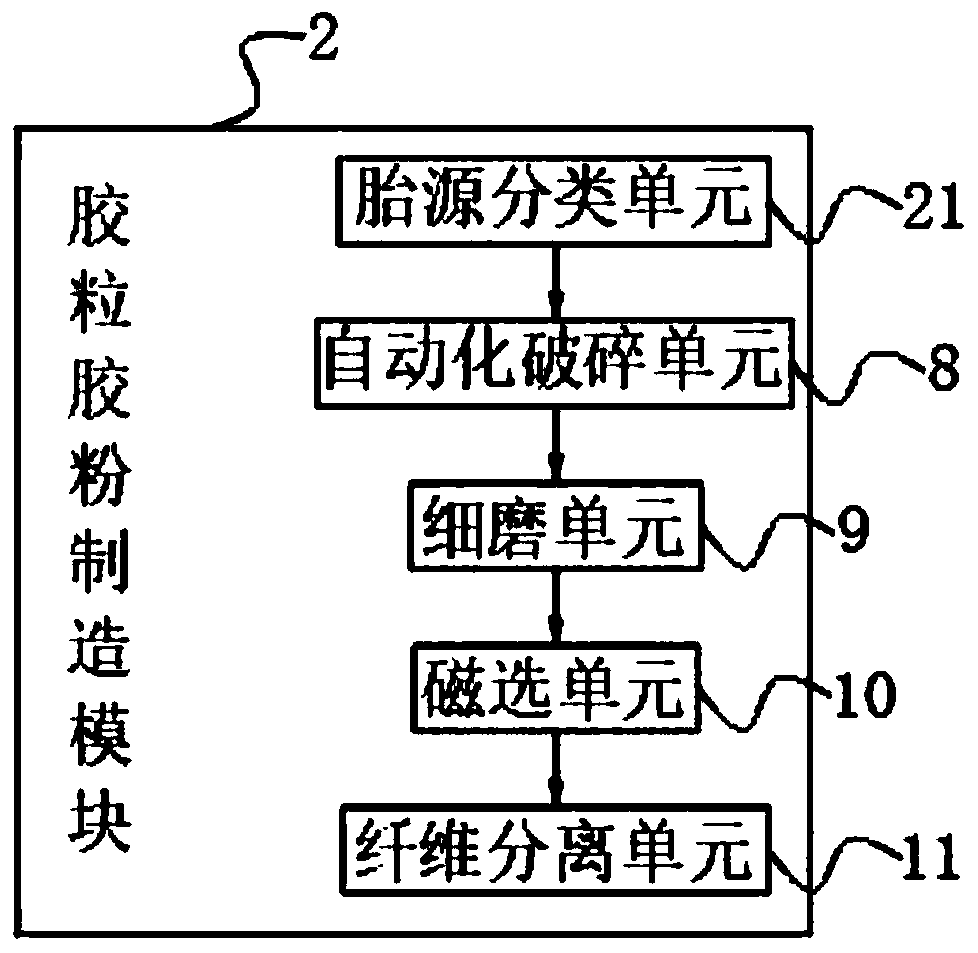

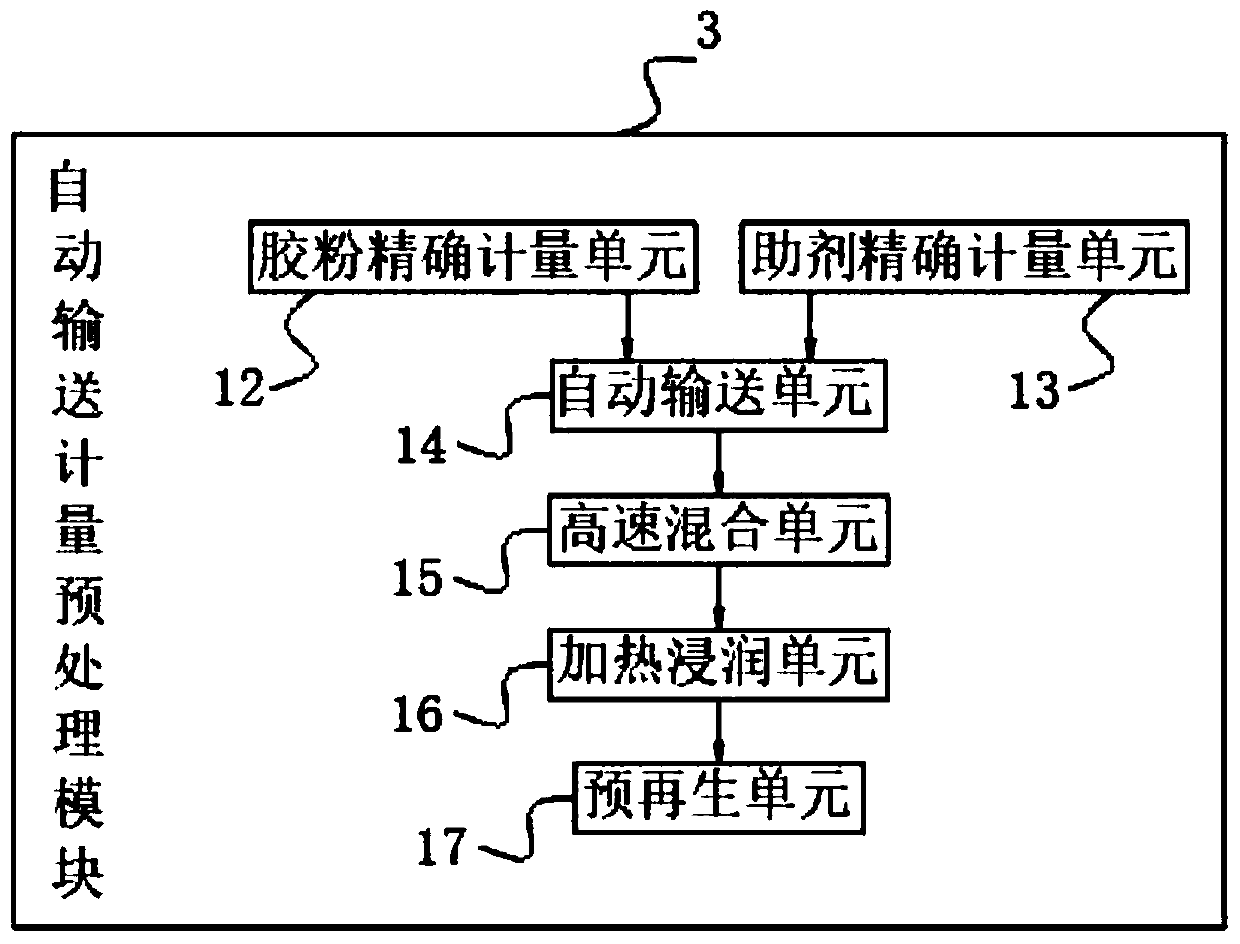

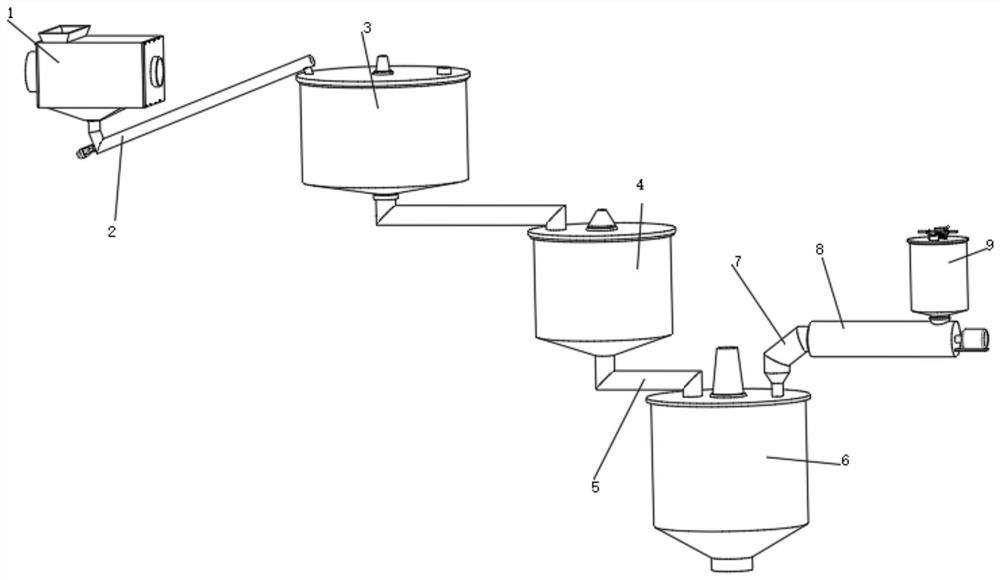

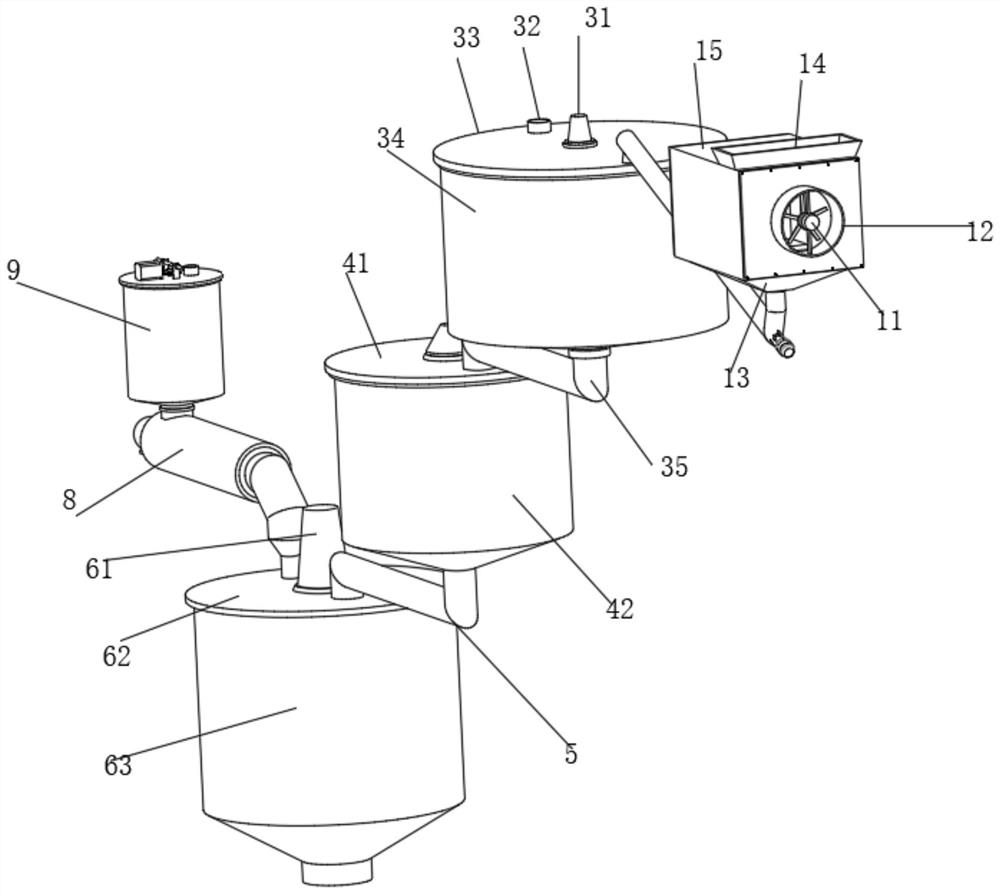

InactiveCN111300683APromote environmental protectionReduce labor intensityPlastic recyclingControl systemResource recovery

The invention discloses a recycling system and recycling method of renewable resources. The recycling system of the renewable resources comprises an intelligent remote centralized control system, wherein a database for monitoring various modules is arranged in the intelligent remote centralized control system, and the intelligent remote centralized control system realizes bidirectional connectionwith a rubber particle powder manufacturing module, an automatic conveying and metering pretreatment module, a normal pressure continuous regeneration module, an efficient multi-screw post-processingmodule, a rubber filter forming and automatic stacking module and a tail gas treatment module correspondingly; and the output end of the rubber particle powder manufacturing module is electrically connected with the input end of the automatic conveying and metering pretreatment module. The invention relates to the technical field of the renewable resources. According to the recycling system and recycling method of the renewable resources, no waste water and waste gas discharge in the whole line is realized by adopting a novel environment-friendly formula system and combining closed continuousproduction equipment through a normal pressure medium temperature production process, so that the environmental protection of a production device is improved.

