Fuselage structure for the combined fastening of an insulation mattress and devices, and aircraft including such a structure

A technology of fixing structure and isolation pad, applied in the direction of fuselage, fuselage bulkhead, fuselage insulation, etc., can solve the problems of damage to the outer skin of the fuselage, difficulty in setting fastening points, and difficulty in perforating Ω-shaped stringers, etc. Achieve fixed and stable improvements, reduce weakening, and eliminate weakening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

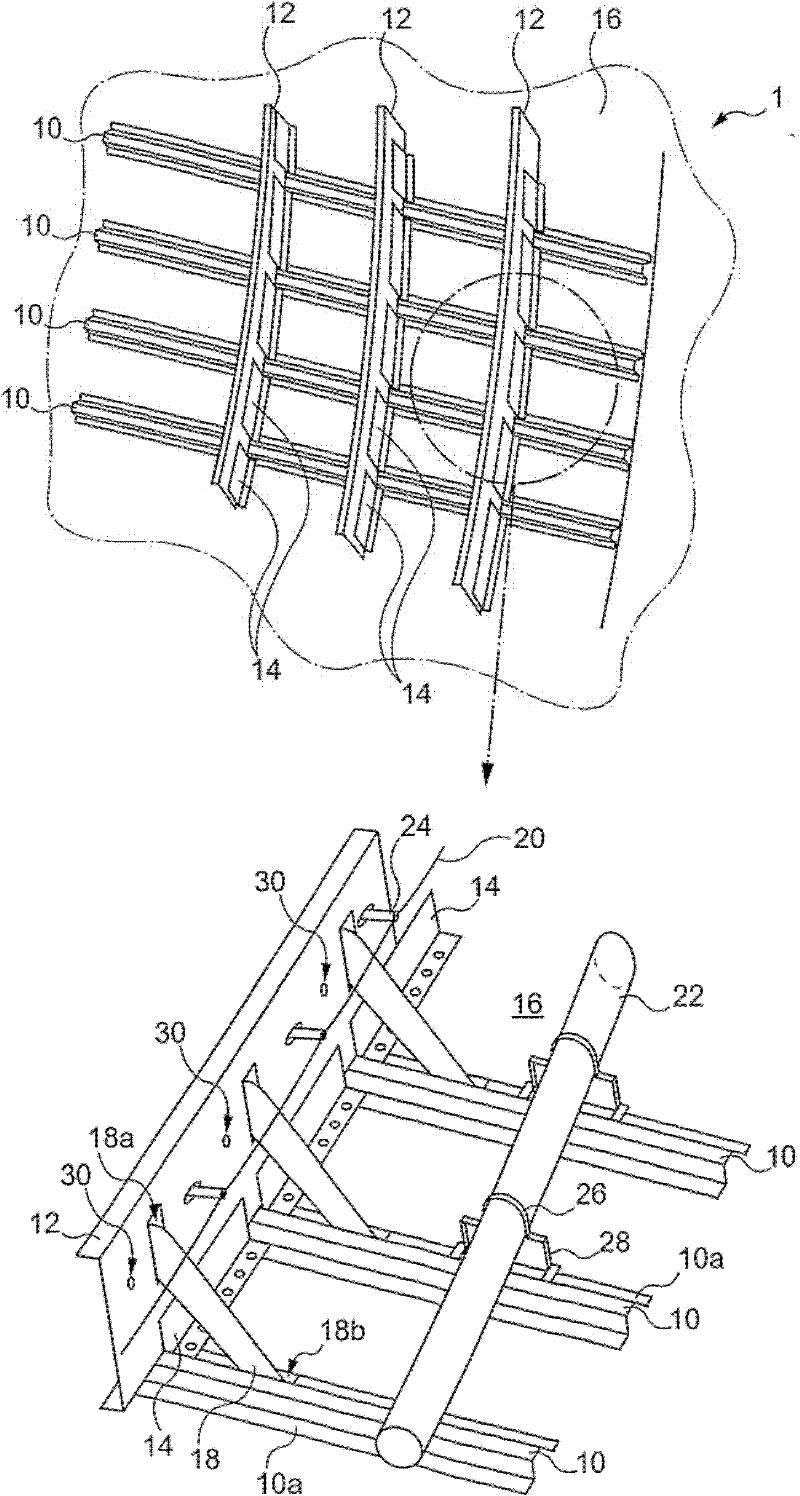

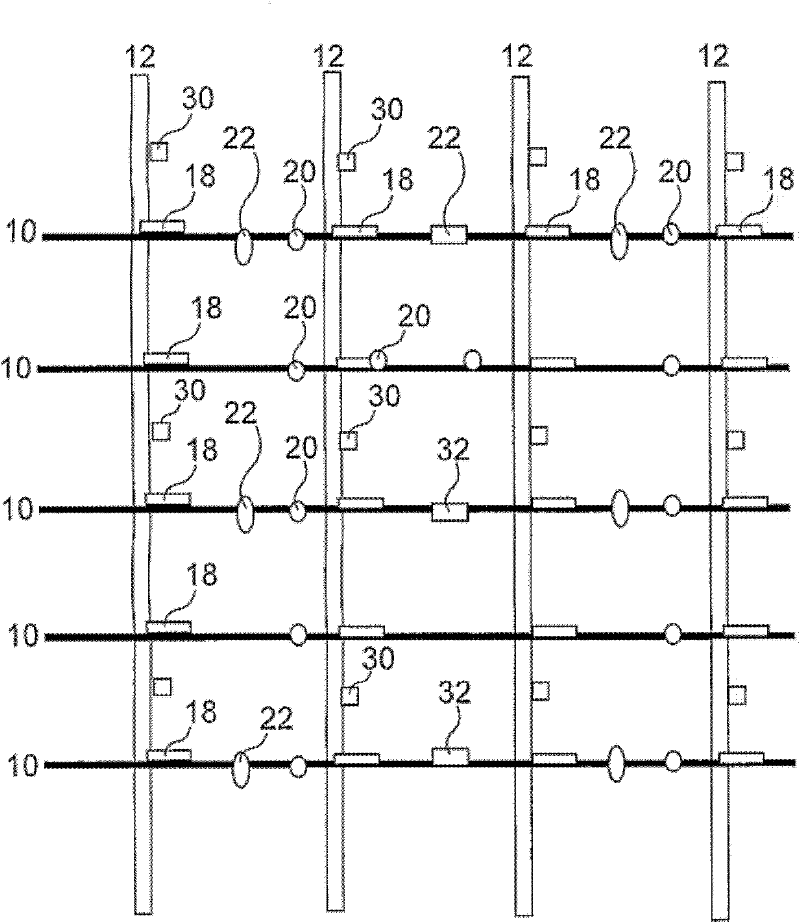

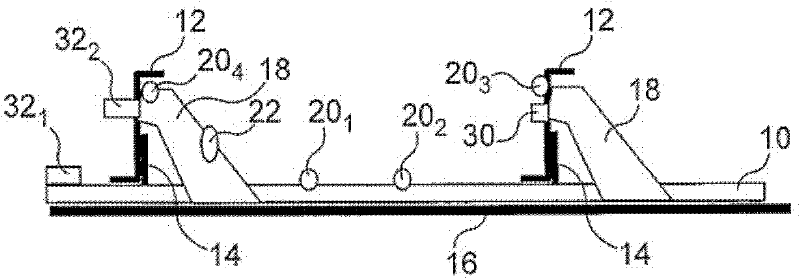

[0043] Figures 1 to 3 The prior art fuselage structure 1 shown above has omega-shaped longitudinal stringers 10 and frames 12 which bear vertically on the stringers 10 at constant distances. An "L" shaped retaining clip 14 of the frame is located at the frame 12 between two adjacent stringers 10 and is secured to the frame and the bottom plate 10a of the stringers, respectively. The skin 16 of the fuselage is attached to the bottom plate 10a of the stringer 10 and to the clips 14 by riveting.

[0044] Such as figure 1 Stabilizers 18 are arranged at each intersection between the frame 12 and the stringers 10 as shown in the detail drawing of . Said stabilizer 18 has a core plate terminating at both ends in vertical flanges 18a and 18b in order to fix them by riveting to the frame 12 and the corresponding stringer 10 respectively. In particular, the stabilizer is fixed at the bottom plate 10a of the stringer.

[0045] The function of the stabilizer 18 is to hold the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com