Patents

Literature

38results about How to "Reduce equipment input costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

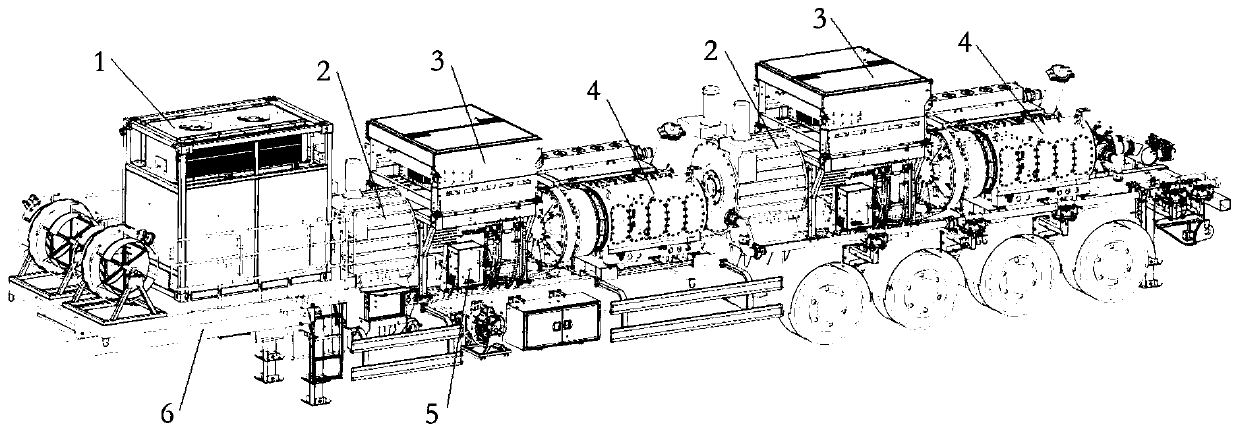

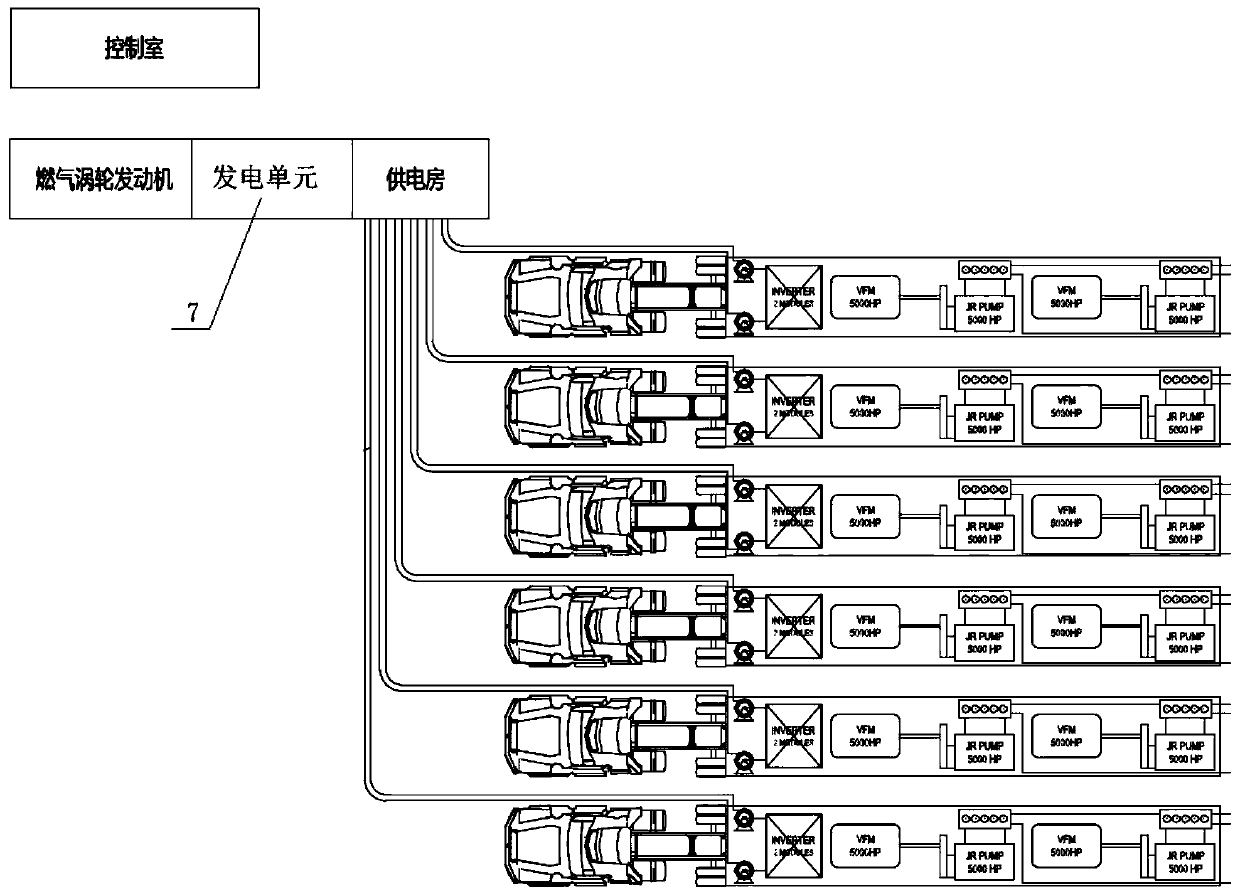

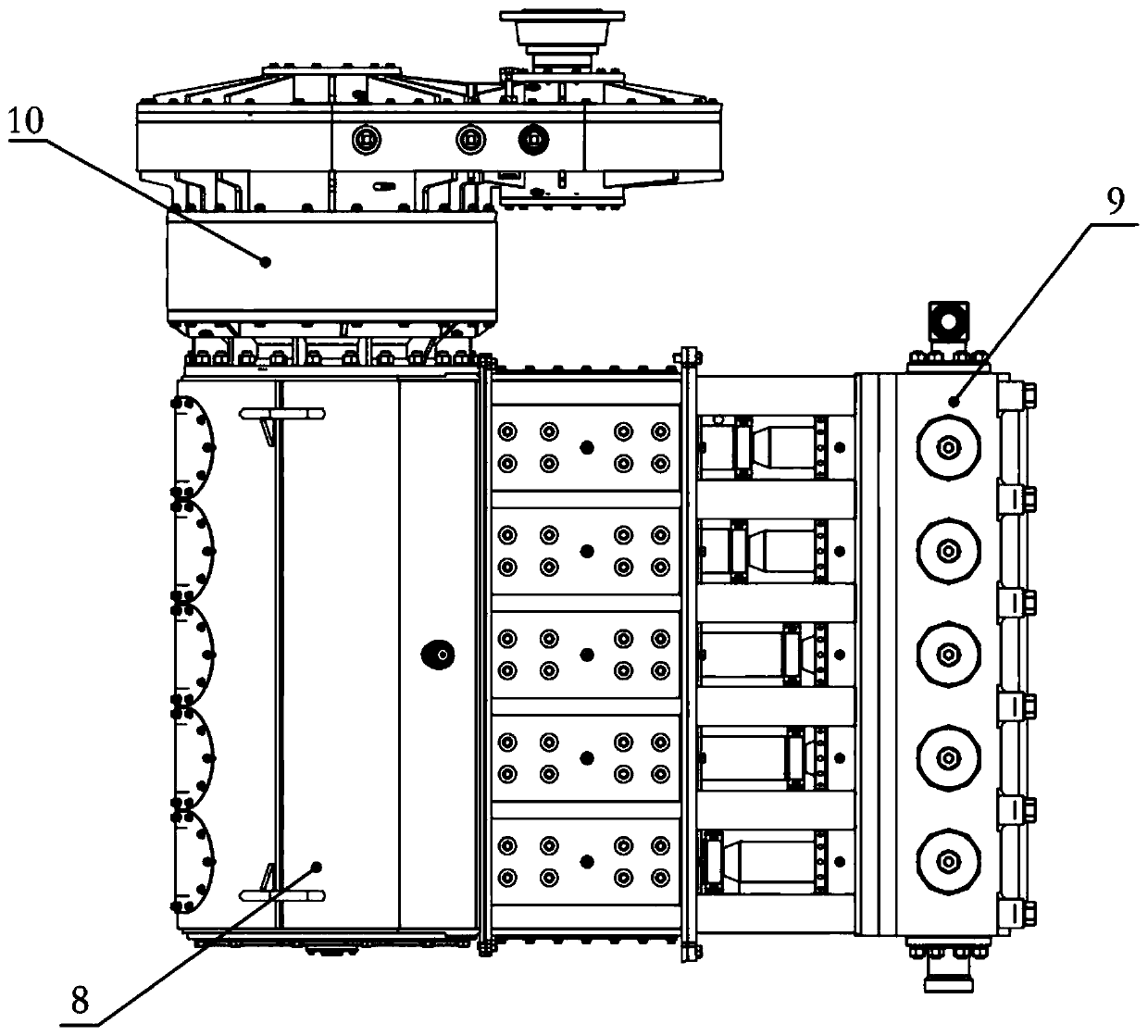

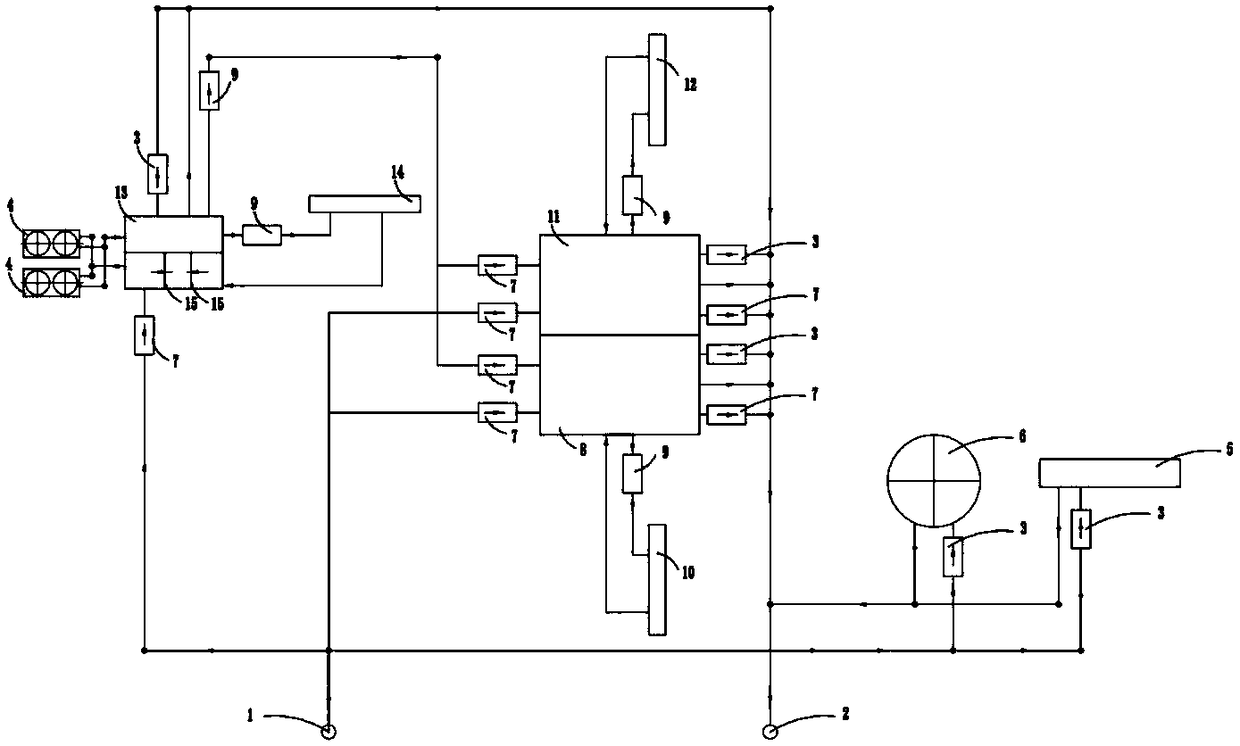

Electric drive fracturing semitrailer with dual engines and dual pumps

PendingCN109882144ARealized pump powerReduce investmentAssociation with control/drive circuitsPositive displacement pump componentsDrive shaftElectrical control