Owner:山东水发再生资源有限公司

Ingredients of bacillus chicken feed and preparation method of bacillus chicken feed

InactiveCN105010866ALow costImprove benefitsFood processingAnimal feeding stuffSunflower seedMethionine biosynthesis

The invention provides ingredients of a bacillus chicken feed and a preparation method thereof. The feed is prepared from the following raw materials in parts by weight: 3-5 parts of corn, 4-9 parts of sunflower seed meal, 4-6 parts of soybean cake, 5-9 parts of detoxified rapeseed meal, 5-9 parts of degossypolized cottonseed protein, 5-10 parts of high gluten flour, 25-45 parts of wheat straw powder, 1-3 parts of green Chinese onion powder, 0.8-1.8 parts of phytic acid, 0.6-1.2 parts of rapeseed oil, 0.015-0.055 part of calcium carbonate, 0.12-0.48 part of methionine, 4-16 parts of cedrela sinensis powder, 0.04-0.06 part of lipoic acid and 85-95 parts of auxiliary liquid. The feed and the preparation method thereof can be used for solving the problem that the proportion of food crop ingredients for replacing in the chicken feed is not high due to the fact that low content of amino acid of the bio-oxidized wheat straw powder.

Owner:JIANGSU UNISON BIOTECH DEV

Whole wheat flour production process and processing device for intermediate extraction treatment of gluten materials

The invention relates to the technical field of wheat processing, in particular to a whole wheat flour production process and processing device for intermediate extraction treatment of gluten materials. The whole wheat flour production process and processing device comprise a winnowing structure, an auger discharging pipe, a wheat wetting structure, a smashing structure, a first connecting pipe, asecond connecting pipe, an extrusion bulking machine and a fermentation drying structure, wherein the wheat wetting structure is provided with the smashing structure, the bottom of a fourth box bodyis fixedly connected with the extrusion bulking machine for wheat bran extrusion bulking through a pipeline, and a discharging pipe of the extrusion bulking machine is fixedly connected with a secondconnecting pipe; and the first connecting pipe and the second connecting pipe are connected to a micro smashing mechanism for micro-smashing powder uniformly. The invention is beneficial to improve full contact of a fermentation liquor with wheat bran, so that the wheat bran is fermented quickly, the fermentation time is shortened, the fermented bran is dried, the drying degree of the bran is consistent, and the bran effect is exerted favorably.

Owner:张云路

Bamboo leaf green tea making process

InactiveCN103583726AEnhance memoryFull of nutritionPre-extraction tea treatmentGeneral purposeComing out

A bamboo leaf green tea making process is characterized in that new bamboo leaves in the current year are chosen, cleared up, cut into 1 cm blades, and crushed with tabasheer and bamboo shavings to form coarse powder, the mixture is stirred with honey, then put into a general-purpose equipment steaming device, added with purified water, and steamed by using a general-purpose equipment steam method for 40min until the mixture is well steamed, then the steamed mixture is put into a fermentation tank to brew for 72 h, so as to obtain a comprehensive fermentation liquor for later use, fresh bamboo leaves are additionally taken and steamed by using the steaming method for 5 min, the steamed bamboo leaves are put into a stir pan for stir-frying, and the leaves are discharged from the pan until the leaves are naturally curled and fresh scent comes out of the pan, and finally, the comprehensive fermentation liquor and the fried bamboo leaf tea are fully stirred and dried, taken out, cooled and cleared up to obtain the bamboo leaf green tea.

