Metal pipe fitting end machining device

A technology for metal pipe fittings and processing devices, applied in the field of metal pipe fitting end processing devices, can solve the problems of difficulty in control, large human factors, and large flying chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

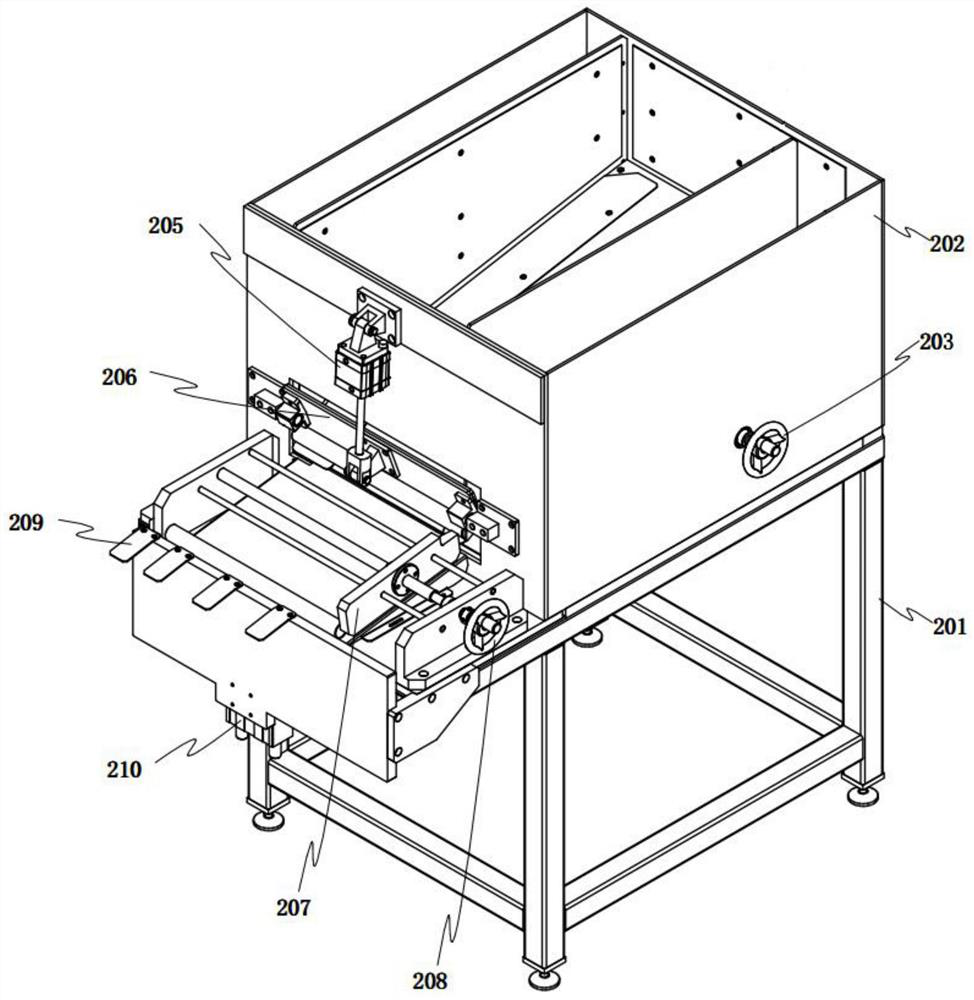

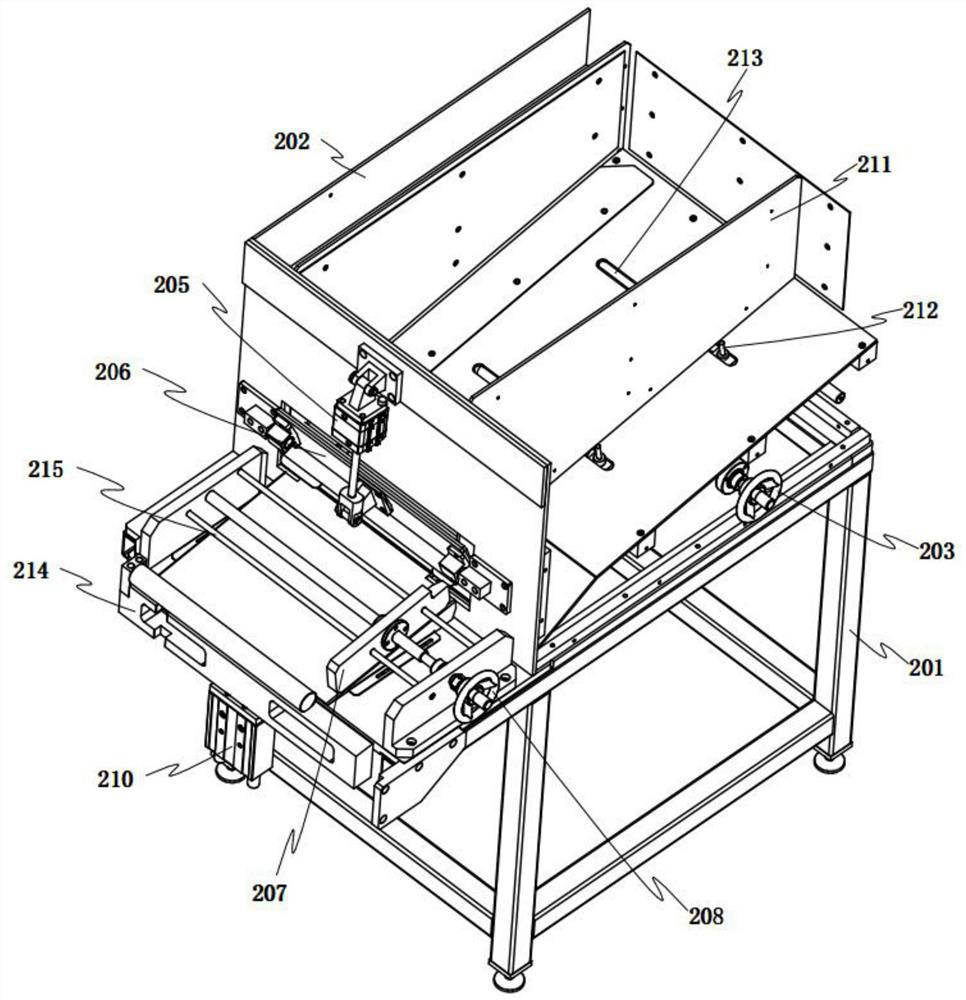

[0038] When the processing device was working, the opening and closing cylinder 205 of the metal pipe fitting storage input mechanism 2 first drove the opening and closing door 206 to open the front side frame opening of the storage frame 202, so that the metal pipe fittings stored in the storage frame 202 were released from the frame under the action of gravity. The mouth rolls down to the output port of the mechanism chassis 201, and then the ejection block 214 is driven by the ejection cylinder 210 to lift the metal pipe on the output port, and rolls out along the export tongue plate 209 to the pipe processing support seat I8, Among them, the movable side frame edge 211 in the pipe storage frame 11 can be adjusted by the adjustment wheel lever I 203 to slide along the guide chute 213, thereby changing the size of the space in the storage frame 202 to adapt to the storage of metal pipes of different lengths. The movable frame edge 207 on one side of the head can be driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com