Thermal control device

a control device and thermal control technology, applied in the direction of indirect heat exchangers, machines using electric/magnetic effects, lighting and heating apparatus, etc., can solve the problem of increasing the mass and achieve the effect of increasing the thermal conductivity of the loop heat pip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

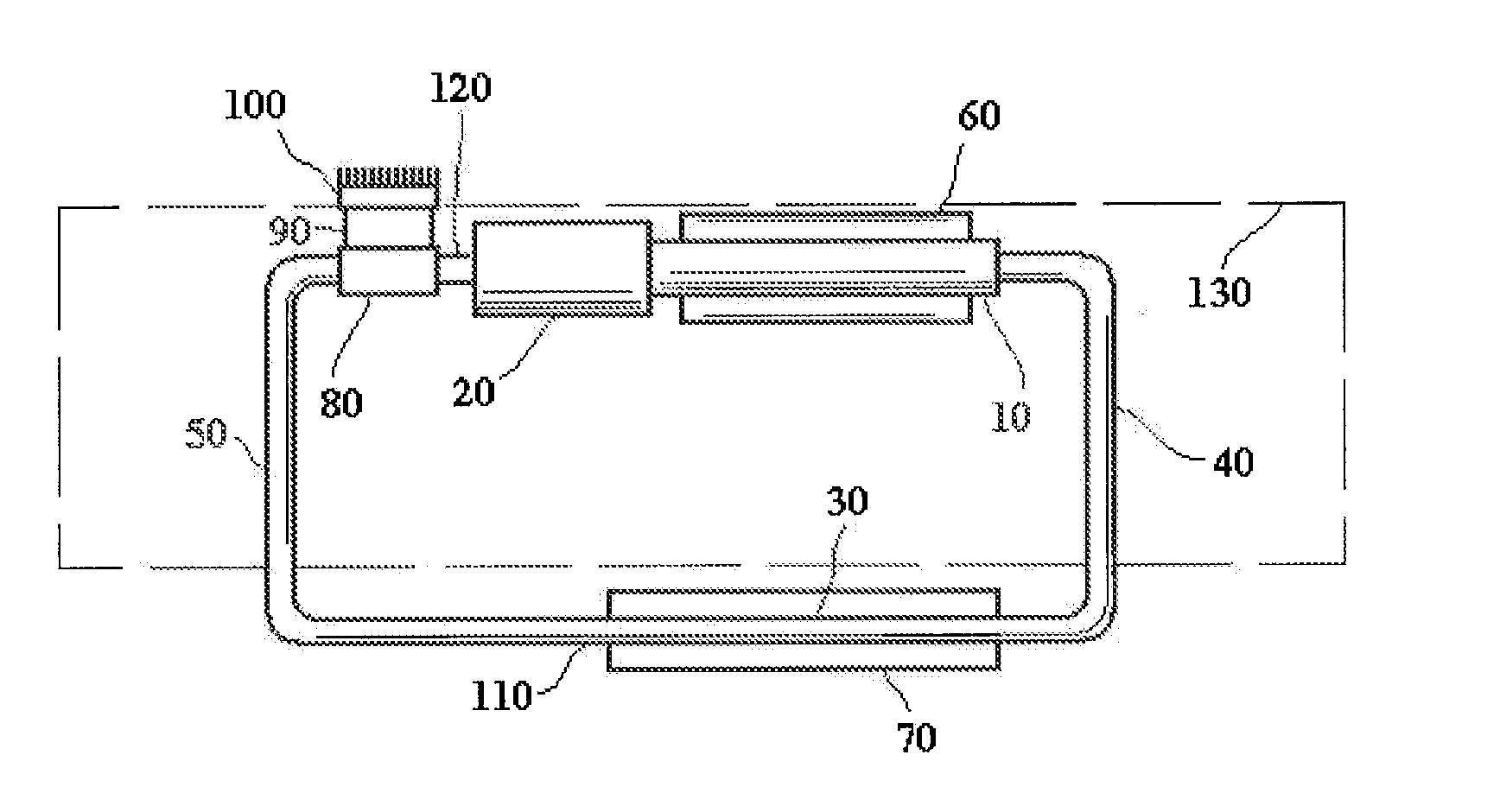

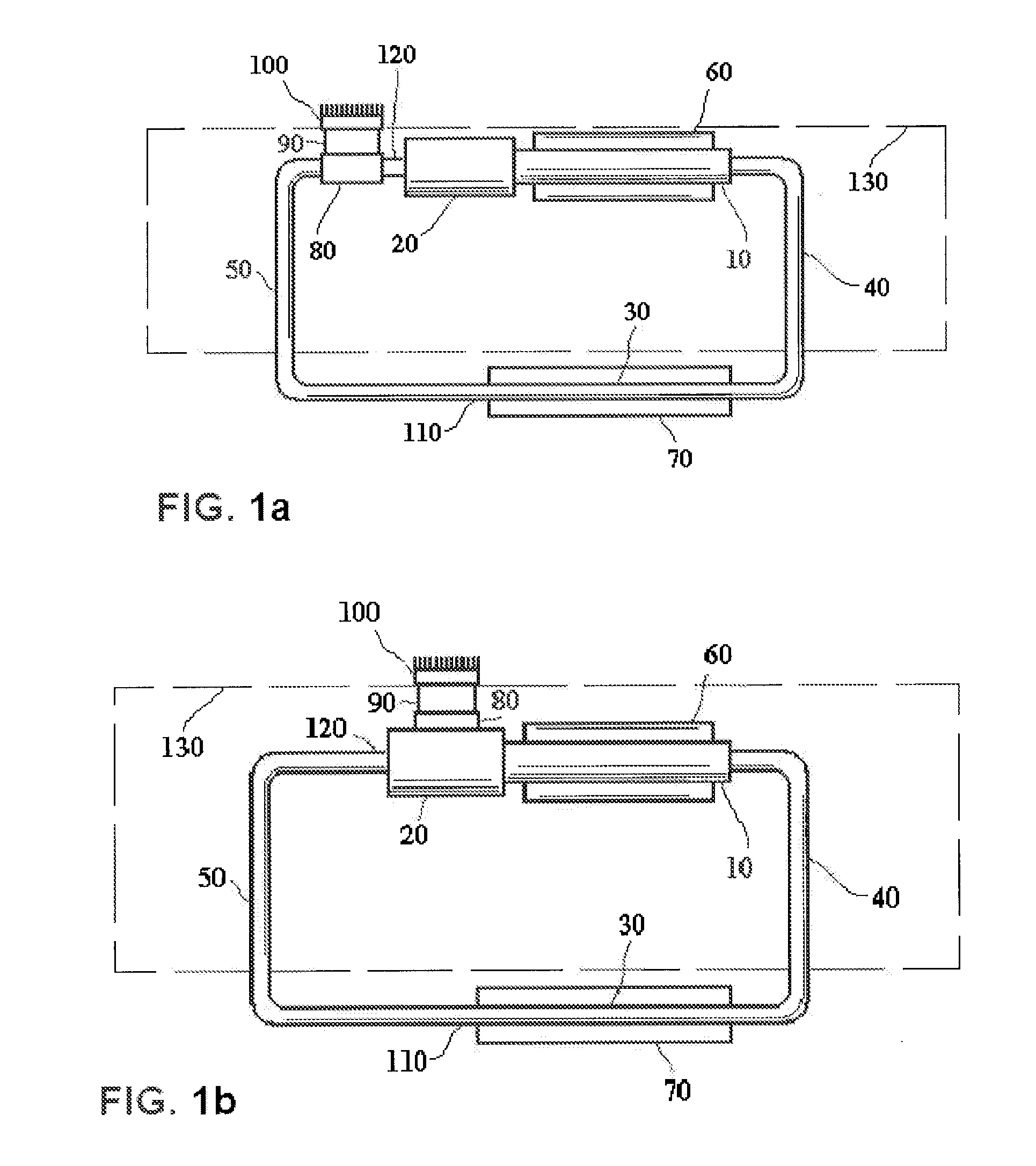

[0026]A loop heat pipe, as shown in FIG. 1, is an effective heat transfer or thermal control device, comprising an evaporator 10, a compensation chamber 20, a condenser 30, a vapour transport line 40 and a liquid transport line 50 connecting them. The evaporator 10, typically cylindrical, is located inside an evaporator saddle 60, to which heat dissipating devices are attached. The condenser 30 is embedded to a radiator 70, in order to increase the area of heat rejection.