Owner:郭超民

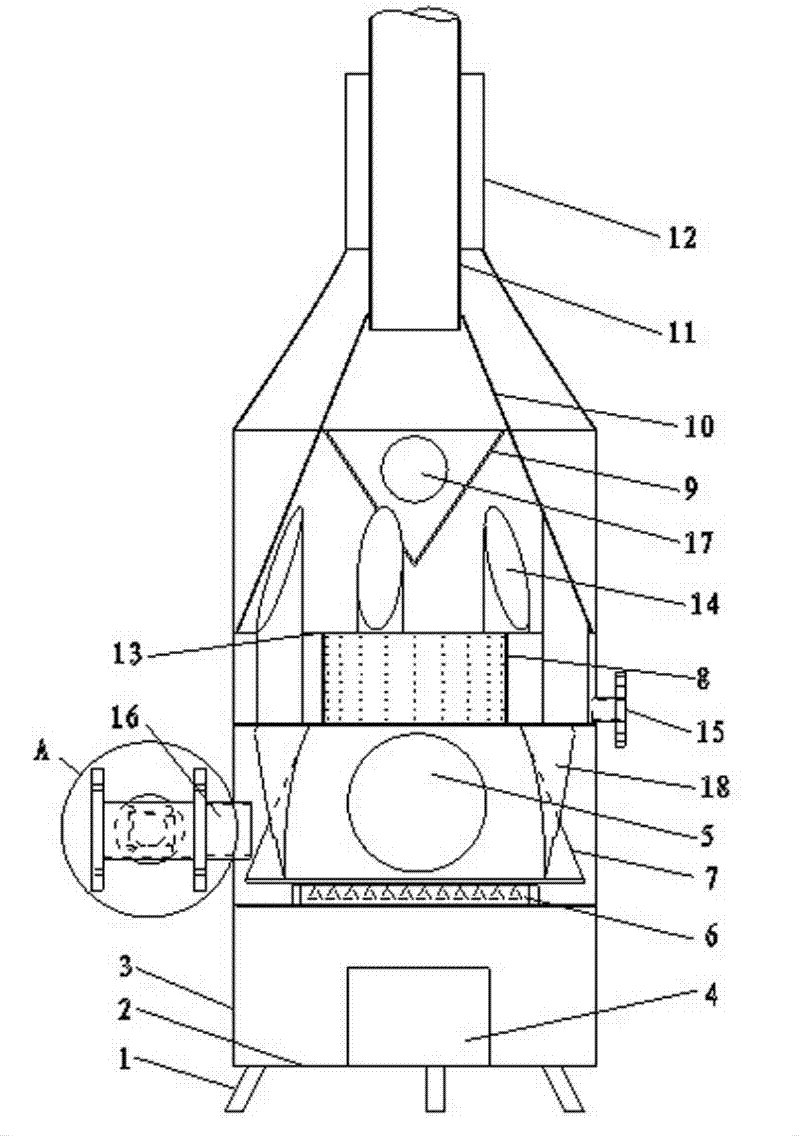

Mechanical straw temperature rising device for sunlight greenhouse

InactiveCN102210248ABurn fullyAdjustable temperatureClimate change adaptationAir heatersVertical tubeExtinction

The invention belongs to the technical field of greenhouse temperature rising equipment, in particular relates to a mechanical straw temperature rising device for a sunlight greenhouse and solves the problem that the conventional sunlight greenhouse is difficult and expensive to warm. The mechanical straw temperature rising device for the sunlight greenhouse comprises a furnace outer cylinder, wherein the furnace outer cylinder is provided with a fuel port and an ash outlet; a furnace grate assembly is arranged between the fuel port and the ash outlet; a conical primary burner, a cylindrical secondary burner, a reversely conical fire extinction dust reducer and a conical secondary heat exchanger are arranged inside the furnace outer cylinder from bottom to top; a hot air outlet is formed on the furnace outer cylinder; and a plurality of vertical tube nests are arranged outside the secondary burner. The device has the advantages that: various waste straws in rural areas are utilized as fuels to supply heat to the sunlight greenhouse in winter, the heat energy utilization rate is high, the sunlight greenhouse is uniformly heated, has no dust discharge and is environment-friendly, and a good growth environment is provided for crops; and agricultural output is improved, farmer benefits are improved, and socialistic new countryside construction is powerfully promoted.

Owner:王曦

Production method of kidney-nourishing ginseng coffee

InactiveCN113080287AImprove benefitsGood kidney effectRoasted coffee treatmentBiotechnologyEngineering

