Whole wheat flour production process and processing device for intermediate extraction treatment of gluten materials

A technology of processing equipment and production technology, which is applied in grain processing, grain milling, food science, etc., can solve the problems of reducing the benefits of whole wheat flour, not fully activating the activity of wheat bran, and not designing the fermentation process of wheat bran, so as to improve the nutrition The effect of the wheat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

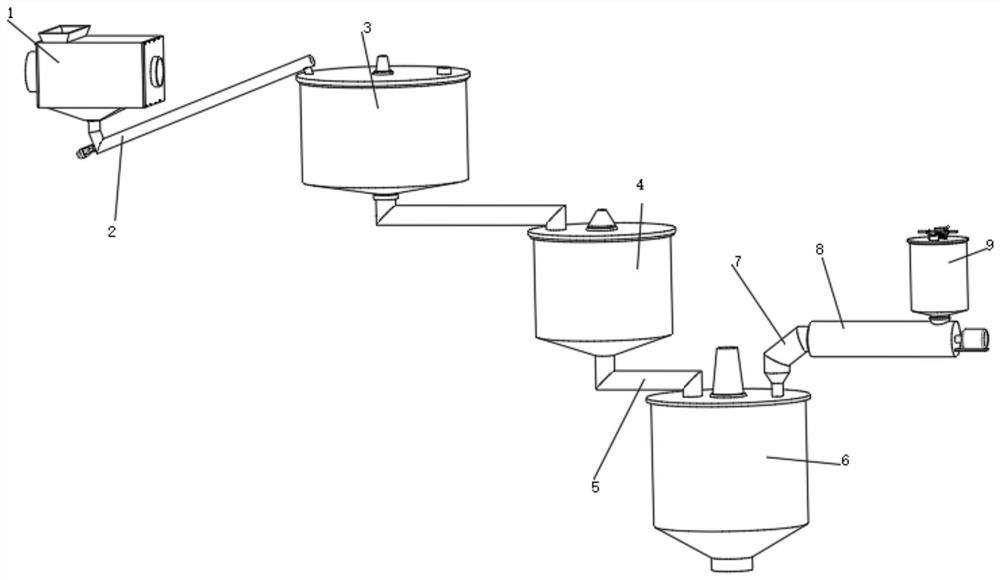

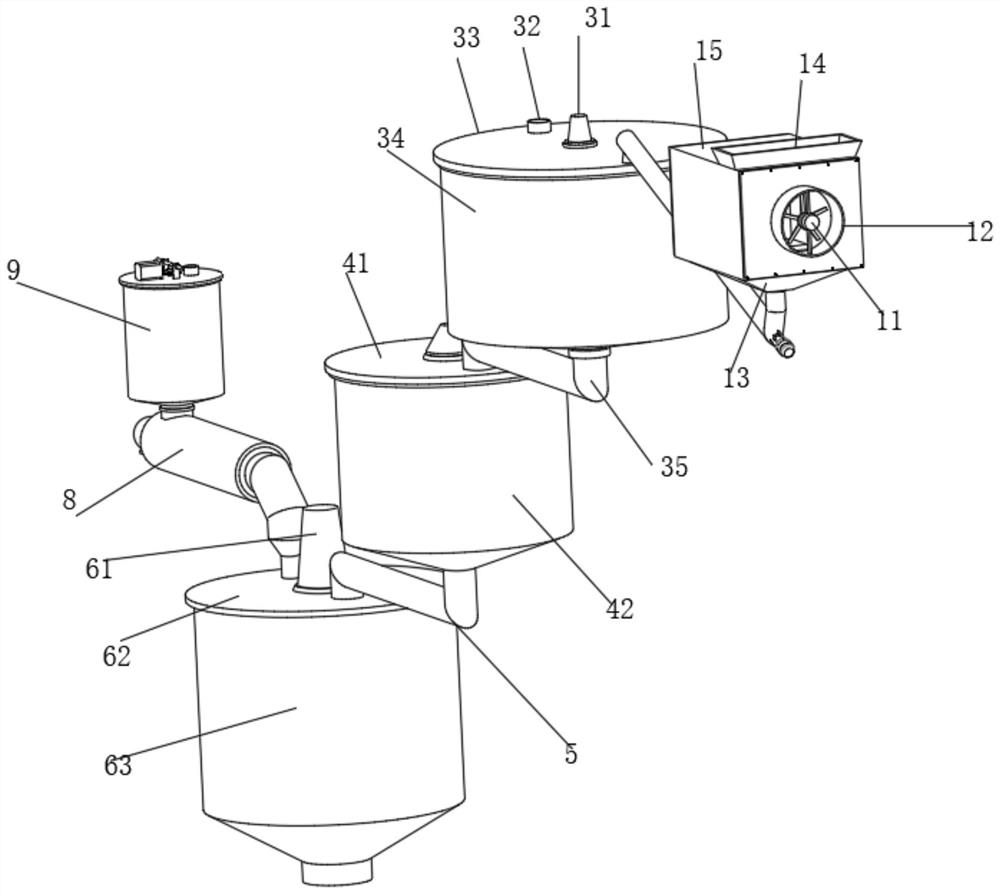

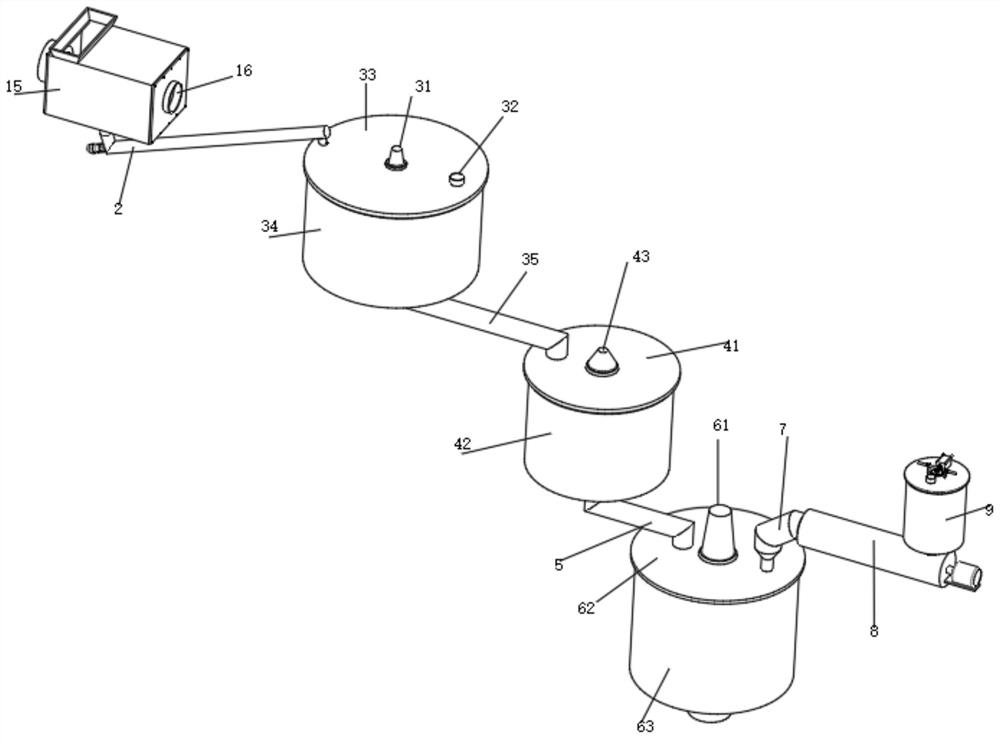

[0048] like Figure 1-10 A whole wheat flour production and processing device for intermediate extraction and processing of gluten materials is shown, including winnowing structure 1, auger discharge pipe 2, wheat moistening structure 3, crushing structure 4, first connecting pipe 5, and second connecting pipe 7 , extruder 8 and fermentation drying structure 9, winnowing structure 1 comprises blower fan 11, inlet pipe 12, discharge hopper 13, the first feed pipe 14, winnowing box 15 and outlet pipe 16, winnowing box 15 The top of the left end is fixedly connected with the first feeding pipe 14 for feeding, the winnowing box 15 is fixedly connected with the air inlet pipe 12 and the air outlet pipe 16 respectively in the through holes at the left and right ends, and the air inlet pipe 12 is fixedly connected with the pipe for air flow. Fan 11, the bottom of winnowing box 15 is fixedly connected with discharge hopper 13, and the bottom of discharge hopper 13 is fixedly connected...

Embodiment 2

[0050] Embodiment 2 is a further improvement to Embodiment 1.

