Multi-stage thermal desorption technology and device for waste salt refining

A thermal desorption and equipment technology, applied in the field of hazardous waste salt treatment, can solve the problems of equipment waste, insufficient equipment space, and equipment that cannot be reused, and achieves the effect of saving investment and operating costs, remarkable innovation, and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

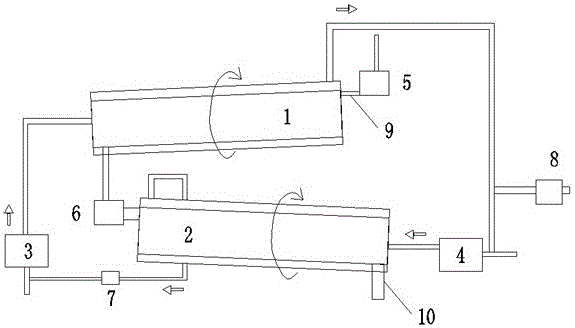

Method used

Image

Examples

Embodiment 1

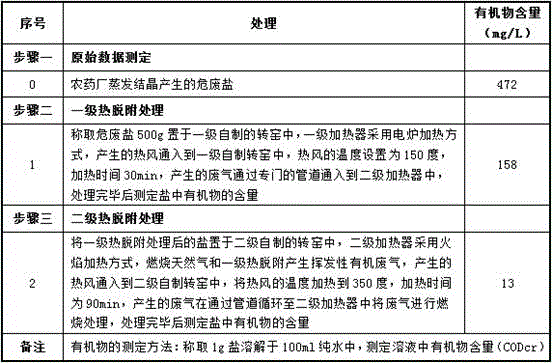

[0032] Example 1: The hazardous waste salt refined in the experiment comes from the evaporation crystallization salt of a pesticide factory in Shandong, which is a typical hazardous waste salt. It contains a large amount of pesticide organic matter, which is very dangerous to the environment. The thermal desorption treatment process of hazardous waste salt is mainly to remove organic matter, so this experiment mainly focuses on the removal effect of organic matter in hazardous waste salt. The experimental procedures and experimental results are shown in Table 1.

[0033] Table 1 Experimental procedures and experimental results of hazardous waste salt refining

[0034]

[0035]It can be seen from the experimental data in Table 2 that the initial organic concentration in hazardous waste salt is 472mg / L. In the first-level thermal desorption process, the temperature of the first-level thermal desorption is set to be 150 degrees, and the thermal desorption time is 30min. The ...

Embodiment 2

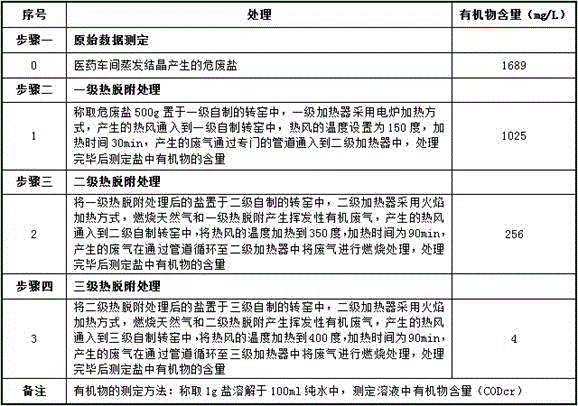

[0036] Example 2: The hazardous waste salt refined in the experiment comes from the evaporation crystallization salt of a pesticide factory in Shandong, which is a typical hazardous waste salt. It contains a large amount of pesticide organic matter, which is very dangerous to the environment. The thermal desorption treatment process of hazardous waste salt is mainly to remove organic matter, so this experiment mainly focuses on the removal effect of organic matter in hazardous waste salt. The experimental procedures and experimental results are shown in Table 2.

[0037] Table 2 Experimental procedures and experimental results of hazardous waste salt refining

[0038]

[0039] It can be seen from the experimental data in Table 2 that the initial organic concentration in hazardous waste salt is 472mg / L. In the first-level thermal desorption treatment, the temperature of the first-level thermal desorption is set to 200 degrees, and the thermal desorption time is 30min. The ...

Embodiment 3

[0040] Example 3: The hazardous waste salt refined in the experiment comes from a certain printing and dyeing industry in Lianyungang, which contains a large amount of organic matter and is very dangerous to the environment. Refining experiments were carried out using hazardous waste salt from the printing and dyeing industry. The experimental procedures and experimental results are shown in Table 3.

[0041] Table 3 Experimental procedures and experimental results of hazardous waste salt refining

[0042]

[0043] It can be seen from the experimental data in Table 2 that the initial organic concentration in hazardous waste salt is 878 mg / L. In the first-level thermal desorption process, the temperature of the first-level thermal desorption is set to be 200 degrees, and the thermal desorption time is 40 minutes. The concentration of organic matter in the obtained salt is 345mg / L, and the removal rate of organic matter is 60.7%. In the thermal desorption process, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com