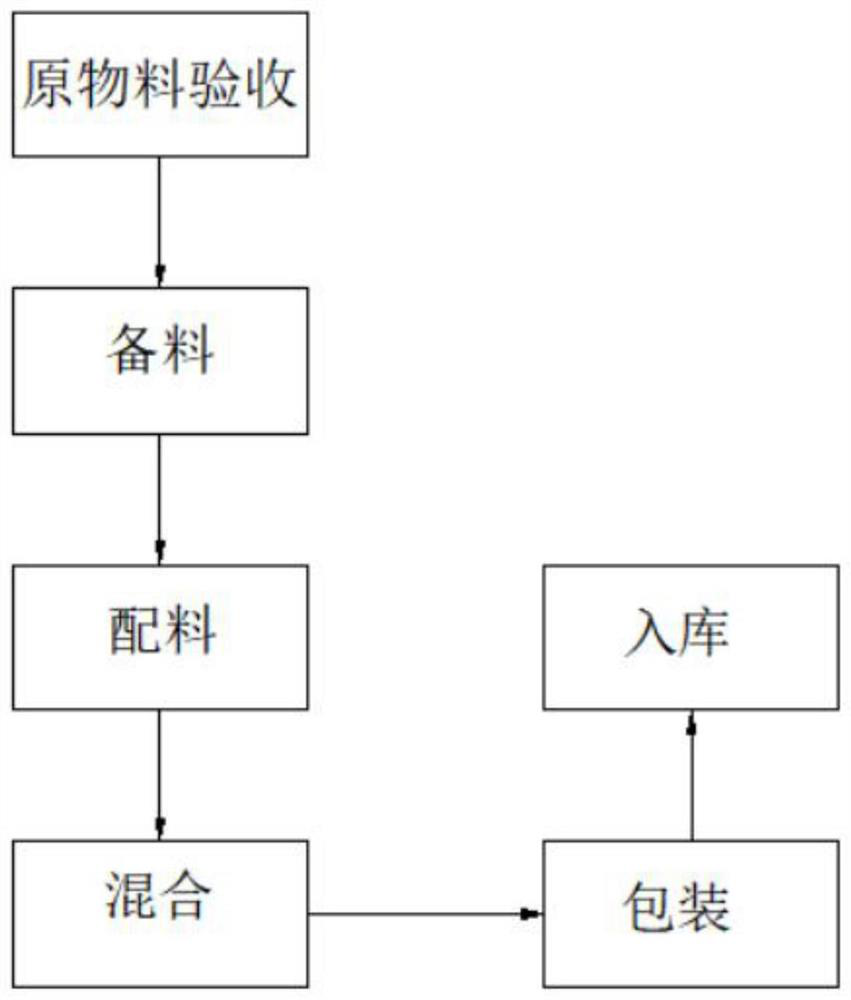

The invention belongs to the technical field of coffee production, and particularly relates to a production method of kidney-nourishing ginseng coffee, which comprises the following specific steps: checking and accepting raw materials: checking and accepting the safety quality of the raw materials; preparing materials, wherein ingredients needed in the coffee production process are prepared; preparing materials: taking 4-6 parts of instant coffee powder, 2-4 parts of non-dairy creamer, 1.5-2.5 parts of white granulated sugar, 2-3 parts of coffee powder, 2-3 parts of maltodextrin, 1-2 parts of maca powder and 3-5 parts of raw selenium ginseng; mixing: pouring several ingredients into a three-dimensional stirrer, stirring for 10-20 minutes, and after mixing and stirring, pouring the mixture into a turnover barrel with a bag cover; and packaging: weighing and packaging the mixed materials according to the needs of customers, printing the date of the day, and packaging two or ten bags in each box according to the needs, so that the ginseng coffee can effectively soothe the nerves of the human body, has a very good kidney tonifying effect, and greatly improves the benefits to the human body.

Owner:易广大

Traditional Chinese medicine bag formula for marinating meat

The invention discloses a traditional Chinese medicine bag formula for marinated meat, and belongs to the technical field of seasoning powder, wherein the traditional Chinese medicine bag formula comprises the following raw materials: nutmeg, fructus cinnamomi, clove, rhizoma kaempferiae, licorice, amomum cardamomum, amomum kravanh, bay leaf, ligusticum chuanxiong, fennel, star anise, cassia bark,coriander seeds, angelica dahurica, fructus amomi, areca-nut, fructus caryophylli, purple perilla, white pepper, red cape jasmine, tsaoko amomum fruits, cinnamon, radix aucklandiae and murraya paniculata. The formula for marinating meat provided by the invention does not contain any chemical additive, is green, healthy and safe, and does not have any chemical harm to human bodies; the prepared marinated meat is fragrant and sweet in taste, fresh in color and not greasy; and meanwhile, traditional Chinese medicine components are added into the formula, so that the formula has great benefits tohuman bodies and can strengthen the bodies when being eaten.