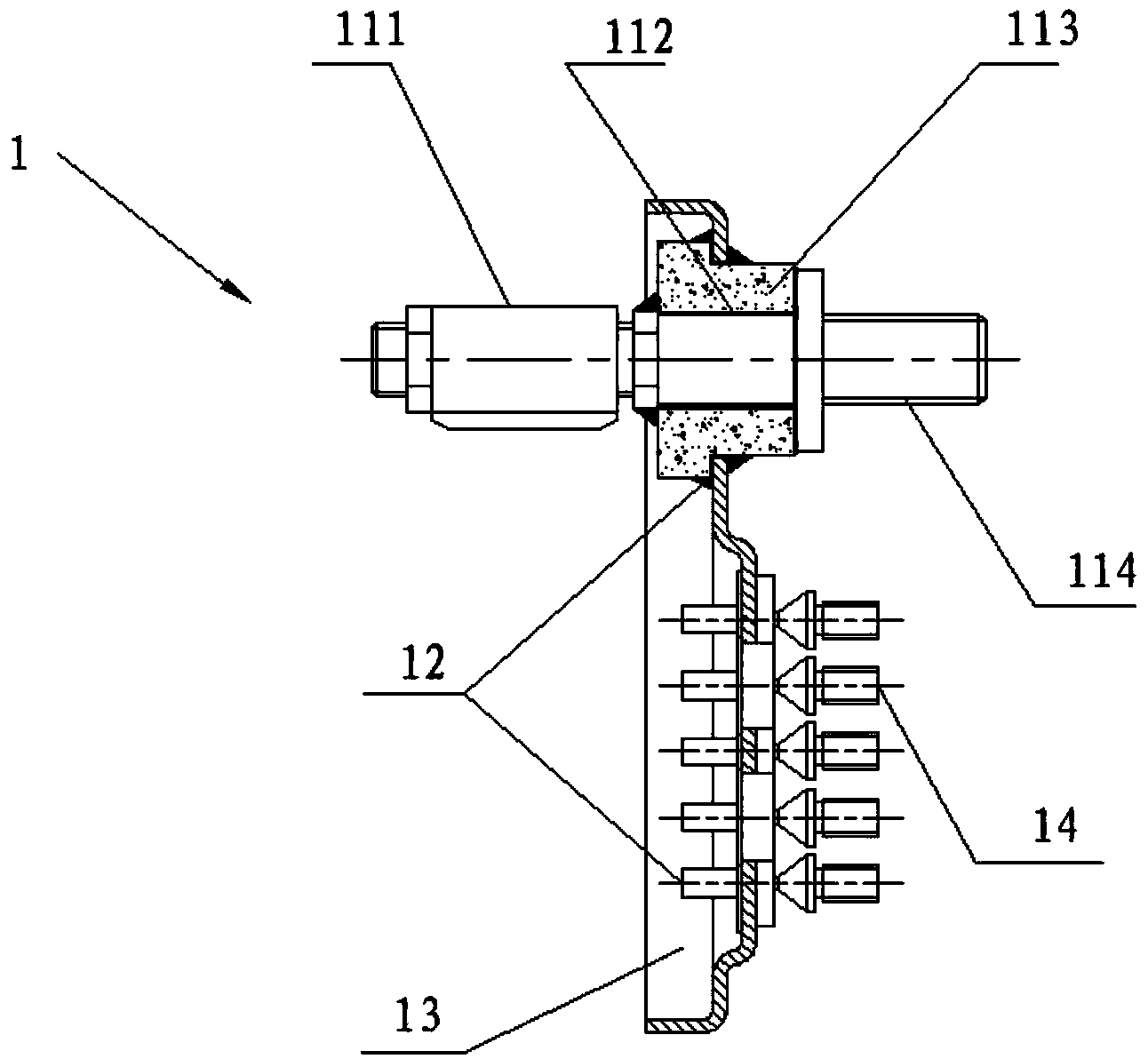

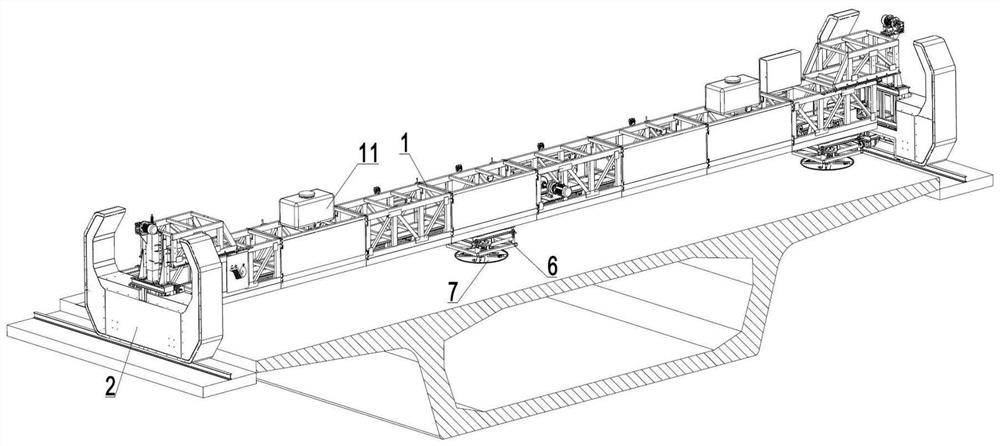

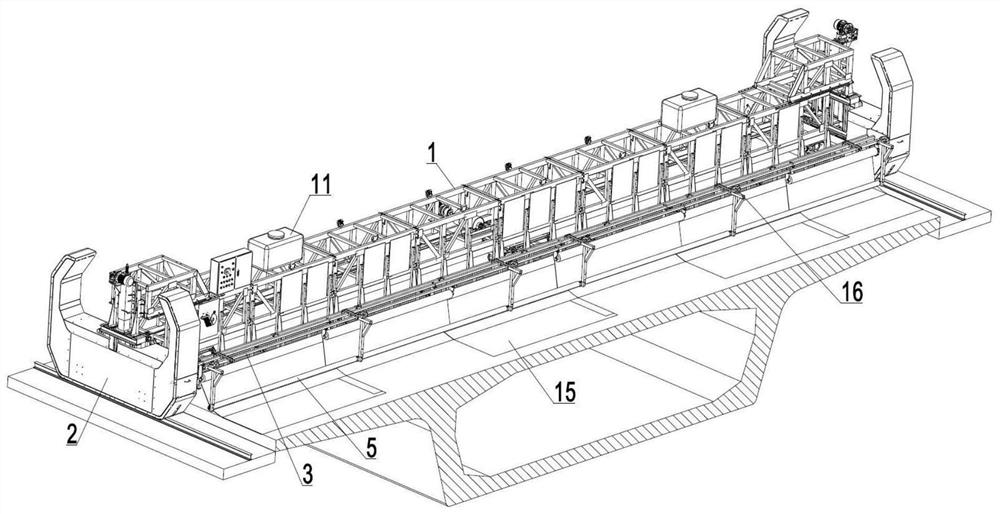

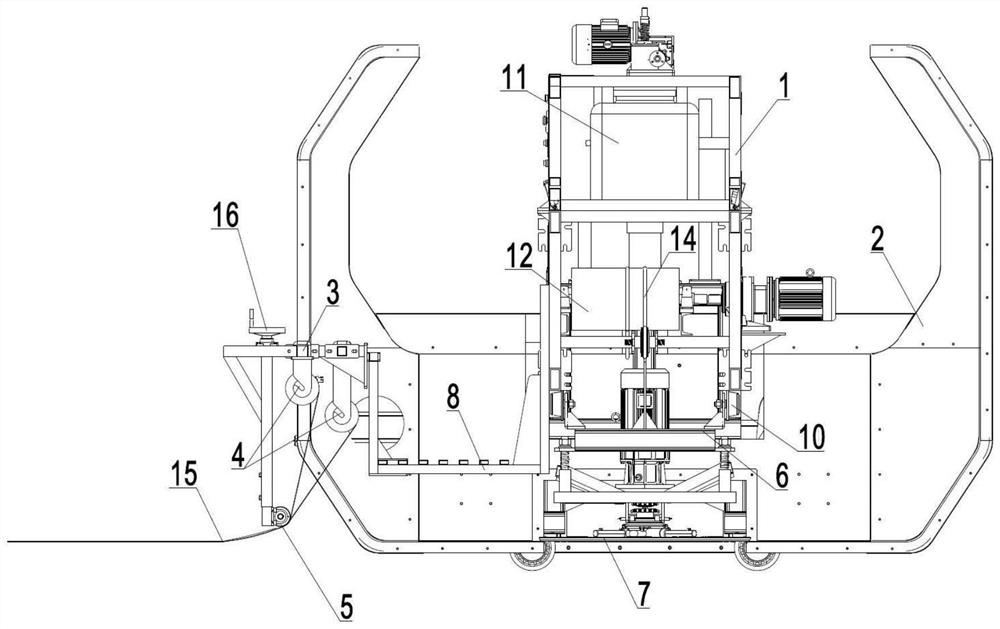

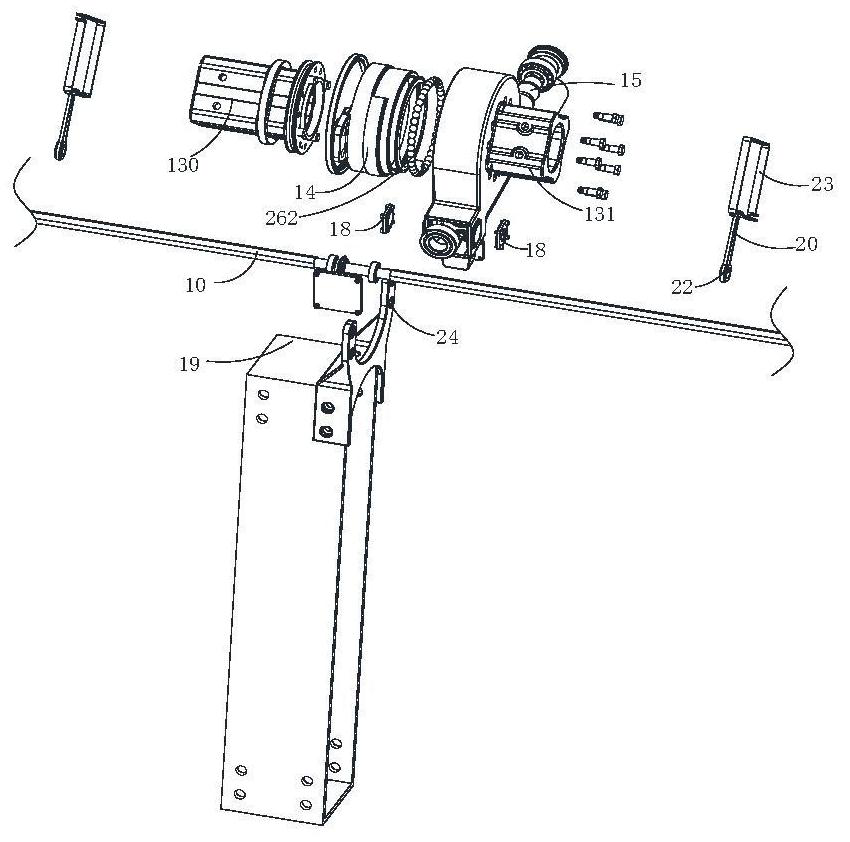

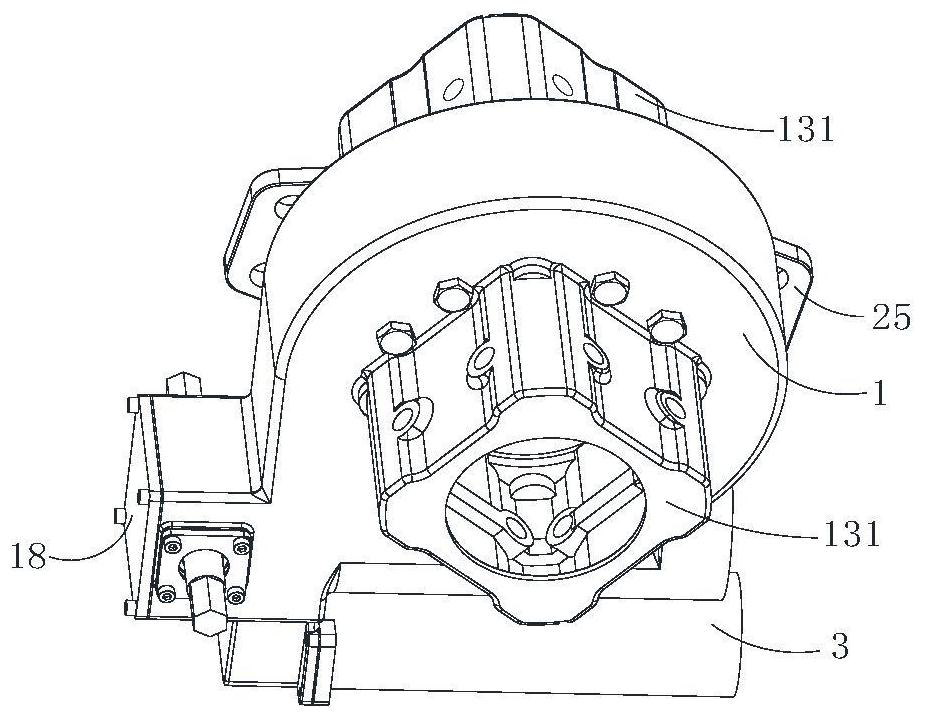

The invention discloses an electric drive fracturing semitrailer with dual engines and dual pumps. The electric drive fracturing semitrailer with the dual engines and the dual pumps comprises a semitrailer body, two plunger pumps, two radiators and an electrical control cabinet. The electric drive fracturing semitrailer with the dual engines and the dual pumps is characterized by further comprising two electromotorsand an inverter unit. The plunger pumps, the radiators, the electrical control cabinet, the electromotors and the inverter unit are integrated in the semitrailer body, the inverterunit is arranged on the gooseneck of the semitrailer body, the output end of the inverter unit individually drives the two electromotors, the other ends of the two electromotors are connected with theplunger pumps correspondingly, lubricating oil of the plunger pumps is cooled through the radiators, and local operation of the electric drive fracturing semitrailer with the dual engines and the dual pumps is realized through the electrical control cabinet. The electric drive fracturing semitrailer with the dual engine and the dual pump has the beneficial effects that the electromotors are adopted to drive the plunger pumps through a transmission shaft, the volume is small, and the economic efficiency, energy conservation and environment protection are achieved. The signal pump power of theplunder pumps is improved, design that the dual pumps are driven by the two electromotors is adopted by the whole fracturing device, the output power of the fracturing device is greatly improved, andthe using requirements are better met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Ferrovanadium nitride alloy and preparation method thereof

This invention is azotize ferro-vanadium and method for making same. The composition of azotize ferro-vanadium is: vanadium 47-81%, nitrogen 8-16%, iron 4-44%, carbon<=1%, silicon<=1.50%, aluminium<=0.01%, manganese<=0.50%, sulfur<=0.05%, phosphor<=0.05%; the method includes following steps: mixing powderedvanadium compound, carbonaceous reducer and ferrous powder, then adding agglomerant, briquetting, putting them into metallurgical furnace with protective atmosphere when they have been dry to do carbon thermal reduction, nitridation and sintered reaction, the temperature of carbon thermal reduction part is: 900-1200DEG C, the temperature of nitridation part is: 1200DEG C-1350 DEG C, the temperature of sintered reaction part is: 1350DEG C-1490DEG C, the total reaction time is: 2-18 hours. This invention simplifies traditional technique, greatly shortens reaction period, reduces the equipment input and cost of production, the obtained products is of stable quality, high vanadium yield, large density, low fusing point in steel application.

Owner:闵小兵

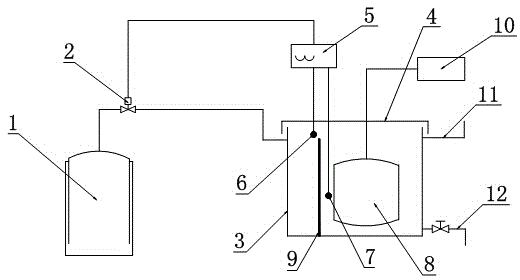

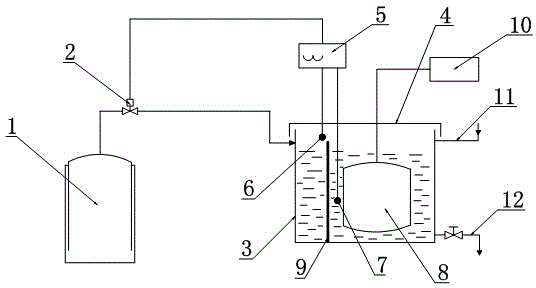

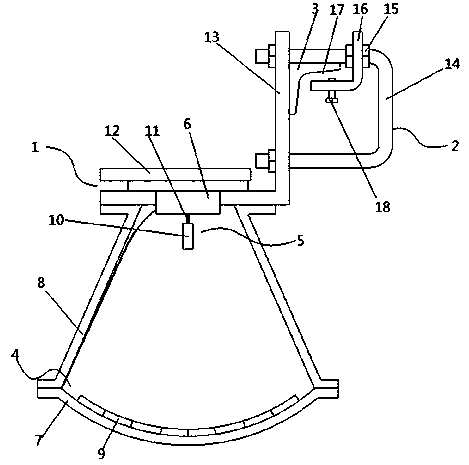

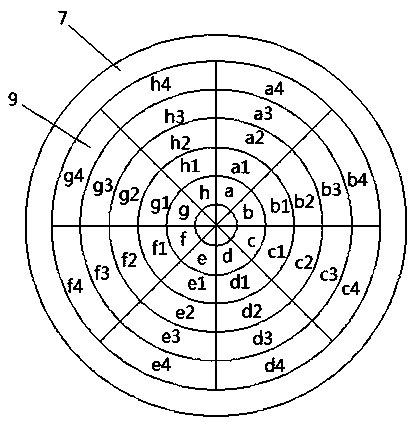

Liquid nitrogen cooling cryogenic device and implementation method for same

ActiveCN104677000AReduce equipment input costsLow running costLighting and heating apparatusCooling fluid circulationProcess engineeringTemperature measurement

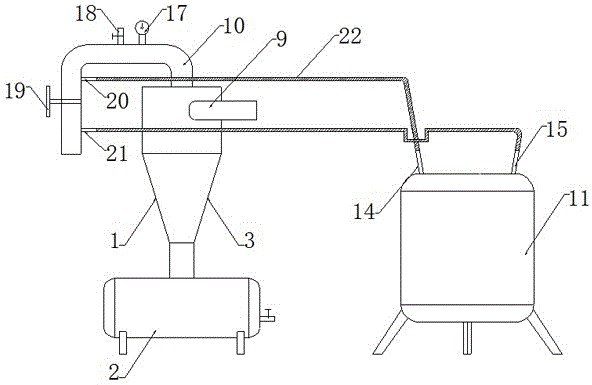

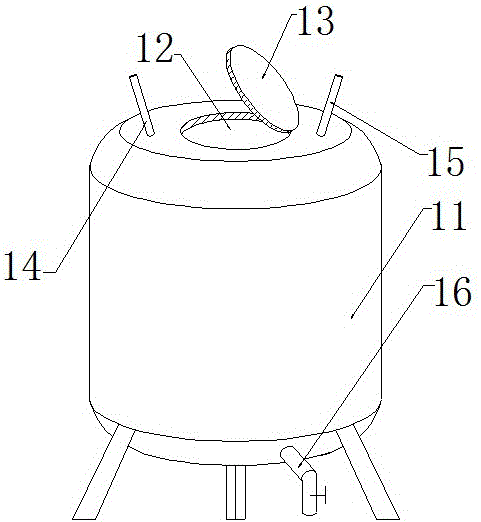

The invention discloses a liquid nitrogen cooling cryogenic device and an implementation method for the same. The cryogenic device comprises a self-pressurization liquid nitrogen tank, a cryogenic container, a liquid nitrogen dedicated cryogenic electromagnetic valve, a temperature control alarm and a sample container, wherein the cryogenic container is connected with a liquid outlet of the self-pressurization liquid nitrogen tank through a liquid nitrogen pipeline; the liquid nitrogen dedicated cryogenic electromagnetic valve is arranged in the liquid nitrogen pipeline; the temperature control alarm is connected with the liquid nitrogen dedicated cryogenic electromagnetic valve, and is provided with a first temperature measurement probe and a second temperature measurement probe; the sample container is arranged in the cryogenic container; both the first and second temperature measurement probes are positioned in the cryogenic container; the second temperature measurement probe is lower than the first temperature measurement probe; an organic matter medium filling pipe and an organic matter medium discharging pipe are further arranged on the cryogenic container respectively. The cryogenic device is simple in structure, low in cost and convenient to control, and has good cryogenic cooling and cryogenic constant temperature control effects, so that the requirements of a miniature cryogenic device in a laboratory can be met, and the requirements of larger-sized engineering operation can further be met.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

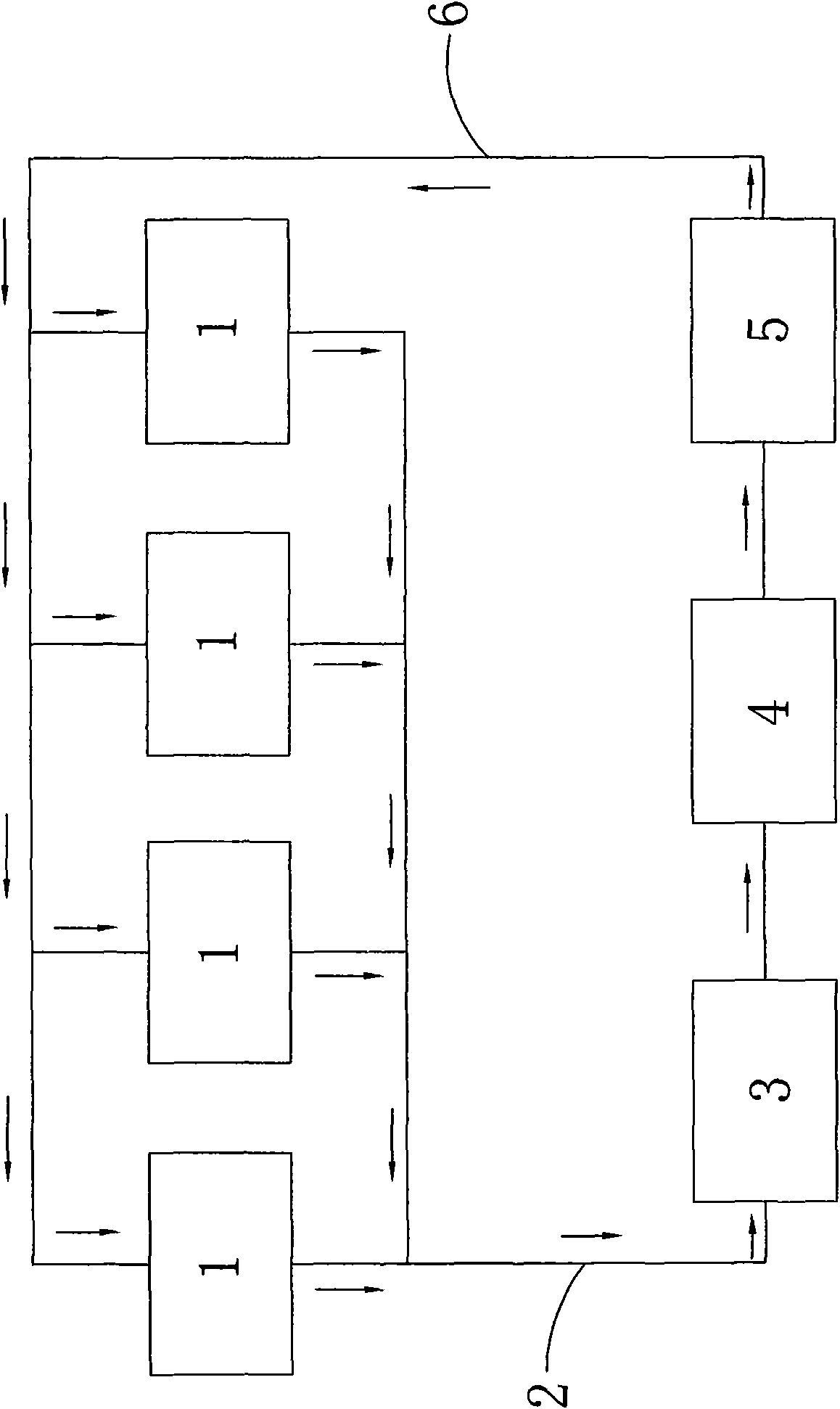

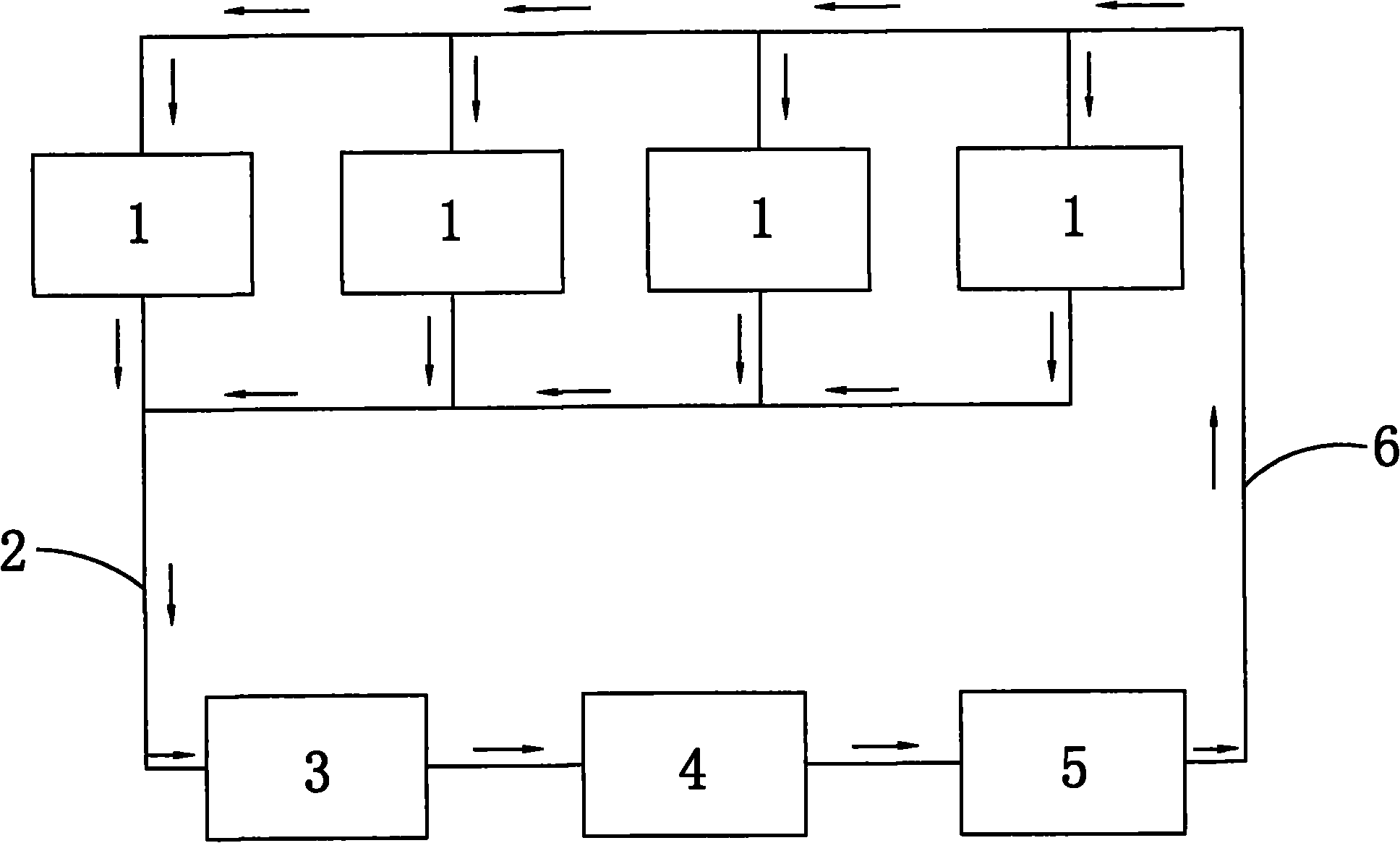

Centralized recovery processing equipment for copper powder of multiple circuit board surface brushing machines

InactiveCN101992423AReduce equipment input costsSave electricity costsFiltration circuitsGrinding/polishing safety devicesFilter cakeCopper

The invention discloses centralized recovery processing equipment for copper powder of multiple circuit board surface brushing machines. Copper-containing wastewater produced by the washing and brushing sections of multiple circuit board surface brushing machines converges and flows into a first pipe and then into a copper powder sedimentation basin through the first pipe; the copper-containing wastewater naturally settles in the copper powder sedimentation basin, and copper powder settles in the bottom of the copper powder sedimentation basin; with the increase of the copper-containing wastewater, the upper part of the copper powder sedimentation basin is relatively clear while the liquid containing copper powder floatage overflows from an overflow port and flows into a pressure filter to be subject to pressure filtering; the pressure filter presses the copper powder floatage into filter cakes and recovers the filter cakes; and the clear water filtered by the pressure filter flows into an overflow water centralization basin, and the clear water in the overflow centralization basin is returned to the washing and brushing sections of the circuit board surface brushing machines to be reused. Circularly used in the such way, the centralized recovery processing equipment for copper powder of multiple circuit board surface brushing machines has the advantages that the cost and labor are saved, the production efficiency and quality are improved and simple structure, low cost and easy implementation are ensured.

Owner:竞陆电子(昆山)有限公司

A silicon-carbon negative electrode material for a lithium ion battery and a preparation process thereof

InactiveCN109088058APrevents CMC from agglomeratingReduce equipment input costsElectrode manufacturing processesSecondary cellsIonSodium carboxymethylcellulose

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation process thereof. The material contains, in percentage by weight, 41 to 48 percent of a silicon-carbon negative electrode, 0.5 to 1 percent of conductive carbon black, 0.5 to 1 percent of instant anionic sodium carboxymethylcellulose, 0.5 to 1.2 percent of butadiene styrene rubber and 50to 57 percent of deionized water. The specific energy of the lithium ion battery manufactured from the negative electrode material of the invention is obviously improved, and the rate discharge capacity is obviously improved.