[0051] like Figure 1-10A whole wheat flour production and processing device for intermediate extraction and processing of gluten materials is shown, including winnowing structure 1, auger discharge pipe 2, wheat moistening structure 3, crushing structure 4, first connecting pipe 5, and second connecting pipe 7. Extrusion extruder 8 and fermentation drying structure 9, winnowing structure 1 includes fan 11, air intake pipe 12, discharge hopper 13, first feed pipe 14, winnowing box 15 and air outlet pipe 16, winnowing box 15 The top of the left end of the left end is fixedly connected with the first feed pipe 14 for feeding, and the winnowing box 15 is fixedly connected with the air inlet pipe 12 and the air outlet pipe 16 respectively in the through holes at the left and right ends, and the air inlet pipe 12 is fixedly connected with a pipe for air flow. The blower fan 11, the bottom of the winnowing box 15 are f...

Embodiment 3

[0053] Embodiment 3 is a further improvement to Embodiment 1.

[0054] like Figure 1-10 A whole wheat flour production and processing device for intermediate extraction and processing of gluten materials is shown, including winnowing structure 1, auger discharge pipe 2, wheat moistening structure 3, crushing structure 4, first connecting pipe 5, and second connecting pipe 7. Extrusion extruder 8 and fermentation drying structure 9, winnowing structure 1 includes fan 11, air intake pipe 12, discharge hopper 13, first feed pipe 14, winnowing box 15 and air outlet pipe 16, winnowing box 15 The top of the left end of the left end is fixedly connected with the first feed pipe 14 for feeding, and the winnowing box 15 is fixedly connected with the air inlet pipe 12 and the air outlet pipe 16 respectively in the through holes at the left and right ends, and the air inlet pipe 12 is fixedly connected with a pipe for air flow. The blower fan 11, the bottom of the winnowing box 15 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com