Multi-station rotating and lifting combination feed storage device

A rotary lifting and multi-station technology, which is applied in metal processing, transportation and packaging, and unstacking of objects, etc., can solve the problems of large gaps, inability to adjust pallets adaptively, and low positioning accuracy of feeding, so as to achieve large storage capacity, The effect of improving the automatic detection function and meeting the processing needs of high-efficiency mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

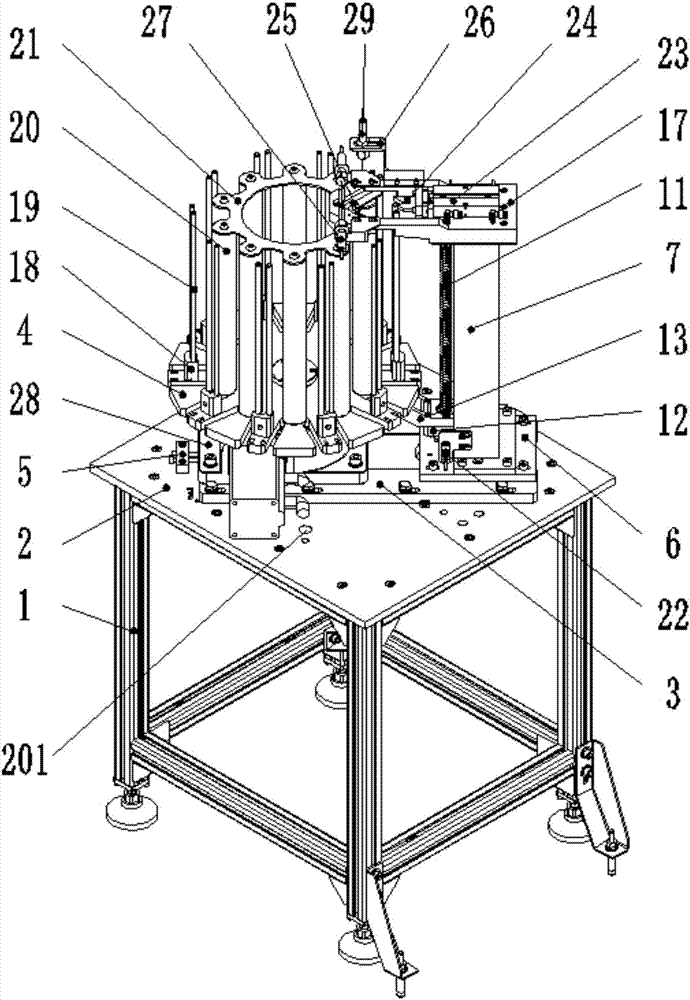

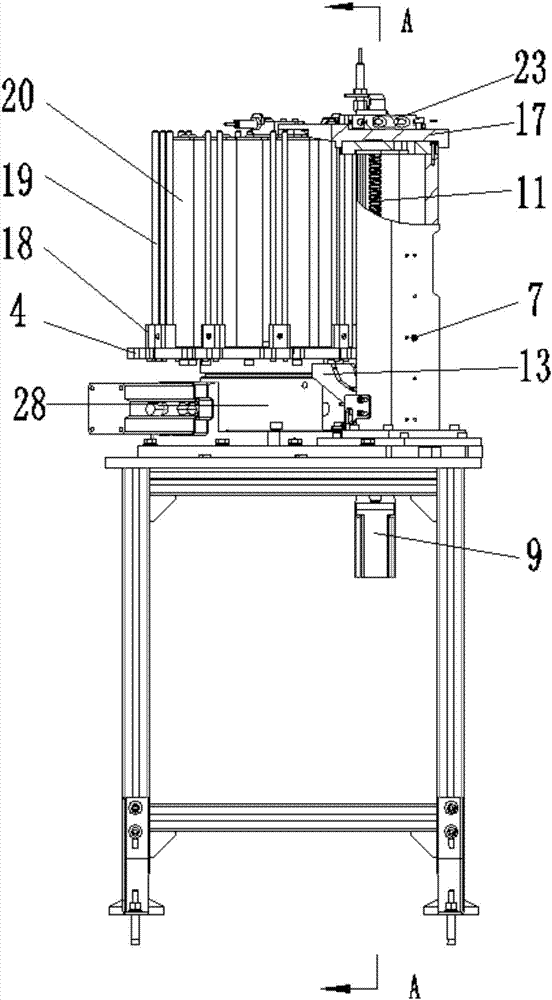

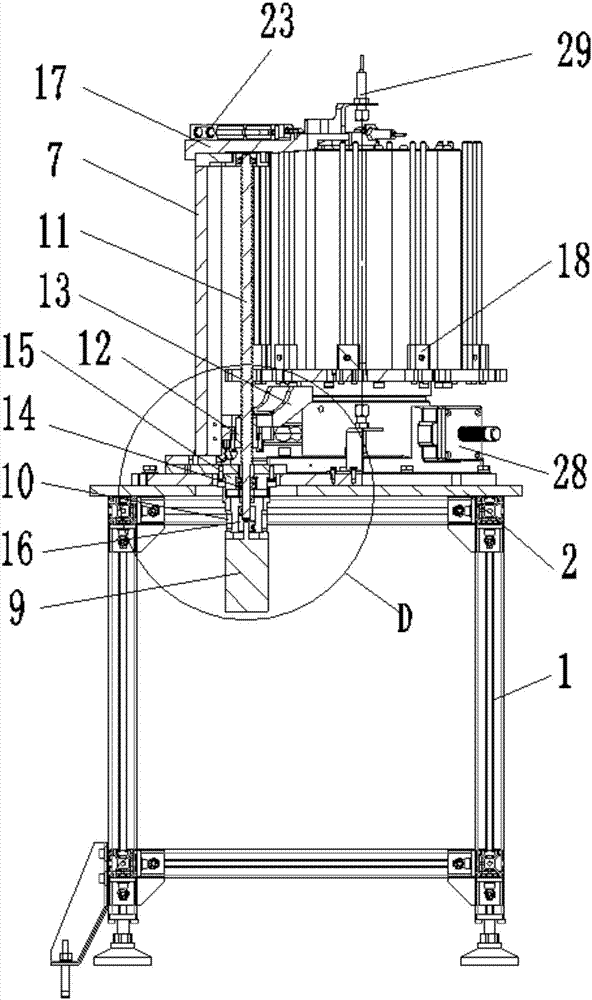

[0022] Attached below Figure 1-5 An embodiment of the present invention is described.

[0023] The multi-station rotary lifting combined feeding storage device has a body 1, which is similar to the structure of the rotary lifting combined automatic feeding device with the advantage of smaller volume space and larger capacity storage advantages in the prior art. The body 1 A loading mechanism for stacking materials by means of a rotating disk 4 is installed on the top, and the loading mechanism includes a rotating mechanism for rotating and feeding materials. One side of the rotating mechanism is fixedly provided with a lifting mechanism for lifting and feeding materials. It is characterized in that: Solve the technical problem that the materials carried on the rotating disk 4 of the rotating mechanism in the prior art cannot be accurately positioned. In the mechanism, the rotating disk 4 has too many components for carrying materials, the structure is too complicated, the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com