Owner:河南新太行电源股份有限公司

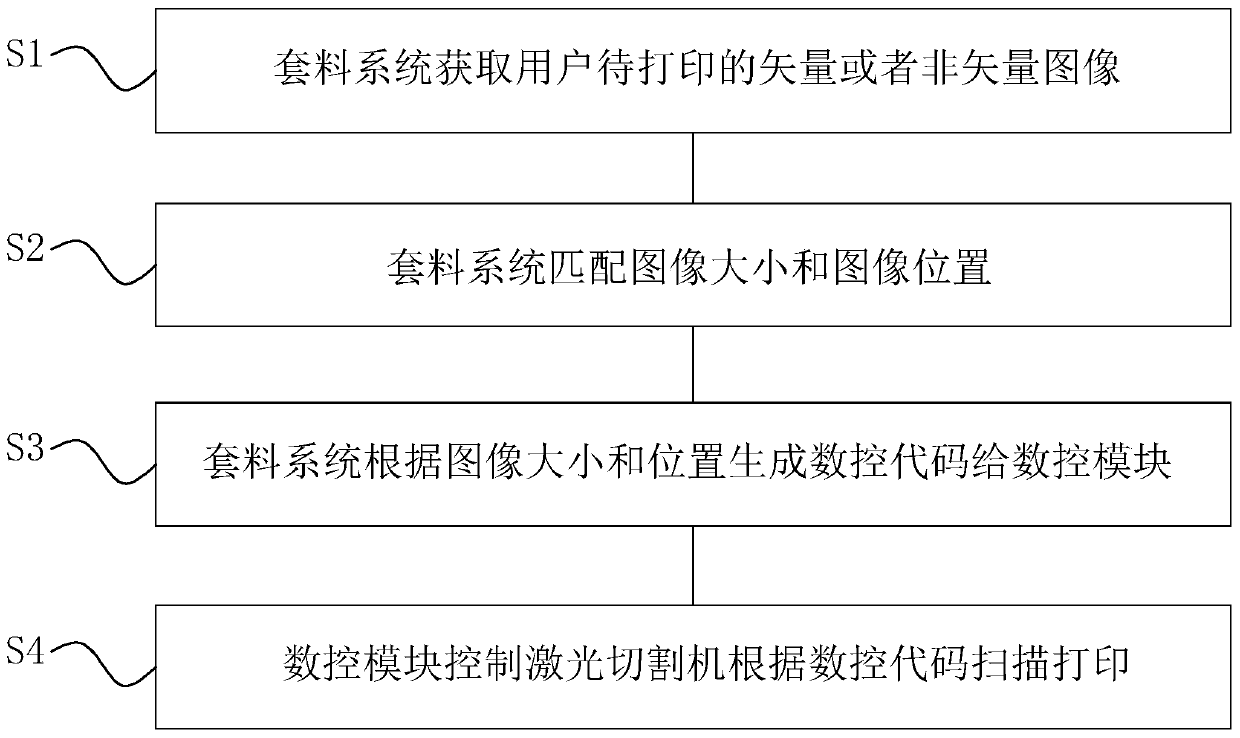

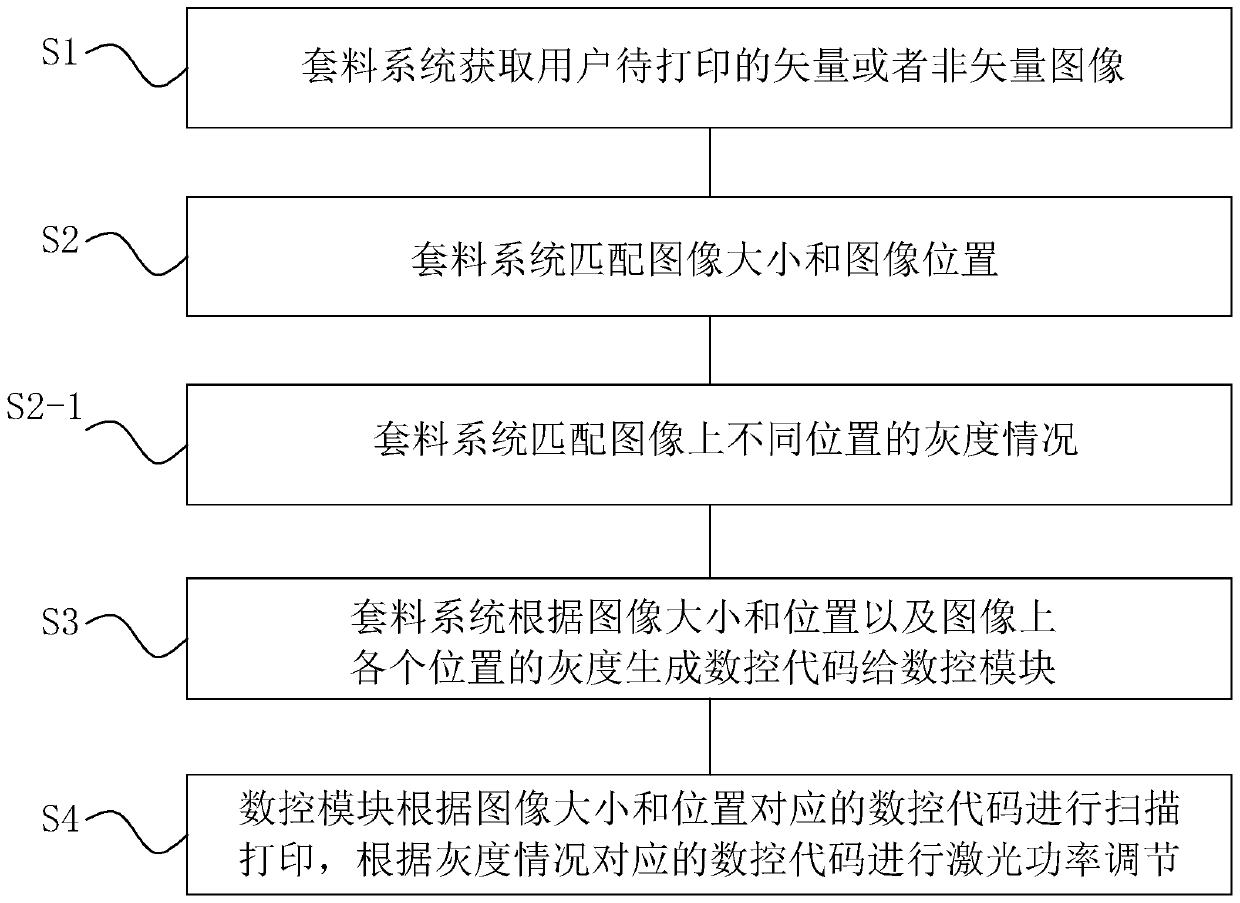

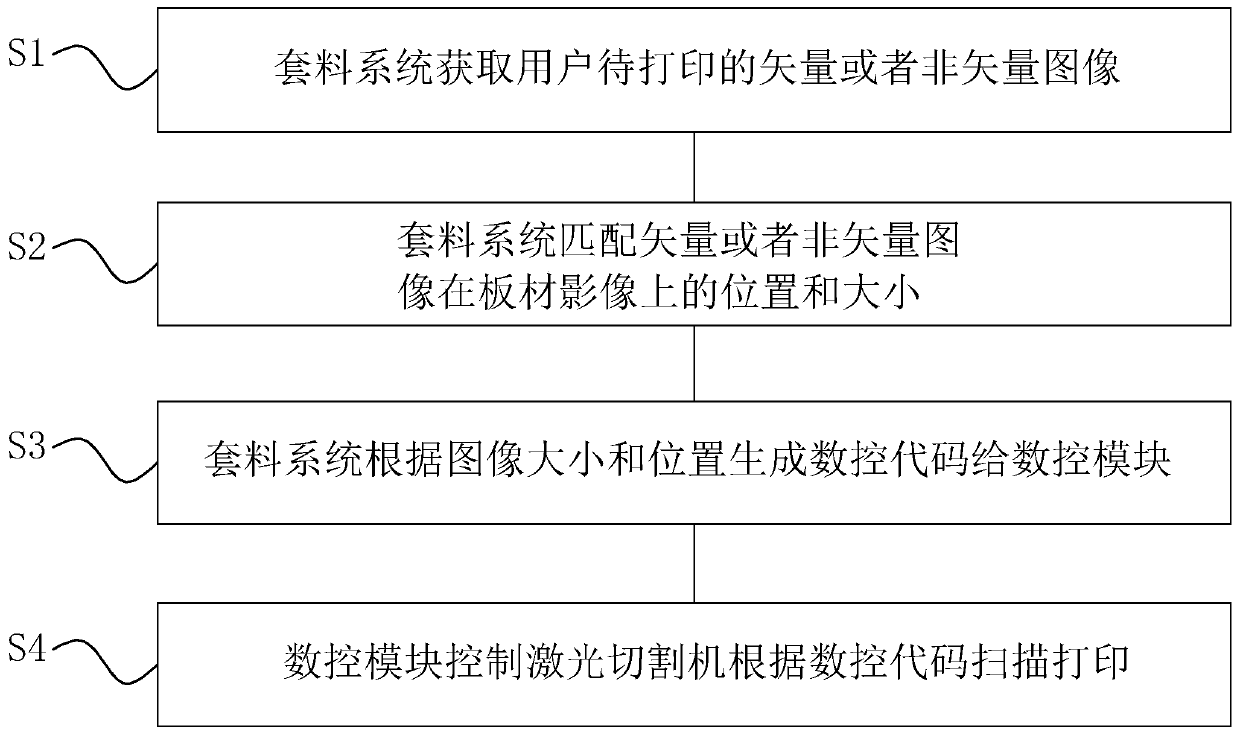

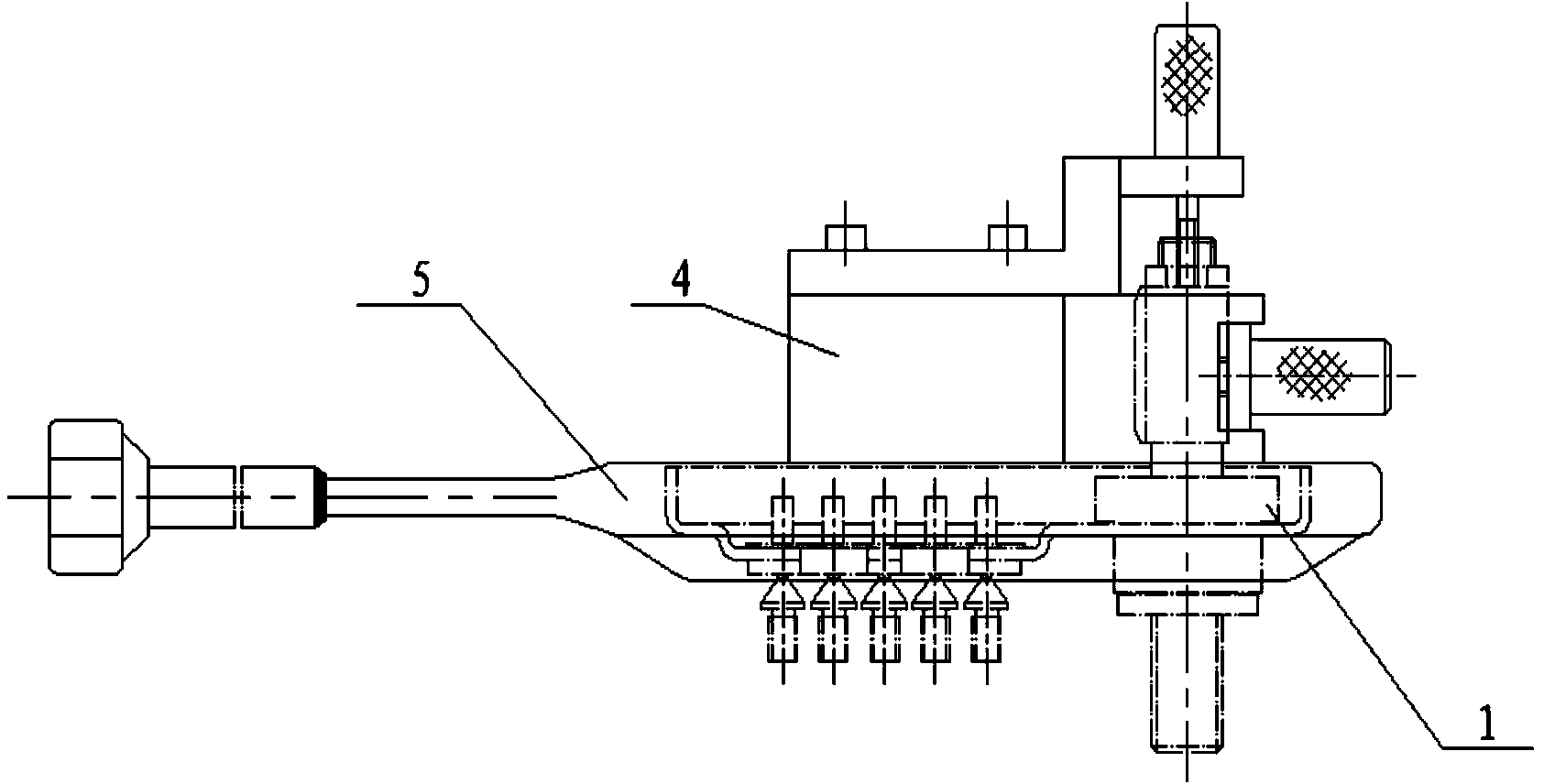

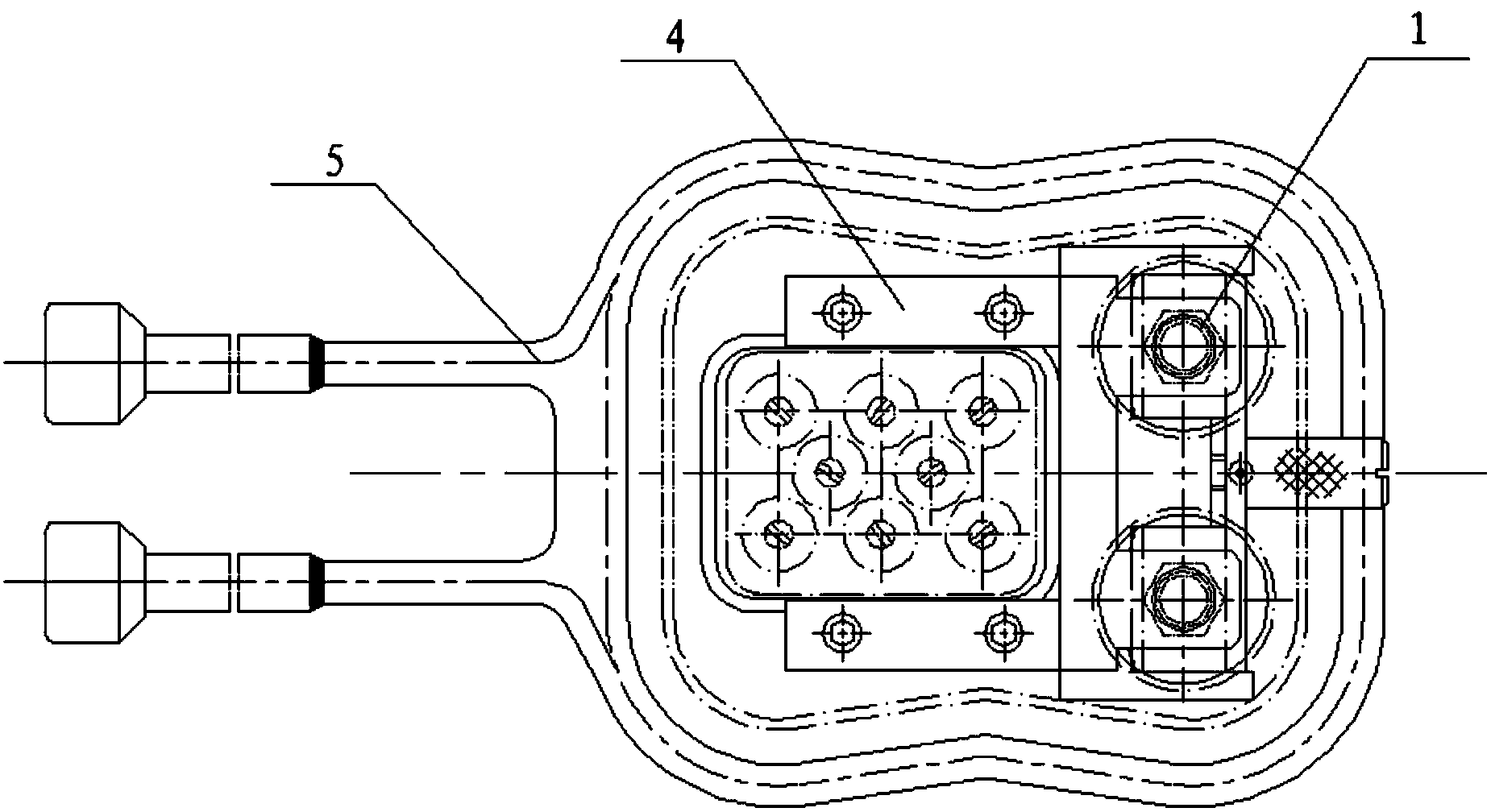

Laser processing method integrating raster scanning, printing and cutting

InactiveCN110465747AReduce equipment input costsImprove efficiency and qualityLaser beam welding apparatusLaser scanningEngineering

The invention discloses a laser processing method integrating raster scanning, printing and cutting.A laser cutting machine, a numerical control module and a nesting system connected with the numerical control module in a communication mode are adopted,the steps for matching the printing between the laser cutting machine, the numerical control module and the nesting system comprise the following steps thatstep 1, the nesting system obtains a vector or a non vector image to be printed by a user; step 2,the nesting system is matched with the image size and an image position; step 3, the nestingsystem generates a numerical control code to the numerical control module according to the image size and the position; and step 4: the numerical module controls the laser cutting machine to scan andprint according to the numerical module code. According to thelaser processing method, the devoted cost of marking equipment can be saved, and efficiency is improved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

Soldering method of seat plate assembly, induction coil for soldering and manufacturing method of induction coil

ActiveCN103551691AReduce welding defectsReduce equipment input costsHeating appliancesMetal working apparatusSolderingDip soldering

The invention relates to a soldering method of a seat plate assembly, an induction coil for soldering and a manufacturing method of the induction coil. The method comprises the following steps of sheathing the induction coil conducted with high-frequency current onto the seat plate assembly with filling solder, and using the heat generated by the induction coil to melt the filling solder so as to seal and solder the seat plate assembly. The method has the advantage that by adopting the high-frequency induction principle, the movement of molecules in a soldering piece is simulated, the heat is generated in the metal to melt the soldering material, and then the soldering piece is welded, so the number of soldering defects is little, the investment cost of equipment is less, the soldering cost is low, the operability is good, and the body health of operators is favorable.

Owner:GUIZHOU TIANYI ELECTRICAL

Surface finishing and film covering all-in-one machine

PendingCN112301897AImprove construction effectReduce equipment input costsBridge structural detailsBridge erection/assemblySurface finishingStructural engineering

The invention relates to a surface finishing and film covering all-in-one machine, and belongs to the technical field of road and bridge construction machinery. The machine comprises a surface finishing part and a film covering part adopting a longitudinal film covering mode; and the surface finishing part comprises a main frame, longitudinal walking mechanisms arranged at the two ends of the mainframe and a troweling surface finishing mechanism arranged at the lower end of the main frame. The longitudinal walking mechanisms are connected with the main frame through a lifting mechanism, and the troweling surface finishing mechanism is driven by a linear moving mechanism to transversely move along the main frame. The film covering part comprises a connecting frame, a maintenance film crossrod and a height-adjustable pressing roller, wherein the connecting frame is arranged behind the main frame, and the maintenance film cross rod is hinged to the pressing roller at the rear end of theconnecting frame; and the maintenance film is sleeved on the maintenance film cross rod and downwards penetrates through the pressing roller to be paved on the concrete surface after surface finishing. According to the machine, integrated construction of trowelling surface finishing and film covering of the concrete pavement can be achieved, film covering maintenance can be conducted in time after trowelling surface finishing, and thus the overall construction effect of the concrete pavement is improved.

Owner:河北星斗机械科技有限公司

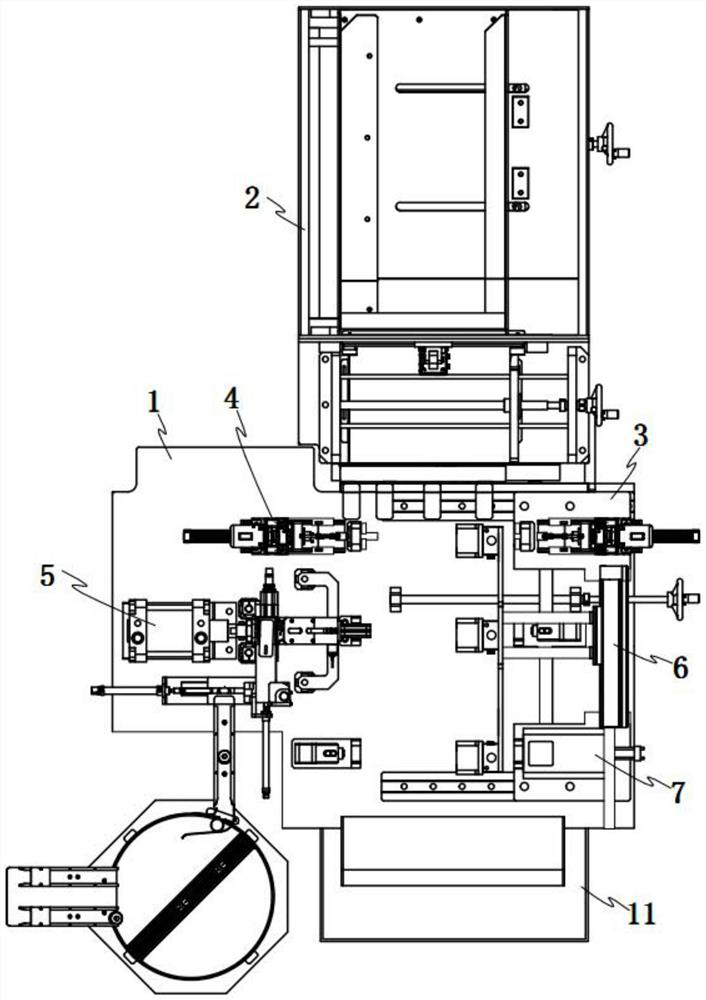

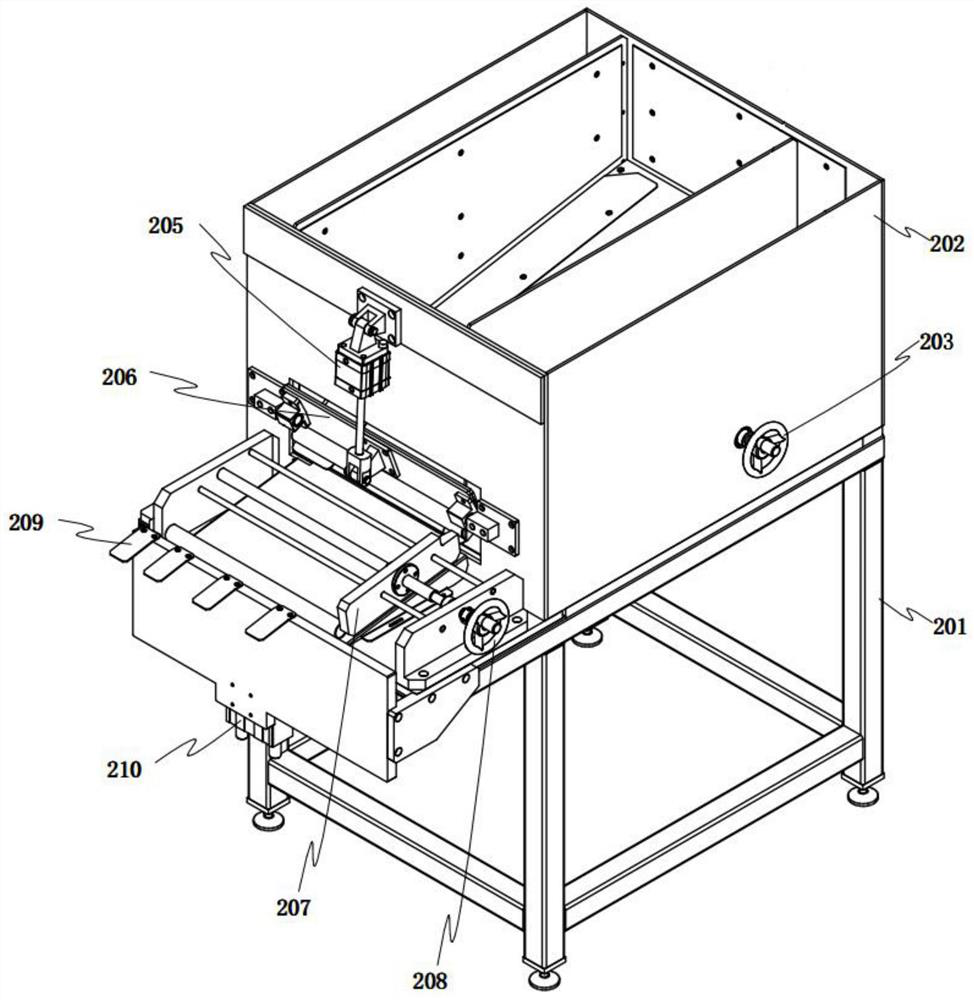

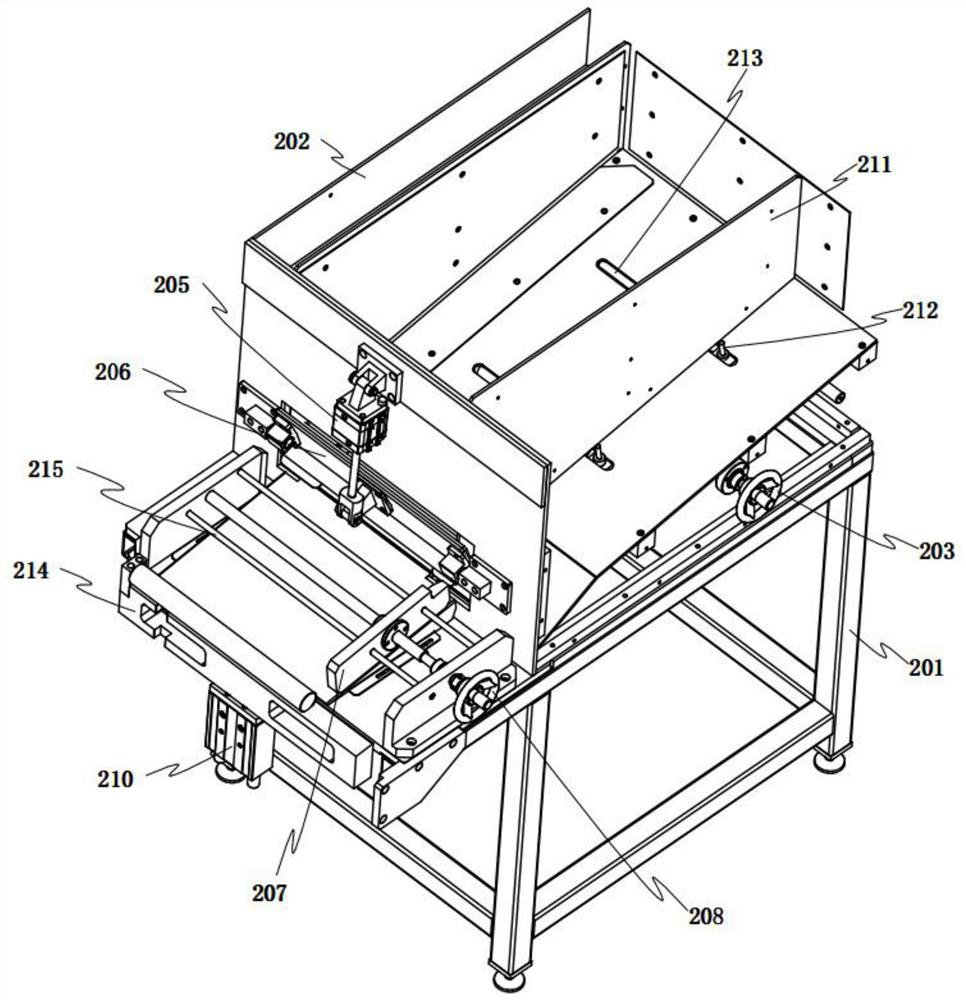

A metal pipe fitting end processing device

ActiveCN112605662BRealize mechanical automation processingImprove processing efficiencyOther manufacturing equipments/toolsPipe fittingEngineering

