Circulating water loading device for high-speed optical fiber secondary coating and secondary coating cooling method

A loading device and secondary coating technology, applied in the field of secondary coating of optical fiber, can solve the problem of not being able to meet the secondary coating process of high-speed optical fiber, and achieve the effect of obvious speed-up effect, low R&D investment, and obvious improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

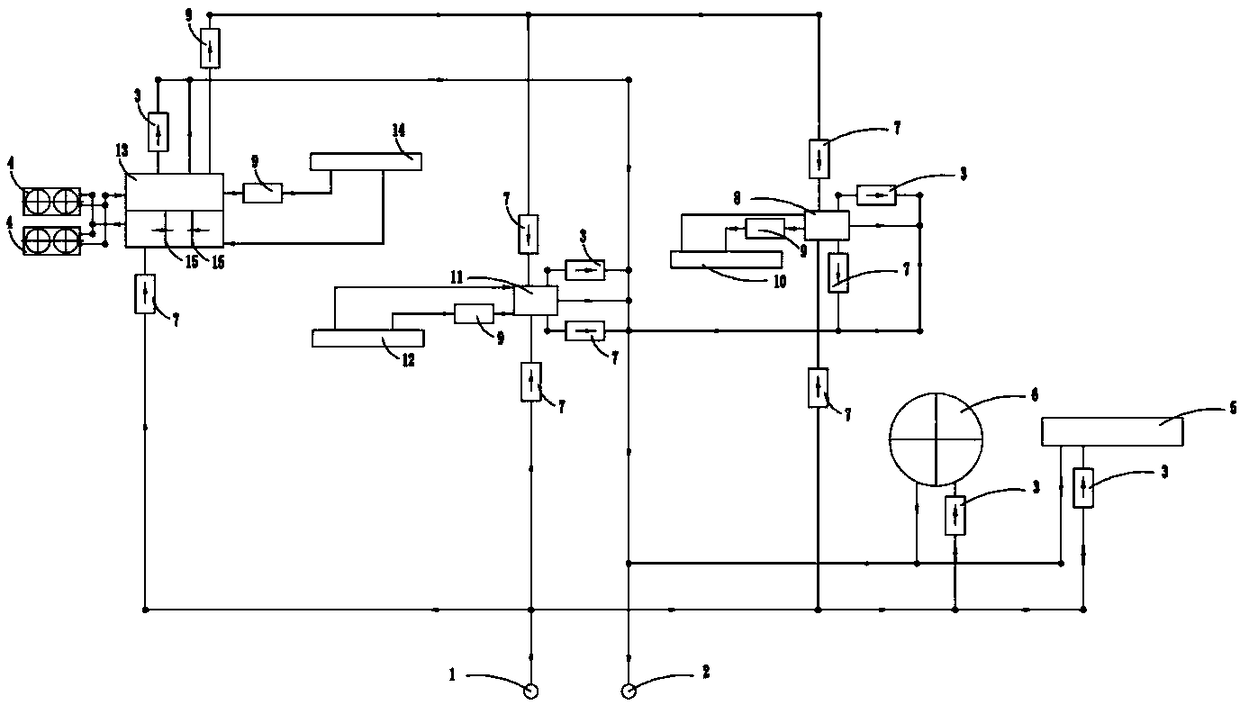

[0071] A circulating water loading device for high-speed optical fiber secondary coating, such as figure 1 As shown, it is suitable for the high-speed optical fiber secondary coating process not exceeding 1000m / min, including the chiller 4 for active cooling, the cold water tank 13, and the number of cooling water tanks matching the number of cooling water tanks for the optical fiber secondary coating extruder 6 3 cold water interfaces for distributing cold water to the circulating water of the extruder 6, namely the first-level cold water interface, the second-level cold water interface and the third-level cold water interface; the first-level cold water interface passes through the first-level circulating water tank It communicates with the first cooling water tank 12 of the extruder 6 ; the second-level cold water interface communicates with the second cooling water tank 10 through the second-level circulating water tank, and the third-level cold water interface directly com...

