Multistation automatic angle grinder

A multi-station, automatic technology, applied to grinding machines, machine tools suitable for grinding the edge of workpieces, manufacturing tools, etc., can solve problems such as high requirements for workers' ability, low efficiency of manual grinding, and impact on the quality of finished chips. , to achieve the effect of low worker ability requirements, high yield and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

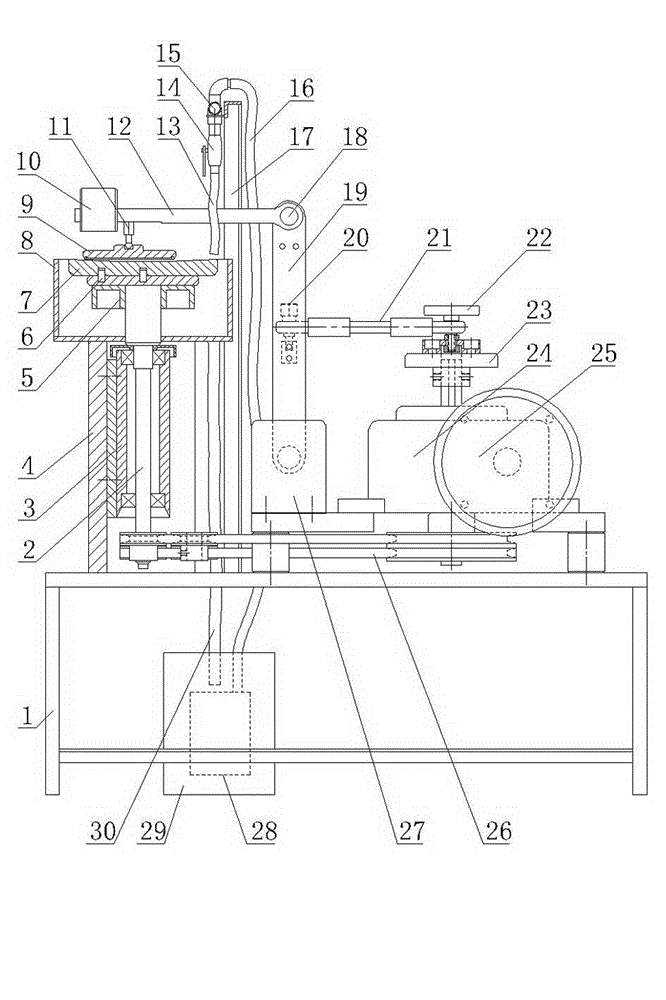

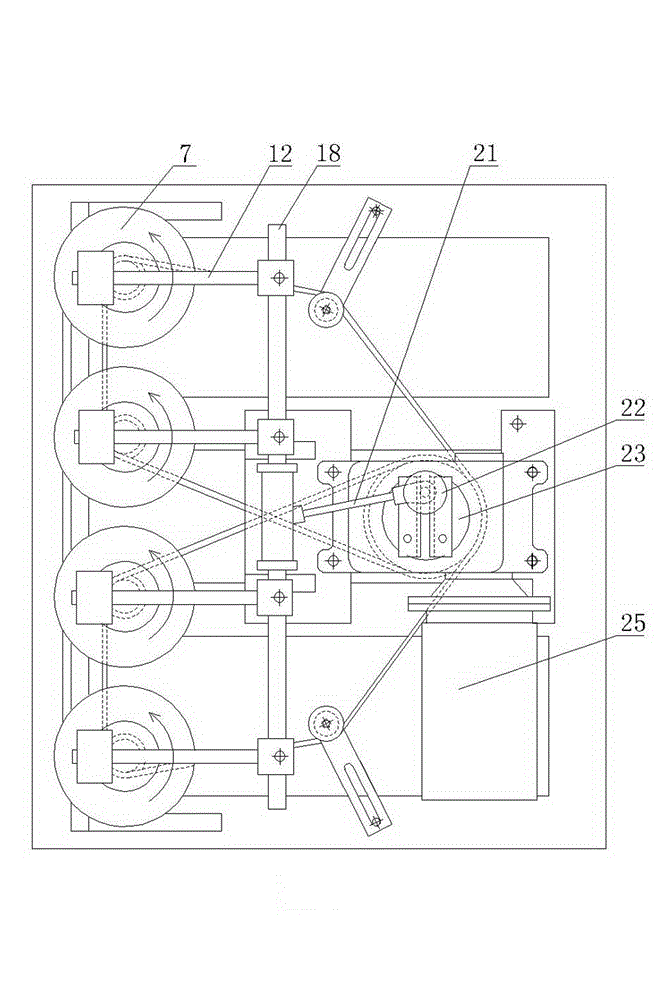

[0014] As shown in the figure, the multi-station automatic angle grinding machine includes a frame 1, a vertical plate 4 is fixed on the front of the frame 1, and a plurality of shaft sleeves 3 and bearings are evenly installed on the vertical plate 4 The vertically arranged main shaft 2, the present embodiment takes four main shafts as an example, the upper ends of the main shaft 2 are respectively fixed with a support plate 5, and the upper surface of the support plate 5 is respectively provided with a grinding disc 7 whose upper surface is a concave arc surface. A bayonet pin 6 is provided at the center of the upper surface and near the edge respectively, and the support plate 5 and the grinding plate 7 are driven by the bayonet pin 6 inserted into the support plate 5 . A chip platen 9 is placed on the grinding plate 7 .

[0015] A driving device is installed at the frame 1 rear portion, and the driving device is formed by connecting a motor 25 and a speed reducer 24 . On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com