The invention relates to a metal pipe fitting end processing device, comprising a processing table body, a metal pipe fitting storage and input mechanism is arranged at one end of the processing table body, and a pipe fitting storage frame is arranged at the other side, and the table top of the processing table body is arranged in sequence There are pipe fitting processing support seat I, pipe fitting processing support seat II and pipe fitting processing support seat III. The opening sealing mechanism, and the side part of the pipe fitting processing support seat III is provided with an end drilling mechanism fixed on the position adjustment mechanism. The invention realizes the mechanical automatic processing of grinding the inner and outer pipe walls of the metal pipe fitting port, port drilling and pipe mouth sealing. At the same time, the processing device can be adjusted according to the length of the pipe fitting to meet the processing requirements of pipe fittings of different lengths, which not only improves the processing efficiency of pipe fittings , reducing labor and equipment input costs, and reducing the impact of human factors.

Owner:沧州东海电力管件有限公司

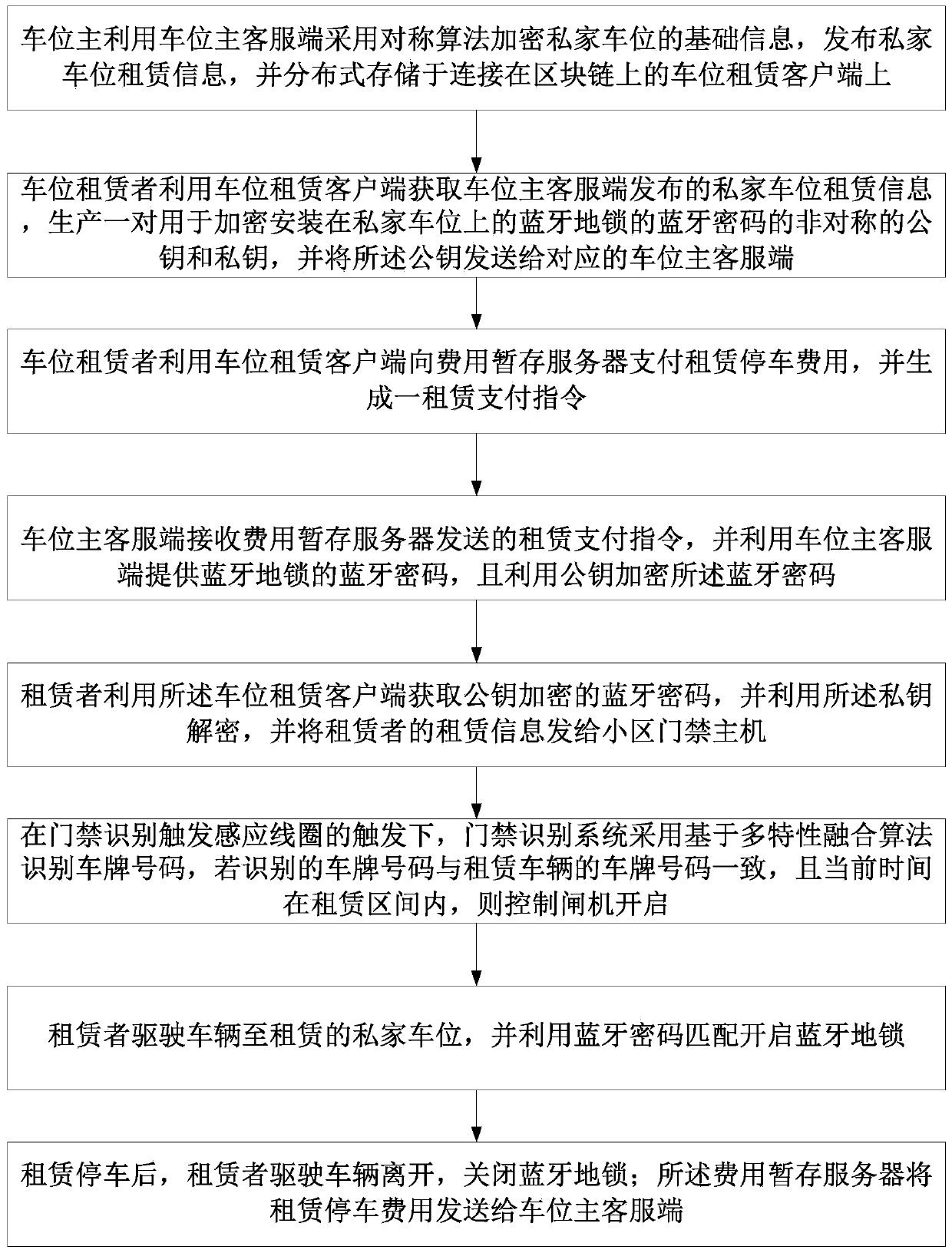

Private parking space renting comprehensive management system based on block chain and implementation method of system

InactiveCN110176082ASimple structureReduce equipment input costsKey distribution for secure communicationTicket-issuing apparatusParking spaceEngineering

The invention discloses a private parking space renting comprehensive management system based on a block chain. The system comprises a plurality of parking space renting clients which are used for acquiring information about to-be-rented private parking spaces and applying for renting the idle private parking spaces, a plurality of parking space main customer service sides which are used for publishing parking space renting information, a Bluetooth ground lock which is arranged on the private parking space corresponding to a parking space owner and is used for opening or closing under the pairing of a Bluetooth password, a community access control host which is used for receiving the information of the rented vehicle, an entrance guard identification system which is used for identifying the license number of the rented vehicle based on a multi-feature fusion algorithm, an entrance guard identification triggering induction coil which is pre-buried in an entrance and exit of a communitydoor, a gate which is in communication connection with the entrance guard identification system, a timing device which is in communication connection with the entrance guard identification system, anda temporary fee storage server which is respectively connected to the parking space renting clients and the parking space main customer service sides. The system has the advantages of being simple instructure, low in equipment investment cost, high in private parking space utilization rate and the like.

Owner:博生(广州)信息科技有限公司

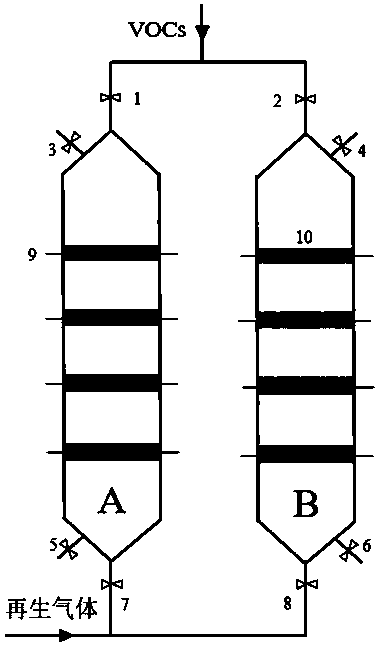

Novel regeneration method for VOC (volatile organic compound) adsorbent

ActiveCN108745328ALow running costReduce equipment input costsGas treatmentDispersed particle separationVolatile organic compoundIndustrial waste

The invention provides a novel regeneration method for a VOC (volatile organic compound) adsorbent, and belongs to the new technical field of control of atmospheric pollutants. Industrial waste gas containing NOx, SOx and CO is taken as regeneration gas, and regeneration of the adsorbent with saturated adsorption of VOCs is completed at lower temperature. According to the reaction mechanism, the VOCs are adsorbed on the adsorbent, content of functional groups on the adsorbent surface is increased by 50%-200%, the reduction effect of the adsorbent is enhanced, then the regeneration gas is introduced, a reaction is performed to enable the VOCs to be mineralized into CO2, so that the purpose of adsorbent regeneration is achieved, and the regeneration gas can be recycled for adsorbent regeneration. Specific surface area loss amount of the adsorbent regenerated with the method is smaller than 0.05%; average pore size reduction amount is smaller than 0.3%; mass loss amount of the adsorbent is smaller than 0.1%, and the discharged industrial waste gas meets the green emission standards, and the process is a novel, simple and efficient method for regenerating the VOC adsorbent.

Owner:SHANGHAI UNIV

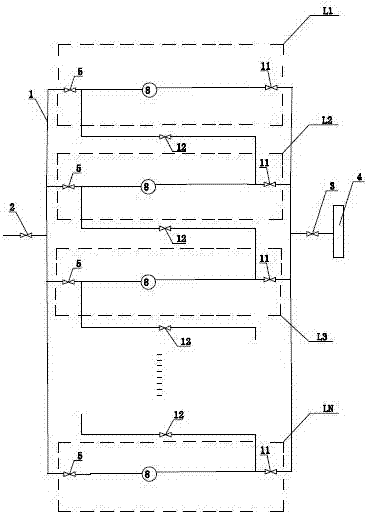

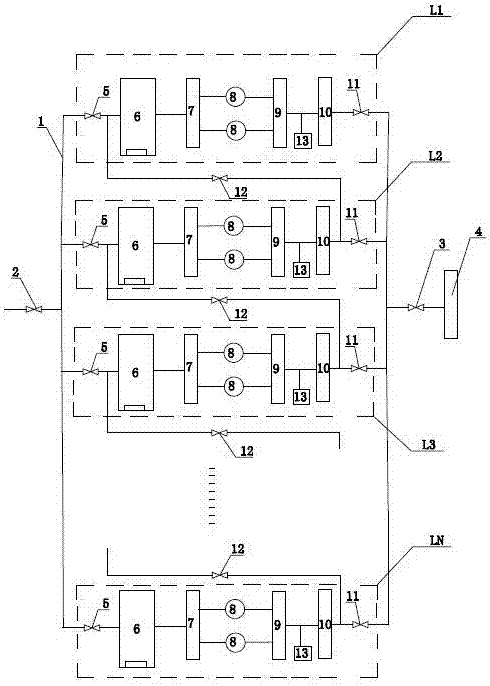

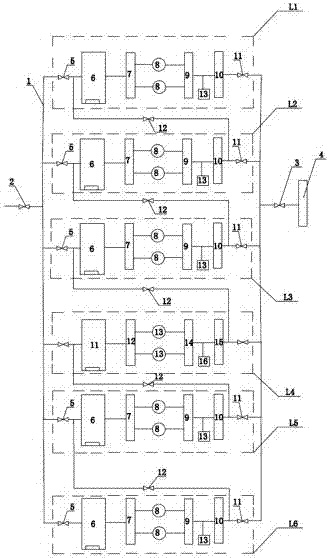

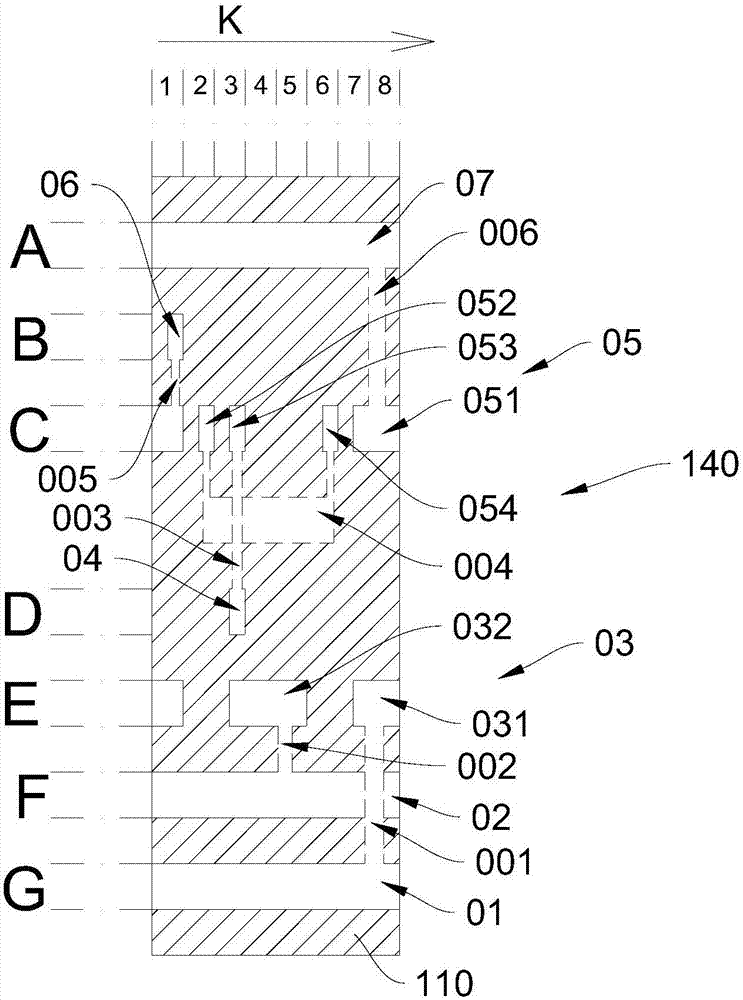

Compression level switchable compressor and use method thereof

InactiveCN106930927AExpand the scope of applicable working conditionsReduce equipment input costsPositive displacement pump componentsPipeline systemsParallel compressionComputer engineering

The invention discloses a compressor with switchable compression stages and a method for using the same, comprising a pipeline, an inlet valve and an outlet valve are arranged on the pipeline, and N parallel compressors are arranged on the pipeline between the inlet valve and the outlet valve. Pipelines, N≥2, each compression pipeline is provided with a front valve, a compression cylinder, and a rear valve in sequence; there is also a series-parallel regulating valve between any two adjacent compression pipelines, and the series-parallel regulating valve is located in the pipeline. One end is connected to the pipe between the compression cylinder and the rear valve of one of the compression lines, and the other end is connected to the pipe between the compression cylinder and the front valve of the other compression line. The compressor of the present invention can realize compression level switching.

Owner:SHANDONG KERUI COMPRESSOR

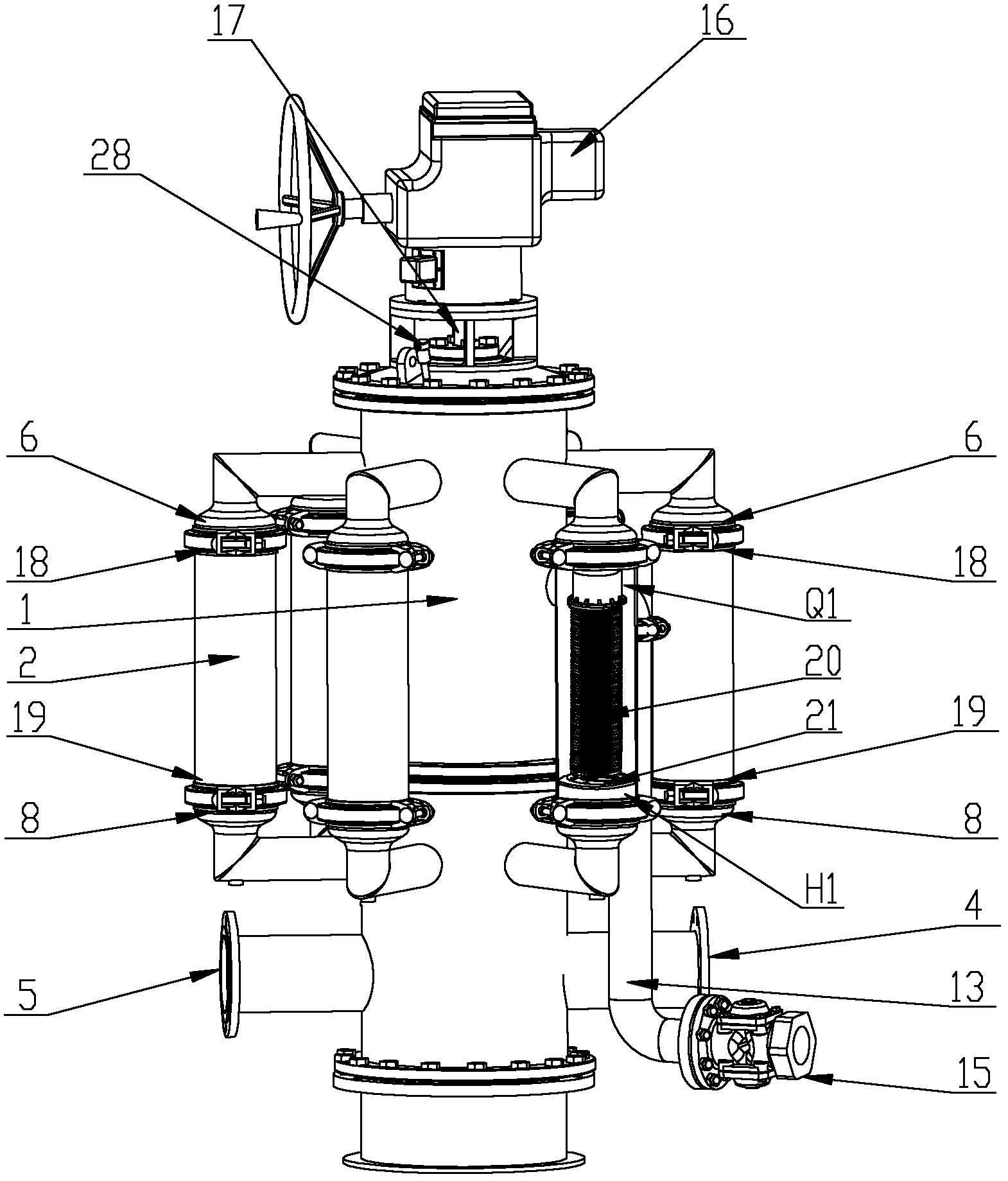

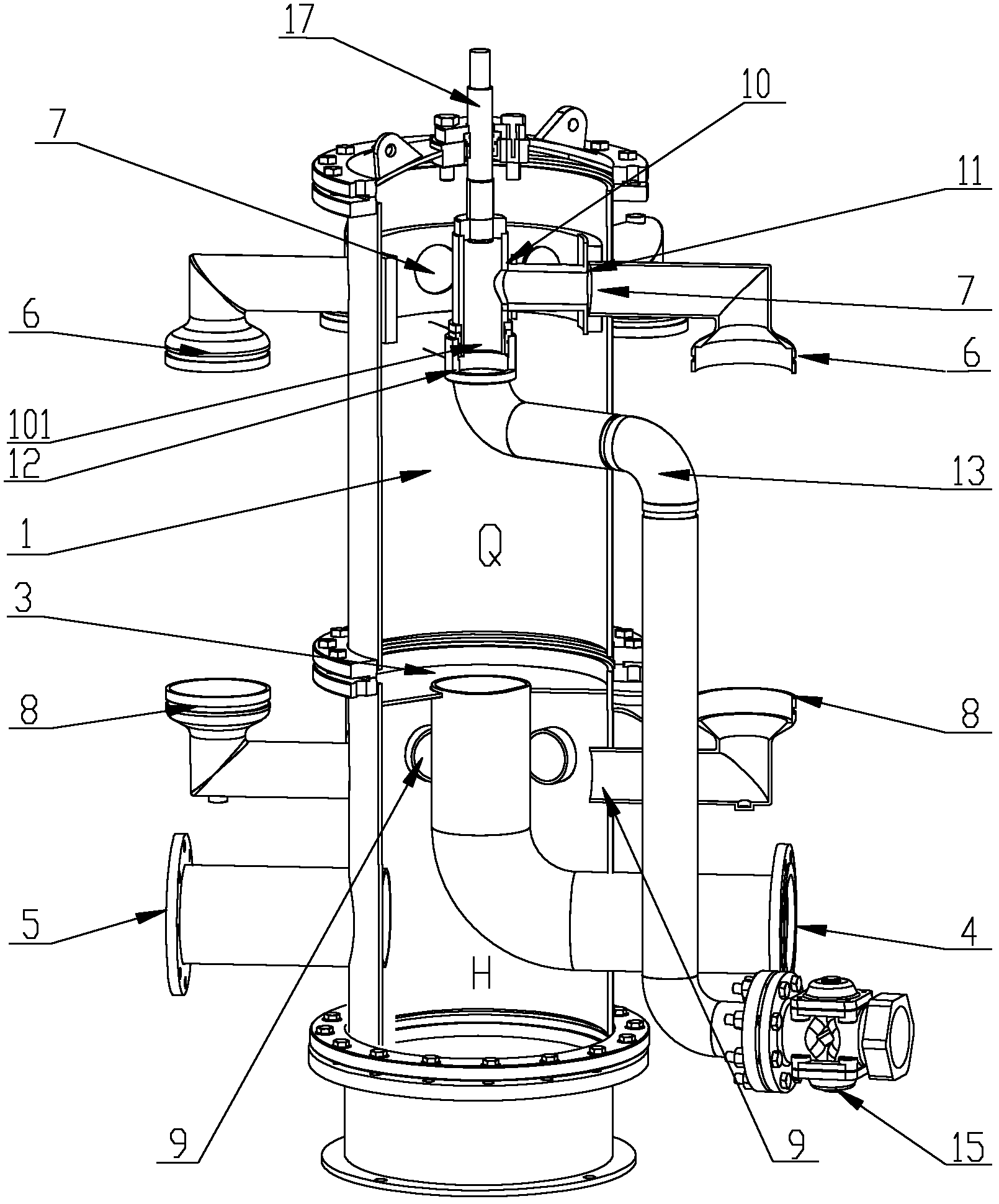

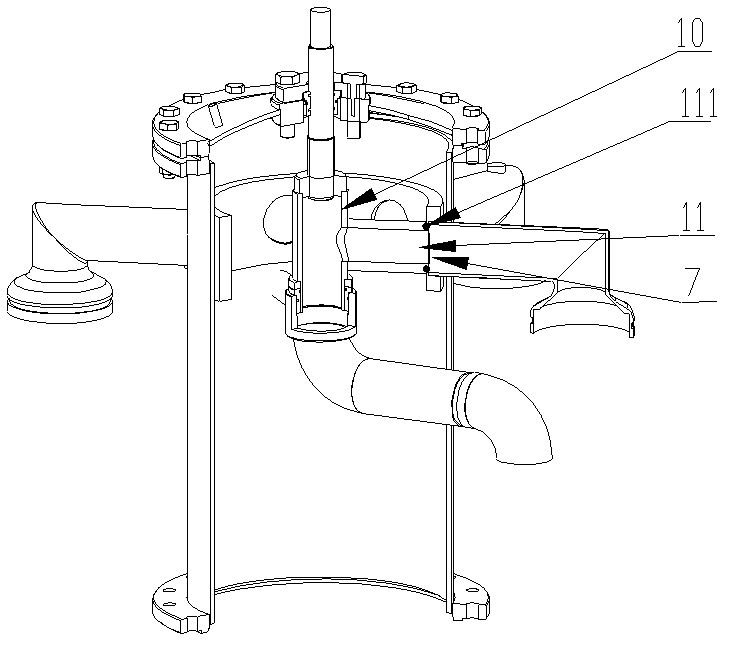

Back cleaning filter having filtration units on the outer side of device body

ActiveCN102921220AReduce equipment input costsSolve maintenance troublesDispersed particle filtrationStationary filtering element filtersHigh pressureFiltration