Embodiment 2

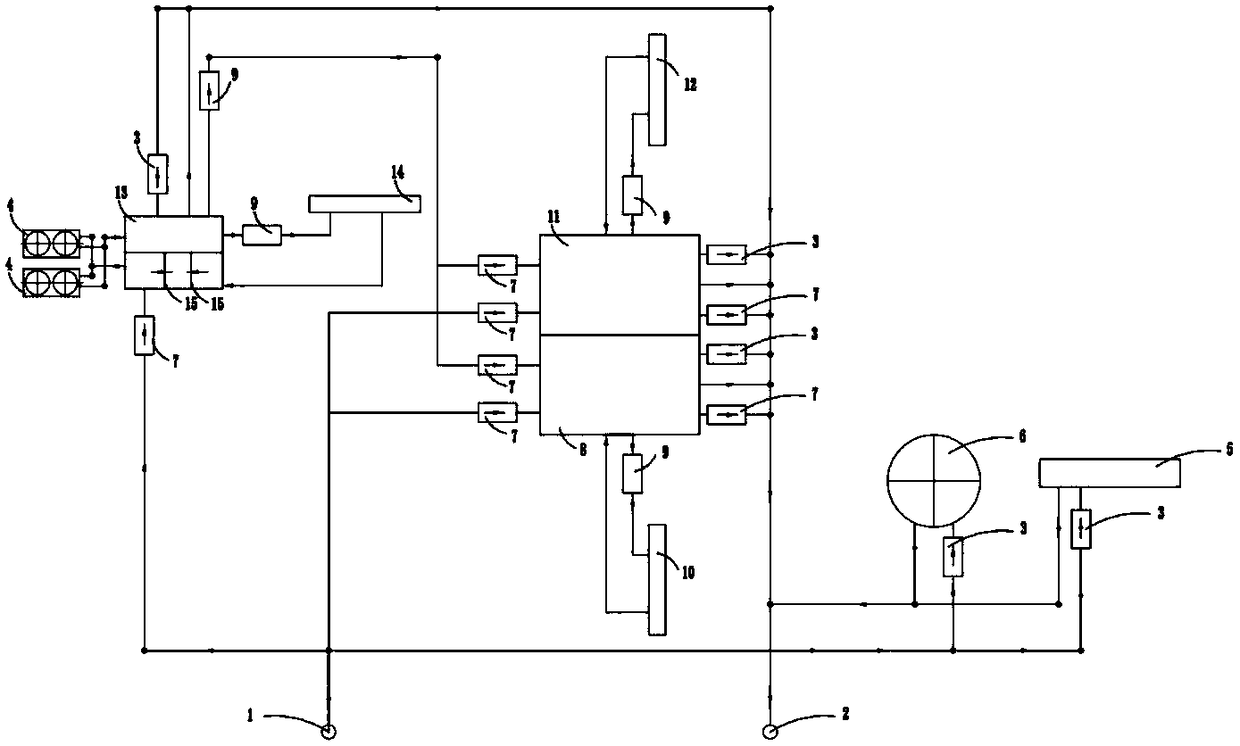

[0094] A circulating water loading device for high-speed optical fiber secondary coating, such as figure 2 As shown, it is suitable for the high-speed optical fiber secondary coating process of 800m / min to 1000m / min, including the chiller 4 for active cooling, the cold water tank 13, and the number of cooling water tanks corresponding to the extruder 6 for optical fiber secondary coating Three matched cold water interfaces for distributing cold water to the circulating water of the extruder 6, that is, the first-level cold water interface, the second-level cold water interface and the third-level cold water interface; the first-level cold water interface passes through the first-level The circulating water tank communicates with the first cooling water tank 12 of the extruder 6 ; the second-level cold water interface communicates with the second cooling water tank 10 through the second-level circulating water tank, and the third-level cold water interface directly communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com