Owner:武汉周记食品技术开发有限公司

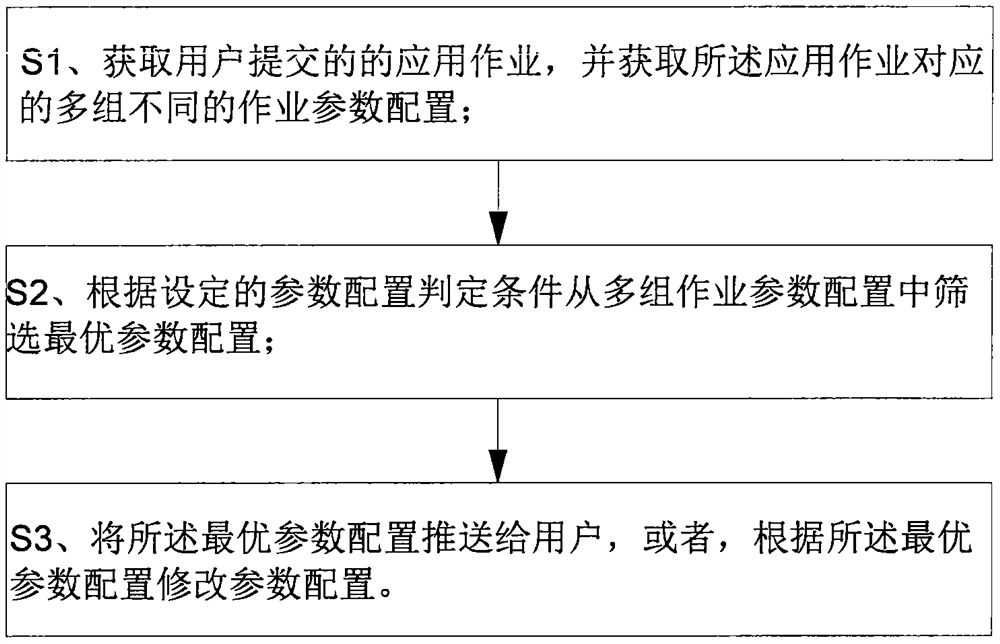

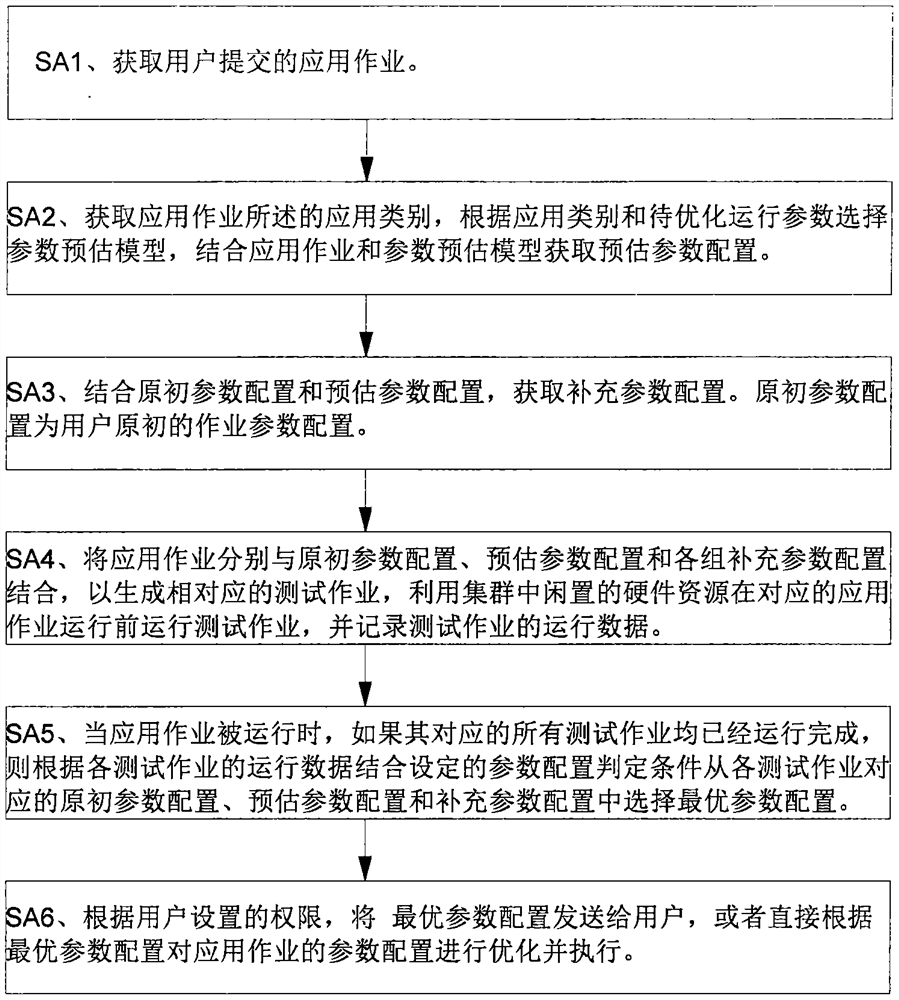

Job operation parameter optimization method applied to super-computing cluster scheduling

ActiveCN114048027AGood calculation efficiencyMake up for the lack of parameter configuration optimization capabilitiesResource allocationConfiguration optimizationScheduling (computing)

A job operation parameter optimization method applied to super-computing cluster scheduling comprises the following steps: acquiring an application job submitted by a user, and acquiring multiple groups of different job parameter configurations corresponding to the application job; screening an optimal parameter configuration from the multiple groups of operation parameter configurations according to a set parameter configuration judgment condition; and pushing the optimal parameter configuration to the user, or modifying the job parameter configuration of the application job submitted by the user according to the optimal parameter configuration. According to the method, automatic optimization of the parameter configuration of the application job submitted by the super-computing cluster user is realized, the defect that most users do not have the parameter configuration optimization capability is made up, and the calculation efficiency of the super-computing cluster is improved on the whole.