The present invention relates to an apparatus for filtering a fluid medium conveyed by a pipeline, specifically to a back cleaning filter having filtration units on the outer side of a device body, wherein the back cleaning filter is provided for carrying out filtering and back cleaning on impurities in a medium. The back cleaning filter mainly comprises a device body and n filtration units, wherein a unit inlet of the filtration unit is connected with an outlet interface of the device body through a connection member, a unit outlet is connected with an inlet interface of the device body through a connection member, the N outlet interfaces are correspondingly communicated with n cavity outlets through pipelines, filtration cores are arranged inside the filtration units, the device body is provided with a sewage discharge device and a sewage collection device, the sewage discharge device is provided with sewage suction ports, the device body is provided with a sewage discharge pipeline, the sewage discharge pipeline is communicated with the sewage discharge device and the sewage suction port through the sewage collection device, and a driving device is arranged on the outer side of the device body, and acts to drive the sewage discharge device, such that the sewage suction ports are individually aligned to the N cavity outlets. With the present invention, problems of trouble maintenance, more control elements, complex control, high failure, high maintenance rate and even incapable use in high temperature and high pressure environments, and the like of the back cleaning filter are solved.

Owner:罗兰德流体控制(营口)有限公司

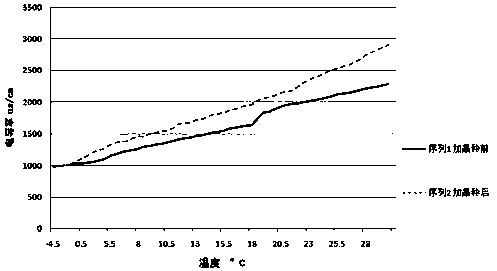

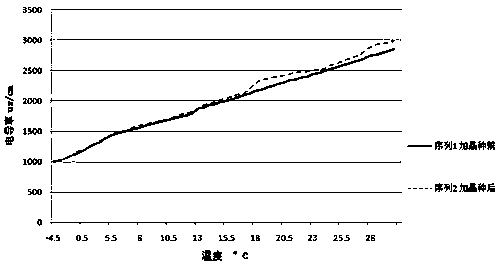

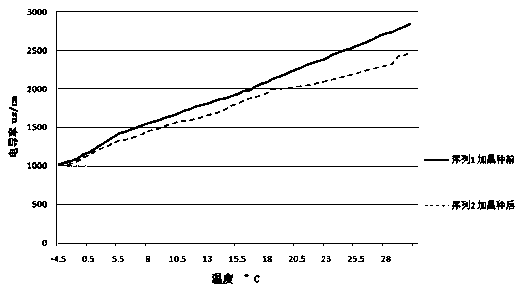

Method for detecting stability of potassium hydrogen tartrate in wine

ActiveCN109342433AImprove accuracyReduce equipment input costsMaterial analysis by optical meansChemistryTartrate

Owner:COFCO GREAT WALL WINE YANTAI

Method for performing pre-desiliconization on molten iron by utilizing CAS-OB refining furnace

ActiveCN104419798AReduce equipment input costsReduce site occupancyProcess efficiency improvementSlagFerrosilicon

The invention discloses a method for performing pre-desiliconization on molten iron by utilizing a CAS-OB refining furnace. The method comprises the following steps of performing desiliconization treatment on molten iron by utilizing the existing CAS-OB refining furnace of a steel plant, providing low-silicon molten water for a converter or an electric furnace. The special process is as follows: performing slagging-off treatment on the molten iron by adopting a special high-temperature-resistant magnesia carbon brick molten iron tank for desiliconization, blowing oxygen gas or air by utilizing a spray gun above an immersion cover of the refining furnace, controlling the flow rate to 5-10Nm<3> / h.t, stopping blowing gas from the top spray gun when a slag layer reaches 30-80mm, opening a bottom-blowing gas valve to blow gas and stir, wherein the gas flow rate is 80-100Nm<3> / h; descending the cover after removing the slag layer, blowing oxygen gas or air by adopting the spray gun above the immersion cover to control the flow rate to 5-10Nm<3> / h.t, and transporting the molten iron to a slag removing position to remove the slag. According to the method disclosed by the invention, desiliconization is performed on the molten iron by utilizing the original refining furnace of the plant, so that a great deal of equipment investment cost and the occupied space are saved, and efficient low-cost production of low-silicon molten iron is realized.

Owner:ANGANG STEEL CO LTD

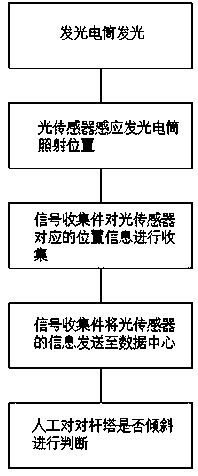

Online tower inclination monitoring device and monitoring method thereof

PendingCN110657793ASimple equipment structureReduce equipment input costsReference line/planes/sectorsEmbedded systemEngineering

The invention provides an online tower inclination monitoring device and a monitoring method thereof. A monitor and a fixing frame fixedly connected with the monitor are included; the monitor comprises an induction compass assembly, a signal generation assembly and a signal collection part; and the induction compass assembly is fixedly connected with the fixing frame, both the signal generation assembly and the signal collection part are both fixedly installed on the induction compass assembly, the induction compass assembly is fixedly connected with the fixing frame, the signal generation assembly is adapted to the induction compass assembly, the signal generation assembly is used for sending a signal, the induction compass assembly is used for sensing the signal sent by the signal generation assembly, the signal collection part is electrically connected with the induction compass assembly, and the signal collection part is used for collecting signals received by the induction compassassembly. The monitoring device is simple in structure, can effectively reduce the equipment cost for online monitoring, and reduce the operation cost.

Owner:HARBIN UNIV OF SCI & TECH

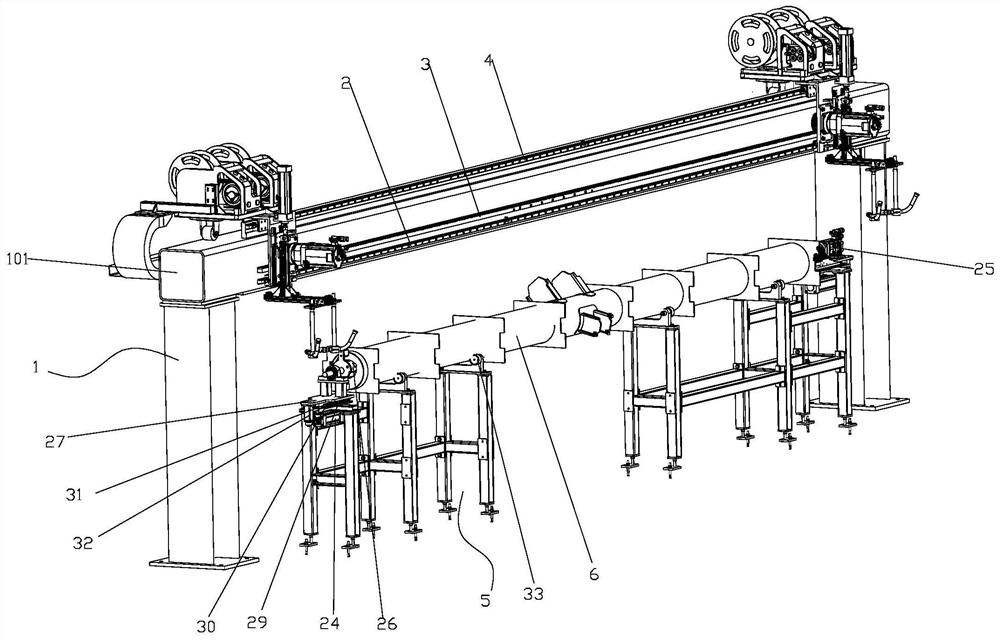

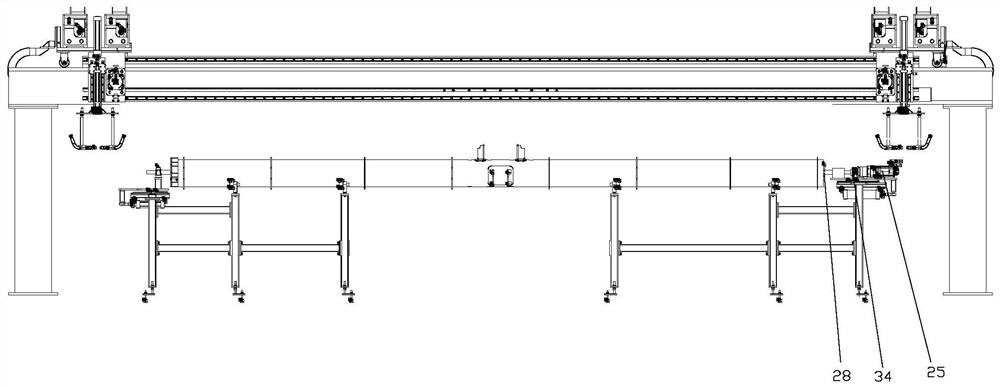

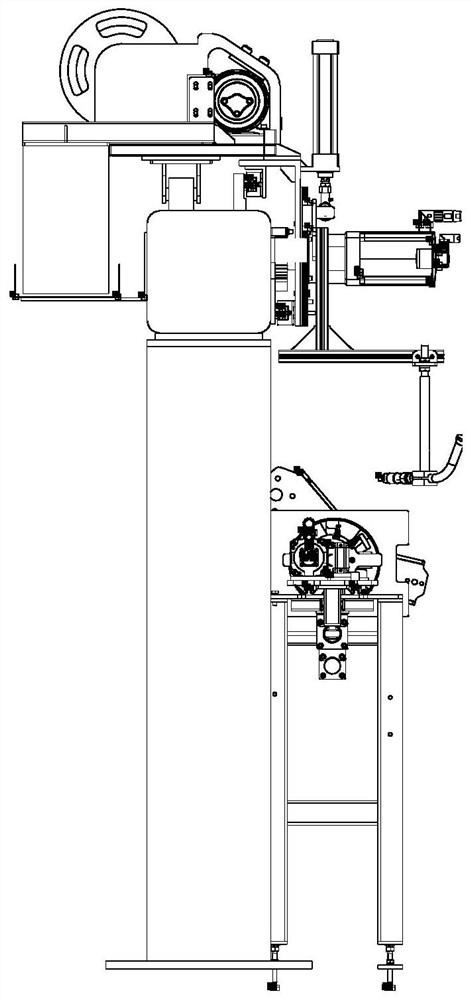

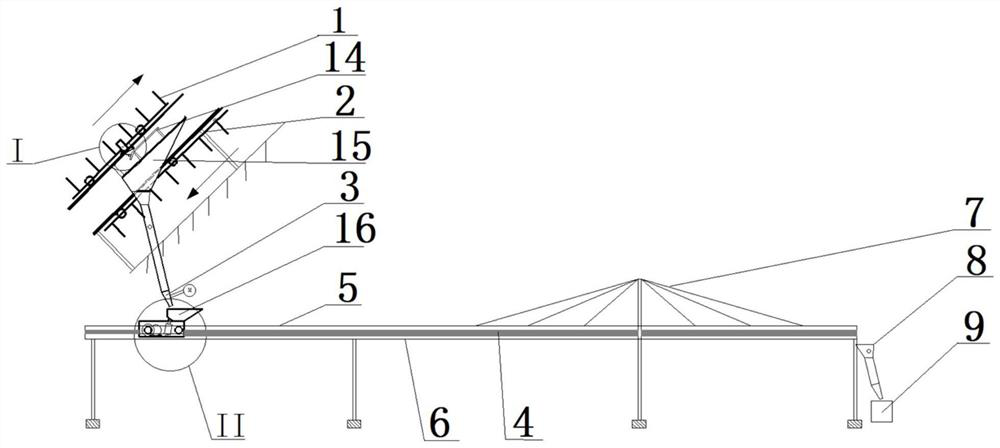

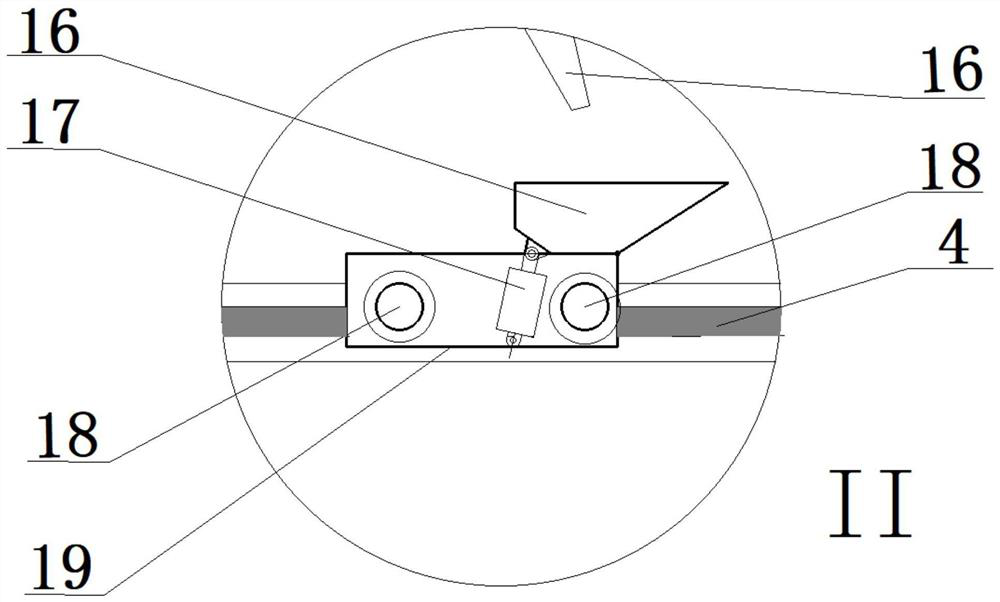

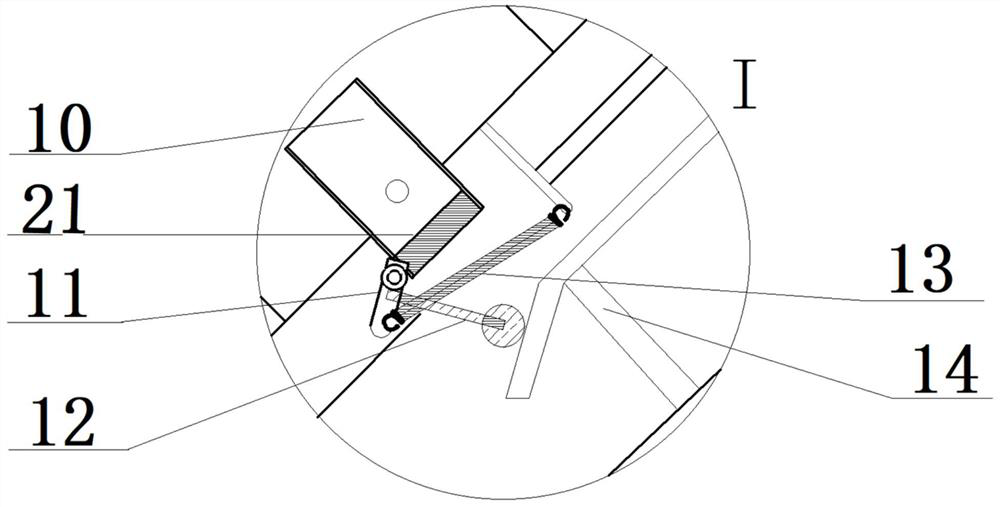

Special double-head automatic welding machine for welding strut beams of heliostat support main beam

PendingCN112427846ARealize automatic welding processShorten welding timeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The embodiment of the invention provides a special double-head automatic welding machine for welding strut beams of a heliostat support main beam. The machine comprises a gantry frame, welding gun clamping fixing devices, welding gun lifting devices, wire feeder fixing devices and rotary position-changing mechanisms, wherein a guide rail and a rack are arranged on the side face of a main crossbeamof the gantry frame, a first guide rail is arranged at the top of the main crossbeam, the welding gun lifting devices are mounted on the main crossbeam of the gantry frame, the wire feeder fixing devices are mounted on the gantry frame, the top of each welding gun lifting device is fixed to the corresponding wire feeder fixing device, each welding gun clamping fixing device is mounted at the bottom of the corresponding welding gun lifting device, two fixing frames are arranged at the two sides of the gantry frame, a workpiece is placed on the two fixing frames, and the rotary position-changing mechanisms are mounted on the two fixing frames and are connected with the two ends of the workpiece. On the basis of guaranteeing the welding quality, the welding speed is increased, and the laborintensity of workers is reduced.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

