Laser processing method integrating raster scanning, printing and cutting

A laser processing method and integrated technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming, low marking quality clarity, and inability to make, and improve efficiency and quality. , the effect of saving equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

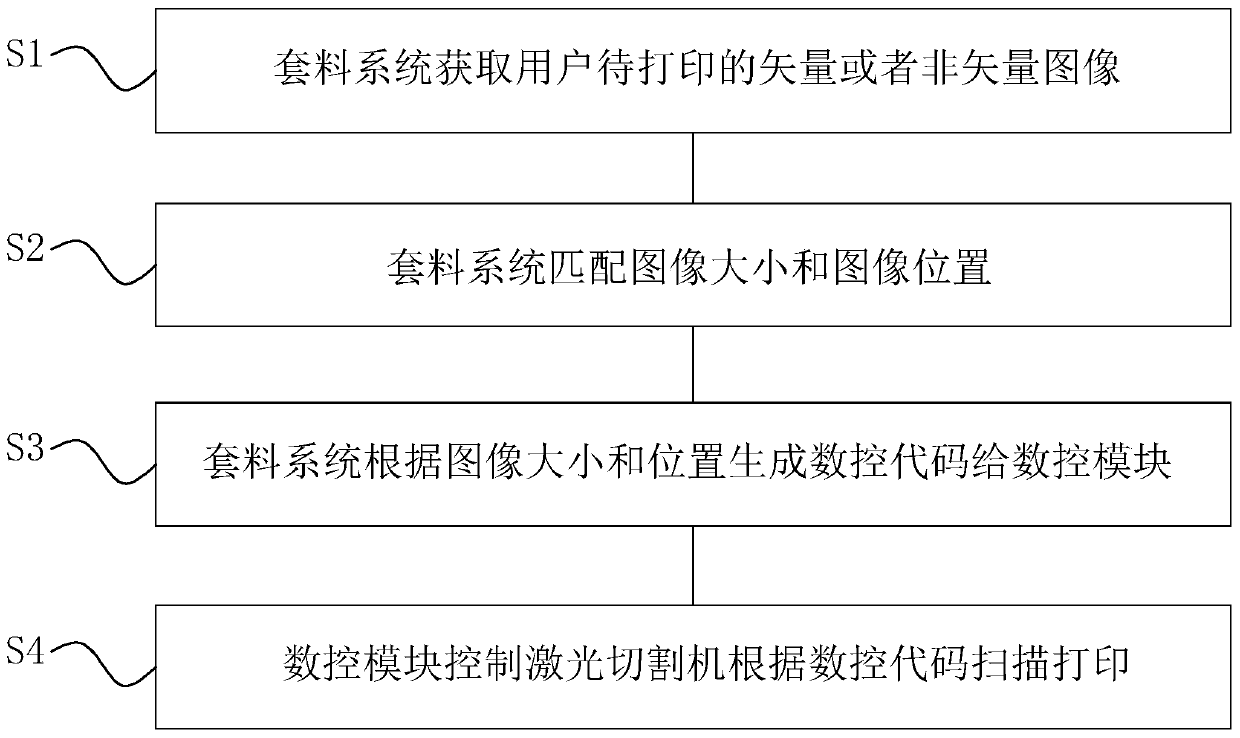

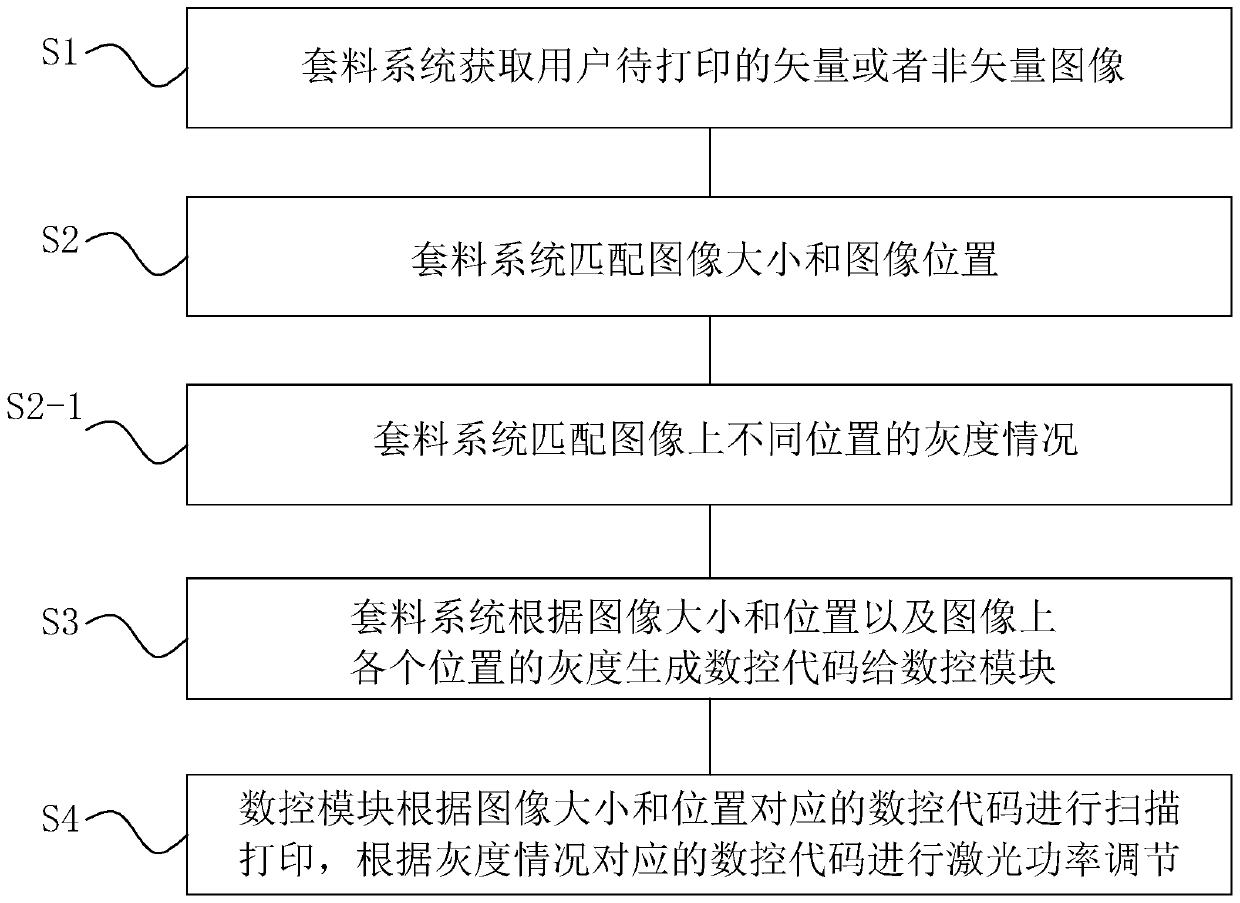

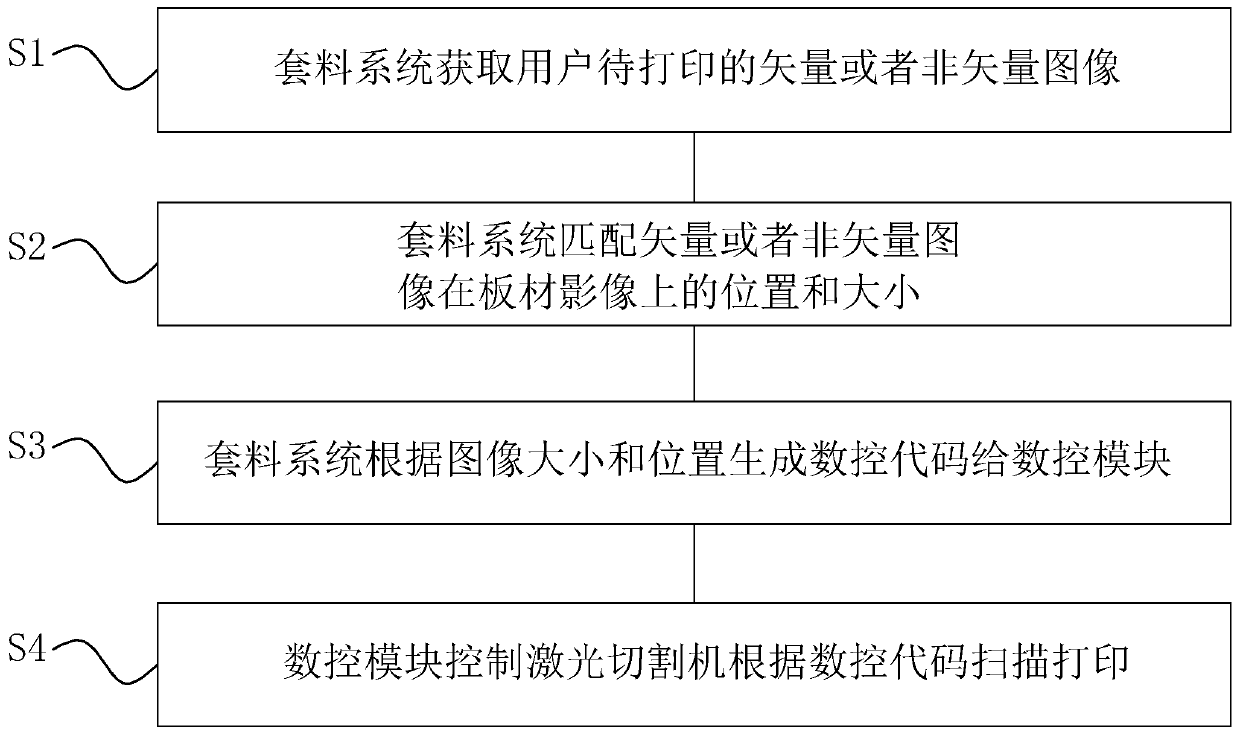

[0025] refer to Figure 1-6 As shown, a laser processing method integrating raster scanning, printing and cutting in this embodiment includes a laser cutting machine 1, and also includes a numerical control module 2 and a nesting system 3 communicating with the numerical control module 2. The laser cutting machine 1. The steps of the cooperative printing between the CNC module 2 and the nesting system 3 are as follows:

[0026] Step 1, the nesting system 3 obtains the vector or non-vector image to be printed by the user;

[0027] Step 2, nesting system 3 matches image size and image position;

[0028] Step 3, the nesting system 3 generates numerical control codes for the numerical control module 2 according to the size and position of the image;

[0029] Step 4. The CNC module 2 controls the laser cutting machine 1 to scan and prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com