Owner:UNIV OF SCI & TECH OF CHINA

Primary tea manufacturing method

InactiveCN105192109AQuality improvementSimplify operation stepsPre-extraction tea treatmentWater contentEngineering

The invention discloses a primary tea manufacturing method. The primary tea manufacturing method includes the following steps of raw material picking; tea leaf spraying; fermenting, wherein the tea leaves are piled up for fermentation in the mode of being covered with a wet gunny bag or tarpaulin; stirring, wherein on the next day after the tea leaves are piled for fermentation newly, pile-turning must be carried out to make the water content of the retting tea leaves uniform, pile-turning is carried out once every six to eight days, pile-turning stirring needs to be carried out five to eight times to finish fermentation, heat is dissipated through pile-turning stirring, the water content of the tea leaves is reduced, fermentation is even, pile-turning stirring should be uniform, and then deblocking is carried out; drying, wherein in the drying process, fermentation piles are ditched for ventilation and drying, when the water content of the tea leaves is 14-20%, the piles are ditched every three to five days; screening; packaging. After adopting the method, the product quality is greatly improved by adopting the scientific and reasonable manufacturing method and reasonable parameters; meanwhile, the operation steps are simple, and processing cost is reduced, which is beneficial for increasing benefits.

Owner:ZHENJIANG WUFENG TEA PLANTATION

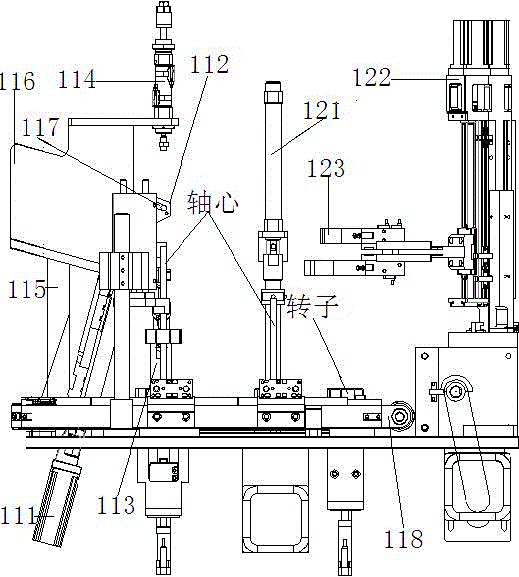

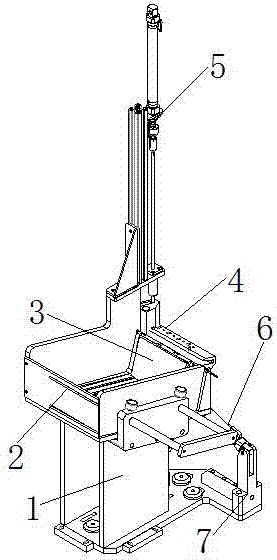

Shaft inserting mechanism

InactiveCN107116352AImprove benefitsHigh degree of automationMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a shaft inserting mechanism which comprises a rack, a shaft storage mechanism, a shaft pushing feeding sliding table, a shaft overturning mechanism and a shaft pressing mechanism, wherein the shaft storage mechanism is arranged on the top of the rack and is arranged at the upper part of the rack in an inclined structural form; the shaft pushing feeding sliding table is arranged horizontally on the inner side of the lower end part of the shaft storage mechanism; the shaft overturning mechanism is correspondingly arranged on the edge of the top part of the outer side of the lower end part of the shaft storage mechanism; the shaft pressing mechanism is correspondingly arranged above the shaft overturning mechanism. The shaft inserting mechanism is high in automation degree, the quality of an assembly product is easily guaranteed, and the labor cost is reduced; and meanwhile, the production efficiency is improved, and the enterprise benefit is improved.

Owner:林育键

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com