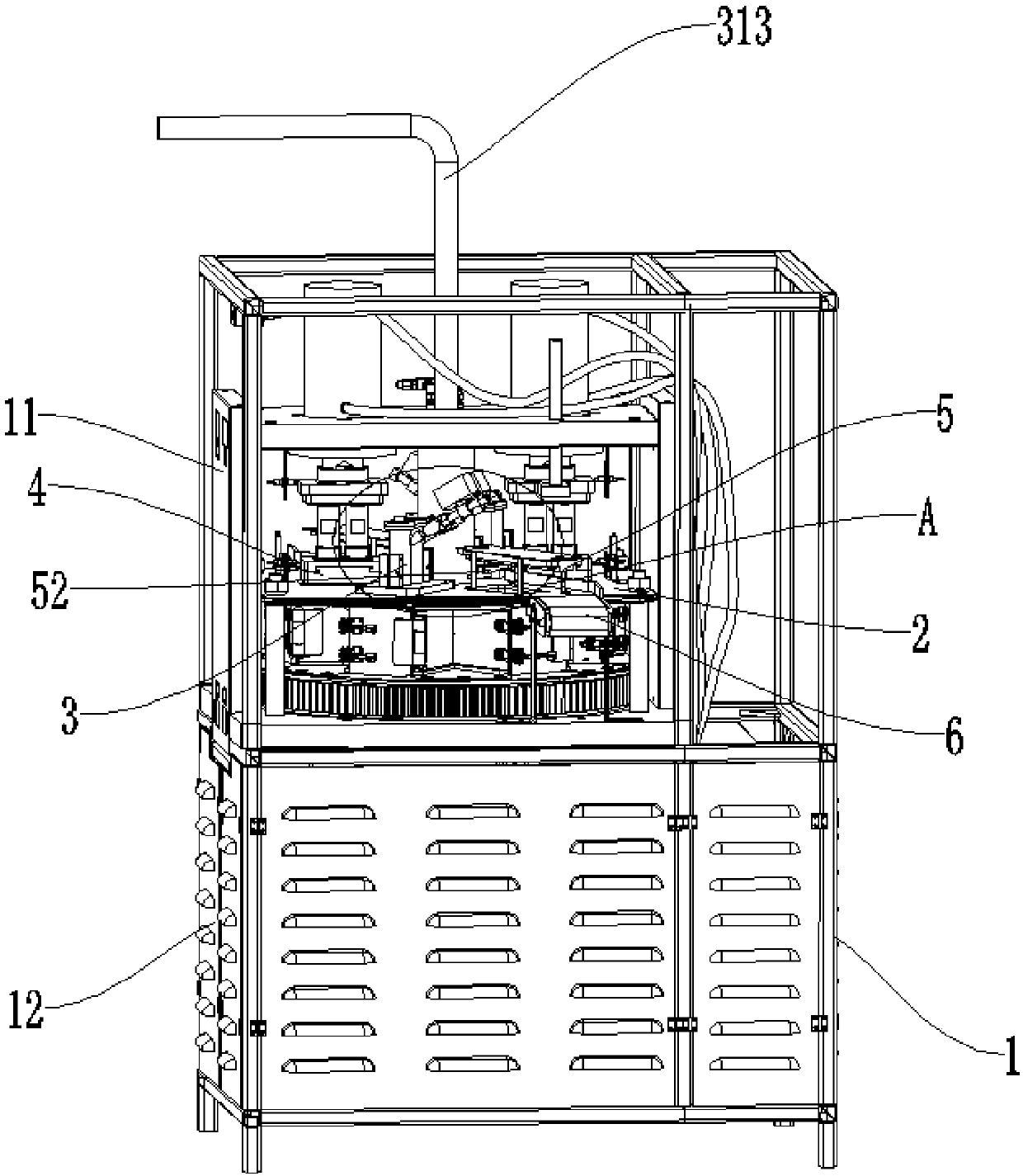

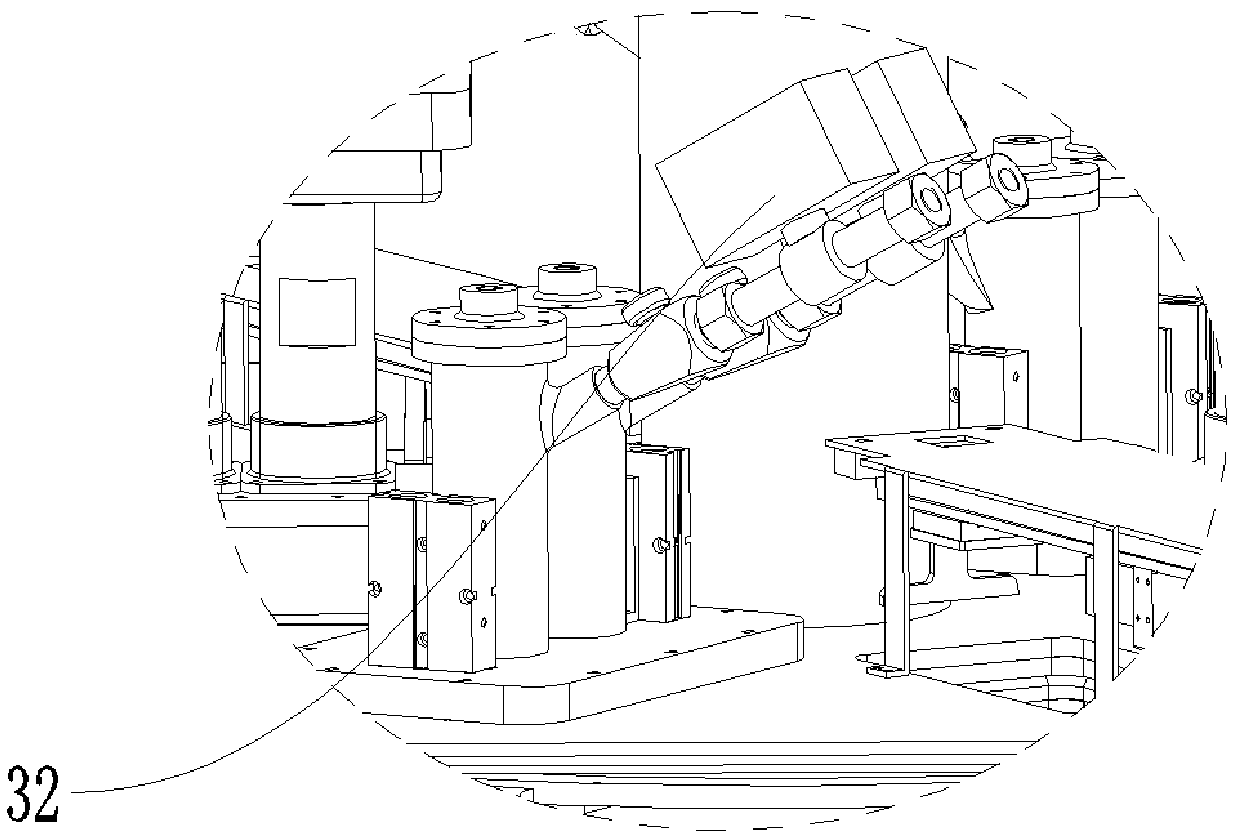

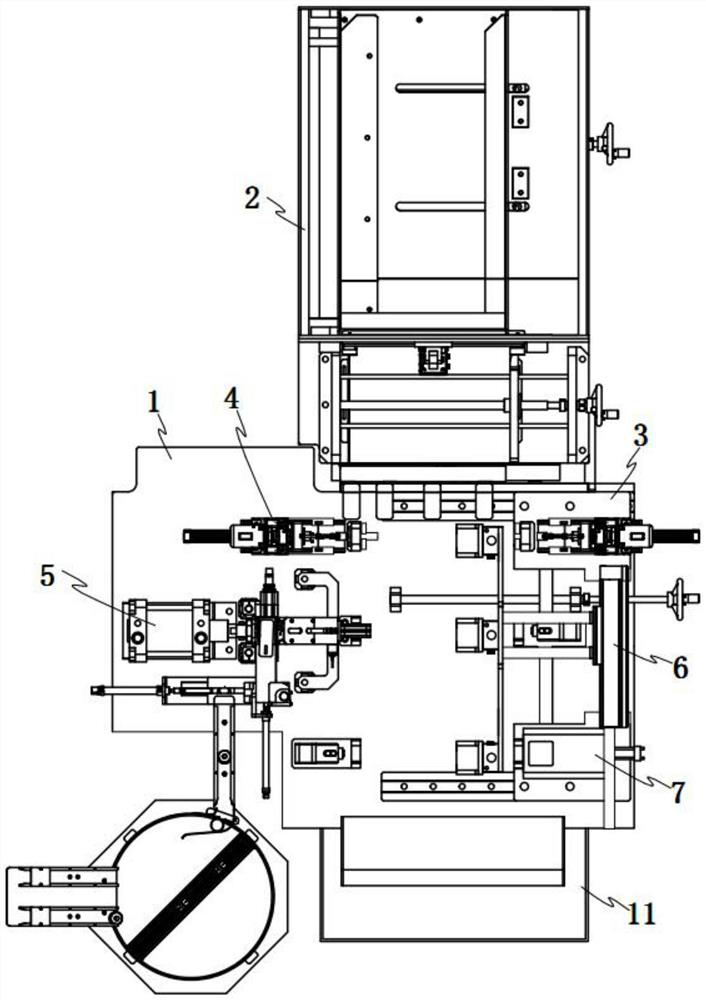

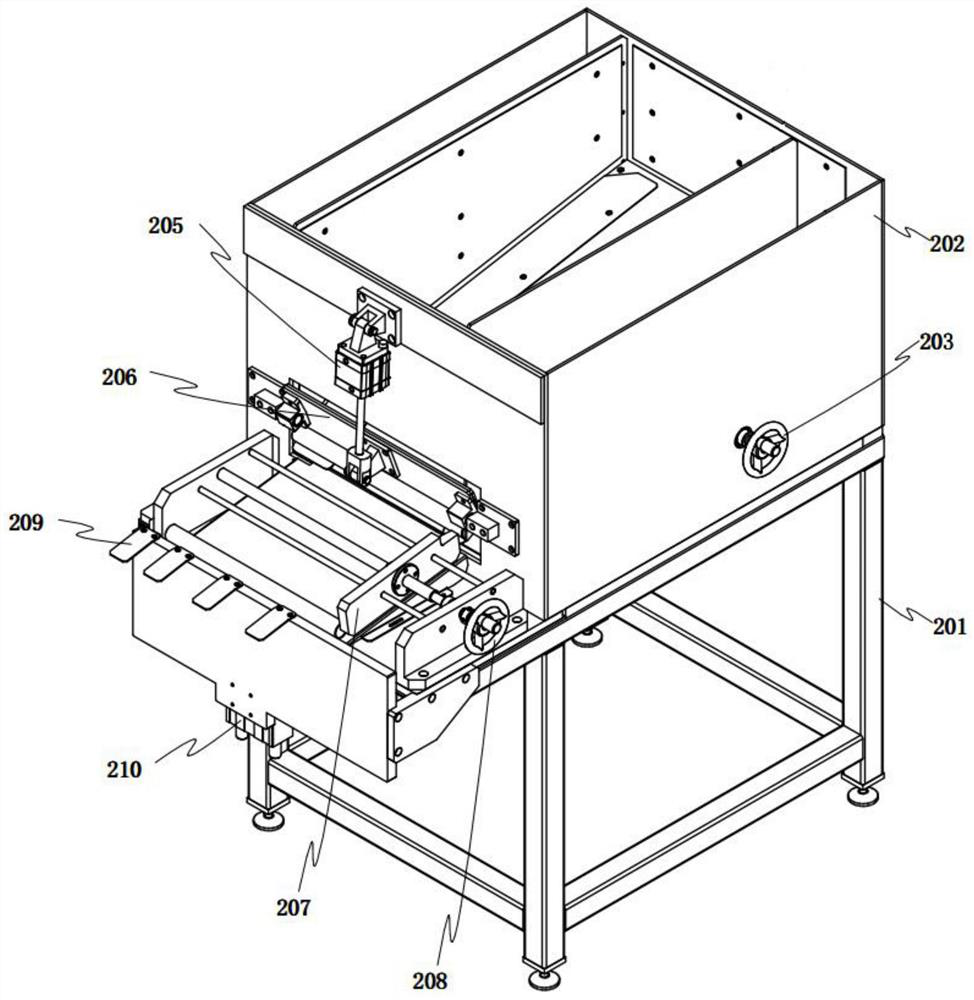

Intelligent sampling and conveying device

PendingCN112393948AReduce equipment input costsLow input costWithdrawing sample devicesStructural engineeringIndustrial engineering

The invention discloses an intelligent sampling and conveying device which structurally comprises a rail mechanism, an automatic sampling device, an intelligent conveying device and an automatic sample unloading device; the rail mechanism is composed of a rail, a rail support, a slide wire and a rain cover, and the automatic sampling device is composed of a sampling box, a discharging scraper-trough conveyer and a gate valve. The intelligent conveying device is composed of a moving trolley and a material receiving hopper, and the automatic sample unloading device comprises a hydraulic push rod, a discharging hopper and a collecting container.

Owner:吉林金隅冀东环保科技有限公司

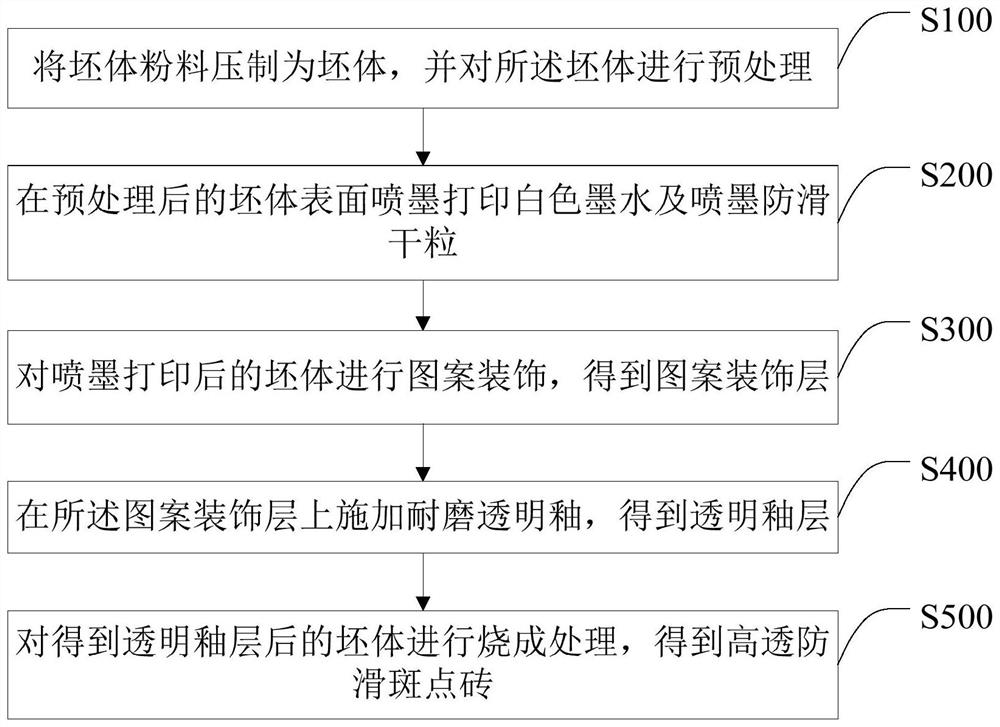

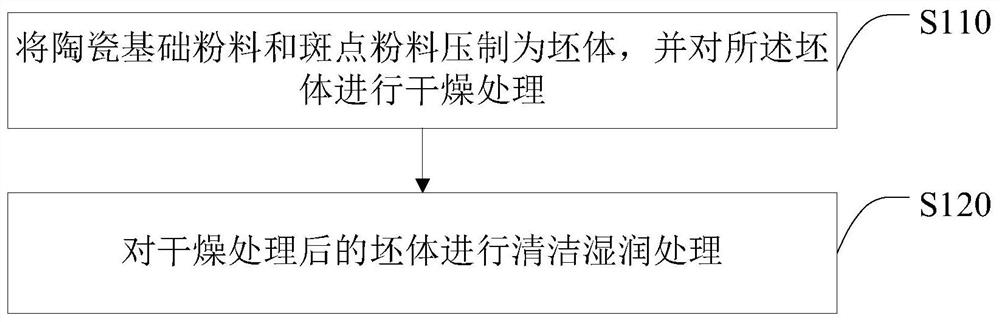

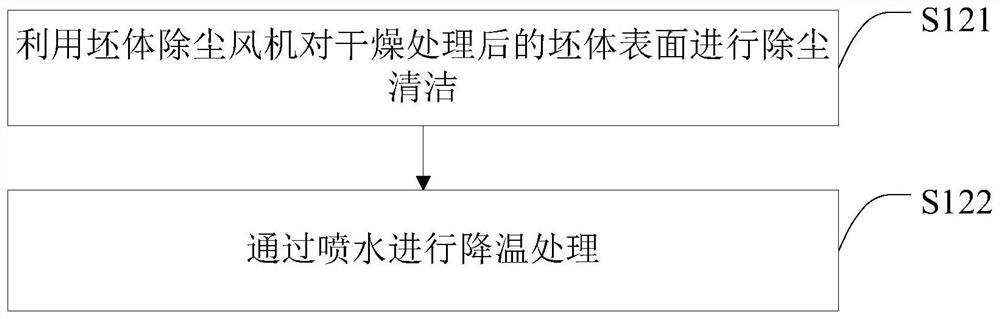

Preparation method of high-transmittance anti-skid spot brick and high-transmittance anti-skid spot brick

The invention provides a preparation method of a high-transmittance anti-skid spot brick and the high-transmittance anti-skid spot brick, and the preparation method of the high-transmittance anti-skid spot brick comprises the following steps: pressing green body powder into a green body, and pretreating the green body; carrying out ink-jet printing of white ink and ink-jet anti-skid dry particles on the surface of the pretreated green body; performing pattern decoration on the green body subjected to ink-jet printing to obtain a pattern decoration layer; applying wear-resistant transparent glaze to the pattern decoration layer to obtain a transparent glaze layer; and sintering the green body with the transparent glaze layer, so as to obtain the high-transmittance anti-skid spot brick. The white ink and the ink-jet anti-skid dry particles are printed on the green body in an ink-jet mode, an existing engobe and anti-skid dry particle (or transparent glaze) glaze layer process is replaced, the glaze layer thickness of the spot brick is greatly reduced, the transparency of spots is not affected, and the high-transmittance spot performance of the anti-skid spot brick is achieved.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

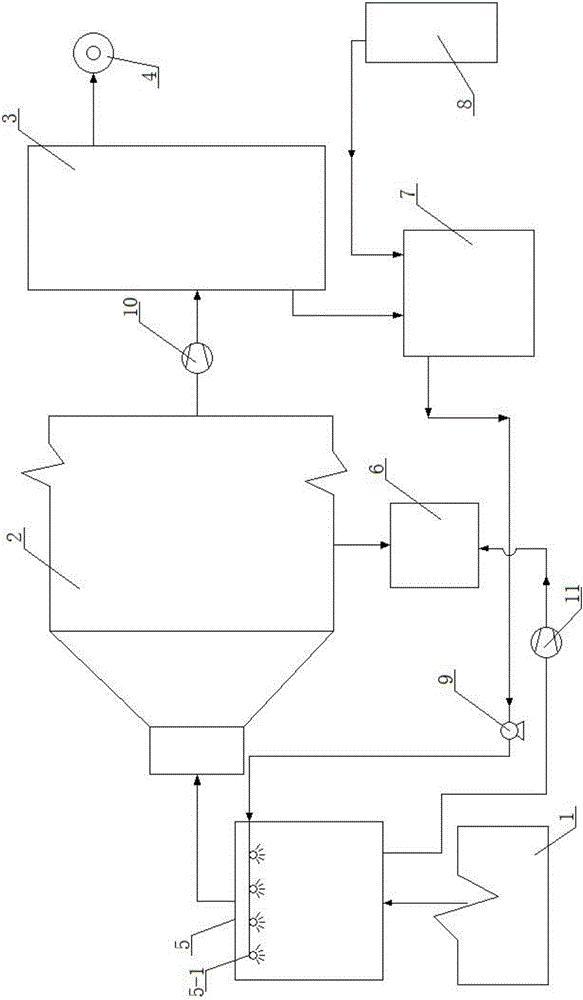

Desulfurization wastewater recycling and utilizing process and device

PendingCN106145497AReduce equipment input costsImprove work efficiencyGas treatmentUsing liquid separation agentZero emissionProcess engineering

The invention discloses a desulfurization wastewater recycling and utilizing process and a desulfurization wastewater recycling and utilizing process device. The device comprises a wastewater treatment system and a collaborative removal system; the wastewater treatment system comprises a wastewater treatment pond and an additive adding system; the collaborative removal system comprises a collaborative removal tower; the collaborative removal tower is a vertically through tubular cavity; spraying equipment is arranged at the top of the collaborative removal tower; an opening in the bottom of the collaborative removal tower is connected with a flue gas outlet of an air pre-heater; an opening in the top of the collaborative removal tower is connected with a gas inlet of a dust removal device; a dust discharging opening of the dust removal device is connected with a dust conveying system; an exhaust opening of the dust removal collector is connected with a wet desulfurization system; an exhaust opening of the wet desulfurization system is connected with a chimney; a waste liquid outlet of the wet desulfurization system is connected with the wastewater treatment pond; the additive adding system is connected with the wastewater treatment pond; a water outlet of the wastewater treatment pond is connected with the spraying equipment through a wastewater pump. According to the desulfurization wastewater recycling and utilizing process and the desulfurization wastewater recycling and utilizing process device, the treatment disposal problems of desulfurization wastewater are solved; zero emission of the wastewater is realized; wastewater resources are realized.

Owner:山东奥特高科环保科技有限公司

Planting method for interplanting houttuynia cordata and roxburgh rose

InactiveCN108713457AIncrease productionImprove qualityCalcareous fertilisersBiocideGrowth managementAgronomy

The invention provides a planting method for interplanting houttuynia cordata and roxburgh rose, and belongs to the technical field of traditional Chinese medicinal material planting. The method comprises the steps of 1 planting field selection; 2, deep ploughing, planting pit digging, base fertilizer and nutrition medium application; 3, planting; 4, growth management; 5, houttuynia cordata planting and the like. The method has the advantages of adjusting measures to local conditions, reducing planting cost of the houttuynia cordata, and improving the yield and quality of the roxburgh rose.

Owner:六枝特区舰航种养殖场

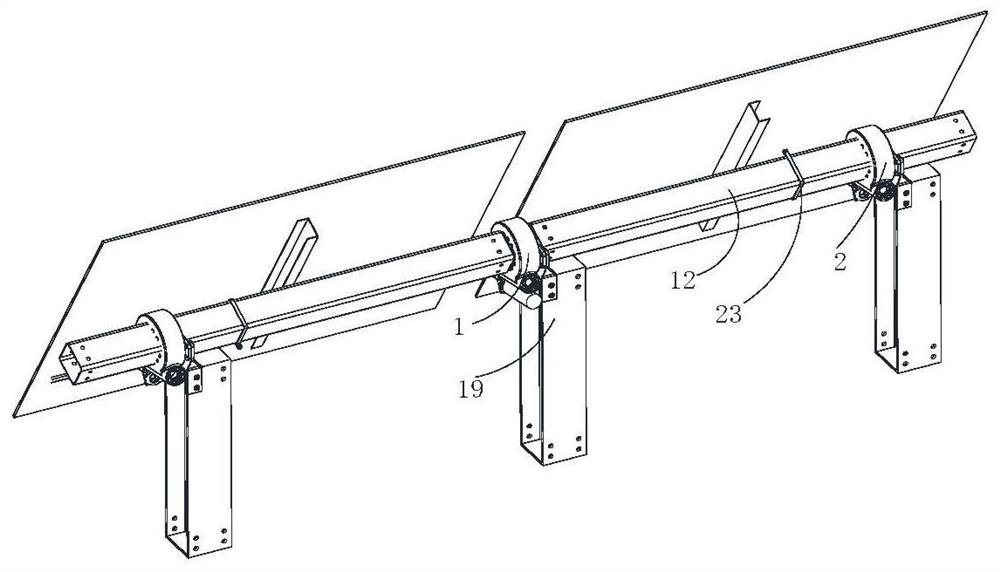

Photovoltaic tracking system with multiple mounting directions of motor

ActiveCN112636678AExtended service lifeReduce equipment input costsPhotovoltaic supportsSolar heating energyElectrical and Electronics engineeringDrive shaft

The invention discloses a photovoltaic tracking system with multiple mounting directions of a motor. The system comprises a main beam and at least one rotary speed reducer, one rotary speed reducer is connected with the motor, the rotary speed reducer is in transmission connection with the motor through a transmission shaft, and the lower portion of a shell of the rotary speed reducer is provided with an installation position where the motor can be placed. Through the arrangement of the mounting position, when the main beam rotates, the main beam does not collide with the motor, the stability of equipment during operation is guaranteed, and the motor is arranged at the mounting position, so that the space occupancy rate is reduced, and the whole rotary speed reducer is more attractive.

