Vaseline recycling system

A technology of recycling and vaseline, which is applied in the recovery/refining of mineral wax, cleaning hollow objects, and processing hydrocarbon oil, etc., can solve the problem of low precision, achieve the effect of increasing enterprise benefits, simple structure, and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

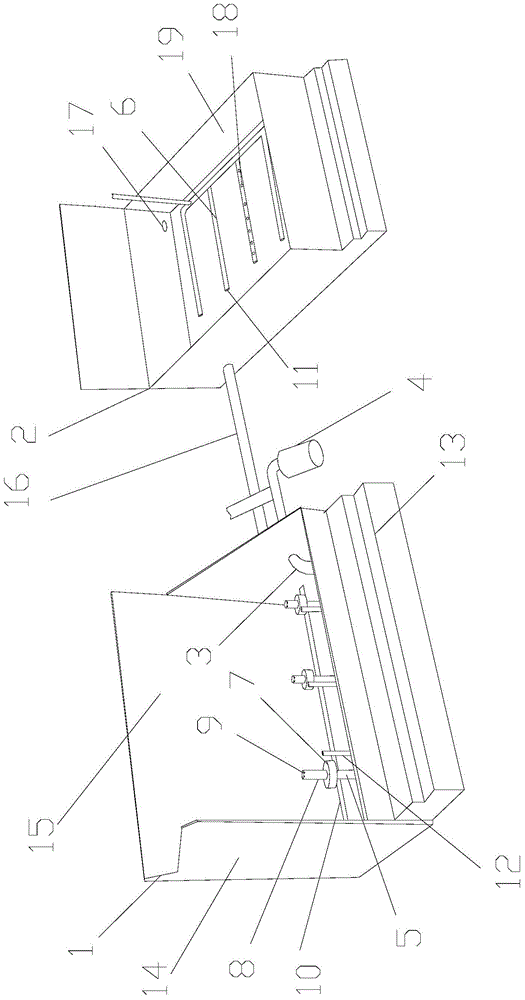

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with accompanying drawing and preferred embodiment, as figure 1 Described, a kind of petroleum jelly recovery system, comprises cleaning box body 1, recovery box 2, steam pipeline 3, high-pressure pump 4, described cleaning box interior is vertically provided with steam branch pipe 5, and described recovery box is provided with disc Pipe 6, the steam branch pipe and the coil pipe are respectively communicated with the steam pipeline, the steam pipeline is connected with the steam boiler, and the high-pressure pump is communicated with one side of the steam pipeline; Lan 7 is connected with a steam spray head 8, the circumference of the steam spray head is provided with an air outlet 9, and the two sides of the steam branch pipe are provided with support beams 10 for placing recovery buckets; the coil pipes are at least two, arranged in parallel At the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com