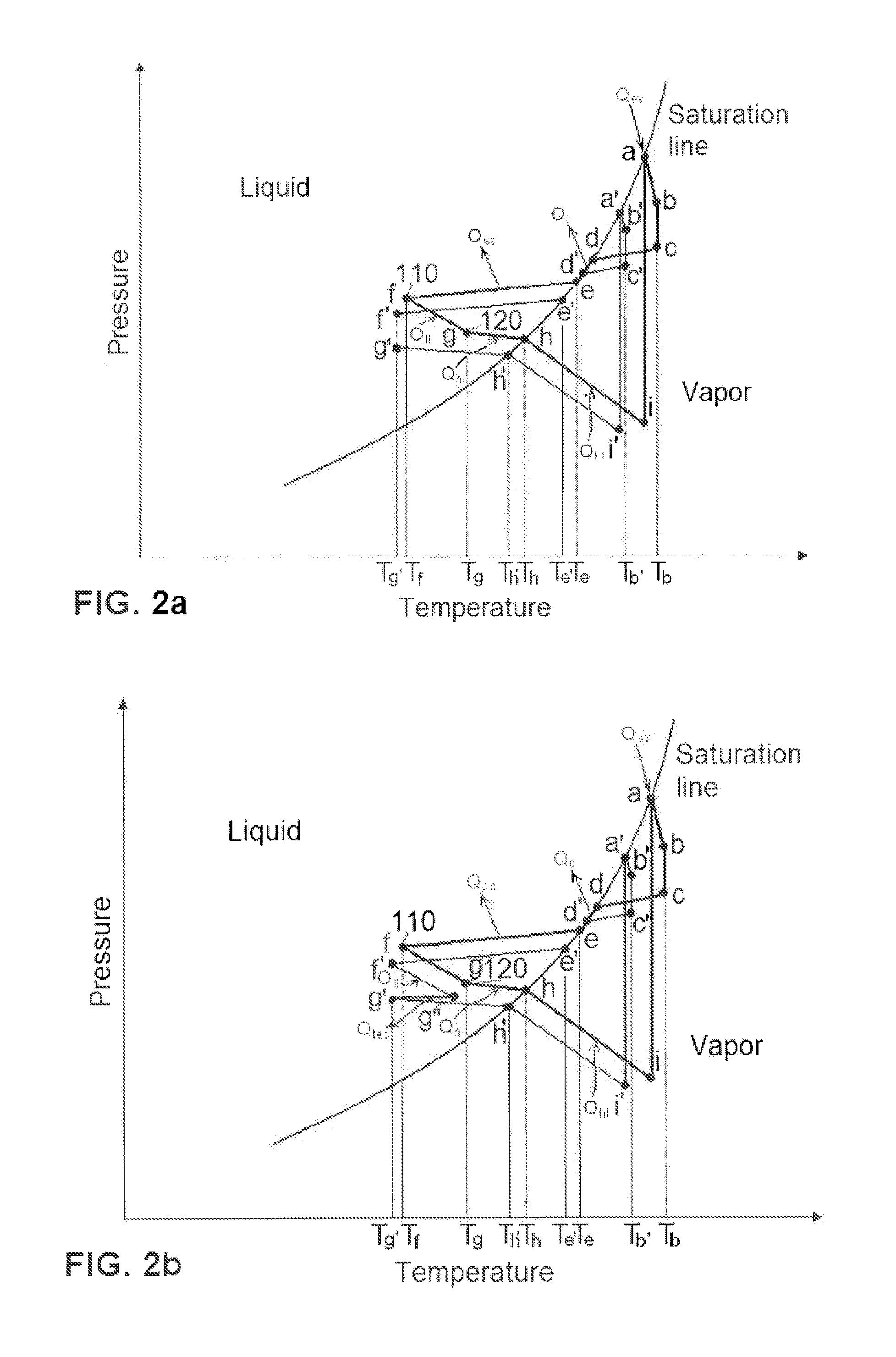

[0027]The evaporator 10 comprises inside a porous wick, and the loop heat pipe is charged with working fluid. Part of the inner volume of the loop heat pipe (wick, liquid transport line 50, and the compensation chamber 20 and the condenser 30, partially) is filled with the liquid phase of the working fluid, while part of the inner volume of the loop heat pipe (the vapour transport line 40, partially the compensation chamber 20 and the condenser 30, as well as vapour channels and grooves in the evaporator 10) is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com