Owner:浙江恒星传动科技有限公司

Agricultural multifunctional sprinkler device

InactiveCN106171224AReduce labor input costsReduce equipment input costsPressurised distribution of liquid fertiliserInsect catchers and killersWater pipeAgriculture

The invention provides an agricultural multifunctional sprinkler device. The device comprises a draining device, and a distribution device, wherein a liquid inlet is formed in the water outlet pipe at the center of the upper end part of the draining device and above a water-blocking valve, and a liquid inlet is formed in the water outlet pipe at the center of the upper end part of the draining device under the water blocking valve; the whole distribution device is a closed cylindrical tank with bottom support; the top of the distribution device is provided with a feeding opening and a seal valve cap A which can be used for plugging the feeding opening; a liquid outlet pipe and a liquid inlet pipe are arranged at the top of the distribution device, the liquid outlet pipe extends into the distribution device at a depth more than half depth of the distribution device, and the liquid inlet pipe is arranged on the surface of the distribution device and is communicated with the inside of the distribution device; a drain valve is arranged at the bottom of the distribution device; and the liquid outlet pipe on the distribution device is connected and communicated with the liquid inlet in the water outlet pipeline through a water pipe, and the liquid inlet pipe on the distribution device is connected and communicated with the liquid outlet on the water outlet pipeline through a water pipe.

Owner:QINGFENG AGRI MACHINERY REPAIRING & MFG FACTORY

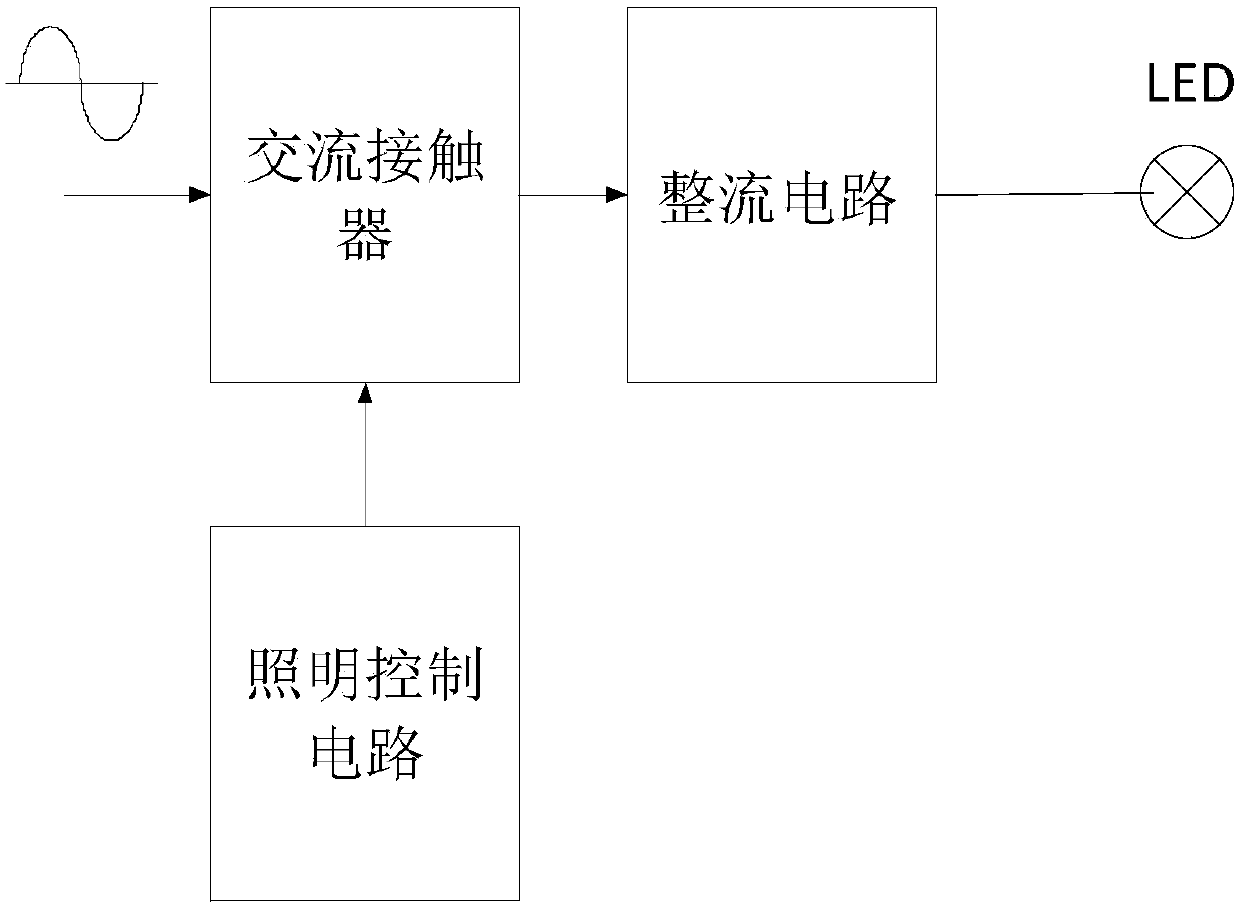

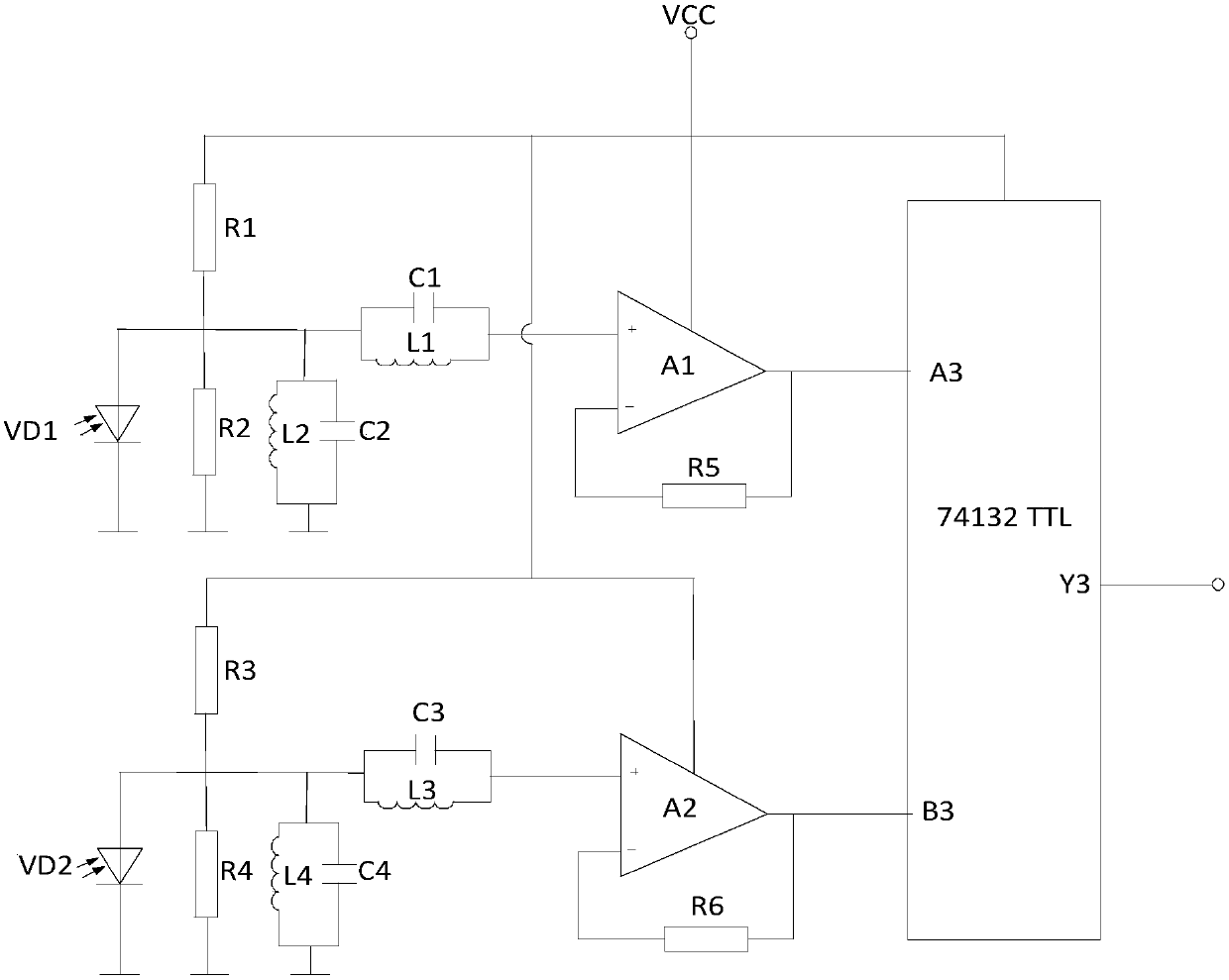

Power amplifier-based outdoor intelligent lighting system

InactiveCN107911901AReduce equipment input costsSolve energy wasteElectrical apparatusElectroluminescent light sourcesContactorAND gate

The invention discloses a power amplifier-based outdoor intelligent lighting system. By the power outdoor intelligent lighting system, the problem that a lighting lamp cannot be automatically turned on and turned off according to an application environment to cause energy waste in the prior art is mainly solved. The power amplifier-based outdoor intelligent lighting system comprises an AC contactor, a rectification circuit, a lighting control circuit and an LED lighting lamp, wherein the AC contactor is externally connected with a sine wave alternating current, the rectification circuit and the lighting control circuit are connected with the AC contactor, the LED lighting lamp is connected with the rectification circuit, and a lighting control circuit comprises a two-input four-and gate chip, a power amplifier A1, a first filtering circuit, a photosensitive diode VD1, a power amplifier A2, a second filtering circuit and a photosensitive diode VD2. By the scheme, the power amplifier-based outdoor intelligent lighting system has the advantages of simple structure, low cost, running stability, energy saving, detection accuracy and the like, and has high practical value and promotion value in the technical field of lighting.

Owner:CHENGDU UNIV OF INFORMATION TECH

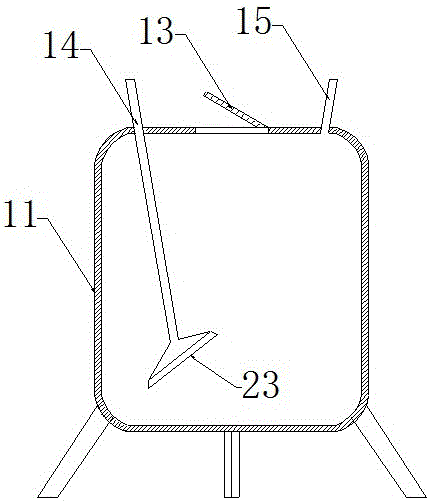

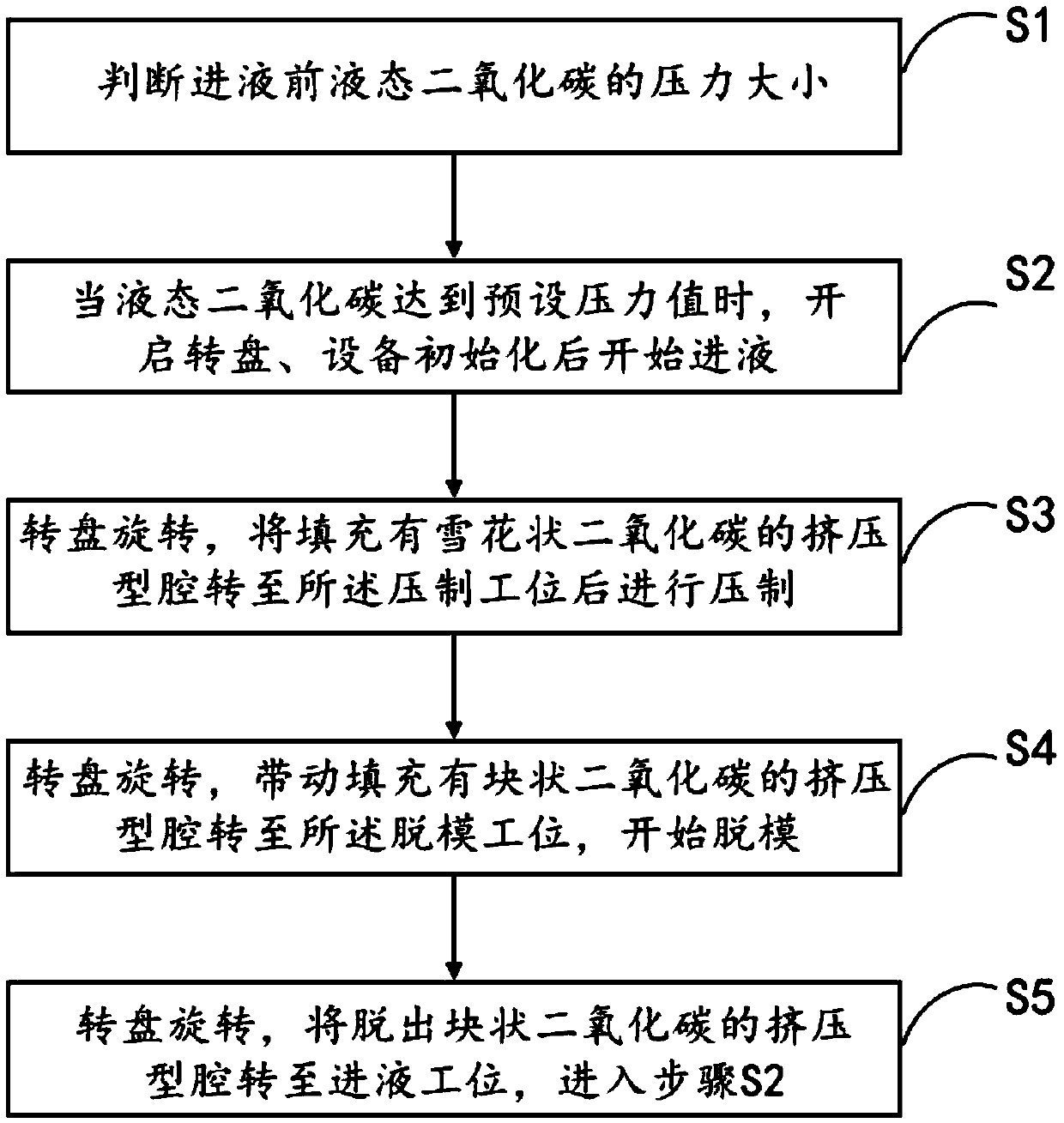

Control method for preparation of high-density carbon dioxide

ActiveCN109553102ASmall shock and vibrationReduce equipment input costsProductsReagentsEngineeringMechanical engineering

The invention provides a control method for preparing high-density carbon dioxide. The control method comprises the following steps: judging the pressure of liquid carbon dioxide before the liquid carbon dioxide enters; when the pressure of the liquid carbon dioxide reaches a preset pressure value, opening a rotating disk, and after a device is initialized, starting feeding the liquid carbon dioxide; allowing the rotating disk to rotate to drive an extrusion type cavity filled with snowflake-like carbon dioxide to be rotated to a press molding station, and carrying out press molding; allowingthe rotating disk to rotate to drive the extrusion type cavity filled with block-shaped carbon dioxide to be rotated to a demolding station, and carrying out demolding; allowing the rotating disk to rotate to drive the block-shaped carbon dioxide demolded extrusion type cavity to be rotated to a liquid feeding station; and cyclically performing the step 2 to the step 5, and simultaneously performing liquid feeding, press molding and demolding respectively at the liquid feeding station, the press molding station and the demolding station. According to the invention, through controlling of the rotating disk to a plurality of stations, the steps of liquid feeding, press molding and demolding are simultaneously carried out at different stations, so equipment operation is streamlined; the costof investment is reduced; and the efficiency of working is improved.

Owner:XIAMEN UNIV OF TECH

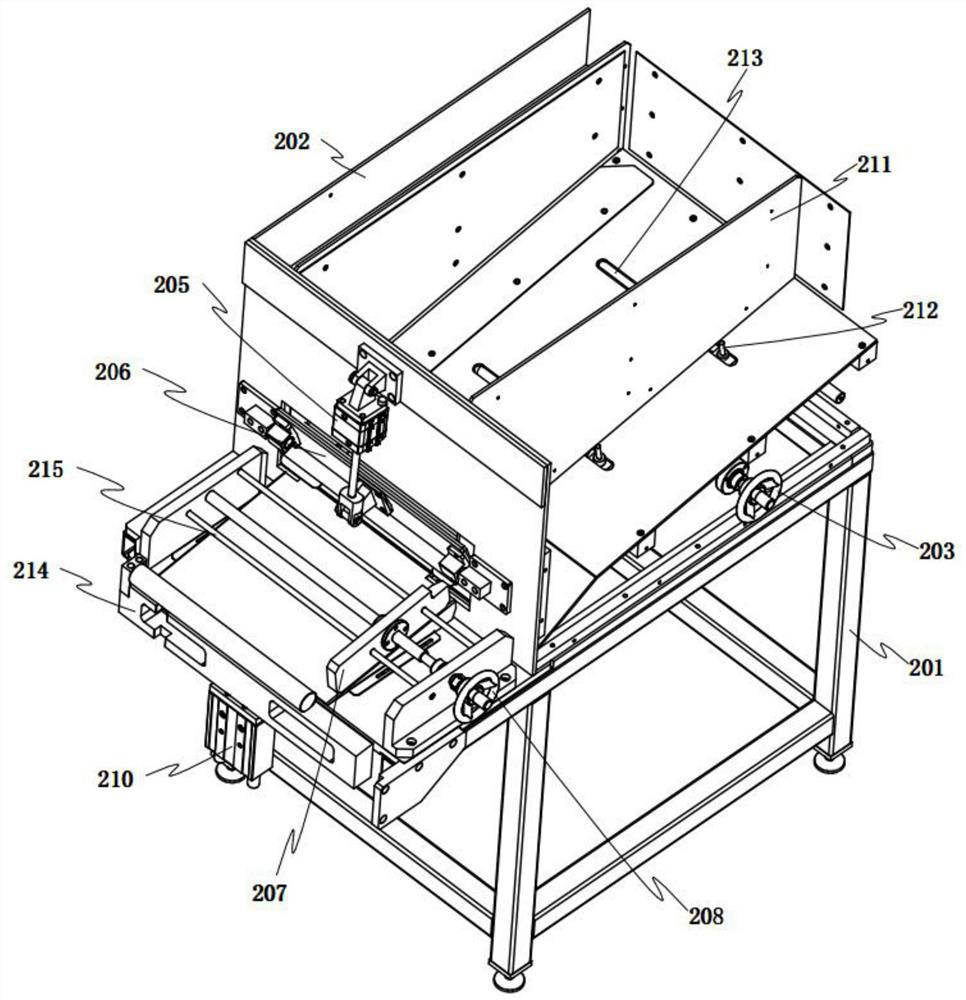

Metal pipe fitting end machining device

ActiveCN112605662ARealize mechanical automation processingImprove processing efficiencyOther manufacturing equipments/toolsGrindingDrill hole

The invention relates to a metal pipe fitting end machining device. The device comprises a machining table body, a metal pipe fitting storage and input mechanism is arranged at the end of one side of the machining table body, a pipe fitting storage frame is arranged on the other side of the machining table body, and a pipe fitting machining supporting base I, a pipe fitting machining supporting base II and a pipe fitting machining supporting base III are sequentially arranged on a table top of the machining table body. A pipe orifice grinding mechanism is arranged on the side edge portion of the pipe fitting machining supporting base I, a pipe orifice blocking mechanism is arranged on the side edge portion of the pipe fitting machining supporting base II, and an end drilling mechanism fixed to a position adjusting mechanism is arranged on the side edge portion of the pipe fitting machining supporting base III. According to the device, mechanical and automatic machining of metal pipe fitting port inner and outer pipe wall face grinding, port drilling and pipe orifice blocking is achieved, meanwhile, the machining device can be adjusted according to the lengths of pipe fittings so as to meet the machining requirements of pipe fittings with different lengths, the pipe fitting machining efficiency is improved, the labor and equipment investment cost is reduced, and the influence of human factors is reduced.

Owner:沧州东海电力管件有限公司

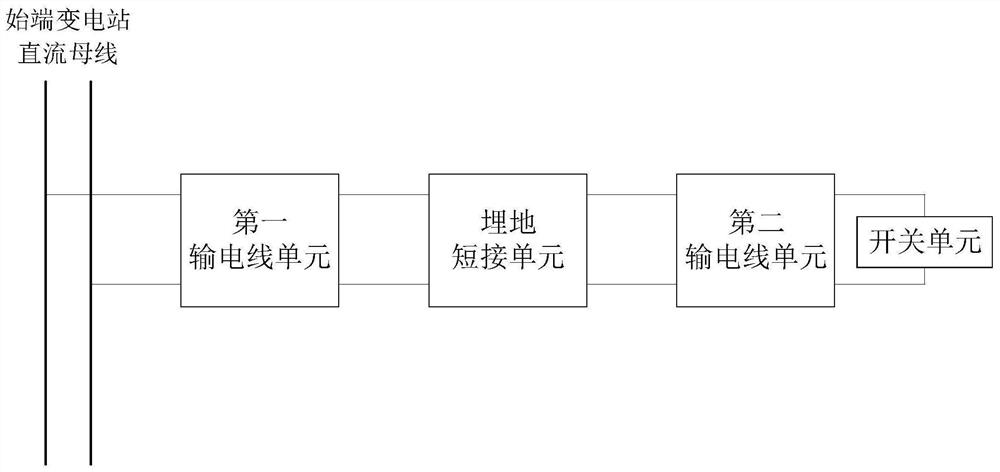

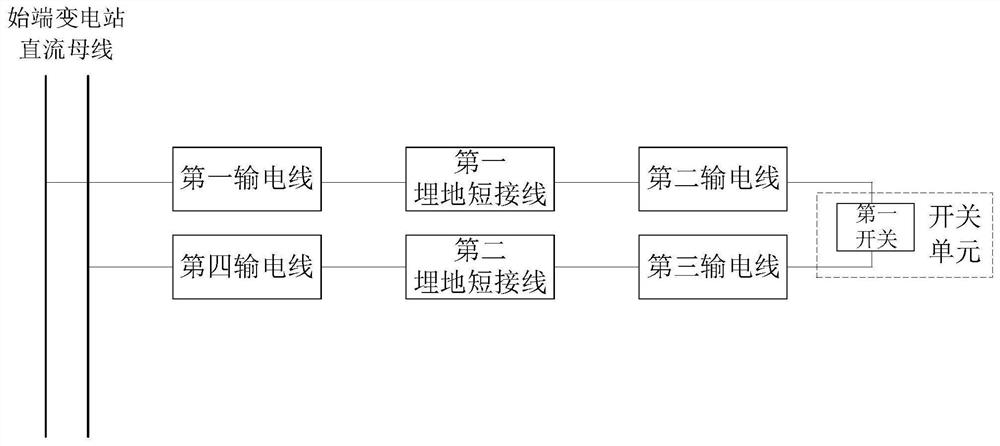

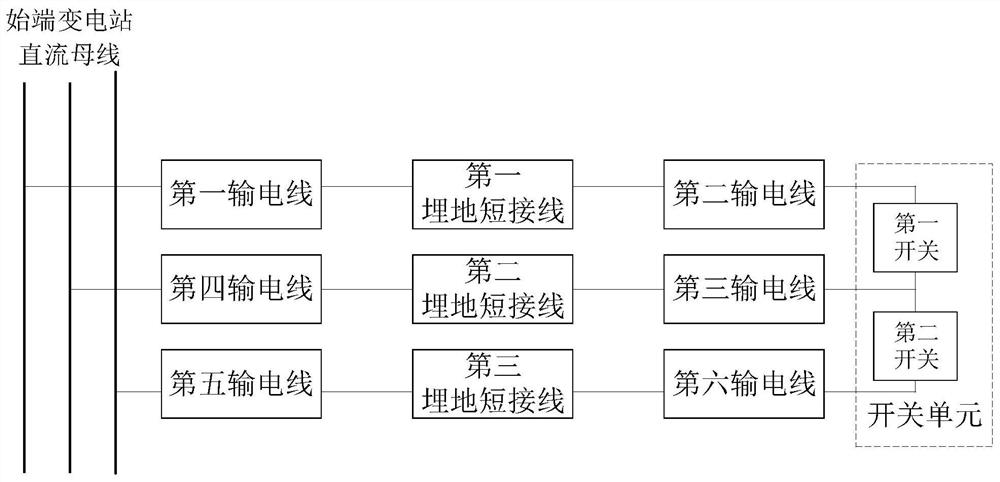

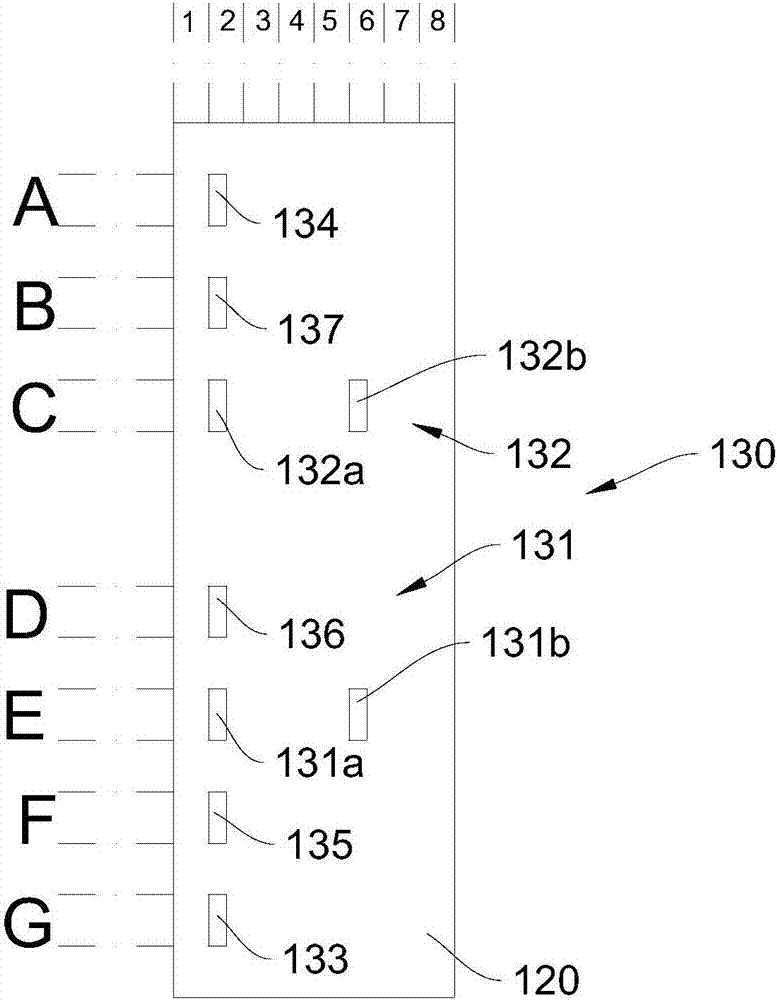

Direct-current tandem ice melting device and system

ActiveCN111668791AImprove equipment utilizationReduce equipment input costsOverhead installationPower transmissionPower substation

The invention relates to a direct-current tandem ice melting device and system. The device comprises a first power transmission line unit, a second power transmission line unit, a buried short circuitunit and a switch unit. The buried short-circuit unit is used for being connected with spacing equipment of an intermediate substation in parallel. The first power transmission line unit is connectedbetween a direct-current bus of a starting-end transformer substation and the buried short-circuit unit, and the buried short-circuit unit is connected with the switch unit through the second power transmission line unit. And the buried short circuit unit is used for connecting corresponding lines between the first power transmission line unit and the second power transmission line unit accordingto the on-off state of the switch unit and short-circuiting corresponding interval equipment in the intermediate substation. Based on the above device, direct-current ice melting equipment in the starting-end transformer substation provides ice melting direct current for a loop between a first power transmission line unit between the starting-end transformer substation and the middle transformersubstation and a second power transmission line unit between the middle transformer substation and the tail-end transformer substation through a direct-current bus, ice melting equipment does not needto be allocated and configured for adjacent transformer substations, and the equipment cost is greatly reduced.

Owner:CHINA SOUTHERN POWER GRID DIGITAL GRID RES INST CO LTD

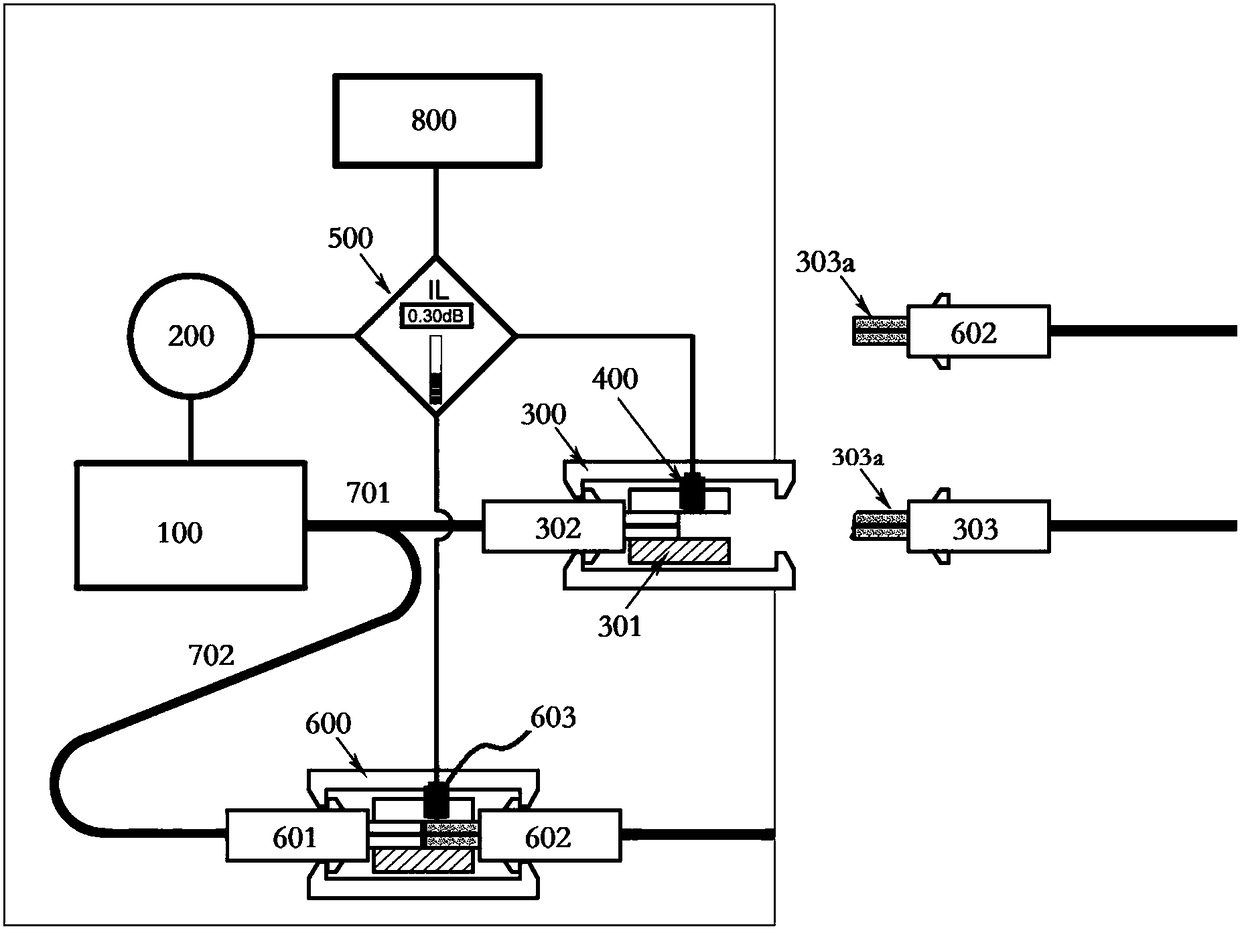

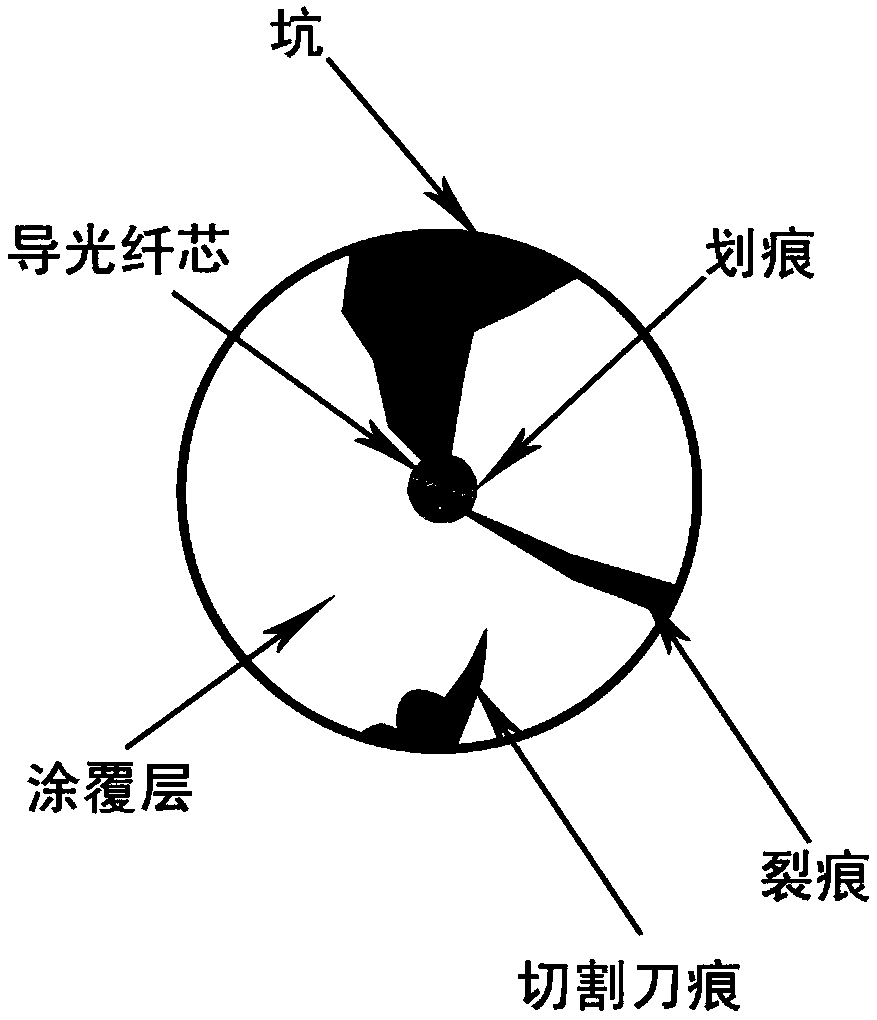

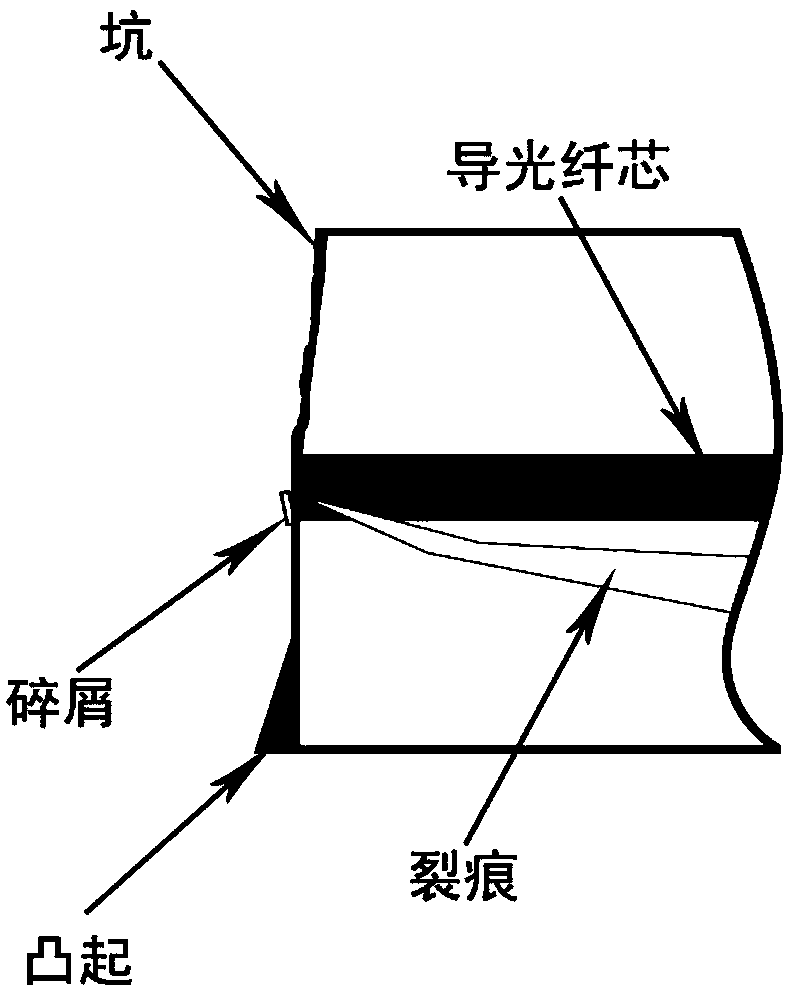

Formed end surface quality detection device and method for contact-type optical fiber connector

PendingCN108534987AReduce equipment input costsReduce volumeOptical apparatus testingOptical fiber connectorJunction point

The invention discloses a formed end surface quality detection device and method for a contact-type optical fiber connector. The detection device comprises an emission assembly, a power wavelength adjustment assembly, an adapter component and a detection assembly, wherein the emission assembly is connected with a first standard connector by virtue of an optical fiber connecting line and transmitsdetection light waves to an optical fiber connector coupled with the emission assembly by virtue of the first standard connector; the power wavelength adjustment assembly is connected with the emission assembly and used for adjusting emission power or light wavelength of the emission assembly; the detection assembly is arranged above a sleeve. According to the detection device disclosed by the invention, by sensing the existence and amount of light refraction and diffuse reflection brought by formed end surface defects of the optical fiber connector, the formed end surface quality of the optical fiber connector is judged, the defects that standards are non-uniform during detection by adopting an optical fiber end face magnifying lens and the optical fiber connecting quality cannot be intuitively detected are overcome, the condition that an optical power meter cannot sense connecting quality of a single optical fiber connecting point is avoided, and the construction site equipment invested cost is greatly reduced. Moreover, the detection device is small in size, reliable and favorable for large-area popularization.

Owner:NANJING XIUDEA COMM TECH CO LTD

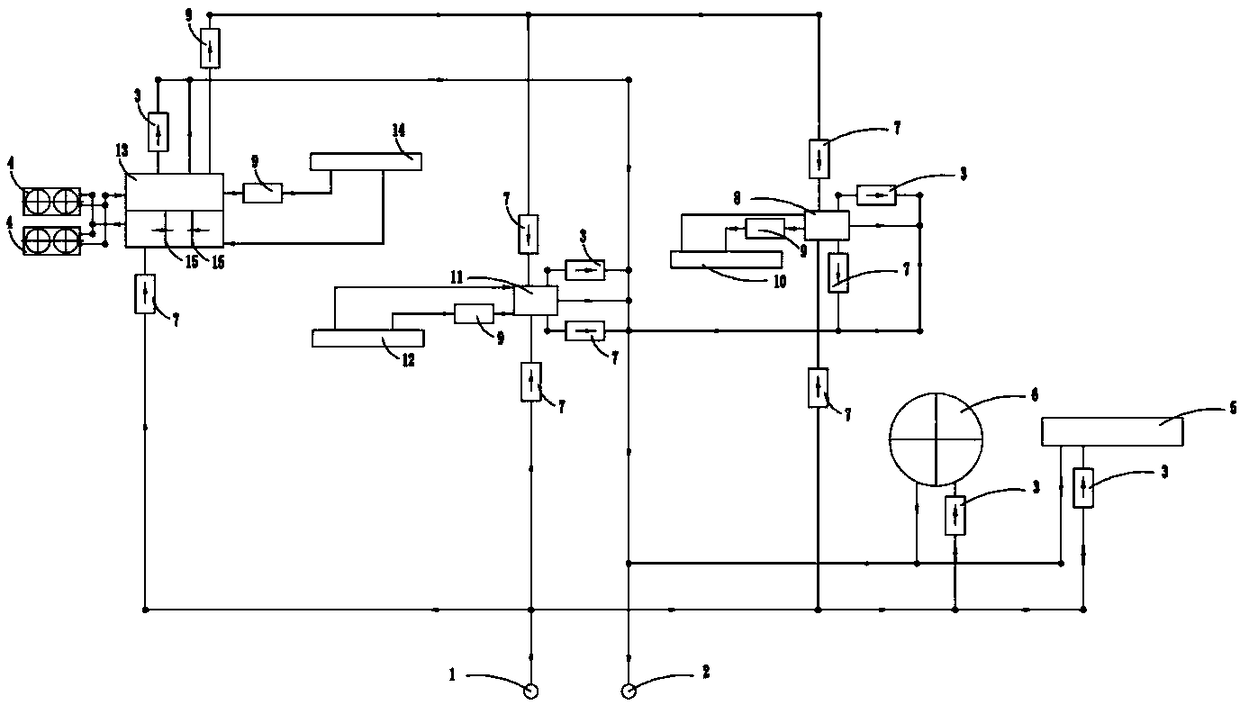

Circulating water loading device for high-speed optical fiber secondary coating and secondary coating cooling method

The invention discloses a circulating water loading device for high-speed optical fiber secondary coating. The circulating water loading device comprises a cold water machine used for active refrigeration, a cold water tank and a plurality of cold water interfaces which are matched with cooling water tanks in number of a plastic extruding machine for high-speed optical fiber secondary coating, wherein the cold water machine is provided with a water inlet, a refrigerator and a water outlet, cooling water flowing into the water inlet flows out from the water outlet after being cooled through therefrigerator, and the water outlet communicates with an water inlet of the cold water tank; and the cold water tank communicates with the cooling water tank through the plurality of cold water interfaces. The invention further provides a secondary coating cooling method. The cooling method is characterized in that when the temperature of the cooling water tank is higher than the corresponding preset temperature range, cold water is supplied through the corresponding cold water interface, and the temperature of the cooling water tank is controlled to be within a corresponding preset temperature range. The circulating water loading device for high-speed optical fiber secondary coating is low in equipment investment, low in research and development cost, good in cooling effect and flexible to apply.

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

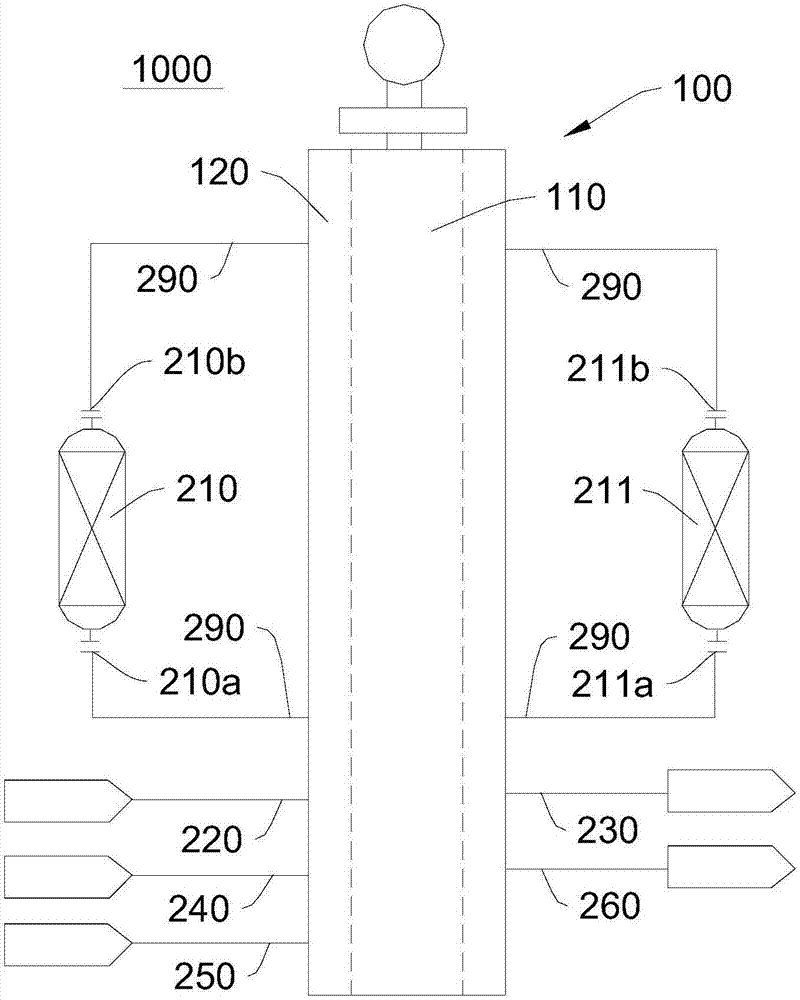

O2 purifying system, and gas treatment system

PendingCN107185355ALess consumablesReduce equipment input costsGas treatmentDispersed particle separationRotary valveGas pipeline

The invention discloses an O2 purifying system, and a gas treatment system, and belongs to the technical field of O2 purifying. The O2 purifying system comprises a raw material gas pipeline, a product gas pipeline, a vacuumizing pipeline, a rotary valve, and an adsorption tower; the rotary valve comprises a non-rotational part and a rotational part; the non-rotational part is provided with a first runner; the rotational part is provided with a second runner; the rotational part is driven to rotate so as to realize communication of the raw material gas pipeline, the product gas pipeline, the vacuumizing pipeline, and the adsorption tower via the second runner; and the gas treatment system comprises the O2 purifying system. Both the O2 purifying system and the gas treatment system are used for realizing control of multiple pipelines via the same rotary valve; cost is reduced; and control is convenient.

Owner:CHENGDU SEPMEM SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com